Labeling device and labeling method

A labeling and labeling technology, applied in labeling, labeling machines, packaging, etc., can solve the problems of label separation rate decline, product leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

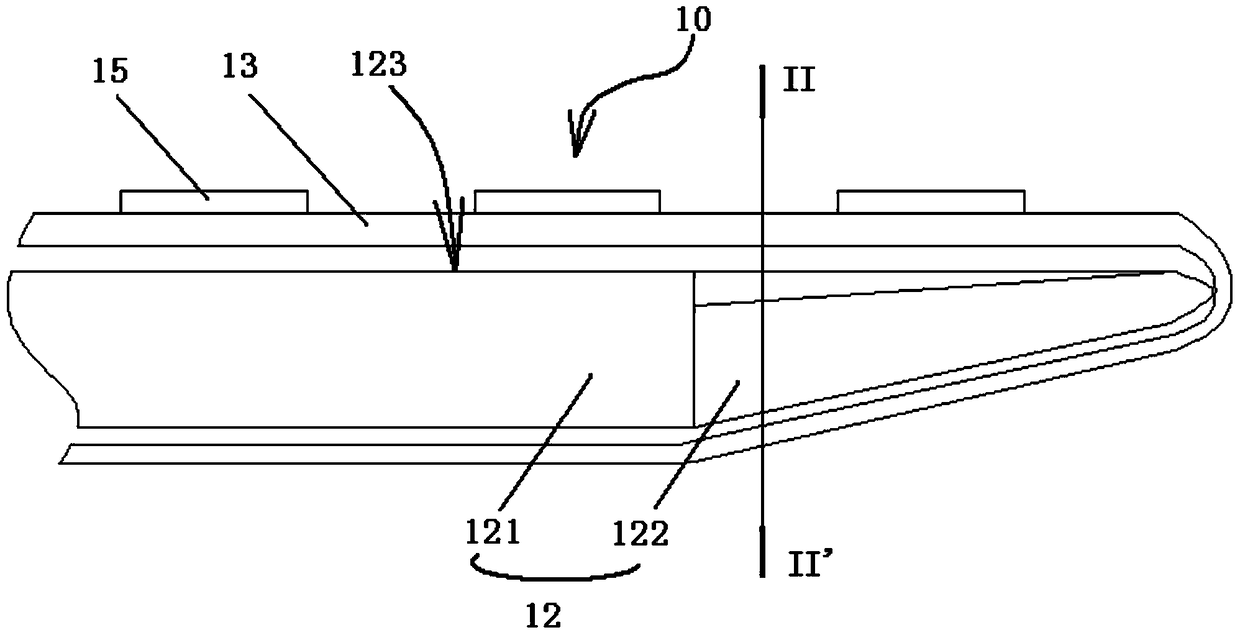

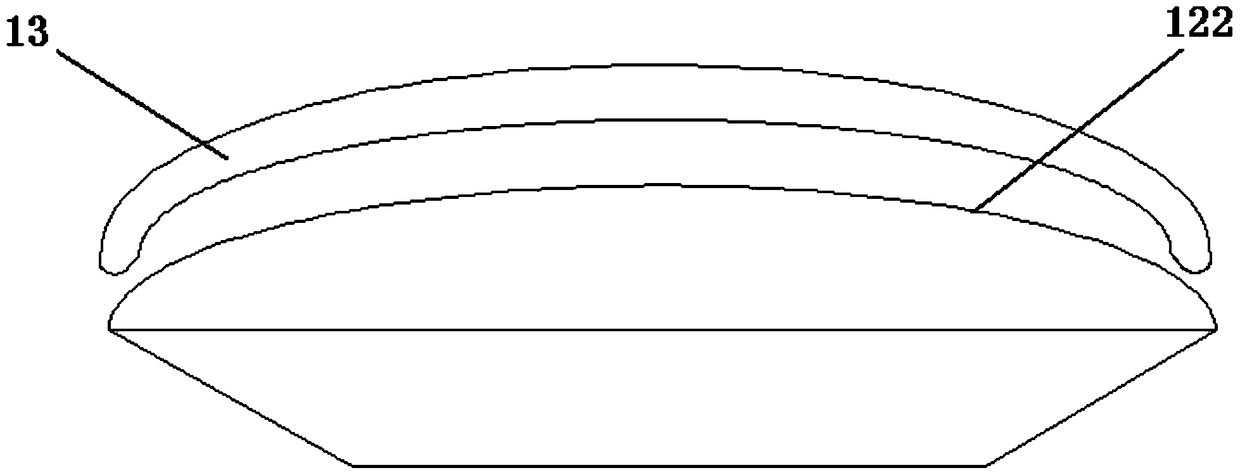

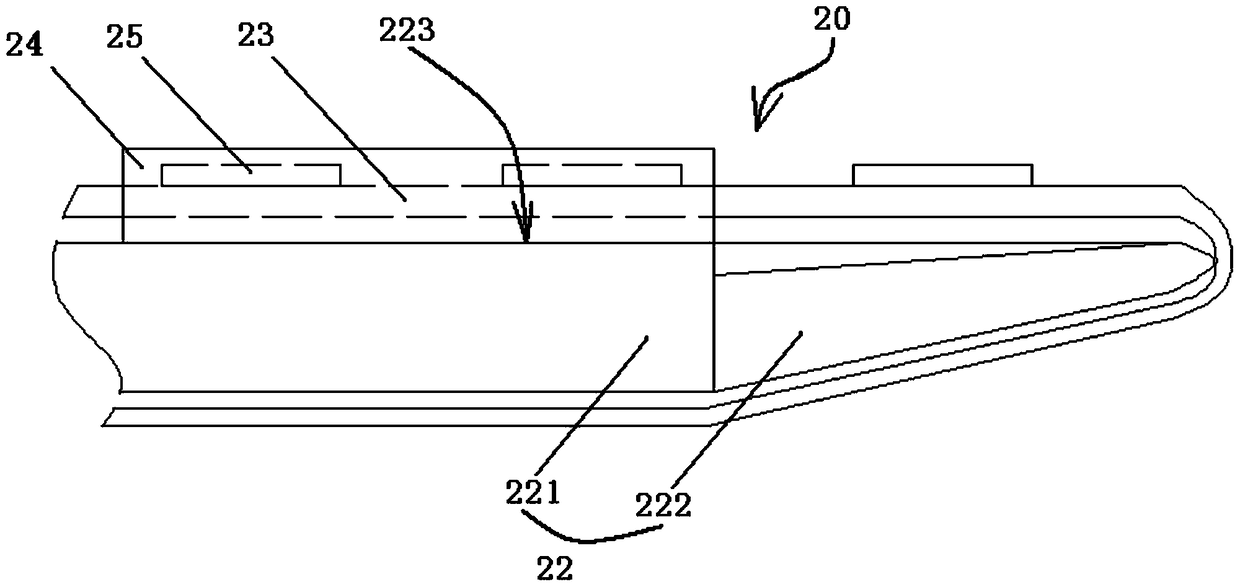

[0023] The labeling device and labeling method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] The labeling device of the embodiment of the present invention can be applied in the transfer process of ultra-thin labels to solve the problem that in the prior art, because the flexibility of ultra-thin labels becomes larger and the rigidity is insufficient, in the traditional separation process, the liner will Turn over the label separation part without being stripped, resulting in a decrease in product yield and affecting work efficiency. The labeling device of the embodiment of the present invention starts from improving the relative rigidity of the label, creating an effect that can facilitate the easy separation of ultra-thin labels, thereby improving the separation rate of the label. It can be understood that the present invention is not limited thereto, and in other embodiments, the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com