Patents

Literature

30results about How to "Easy to warp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

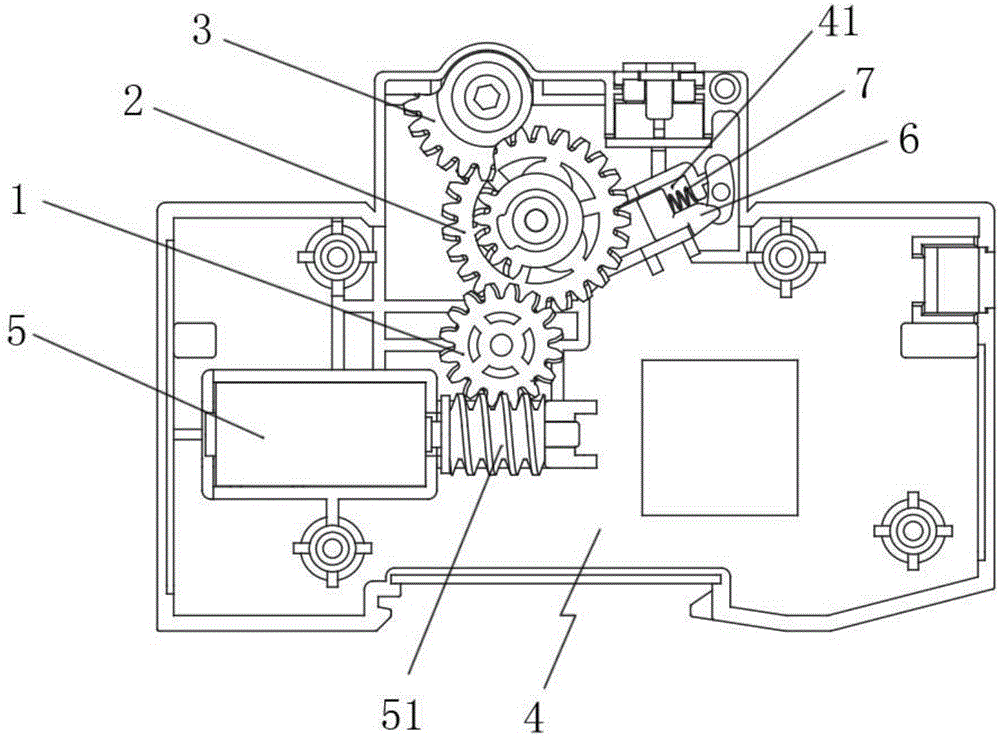

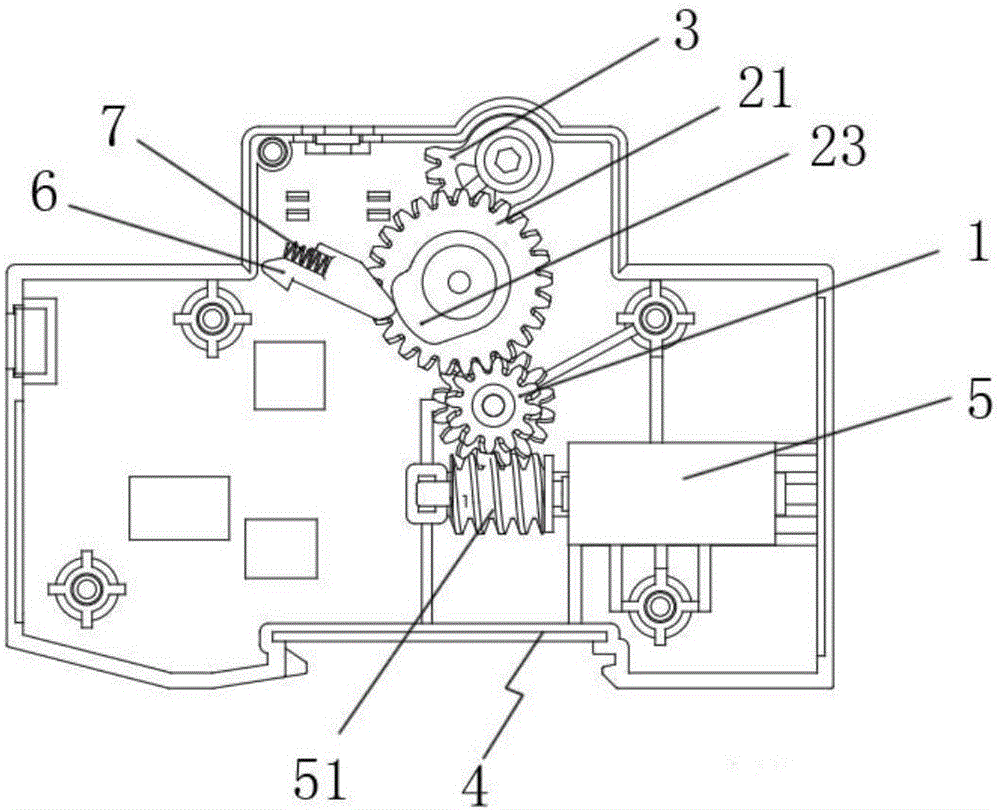

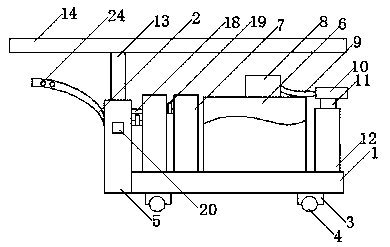

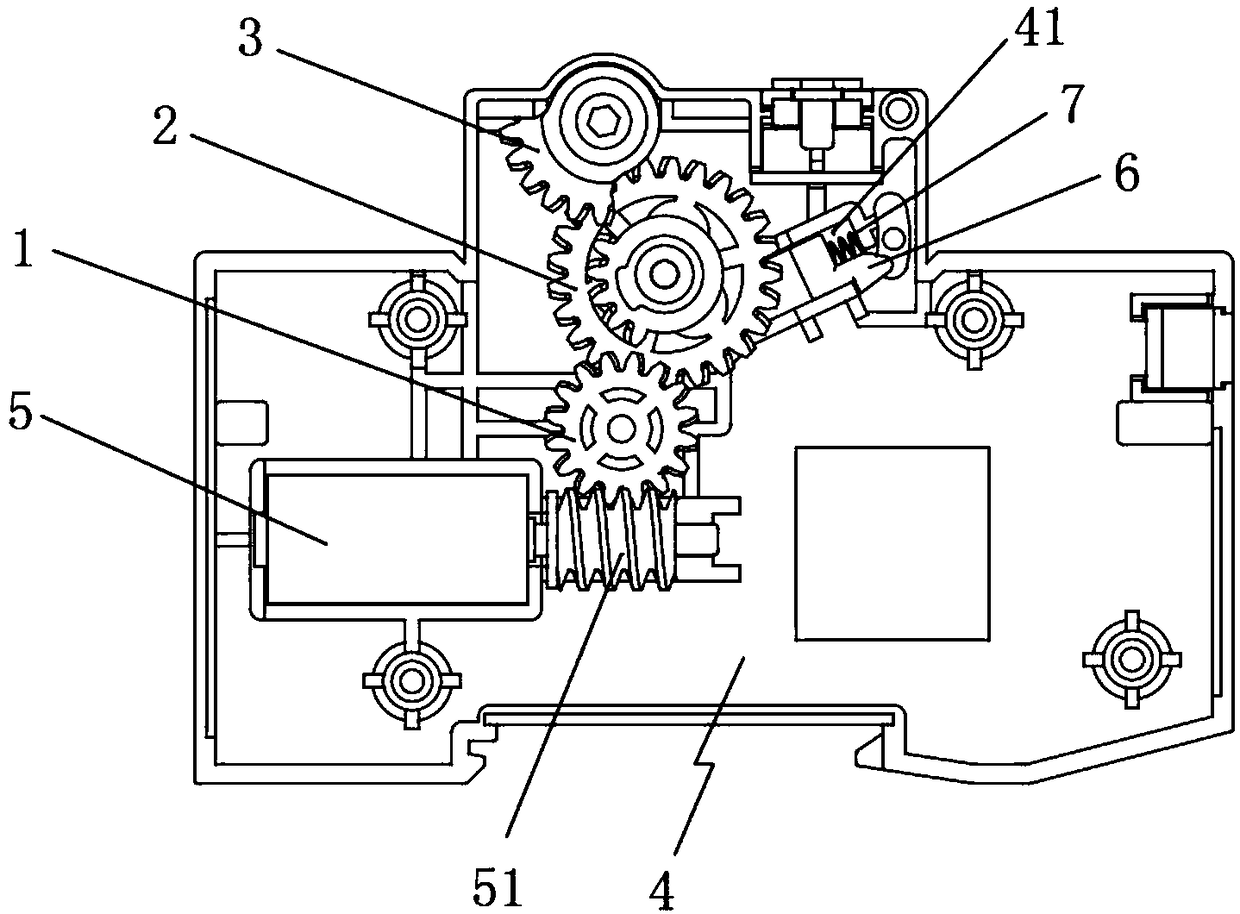

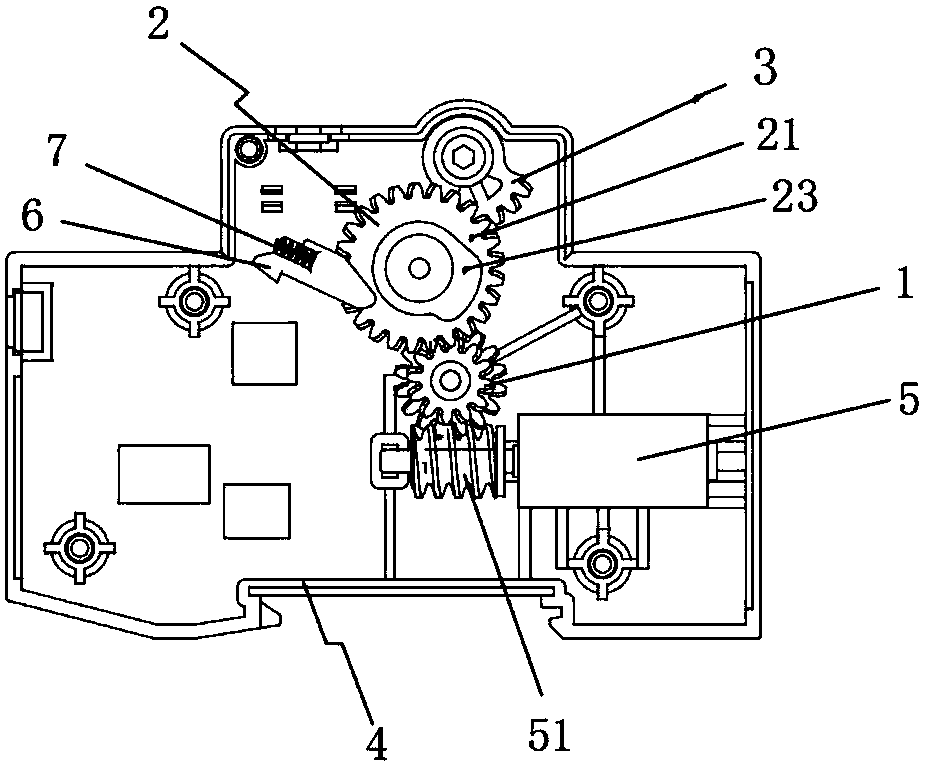

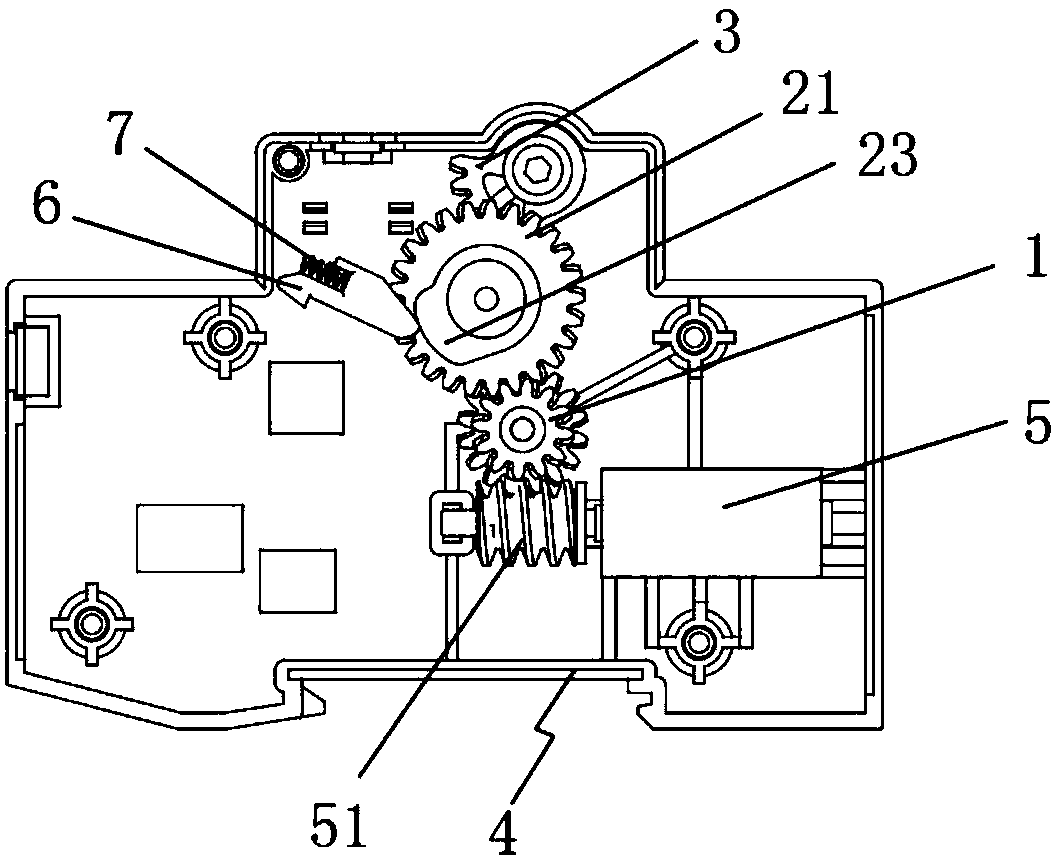

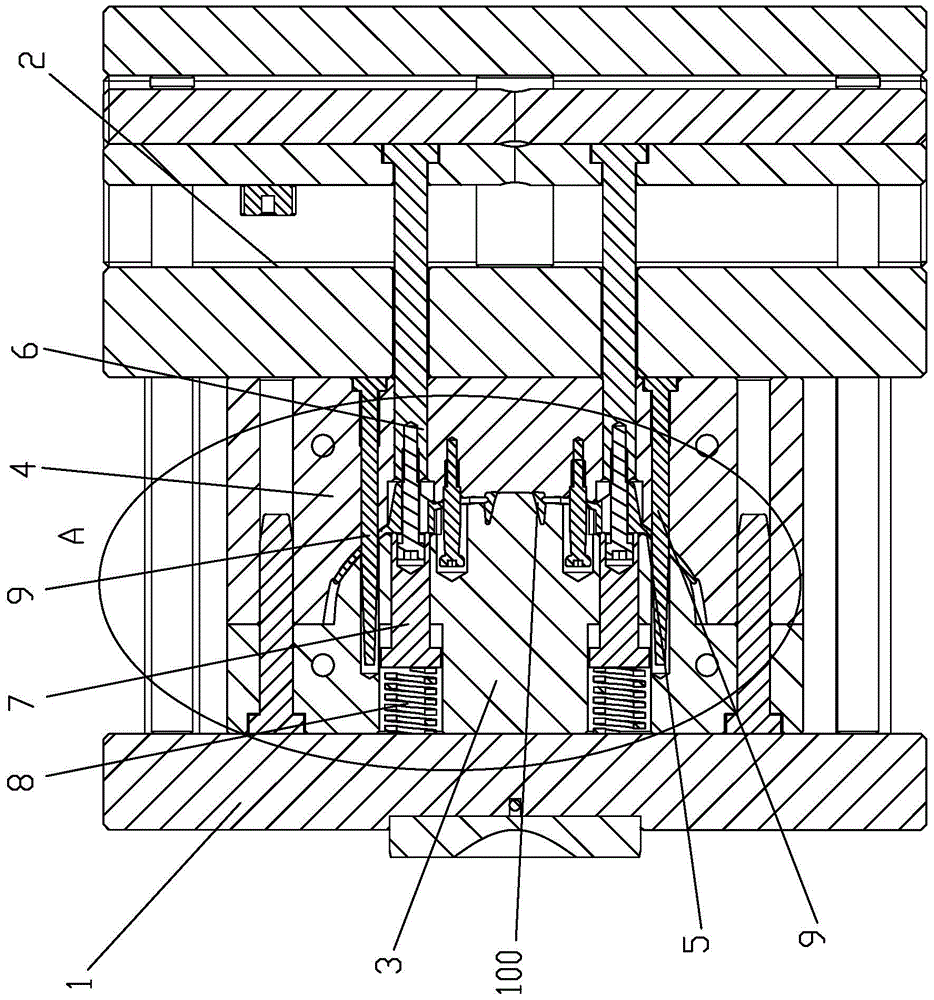

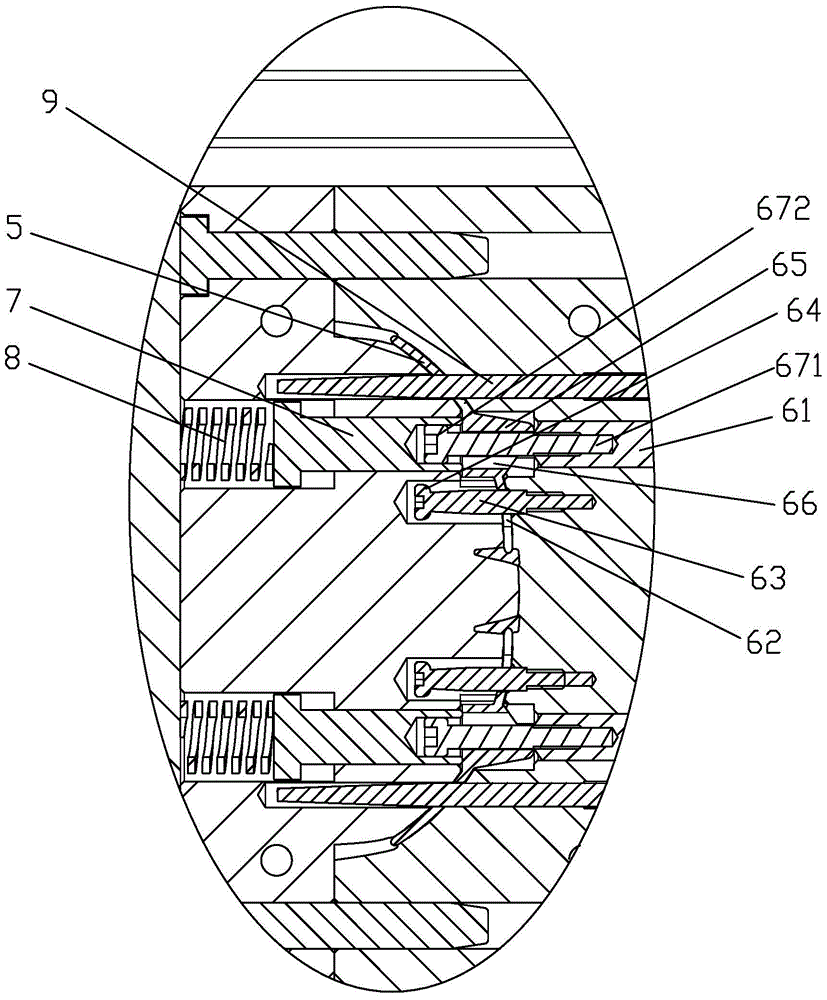

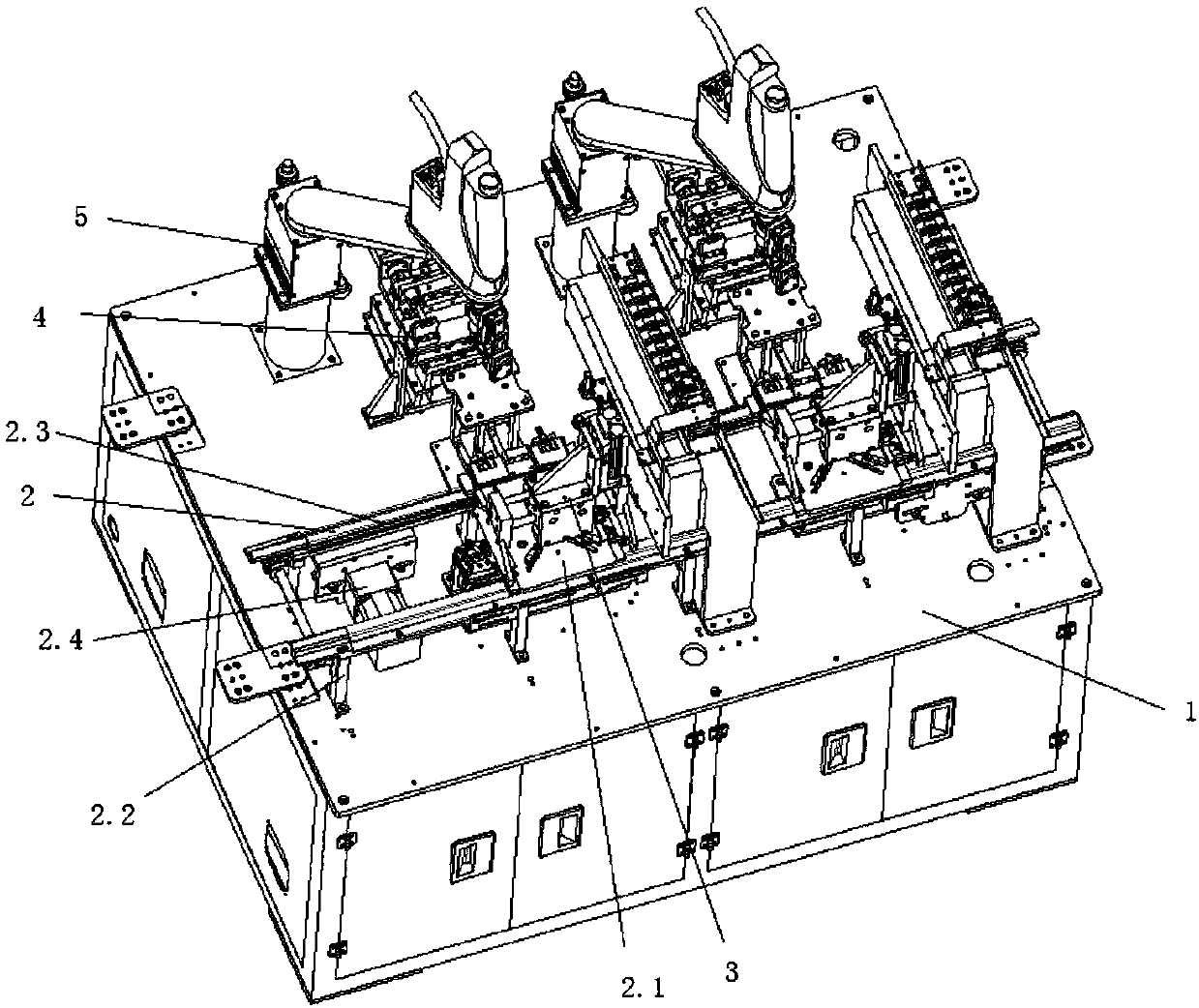

Automatic reclosing lock device of breaker

ActiveCN106356263ANo shakingSolve the unstable transmissionProtective switch operating/release mechanismsDrive motorEngineering

The invention provides an automatic reclosing lock device of a breaker. The automatic reclosing lock device comprises a drive motor, a linkage tripping mechanism, a transmission gear mechanism and a breaker handle mechanism, wherein the transmission gear mechanism comprises a first transmission gear, a second transmission gear and a third transmission gear which are adjacently meshed with one other, a cam portion of the second transmission gear can drive a push rod to shift a tripping rod, so as to quickly separate the breaker, the second transmission gear can drive an incomplete gear to rotate continuously, and the incomplete gear and the third transmission gear are in mesh transmission to drive a handle to switch on automatically through a linkage rotation shaft. The automatic reclosing lock device has the advantages of being reliable in transmission, strong in stability and capable of enabling the second transmission gear not to be prone to shaking or rising; thus, the automatic reclosing lock device can avoid the problem of tripping clamping stagnation or tripping slide when being matched with a linkage tripping part, the use performance of a product is favorably improved, and the service life of the product is favorably prolonged.

Owner:ZHEJIANG ZHONGFU ELECTRIC

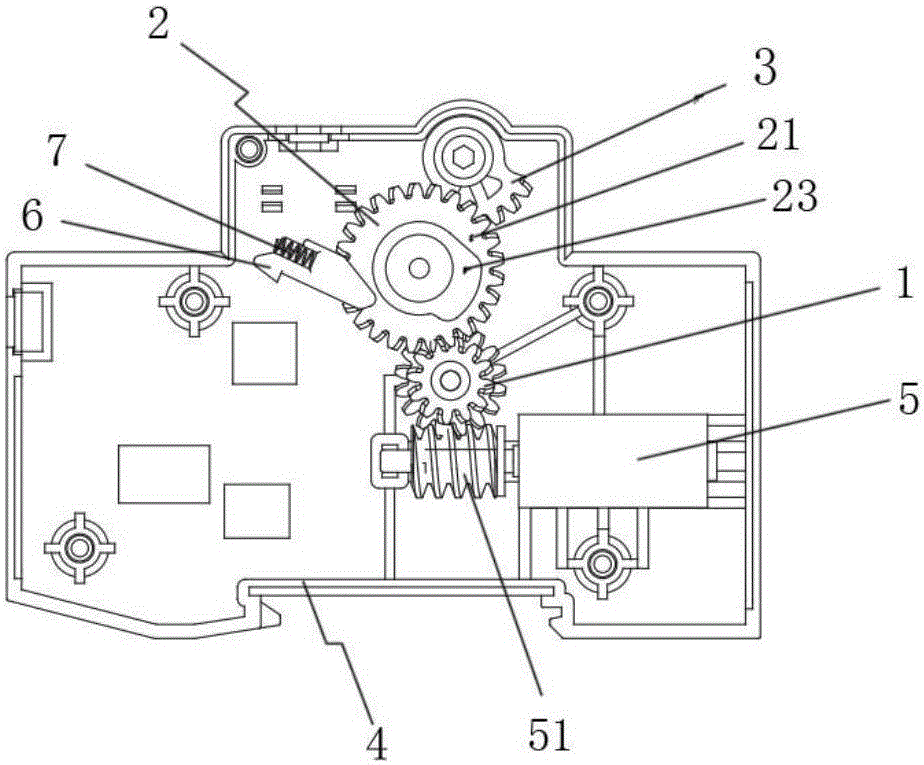

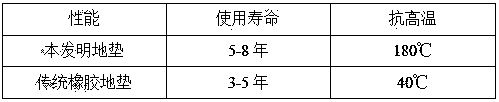

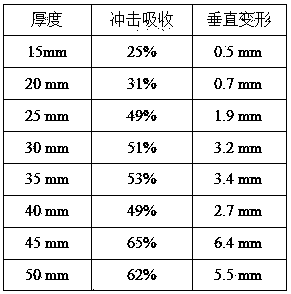

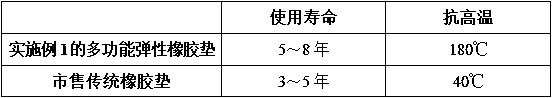

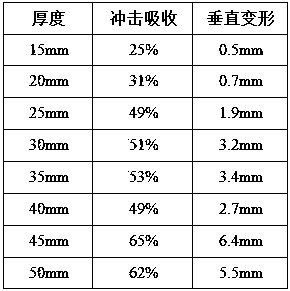

Colorful rubber floor mat and manufacturing method of colorful rubber floor mat

ActiveCN104000463AAvoid deformationExtended service lifeSynthetic resin layered productsLaminationPolymer scienceAdhesive

The invention discloses a colorful rubber floor mat and a manufacturing method of the colorful rubber floor mat. The manufacturing method of the colorful rubber floor mat includes the steps that waste rubber is smashed to serve as bottom-layer particles, then the smashed waste rubber and adhesives are evenly mixed, and a molded bottom layer is formed in a heated and pressurized mode; raw materials including ethylene-propylene-diene monomer, rubber oil, toner, white carbon black, ultraviolet-resistant agents, accelerants, zinc oxide, antioxidants, calcium carbonate and the like are evenly mixed, banburying and open milling are sequentially carried out, rubber is cut into pieces, the rubber pieces are cooled and smashed to serve as face-layer particles, then the smashed rubber pieces and adhesives are evenly mixed, and a molded face layer is formed in a heated and pressurized mode; finally the bottom layer and the face layer are bonded with the hot mold technology. The service life of the colorful rubber floor mat manufactured with the manufacturing method is as long as 5 years-8 years; the colorful rubber floor mat can be resistant to the 180-DEG C high temperature; the buffering performance is good; a slightly-protruding particle feeling is achieved on the surface, a special soft feeling is achieved during treading, and the colorful rubber floor mat has the elasticity and is resistant to sliding; no harmful matter is contained; the colorful rubber floor mat is basically free of influences of expansion caused by heat and contraction caused by cold, and is safe, comfortable, durable and attractive in appearance.

Owner:QINGYUAN CHUANAO HI TECH MATERIAL CO LTD

Safe high-efficiency fire extinguishing equipment

The invention discloses safe high-efficiency fire extinguishing equipment. The safe high-efficiency fire extinguishing equipment comprises a base and a pushing handle; one side of the upper end of thebase is fixedly provided with a support frame; a support rod is welded to the upper end of the support frame; the top end of the support rod is fixedly provided with a protective plate; two baffles are arranged at the positions, located on one side of the support rod, of the protective plate; the upper end of the base is fixedly provided with a water storage tank and a fire extinguisher; output ends of the fire extinguisher are connected with gas pipes; one ends of the gas pipes are arranged in the support frame and connected with a nozzle; the middle of the nozzle is arranged on a support lantern ring in a sleeving mode; one end of the support lantern ring is welded to the inner side wall of the support frame; and one side of the top end of the nozzle is fixedly connected to a hydraulicrod at one end of a hydraulic cylinder. By arranging the protective plate and the baffles, fire extinguishing facilities can be protected against damage, and the safety of firefighters is ensured; andthe efficiency of fire extinguishing can be effectively improved.

Owner:曾凡旺

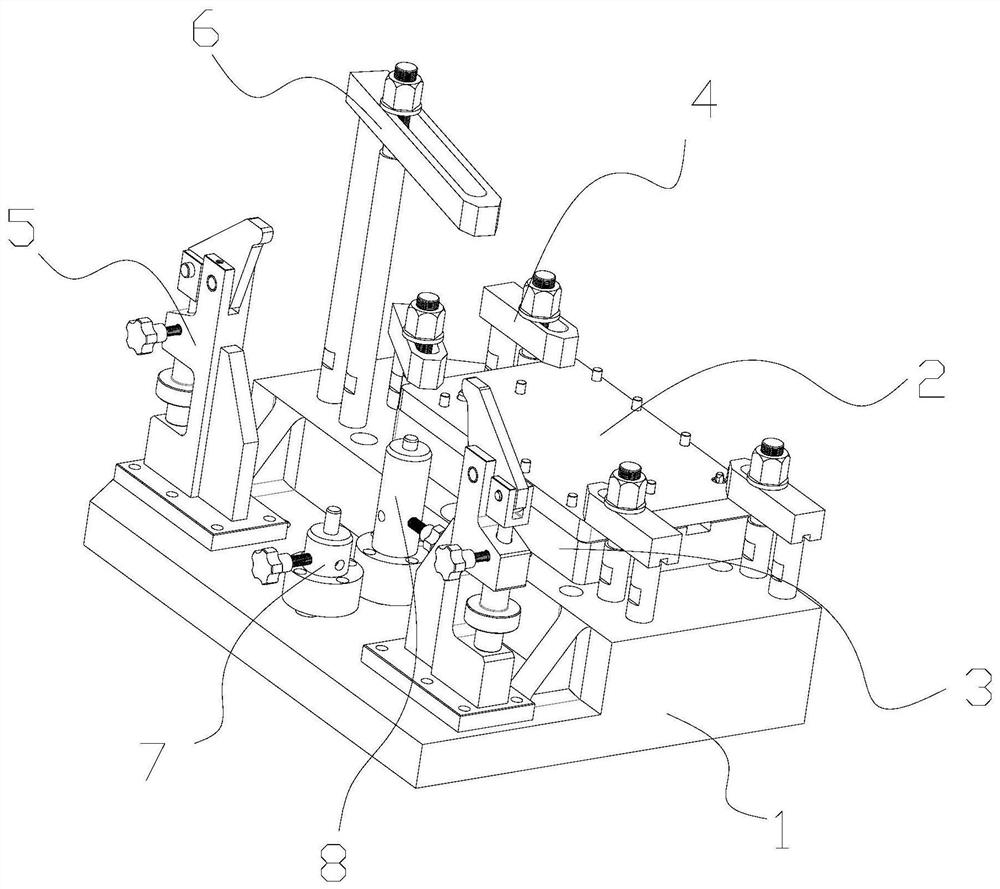

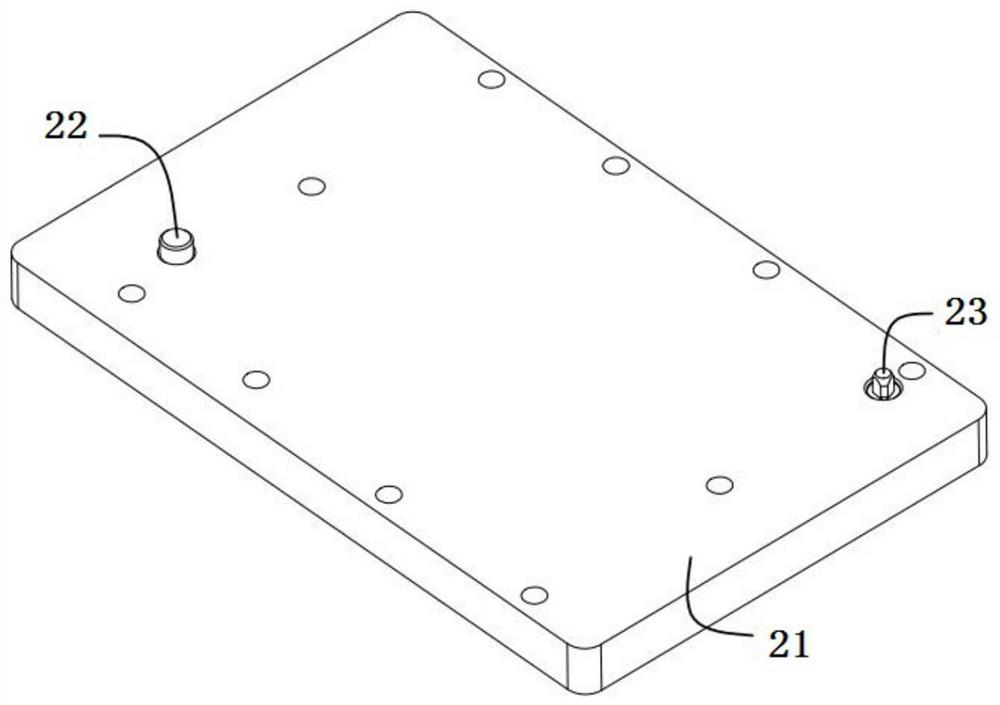

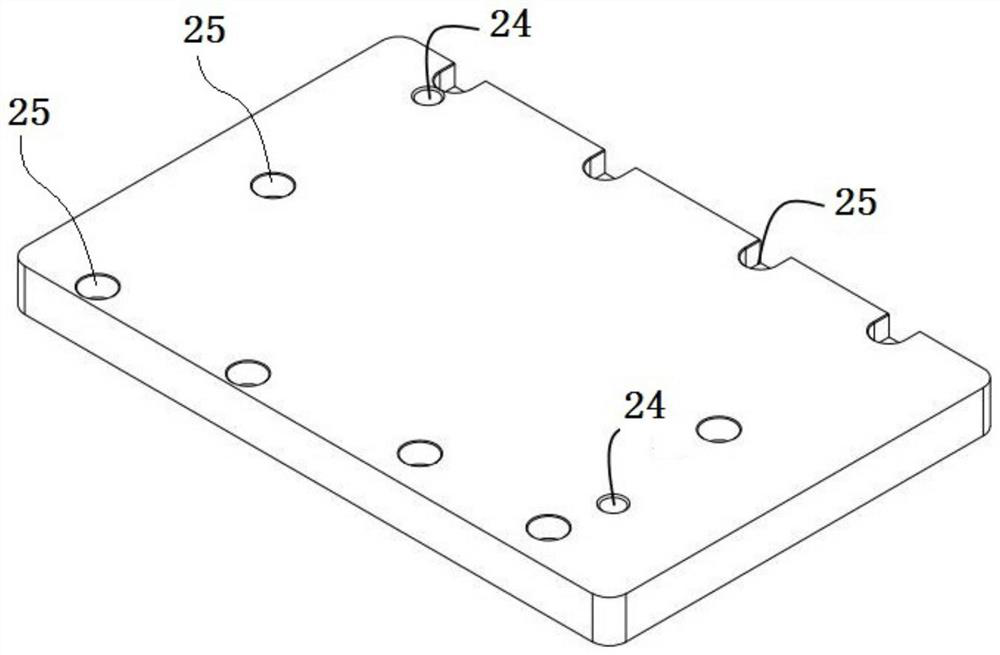

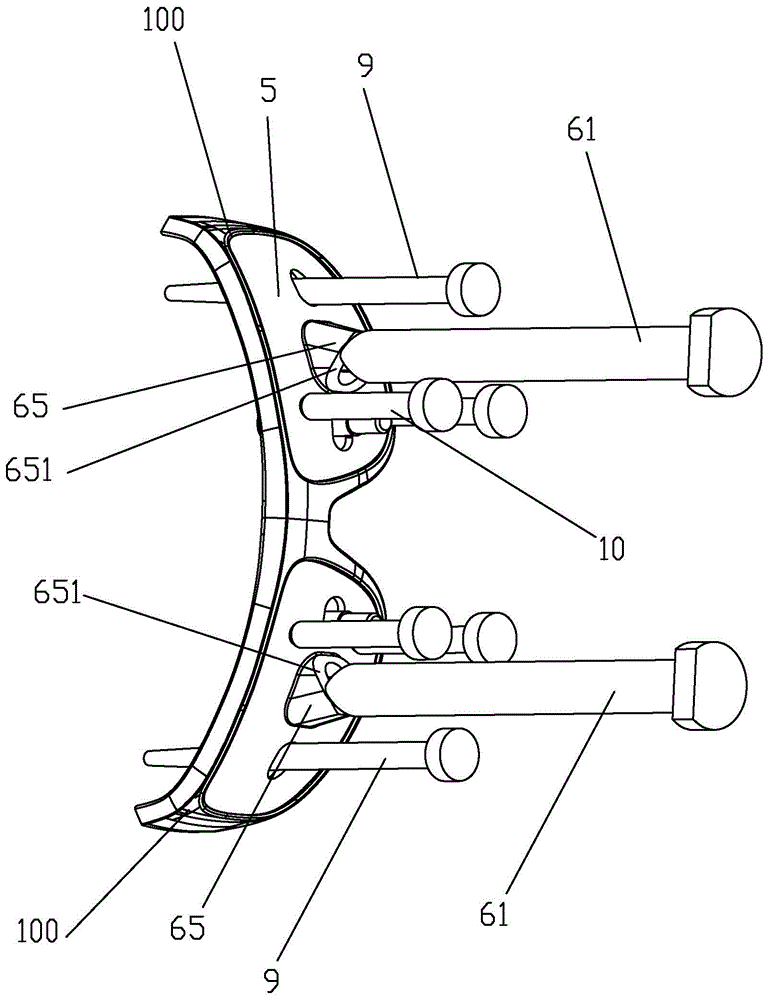

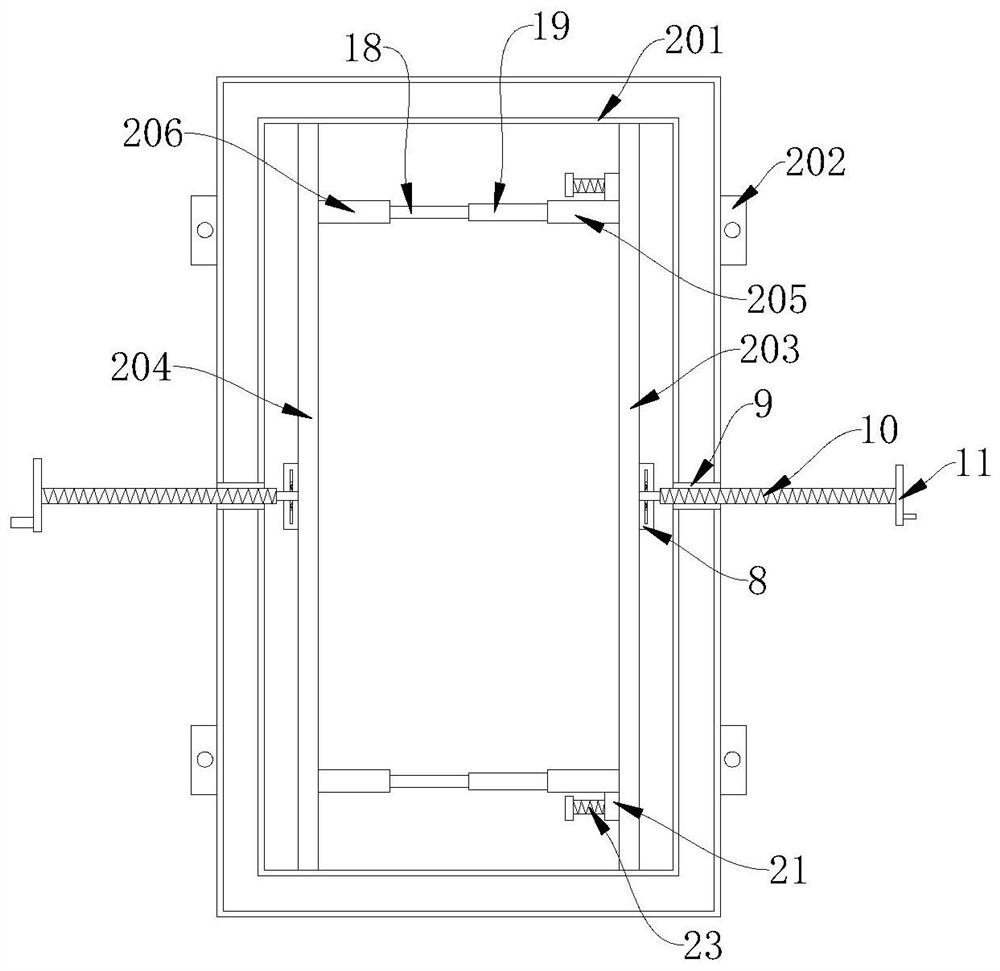

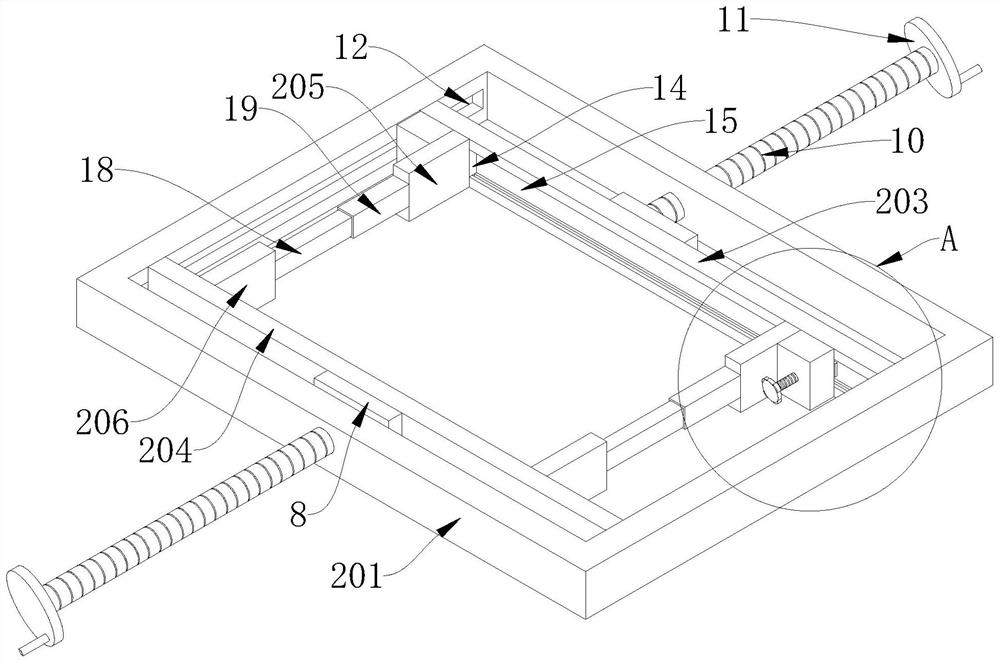

Clamp for finish machining of gearbox shell and clamping method

ActiveCN113021033AGuaranteed finishing hole sizeImprove consistencyWind energy generationPositioning apparatusStructural engineeringMachining

The invention discloses a clamp for finish machining of a gearbox shell. The clamp for finish machining of the gearbox shell comprises a base, a transition plate, a connecting plate, a first pressing assemblies and an outer circle holding assembly, wherein the first pressing assemblies and the outer circle holding assembly are connected to the top face of the base, the top face of the transition plate is connected with the window face of the gearbox shell, the bottom face of the transition plate is connected with the top face of the connecting plate, the bottom face of the connecting plate is connected with the base, the top ends of the multiple first pressing assemblies are pressed on the top face of the transition plate, and the outer circle holding assembly is clamped on the outer circle of the gearbox shell. The invention further discloses a clamping method of the clamp. The clamp for finish machining of the gearbox shell has the beneficial effects that the transition plate is adopted for connection, stable clamping and effective clamping and supporting are achieved, the size and precision of finish machining holes of the gearbox shell can be guaranteed, stability and reliability are achieved, and consistency is good.

Owner:ANHUI QUANCHAI ENGINE

Rubber mat layer for anti-slip carpet

PendingCN110421913ANot easy to fall offExtended service lifeSynthetic resin layered productsCarpet fastenersPolyesterCombined use

The invention discloses a rubber mat layer for an anti-slip carpet. The rubber mat layer for the anti-slip carpet comprises a bottom non-slip water-repellent layer and an upper bonding layer, whereinthe bonding layer is a single-sided fabric which is provided with a plurality of monofilament protrusions. The bonding layer is the single-sided fabric prepared from monofilaments with a fineness of 20 D or above and having protrusions or is a single-sided structure layer formed by cutting a three-dimensional mesh structure layer from the middle; and the three-dimensional mesh structure layer is composed of an upper warp-knitted eyelet fabric layer, a lower warp-knitted eyelet fabric layer and a plurality of polyester fibers, polypropylene fibers or nylon monofilaments which are vertically arranged in the middle and connect the upper and lower warp-knitted mesh fabric layers. The rubber mat layer for the anti-slip carpet in the invention can be bonded with a plurality of carpet surfaces for use; the rubber mat layer has moderate bonding strength, and is free of the phenomenon of damage to carpet surfaces during dismounting due to too high bonding force or the phenomena of easy shiftingand warpage of the carpet surfaces due to too low bonding force; and the rubber mat layer has the advantages of rollability, foldability, machine-washability, easiness in laying, convenience in transporting, etc.

Owner:KUNSHAN YIJIAJU TEXTILE CO LTD

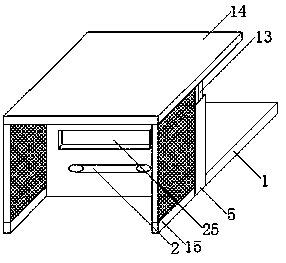

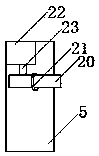

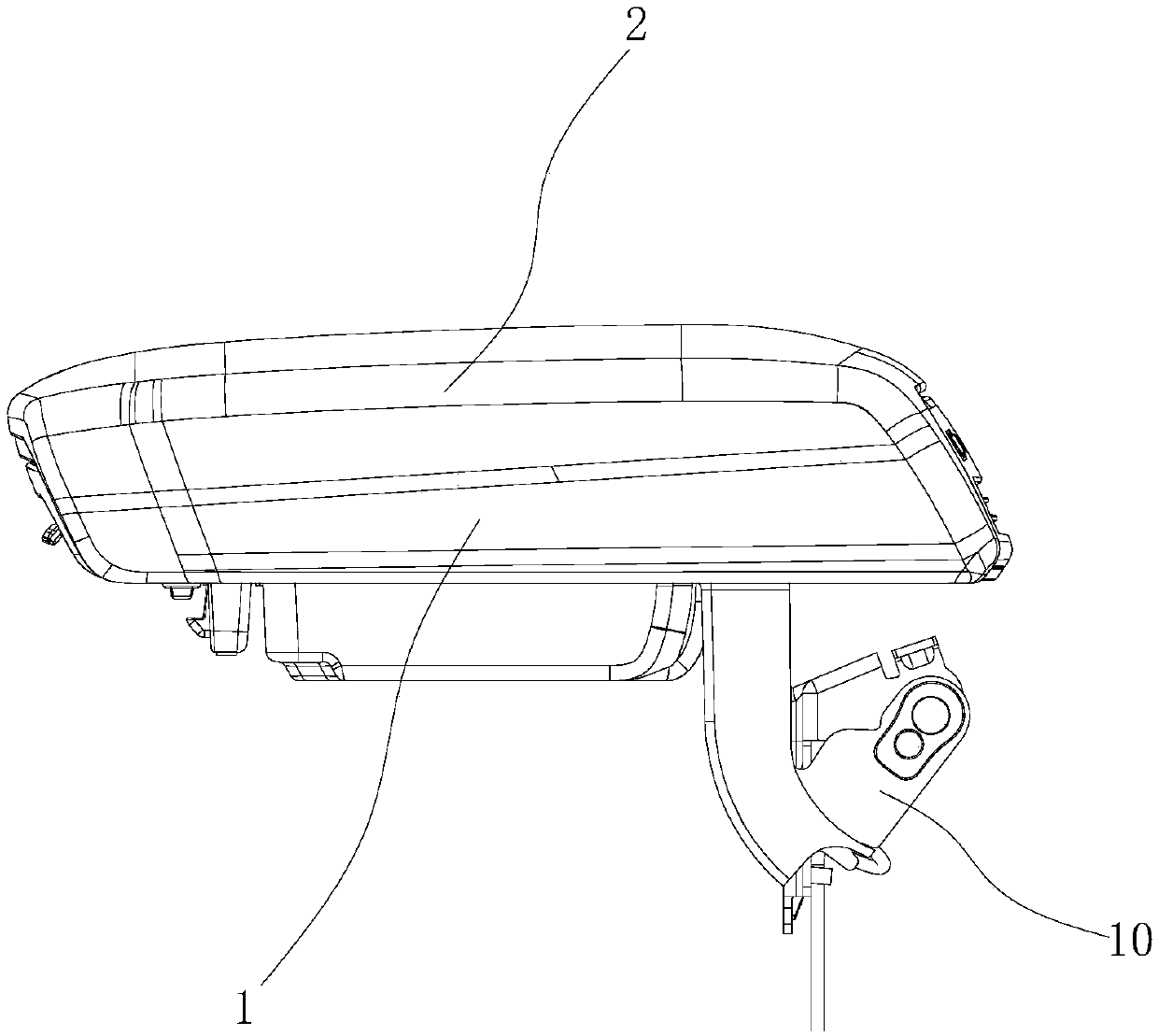

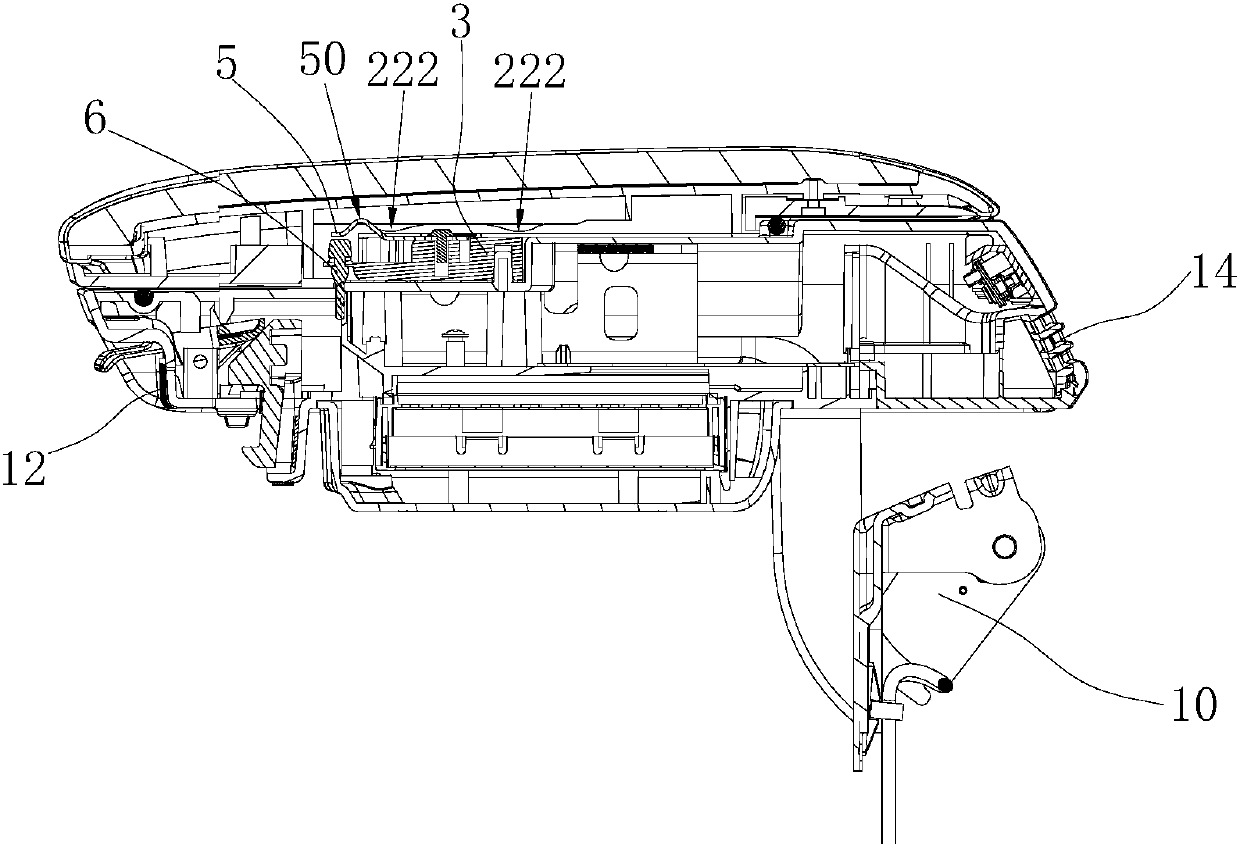

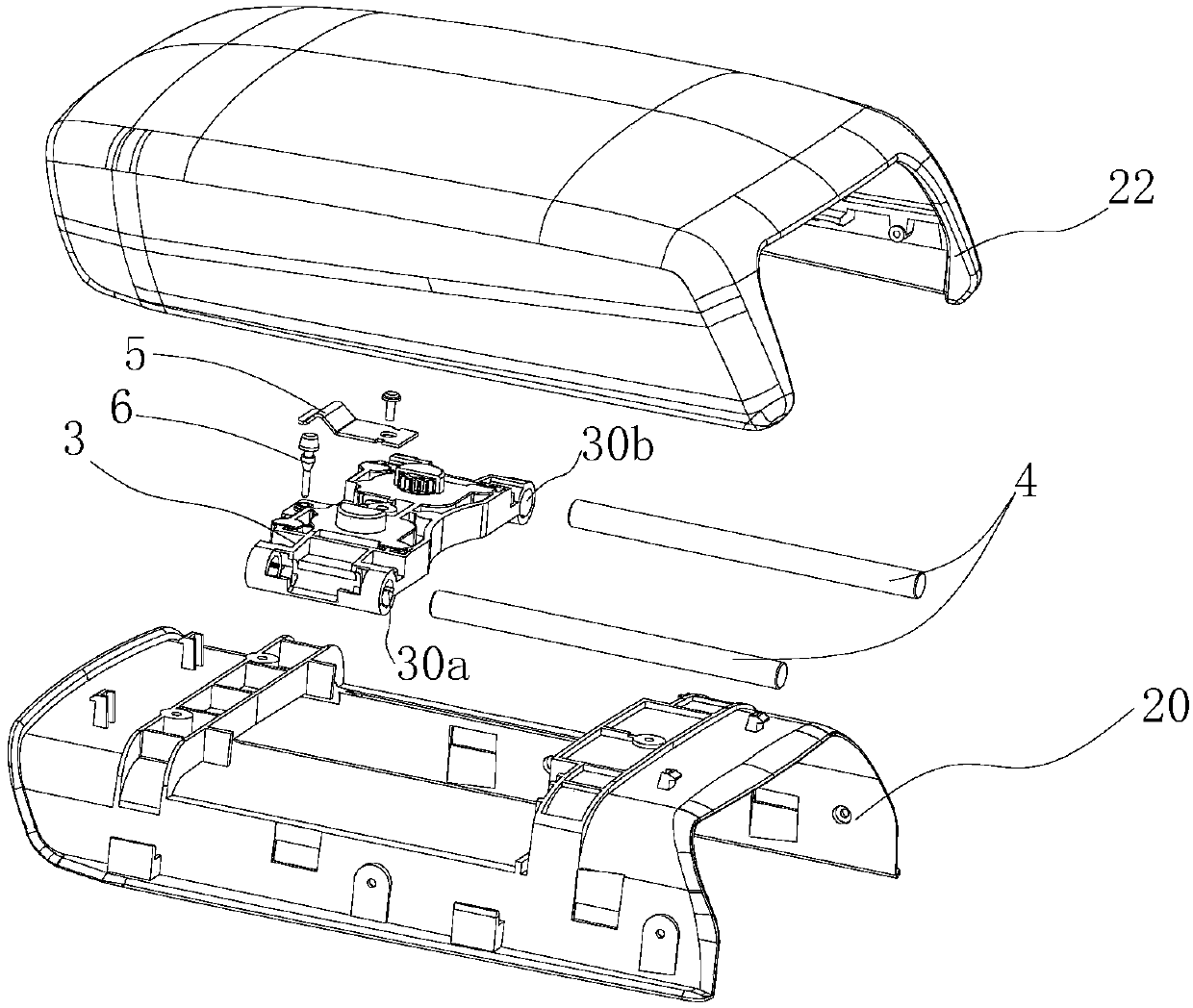

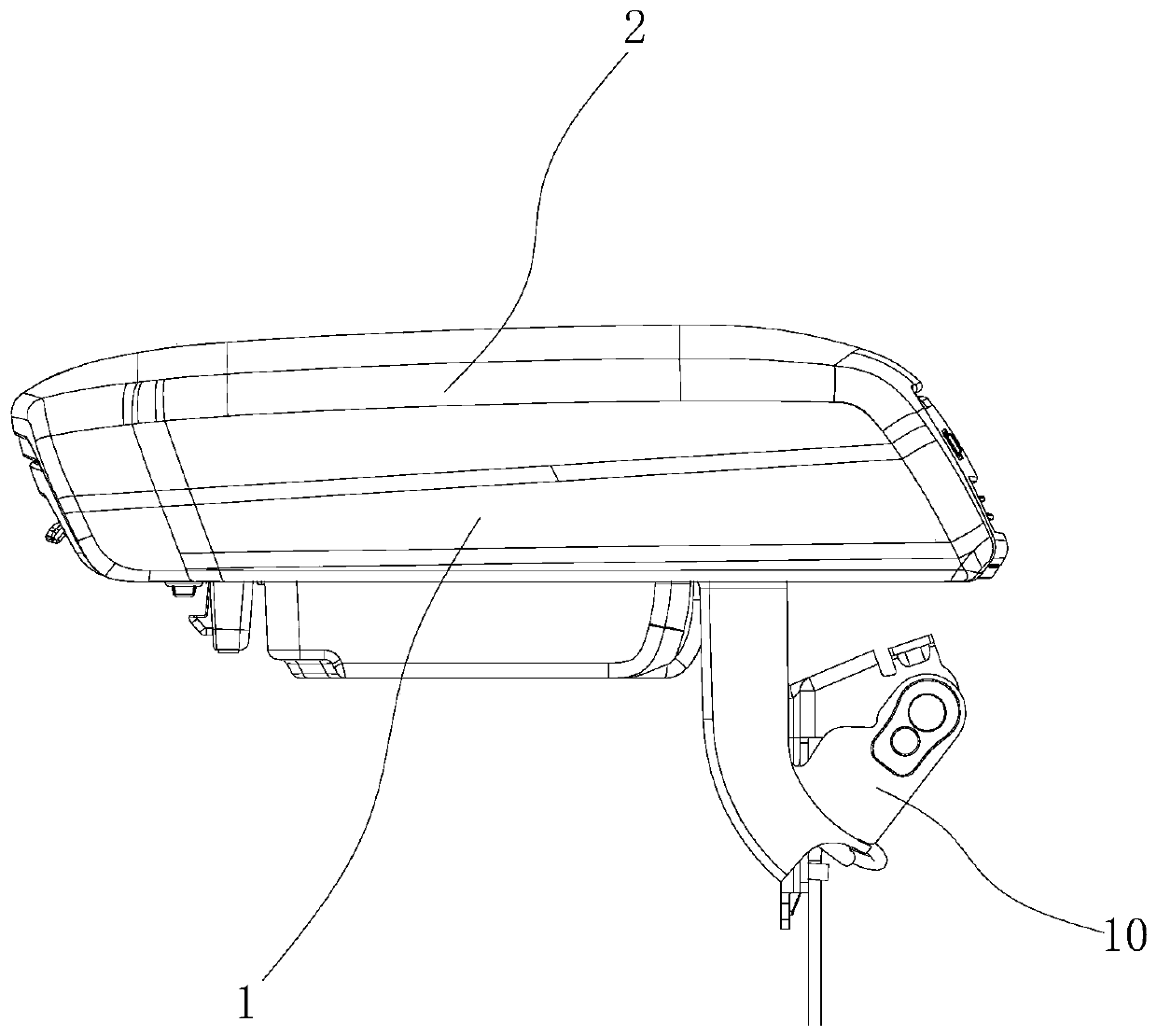

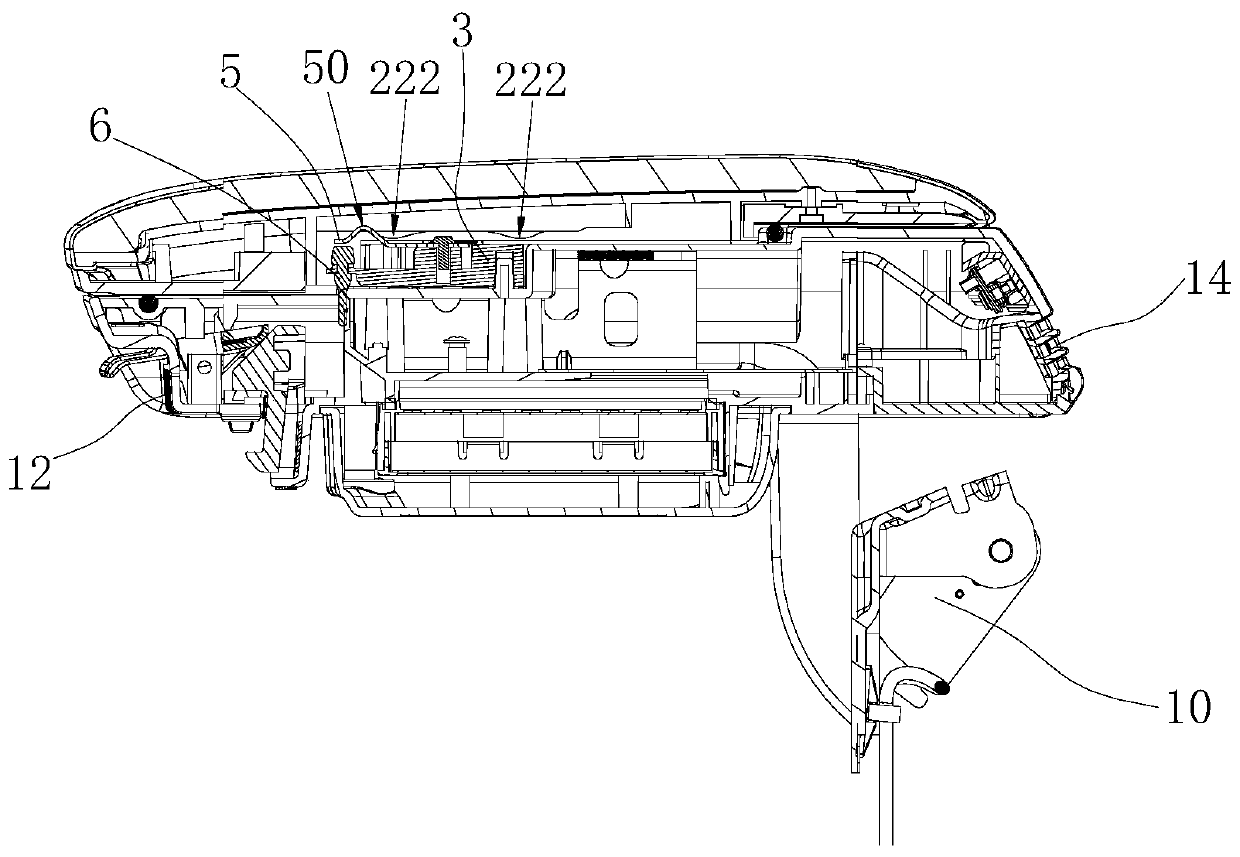

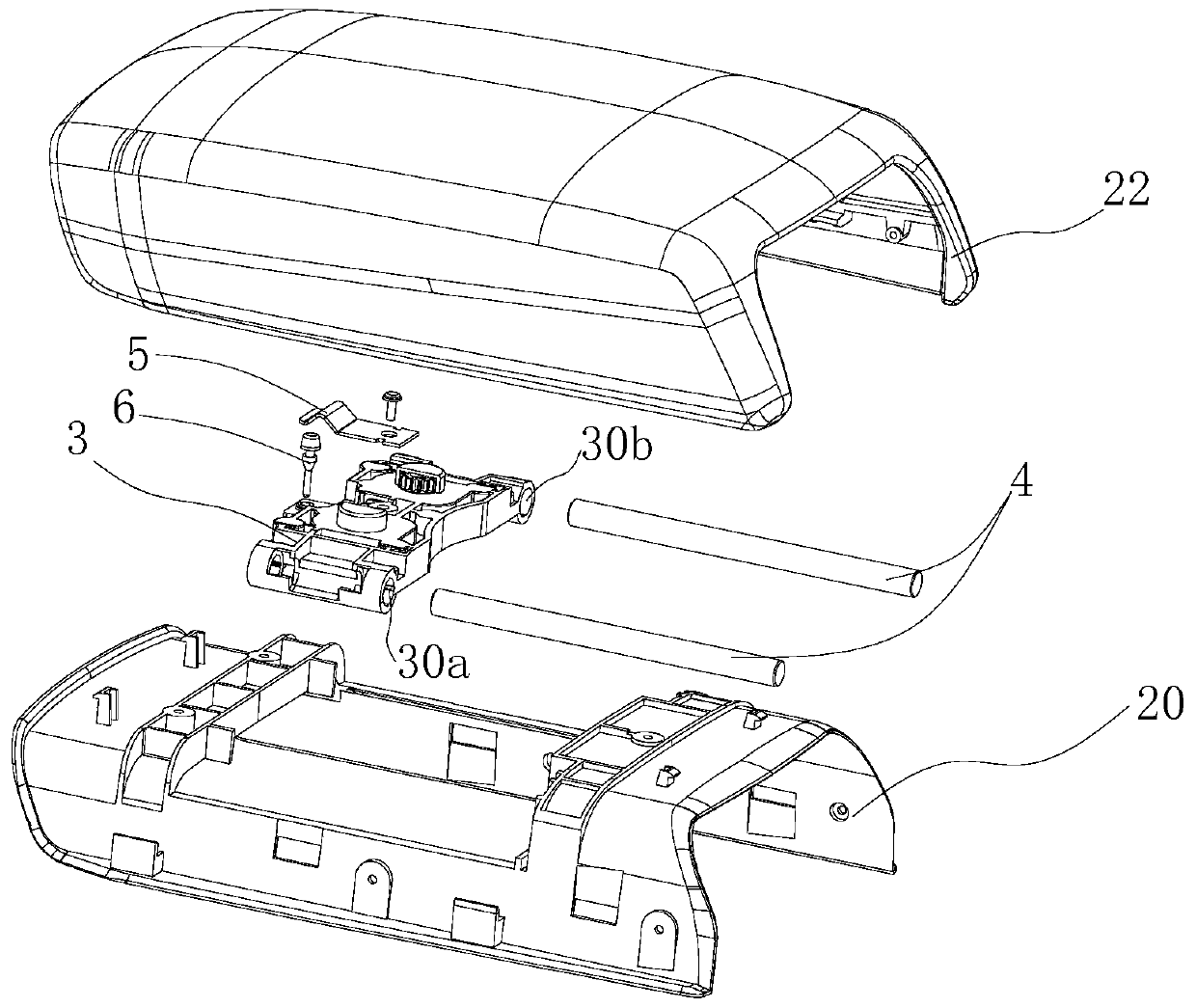

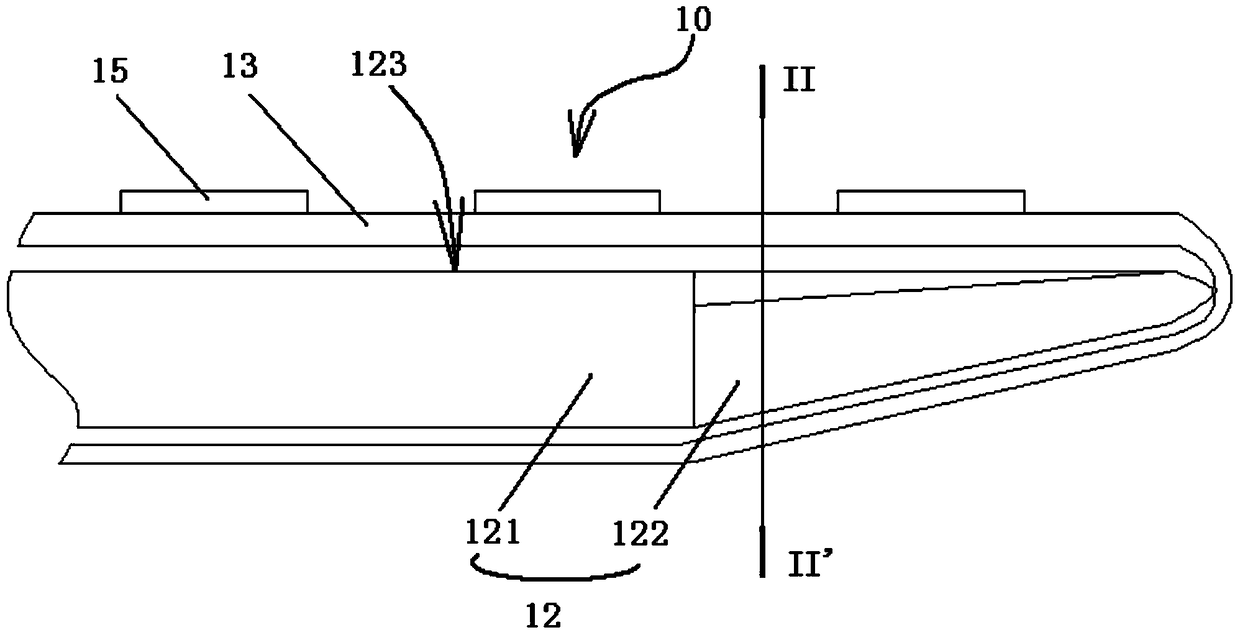

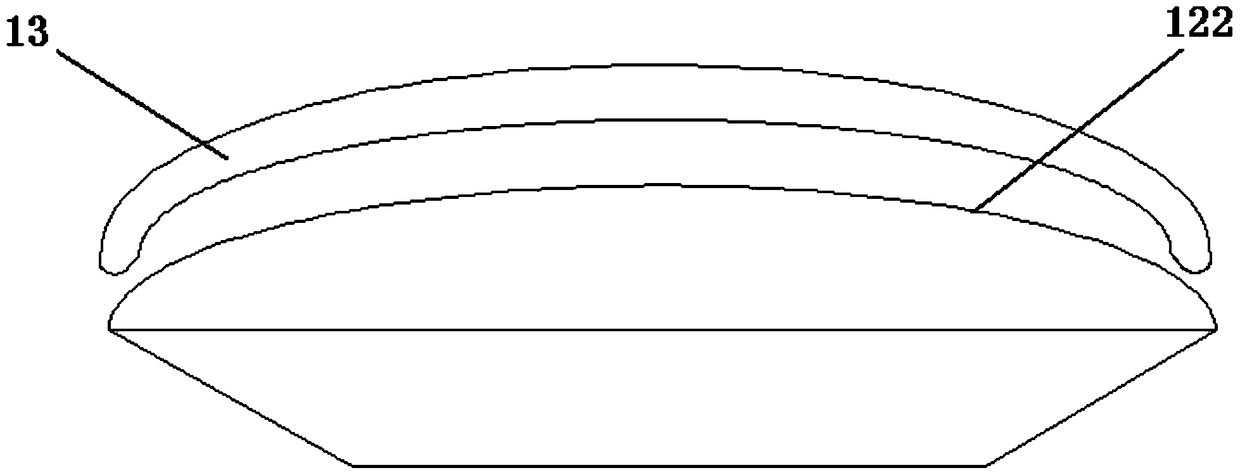

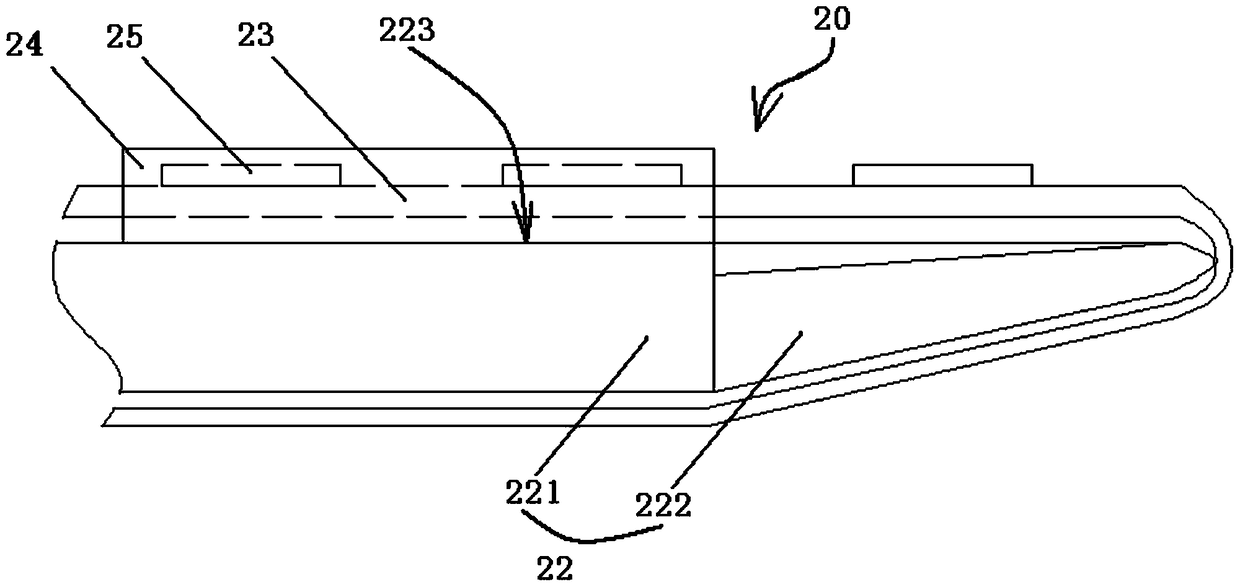

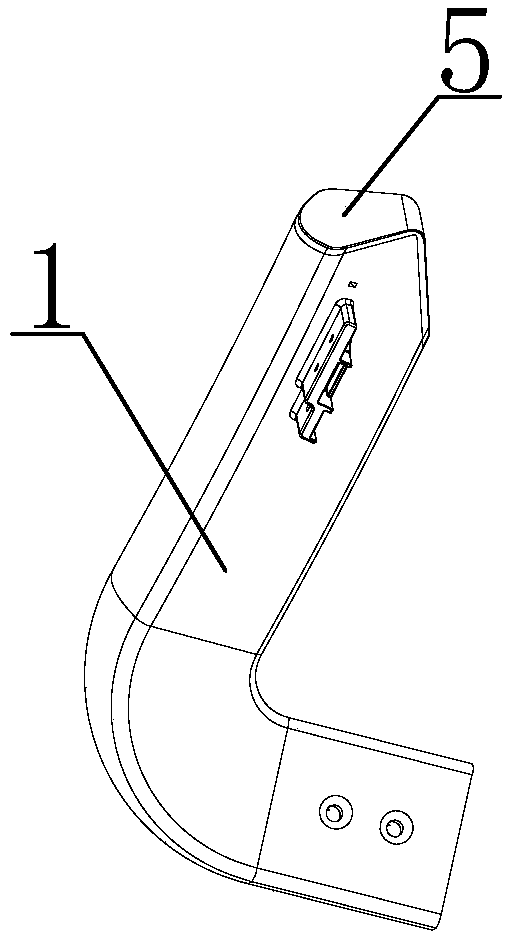

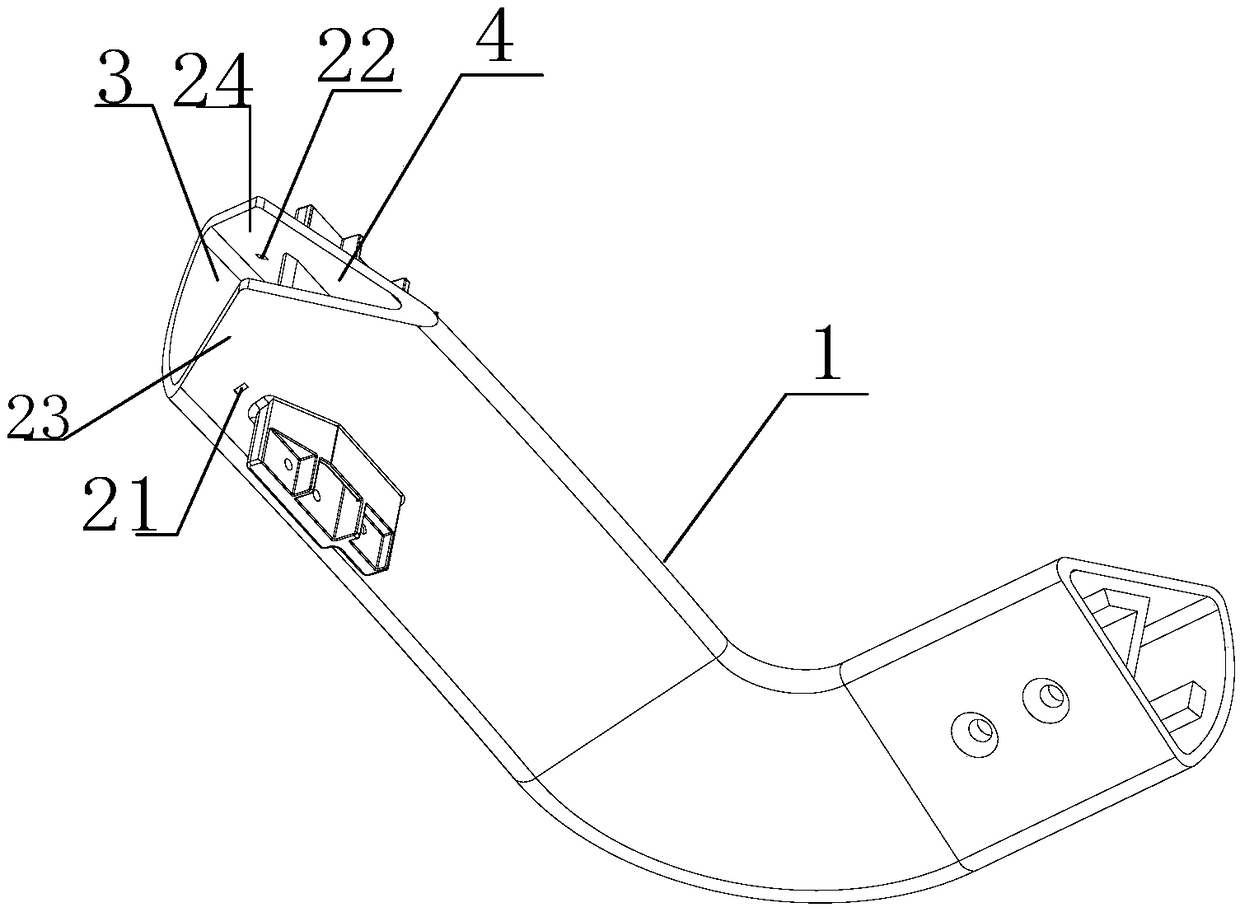

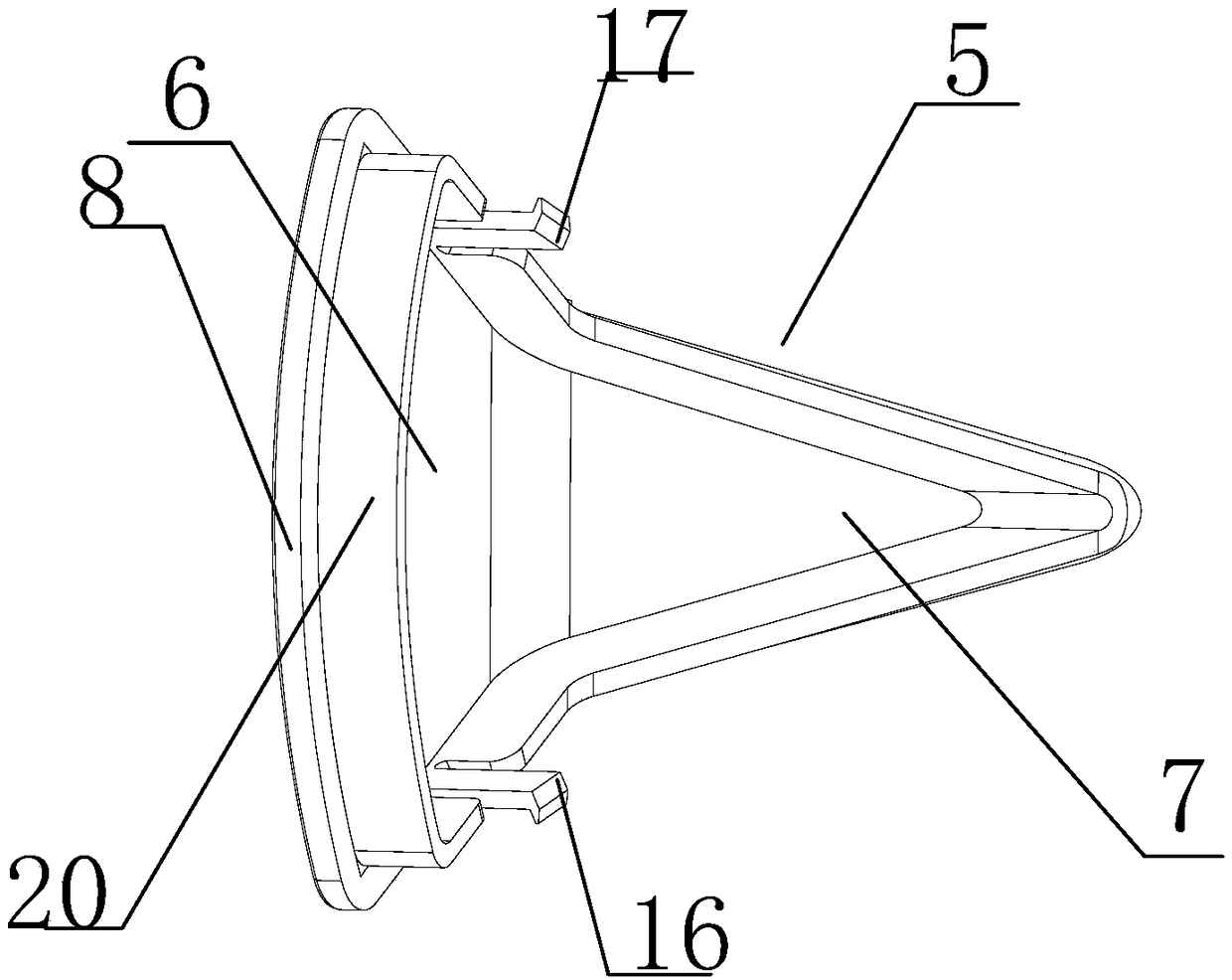

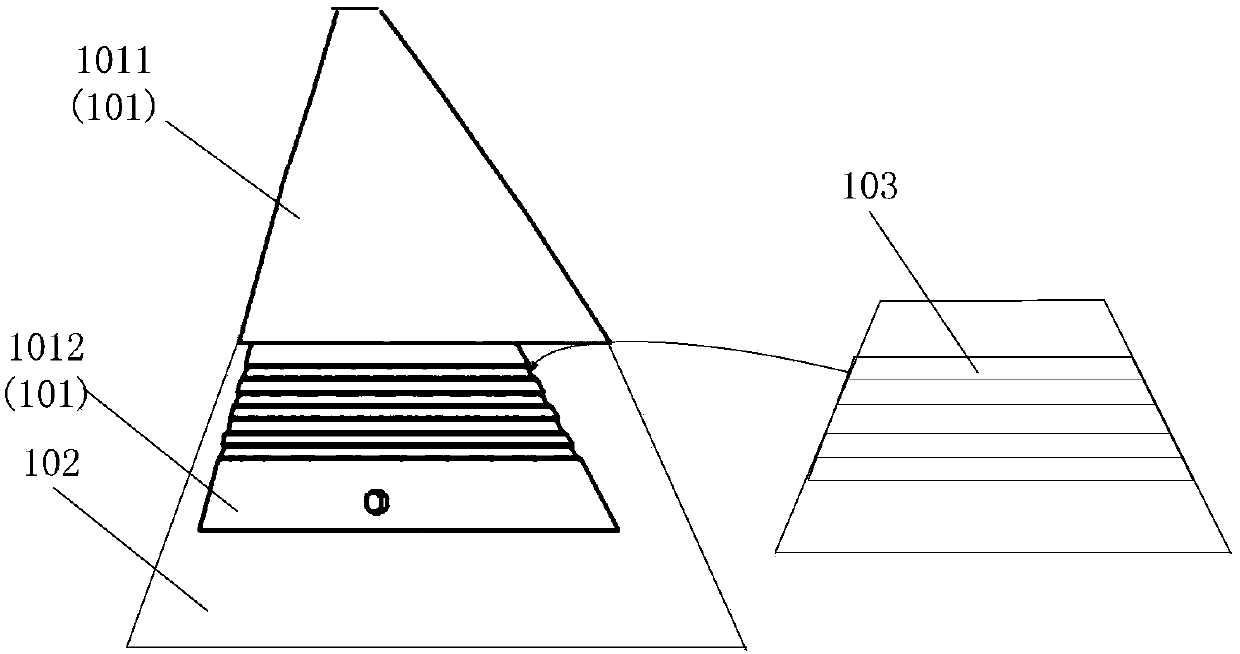

Shell body matched with armrest box and armrest type vehicle-mounted air purifier

ActiveCN108032812AGuaranteed stabilityImprove positionAir-treating devicesPassenger spaceHandrailKinematic pair

The invention provides a shell body matched with an armrest box and an armrest type vehicle-mounted air purifier. The shell body is arranged in a shape of an armrest box cover, the shell body comprises a base, an upper cover and a first sliding kinematic pair, the base is provided with a connecting part matched with an armrest box substrate, the sliding kinematic pair is arranged between the baseand the upper cover for relatively sliding, the first sliding kinematic pair is sliding blocks and a sliding rod inserted in the sliding blocks, so that the problems that sliding stroke of the existing armrest box cover is limited and the existing armrest type air purifier can not adjust the armrest position.

Owner:XIAMEN MAXMAC AIR TECH

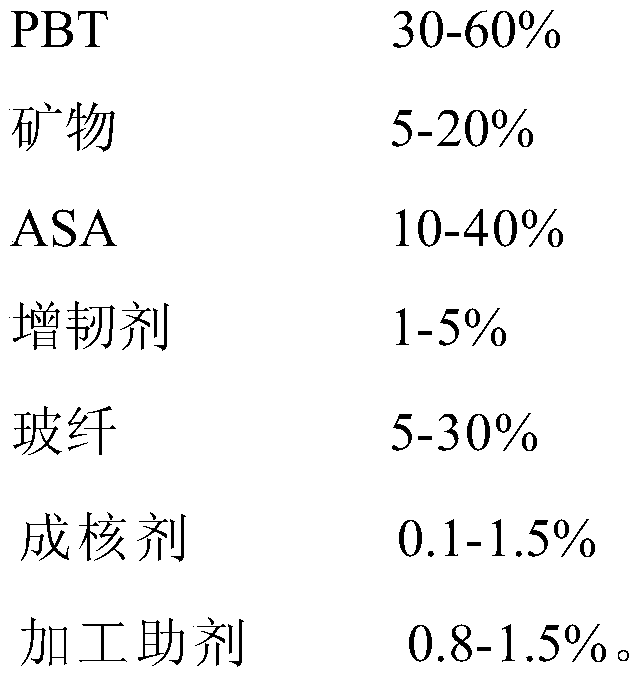

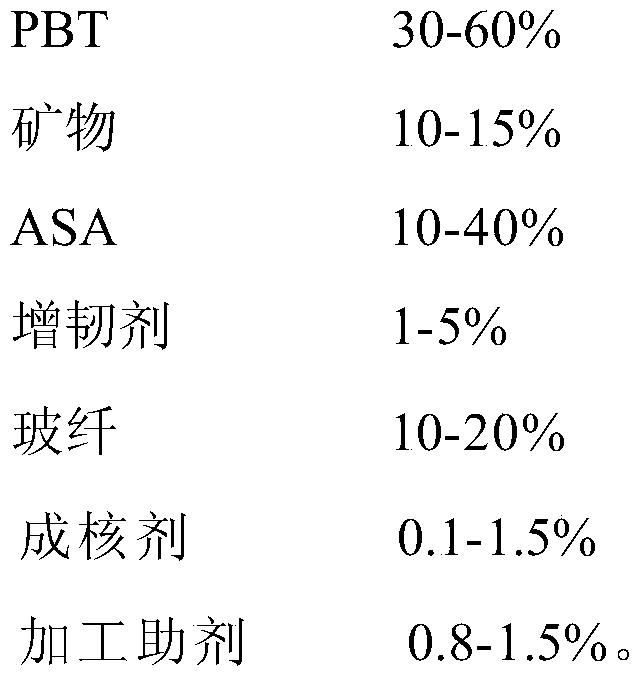

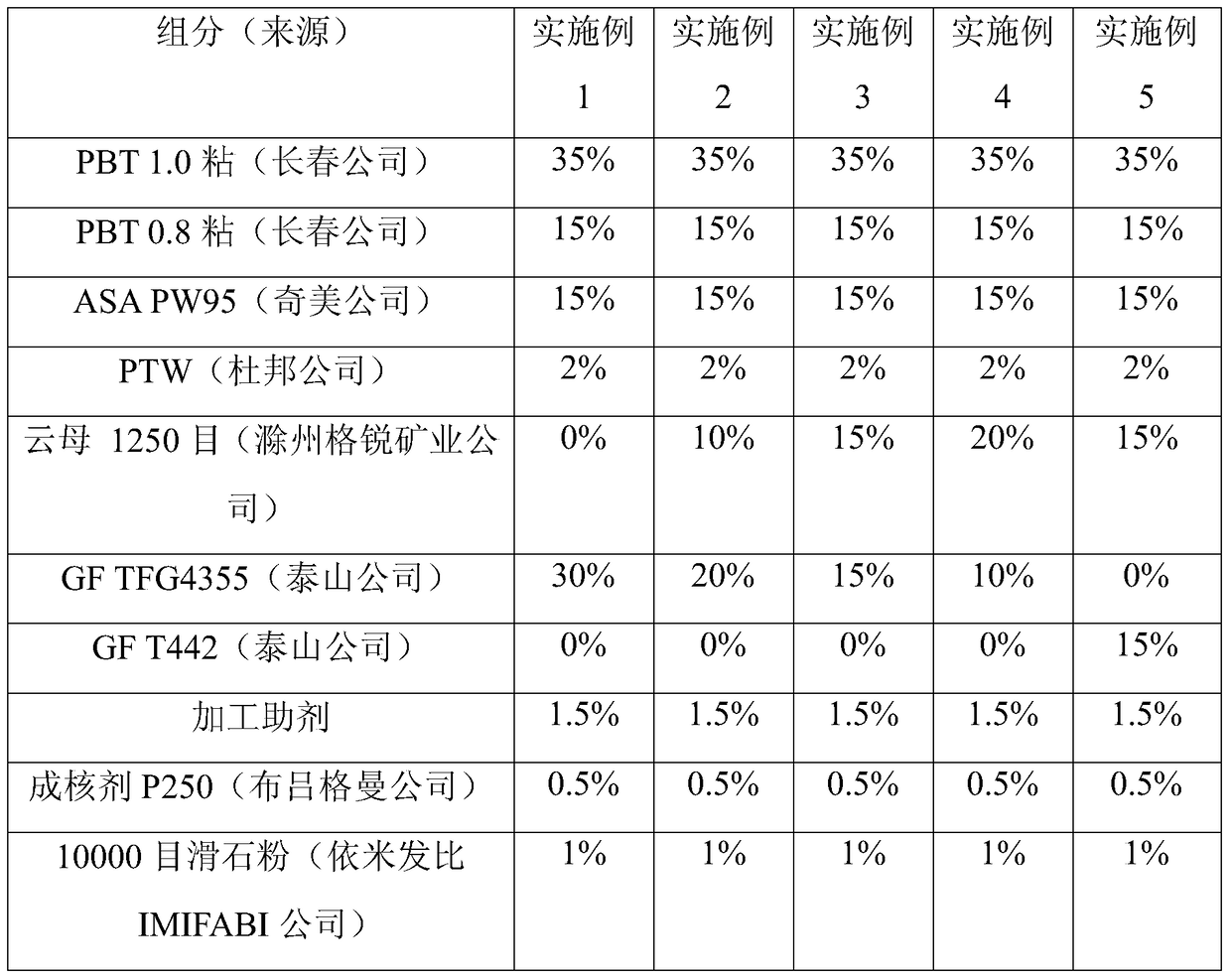

A high-performance anti-warping glass fiber reinforced pbt/asa alloy material

The invention discloses a high-performance anti-warping glass fiber reinforced PBT / ASA alloy material. The high-performance anti-warping glass fiber reinforced PBT / ASA alloy material is characterized by being prepared from, by weight, 30%-60% of PBT, 5%-20% of minerals, 10%-40% of ASA, 1%-5% of toughening agents, 5%-30% of glass fibers, 0.1%-1.5% of nucleating agents and 0.8%-1.5% of processing aids. The invention provides the glass fiber reinforced PBT / ASA alloy material which has excellent mechanical property and excellent anti-warping property, the novel alloy can be applied to workpieces such as truck outward turning decoration strips which are prone to warping and high in aging requirement, and a wide industrial application prospect is achieved.

Owner:中广核俊尔(上海)新材料有限公司

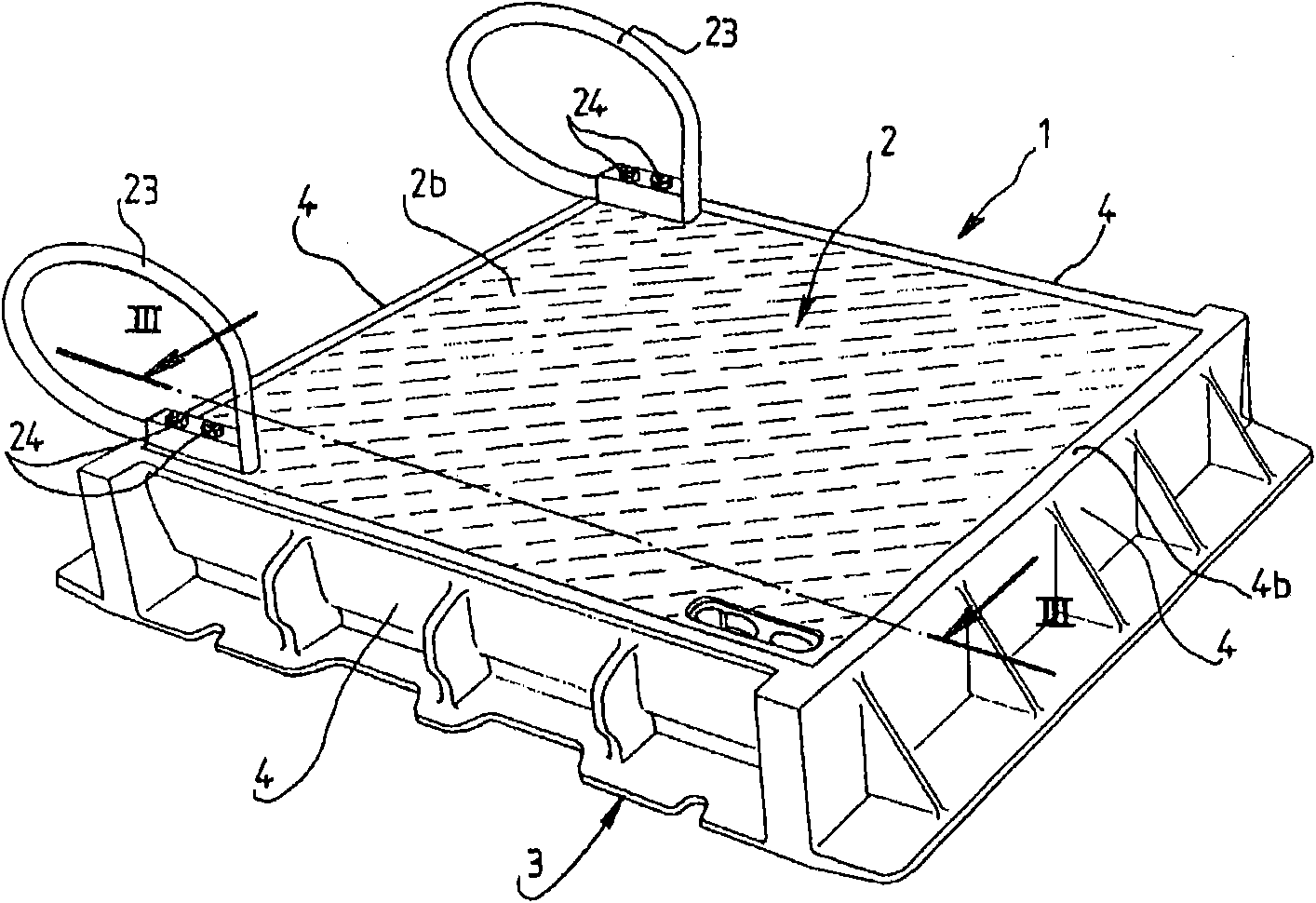

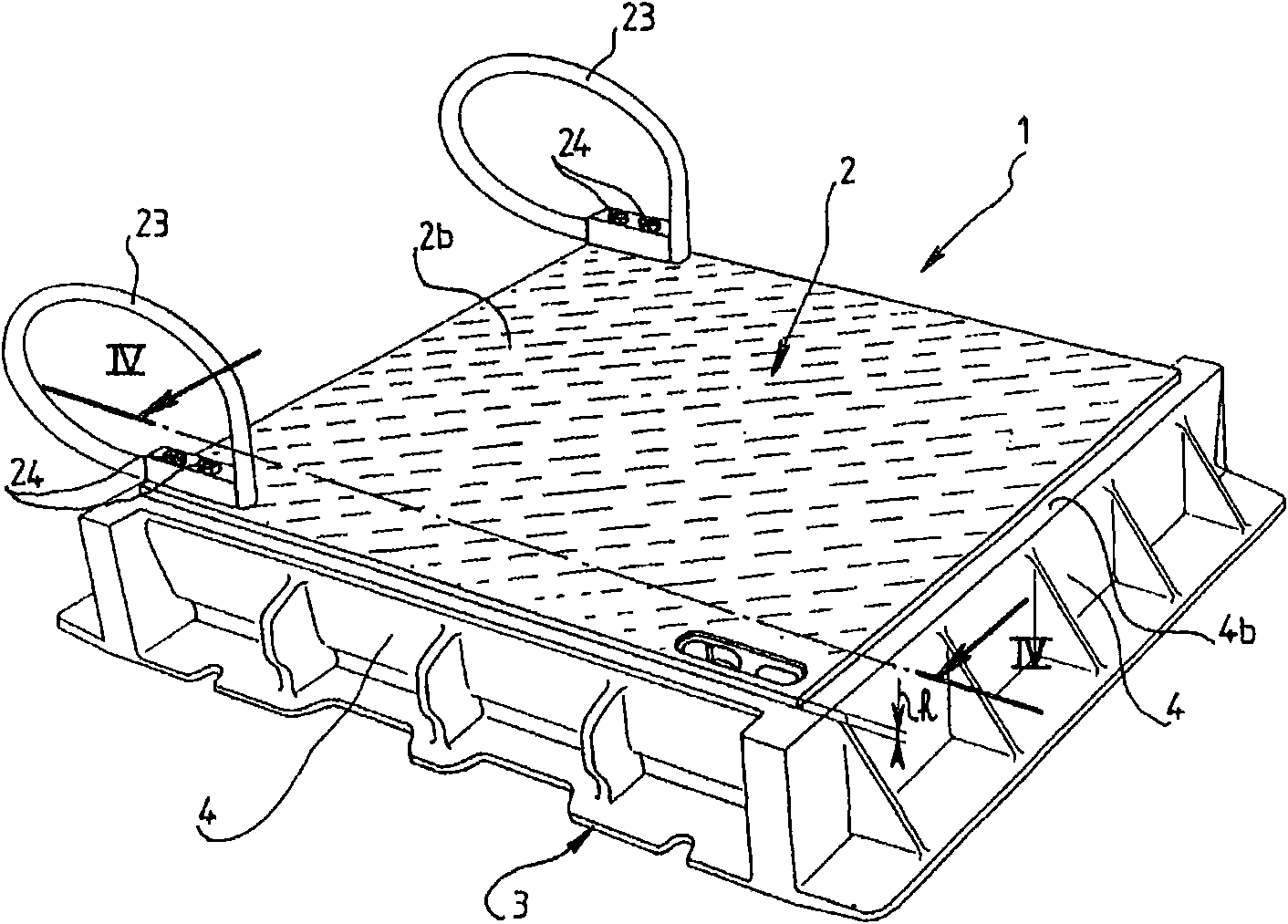

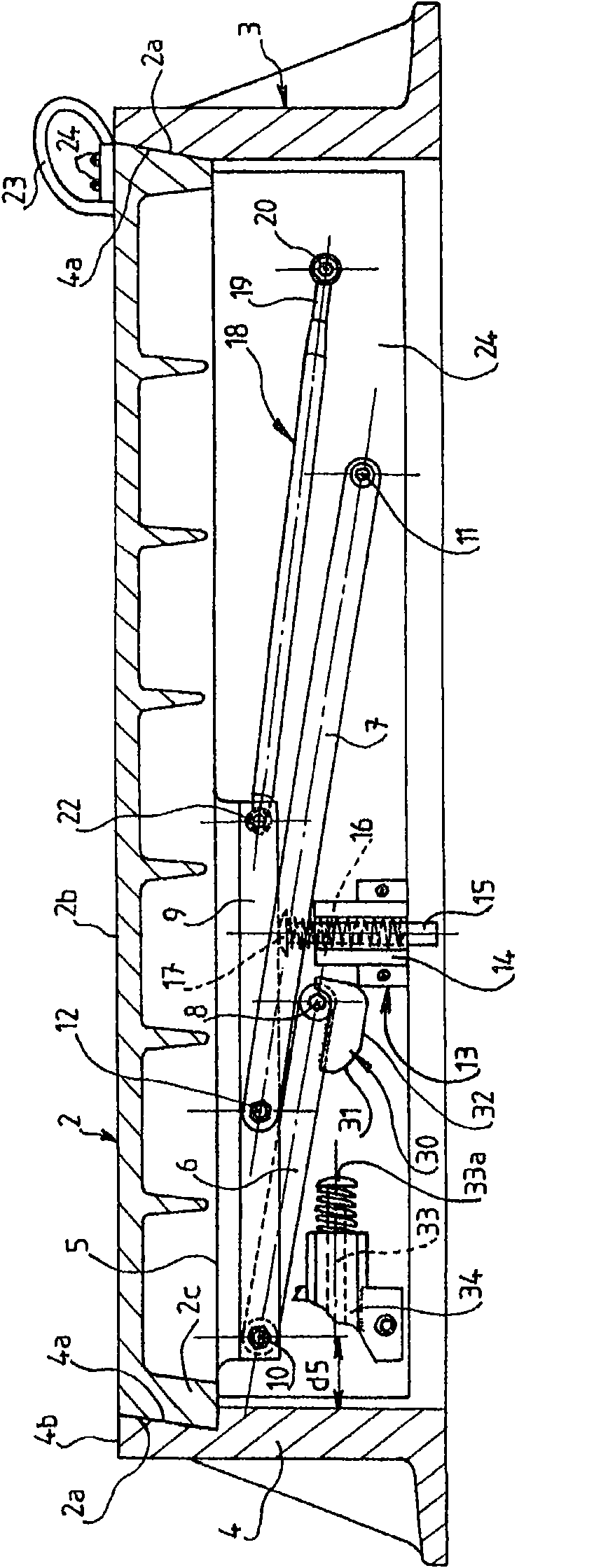

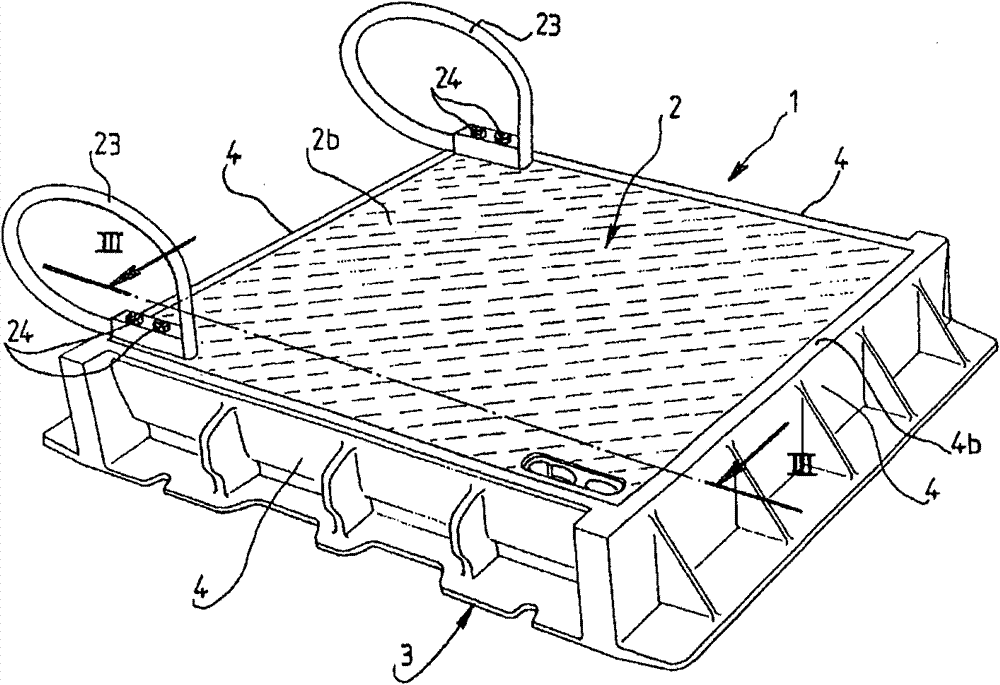

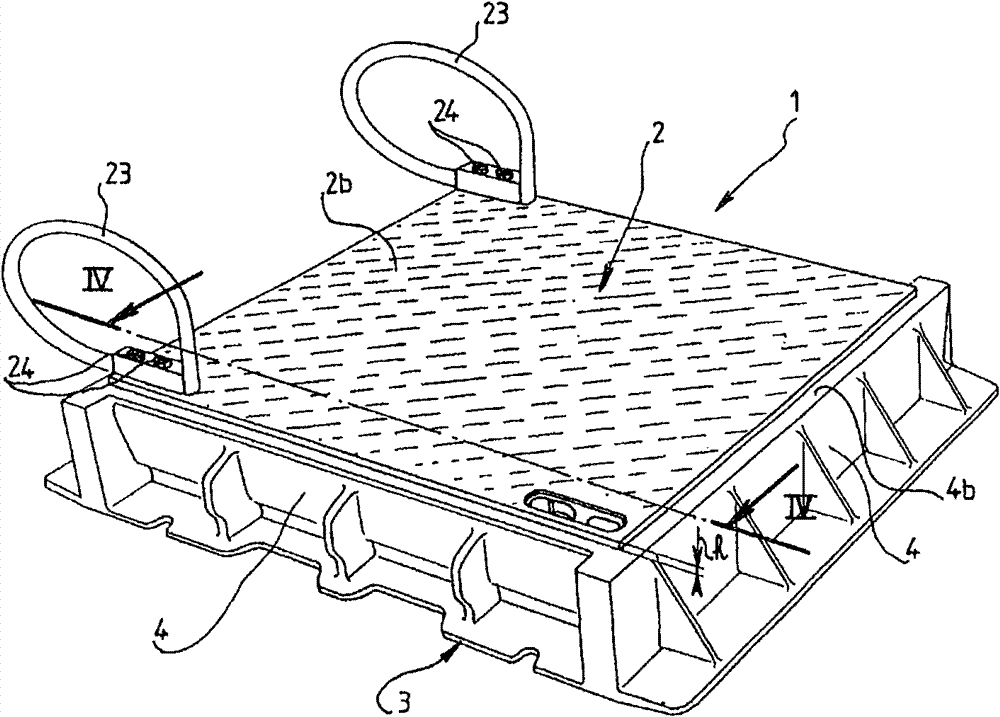

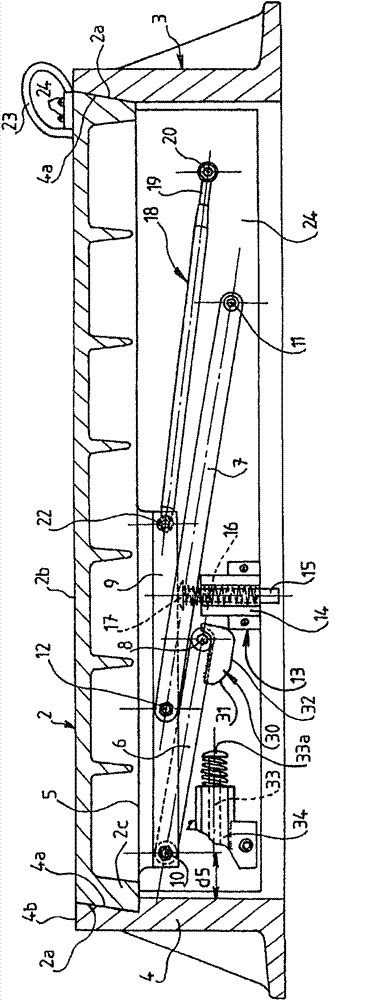

Device for hinging a lid or cover to a frame, such as a manhole

InactiveCN101583764ASimple structureEasy to warpArtificial islandsUnderwater structuresComing outEngineering

Owner:NORINCO SA

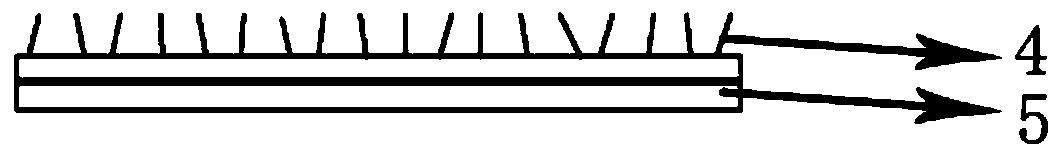

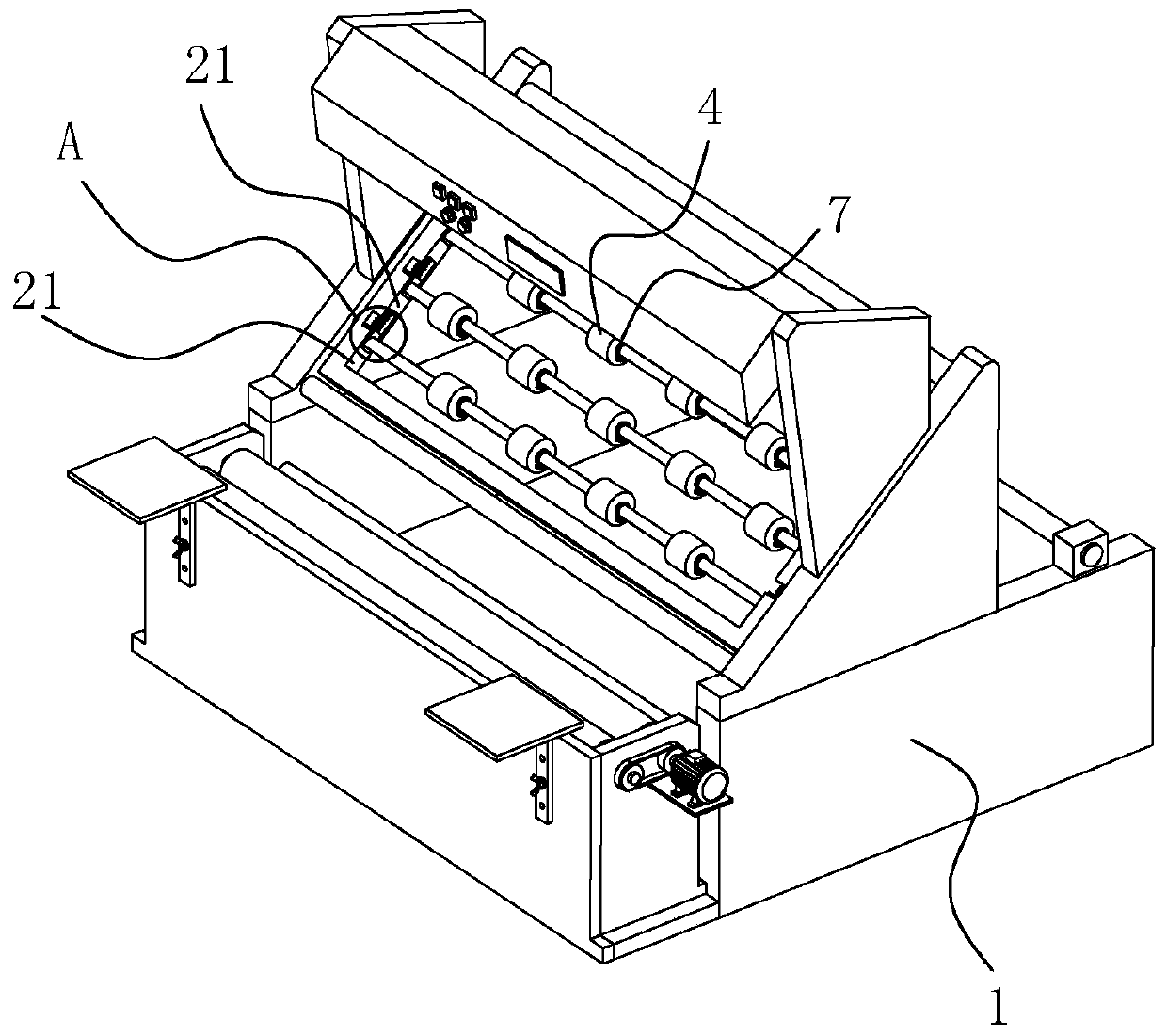

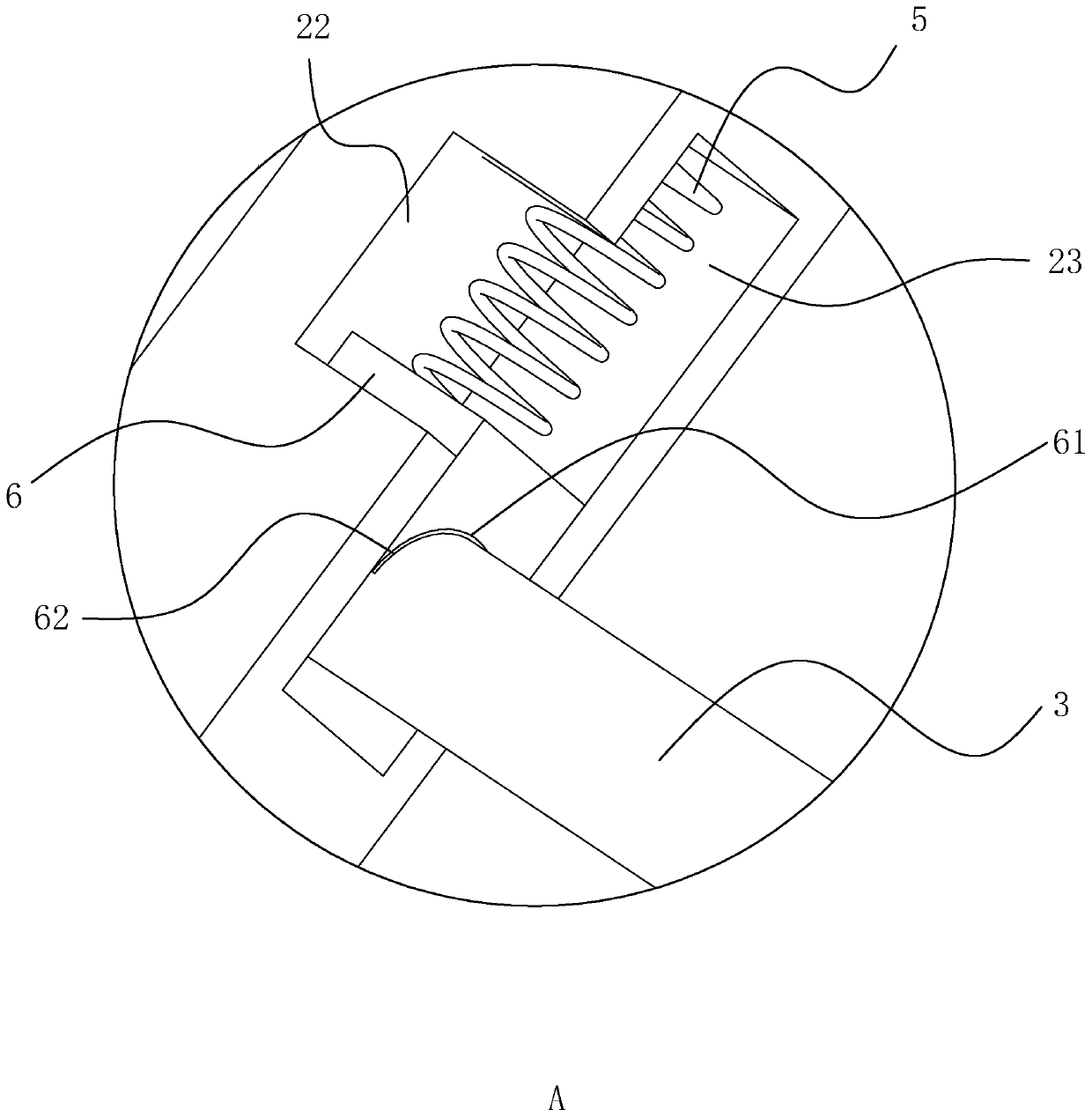

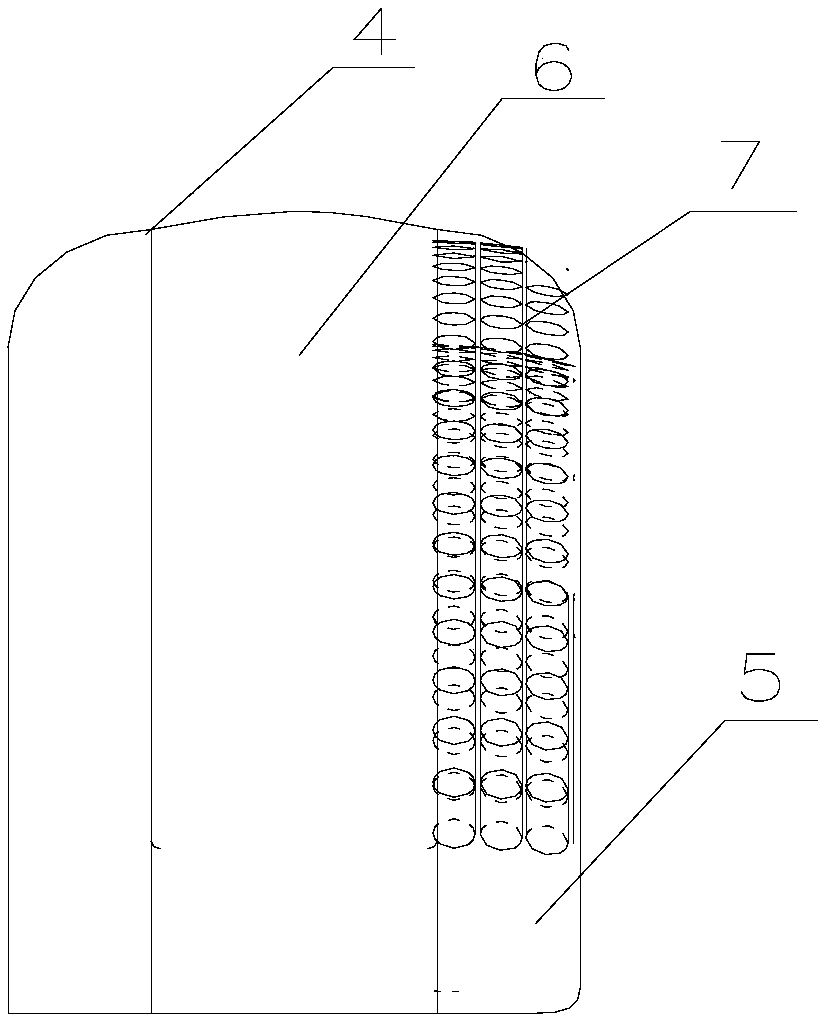

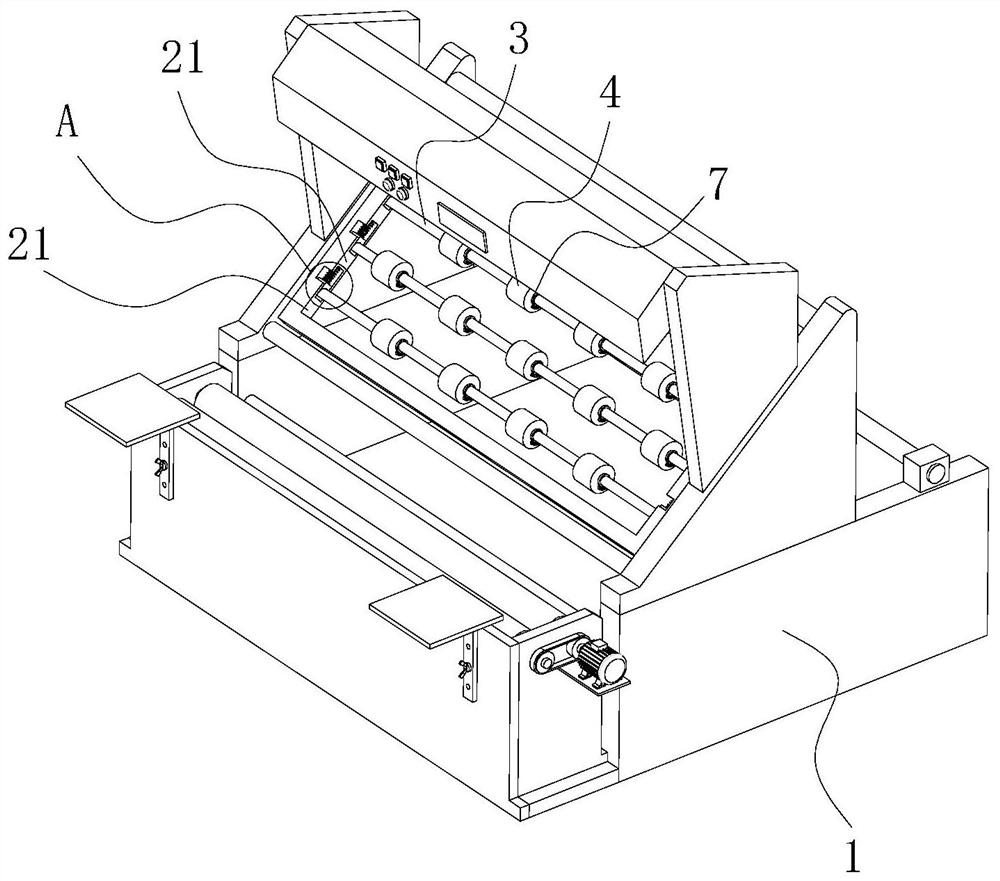

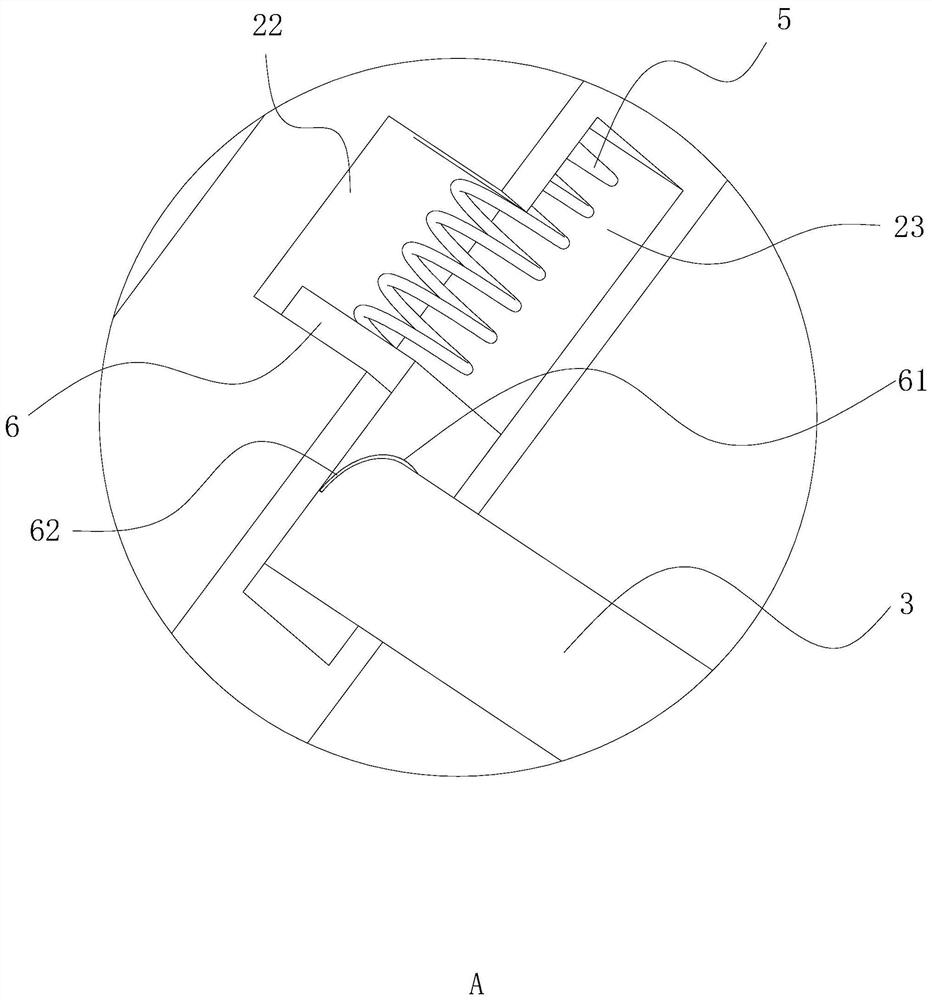

Yarn cutting and warping device for tape yarn production and yarn cutting device

InactiveCN104120532AReduce waste silkAvoid it happening againOther manufacturing equipments/toolsTextiles and paperYarnEngineering

The invention discloses a yarn cutting and warping device for tape yarn production. The yarn cutting and warping device comprises a yarn cutting device and a warping machine. The yarn cutting device is provided with a rack, a feeding mechanism, a slitting mechanism, a discharging tension adjusting mechanism and a control panel. The feeding mechanism, the slitting mechanism, the discharging tension adjusting mechanism and the control panel are arranged on the rack, and the feeding mechanism and the discharging tension adjusting mechanism are located on the two sides of the slitting mechanism respectively. The control panel is provided with a PLC capable of controlling the cutting speed of the slitting mechanism. The warping machine is used for tidying tape yarn at the discharging tension adjusting mechanism. According to the yarn cutting and warping device, the cut tape yarn can be warped directly, the spooling step is omitted, and the waste yarn amount is reduced. The invention further provides the yarn cutting device corresponding to the yarn cutting and warping device. The cutting speed of the yarn cutting device is stable, the cut tape yarn can be conveniently and directly warped, the spooling step in tape yarn production is omitted, and the waste yarn amount is reduced.

Owner:江苏易可纺家纺有限公司

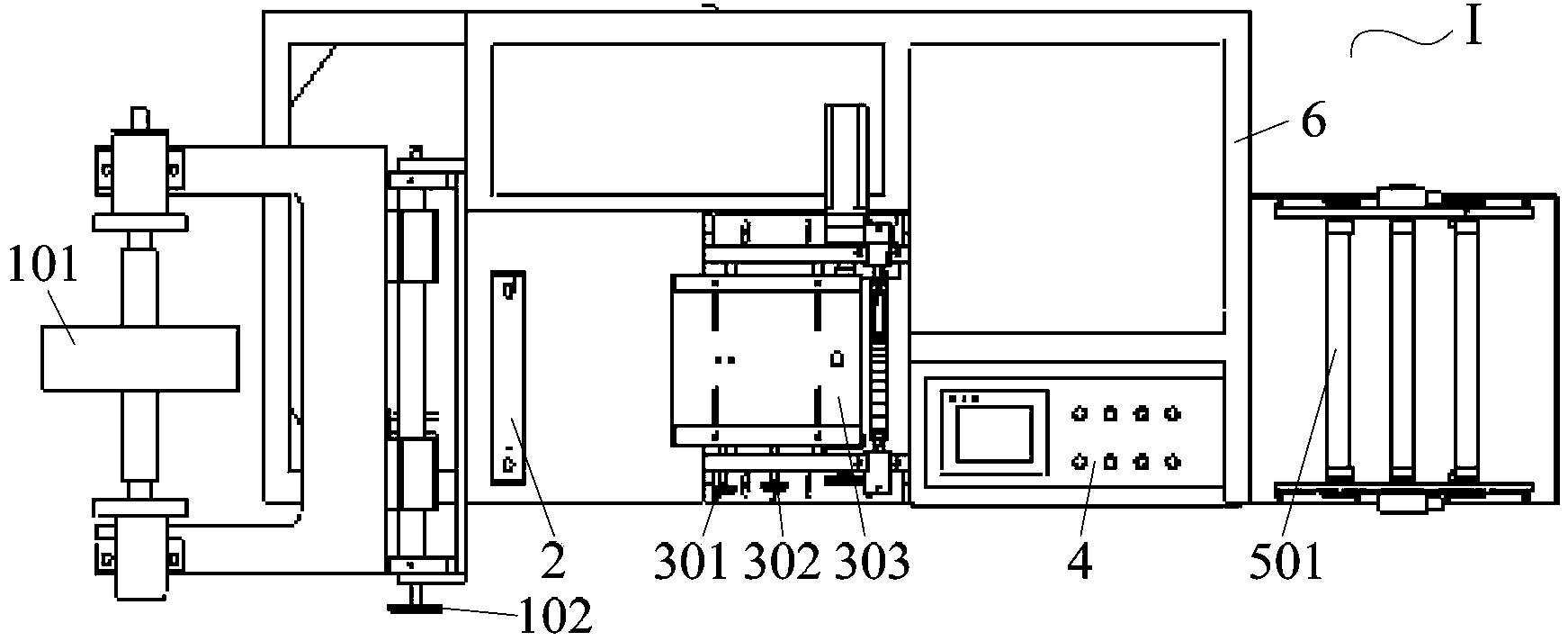

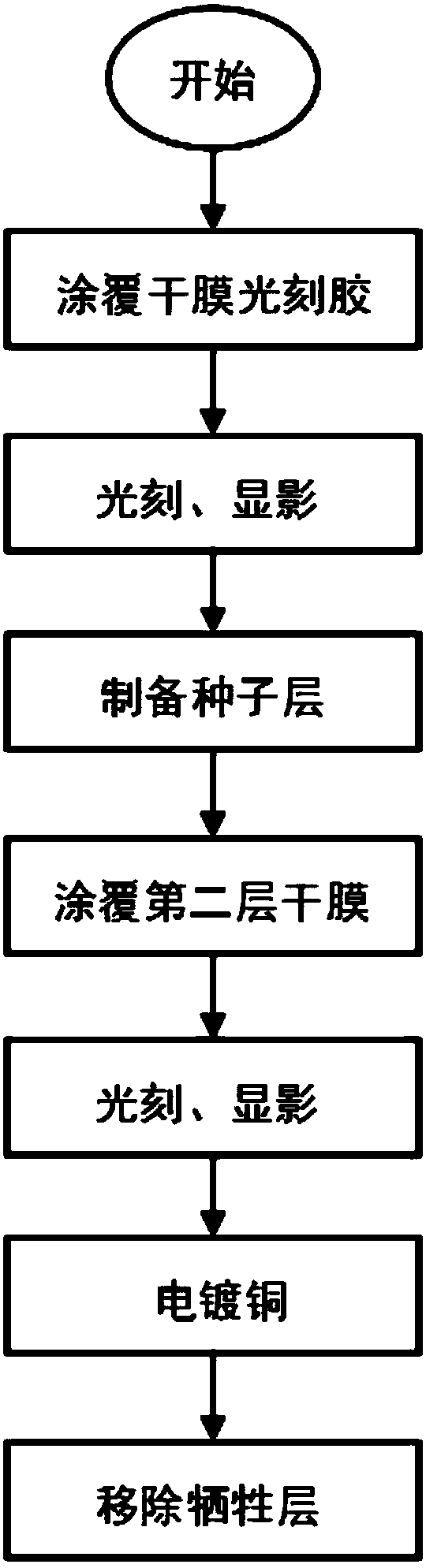

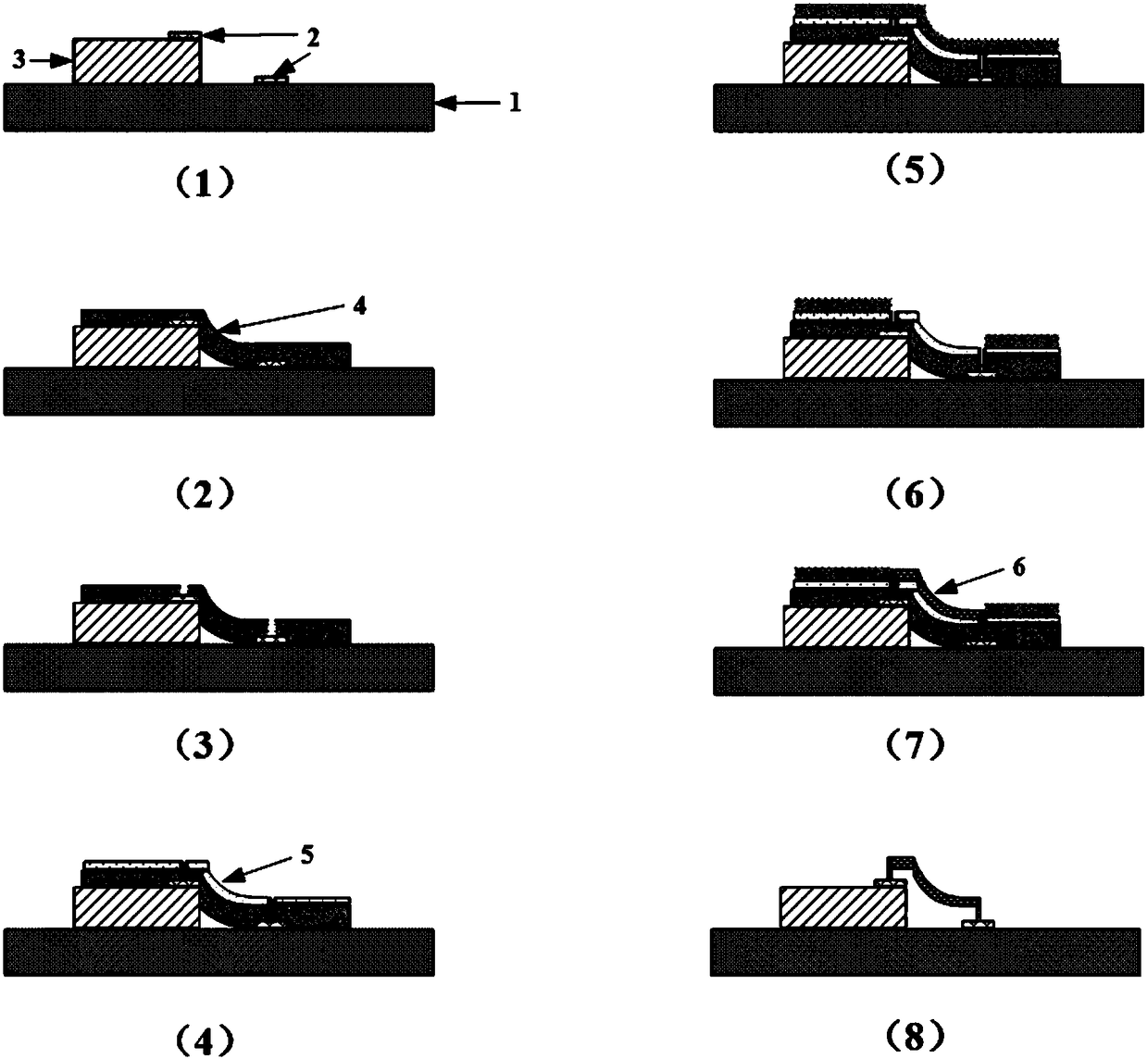

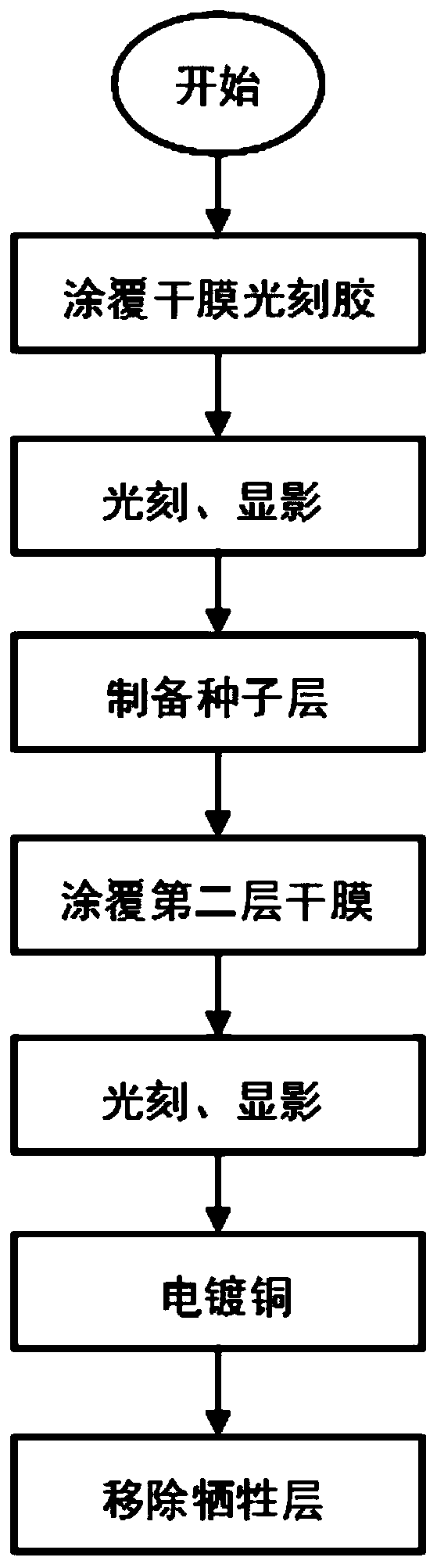

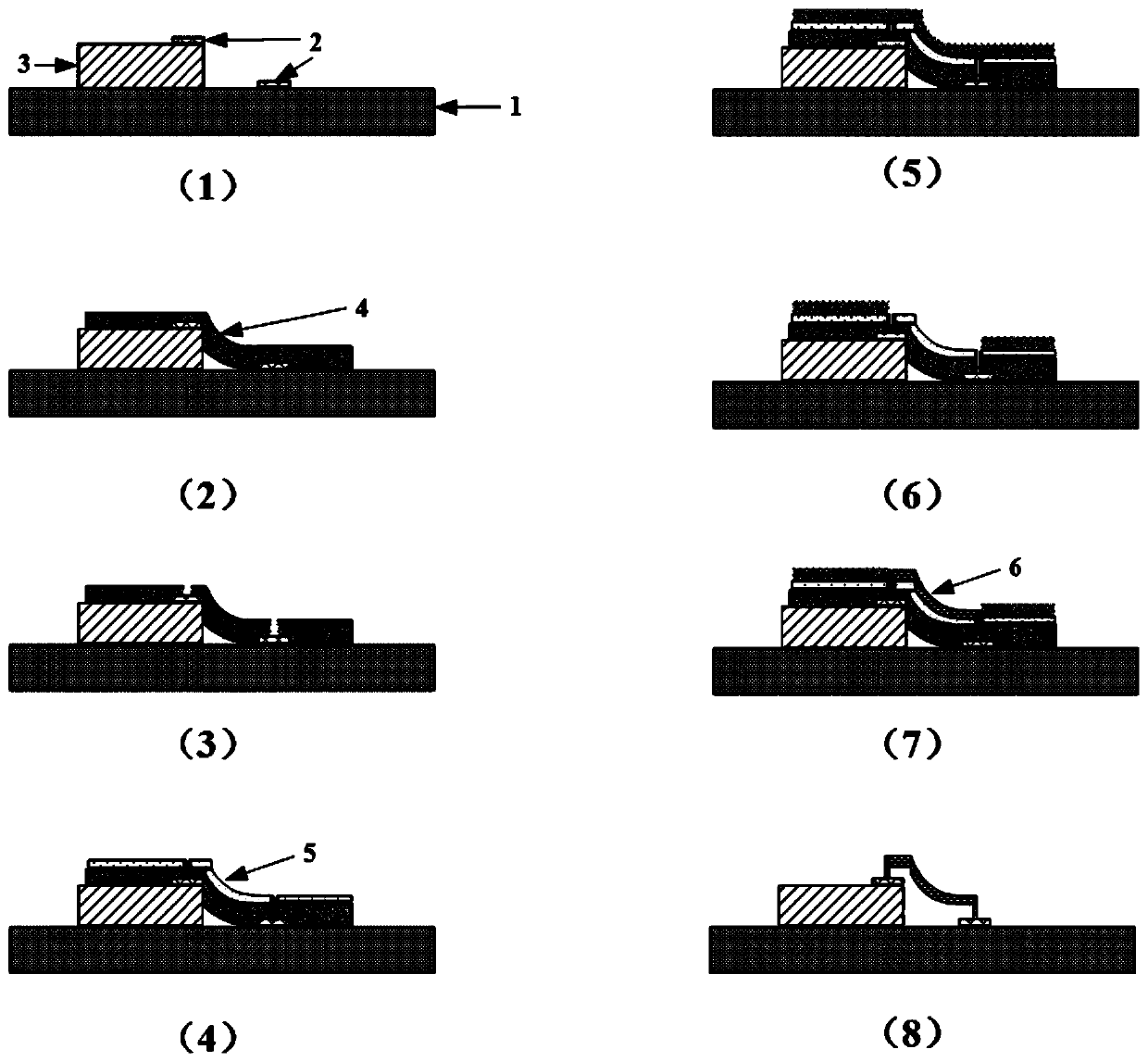

Method for realizing ultra-fine package lead based on photolithography and electroplating

ActiveCN108242433AAchieve connectionSolve Oxidation ProblemsSemiconductor/solid-state device detailsSolid-state devicesUltra fineCopper

The invention discloses a method for realizing ultra-fine package lead based on photolithography and electroplating. The method comprises a step of coating a surface of a substrate with the fixation of a chip and metal pads with a layer of dry film photoresist, a step of carrying out photolithography and development and showing through holes in a dry film on the chip and the metal pads, a step ofpreparing a seed layer on a formed surface, a step of coating the surface of the seed layer with a layer of dry film photoresist, a step of carrying out photolithography and development again such that the through holes on the metal pads and the seed layer under a lead between the through holes are exposed, a step of plating the surface of the exposed seed layer with a layer of copper and forminga lead between the metal pads, and a step of removing the dry film photoresist and the seed layer as sacrificial layers and finally forming a floating lead interconnect structure. According to the method, wire bonding is replaced by the photolithography and electroplating process, the connection between the chip and the substrate pads is achieved, the size of the lead is not restricted by a traditional wire bonding process, and so the feature size of the lead can be further reduced to the precision of photolithography.

Owner:SHANGHAI JIAO TONG UNIV

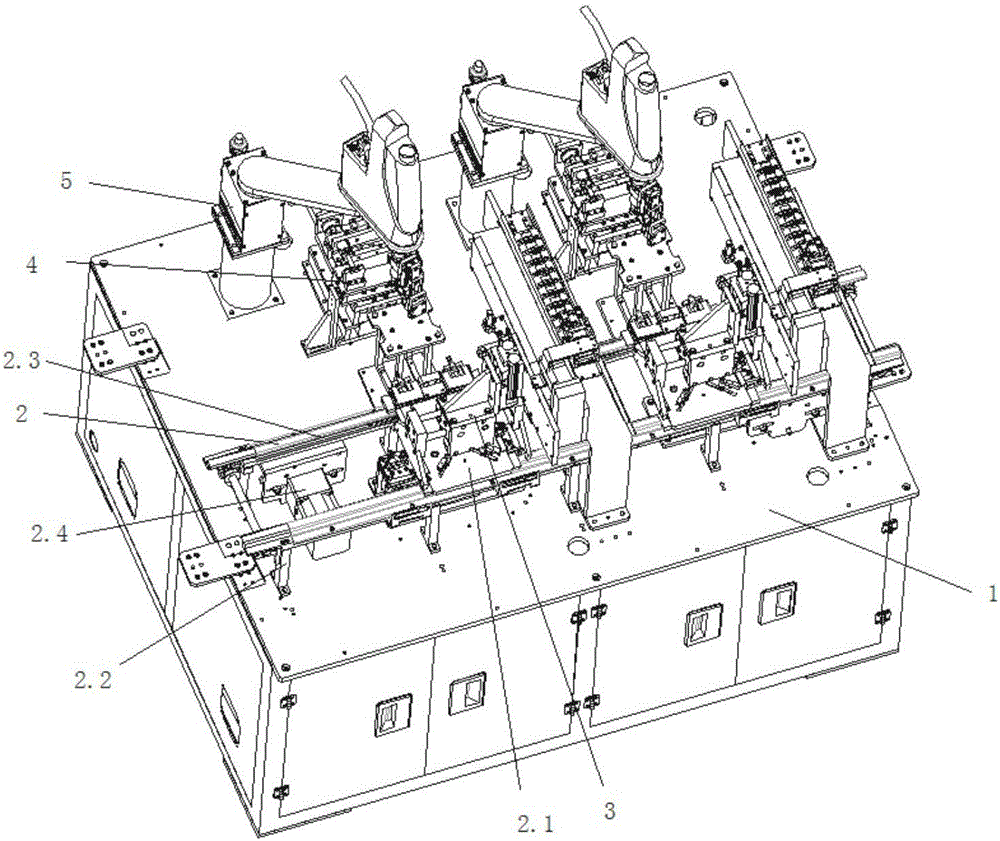

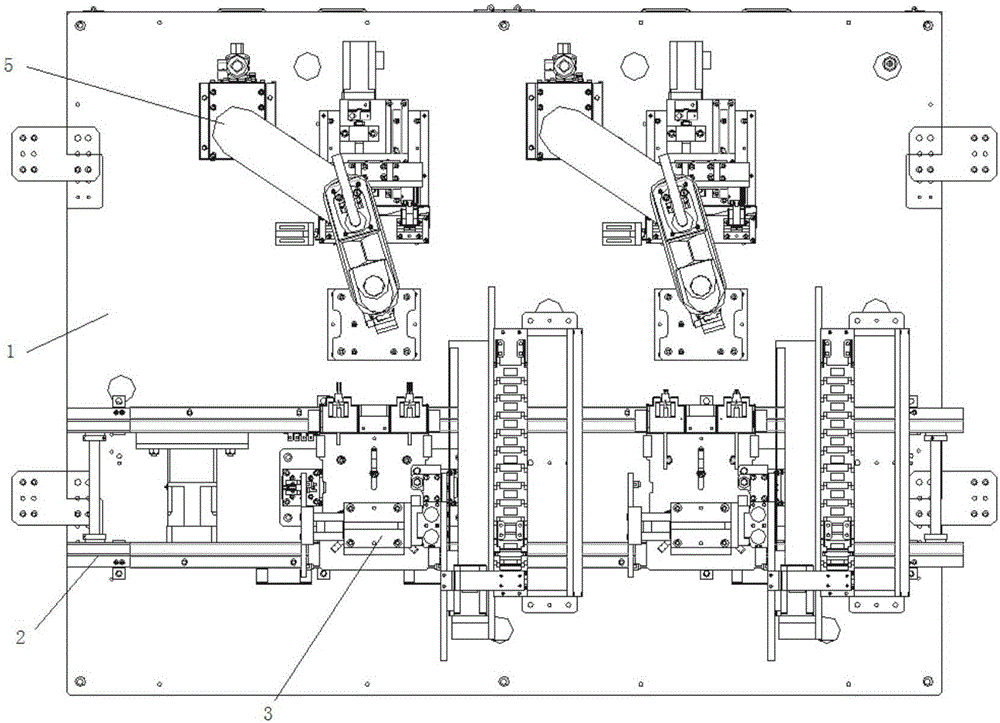

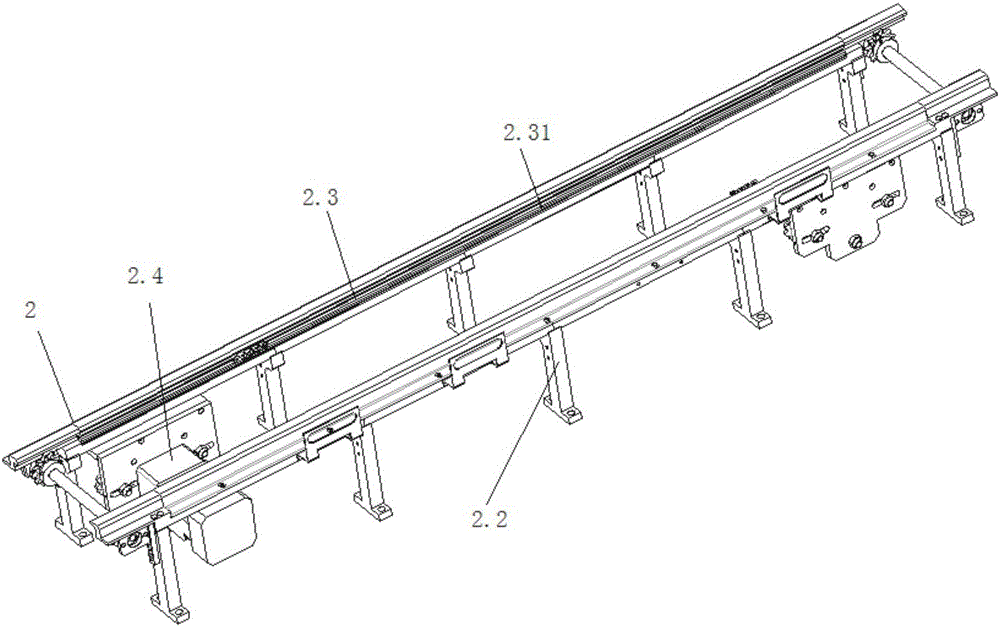

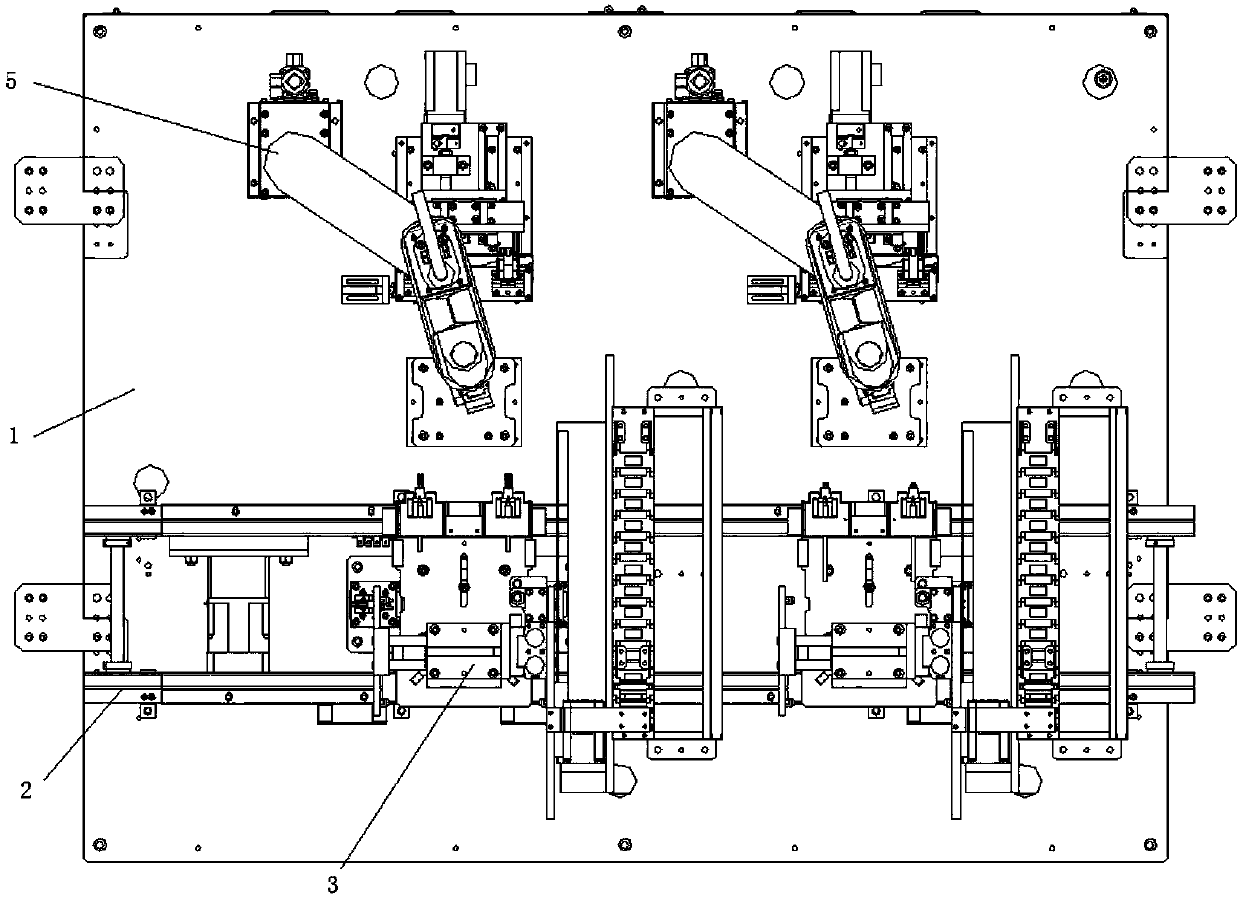

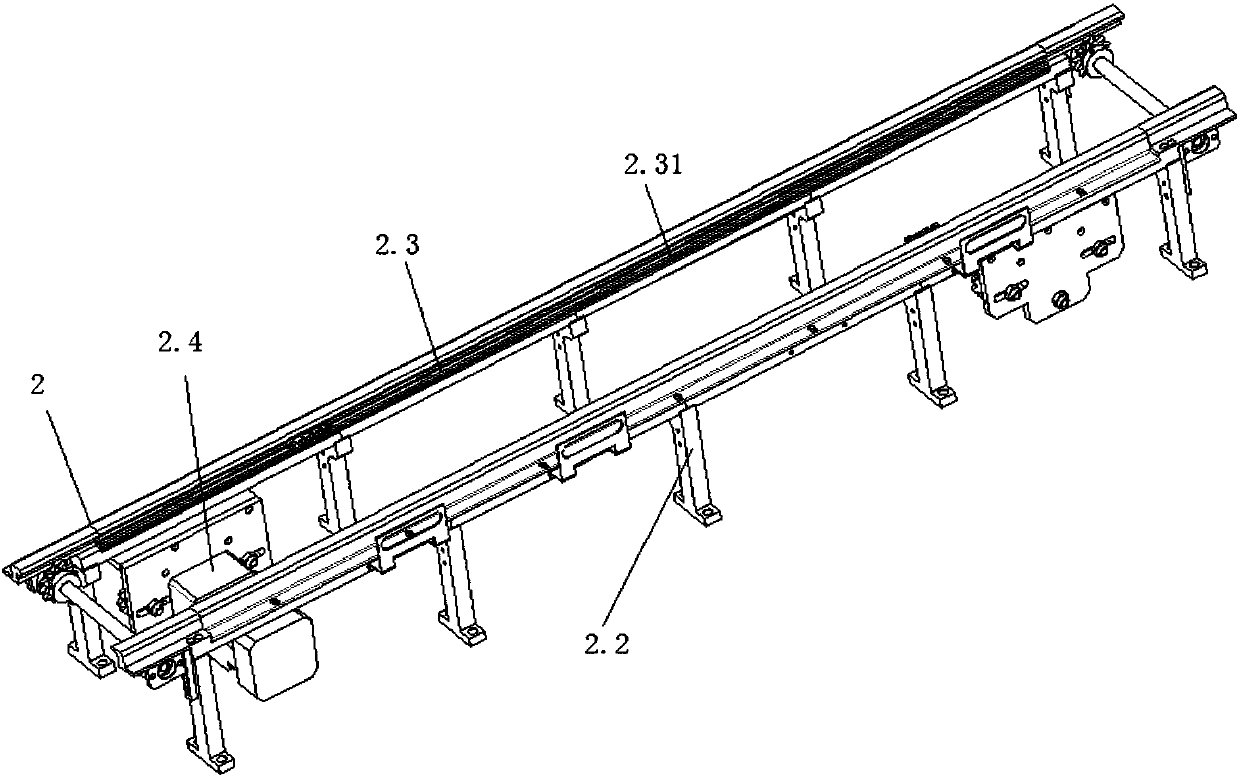

Automatic wire arranging system

ActiveCN106067648AImprove work efficiencyPrecise positioningLine/current collector detailsIndustrial engineering

The invention provides an automatic wire arranging system comprising a work table board and at least one wire arranging work group arranged on the work table board; the wire arranging work group comprises a conveying device, a jacking and shifting module group, an insulating layer detaching module group and a wire arranging and cutting module group; the specific number of the wire arranging work group is decided according to actual production requirements; the following modes of configuration are feasible for satisfying different requirements: only one wire arranging work group is put in place, a plurality of wire arranging work groups are connected in series, and a plurality of wire arranging work groups are connected in parallel; wire material is conveyed onto a work position to be jacked via the conveying device, the wire material is shifted to a work position to be processed via the jacking and shifting module group, part of an insulating layer on the wire material is detached via the insulating layer detaching module group in such a way that a wire core of certain length is exposed, the wire core of the wire material is subjected to wire arranging and cutting operation via the wire arranging and cutting module group, whole processes are finished via machines without manual labor, and work efficiency can be greatly improved.

Owner:CHANGSHA KINAL AUTOMATION TECH CO LTD

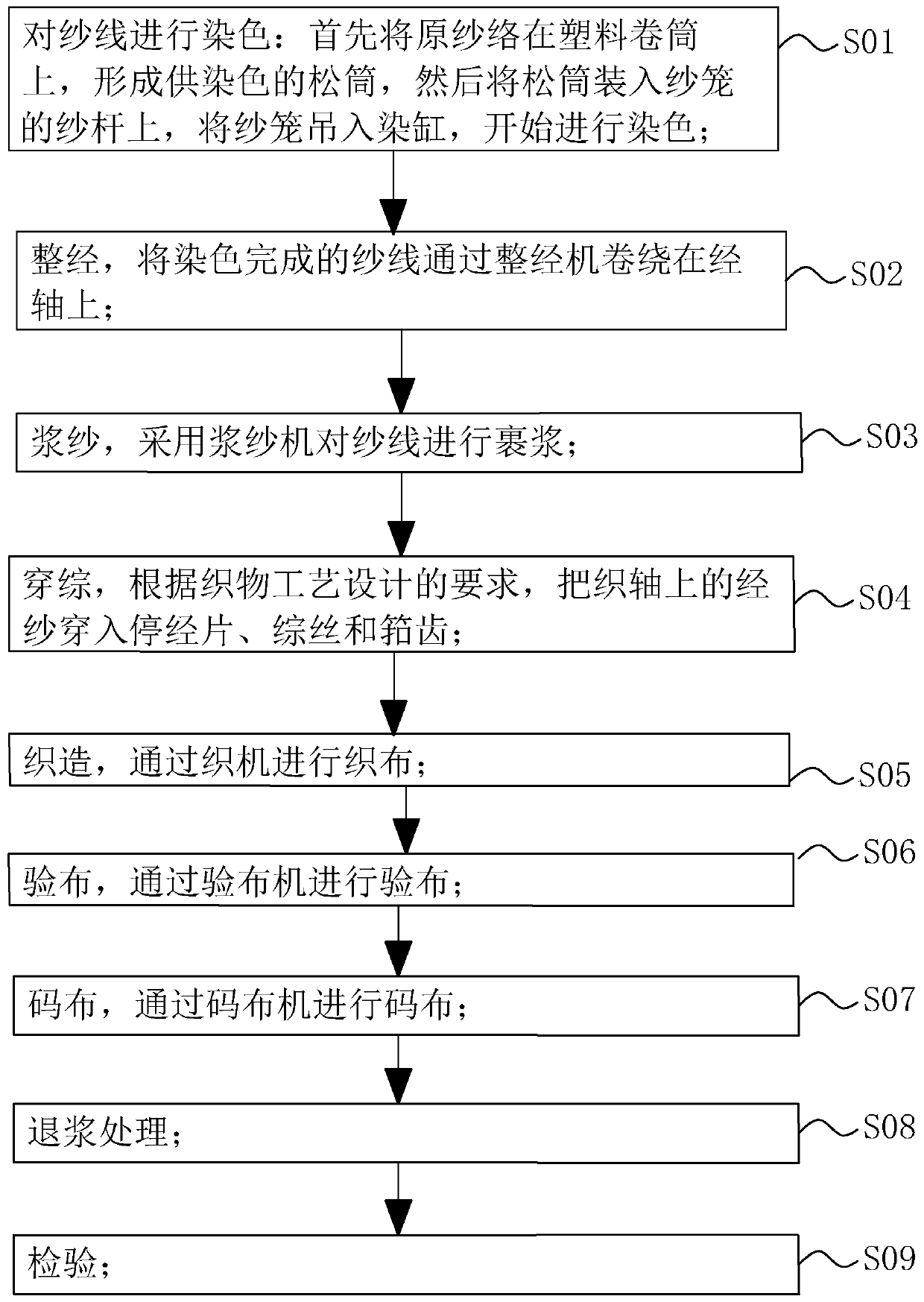

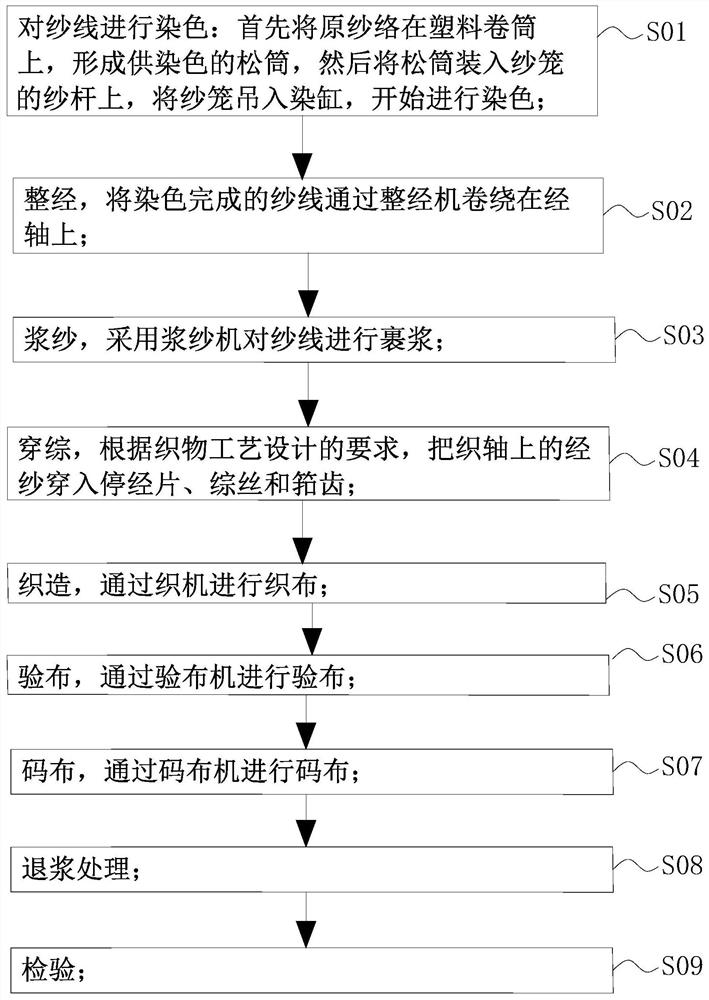

Production process of yarn-dyed fabric

ActiveCN111593460ADip dyed evenlyQuality improvementSucessive textile treatmentsInspecting textilesYarnIndustrial engineering

The invention relates to a production process of a yarn-dyed fabric. The production process comprises the following steps of (S01) dyeing yarns: netting grey yarns on a plastic reel first so as to form a pipe barrel for dyeing, then putting the pipe barrel on a yarn rod of a yarn cage, and lifting the yarn cage into a dye vat so as to dye; (S02) warping: winding the dyed yarns on a warp beam through a warping machine; (S03) slashing: binding the yarns by adopting a slashing machine; (S04) drafting: threading warps on the warp beam through droppers, harness wires and dents according to the requirement of fabric process design; (S05) weaving: weaving through a weaving machine; (S06) inspecting the fabric: inspecting the fabric through a fabric inspecting machine; (S07) plaiting: plaiting through a plaiting machine; (S08) desizing; and (S09) inspecting. The production process has the advantages that the subsequent process is optimized, and the overall quality of the fabric is increased.

Owner:南通博赢特阔织造有限公司

A method for realizing ultra-fine packaging leads based on photolithography and electroplating

ActiveCN108242433BAchieve connectionSolve Oxidation ProblemsSemiconductor/solid-state device detailsSolid-state devicesLead bondingPhotoresist

The invention discloses a method for realizing ultra-fine packaging leads based on photolithography and electroplating, specifically: coating a layer of dry film photoresist on the surface of a substrate on which chips and metal pads are fixed; Via holes are shown in the dry film on the chip and the metal pad respectively; a layer of seed layer is prepared on the formed surface; a layer of dry film photoresist is coated on the surface of the seed layer; photolithography and development are carried out again, so that The vias above the metal pads and the seed layer below the leads between the vias are exposed; then a layer of copper is electroplated on the surface of the exposed seed layer to form the leads between the metal pads; finally, the dry film as a sacrificial layer is removed Photoresist and seed layer, and finally form the suspended lead interconnect structure. The invention replaces wire bonding with photolithography and electroplating technology to realize the connection between the chip and the substrate pad. The size of the wire is not restricted by the traditional wire bonding process, so that the characteristic size of the wire can be further reduced to that of photolithography. precision.

Owner:SHANGHAI JIAO TONG UNIV

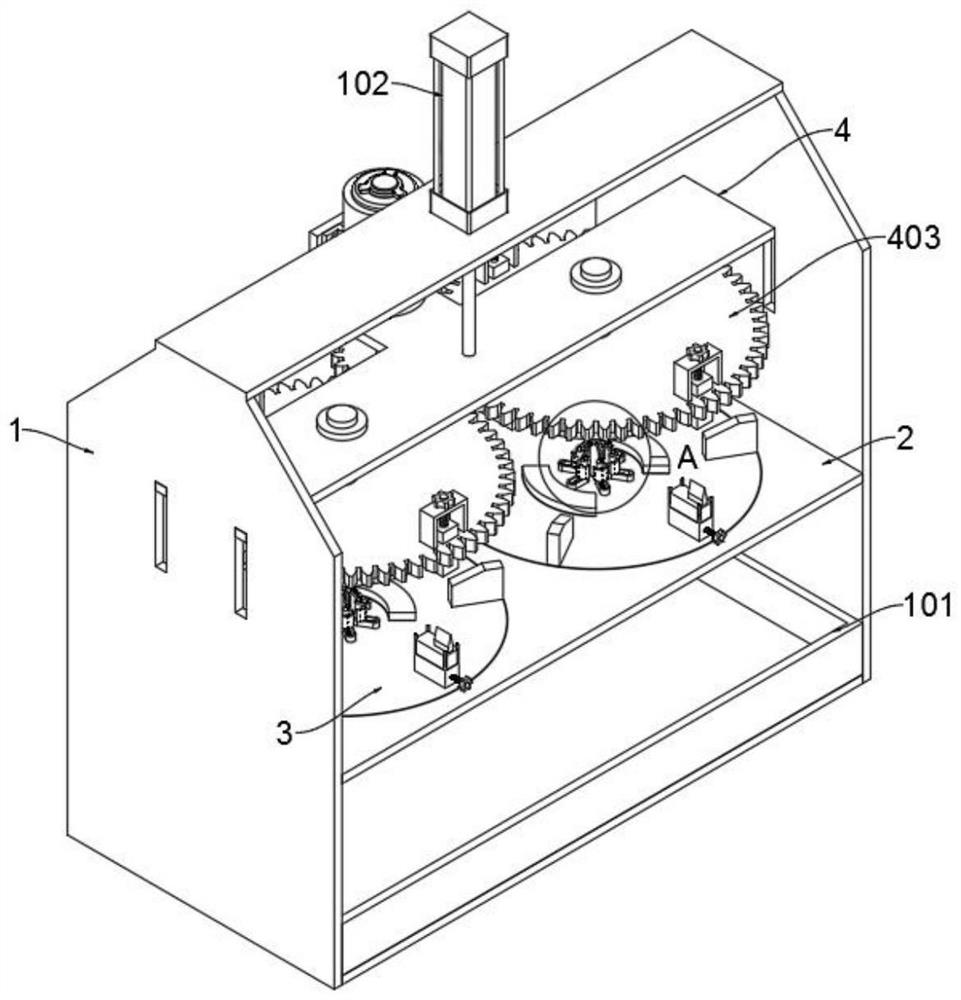

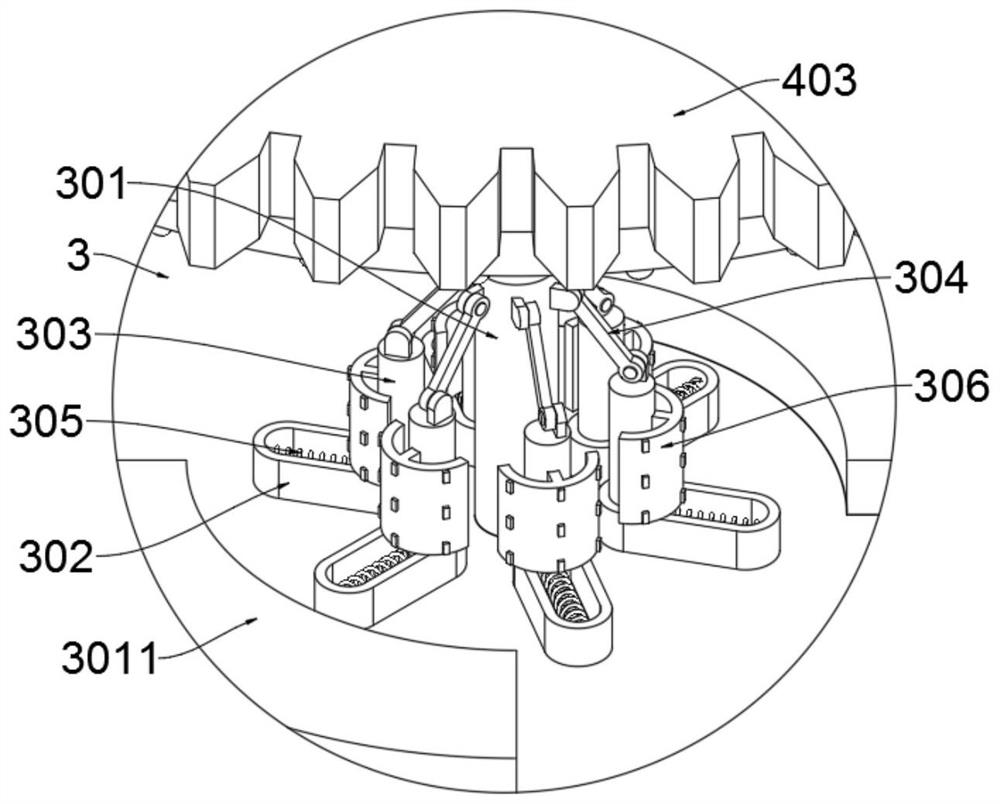

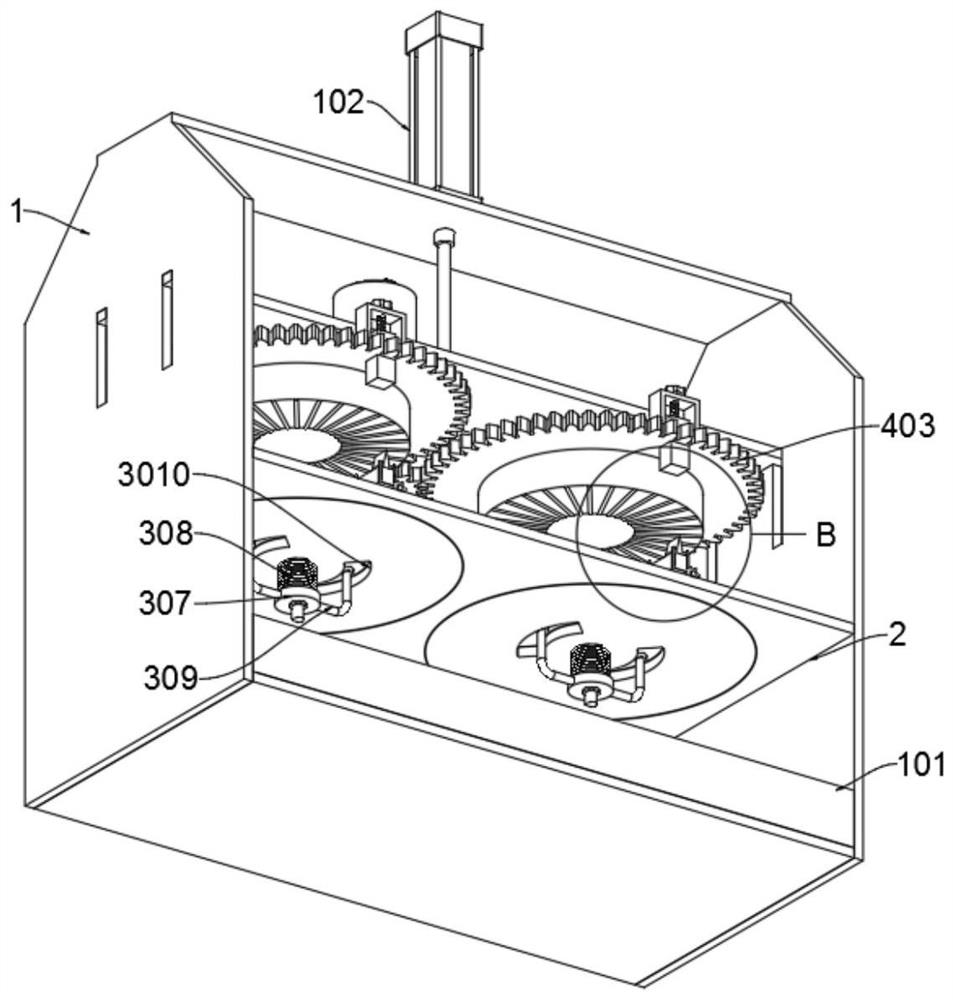

Grinding wheel disassembling and assembling machine with Teflon heat insulation cloth and disassembling and assembling method of grinding wheel disassembling and assembling machine

ActiveCN114211416APrevent savingAvoid disassembly efficiency reductionPlastic recyclingMetal working apparatusElectric machineryElectric power equipment

The invention provides a grinding wheel disassembling and assembling machine with Teflon heat insulation cloth and a disassembling and assembling method thereof, and relates to the technical field of grinding wheel machining. The grinding wheel disassembling and assembling machine comprises a main body frame, and a containing box is arranged at the bottom end of the interior of the main body frame; a circular groove is formed in the top of the carrying plate, and a loading disc is arranged in the circular groove. Sliding grooves are formed in the left side and the right side of the main body frame, and a loosening frame is slidably installed in the sliding grooves. And a dismounting frame is arranged on the outer side of the top of the loading disc. The loosening mechanism and the shoveling mechanism can be driven by one motor to synchronously work, the arrangement number of electrical equipment is reduced, the production cost of the device is reduced, in addition, loosening work and shoveling work are synchronously carried out, and then the purpose of efficient disassembly is achieved. The problems that a loosening mechanism and a shoveling mechanism in an existing disassembling and assembling machine are lack of certain linkage, the two kinds of work cannot be conducted synchronously, and the disassembling efficiency of the disassembling and assembling machine is indirectly reduced are solved.

Owner:临沂市大鹏五金磨具有限公司

A kind of multifunctional elastic rubber pad and its manufacturing method

ActiveCN105856784BNot easy to fadeColorfulNon-macromolecular adhesive additivesLaminationPublic placeSurface layer

Owner:QINGYUAN CHUANAO HI TECH MATERIAL CO LTD

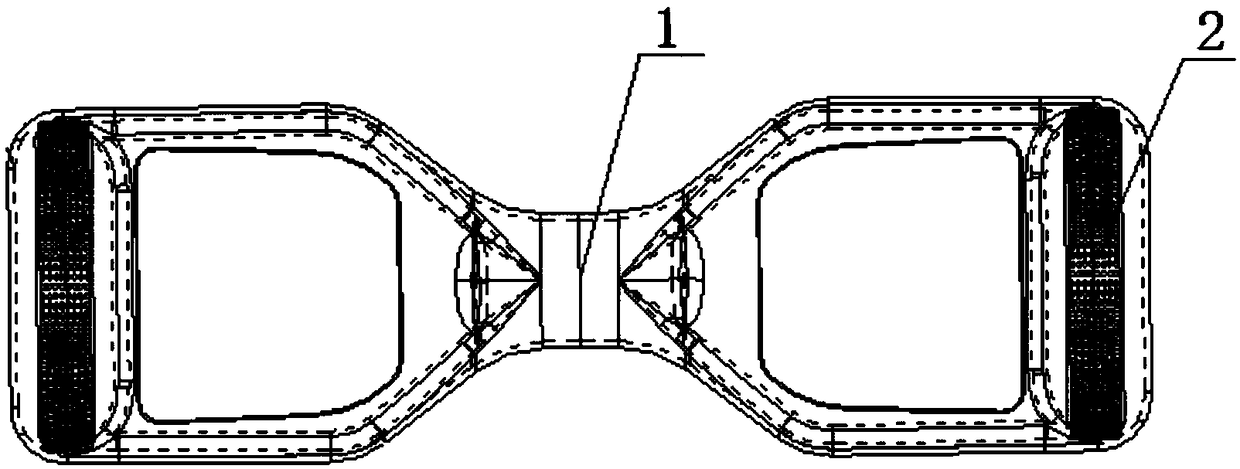

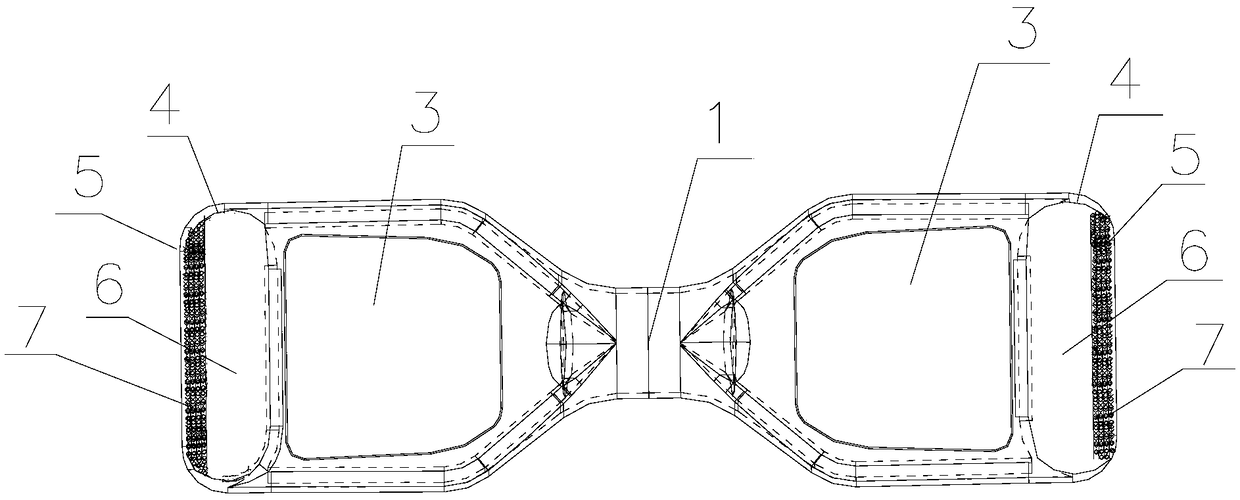

Cleaning tool for cleaning balancing vehicle, and balancing vehicle

ActiveCN109131679AAvoid scratchesAvoider crashCycle equipmentsMotorcyclesEngineeringAutomotive engineering

Owner:深圳市领航致远科技有限公司

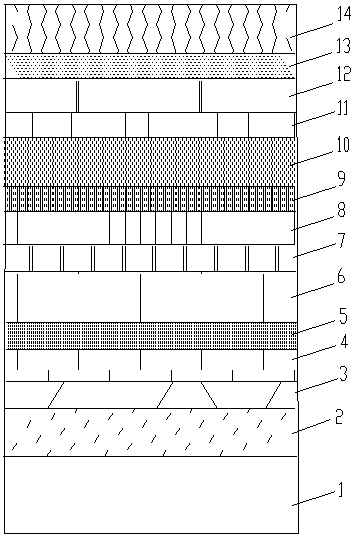

A kind of temperable three-silver low-e glass and its tempering process

ActiveCN104973804BAchieve stabilityImprove heat transfer performanceGlass tempering apparatusGlass productionHeat resistanceRadiance

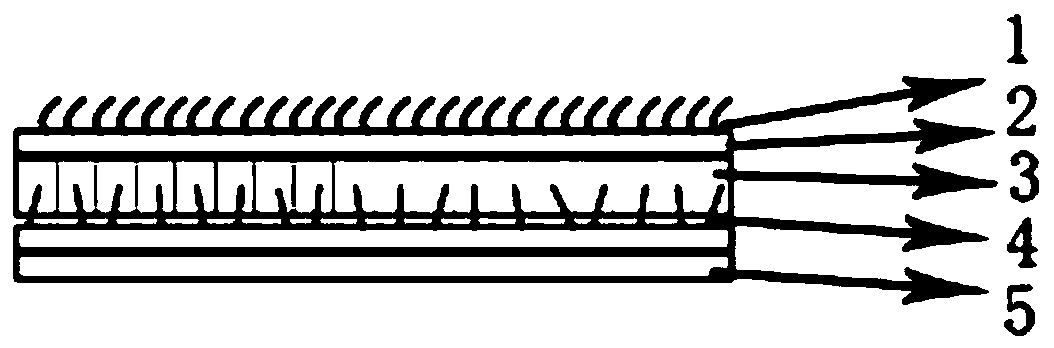

The invention provides a temperable three-silver-layer low-E glass and a tempering process thereof. The glass comprises a glass substrate and the following layers laminated on the glass substrate from top to bottom: a first dielectric film layer, a first barrier layer, a first silver layer, a second barrier layer, a second dielectric film layer, a third barrier layer, a second silver layer, a fourth barrier layer, a third dielectric film layer, a fifth barrier layer, a third silver layer, a sixth barrier layer and a fourth dielectric film layer. The glass film layers has good heat resistance at high temperature; the tempering process employs low-temperature long-time heating, thereby effectively preventing the film layers from damage by high temperature; and the tempered glass has same transmissivity, reflectivity and low radiance as untempered glass and has the characteristics of high strength and good mechanical properties unique to tempered glass.

Owner:TAICANG YAOHUA GLASS

An automatic reclosing device for a circuit breaker

ActiveCN106356263BEliminate shakingEliminate liftProtective switch operating/release mechanismsEngineeringDrive motor

The invention provides an automatic reclosing lock device of a breaker. The automatic reclosing lock device comprises a drive motor, a linkage tripping mechanism, a transmission gear mechanism and a breaker handle mechanism, wherein the transmission gear mechanism comprises a first transmission gear, a second transmission gear and a third transmission gear which are adjacently meshed with one other, a cam portion of the second transmission gear can drive a push rod to shift a tripping rod, so as to quickly separate the breaker, the second transmission gear can drive an incomplete gear to rotate continuously, and the incomplete gear and the third transmission gear are in mesh transmission to drive a handle to switch on automatically through a linkage rotation shaft. The automatic reclosing lock device has the advantages of being reliable in transmission, strong in stability and capable of enabling the second transmission gear not to be prone to shaking or rising; thus, the automatic reclosing lock device can avoid the problem of tripping clamping stagnation or tripping slide when being matched with a linkage tripping part, the use performance of a product is favorably improved, and the service life of the product is favorably prolonged.

Owner:ZHEJIANG ZHONGFU ELECTRIC

A kind of spectacle frame mold structure

Owner:中山兆鸿精密模具注塑有限公司

Device for hinging a lid or cover to a frame, such as a manhole

InactiveCN101583764BSimple structureEasy to warpArtificial islandsUnderwater structuresClassical mechanicsStructural engineering

Owner:NORINCO SA

A shell matching the armrest box and an armrest-type vehicle-mounted air purifier

ActiveCN108032812BImprove positionFriction does not causeAir-treating devicesPassenger spaceKinematic pairAir purifier

The invention provides a shell body matched with an armrest box and an armrest type vehicle-mounted air purifier. The shell body is arranged in a shape of an armrest box cover, the shell body comprises a base, an upper cover and a first sliding kinematic pair, the base is provided with a connecting part matched with an armrest box substrate, the sliding kinematic pair is arranged between the baseand the upper cover for relatively sliding, the first sliding kinematic pair is sliding blocks and a sliding rod inserted in the sliding blocks, so that the problems that sliding stroke of the existing armrest box cover is limited and the existing armrest type air purifier can not adjust the armrest position.

Owner:XIAMEN MAXMAC AIR TECH

Labeling device and labeling method

A labeling device comprising a separating knife having an upper surface, a conveying liner to which a label is attached is adapted to move along the upper surface of the separating knife, the upper surface of the separating knife having a guiding portion and a separating portion, The separation part is connected with the guide part, and the separation part is a curved surface, and the section of the curved surface perpendicular to the moving direction of the conveying pad is a curve. The separating part of the separating tool of the above-mentioned labeling device is a curved surface, and the section of the curved surface perpendicular to the moving direction of the conveying liner is a curve, which can make the label and the conveying liner pass through the separating part due to the curved surface of the separating part. A pre-bend is added to increase the stiffness of the label in the direction of movement, so that when the label continues to move to the tip of the label separation part along with the transfer liner, the label can be easily lifted from the transfer liner, thereby improving the label peeling rate and The yield rate of the posted product.

Owner:文霞

Sealing cover of a steering lever of a walking vehicle and a walking vehicle

Owner:深圳市百汇新健康管理有限公司

An automatic line management system

ActiveCN106067648BRealize continuous deliveryAchieve separationLine/current collector detailsIndustrial engineeringCable management

Owner:CHANGSHA KINAL AUTOMATION TECH CO LTD

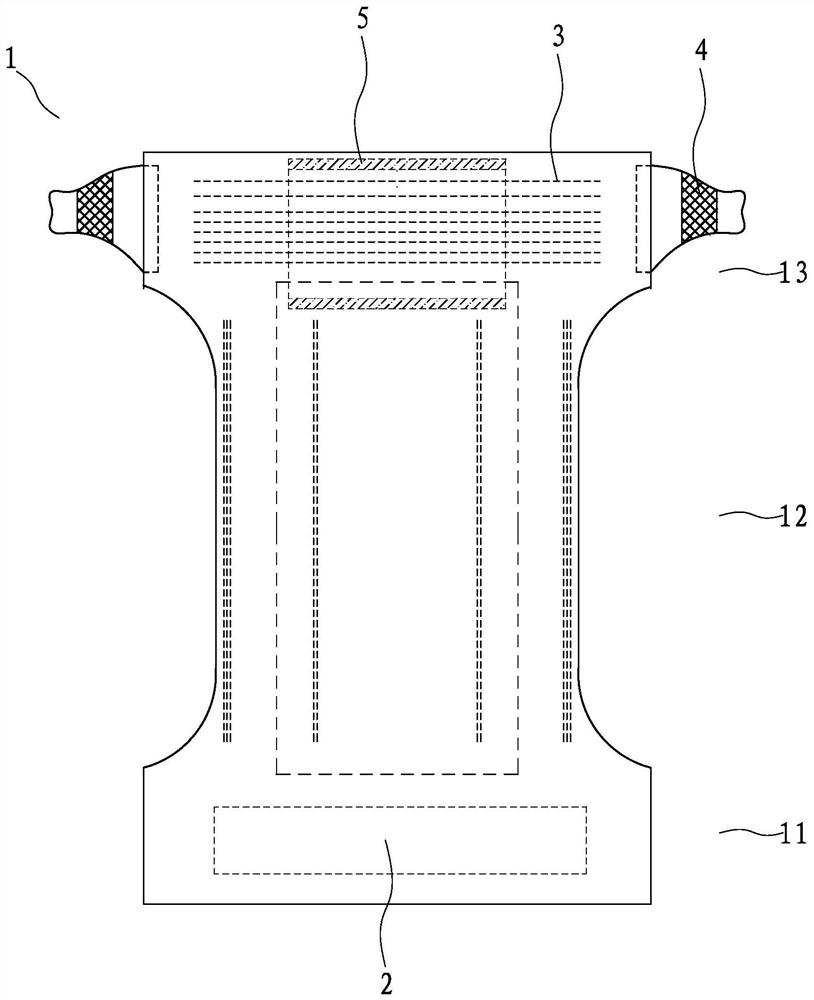

A kind of leash-proof baby diaper

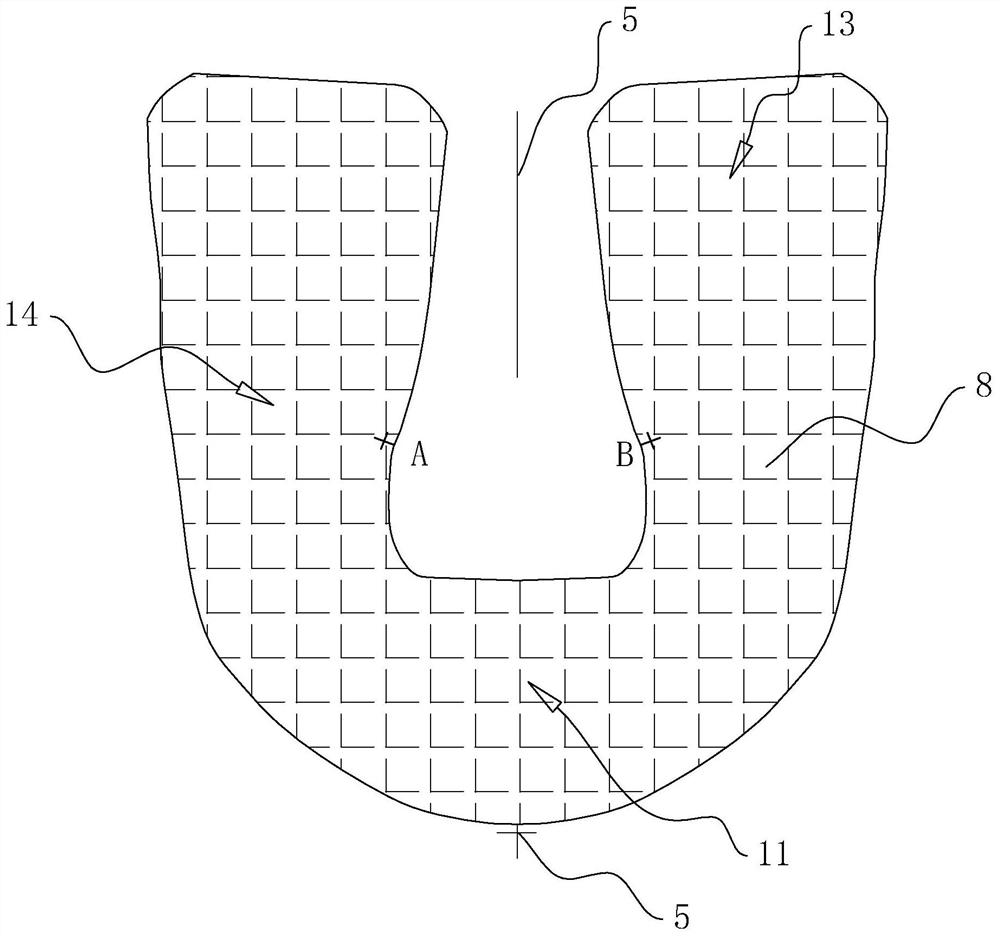

ActiveCN111214331BAvoid influenceShorten the lengthAbsorbent padsBaby linensMedicineWaist Circumferences

The present invention relates to the field of disposable sanitary products, in particular to a baby diaper that prevents strangulation, including a body, the body has a front waist area, a crotch area, and a back waist area along the longitudinal direction, and a front waist area is provided on the front waist area. Waist stickers are provided in the middle of the back waist area, left and right waist stickers are respectively provided on the left and right sides of the back waist area, and a patch is provided on the outer surface of the body. The width is greater than 1 / 4 of the width of the waist elastic. The upper end of the patch is glued to the outer surface of the body to form an upper adhesive part. The patch is made of flexible material. When the patch is folded into the inner surface of the body, The lower end of the patch extends beyond the area covered by the waist elastic. It solves the technical problem that the existing baby diapers tend to produce strangle marks on the back waist.

Owner:FUJIAN HENGAN HLDG CO LTD +2

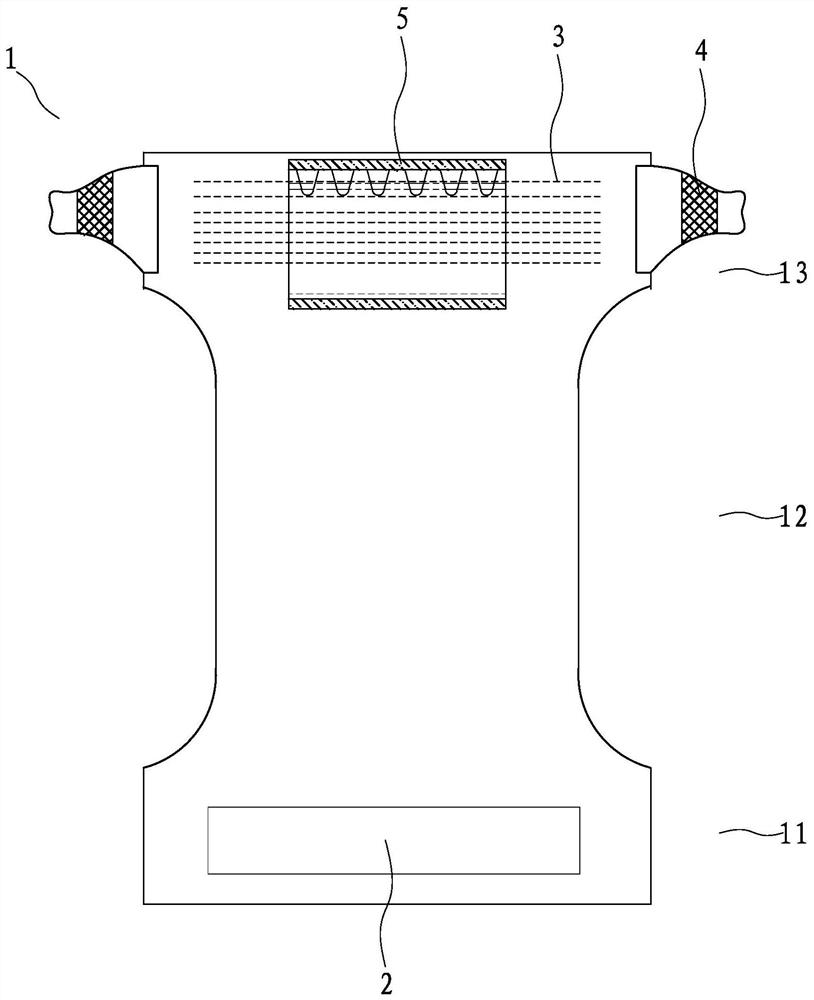

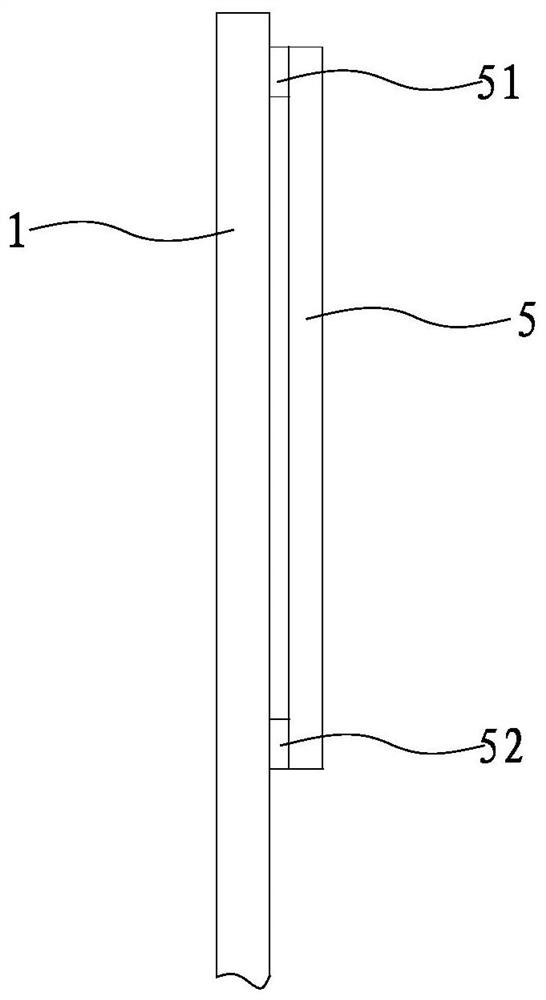

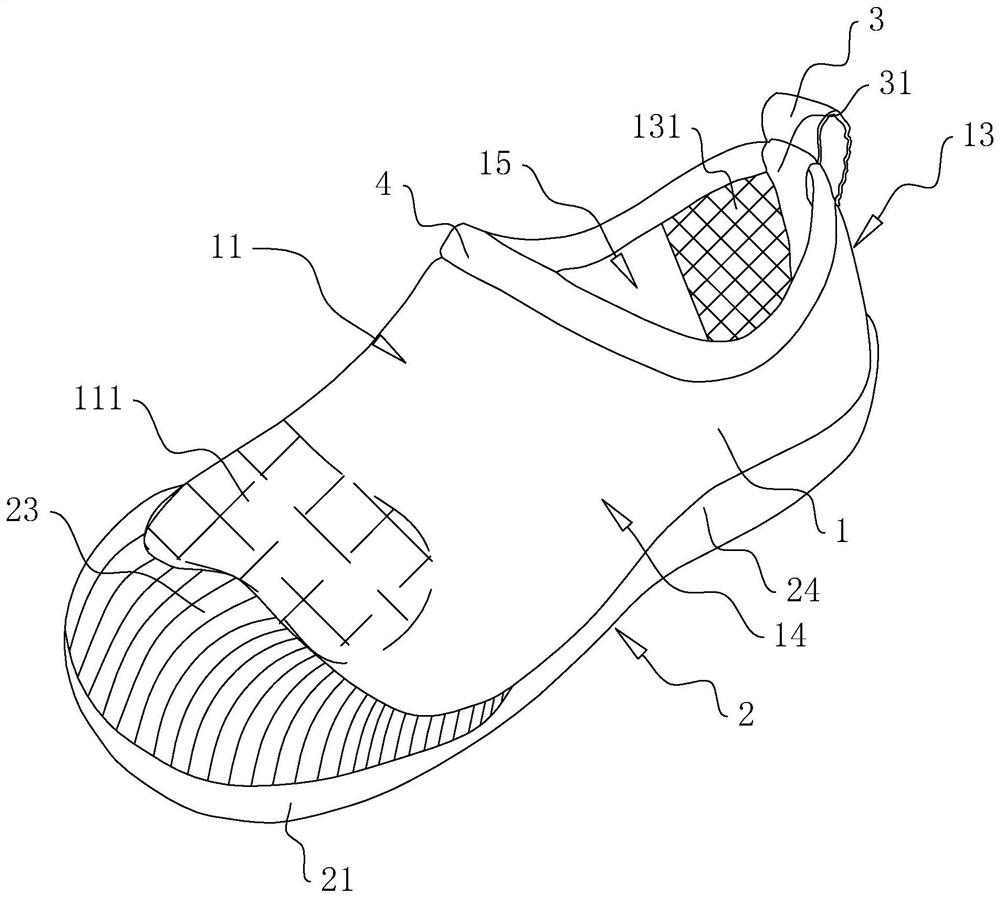

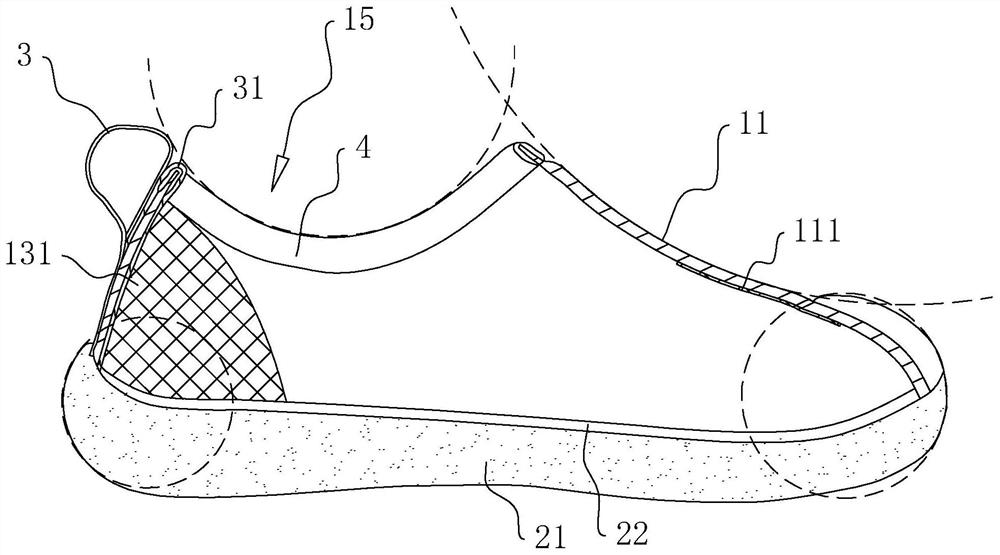

Children shoes and manufacturing process thereof

ActiveCN111938259AImprove fitReduce oppressionShoemaking devicesWeltsStructural engineeringHuman body

The invention relates to children shores and a manufacturing process thereof. The children shoes comprise vamps and soles, the vamps comprise heel parts, instep parts and foot side parts, the vamps enclose inner cavities and welts, the inner cavities and the welts are used for being worn by the feet of a human body, and edge covering strips are sewn at the edges of the welts. The length of the edge covering strip sewn to the edge of the welt of the instep portion is larger than that of the edge of the welt of the instep portion, the instep portion gradually arches upwards in the welt direction, and the section, in the vertical direction and parallel to the length direction of the children shoe, of the instep portion is in an arc shape with an upward opening. By sewing the edge covering strip with the length larger than the length of the edge covering strip on the edge of the welt of the instep, the closer the instep is to the welt, the larger the warping radian is, the instep is more attached to the radian of the joint between the foot and the shank of the human body, and the wrapping performance and attaching performance of the vamp on the foot of the human body in the natural state are improved; under the condition that the shoe is attached to the foot of the human body, compression of the shoe to the foot of the human body is reduced, and normal development of the foot of achild is guaranteed.

Owner:HANGZHOU AFU CHILDREN ARTICLES

A kind of production process of yarn-dyed fabric

ActiveCN111593460BDip dyed evenlyQuality improvementSucessive textile treatmentsInspecting textilesYarnIndustrial engineering

Owner:南通博赢特阔织造有限公司

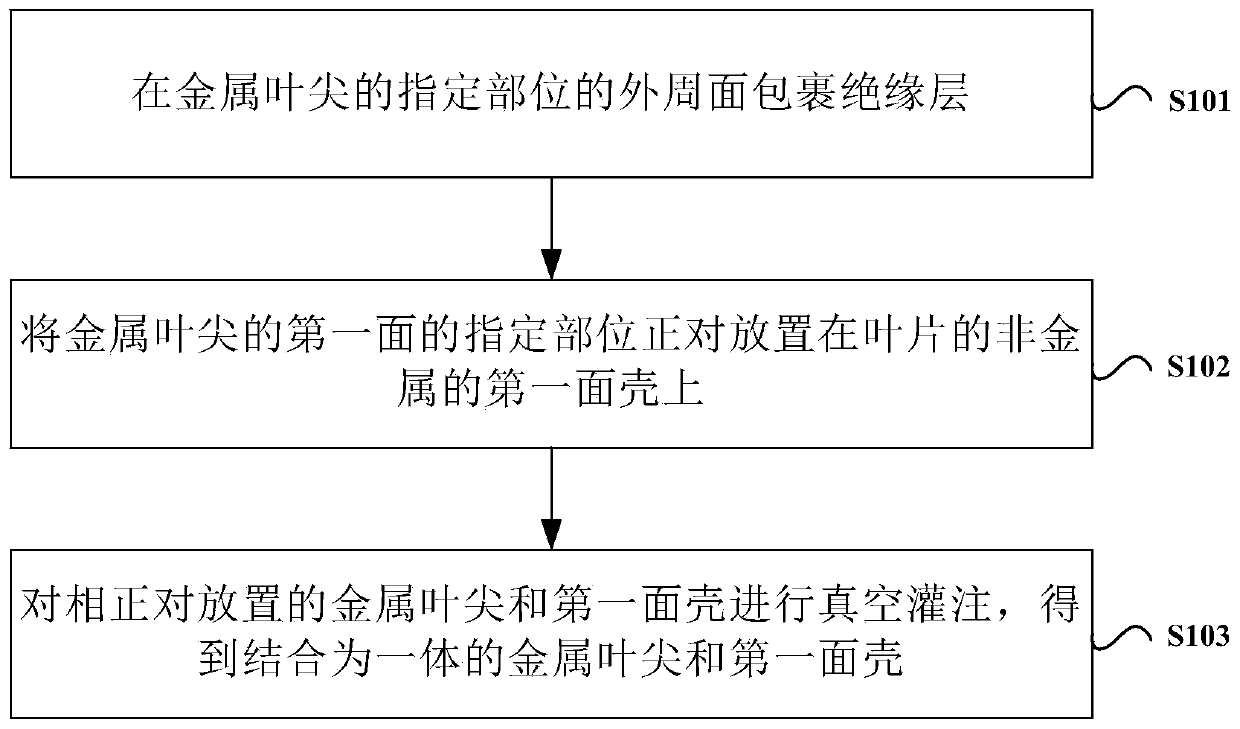

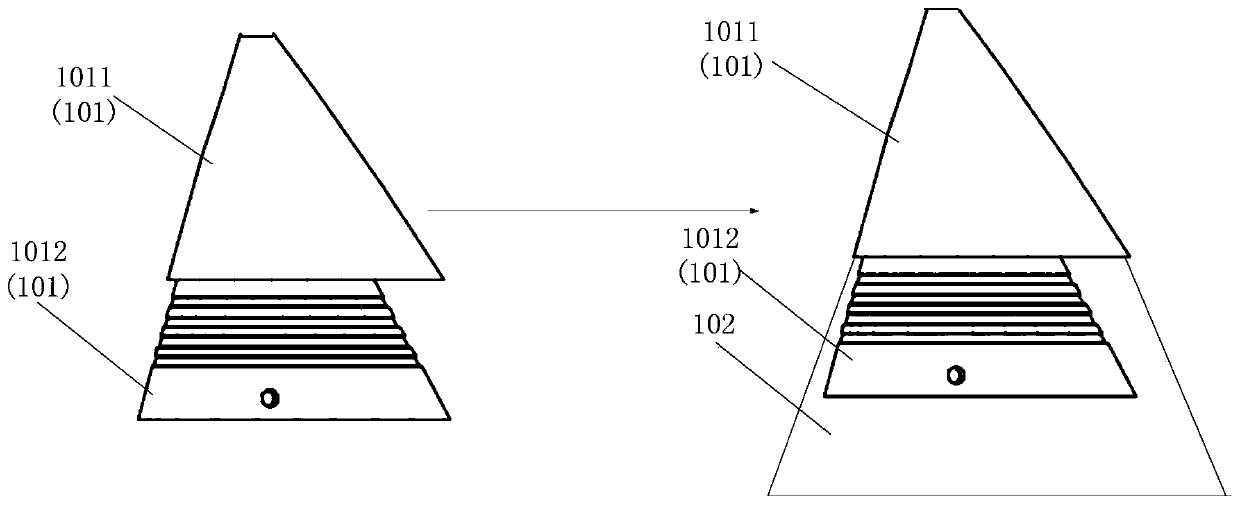

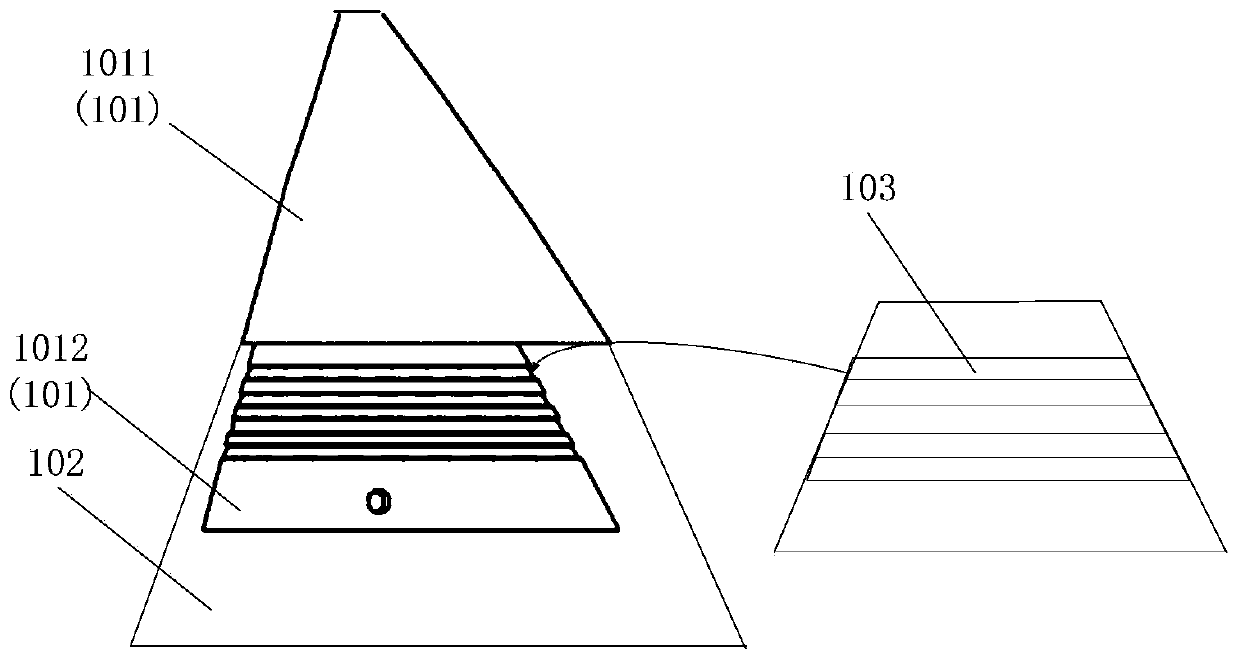

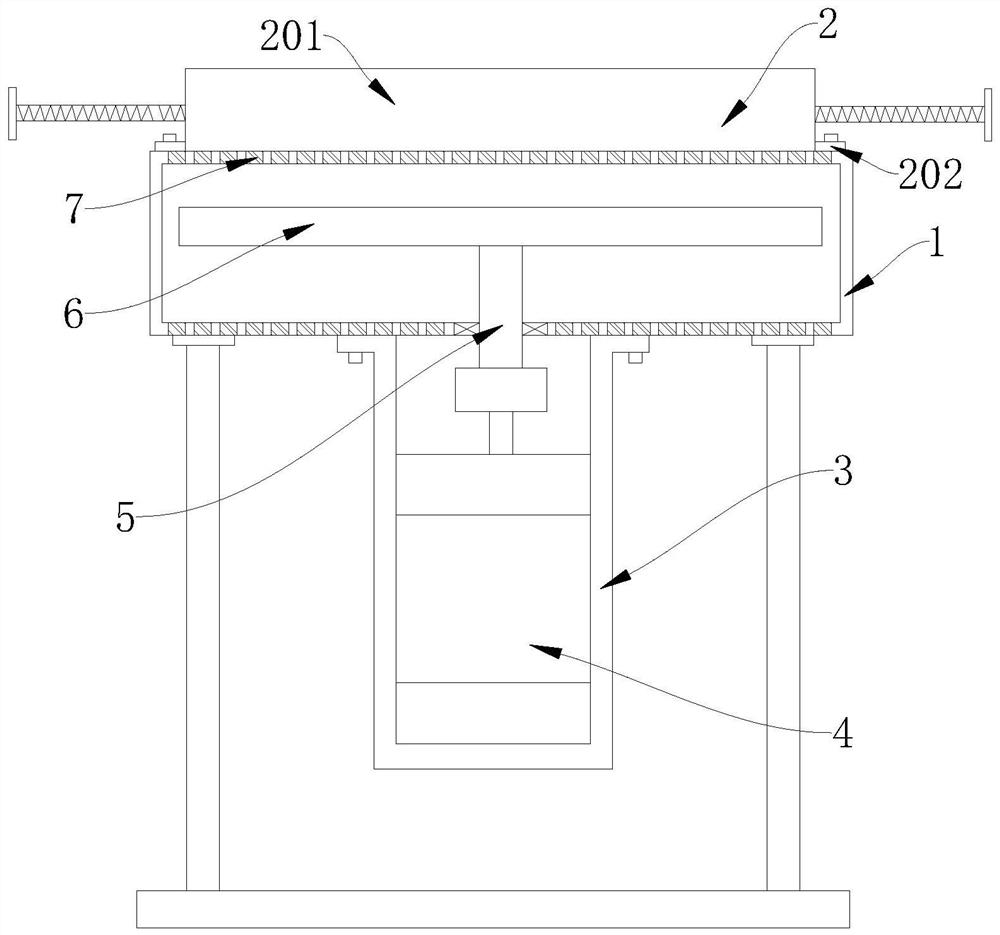

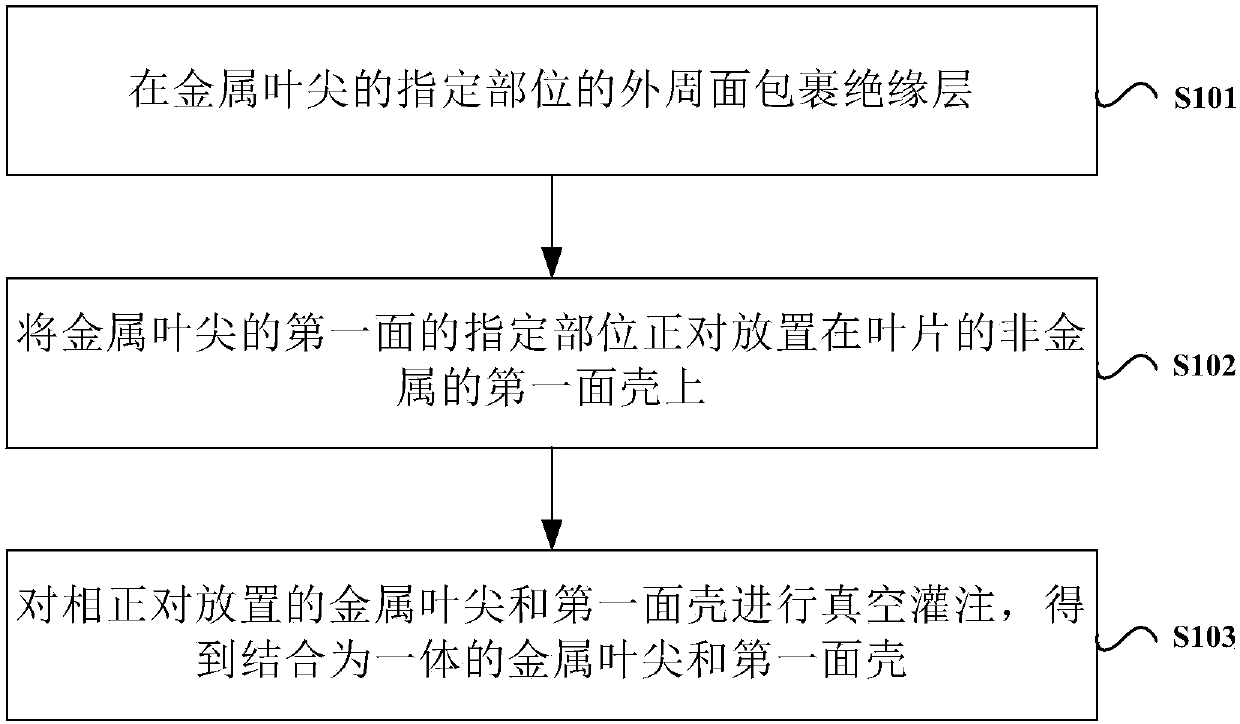

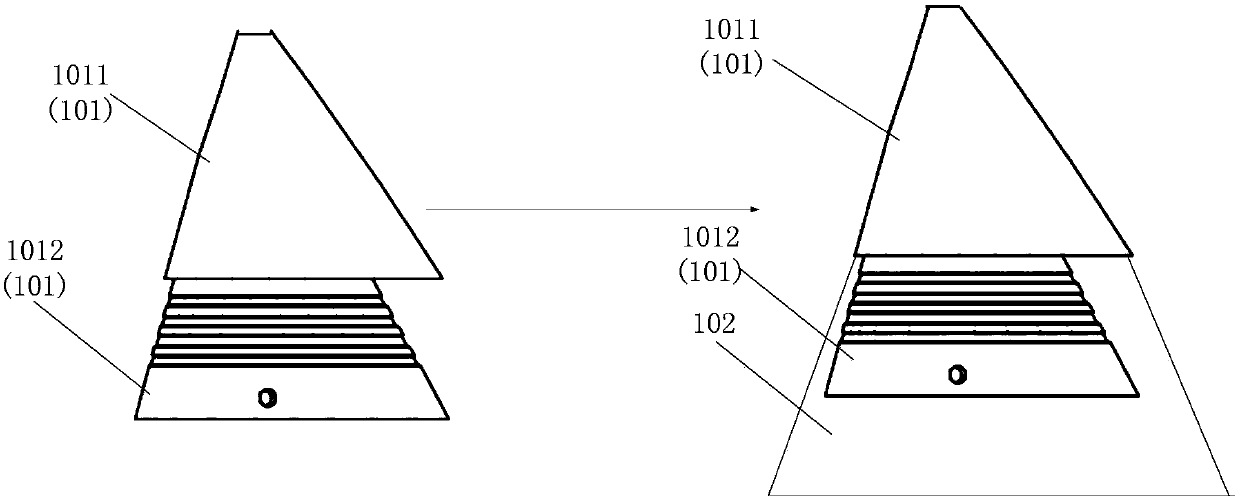

Blade tip of wind power generating set and preparation method thereof

ActiveCN109958586BQuality improvementAvoid misalignmentEngine manufactureFinal product manufactureEngineeringTurbine

The invention provides a blade tip of a wind generating set and a preparation method thereof. The preparation method comprises the following steps that an insulating layer is wrapped around the outerperipheral surface of a designated part of a metal blade tip body; the designated part of the first surface of the metal blade tip body is placed right opposite to a non-metal first surface shell of ablade; and vacuum perfusion is carried out on the metal blade tip body and the first surface shell which are placed opposite to each other so as obtain the metal blade tip body and the first surfaceshell which are combined into a whole. According to the blade tip of the wind generating set and the preparation method thereof, the metal blade tip body and the first surface shell (such as a leewardsurface shell) of the blade are fixedly combined into a whole through a vacuum perfusion method, so that the problem that a metal blade tip body and a blade are staggered can be solved, the quality of the blade tip is improved, and then the performance of the lightning-protection metal blade tip is ensured.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Font installation tool for identifying label and installation method thereof

ActiveCN113380134AQuality improvementEasy to warpBoardsSignsElectric machineryStructural engineering

The invention discloses a font installation tool for an identification label and an installation method thereof, relates to the technical field of identification labels, and aims to solve the problems that fonts on the surface of an existing label are generally manually adhered during installation, and during manual adhesion, a character sticker is difficult to align with the edge of the label so that the character sticker is inclined during installation, and the quality of the label is influenced. A limiting mechanism is arranged above a dust collection fan mounting and fixing box, a driving motor mounting frame is fixedly arranged on the lower end surface of the dust collection fan mounting and fixing box, a driving motor is fixedly mounted in the driving motor mounting frame, and a dust collection fan fixing shaft is arranged at the output end of the driving motor; and the other end of the dust collection fan fixing shaft is rotatably connected with the outer wall of the lower portion of the dust collection fan mounting and fixing box through a bearing, and the other end of the dust collection fan fixing shaft extends into the dust collection fan mounting and fixing box.

Owner:安徽骏飞标识设计制作有限公司

Blade tip of wind generating set and preparation method thereof

ActiveCN109958586AQuality improvementAvoid misalignmentEngine manufactureFinal product manufactureEngineeringLightning

The invention provides a blade tip of a wind generating set and a preparation method thereof. The preparation method comprises the following steps that an insulating layer is wrapped around the outerperipheral surface of a designated part of a metal blade tip body; the designated part of the first surface of the metal blade tip body is placed right opposite to a non-metal first surface shell of ablade; and vacuum perfusion is carried out on the metal blade tip body and the first surface shell which are placed opposite to each other so as obtain the metal blade tip body and the first surfaceshell which are combined into a whole. According to the blade tip of the wind generating set and the preparation method thereof, the metal blade tip body and the first surface shell (such as a leewardsurface shell) of the blade are fixedly combined into a whole through a vacuum perfusion method, so that the problem that a metal blade tip body and a blade are staggered can be solved, the quality of the blade tip is improved, and then the performance of the lightning-protection metal blade tip is ensured.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com