Aluminium-based copper foil clad laminated board and producing technology

An aluminum-based copper cladding and manufacturing process technology, applied in the field of copper clad laminates, can solve the problems of poor heat dissipation performance, easy to fall off, poor adhesion of aluminum plates, etc., to achieve not easy to fall off, good adhesion, and improved thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

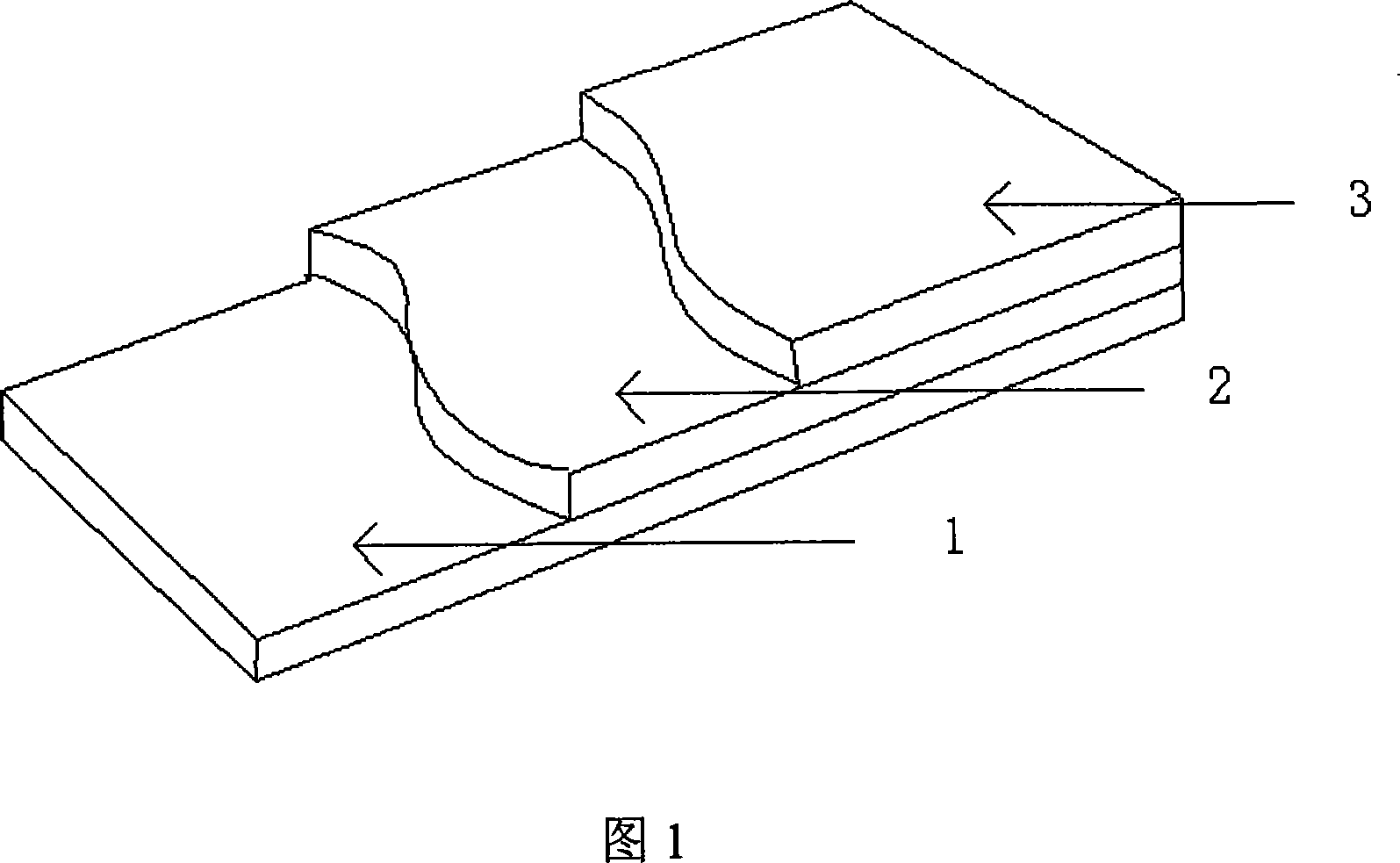

[0021] Embodiment 1: The aluminum-based copper-clad laminate of this example, as shown in Figure 1, includes an aluminum plate 1, the surface of which is coated with a modified epoxy resin insulating layer 2, and the other side of the modified epoxy resin insulating layer is provided with a copper foil 3, The composition and mass percentage of the modified epoxy resin insulating layer are: 20% of o-methyl novolac epoxy resin, 5% of aluminum nitride, 6% of aluminum oxide, and the rest is flame-retardant epoxy resin. The thickness of the modified epoxy resin insulation layer is 0.075mm.

[0022] The manufacturing process of aluminum-based copper clad laminates, the steps are:

[0023] a. Clean, passivate and dry the aluminum plate;

[0024] b. Apply the modified epoxy resin insulating glue directly to the surface of the cleaned and dried aluminum plate by screen printing, roll coating, and spraying, and perform pre-drying, that is, send the aluminum plate into an oven to dry un...

Embodiment 2

[0026] Embodiment 2: The aluminum-based copper-clad laminate of this example, as shown in Figure 1, includes an aluminum plate 1, the surface of which is coated with a modified epoxy resin insulating layer 2, and the other side of the modified epoxy resin insulating layer is provided with a copper foil 3, The composition and mass percentage of the modified epoxy resin insulation layer are: 5% o-methyl novolac epoxy resin, 5% aluminum nitride, and the rest is flame-retardant epoxy resin. The thickness of the modified epoxy resin insulation layer is 0.075mm.

[0027] The manufacturing process of aluminum-based copper clad laminates, the steps are:

[0028] a. Clean, passivate and dry the aluminum plate;

[0029] b. Apply the modified epoxy resin insulating glue directly to the surface of the cleaned and dried aluminum plate by screen printing, roll coating, and spraying, and perform pre-drying, that is, send the aluminum plate into an oven to dry until the modified epoxy resin ...

Embodiment 3

[0031] Embodiment 3: The aluminum-based copper-clad laminate of this example, as shown in Figure 1, includes an aluminum plate 1, the surface of which is coated with a modified epoxy resin insulating layer 2, and the other side of the modified epoxy resin insulating layer is provided with a copper foil 3, The composition and mass percentage of the modified epoxy resin insulating layer are: o-methyl novolac epoxy resin 6%, and the rest is flame retardant epoxy resin. The thickness of the modified epoxy resin insulation layer is 0.075mm.

[0032] The manufacturing process of aluminum-based copper clad laminates, the steps are:

[0033] a. Clean, passivate and dry the aluminum plate;

[0034] b. Apply the modified epoxy resin insulating glue directly to the surface of the cleaned and dried aluminum plate by screen printing, roll coating, and spraying, and perform pre-drying, that is, send the aluminum plate into an oven to dry until the modified epoxy resin The insulating glue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com