High-concentration high-stability transitional metal chalcogen compound printing ink for ink jet printing and preparation method of printing ink

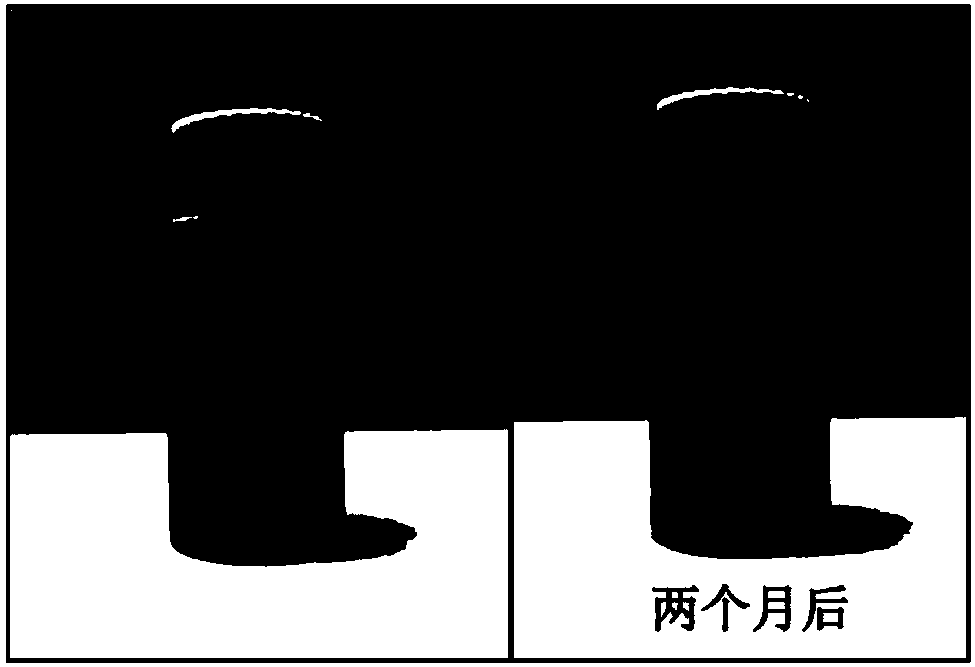

A chalcogen compound and transition metal technology, which is applied in the field of high-concentration and high-stable transition metal chalcogen compound ink and its preparation, can solve the problems of low ink concentration, poor stability, inconvenient use and storage, etc., so as to increase the concentration and inhibit agglomeration , easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

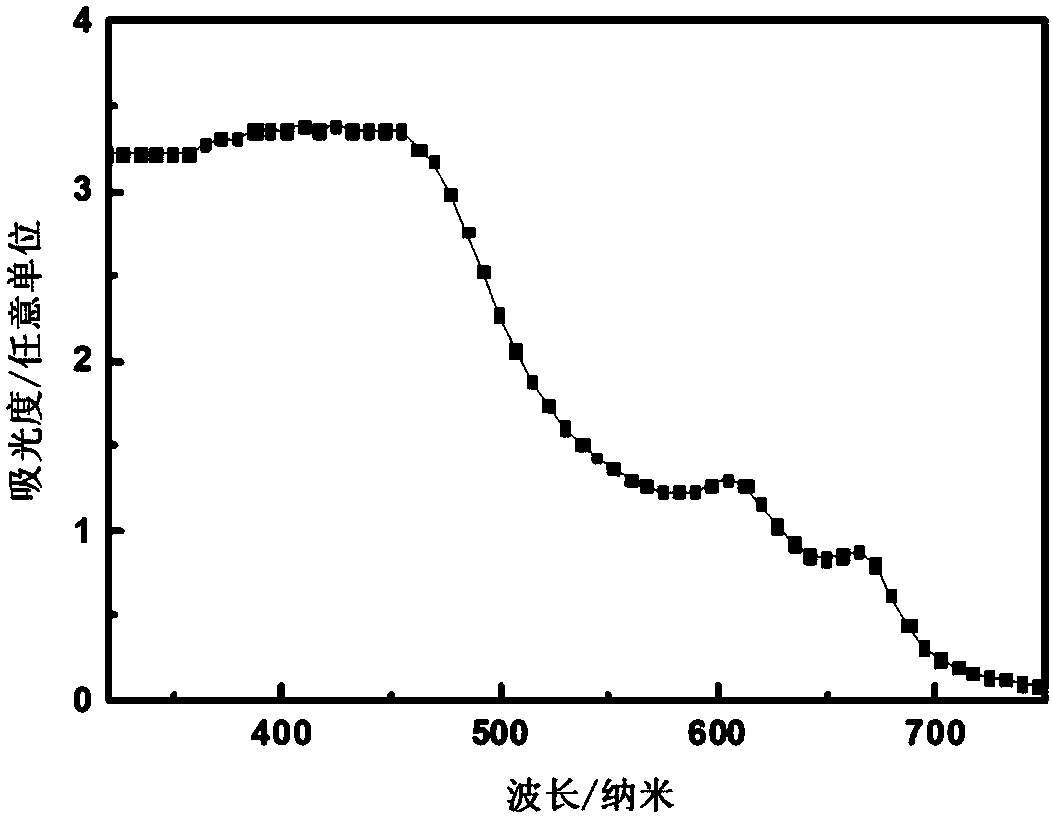

[0034] A method for preparing a high-concentration and high-stable transition metal chalcogenide ink for inkjet printing, comprising the steps of:

[0035] [1] Two stripping solvents were selected and mixed according to a certain ratio to prepare a binary good solvent system, and the specific ratio was calculated according to the Hansen solubility parameter theory.

[0036] [2] In the binary good solvent system that step [1] obtains, add water-soluble polymer compound, obtain mixed solvent; 30%.

[0037] [3] Disperse the transition metal chalcogen compound powder in the mixed solvent obtained in step [2], and then peel off the transition metal chalcogen compound nanosheets from the transition metal chalcogen compound powder by ultrasonic stripping; transition The initial concentration of the metal chalcogen compound powder is 5-40mg / mL.

[0038] [4] Centrifuge the dispersion obtained after the treatment in step [3], and take the supernatant as the transition metal chalcogen ...

Embodiment

[0049] Mix 18mL of ethanol and 22mL of deionized water in a beaker, add 80mg of polyvinylpyrrolidone, then weigh 400mg of molybdenum disulfide powder raw material and disperse it in the mixed solution to prepare molybdenum disulfide suspension with an initial concentration of 10mg / mL liquid. Place the probe head of the probe ultrasonic instrument at 2-3cm below the liquid surface of the molybdenum disulfide suspension, adjust the power of the probe ultrasonic instrument to 300W, and perform cavitation stripping on the molybdenum disulfide suspension, and the stripping time is 30min ; During the stripping process, the temperature of the dispersion is kept at 30° C. by circulating water cooling. After the probe ultrasound is finished, the molybdenum disulfide suspension is transferred to the ultrasonic pool to continue stripping. The power of the ultrasonic pool is 350W, and the stripping time is 18h; similarly, during the stripping process, the temperature of the dispersion is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com