Patents

Literature

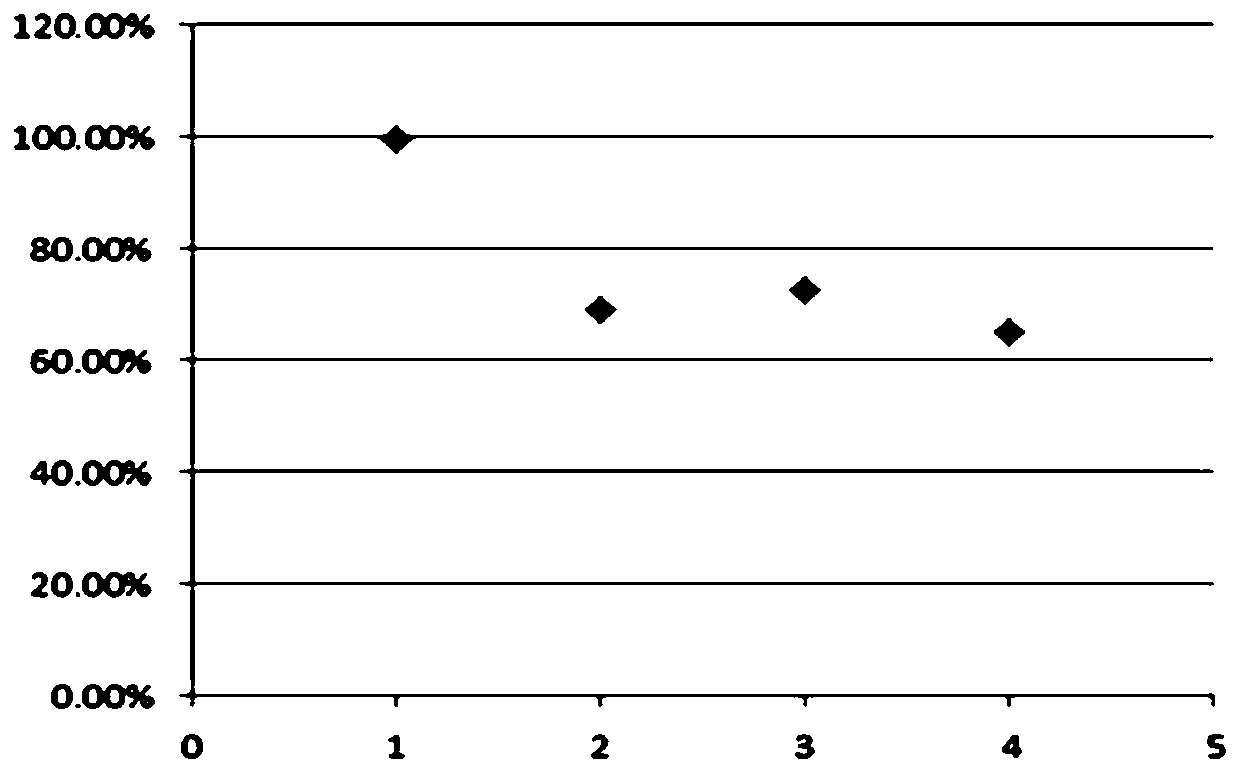

79results about How to "Improve stripping rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

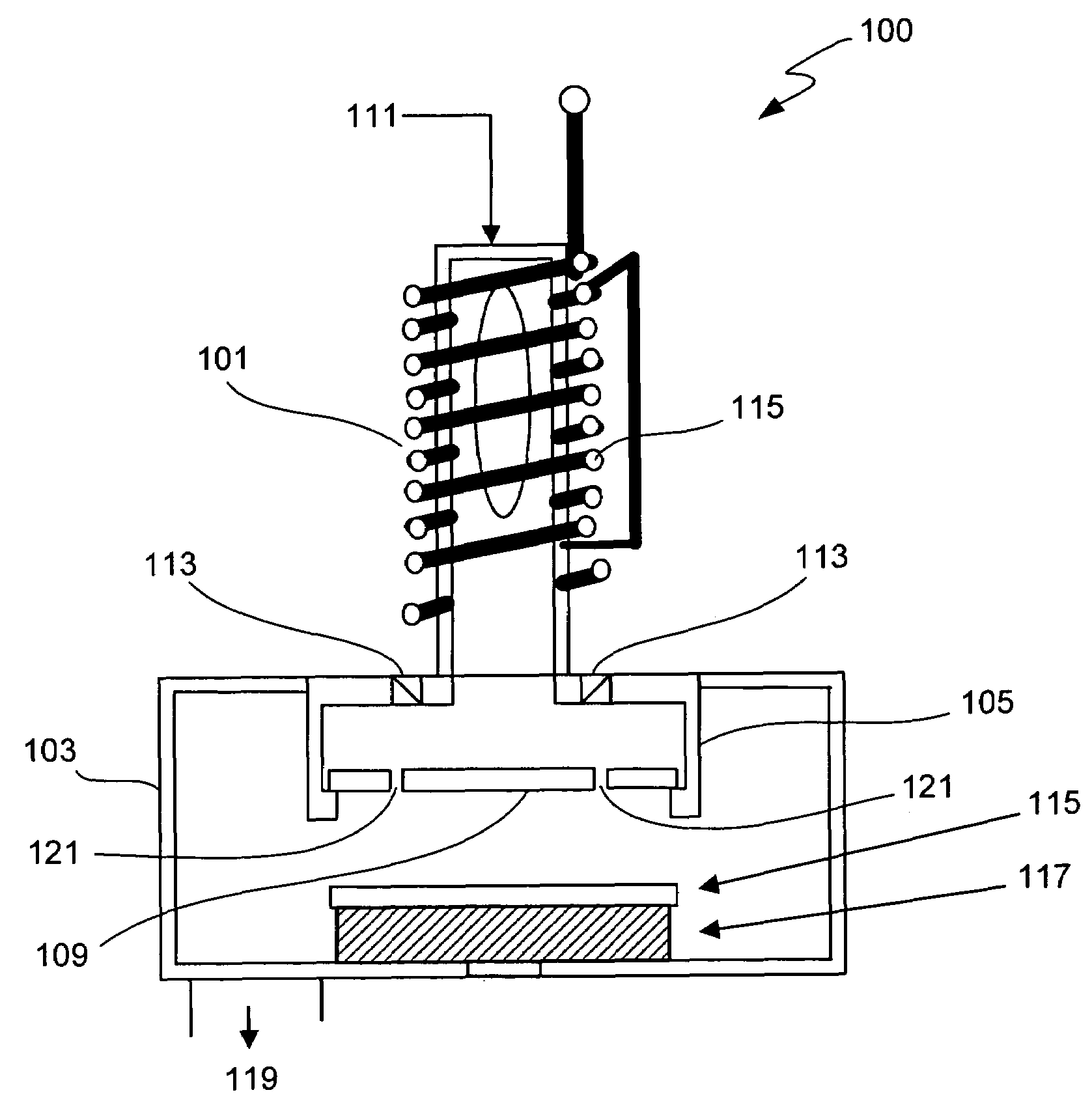

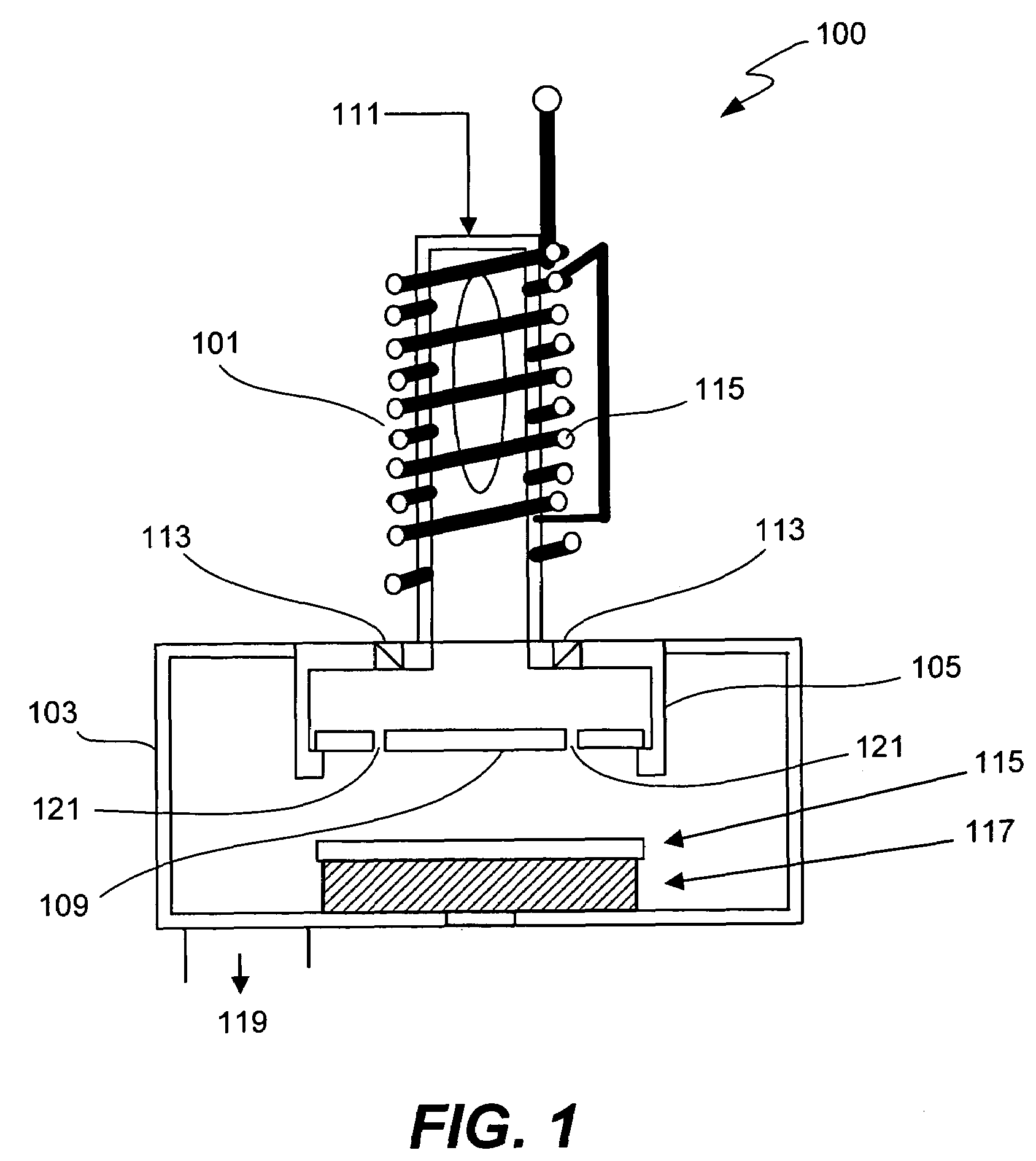

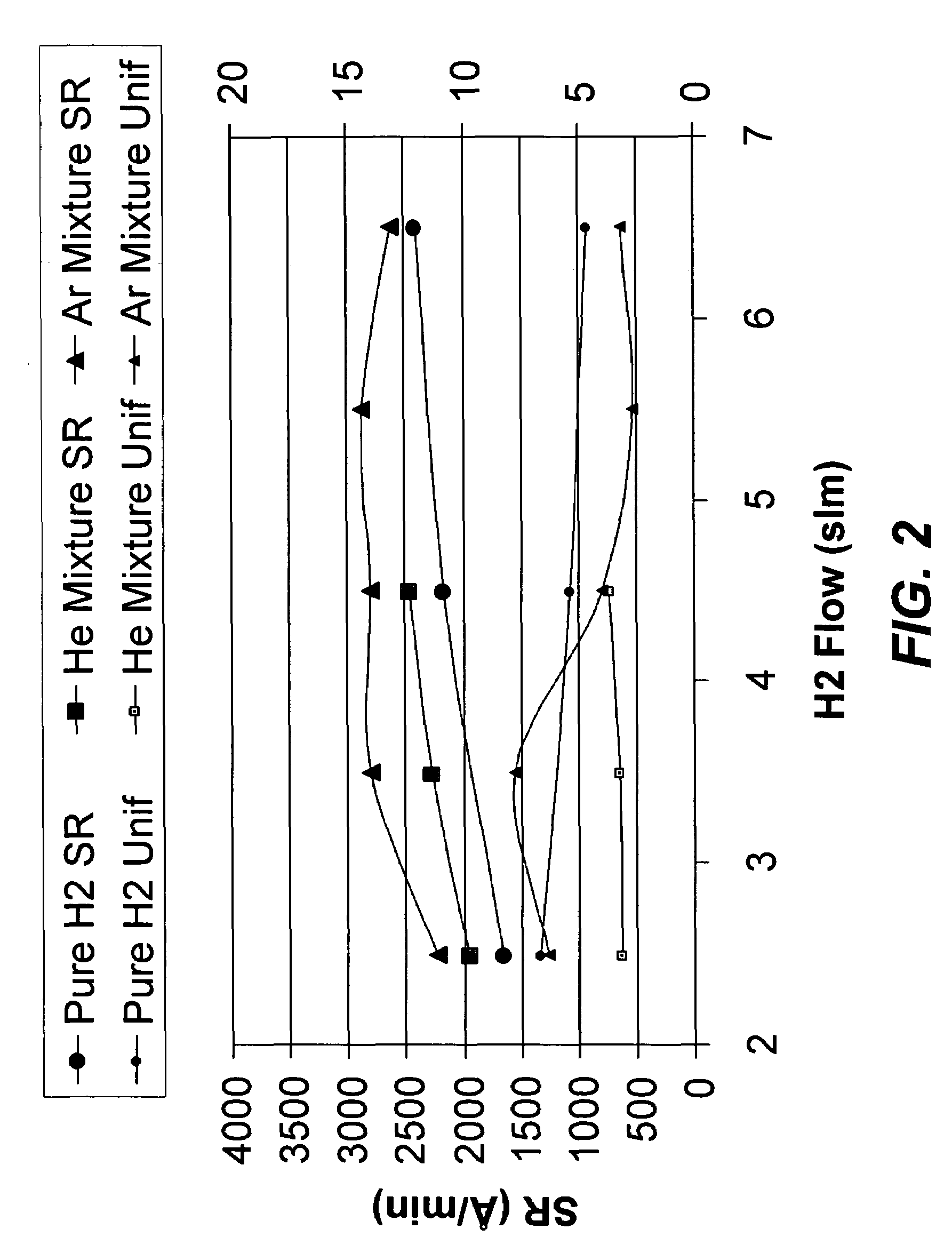

Enhanced stripping of low-k films using downstream gas mixing

ActiveUS7202176B1Reducing required hydrogen flow rateImprove stripping rateHydrogenElectric discharge tubesResistHydrogen

The present invention pertains to methods for removing unwanted material from a work piece. More specifically, the invention pertains to stripping photo-resist material and removing etch-related residues from a semiconductor wafer during semiconductor manufacturing. Methods involve implementing a hydrogen plasma operation with downstream mixing with an inert gas. The invention is effective at stripping photo-resist and removing residues from low-k dielectric material used in Damascene devices.

Owner:NOVELLUS SYSTEMS

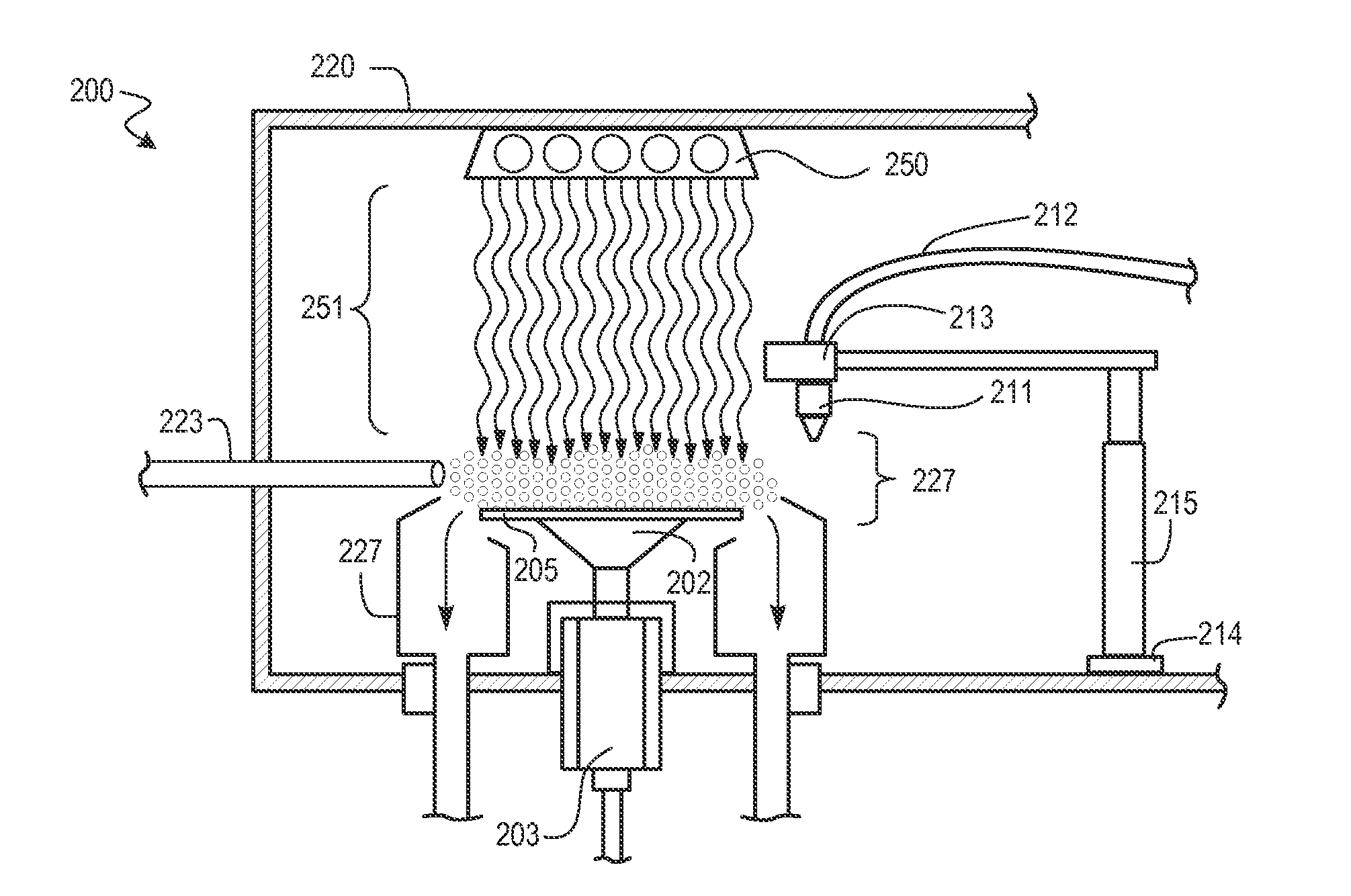

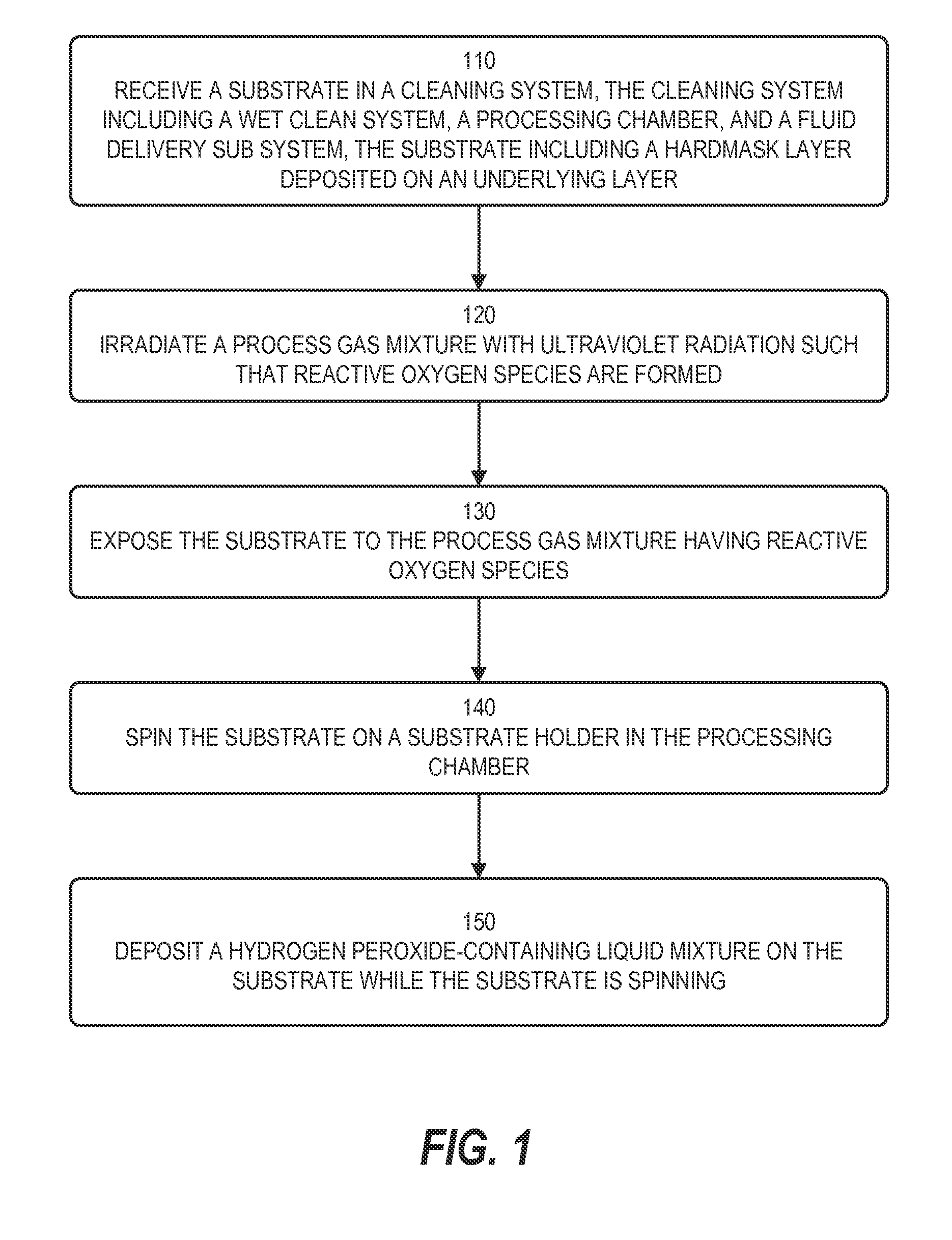

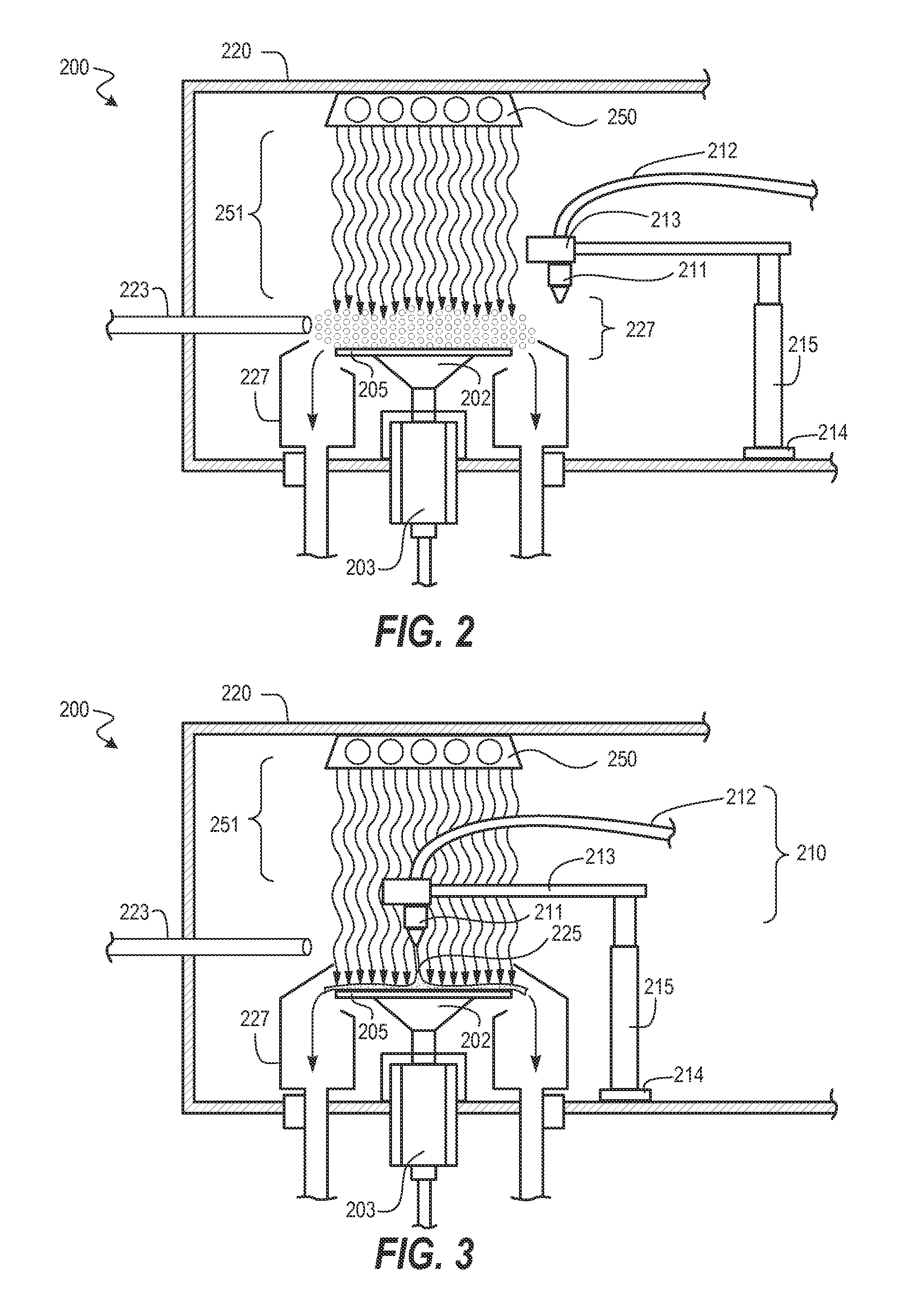

Method and Hardware for Enhanced Removal of Post Etch Polymer and Hardmask Removal

ActiveUS20150128991A1Enhanced sputteringRegulate deliveryElectrostatic cleaningSemiconductor/solid-state device manufacturingHydrogenUltraviolet

Methods for cleaning substrates are described including cleaning substrates having hardmask masks and polymer films, such part of semiconductor fabrication. Cleaning methods include ultraviolet (UV) light exposure of process gas mixtures and liquid cleaning chemistries. A substrate and / or process fluids are exposed to ultraviolet radiation. A process gas mixture being irradiated can include an oxidizing gas mixture (air, clean dry air, oxygen, peroxygen, etc.). Reducing gas mixtures, having hydrogen, can also be irradiated. Reactive species from irradiated gas mixtures are exposed to the substrate to chemically modify film properties, such as by facilitating a subsequent liquid cleaning step. Liquid cleaning chemistries on a substrate surface can also be irradiated. Such cleaning techniques enable shorter cleaning times, lower processing temperatures, and reduced damage to underlying or intermediate layers such as dielectric layers.

Owner:TOKYO ELECTRON LTD

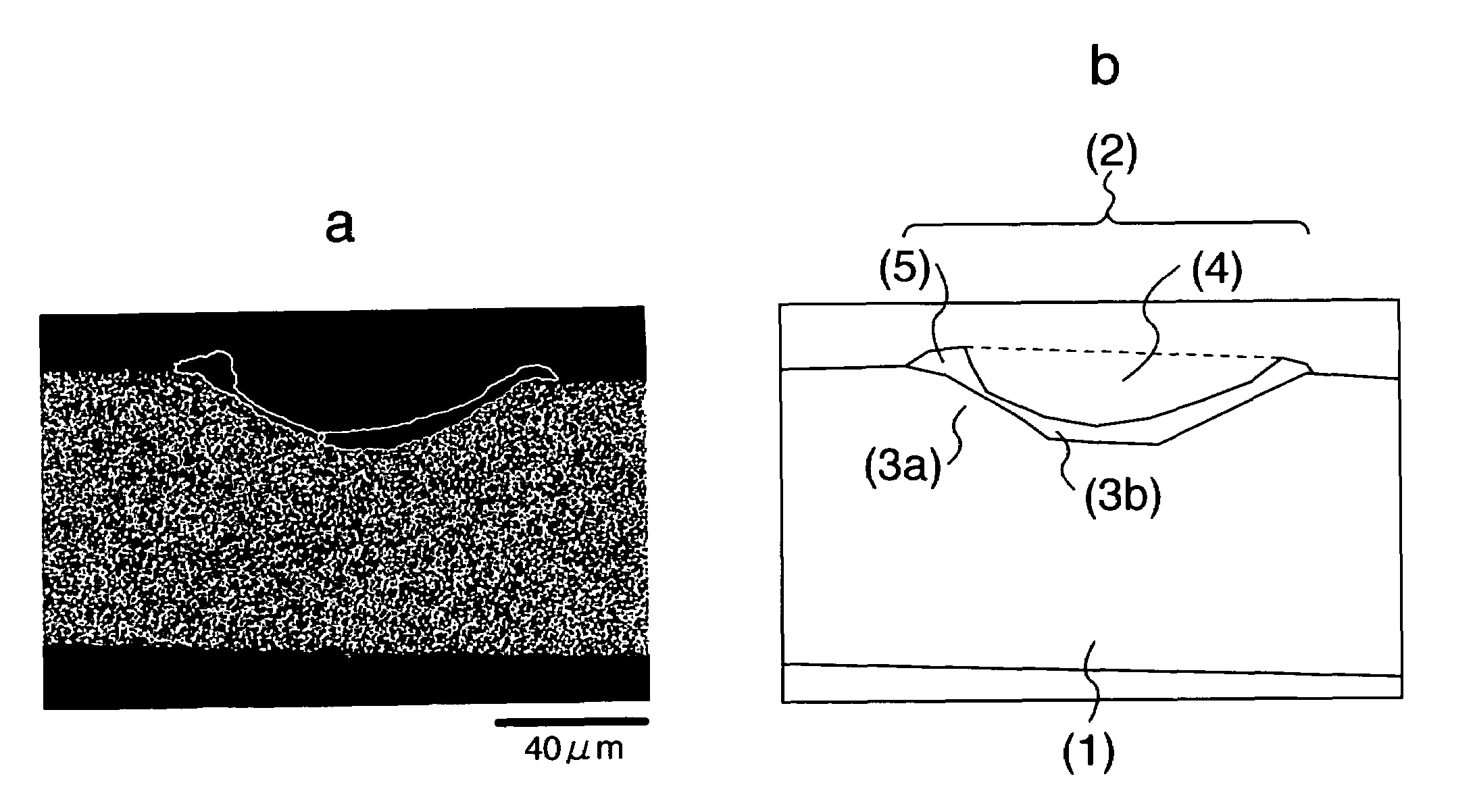

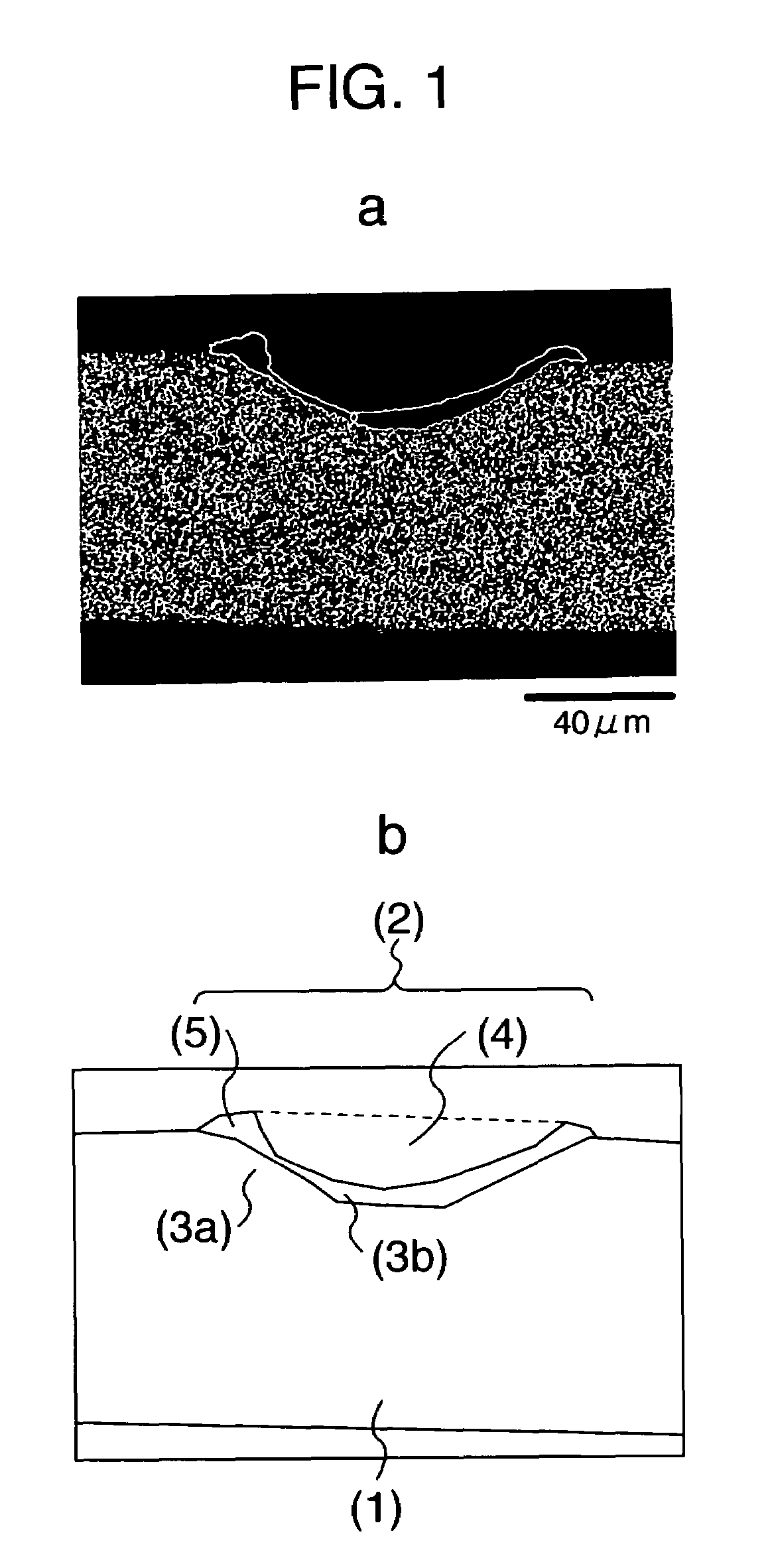

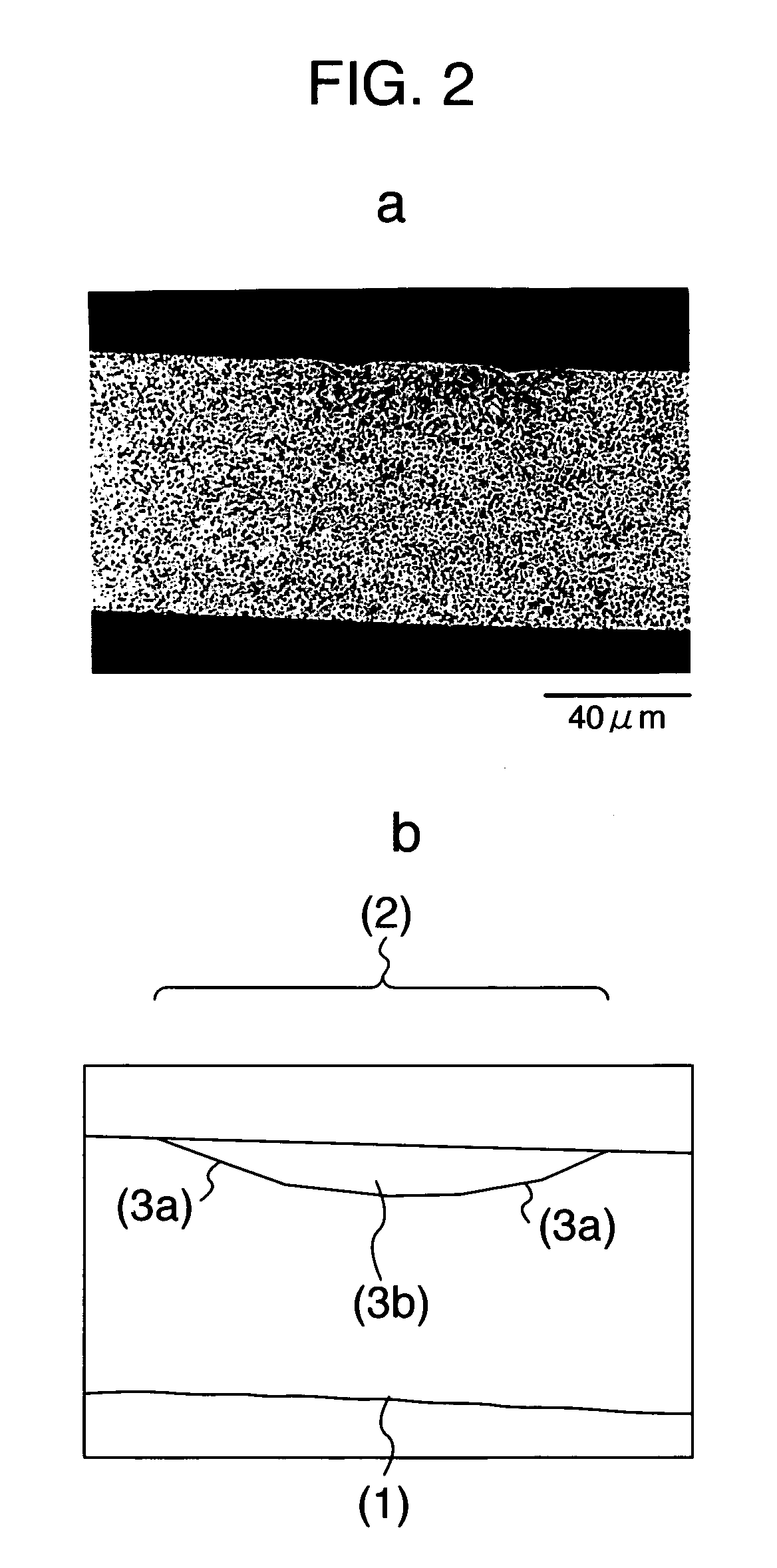

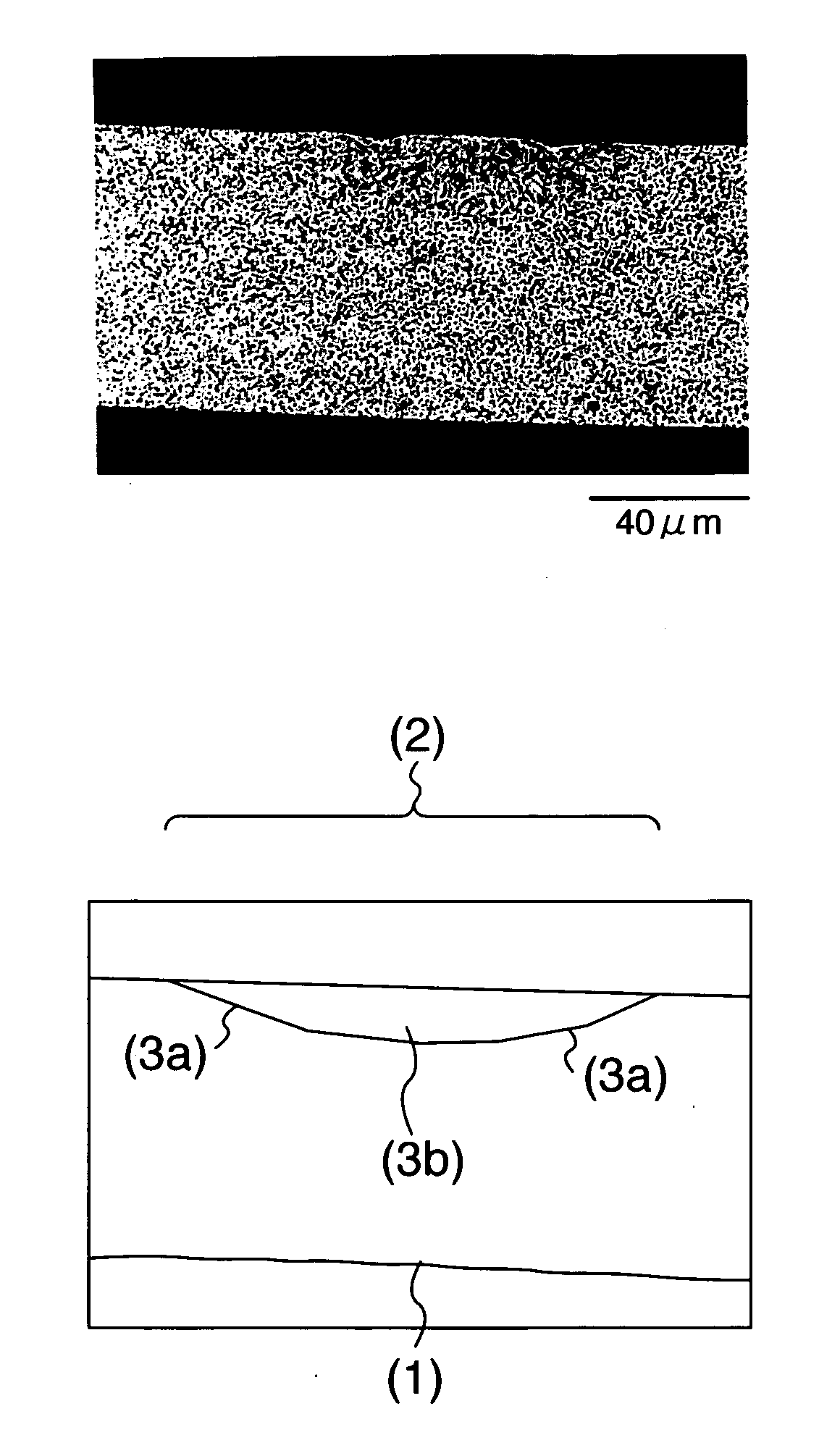

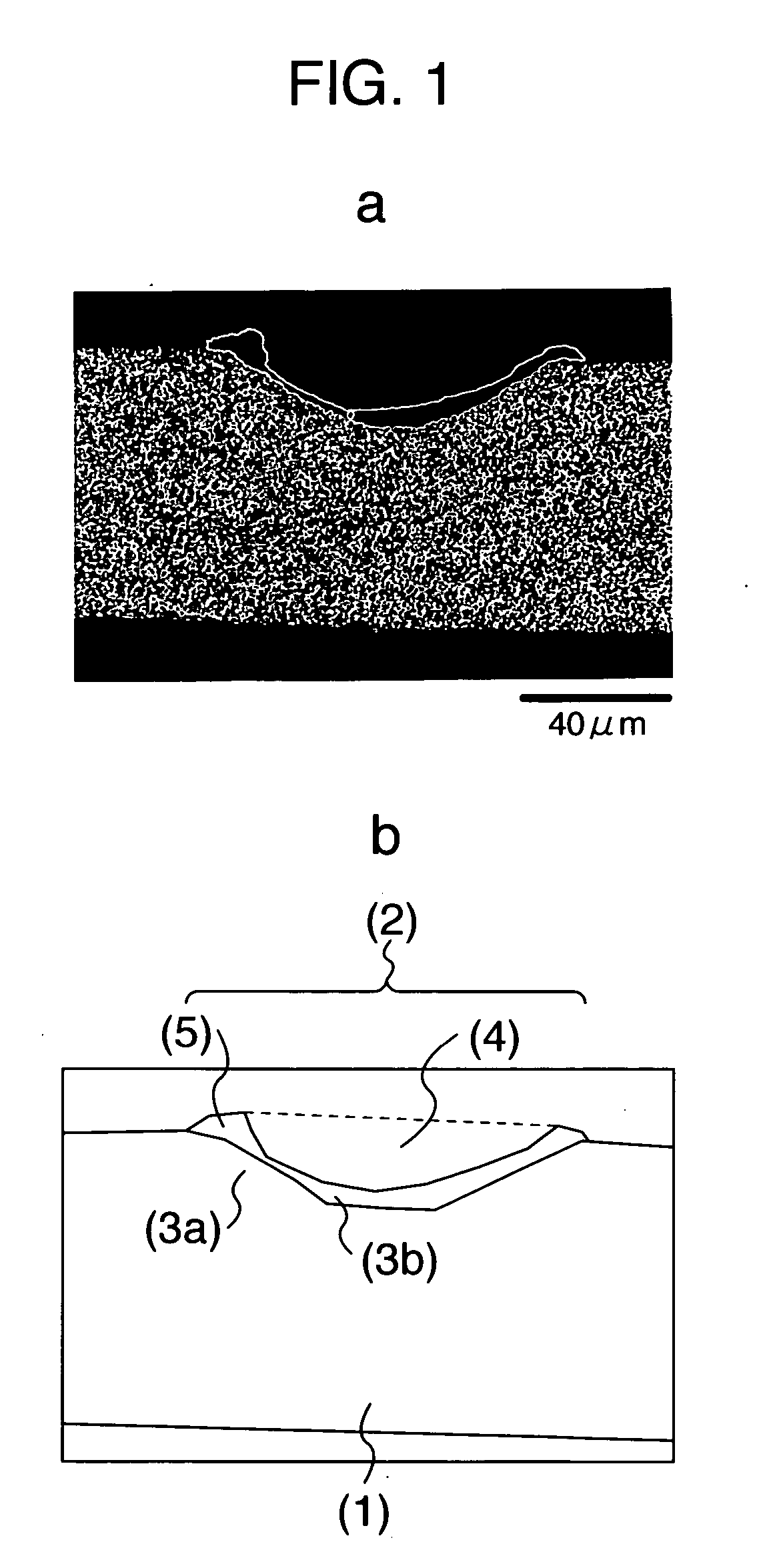

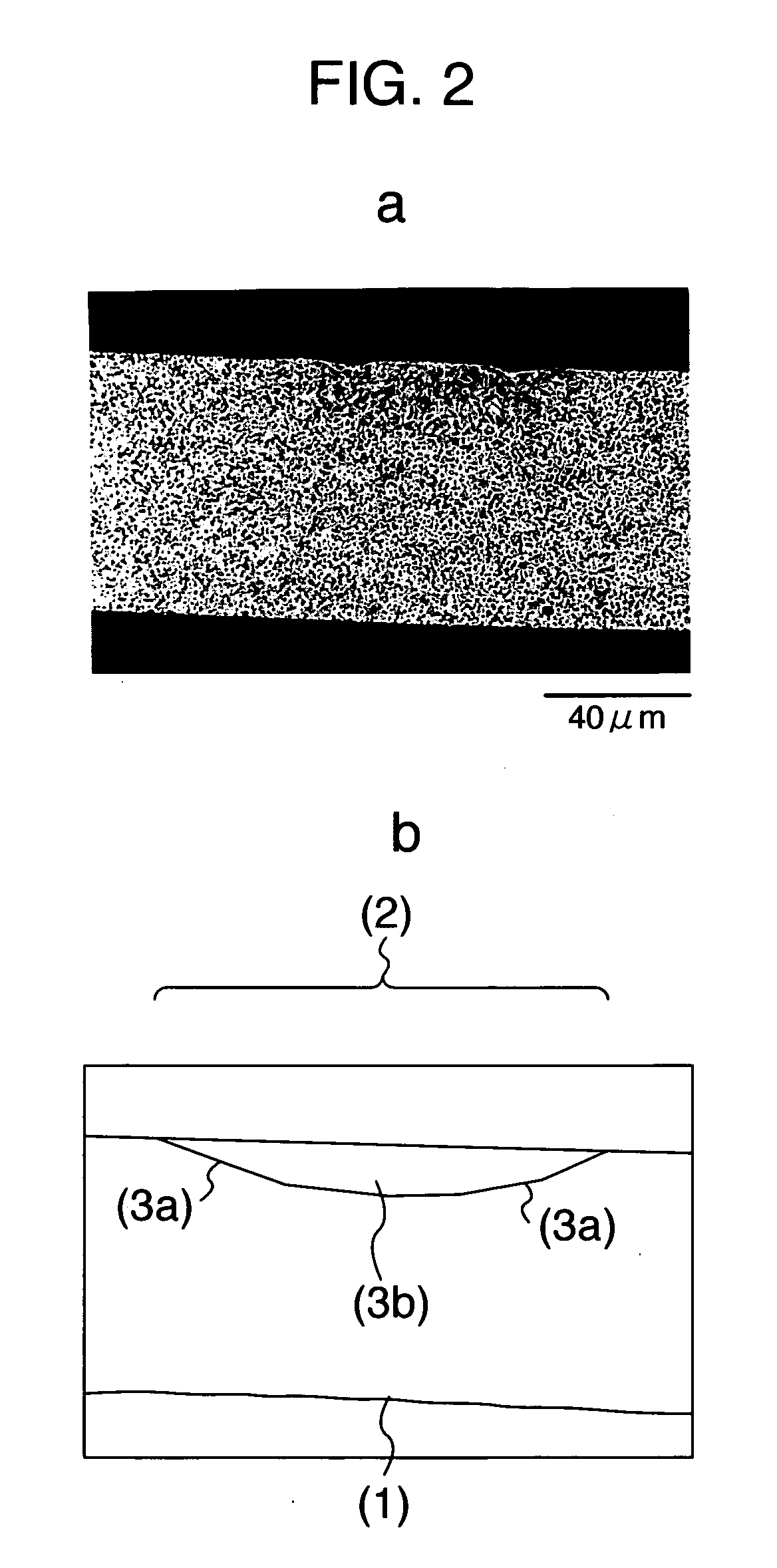

Steel strip for razor blades and method of manufacturing the same

ActiveUS7531052B2Constant form in cross sectionImprove accuracyFurnace typesWelding/soldering/cutting articlesThermal energyMartensitic stainless steel

The present invention provides a martensitic stainless steel strip for razor blades in annealed state comprising a continuous processed groove being formed with thermal energy in a longitudinal direction on one side of the strip at a position with a predetermined distance from one edge; and a continuous changed structure area being formed with thermal energy in a longitudinal direction on opposite side of the strip at a position having a predetermined distance from the edge, wherein the processed groove functions as a splitting portion of the strip.In addition, the present invention provides a method for manufacturing the steel strip for razor blades.

Owner:HITACHI METALS LTD

Preparation method for high-quality recycled concrete aggregates

InactiveCN103332881AEasy to shapeImprove stripping rateSolid waste managementResource utilizationArchitectural engineering

Provided is a preparation method for high-quality recycled concrete aggregates. The preparation method comprises steps of sorting of waste concrete, primary crushing, primary screening, rod milling, secondary screening and cleaning, and then the graded aggregates are mixed according to required gradations to obtain recycled coarse aggregates with different particle sizes. According to the preparation method, the cyclic utilization rate of waste concrete can be close to 80%, the resource utilization of construction waste in cities can be realized, the secondary pollution of construction waste to the environment can be reduced, the land occupation account for landfilling of construction waste can be saved, and the industrialization development of comprehensive utilization of construction waste can be promoted to some extent.

Owner:GUANGXI UNIV +1

Steel strip for razor blades and method of manufacturing the same

ActiveUS20060000526A1Avoid problemsImprove accuracyFurnace typesWelding/soldering/cutting articlesThermal energyMartensitic stainless steel

The present invention provides a martensitic stainless steel strip for razor blades in annealed state comprising a continuous processed groove being formed with thermal energy in a longitudinal direction on one side of the strip at a position with a predetermined distance from one edge; and a continuous changed structure area being formed with thermal energy in a longitudinal direction on opposite side of the strip at a position having a predetermined distance from the edge, wherein the processed groove functions as a splitting portion of the strip. In addition, the present invention provides a method for manufacturing the steel strip for razor blades.

Owner:HITACHI METALS LTD

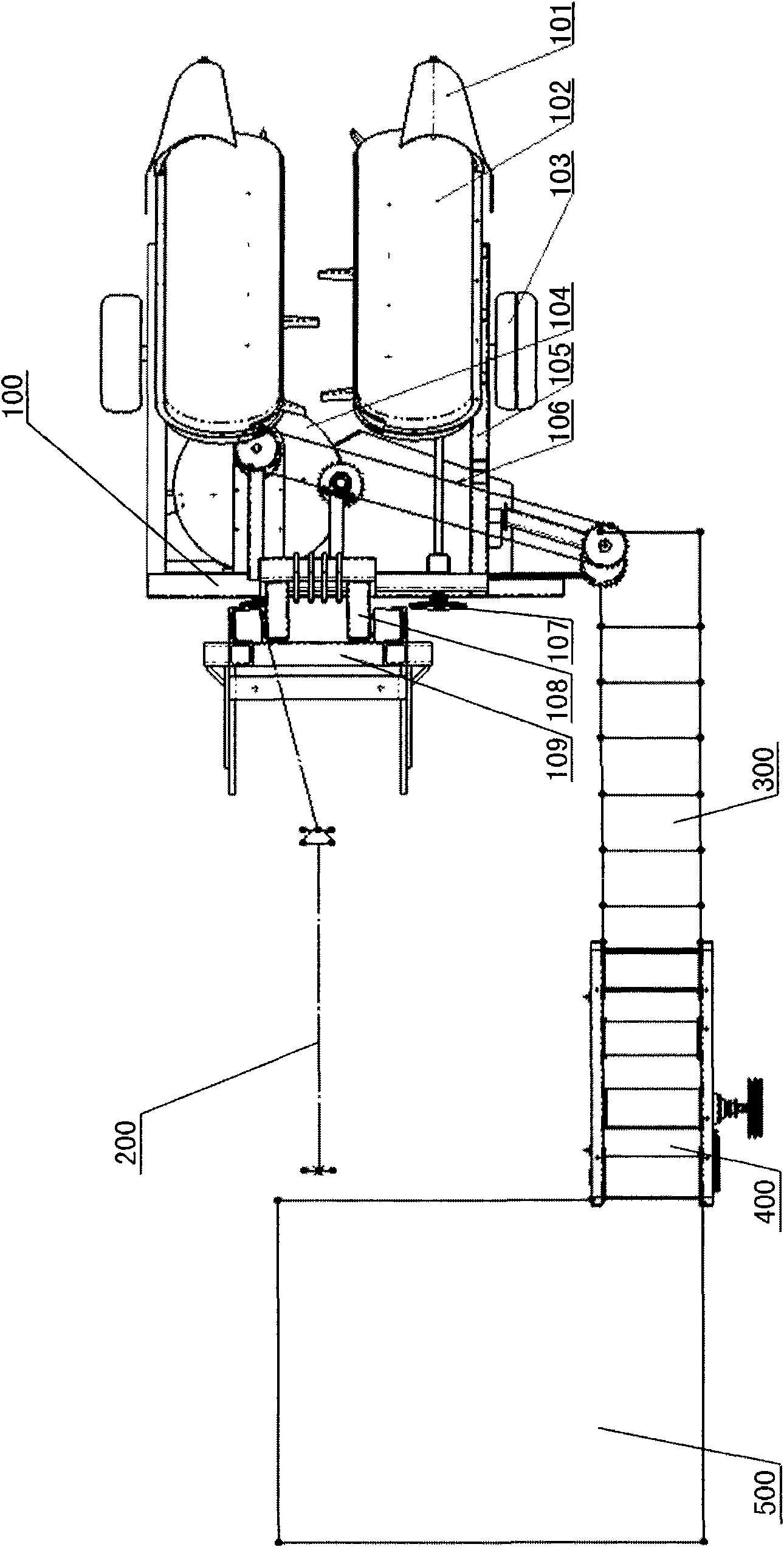

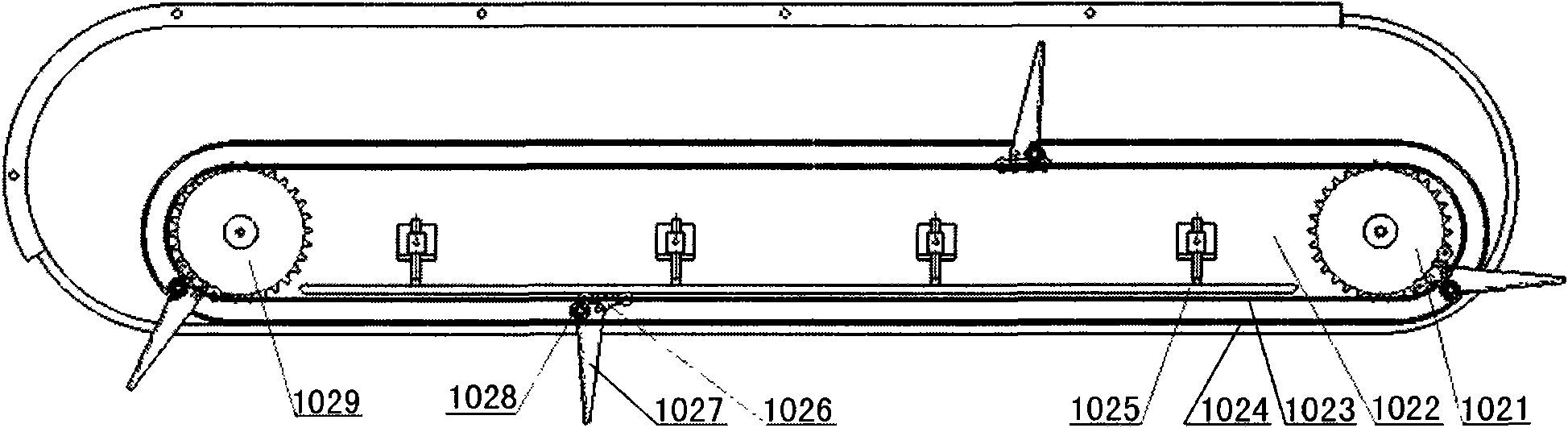

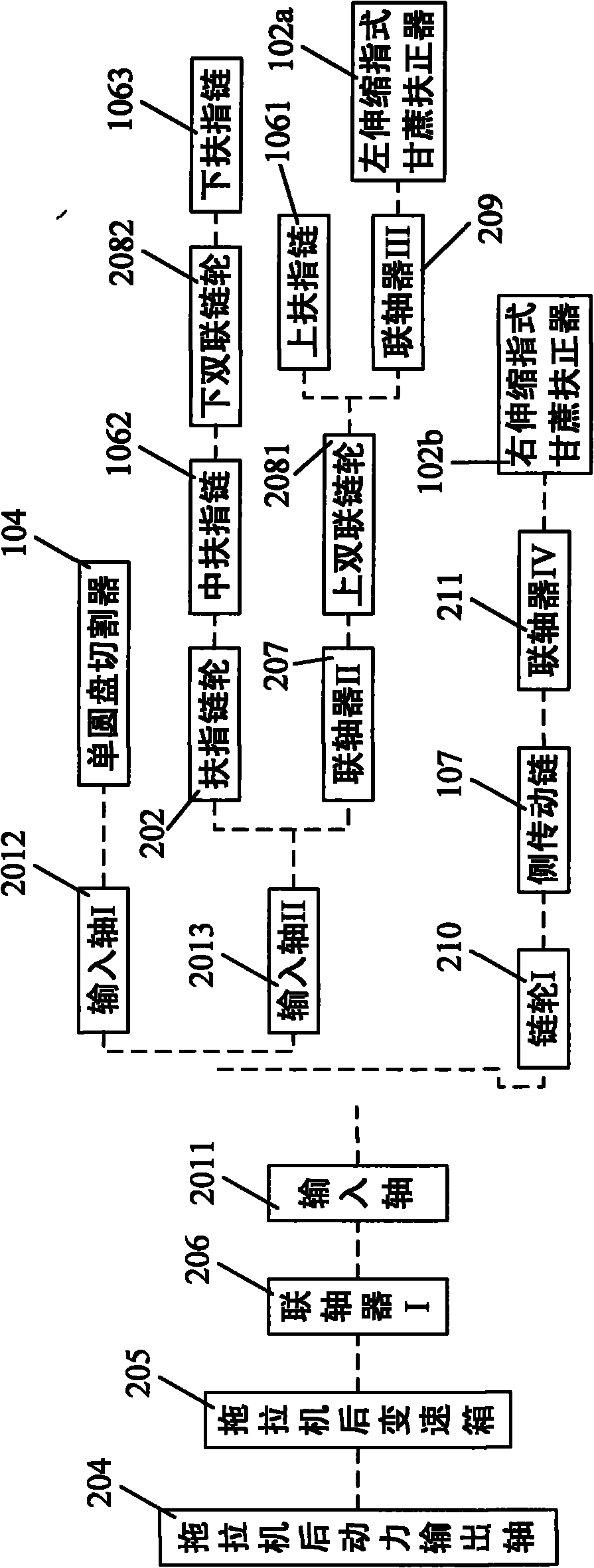

Sugarcane whole stem leaf-peeling device, harvester with same and leaf-peeling method thereof

ActiveCN101836537AReduce power consumptionImprove stripping rateHarvestersVegetable peelingEngineeringDrivetrain

The invention relates to a sugarcane whole stem leaf-peeling device, a harvester with the same, and a leaf-peeling method thereof. The harvester comprises a harvesting device, a power device, a chassis, a side conveying device, a leaf-peeling device and a sugarcane collecting device, wherein the leaf-peeling device comprises a guide cover plate, a pair of tip-cutting rolls, a traverse leaf-peeling roll, a vertical leaf-peeling roll, a speed-limit roll and a power transmission system. A sugarcane is firstly fed into the guide cover plate in a tip-first way, the tip-cutting rolls are oppositely arranged for crushing a growing point of the sugarcane to remove the tip and then fed into the traverse leaf-peeling roll, the transverse leaf-peeling roll and the vertical leaf-peeling roll are fixed with a plurality of rows of lead-peeling brushes, when the sugarcane passes through, leaf-peeling in an upper direction, a lower direction, a left direction and a right direction is completed, and the sugarcane does a certain axial rotation under the drive of the tip-cutting rolls and the speed-limit roll so as to achieve full-direction leaf-peeling. The invention reduces the power consumption, improves the sugarcane whole stem leaf-peeling rate, and can complete integration operations of whole stem buried cutting, transverse and vertical conveying, longitudinal conveying, tip crushing, leaf peeling and pilling placement by one-stop operation.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

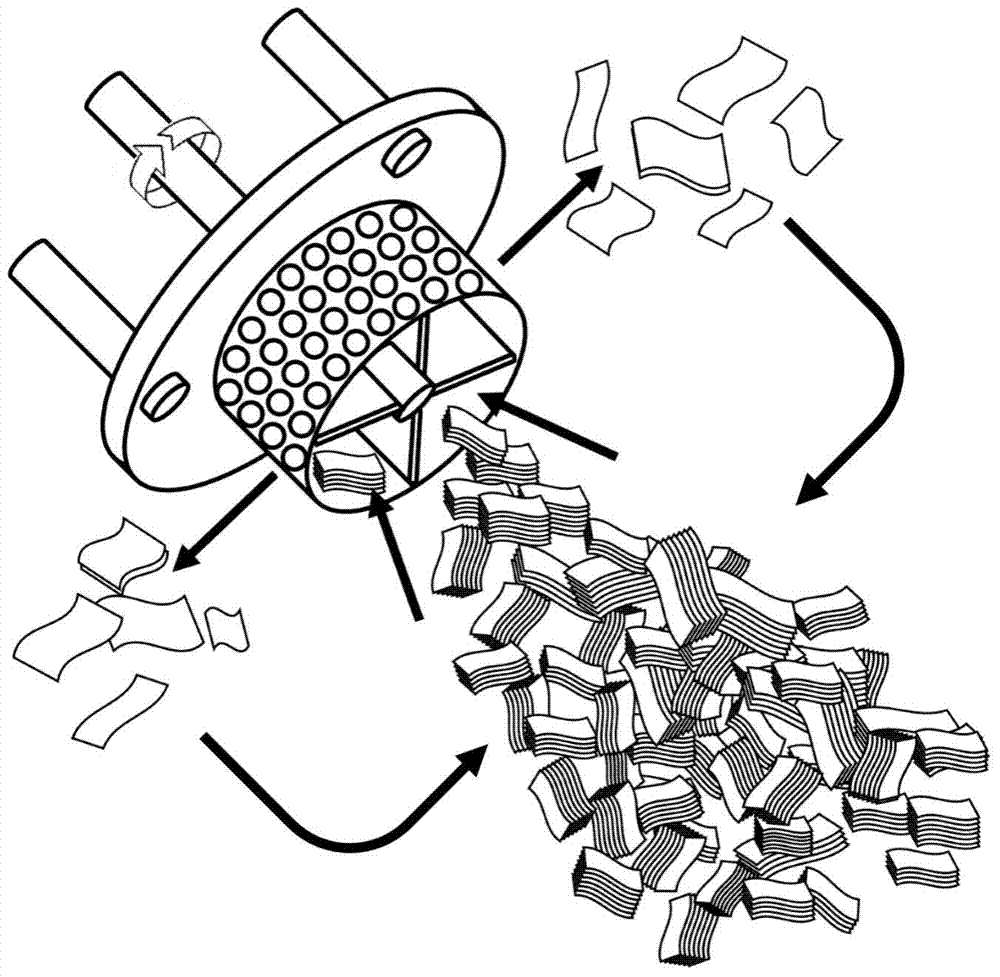

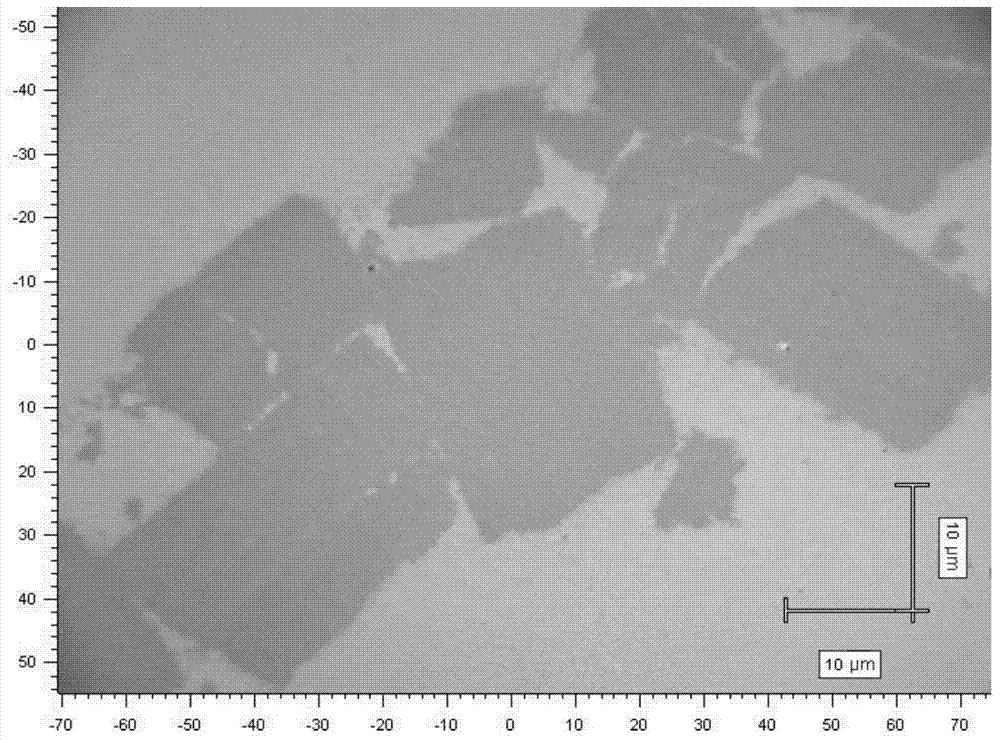

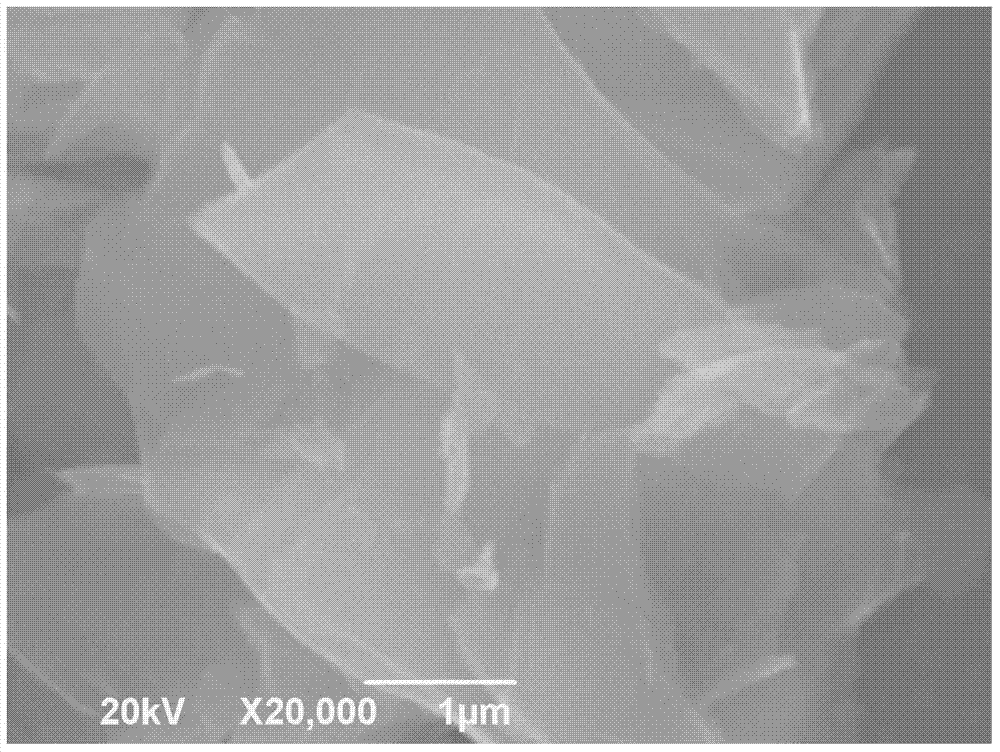

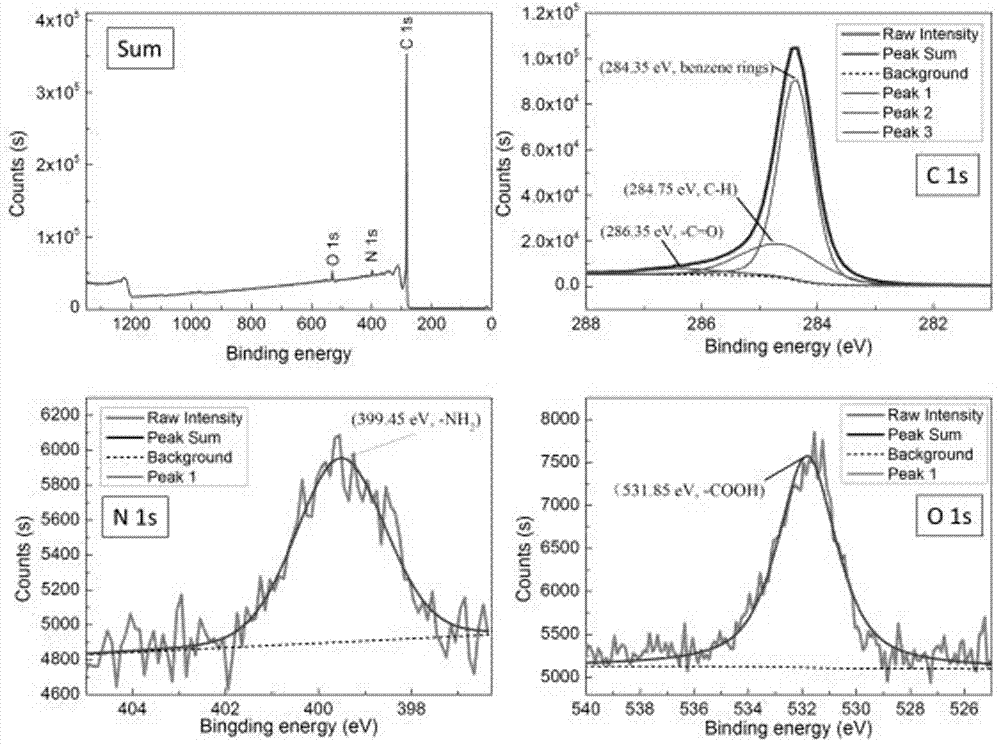

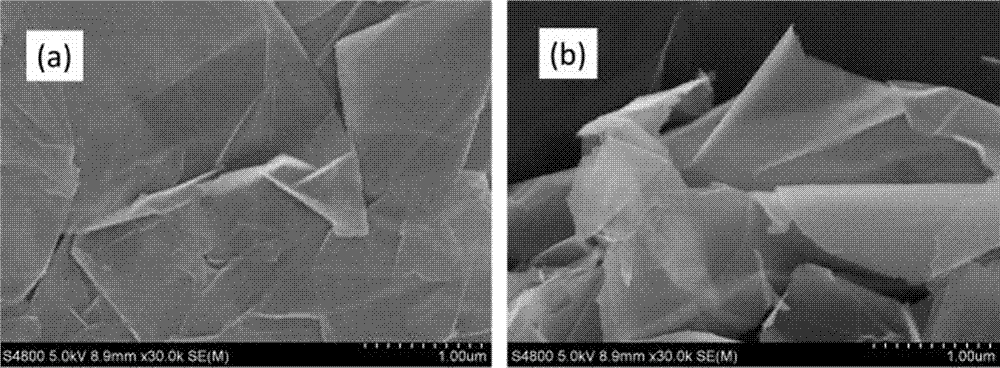

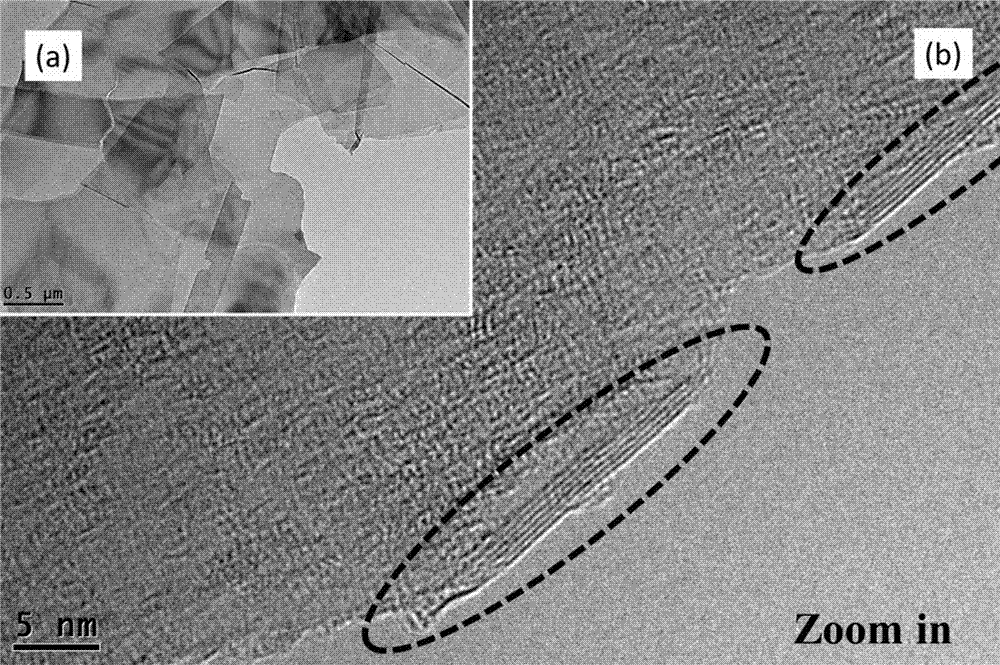

Preparation method of stratified molybdenum disulfide nano material

InactiveCN104495936AGood physical propertiesImprove stripping rateMaterial nanotechnologyMolybdenum sulfidesSolventDislocation

The invention provides a preparation method of a stratified molybdenum disulfide nano material. The preparation method comprises the following steps: adding molybdenum disulfide blocks to a container and adding a stripping solvent to prepare a molybdenum disulfide dispersion; performing hydraulic shearing treatment on molybdenum disulfide dispersion by use of a high-shear emulsifying machine; and centrifuging the hydraulically sheared molybdenum disulfide dispersion, filtering the centrifuged top suspension and drying in vacuum to obtain stratified molybdenum disulfide nanosheets. According to the preparation method of the stratified molybdenum disulfide nano material, the molybdenum disulfide blocks are under a strong combined action in a narrow gap between a stator and a rotor to arouse horizontal dislocation and slippage motion of crystal faces between the molybdenum disulfide layers, and therefore, the molybdenum disulfide is stripped, and finally, stable single-layer or few-layer molybdenum disulfide sheets are obtained; the preparation method is a pure physical method, and is simple in process, low in cost, small in danger, high in stripping ratio, green and environment-friendly; the prepared stratified molybdenum disulfide nanosheets are kept excellent in physical properties and suitable for large-scale industrial production after a pilot plant test.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

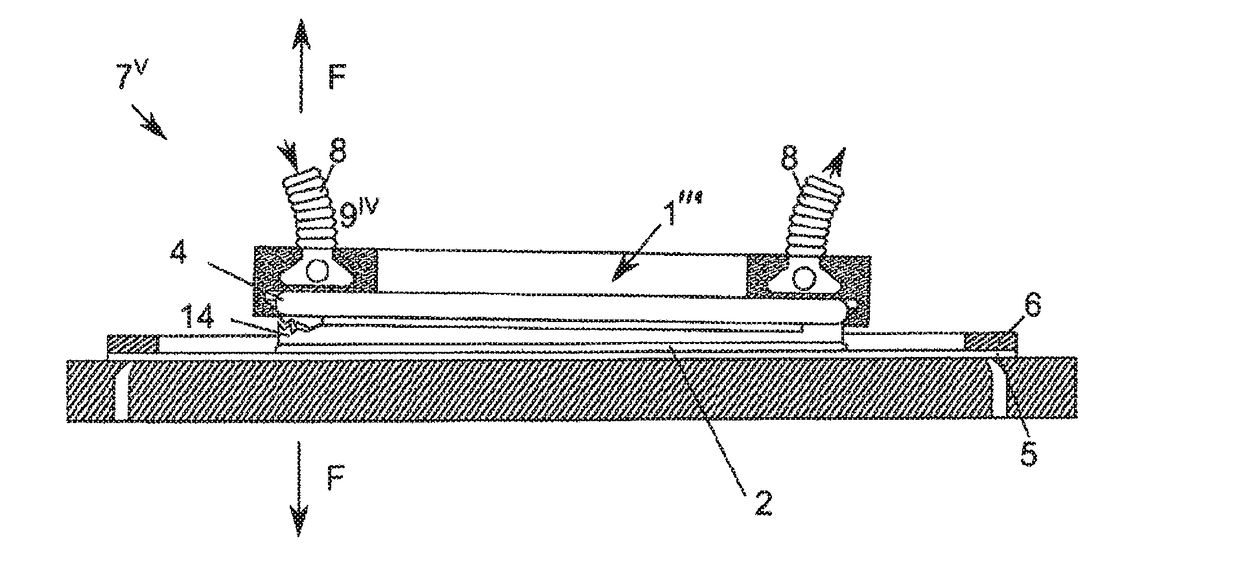

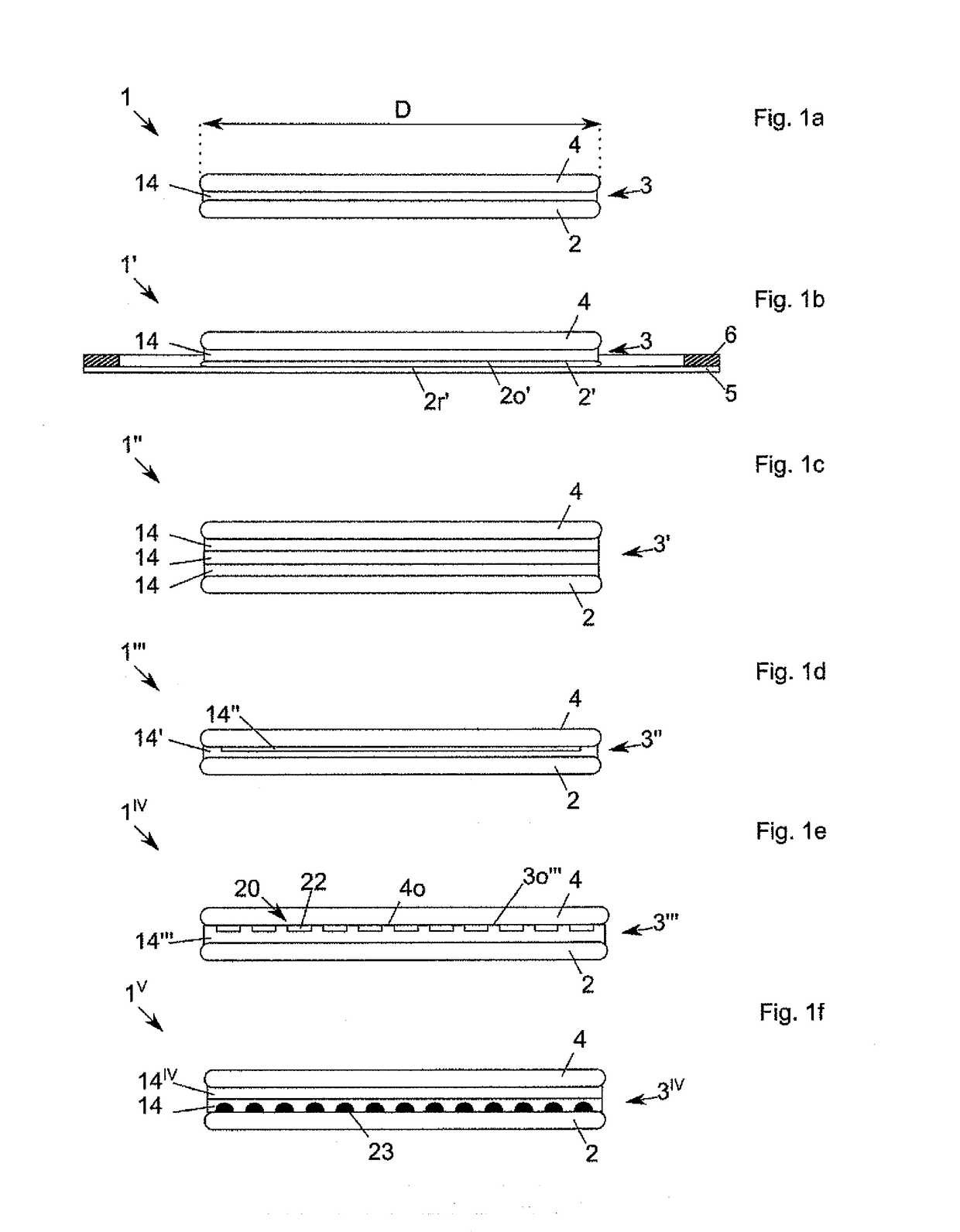

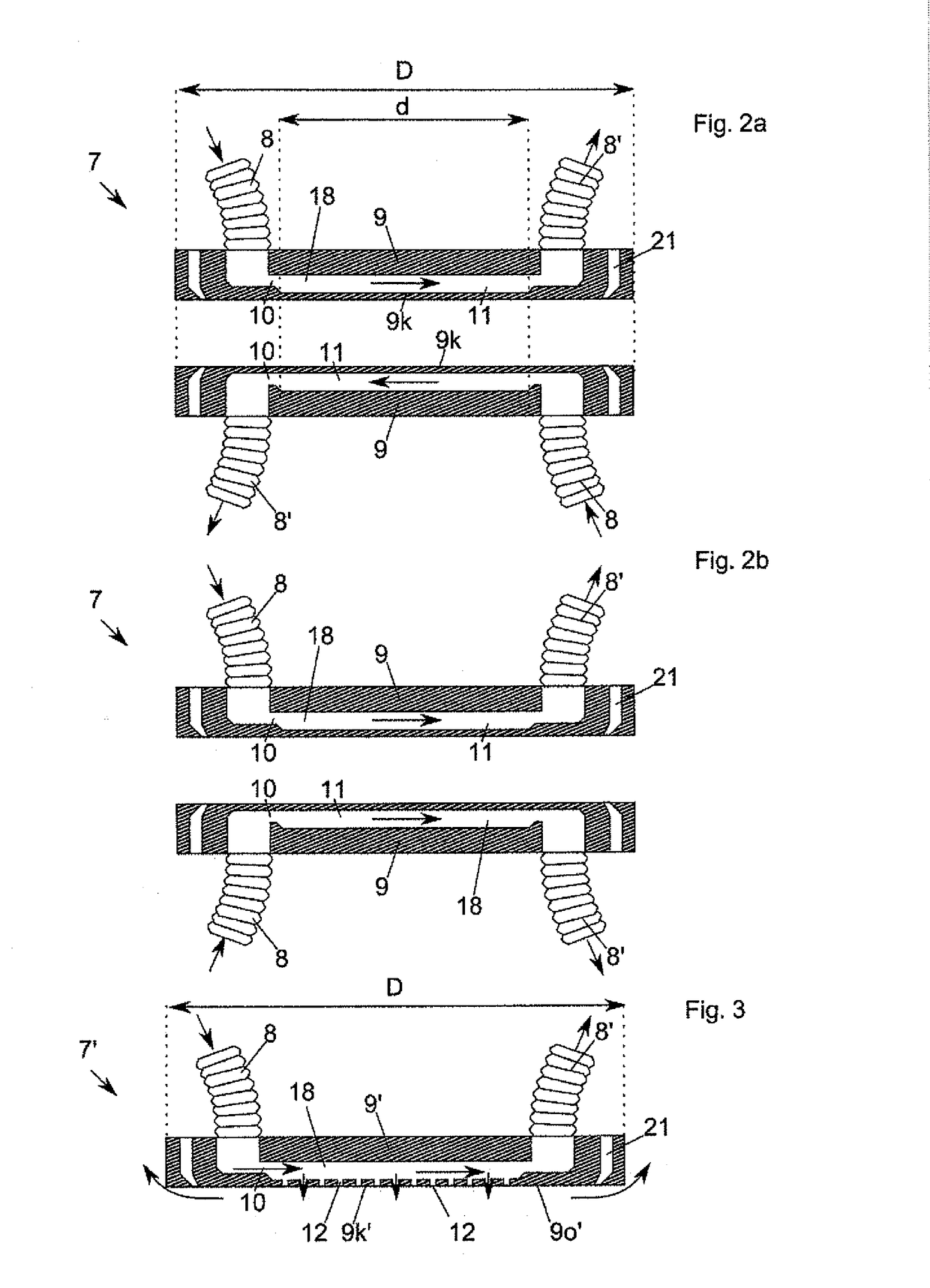

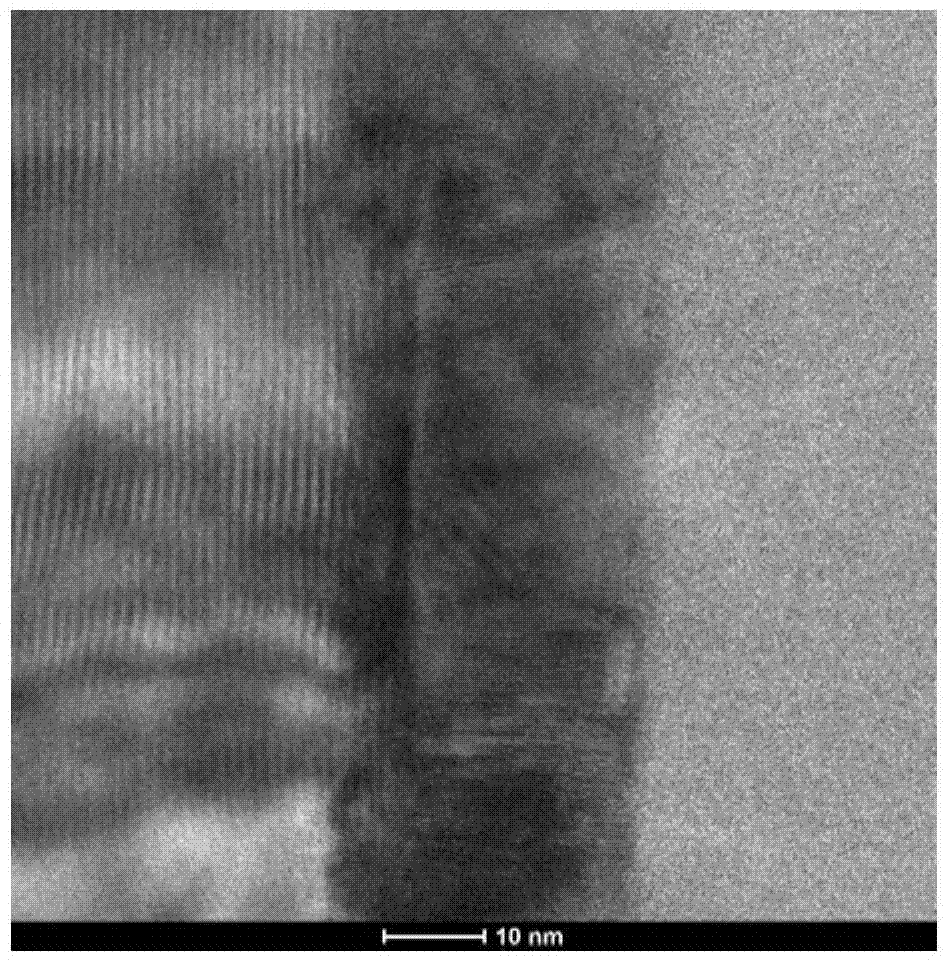

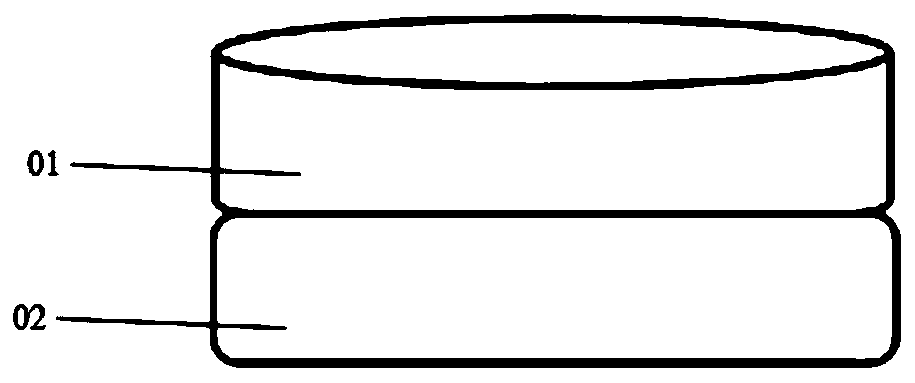

Sample holder, device and method for detaching of a first substrate

ActiveUS20170133243A1Improve stripping rateEconomical efficiency is highLayered product treatmentSolid-state devicesOptoelectronicsEmbrittlement

A method and device for detaching a first substrate, which is connected to a second substrate by an interconnect layer, from the second substrate by embrittlement of the interconnect layer. A method for bonding of a first substrate to a second substrate with an interconnect layer which can be embrittled by cooling. A use of a material which can be embrittled for producing an interconnect layer between first and second substrate for forming a substrate stack. A substrate stack, formed from a first substrate, a second substrate and an interconnect layer located therebetween, the interconnect layer formed from a material which can be embrittled. A wafer chuck for holding a first substrate when the first substrate is being detached from a second substrate with fixing means which can be activated by lowering the temperature.

Owner:THALLNER ERICH

Environment-friendly stainless steel substrate plating stripping agent

The invention discloses an environment-friendly stainless steel substrate plating stripping agent. Nitrate is optimally selected as an oxidizing agent for stripping nickel, chromium, copper, tin, and other plating on a stainless steel substrate, and as generally, nitrate is relatively stable in property and relatively low in toxicity, so that when the stripping agent provided by the invention is used, exhaust gases and waste water are not generated, and the stripping agent is non-corrosive to a device and highly friendly to the environment; at the same time nitrate is matched with citrate, potassium sodium tartrate and a proper amount of polyhydroxyl aldehyde, so that the speed for stripping the nickel plating on the stainless steel substrate is effectively increased, the plating stripping is achieved in a short time, and the production cycle is shortened while the substrate is not damaged; and the stripping rate of the nickel plating on the stainless steel substrate can be effectively increased through the combination of mannitol and sodium diacetate. Relative to the prior art, the stripping agent has the advantages of being free of corrosion, poisonous gases and pollution, high in efficiency, environment-friendly in use, easy and convenient to maintain, and the like.

Owner:HUIZHOU CITY HIROMI CHEM CO LTD

Preparation method of nano tourmaline modified dust removal filter material

ActiveCN107261641AHigh pyroelectric coefficientImprove charging capacityDispersed particle filtrationMembrane filtersEmulsionTest sample

The invention discloses a preparation method of a nano tourmaline modified dust removal filter material, which belongs to the technical field of high-temperature smoke dust removal. The preparation method comprises the following steps: carrying out heat treatment for nano tourmaline powder; weighing sodium hexametaphosphate and sodium polyacrylate, and mixing the sodium hexametaphosphate and sodium polyacrylate with water; weighing nano tourmaline powder, adding water, and mixing with PTFE emulsion; adding the sodium hexametaphosphate and sodium polyacrylate into a mixed solution of the nano tourmaline powder and PTFE emulsion, and obtaining a nano tourmaline treatment solution; soaking a filter material test sample in the nano tourmaline treatment solution, and obtaining a nano tourmaline filter material; and polarizing the nano tourmaline filter material by virtue of electrets, and obtaining the nano tourmaline modified dust removal filter material. By adopting the preparation method, not only is electrets performance high, small dust can be trapped, the dust filter efficiency can be improved, the dust removing rate can be increased, and the equipment resistance is reduced.

Owner:南京际华三五二一环保科技有限公司

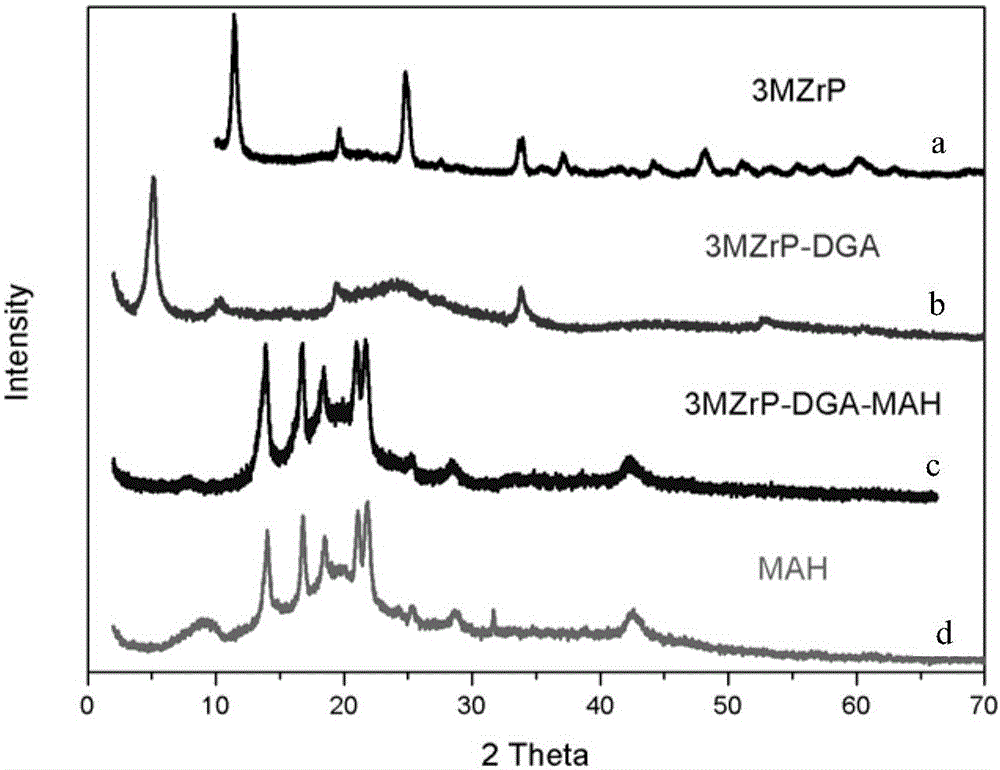

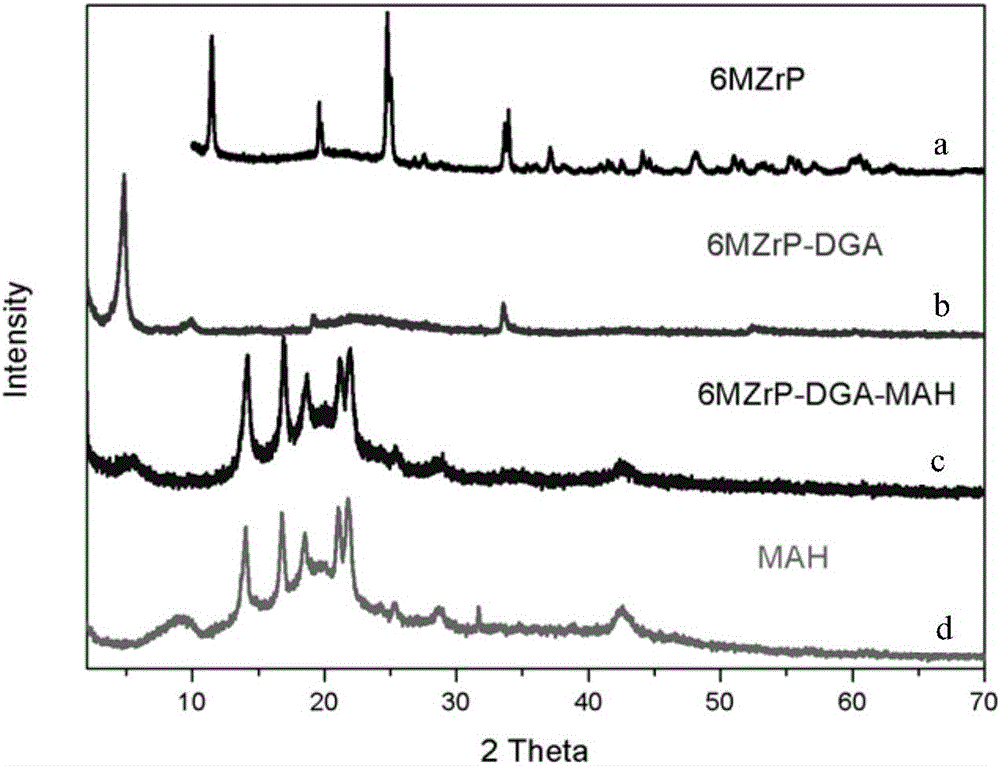

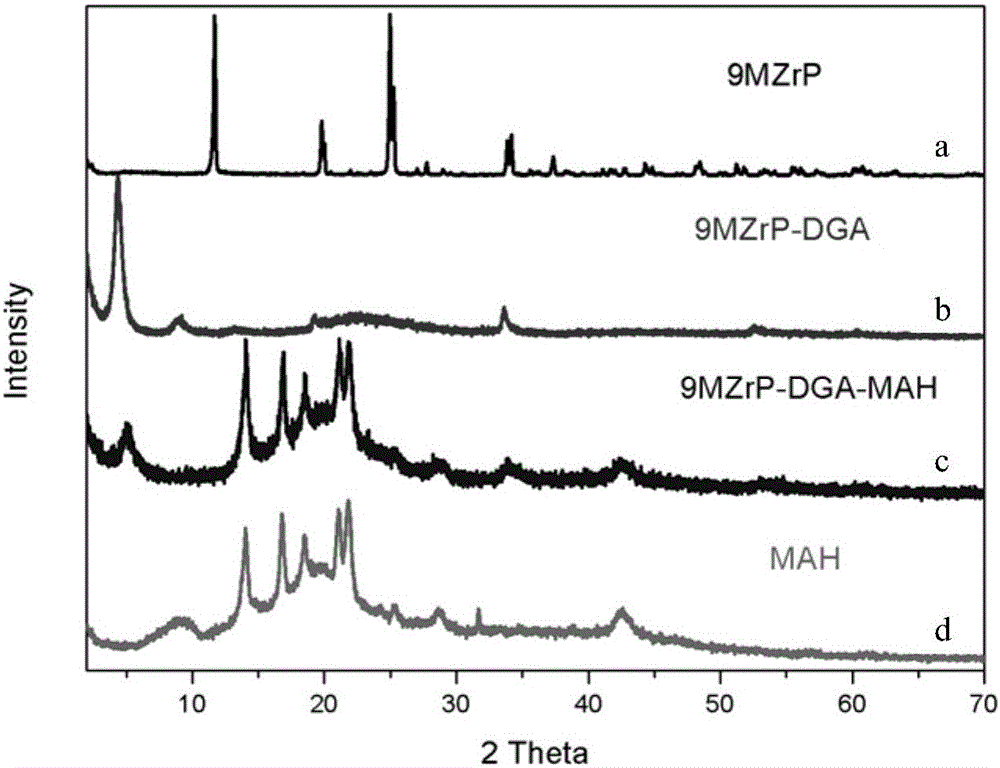

Layered nanoparticles, stripping method and application thereof

ActiveCN105800579AAchieving successful strippingImprove stripping rateMaterial nanotechnologyPhosphorus compoundsNanoparticleAlkene

The invention relates to a method for stripping layered nanoparticles. The method comprises the following steps of: (1) performing intercalation treatment on the layered nanoparticles by adopting an intercalation agent, thereby obtaining intercalated nanoparticles; and (2) performing stripping treatment on the intercalated nanoparticles prepared in the step (1) by adopting a maleic anhydride graft, thereby obtaining the stripped layered nanoparticles. The stripping method comprises the following steps of: performing intercalation treatment on the layered nanoparticles by adopting the intercalation agent, and preparing the intercalated nanoparticles; and stripping the intercalated nanoparticles by adopting the maleic anhydride graft. Because the maleic anhydride graft has a polar group aldehyde group and olefin hydrophobic segments provided by maleic anhydride, and the anhydride group and the polar group (such as amido) are subjected to a generalized dehydration reaction so as to form chemical bonds under the high temperature and screw shear actions, so that incompatible polar and non-polar substances are subjected to chemical coupling. Therefore, the layered nanoparticles are stripped and dispersed, and a coupling compatibility effect is achieved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Source-drain electrode of thin film transistor and manufacturing method thereof and thin film transistor and manufacturing method thereof

ActiveCN104766891AReduce contact resistanceImprove conductivityTransistorSemiconductor/solid-state device manufacturingOxideBonding strength

The invention discloses a source-drain electrode of a thin film transistor. The source-drain electrode is composed of a molybdenum layer and a copper layer in a sequential overlaying mode, and the copper layer is arranged on the molybdenum layer. The molybdenum layer is arranged on an active layer of the thin film transistor; the growth direction of crystal lattices of the molybdenum layer and the growth direction of crystal lattices of the copper layer are perpendicular to each other; the thickness of the molybdenum layer is 20 nm-40 nm; the thickness of the copper layer is 150 nm-250 nm. The invention further discloses a manufacturing method of the source-drain electrode, the thin film transistor comprising the source-drain electrode and a manufacturing method of the thin film transistor. The defects that in the prior art, copper electrodes are prone to being oxidized, and copper atoms diffuse toward oxide after the copper electrodes deposit on the active layer of the metal oxide are overcome, the source-drain electrode has the advantage of high conductivity, stress balance between two layers of electrodes can be achieved, the disbanding ratio of the electrodes is lowered, and the bonding strength is improved.

Owner:SOUTH CHINA UNIV OF TECH

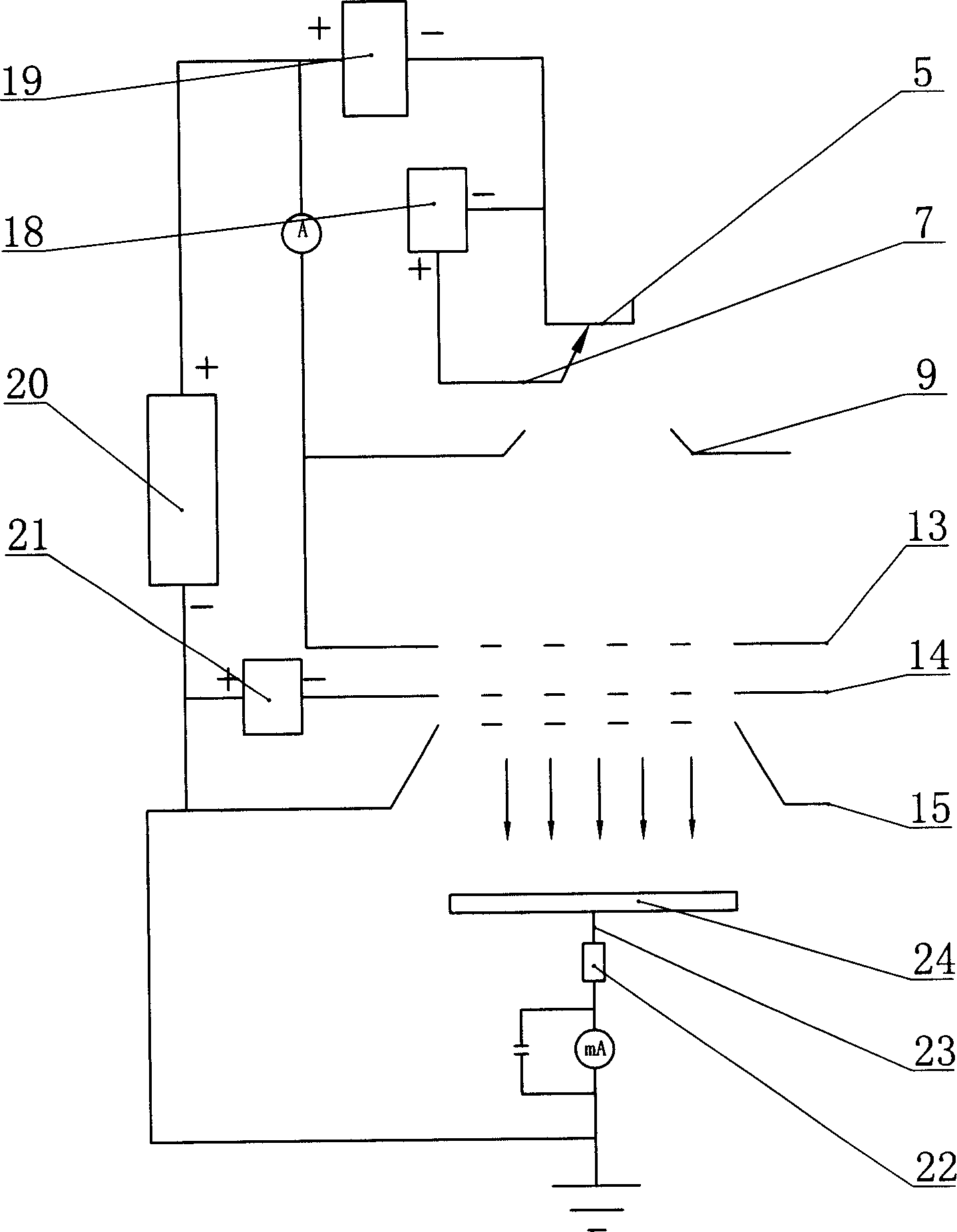

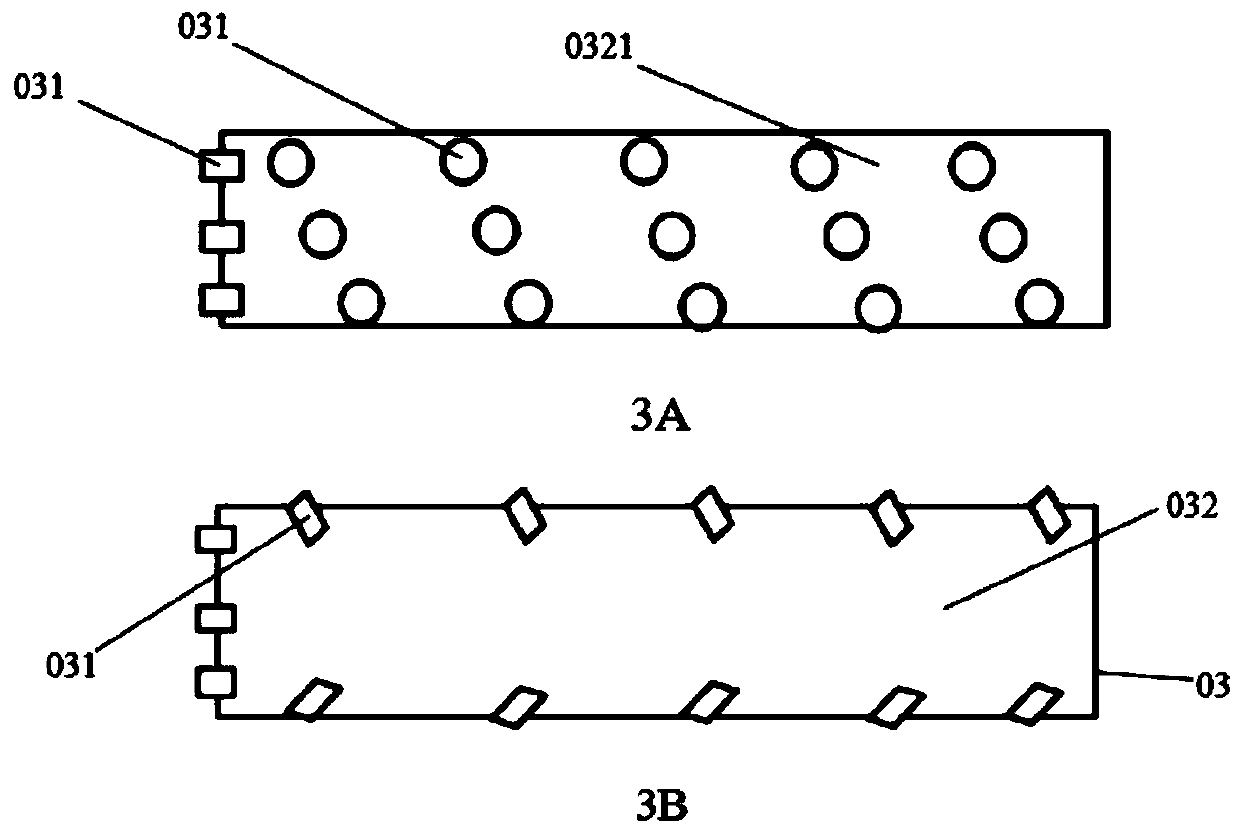

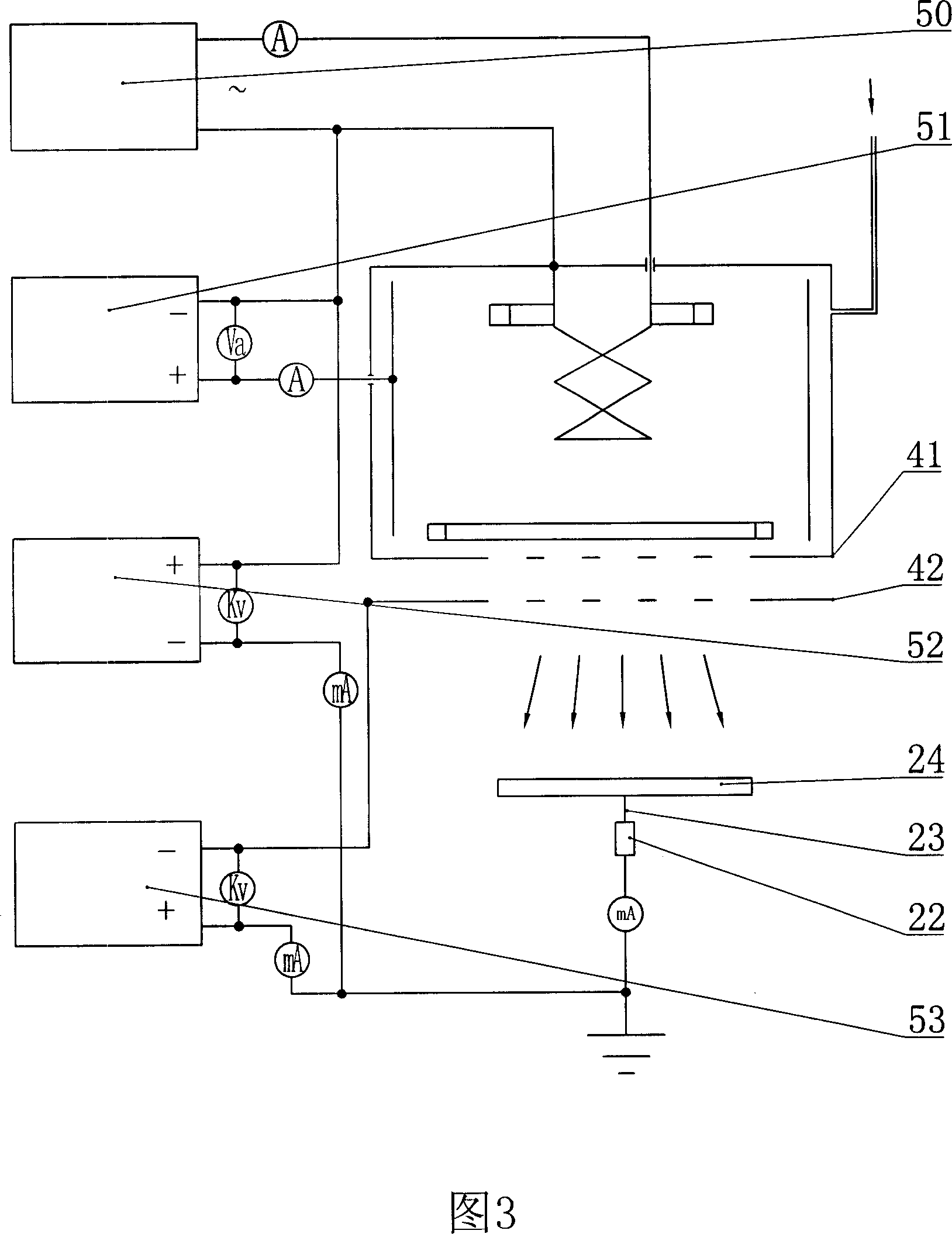

Metal ion implantation machine

InactiveCN1609265ARich varietyBeam intensityVacuum evaporation coatingSputtering coatingThick plateIon beam

The present invention is one metal ion implanter with strong ion beam flow, low ion beam leading out voltage, great ion beam implanting area, short ion implanting period and low workpiece treating cost. The metal ion implanter has metal ion comprising cathode, cathode rack, triggering electrode, insulating cathode sleeve, anode, anode rack, charge chamber, plasma chamber, the first grid, the second grid and the third grid. The interval between the first grid and the second grid is 5-10 mm, and these three grids are 2-5 mm thick plates with 1300-1800 small holes each of 3-5 mm diameter. The arc voltage power source has characteristic impedance of 1 ohm, pulse width of 0.44-0.65 ms and frequency of 5-25 Hz. The present invention is used in the production of metal parts.

Owner:珠海市恩博金属表面强化有限公司

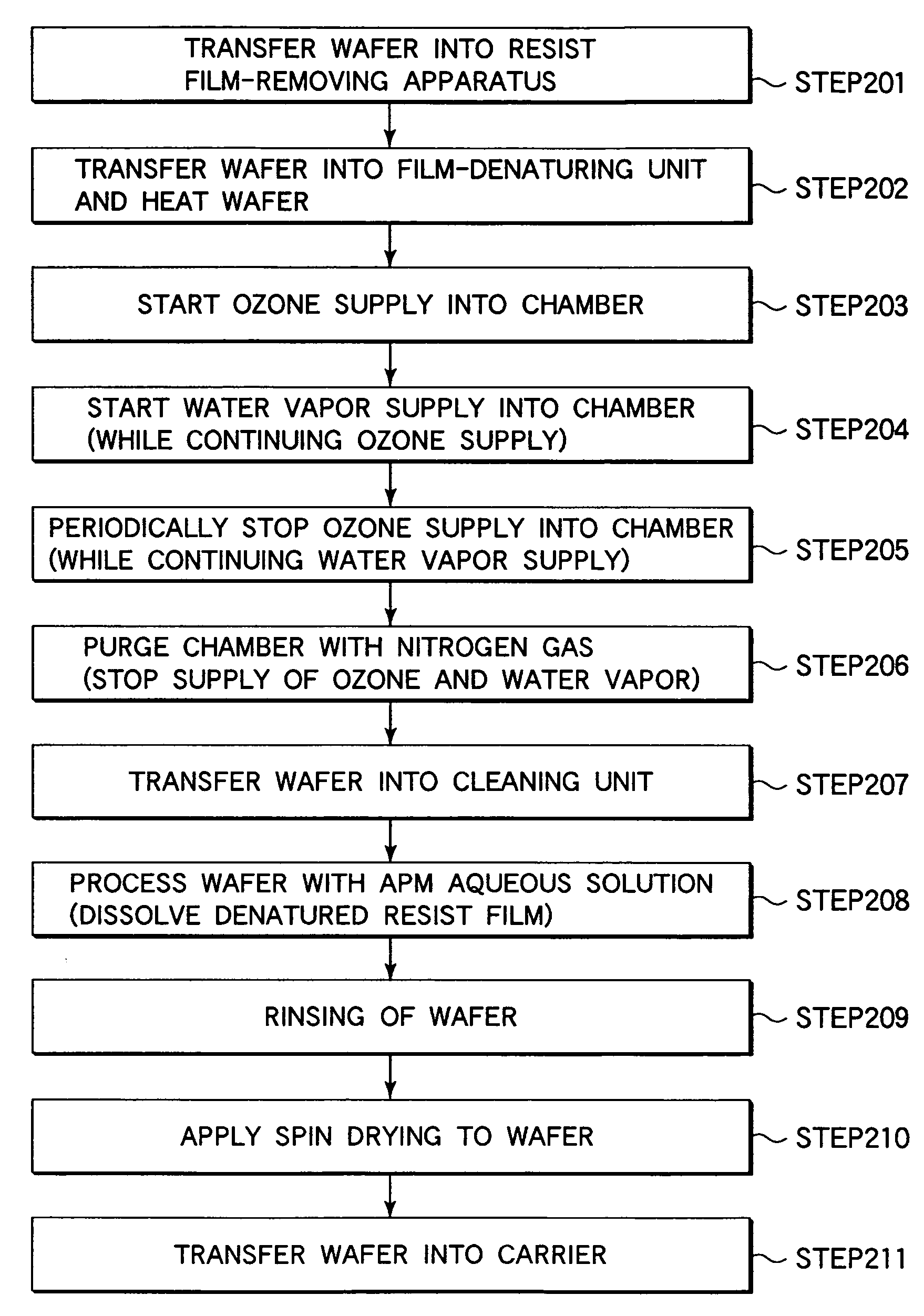

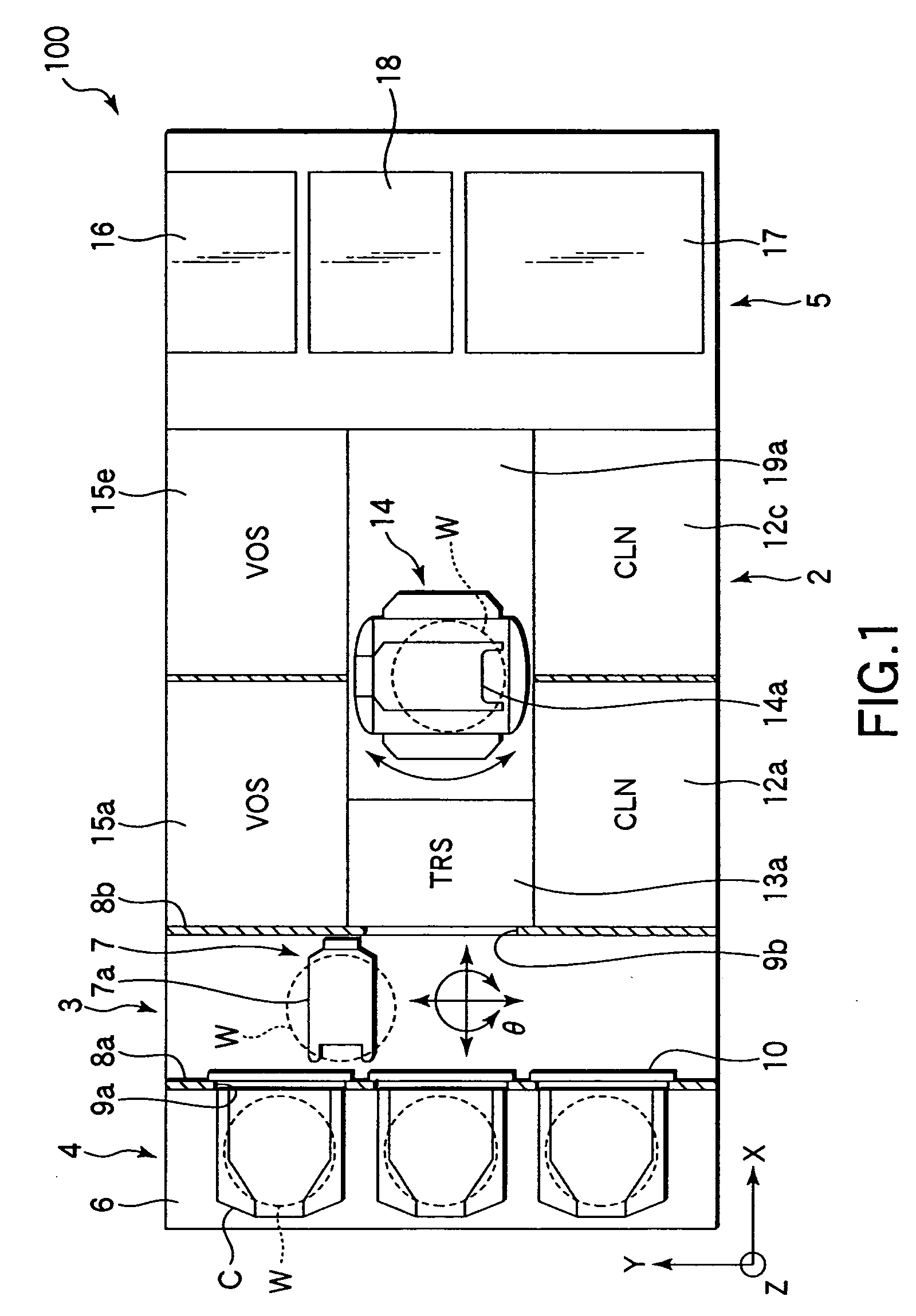

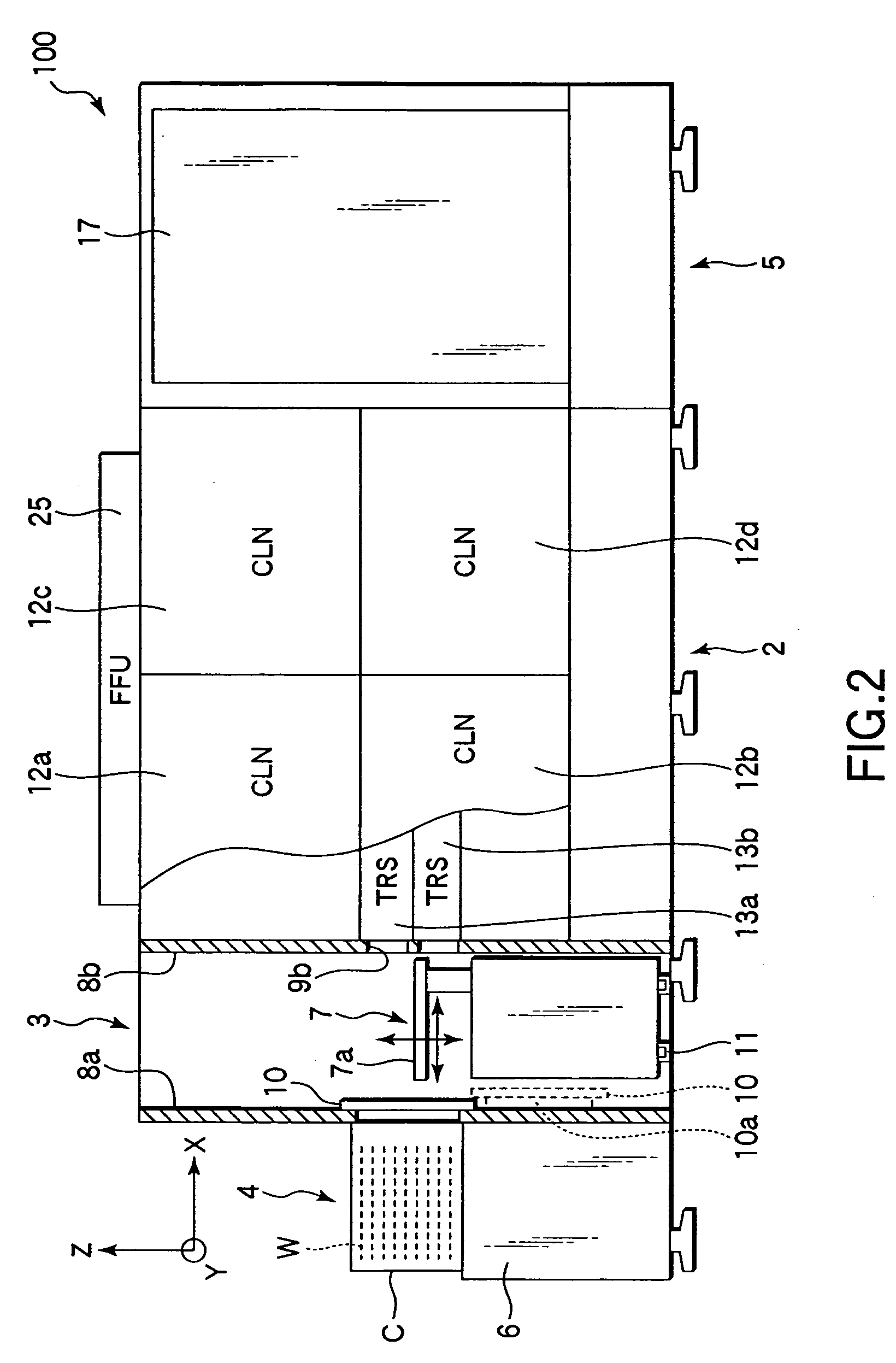

Substrate processing method and substrate processing apparatus

InactiveUS20060079096A1Improving peeling rateImprove stripping rateVacuum evaporation coatingSputtering coatingChemistryResist

A substrate processing method for removing a resist film from a substrate having the resist film formed thereon comprises maintaining the inner region of the chamber at a prescribed temperature by putting a substrate in a chamber, denaturing the resist film by supplying ozone and a water vapor in such a manner that ozone is supplied into the chamber while a water vapor is supplied into the chamber at a prescribed flow rate, the amount of ozone relative to the amount of the water vapor being adjusted such that the dew formation within the chamber is prevented, and processing the substrate with a prescribed liquid material so as to remove the denatured resist film from the substrate.

Owner:TOKYO ELECTRON LTD

Method of using microcrystalline graphite to prepare secondary expanded microcrystalline graphite

InactiveCN107285307AHigh expansion factorImprove corrosion resistanceMaterial nanotechnologyCarbon compoundsMaterials preparationSulfur

The invention belongs to the technical field of material preparation, and particularly relates to a method of using microcrystalline graphite to prepare secondary expanded microcrystalline graphite. The method includes: using the microcrystalline graphite as a raw material, performing chemical intercalation treatment for the first time, filtering, washing and drying a product obtained after intercalation treatment to obtain primary expandable microcrystalline graphite, and adopting a high-temperature expanding method to expand the expandable microcrystalline graphite in a graphite expanding furnace at 800 DEG C to obtain primary expanded microcrystalline graphite; using the primary expanded microcrystalline graphite as a raw material, performing chemical intercalation treatment for the second time, filtering, washing and drying a product obtained after intercalation treatment to obtain secondary expandable microcrystalline graphite, and adopting a high-temperature expanding method to perform high-temperature expanding on the secondary expandable microcrystalline graphite for the second time in the graphite expanding furnace at 900 DEG C to obtain secondary expanded microcrystalline graphite. By the method, 200-287-multiple secondary expanded microcrystalline graphite materials which are high in multiple, sulfur-free and short in production period can be prepared on a large scale.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

High-concentration high-stability transitional metal chalcogen compound printing ink for ink jet printing and preparation method of printing ink

InactiveCN108410265AInhibition of agglomerationReunion won't happenInksHigh concentrationPrinting ink

The invention belongs to the technical field of two-dimensional material preparation, and particularly relates to high-concentration high-stability transitional metal chalcogen compound printing ink for ink jet printing and a preparation method of the printing ink. Specific to the problem that as current transitional metal chalcogen compound nano sheet printing ink is low in concentration and poorin stability, the use and storage are inconvenient, the technical scheme of the invention is characterized in that the preparation method comprises the following steps: [1] selecting two kinds of stripping solvents, and preparing a binary good solvent system; [2] adding a water-soluble high-molecular compound into the binary good solvent system to obtain a mixed solvent; [3] stripping a nano sheet of a transitional metal chalcogen compound from transitional metal chalcogen compound powder by using an ultrasound stripping method; [4] performing centrifugal separation, and taking supernate, i.e., transitional metal chalcogen compound nano sheet dispersion liquid; and [5] adding a conditioning agent with a physical property to obtain the transitional metal chalcogen compound printing ink. The transitional metal chalcogen compound printing ink is suitable for the ink jet printing of a transitional metal chalcogen compound two-dimensional material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

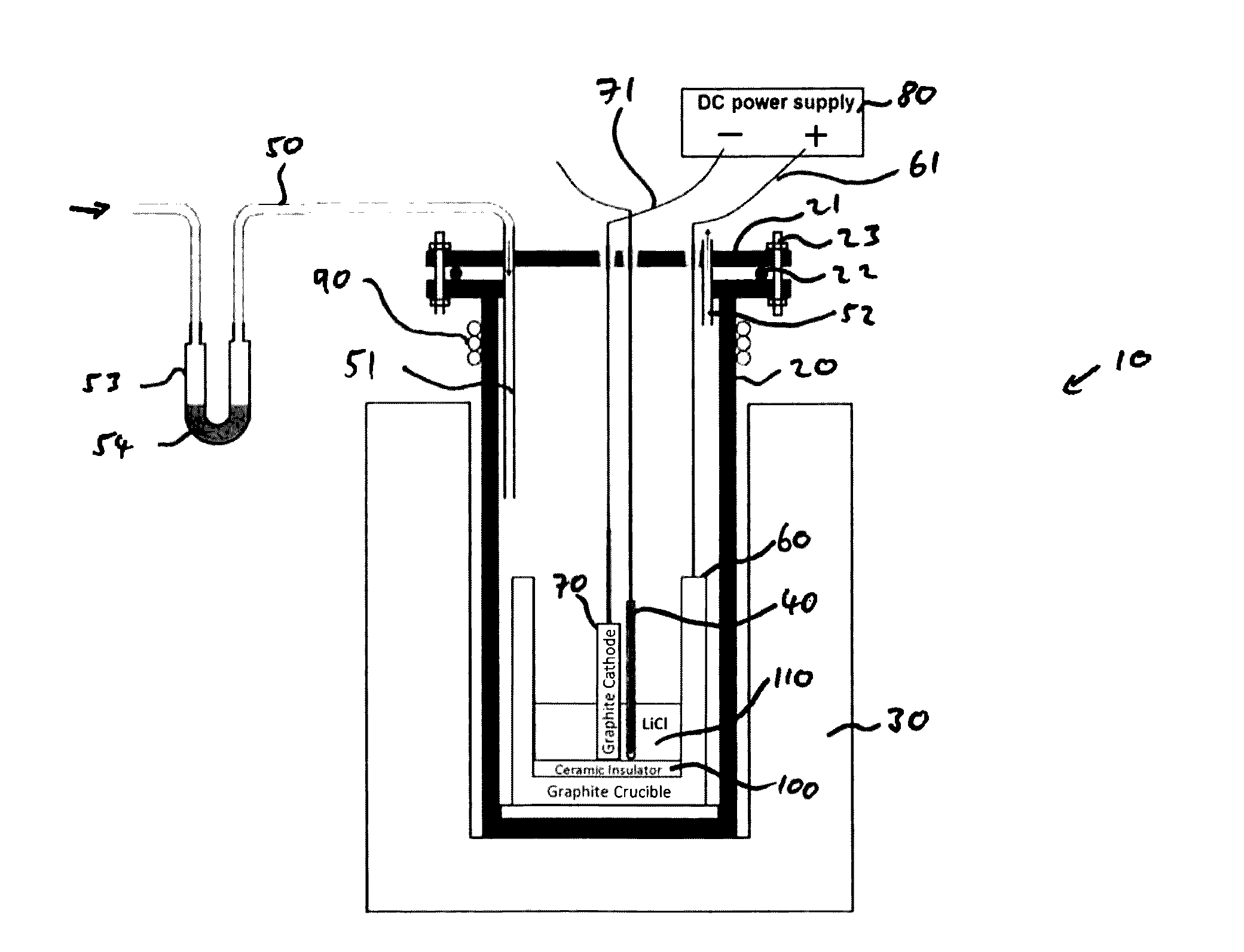

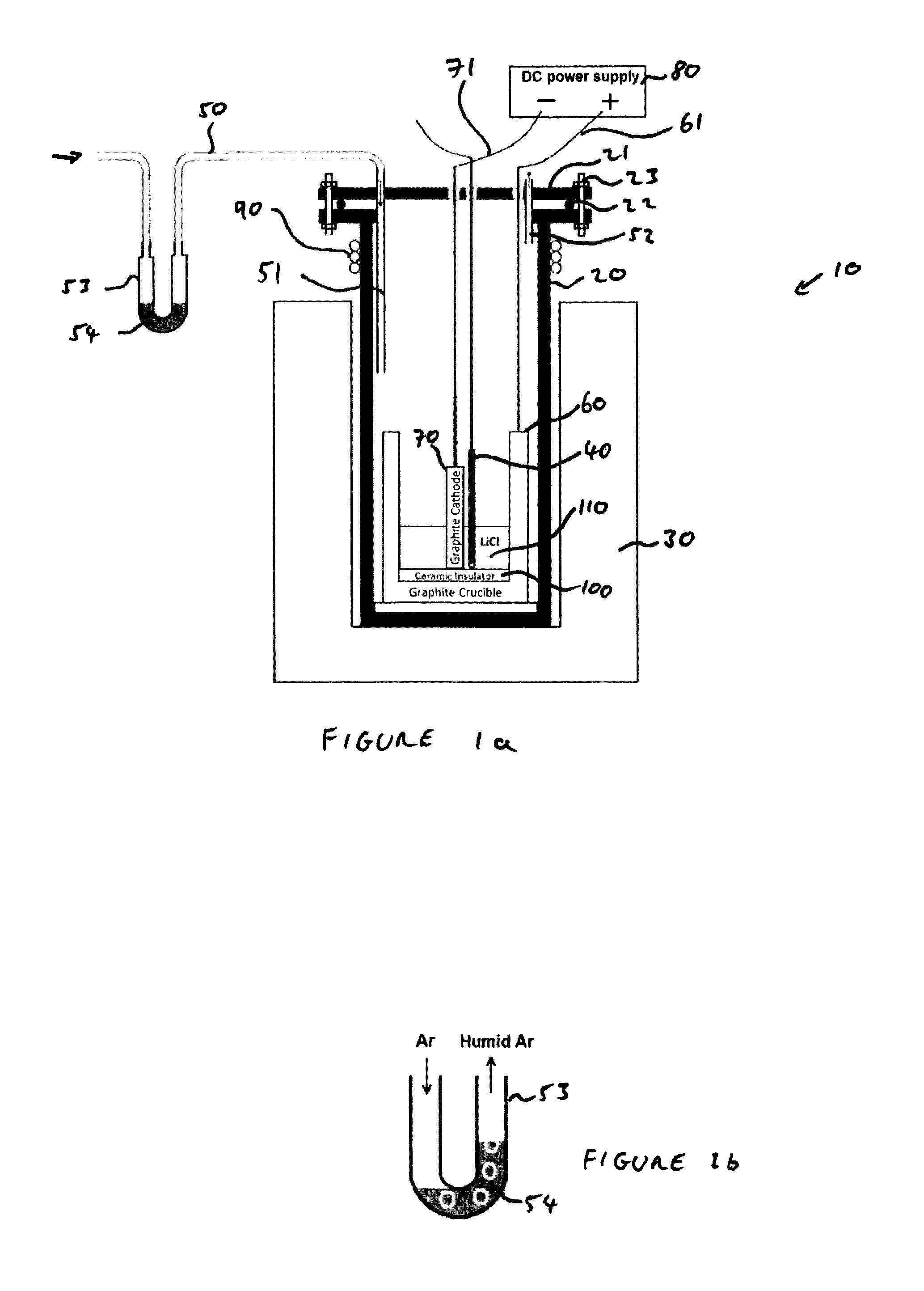

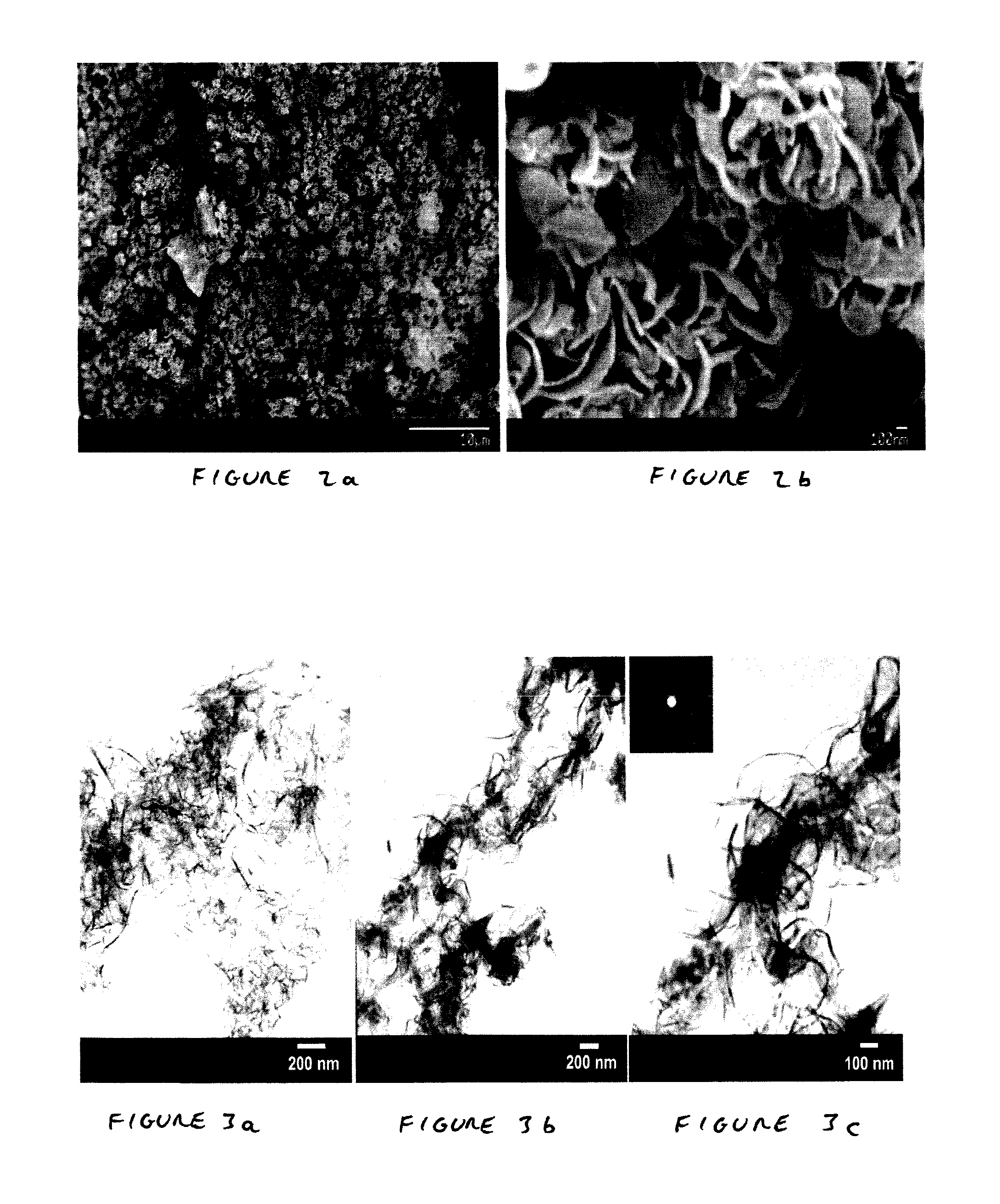

Method of producing graphene

ActiveUS20170050853A1Preventing generation of oxidation defectImprove stripping rateCellsMaterial nanotechnologyProduction rateGraphite electrode

A method of producing graphene sheets comprising the steps of, forming a carbonaceous powder by electrochemical erosion of a graphite electrode in a molten salt comprising hydrogen ions, recovering the resulting carbonaceous powder from the molten salt liquid, and thermally treating the carbonaceous powder by heating the carbonaceous powder in a non-oxidising atmosphere to produce a thermally treated powder comprising graphene sheets. The method allows high production rates of high purity graphene sheets.

Owner:CAMBRIDGE ENTERPRISE LTD

Method for preparing graphene from microcrystalline graphite

The invention belongs to the technical field of preparation of materials and particularly relates to a method for preparing graphene from expanded graphite. Microcrystalline graphite serving as a raw material is subjected to first chemical intercalation treatment, first high-temperature expansion treatment, second intercalation treatment and second high-temperature expansion treatment sequentially, second expanded microcrystalline graphite is obtained and subjected to ultrasonic treatment twice, and a peeling material is obtained and subjected to press filtering, separation and washing, and graphene is obtained. According to the method, the microcrystalline graphite is taken as the raw material, the production technology process is short, and the method is low in cost, produces no sulfur and can be used for mass production of graphene materials.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

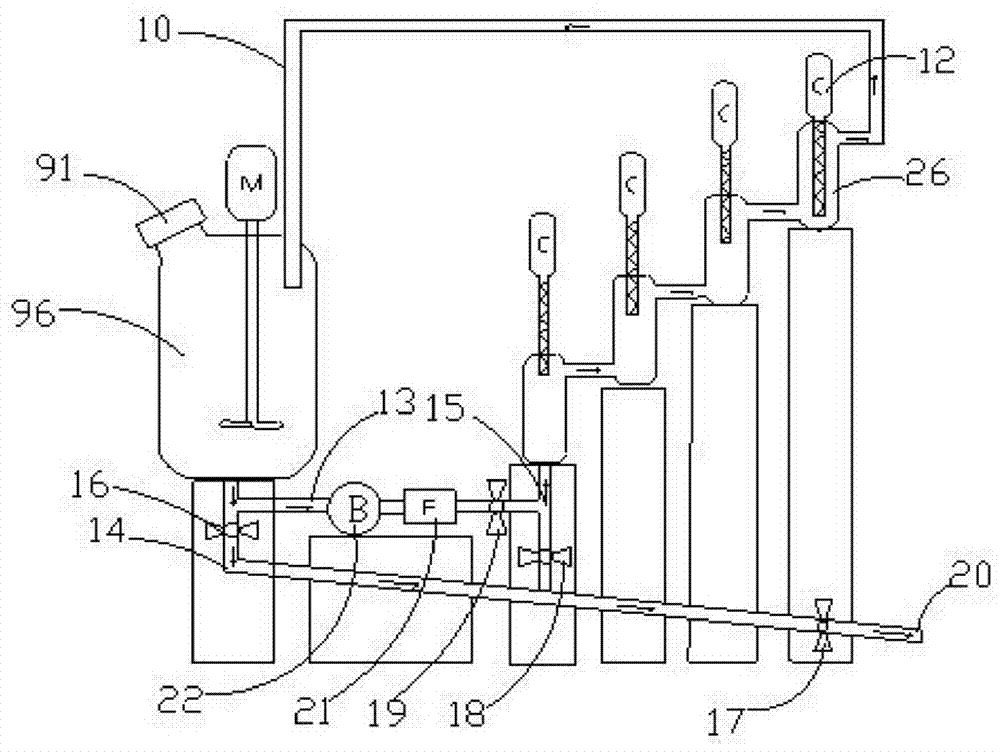

Batch preparation method of graphene and production system therefor

InactiveCN107500279AImprove stripping rateImprove stabilitySingle layer grapheneGraphiteCvd graphene

The invention relates to the field of graphene materials, and discloses a batch preparation method of graphene and a production system therefor. In the invention, a conventional high temperature expansion method is combined with a graphite expansion furnace, and by means of optimum expansion temperature, stability of a product is effectively improved by means of control on raw materials and process parameters on the basis of the expansion temperature, thereby producing expanded graphite with controllable expansion times, namely, distribution ratio with expansion times being 200-300 is highest. With the expanded graphite as a raw material for producing graphene through a mechanical stripping method, stripping rate of graphene is greatly increased. On the basis of the conventional mechanical stripping method for preparing graphene, the graphene is produced in batches with the expandable graphite as raw material and graphene quantum dots as a stripping liquid, wherein a pre-stripping process is added on the basis of the prior art, and secondary ultrasonic treatment is employed with process parameters in the ultrasonic treatment being optimized.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Automatic fail preventing device for ceramic filter

InactiveCN104436918AImprove economyLow costDispersed particle filtrationMetallurgyVacuum ceramic filter

The invention provides an automatic fail preventing device for a ceramic filter. The automatic fail preventing device for the ceramic filter comprises a porous metal protection pipe and a fixing seat, wherein the porous metal protection pipe is fixed at the upper part of a main pipe plate of the filter through the fixing seat, and the position of the porous metal protection pipe corresponds to that of a ceramic filtering pipe up and down; an injecting and blowing pipe is arranged in the porous metal protection pipe, the upper end of the injecting and blowing pipe extends out of the top of the porous metal protection pipe and is communicated with a back flushing distribution pipe, and a spiral drain pump is arranged at the lower end of the injecting and blowing pipe. According to the automatic fail preventing device for the ceramic filter, the pressure drop is relatively low when the ceramic filter safely runs, cleaning gas can smoothly enter an air purification room through the wall of the protection pipe; when a filtering element has failure, large-particle dust can be quickly sealed so as to prevent an integral system from stopping caused by the damage of few of filtering elements. The automatic fail preventing device for the ceramic filter automatically seal damaged filtering elements, and a precise online monitoring device and a corresponding probe for locating the damaged filtering elements do not need to be installed, so that the operation and the installation are convenient, and the error stopping caused by error judgment is also avoided.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

PET/microcrystalline graphene composite heat-conducting film and preparation method thereof

InactiveCN107337804AUniform structureImprove permeabilityHeat-exchange elementsCoatingsProcess optimizationThermal diffusion coefficient

The invention relates to the field of preparation of graphene composites and discloses a PET / microcrystalline graphene composite heat-conducting film and a preparation method thereof. Expanded graphite is creatively prepared from microcrystalline graphite used as a raw material through secondary intercalation, a high-quality graphene product is obtained through ultrasonic treatment with a mechanical exfoliation method, and the PET / microcrystalline graphene composite heat-conducting film with high heat conductivity can be prepared in batches through process optimization of the graphene product. The prepared PET / microcrystalline graphene composite heat-conducting film has the graphene coating thickness of 3-9 mu m, the thermal diffusion coefficient of 8-12 cm<2> / S and the heat conductivity coefficient of 1,400-1,700 W / (m*k).

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Method for quickly extracting and separating polyphenol oxidase from plant leaves

The invention relates to a method for quickly extracting and separating polyphenol oxidase from plant leaves, and belongs to the field of bioseparation. The method for quickly extracting and separating the polyphenol oxidase from the plant leaves comprises the following steps: cleaning plant leaves; adding a buffer solution, mashing, leaching and carrying out suction filtering; collecting a filtrate, centrifugally collecting crude enzyme; extracting by using reverse micelles after ultra-filtration of the crude enzyme; and concentrating, freezing and drying after extraction is ended, so as to obtain polyphenol oxidase powder. The polyphenol oxidase crude enzyme is extracted by using the reverse micelles, and the obtained polyphenol oxidase is high in purity, fewer in impurities, and high in enzyme activity, and the processing method is simple in technology, large in handling capacity and applicable to industrial production.

Owner:GUANGXI UNIV

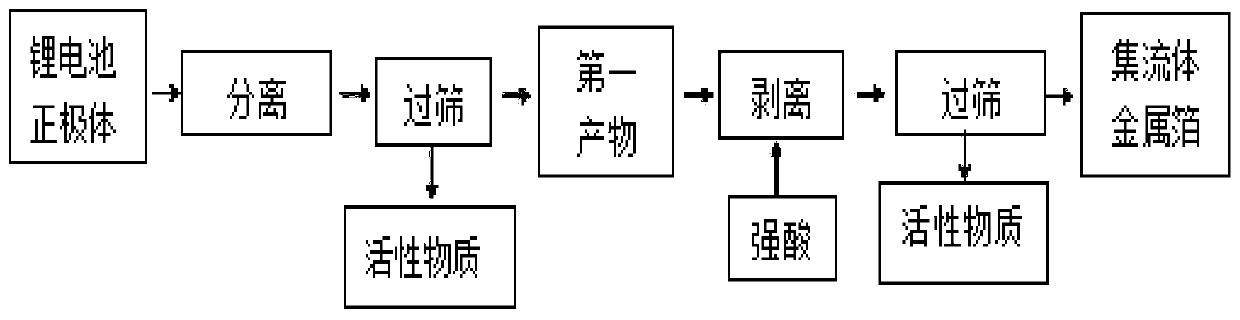

Separation device, stripping device and recovery method of battery positive electrode

The present invention relates to the technical field of chemical material recovery and utilization, in particular to a separation device, a stripping device and a recovery method of a battery positiveelectrode. The separation device structure comprises a screening device and a material receiving device. The screening device is detachably connected with the material receiving device, and the screening device is located above the material receiving device. The stripping device structure comprises a reaction tank and at least one ejection device. The ejection device is arranged on side wall of the reaction tank and / or the inner wall of one end of the reaction tank. The recovery method of the lithium ion battery positive electrode comprises the steps of separation and stripping. The separation device and the stripping device are simple in structure and easy and convenient to operate. The recovery method is short in process flow, simple in equipment and high in stripping rate without by-products added in the production process, and the stripped current collector is pure without inclusion of current collector, electrolyte and the like so as to facilitate subsequent recovery treatment.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

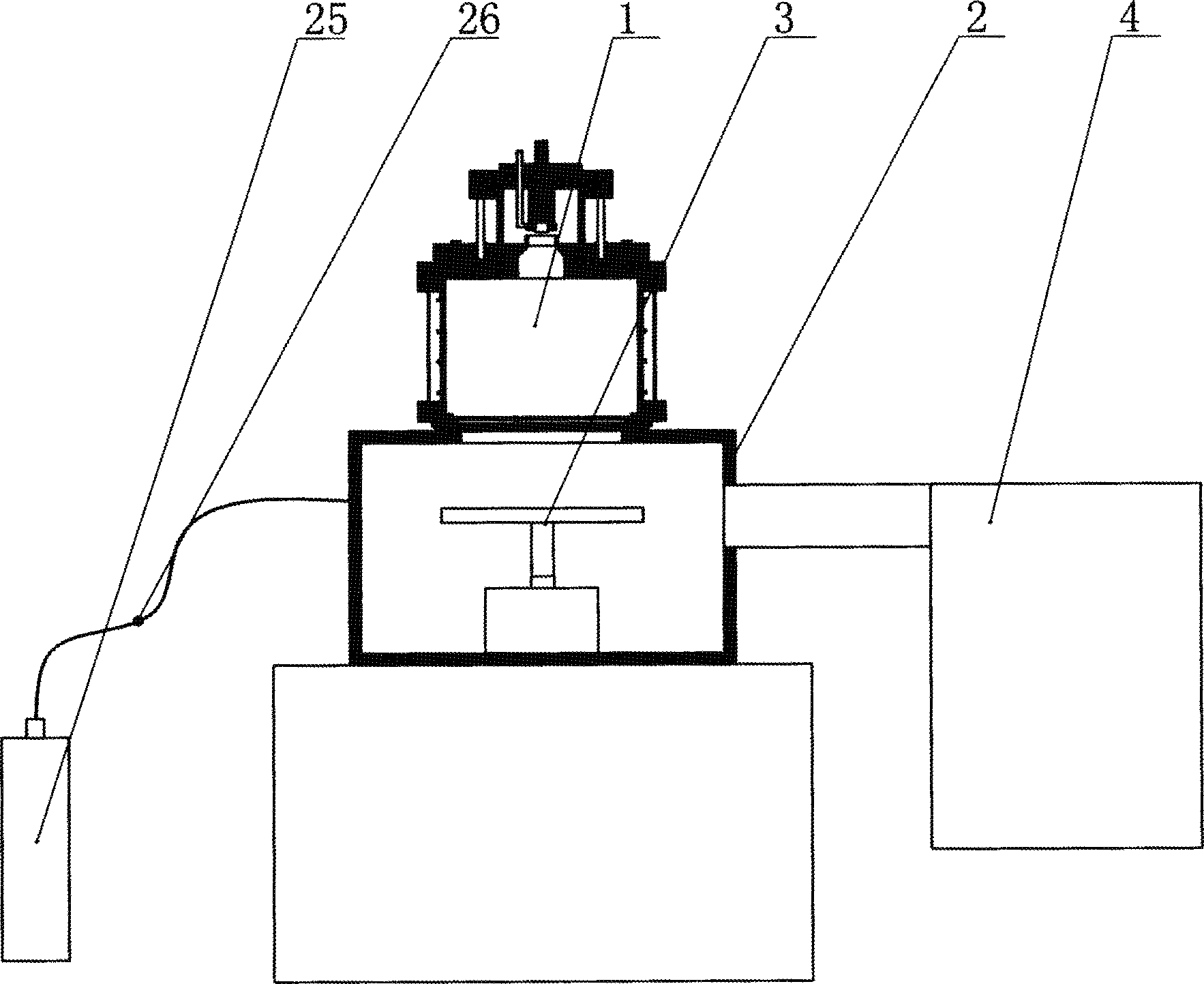

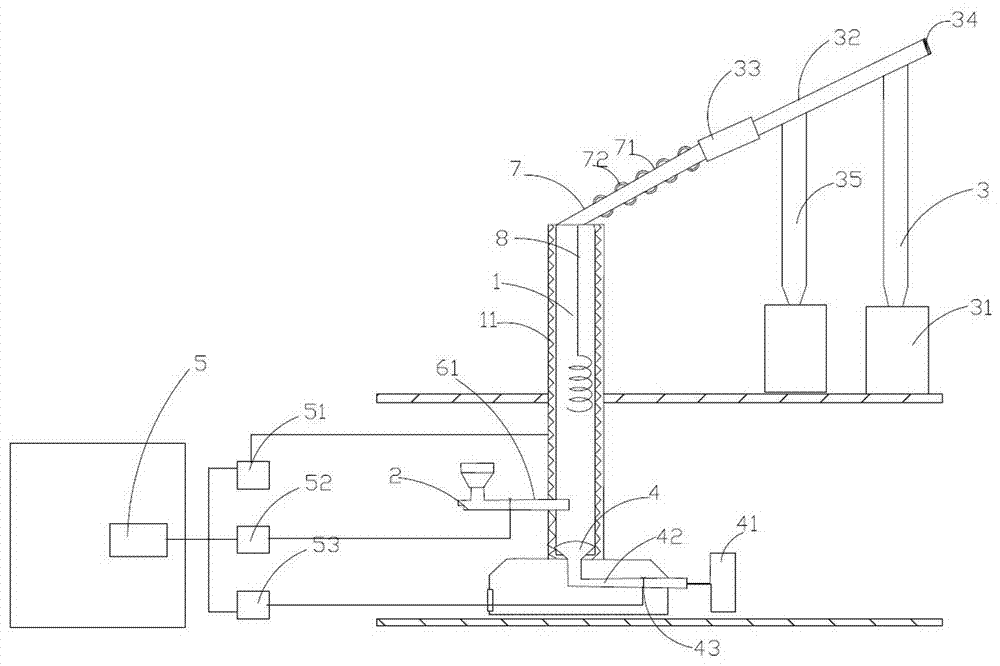

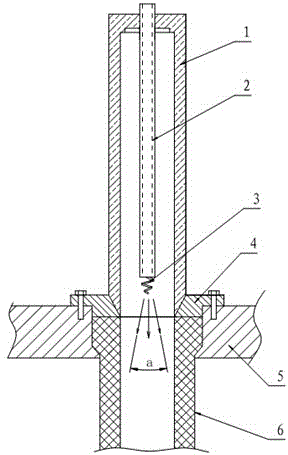

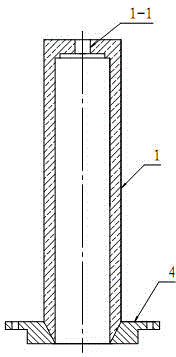

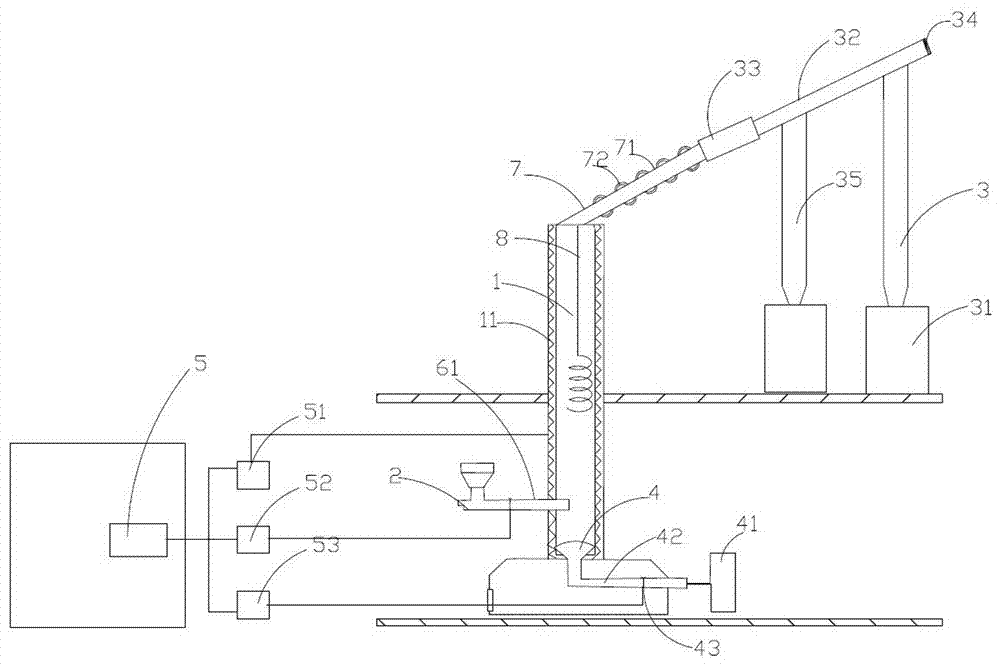

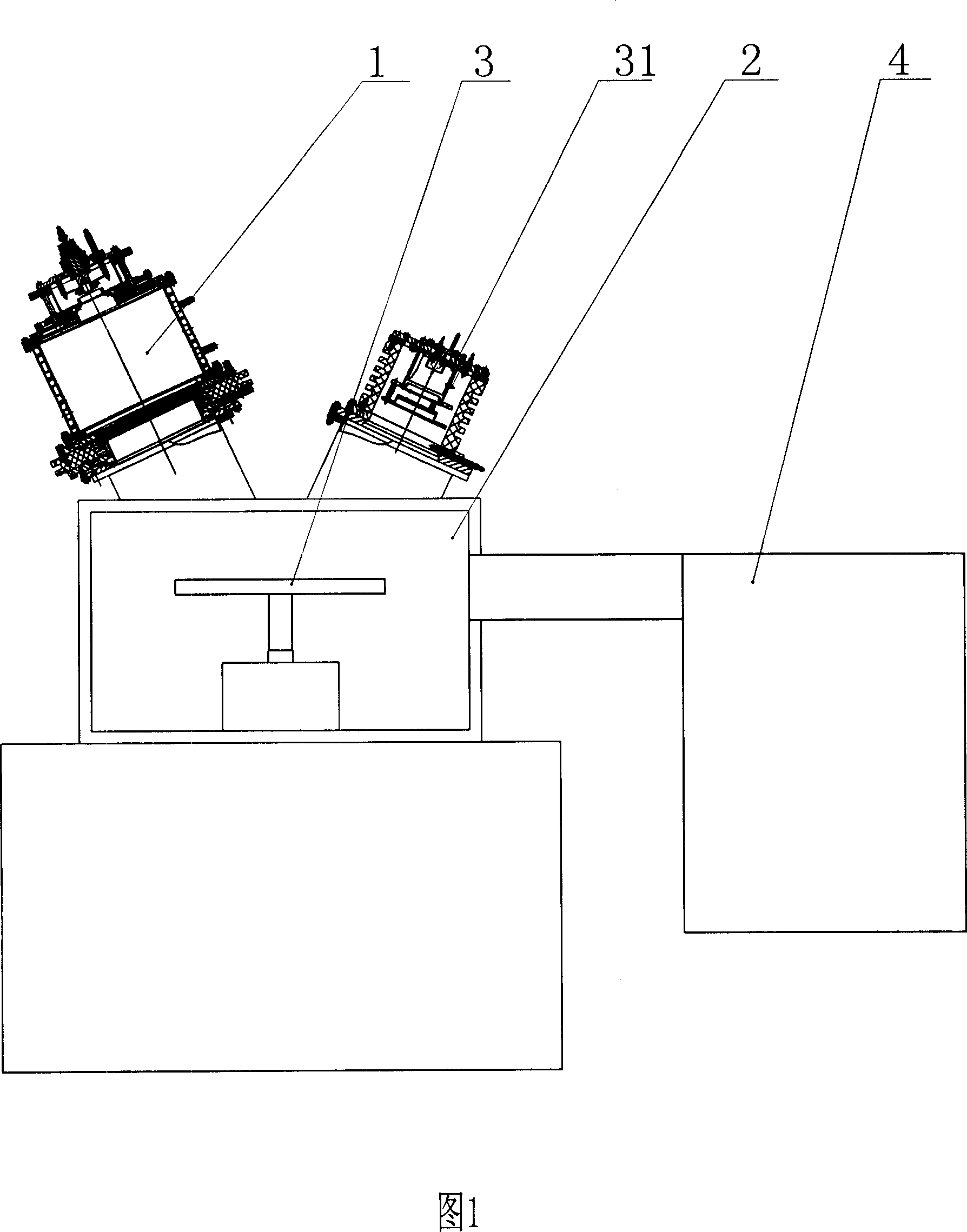

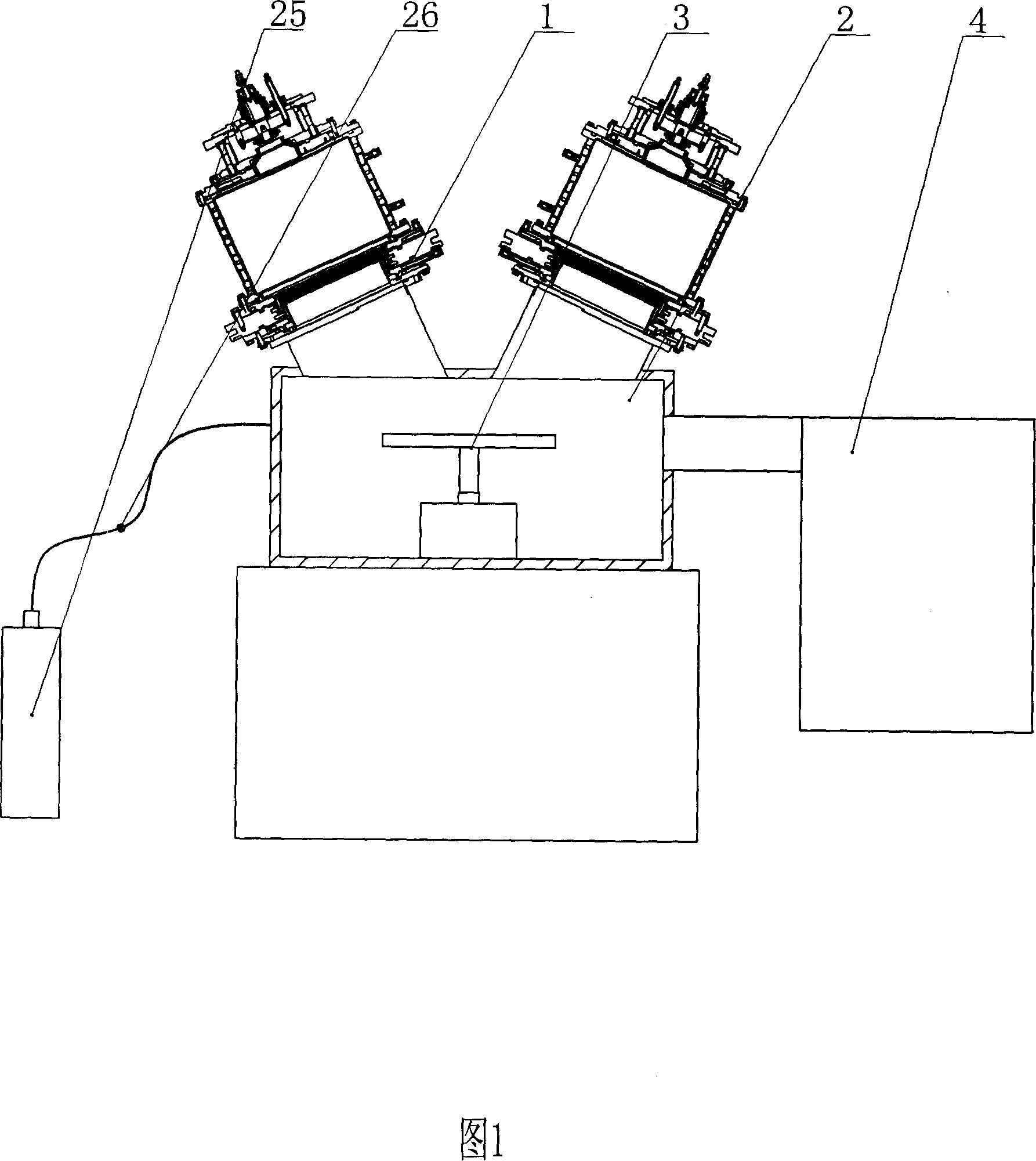

Metal gas mixing ion injector

InactiveCN101017761ALow costSimple structureElectric discharge tubesVacuum evaporation coatingGas supplyVacuum chamber

The disclosed metal gas mixed ion implantor comprises a metal ion source (1), an ion source power, a gas ion source (31), a gas supplying system, a gas ion source power, a vacuum chamber (2), a workpiece target platform (3), a vacuumizing system (4), a cooling system, and a control screen. This invention spreads application range of ion implantation technology greatly.

Owner:珠海市恩博金属表面强化有限公司

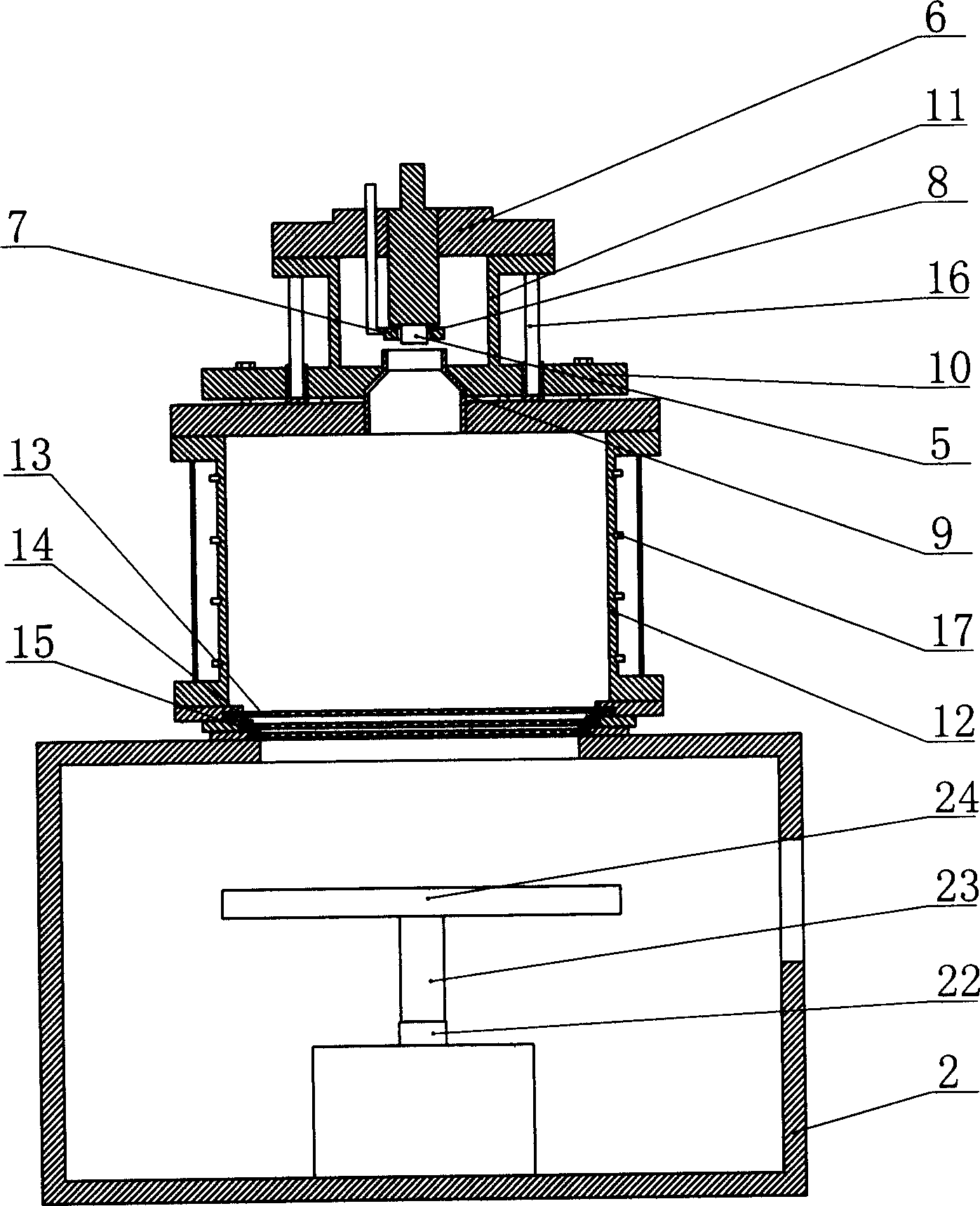

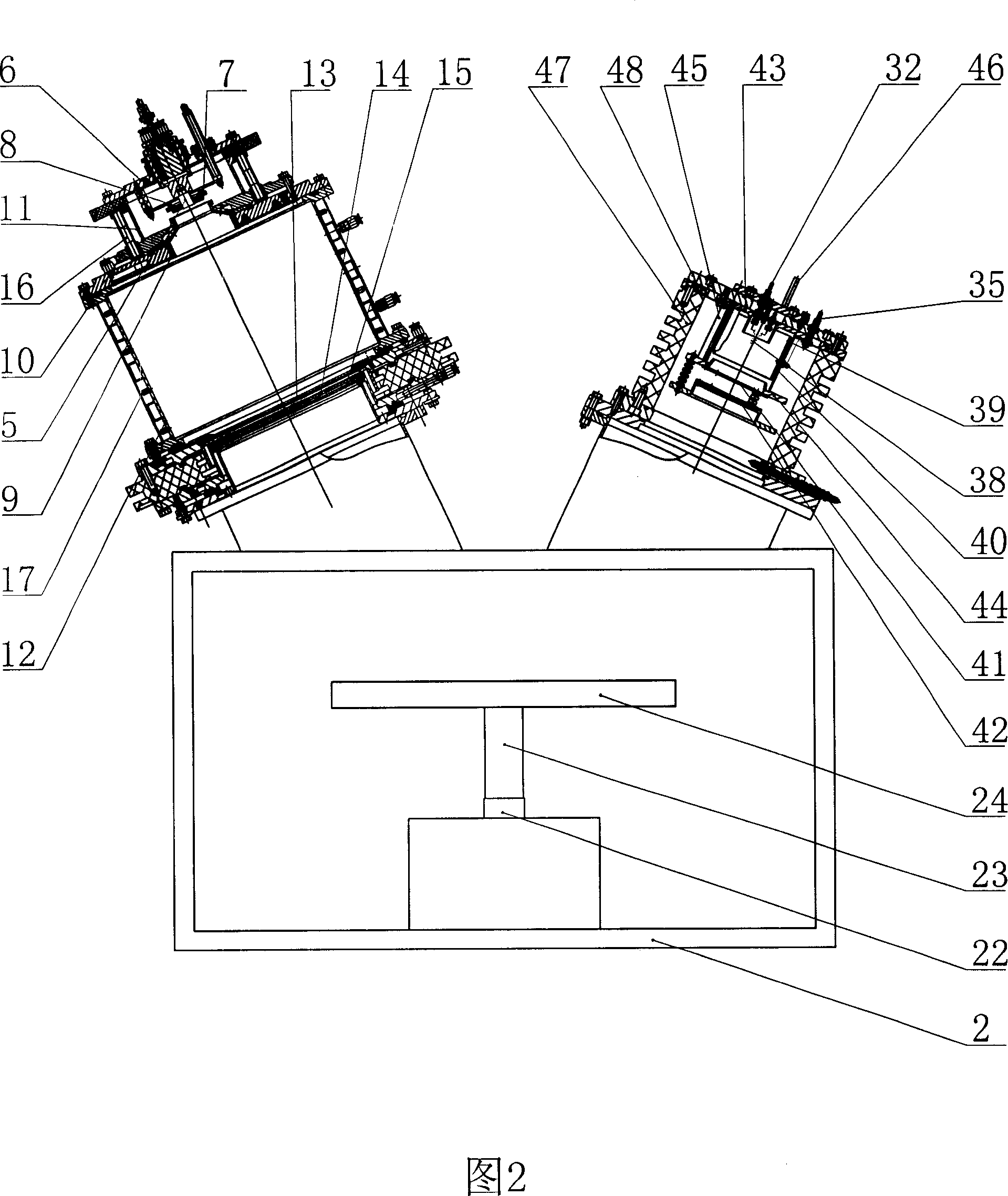

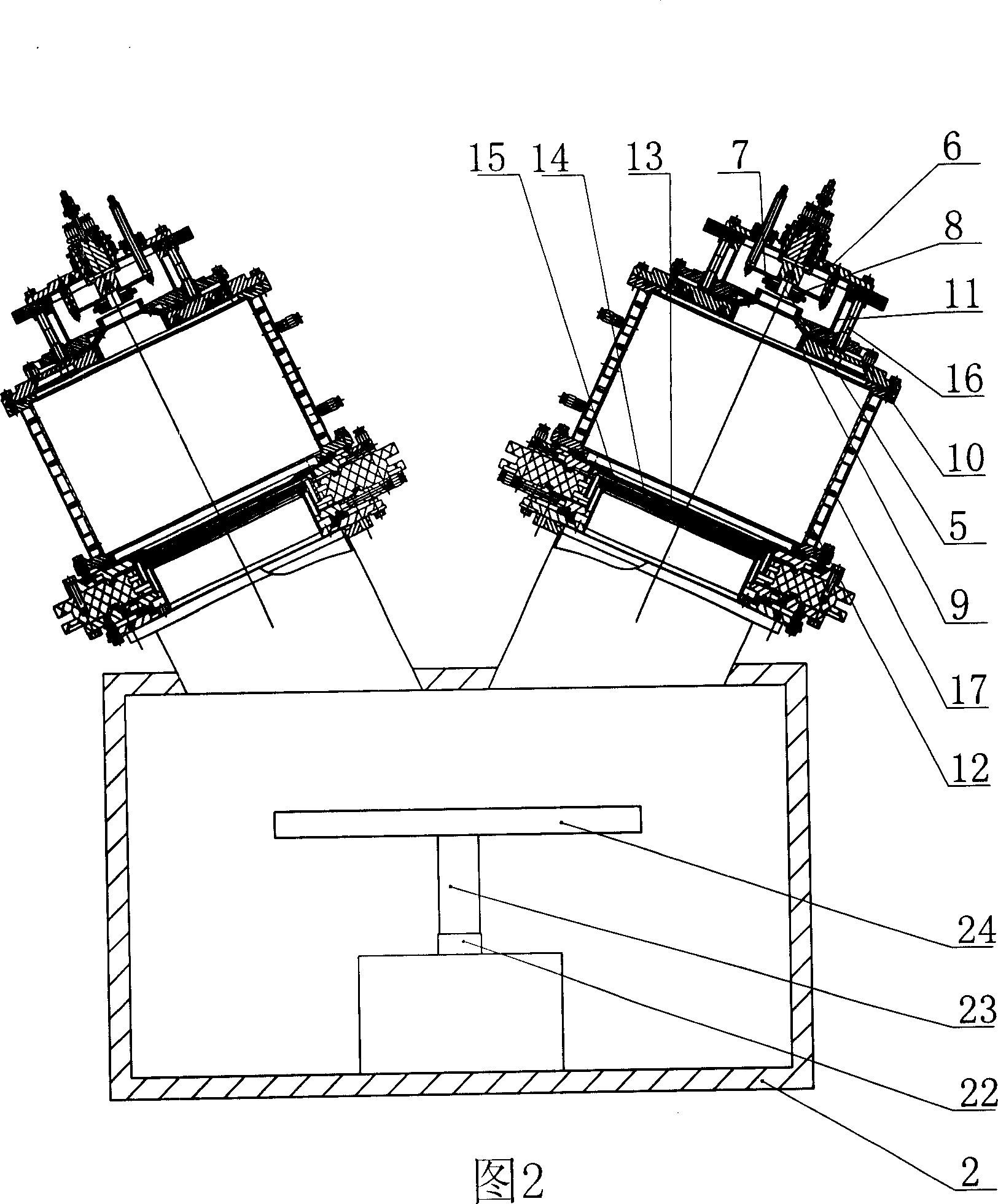

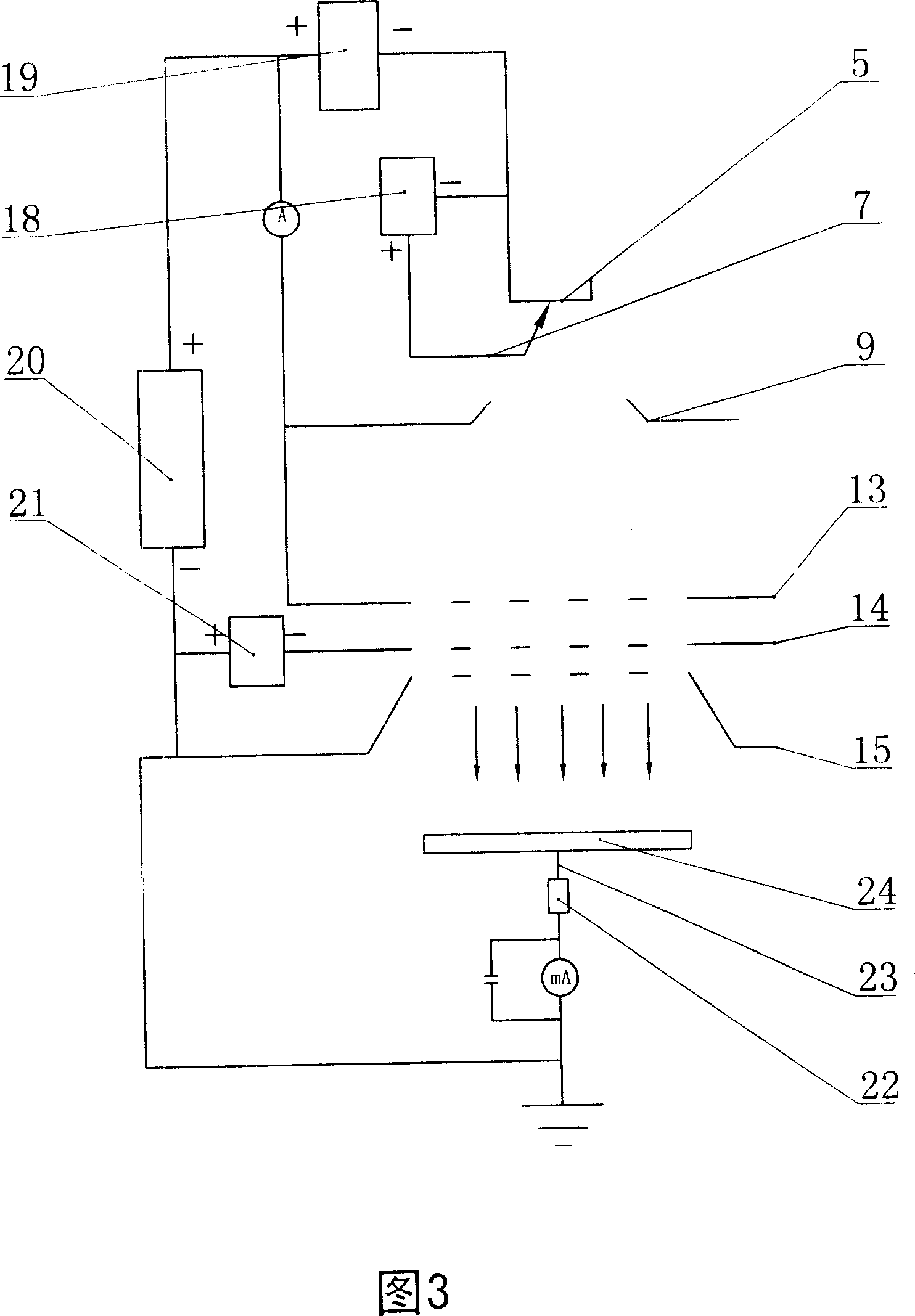

Multi-source metal ion implantation machine

InactiveCN101016621ASimple structureUniform ion implantationVacuum evaporation coatingSputtering coatingInjectorPumping vacuum

The invention discloses a multi-source metallic ion injector, which comprises the following parts: two or more angularly metal ion source (1), ion source electric power system, vacuum chamber (2), work-piece target bench (3), pumped vacuum system (4), cooling system and control panel, wherein the metal ion source (1) includes negative pole (5), negative pole support (6), trigger electrode (7), insulating negative pole sleeve (8), anode (9), anode support (10), arc chamber (11), plasma body chamber (12), first grid (13), second grid (14) and third grid (15).

Owner:珠海市恩博金属表面强化有限公司

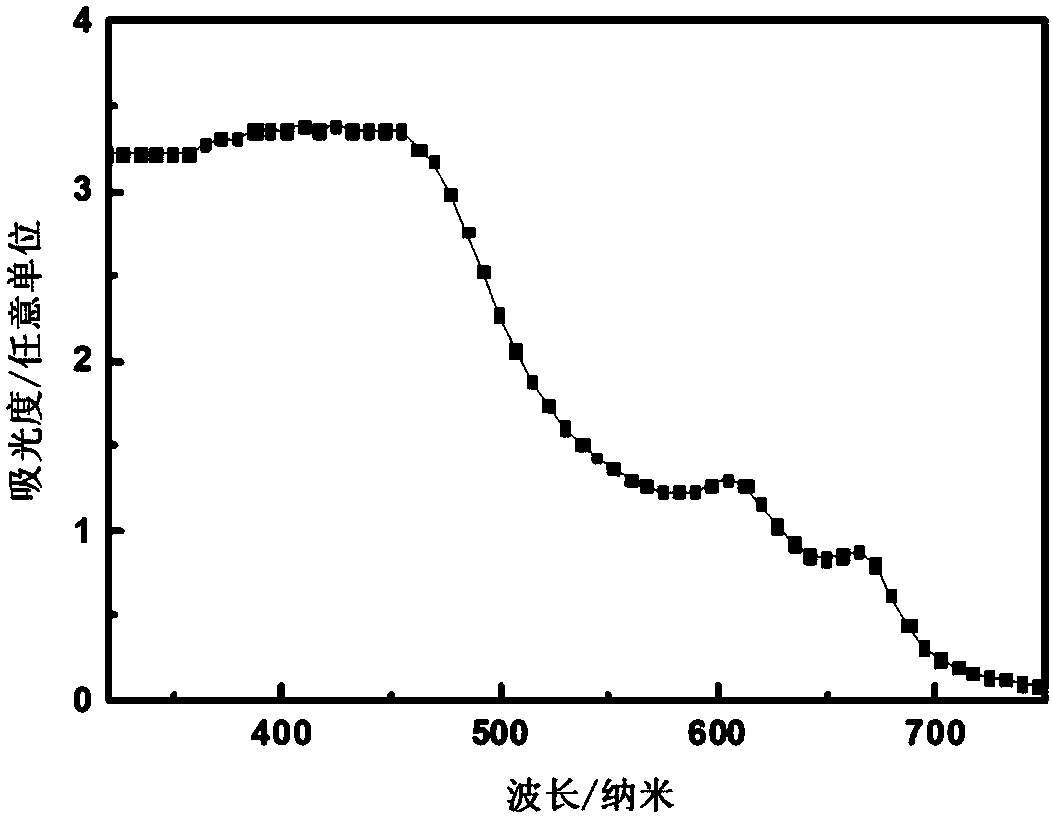

Preparation of high concentration SnS2 nanosheet with liquid phase stripping method

ActiveCN110028098AInhibition of agglomerationImprove physical and chemical activityTin compoundsNanotechnologyDispersityHigh concentration

The invention discloses preparation of a high concentration SnS2 nanosheet with a liquid phase stripping method and belongs to the technical field of biological nanomaterials. The preparation comprises the following steps: S1, adding a certain amount of tin disulfide polycrystalline powder or tin disulfide monocrystal blocks into a closed blue cover ultrasonic bottle, and then adding a certain amount of a polar solvent into the blue cover ultrasonic bottle to form a solution system; S2, carrying out inert gas bubbling treatment to the solution system in the blue cover ultrasonic bottle; S3, putting the blue cover ultrasonic bottle in an ultrasonic cleaner to be ultrasonically treated, and adding ice blocks into the ultrasonic cleaner during ultrasonic treatment to lead to a low temperatureenvironment to play a role of ice bath cooling so as to obtain a saffron yellow SnS2 nanosheet dispersion liquid; and S4, separating the saffron yellow SnS2 nanosheet dispersion liquid. The high concentration SnS2 nanosheet is prepared by employing an ultrasonic stripping method by means of dispersity of the solvent and a solute, and the nanosheet dispersion liquid which is high in stripping rateand high in stability and keeps the semiconductor property of the ice blocks is obtained.

Owner:南京倍格电子科技有限公司

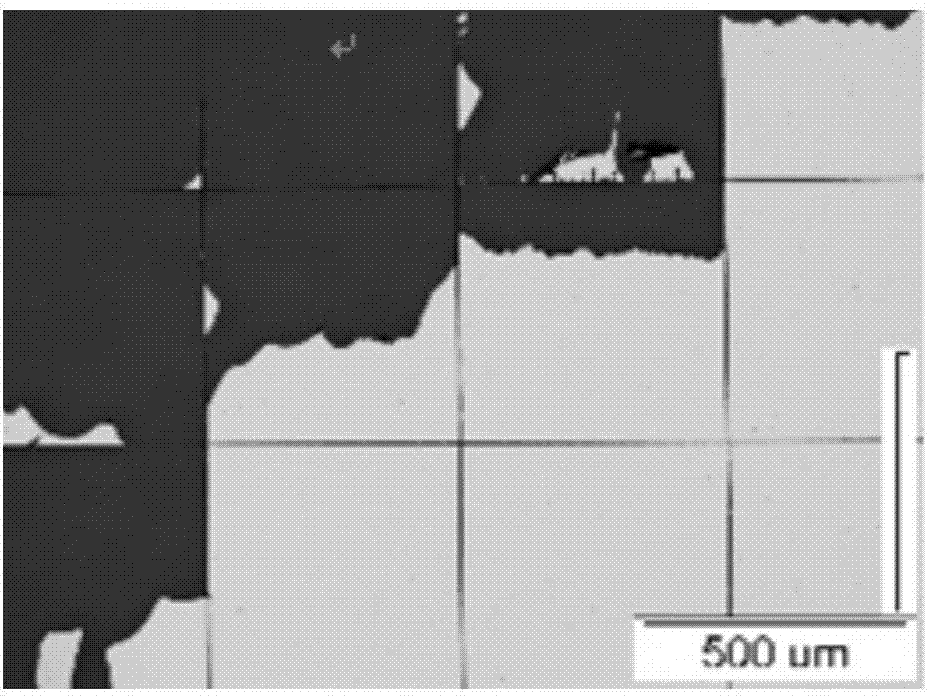

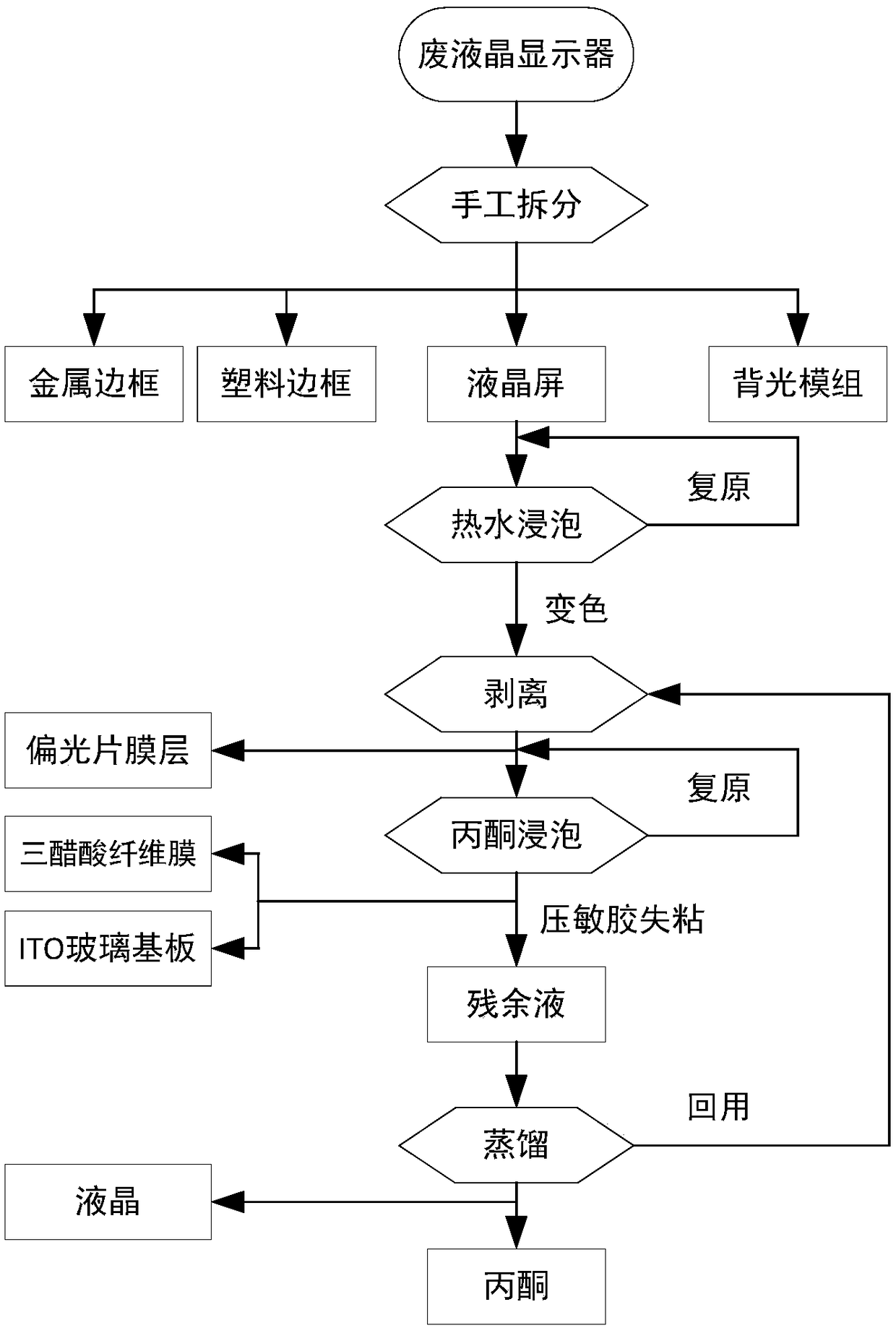

Method for rapidly stripping waste liquid crystal display polarizer

ActiveCN108526196AReduce dosageReduced pressure sensitive adhesiveSolid waste disposalTransportation and packagingFiberEngineering

The invention belongs to the technical field of waste liquid crystal display resource recovery, and particularly relates to a method for rapidly stripping a waste liquid crystal display polarizer. Themethod includes the steps: firstly, soaking a glass panel in a liquid crystal display screen in hot water, taking out the glass panel and then primarily stripping the glass panel to obtain a glass panel only adhered with a triacetate fiber film; secondly, soaking the glass panel in acetone to sharply reduce pressure-sensitive adhesiveness, and accordingly stripping the remaining triacetate fiberfilm. All parts of complete waste liquid crystal displays or waste liquid crystal displays with different breakage degrees can be completely separated, treatment time is as short as 1 hour, acetone soaking time is shorter than 30 minutes, dosage of the acetone can be reduced, the method is green and environmentally friendly, the film and a glass substrate can be separated by means of mechanical stirring or centrifugation after acetone soaking, and toxic and side effects of the acetone on human bodies are avoided. Stripping of the polarizer and liquid crystal recovery can be realized by one-time acetone soaking, and the stripped polarizer cannot be damaged by high temperature and can serve as a plastic recycled by pyrolysis or hydrolysis and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of high-temperature-resistant filtering material

ActiveCN111804063AImprove high temperature resistanceHigh filtration precisionHuman health protectionDispersed particle filtrationTriethoxysilaneBasalt fiber

The invention discloses a preparation method of a high-temperature-resistant filtering material and belongs to the technical field of filtering and dedusting materials. The method comprises the stepsof 1) mixing, 2) opening, 3) lapping, 4) needling, 5) dipping and 6) film covering. The mixing process comprises: uniformly mixing basalt fibers and polybenzimidazole fibers according to a weight ratio of (3-4): (1-2), and the dipping process comprises: padding the needled felt in the treatment liquid, wherein the pick-up rate is 29-33%, drying at the temperature of 190-220 DEG C, baking at the temperature of 250-320 DEG C, controlling the drying and baking speed to be 4-5m / min, and rolling, wherein the treatment liquid is prepared from the following components in percentage by mass: 15 to 26percent of polytetrafluoroethylene dispersion liquid, 2 to 6 percent of dimethyl diphenyl polysiloxane, 0.7 to 3 percent of 3-aminopropyltriethoxysilane, 0.5 to 1 percent of Tween and the balance of water. The filtering material has good high temperature resistance, can resist the temperature of 280-295 DEG C for a long time, can resist the temperature of 320 DEG C instantaneously, and has the service life of 2 years or longer.

Owner:山东兴国新力环保科技股份有限公司

Nano-tourmaline hybrid emulsion and preparation method thereof

InactiveCN107190502AExtended service lifeSmall average pore sizeCombination devicesGas treatmentEmulsionFilter material

The invention discloses nano-tourmaline hybrid emulsion and a preparation method thereof, belonging to the technical field of hybrid emulsion preparation. The nano-tourmaline hybrid emulsion is prepared from sodium hexametaphosphate, sodium polyacrylate, nano-tourmaline powder, polytetrafluoroethylene (PTFE) emulsion and water. The preparation method of the nano-tourmaline hybrid emulsion comprises the following steps: weighing the sodium hexametaphosphate and the sodium polyacrylate, adding water into the weighed materials, putting into a stirrer, and stirring under the condition of heating; weighing the nano-tourmaline powder, adding water into the weighed nano-tourmaline powder, mechanically stirring, then carrying out ultrasonic dispersion, adding the PTFE emulsion, and mechanically stirring; after the sodium hexametaphosphate and the sodium polyacrylate in the step 1 are completely dissolved, adding the obtained water solution into a mixed solution of the nano-tourmaline powder and the PTFE emulsion in the step 2, mechanically stirring, and then carrying out ultrasonic dispersion so as to obtain the evenly dispersed and stable nano-tourmaline treatment fluid. A dust removal filter material prepared from the nano-tourmaline hybrid emulsion has very high electrets performance, can be used for collecting fine dust, increases dust filtering efficiency and dust removing rate, and reduces equipment resistance.

Owner:南京际华三五二一环保科技有限公司

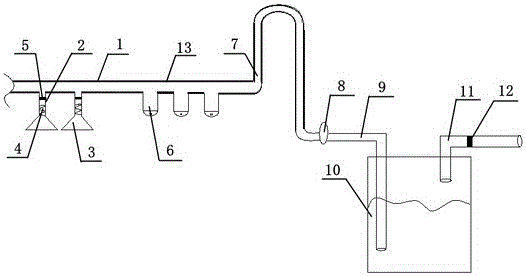

Dust removal and filtering device for chemical workshop

PendingCN106823653AGood high temperature resistanceImprove stripping rateCombination devicesSeparation devicesCorrosion preventionEngineering

The invention discloses a dust removal and filtering device for a chemical workshop. The dust removal and filtering device comprises a dust collection main pipe; a dust collection branch pipe is downward and vertically mounted on the dust collection main pipe; a dust collection cover is mounted at the tail end of the dust collection branch pipe; one group of dust receiver is mounted on the dust collection main pipe at intervals; the dust receivers are located below the dust collection main pipe and are communicated with the dust collection main pipe; the rear side of the dust collection main pipe is connected with a reversed U-shaped air inducing pipe; a draught fan is mounted on the reversed U-shaped air inducing pipe; the other end of the draught fan is connected to the lower side of a water level of a water tank through an exhausting pipeline I; a reversed L-shaped exhausting pipeline II is mounted on the top of the water tank; and high-temperature-resisting and corrosion-prevention layers are arranged on pipeline inner walls of the dust collection main pipe, the dust collection branch pipe and the reversed U-shaped air inducing pipe. The dust removal and filtering device for the chemical workshop is long in service life, high in chemical dust recycling and utilization efficiency, good in filtering effect, small in environmental pollution and high in economic benefits.

Owner:CHENGDU GERUISI CULTURAL COMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com