Automatic fail preventing device for ceramic filter

A technology of ceramic filters and ceramic filter tubes, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. Sex and continuity, easy operation and installation, and the effect of improving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

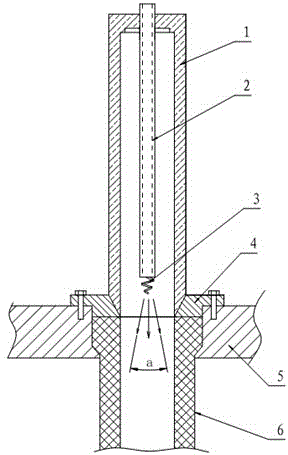

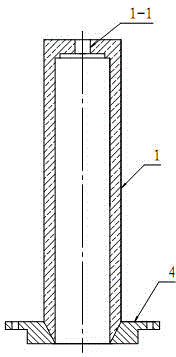

[0029] see figure 1 , figure 2The device of the present invention is provided with a porous metal protective tube 1 made of porous metal, and the porous metal protective tube is fixed on the upper part of the filter main plate 5, and its position corresponds to the ceramic filter tube 6 up and down. The upper end of the porous metal protection tube is provided with an inlet hole 1-1 for installing the injection tube 2, and the inlet hole of the injection tube is matched with the injection tube. Welding, screw holes are provided on the fixing seat, the fixing seat is positioned on the filter main plate by the positioning screw, and the lower end surface of the fixing seat is flush with the upper end surface of the filter element.

[0030] see figure 1 , image 3 , the lower part of the spray pipe 2 is located in the porous metal protection tube, and the top of the spray pipe protrudes from the porous metal protection tube. The lower end of the blowing pipe is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com