Patents

Literature

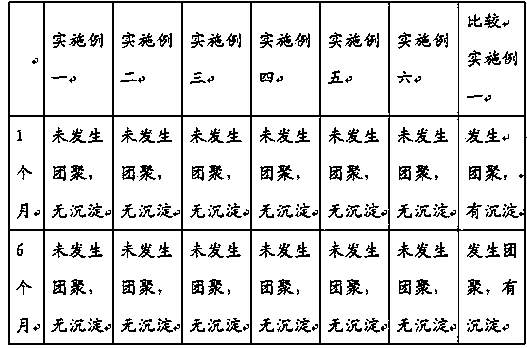

175results about How to "Reunion won't happen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

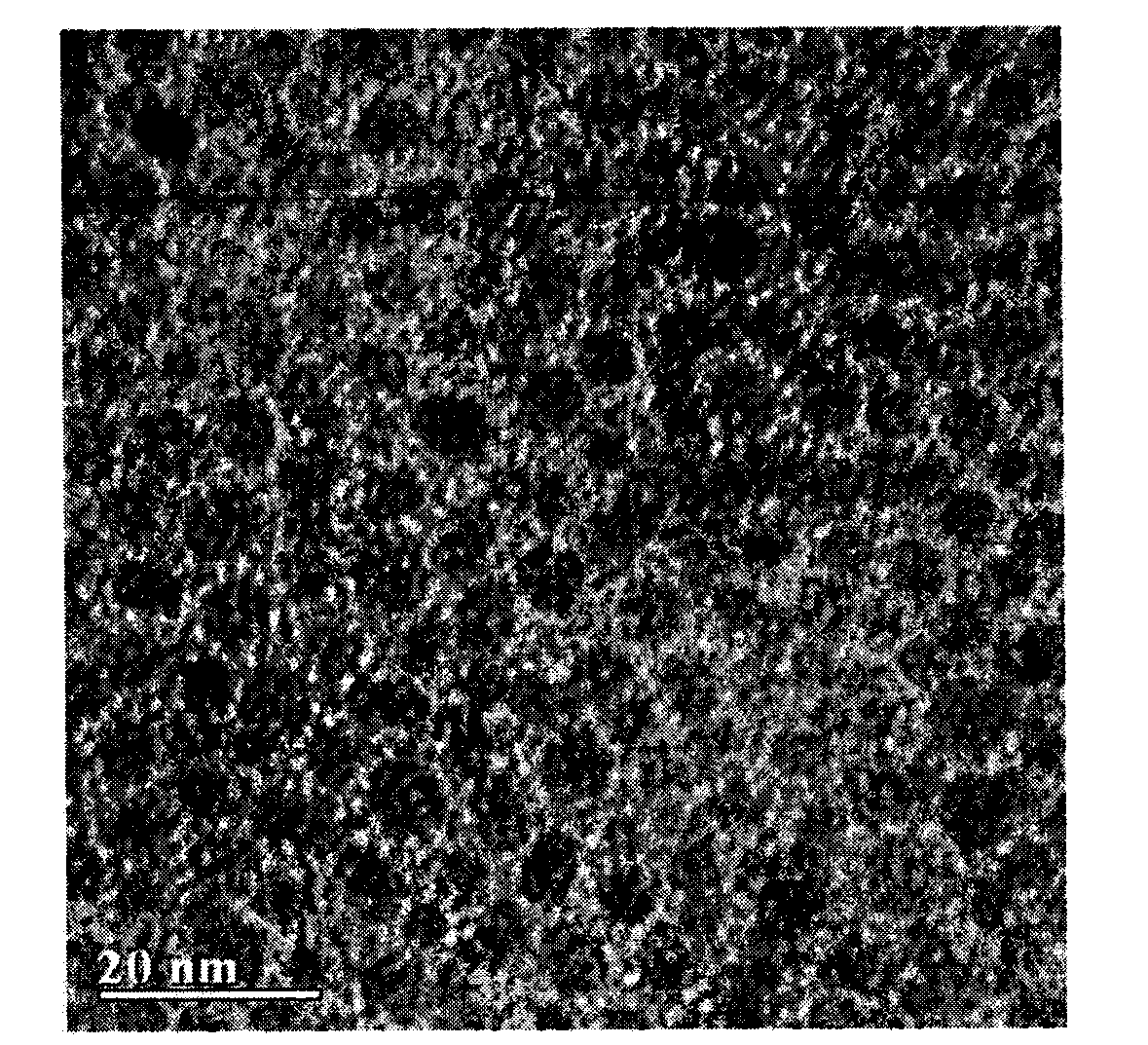

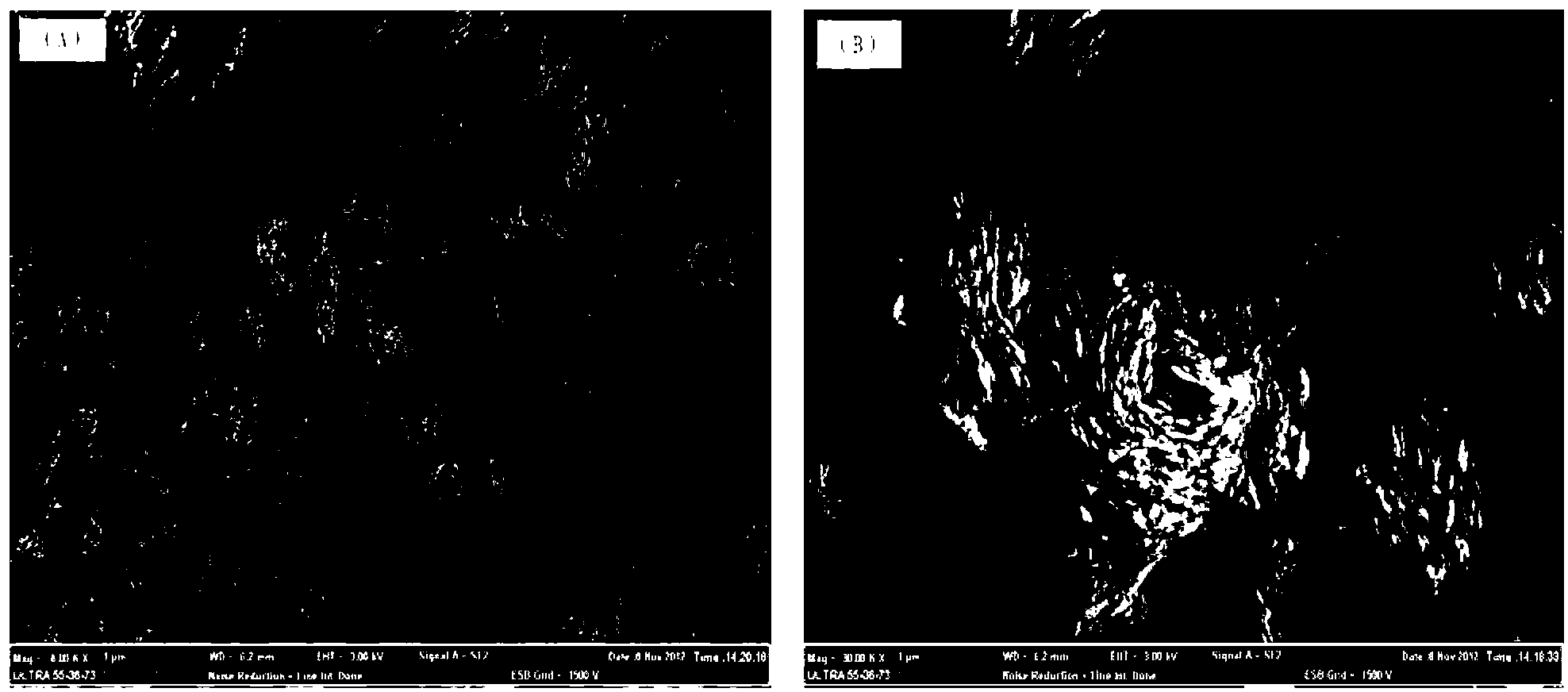

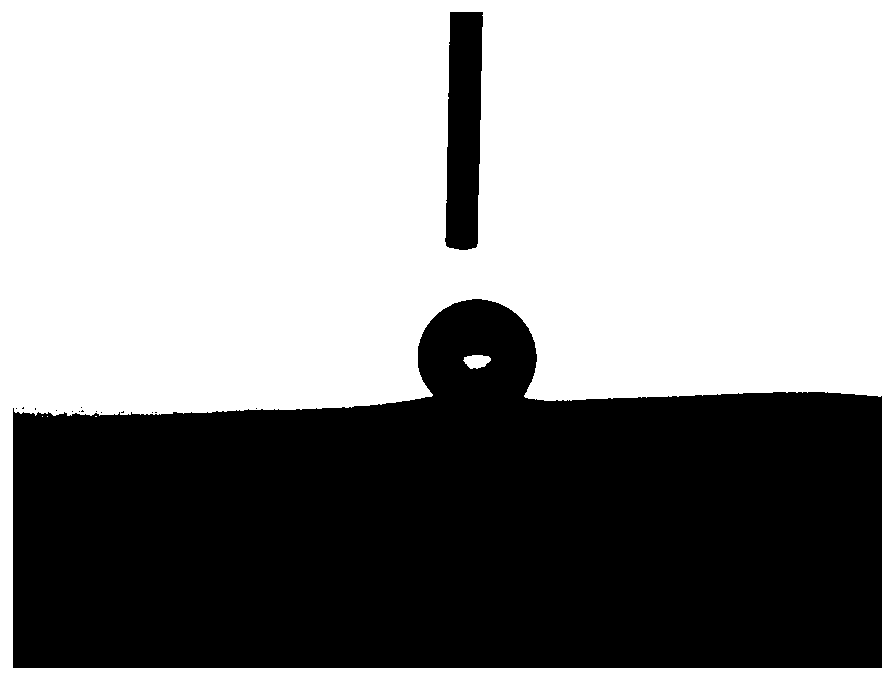

Method for preparing hybrid film through graphene/nano crystalline cellulose dispersion liquid

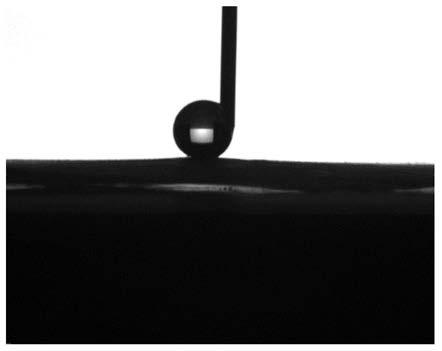

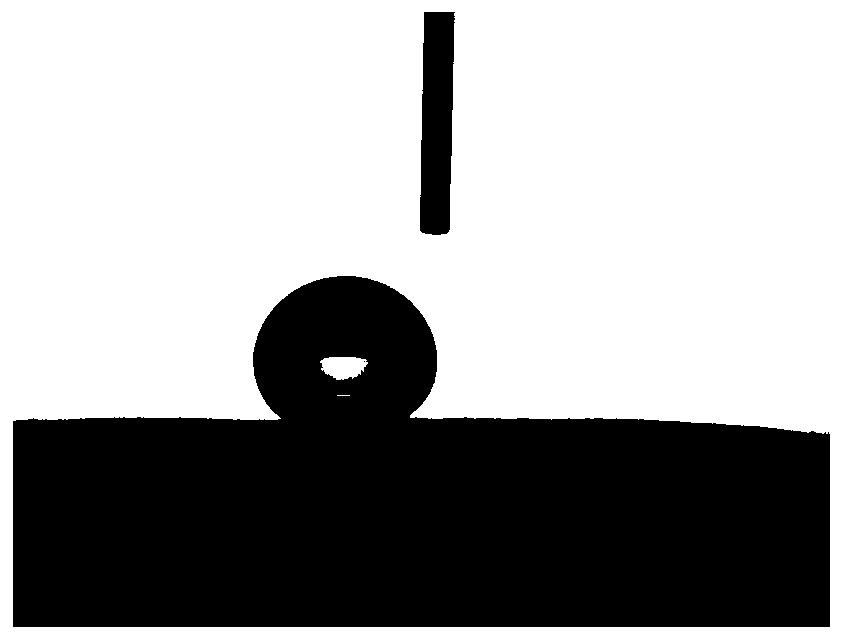

The invention relates to a method for preparing hybrid film through graphene / nano crystalline cellulose dispersion liquid. The preparation method comprises the following steps: respectively dispersing oxidized graphene obtained by oxidation treatment and nano crystalline cellulose in a dispersing agent, and then, gradually dripping nano crystalline cellulose dispersion liquid into oxidized graphene dispersion liquid to obtain graphene / nano crystalline cellulose dispersion liquid, adding a reducing agent under ultrasonic or mechanical stirring condition to reduce the oxidized graphene, inserting the crystalline cellulose between graphene pieces to prevent aggregation between the graphene layers and to form uniformly dispersed and stable graphene / nano crystalline cellulose dispersion liquid, and then, preparing a graphene / nano crystalline cellulose hybrid film through such methods as spin coating, spray coating, film casting, and the like. The prepared hybrid film has high uniformity, and the higher the content of the graphene in the hybrid film, the stronger the thermal stability and conductivity of the hybrid film are; the higher the content of nano crystalline cellulose in the hybrid film is, the smaller the contact angle of the hybrid film is, and the stronger the hydrophilicity is.

Owner:WUHAN TEXTILE UNIV

Honeycombed porous ceramic having high thermal conductivity and ultralow expansion coefficient

ActiveCN103145439AGood coating effectImprove mechanical propertiesCeramicwareCeramic moldingCrystal orientation

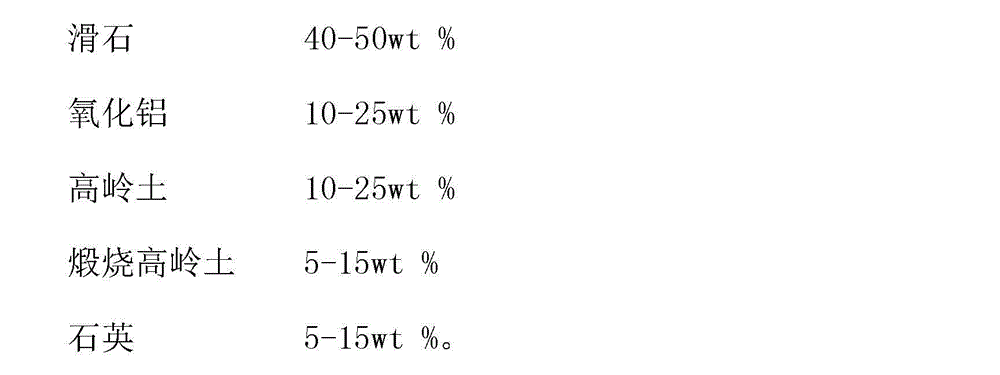

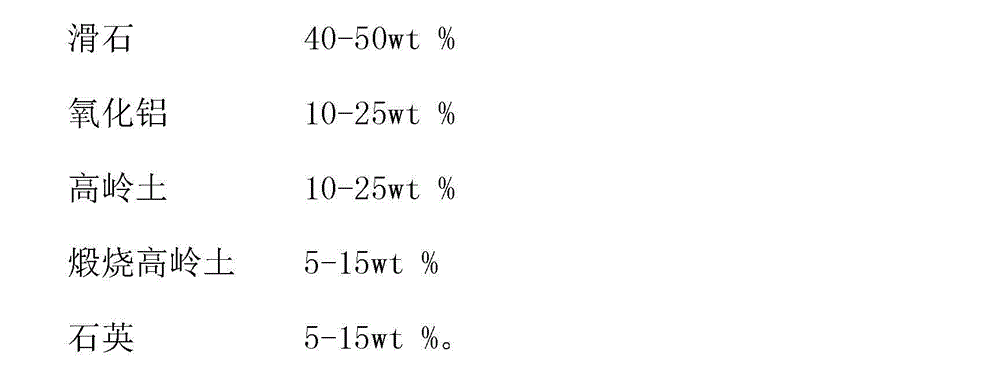

A honeycombed porous ceramic having a high thermal conductivity and an ultralow expansion coefficient relates to the technical field of the silicate industry. The ceramic having a low even negative thermal expansion coefficient and a high thermal conductivity is obtained through treating a rare earth mixture, potassium phosphotungstate, zirconium oxide and amorphous quartz particles as a sintering aid, and expansion coefficient and thermal conductivity adjustment agents, and the ceramic has a high-orientation sheet iolite structure and has a good catalyst coating performance and good mechanical strengths; and ethylene oxide having different molecular weights are adopted as a ceramic molding binder, rapeseed oil or peanut oil is treated as a primary molding lubrication agent, a paste goes through a high-pressure extruder orientation extruding channel, a crystal orientation carding die and a honeycombed porous die to obtain a green body having high-orientation arranged crystals, and a special sintering curve is adopted to obtain the ceramic. The above whole ceramic preparation process flow and the above formula are economic, stable and environmentally-friendly.

Owner:安徽中鼎美达环保科技有限公司

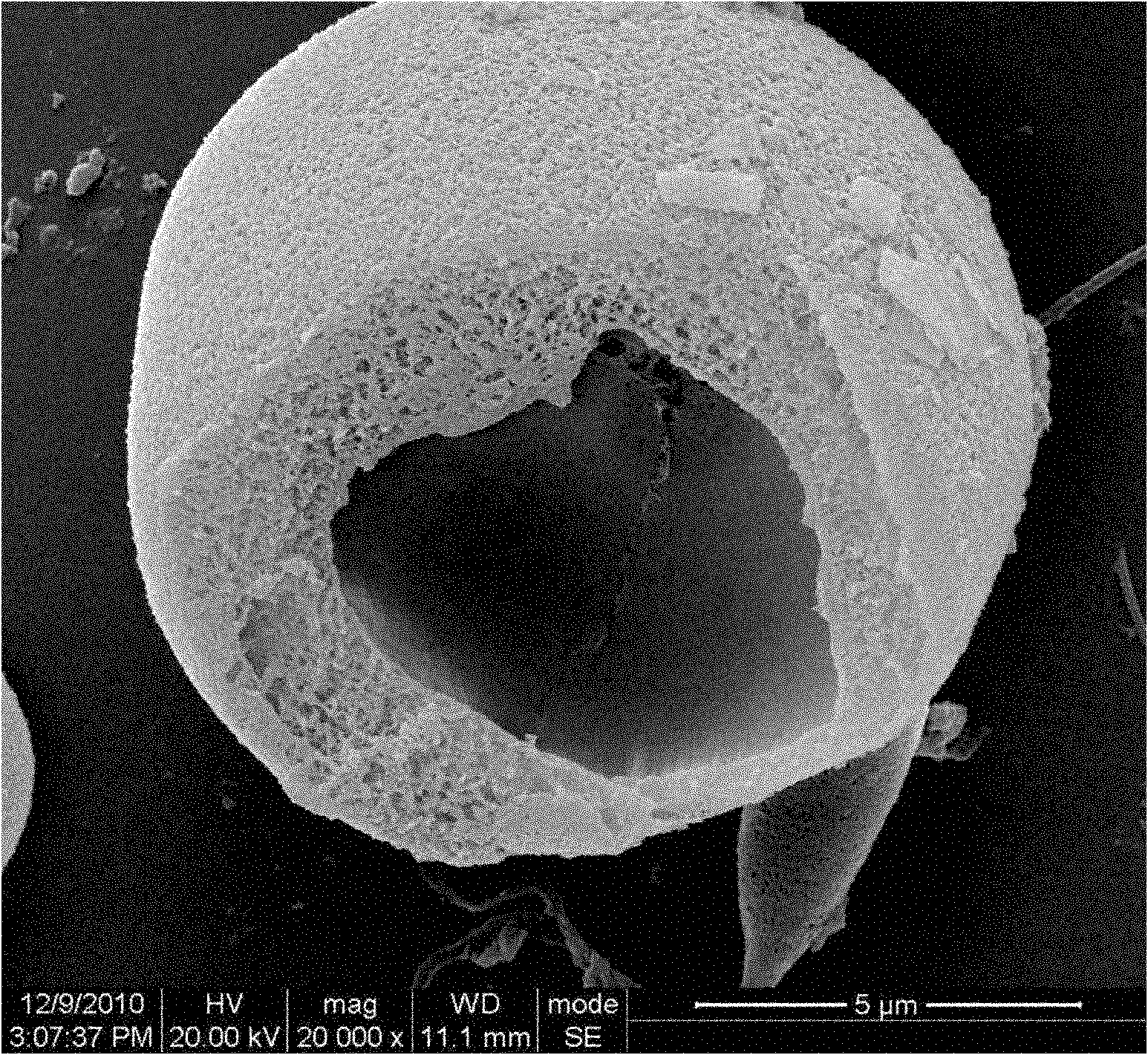

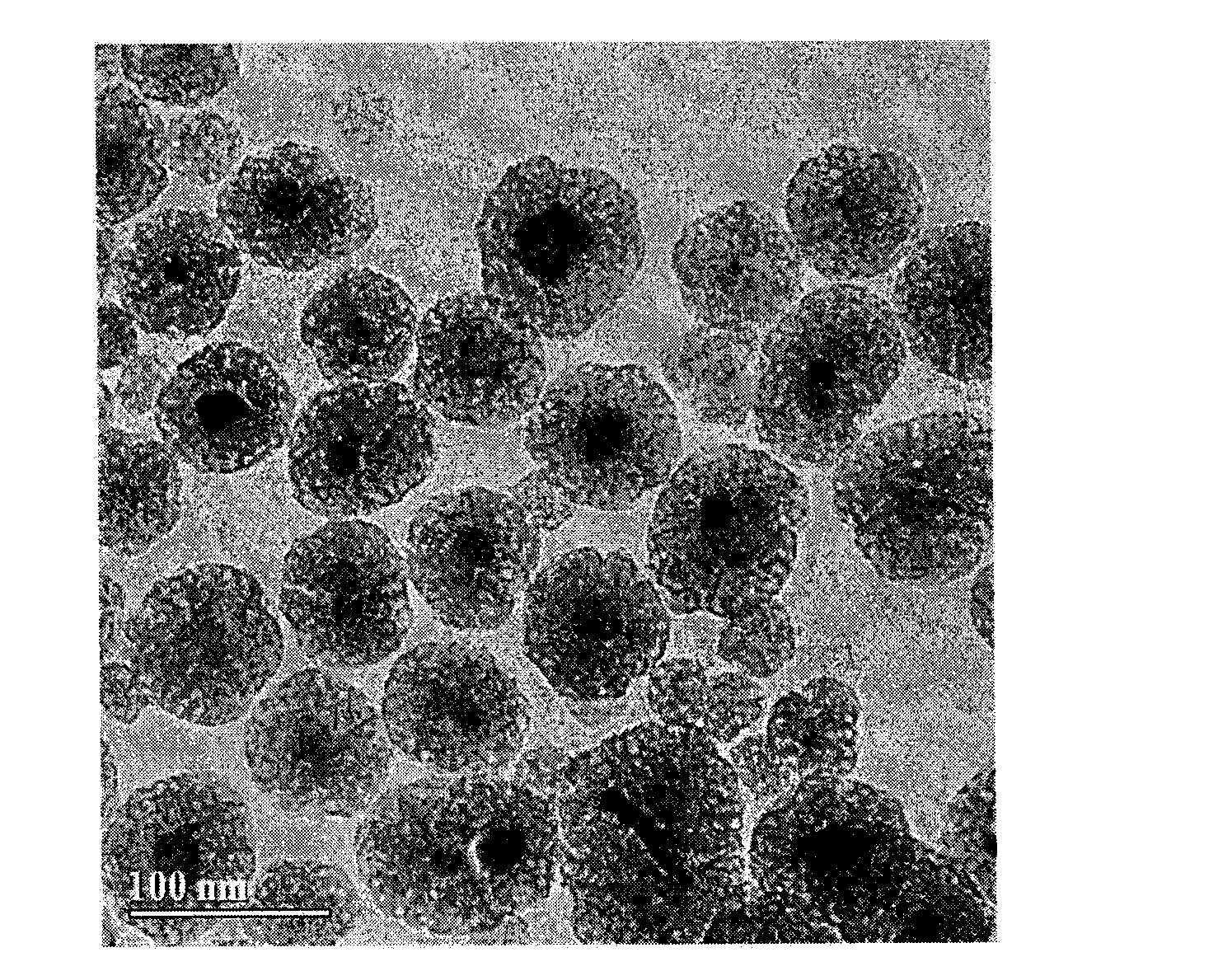

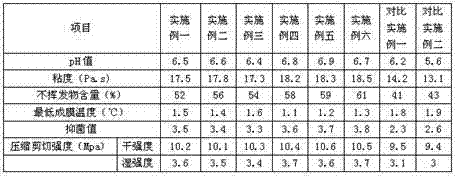

Polymer hollow nano microspheres and preparation method thereof

InactiveCN102127298ASimple equipmentEasy to operateCosmetic preparationsCatalyst carriersSolventThermometer

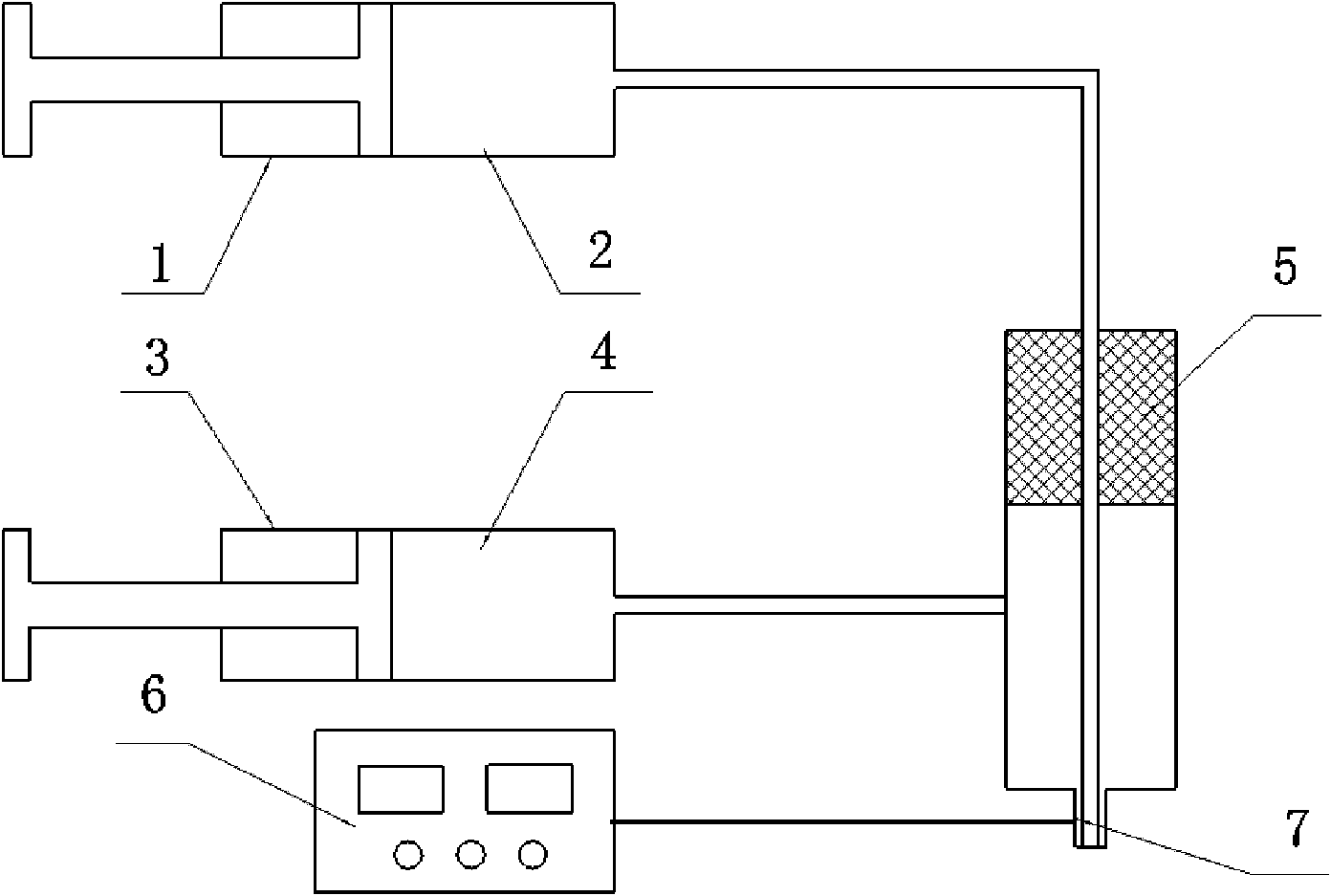

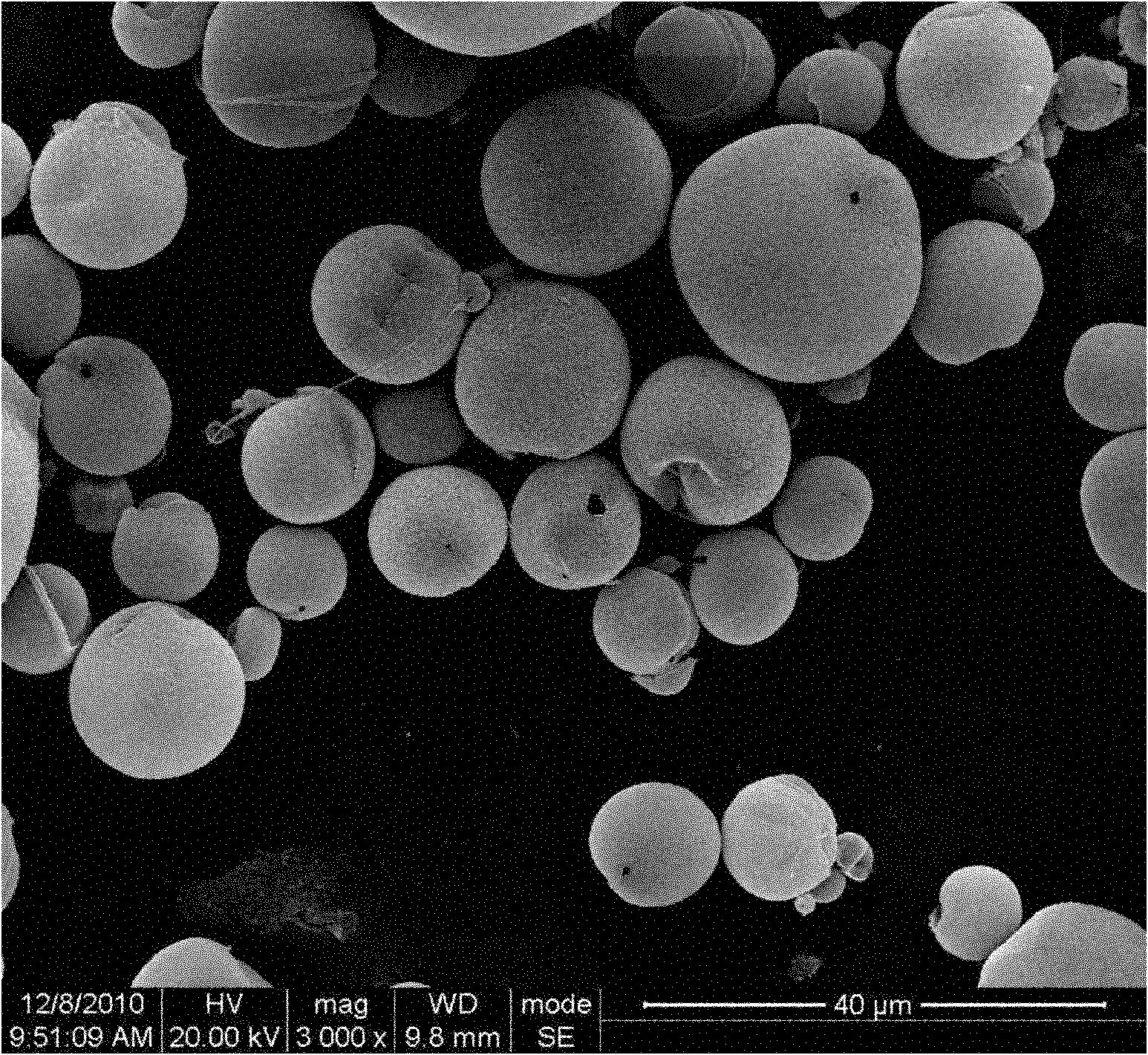

The invention discloses polymer hollow nano microspheres and a preparation method thereof. The preparation method is characterized by comprising the following steps: adding 10-200 parts by weight of polymer A, 0-200 parts by weight of additive and 100-1000 parts by weight of solvent A into a dissolving kettle provided with a stirrer and a thermometer, dissolving by stirring at 30-100 DEG C, debubbling, and aging to obtain a polymer shell solution; adding 0-400 parts by weight of polymer B and 100-1000 parts by weight of solvent B into a dissolving kettle provided with a stirrer and a thermometer, dissolving by stirring at 30-100 DEG C, debubbling and aging to obtain a core solution; putting the polymer shell solution and the core solution in a high-voltage electrostatic field, and carrying out electrostatic spraying by a coaxial electrostatic sprayer to obtain polymer microspheres, wherein the inner diameter of the needle head of the core is 0.4-0.6mm, the solution flow rate is 1-5ml / h, the inner diameter of the needle head of the shell is 0.9-1.2mm, the solution flow rate is 5-10ml / h, the spraying voltage is adjusted to 5-25kV, the spraying distance is 1-10cm, and the temperature of the receiving bath is 10-50 DEG C; and removing core substances of the microspheres to obtain the polymer hollow nano microspheres.

Owner:SICHUAN UNIV

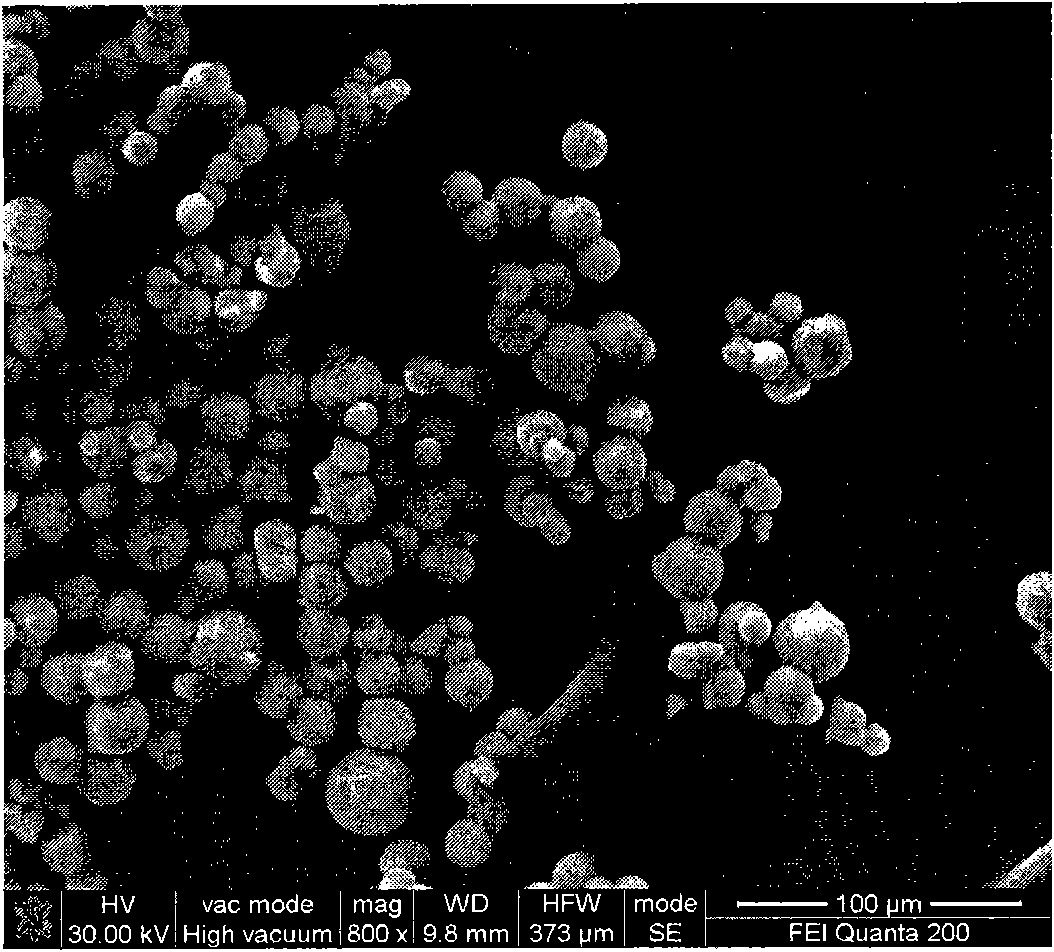

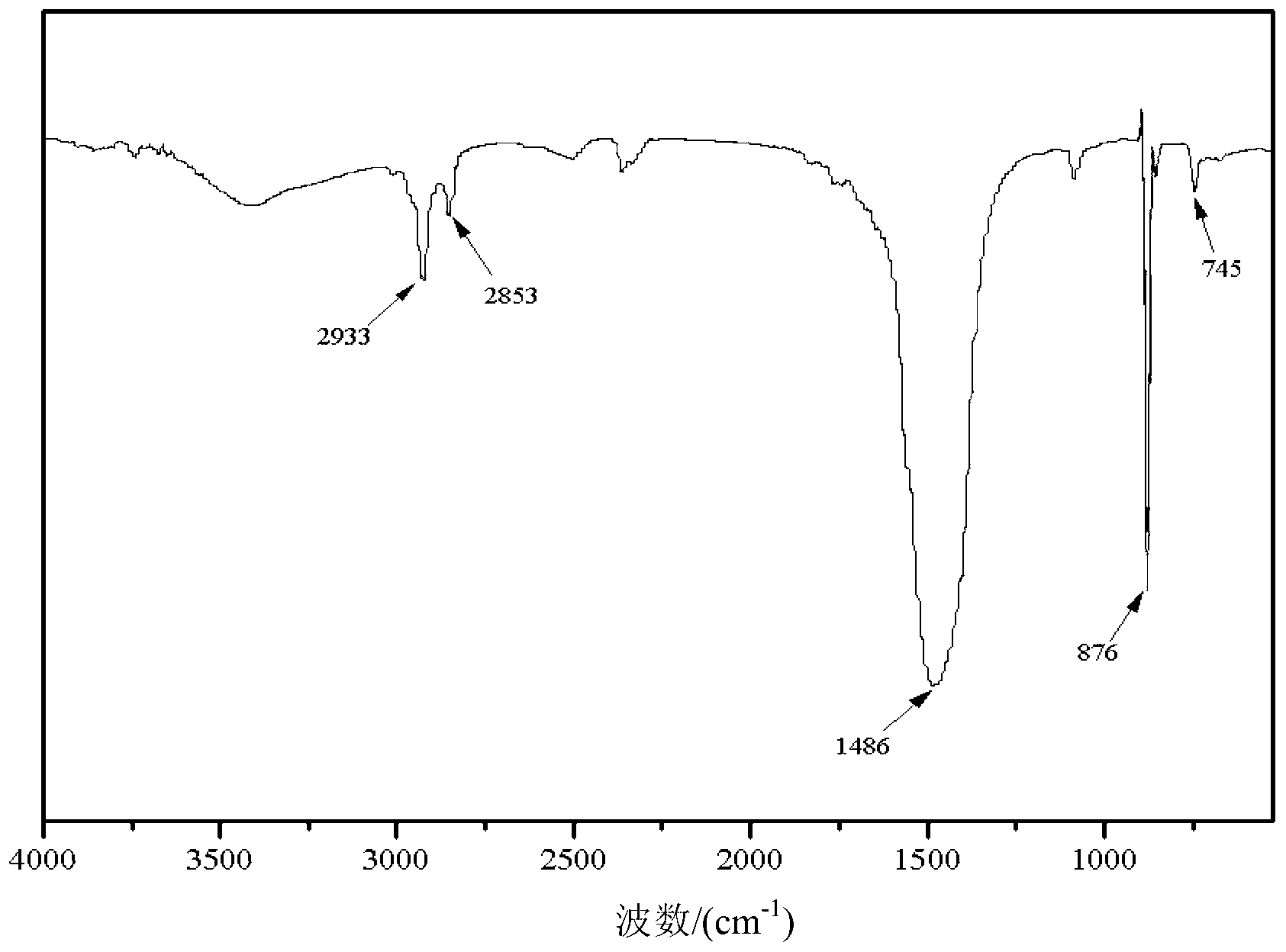

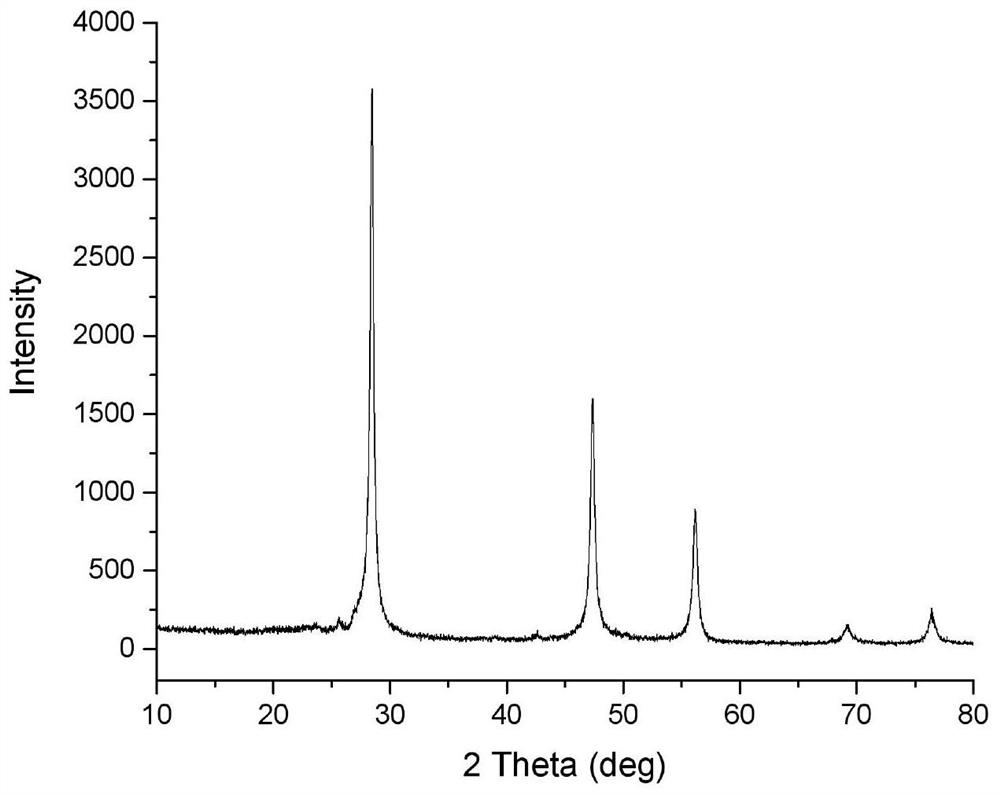

Micro-emulsion method for preparing nano-sulfur particles

ActiveCN101880031ASimple methodUniform and adjustable particle size distributionSulfur preparation/purificationChemical industrySulfur

The invention relates to a method for preparing nano particles of elemental sulfur, belonging to the technical filed of chemistry and chemical industry. In the invention, a micro-emulsion method is utilized to prepare nano-sulfur particles and comprises the following steps: (1) evenly mixing surfactant, cosurfactant and oil phase, adding water solution of sulfur precursor to form micro-emulsion A, wherein the sulfur precursor is a compound capable of performing dismutation under acidic condition to generate the elemental sulfur; (2) evenly the mixing surfactant, the cosurfactant and the oil phase, then adding aqueous acid to form micro-emulsion B; and (3) mixing the micro-emulsion A obtained in step (1) and micro-emulsion B obtained in step (2), after the reaction ends, ageing, breaking emulsion, separating, washing and drying to obtain the nano-sulfur particles. The obtained product is orthorhombic system elemental sulfur, contains no impurity phase, and has evenly particle diameter distribution; and the particle diameter ranges from 10 to 400nm.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

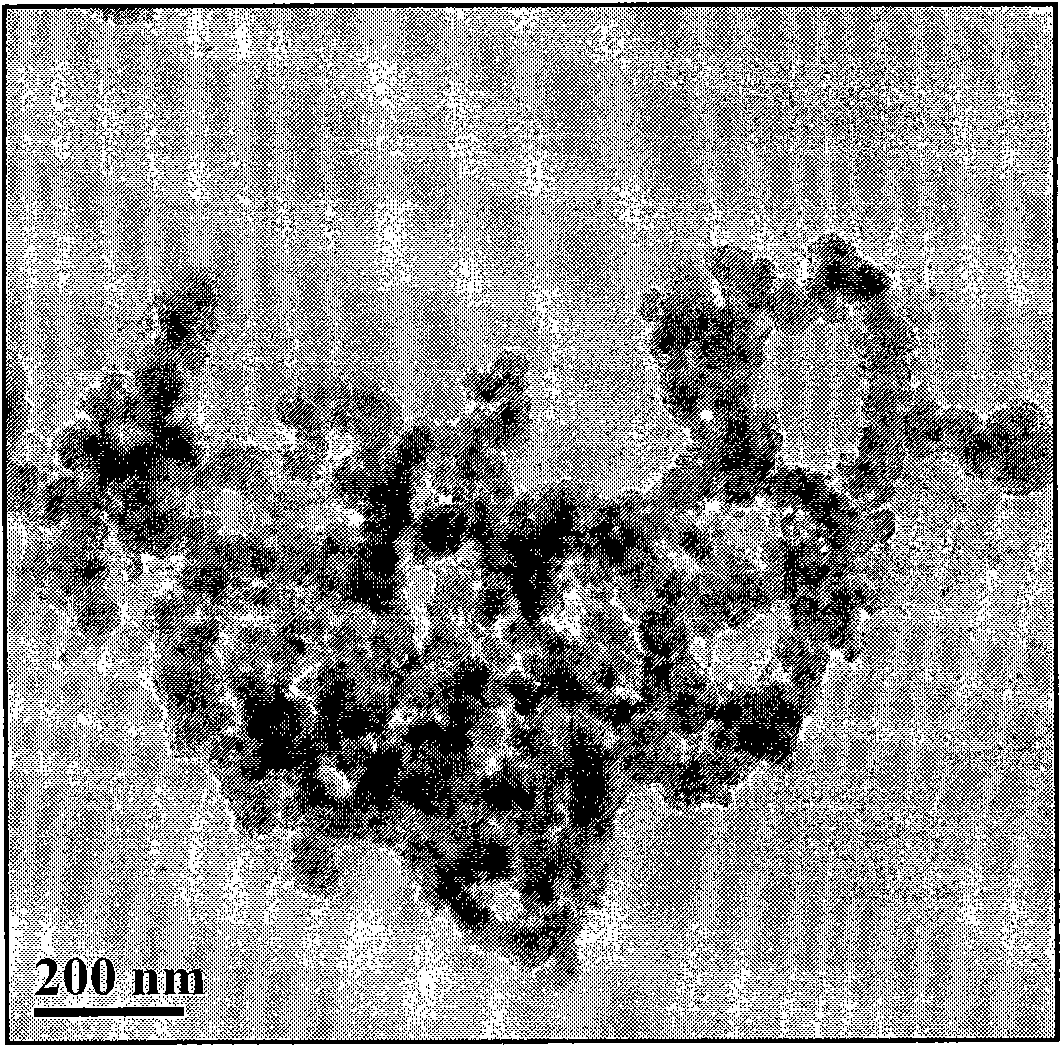

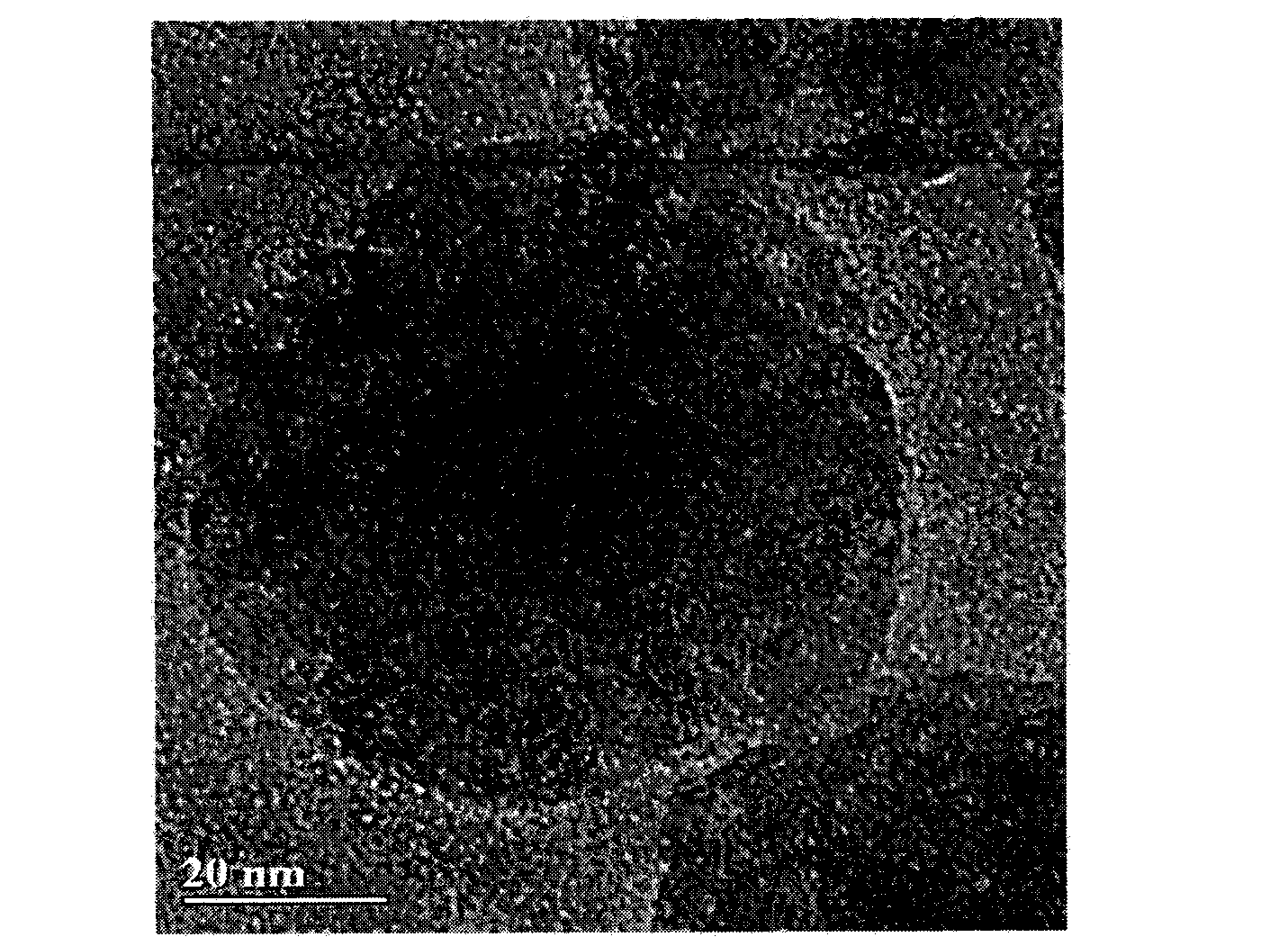

Preparation method of MOx@SiO2 shell-core structure catalyst

ActiveCN103418371AGuaranteed activity and selectivityGood reactivity and stabilityMolecular sieve catalystsDispersed particle separationNano catalystHigh activity

The invention relates to a preparation method of a shell-core structure MOxSiO2, wherein the MOx is one of Mn3O4, Fe2O3, CeO2, Cu2O, or Co3O4. The preparation method comprises following steps: homogenously dispersing 0.01 to 0.1 mol of water-containing inorganic metal salt and 2 to 10 mL of oleic acid into 50 to 100 mL of absolute methanol, then putting the materials in a high-pressure reactor to subject the materials to crystallization reactions for 10 to 48 hours at the temperature of 120 to 240 DEG C, cooling and filtering so as to obtain MOx nano particles, dissolving the MOx nano particles in hexane, adding cetyl trimethyl ammonium bromide solution, subjecting the solution to an ultrasonic treatment, adding sodium hydroxide solution with a concentration of 0.5 M to 2 M, stirring, dropwise adding ethyl orthosilicate, carrying out the reactions at the room temperature for 10 to 24 hours, then subjecting the reaction product to a centrifugation treatment, washing, drying, and burning so as to obtain nano catalyst MOx@SiO2. The preparation method is simple and is easy to be applied to industrial production. The catalyst prepared by the preparation method is applied to the CO oxidation reaction, and has the advantages of low cost, and high activity and stability.

Owner:EAST CHINA UNIV OF SCI & TECH

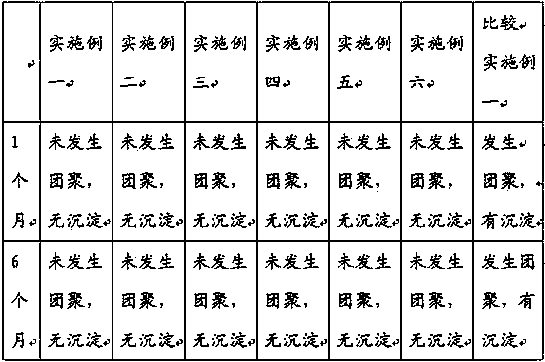

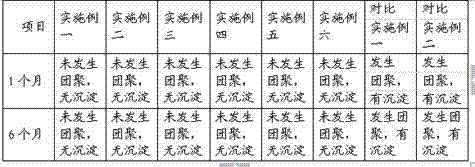

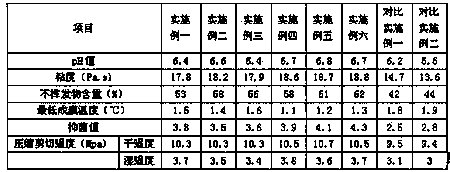

Nano-silver-containing adhesive and using method of adhesive in technical wood

ActiveCN103820056AImprove stabilityGood dispersionNon-macromolecular adhesive additivesAdhesive glueDodecyl sulfate

The invention relates to the field of nanometer materials, and particularly relates to nano-silver-containing adhesive and a using method of the adhesive in technical wood. The nano-silver-containing adhesive is characterized in that nano-silver is uniformly applied to an environmentally friendly glue solution, and flour is used as an additive of glue. A preparation method of the nano-silver comprises the following steps: adding a sodium dodecyl sulfate solution and a hydrazine hydrate solution to a silver nitrate solution so as to obtain mixed liquid, and adding crown ether and an alkali metal-containing reducing agent to the mixed liquid, wherein the molar ratio of the crown ether to the silver nitrate is (1-2): 1, the molar ratio of the alkali metal-containing reducing agent to the silver nitrate is (0.5-1): 1; and controlling a pH value to 8-9, thus obtaining the nano-silver. The using method of the adhesive comprises the following steps: bonding decorative veneer and a base material through the nano-silver-containing adhesive, then feeding into a vacuum tank, and vacuumizing; then carrying out pressurizing treatment; carrying out microwave treatment; and finally taking out, and carrying out cold pressing and hot pressing. The nano-silver-containing adhesive provided by the invention has good stability, dispersity and adhesiveness.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

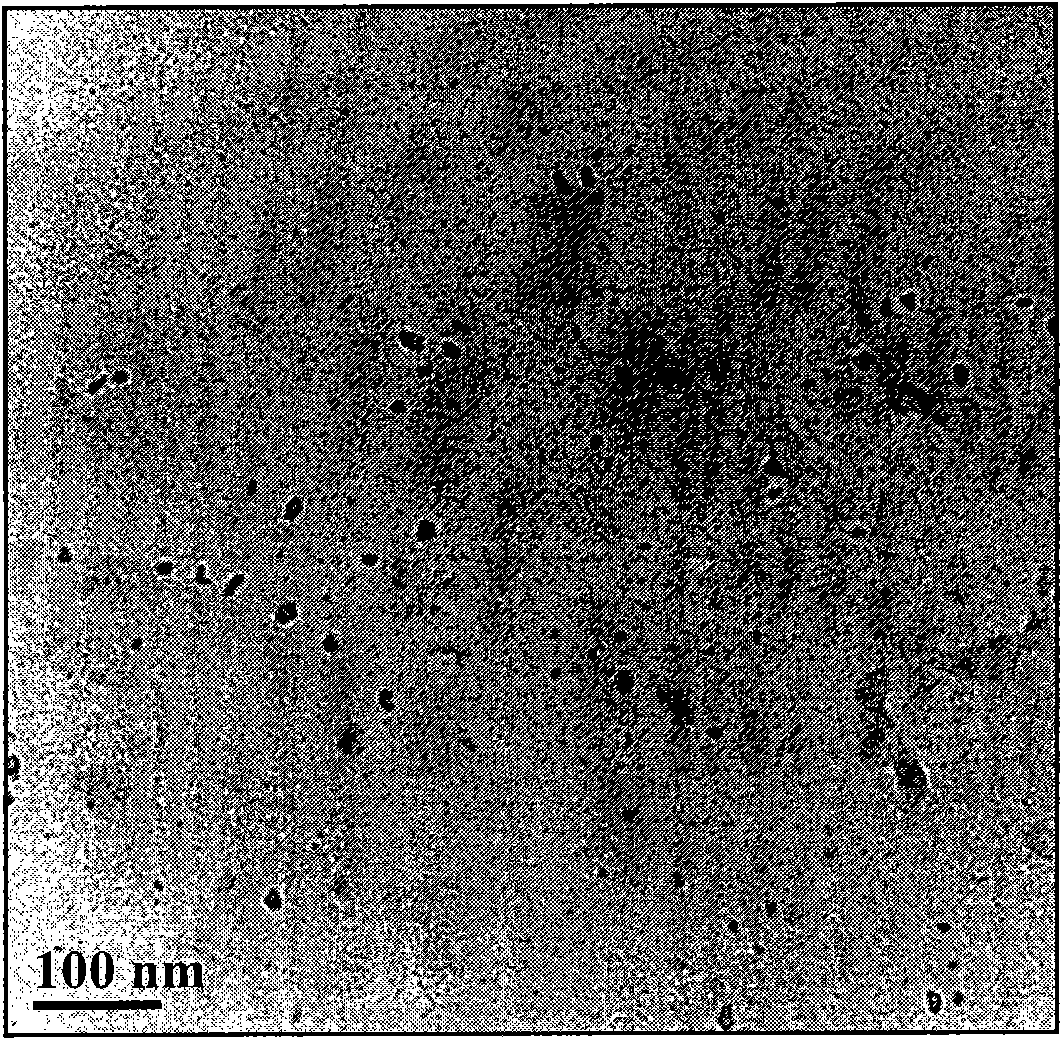

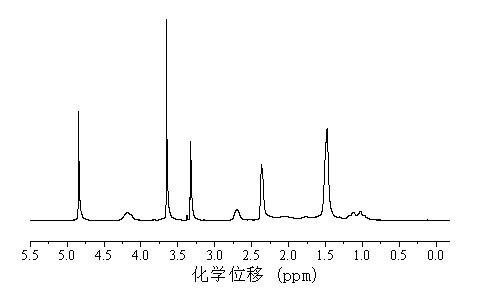

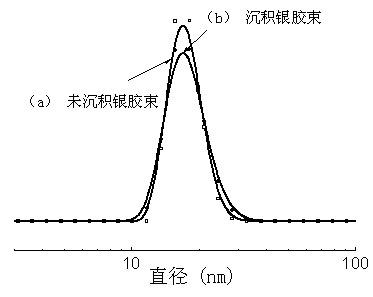

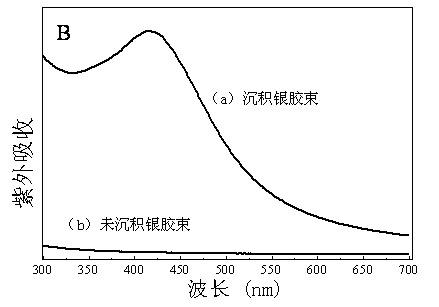

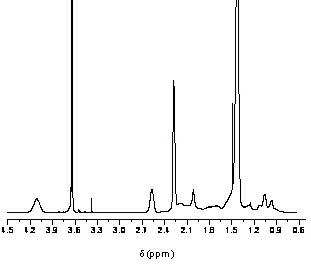

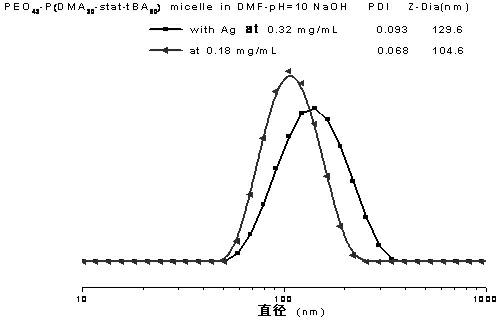

Antibacterial nano silver modified polymeric micelle and preparation method thereof

InactiveCN102671201AEasy to prepareAvoid Solvent Residue ProblemsAntibacterial agentsPowder deliverySelf-assemblyDrug

The invention belongs to the high-molecular nano biomedical materials, and specifically relates to a polymeric micelle in which the antibacterial nano silver is deposited at the core, and a preparation method of the polymeric micelle. Amphiphilic block copolymers form the micelle in a self-assembly manner through a direct dissolution method, and then, nano silver is generated at the core of the micelle in situ. The micelle has biocompatibility and also has certain temperature and pH sensitivity, the core-shell structure of the micelle can package multiple drugs, and simultaneously, with the existence of nano silver, the micelle has the curative effects of sterilization and bacterial inhibition.

Owner:TONGJI UNIV

Hydrophobic organic and inorganic acrylate polymer emulsion with high silicon content and preparation method and application thereof

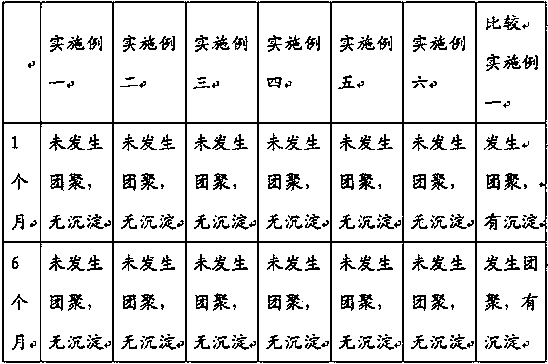

The invention relates to the technical field of organic and inorganic compounds. In order to solve the problems that inorganic nano SiO2 introduced to the polymer emulsion is easy to agglomerate, the content of SiO2 is low in the whole system, and some hydroxyls are contained on the surface of SiO2 to result in deficiency in hardness and hydrophobicity of a film, the invention provides a hydrophobic organic and inorganic acrylate polymer emulsion with high silicon content and a preparation method and an application thereof. The emulsion is prepared from the following components in parts by weight: 30-60 parts of a silica sol, 5-15 parts of a cosolvent, 1-5 parts of a fluorine-containing silane coupling agent, 0.2-2 parts of an emulsifier, 0.1-1 part of an initiator and 40-80 parts of water. The emulsion film has the advantages of inorganic materials and organic high polymers and can be used for preparing coatings with good weather ability, hydrophobicity, scrubbing resistance and stain resistance, and high hardness performance.

Owner:HANGZHOU NORMAL UNIVERSITY

Polymer vesica with antibacterial nano silver deposited on surface and preparation method thereof

InactiveCN102432974AWith temperatureHas dual pH sensitivityPharmaceutical non-active ingredientsCurative effectBiocompatibility Testing

The invention belongs to the field of nano biological medical materials and particularly relates to polymer vesica with the surface deposited with antibacterial nano silver and a preparation method thereof. Amphipathic block polymers are self-assembled by a cosolvent method to form the vesica, and then the nano silver is generated in situ on the surface of the vesica. The polymer vesica has biocompatibility and has certain temperature and pH sensitivity; a cavity structure of the vesica can wrap various medicines; and simultaneously, due to the existence of the nano silver, the vesica also has the curative effects of sterilization and bactriostasis.

Owner:TONGJI UNIV

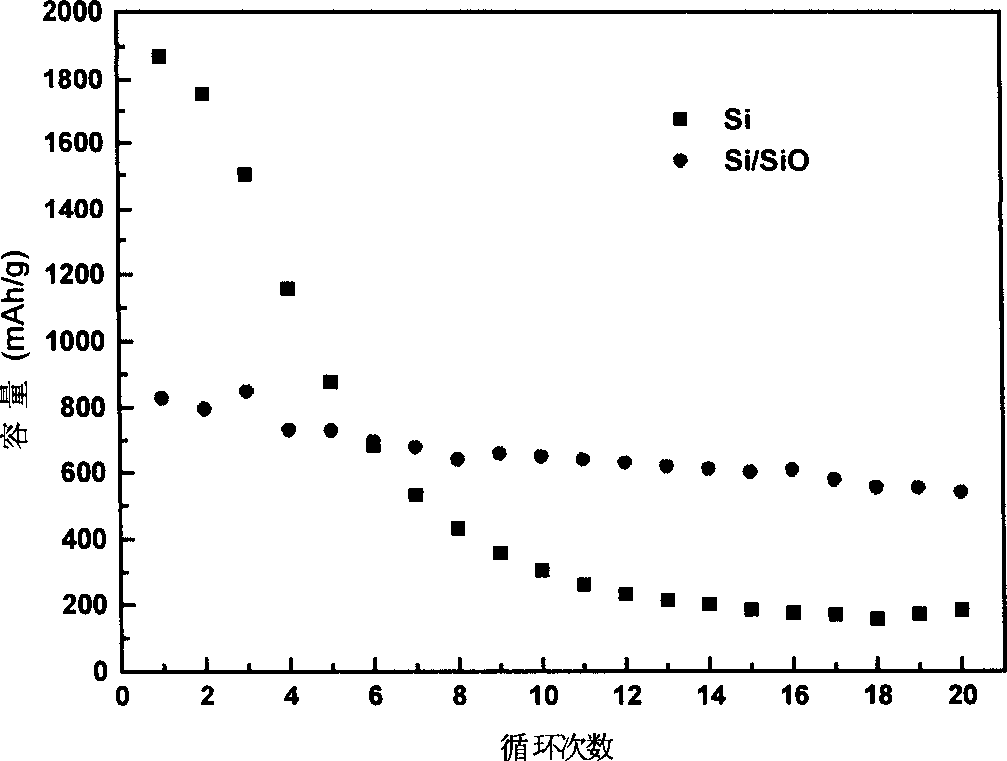

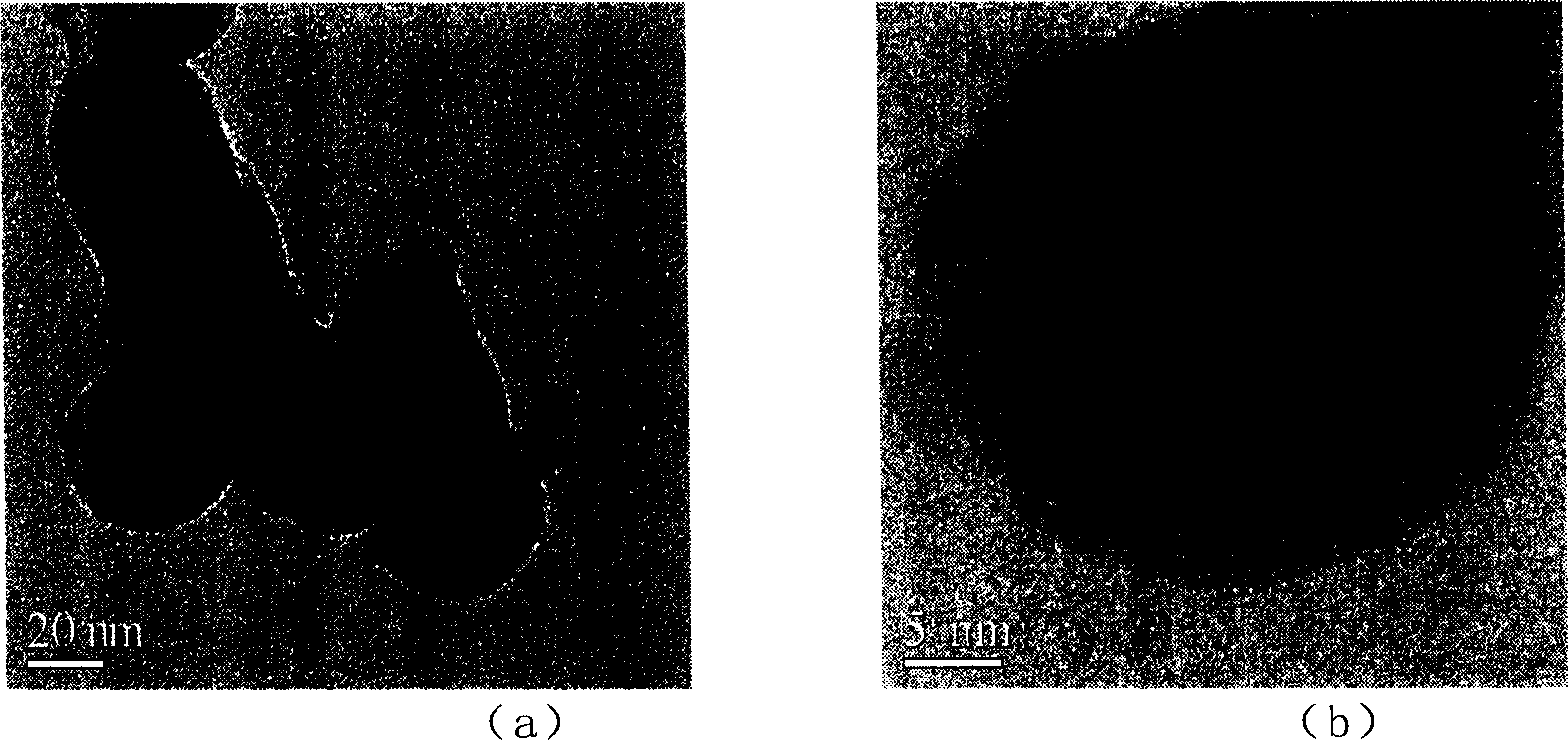

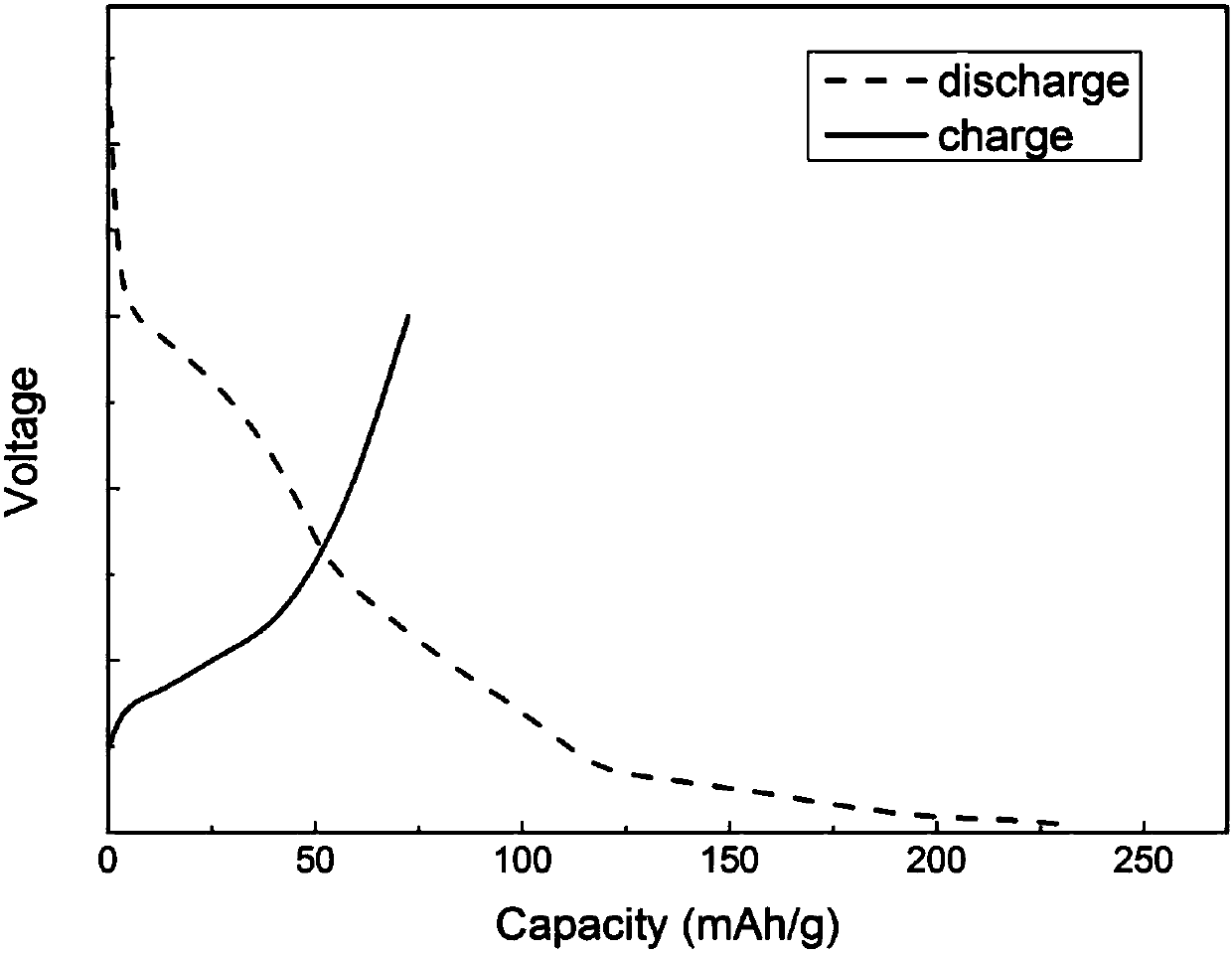

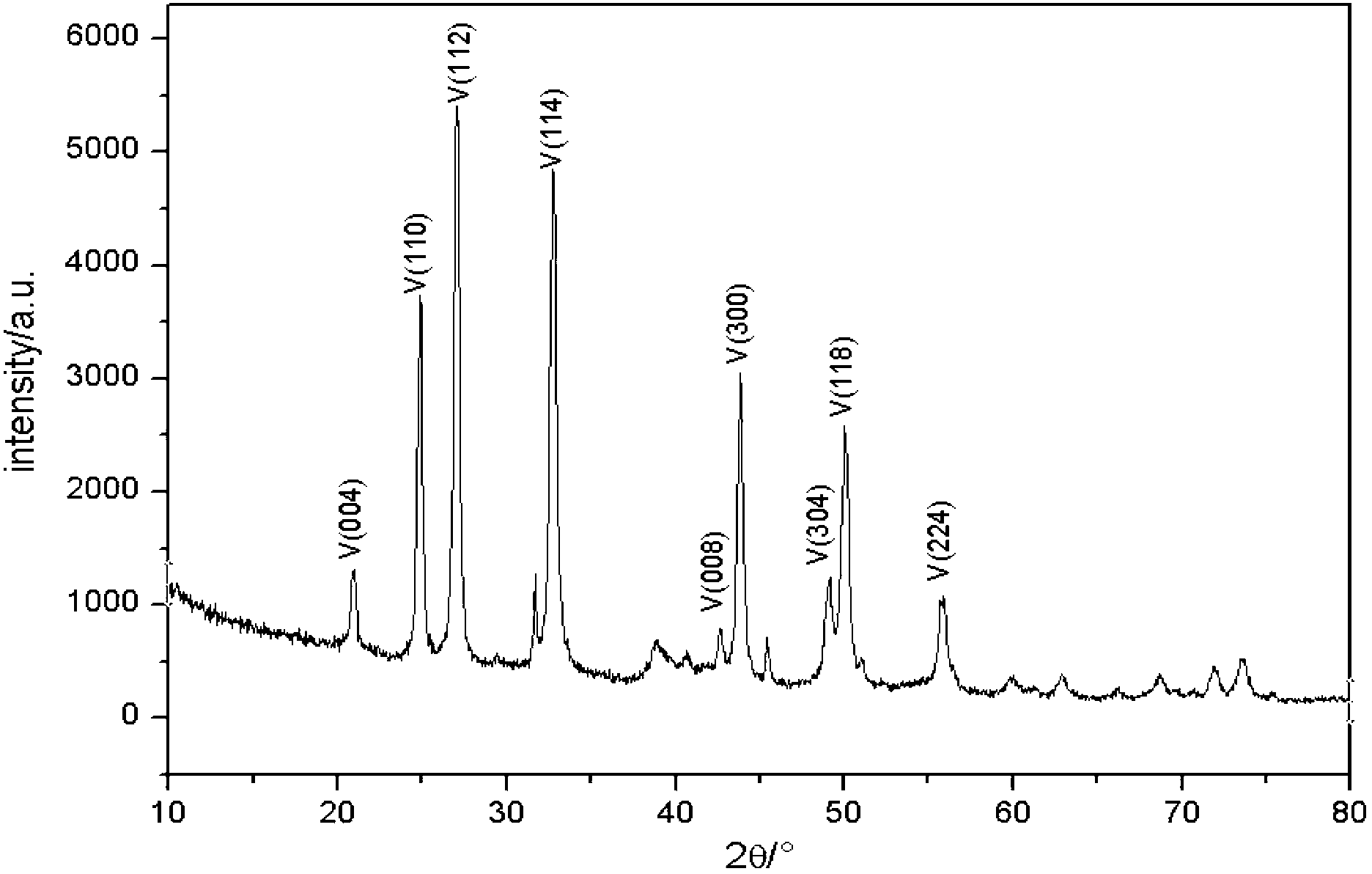

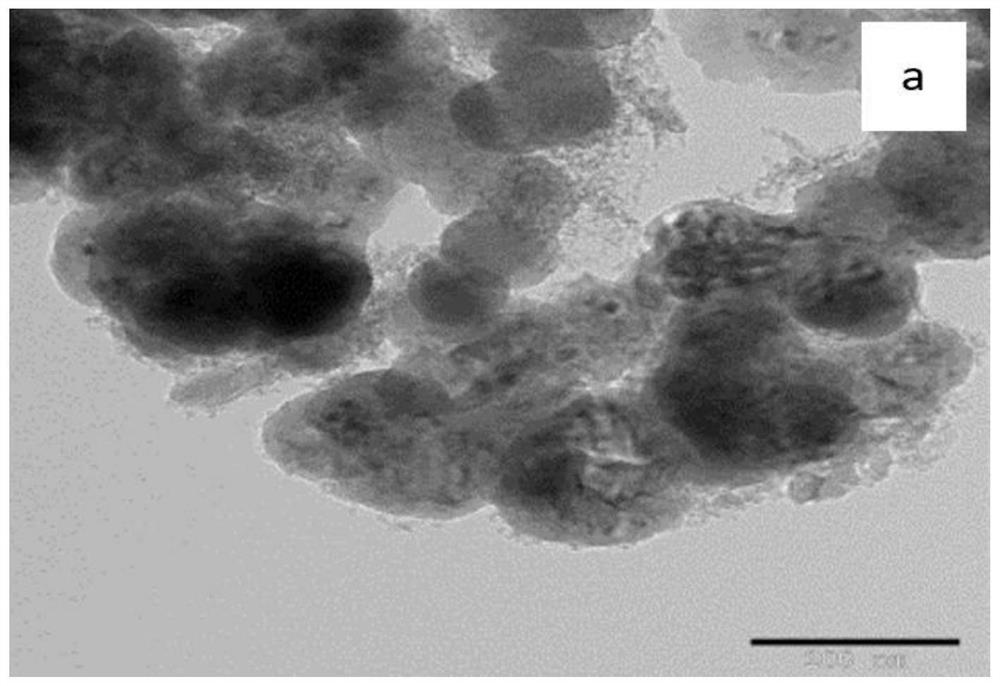

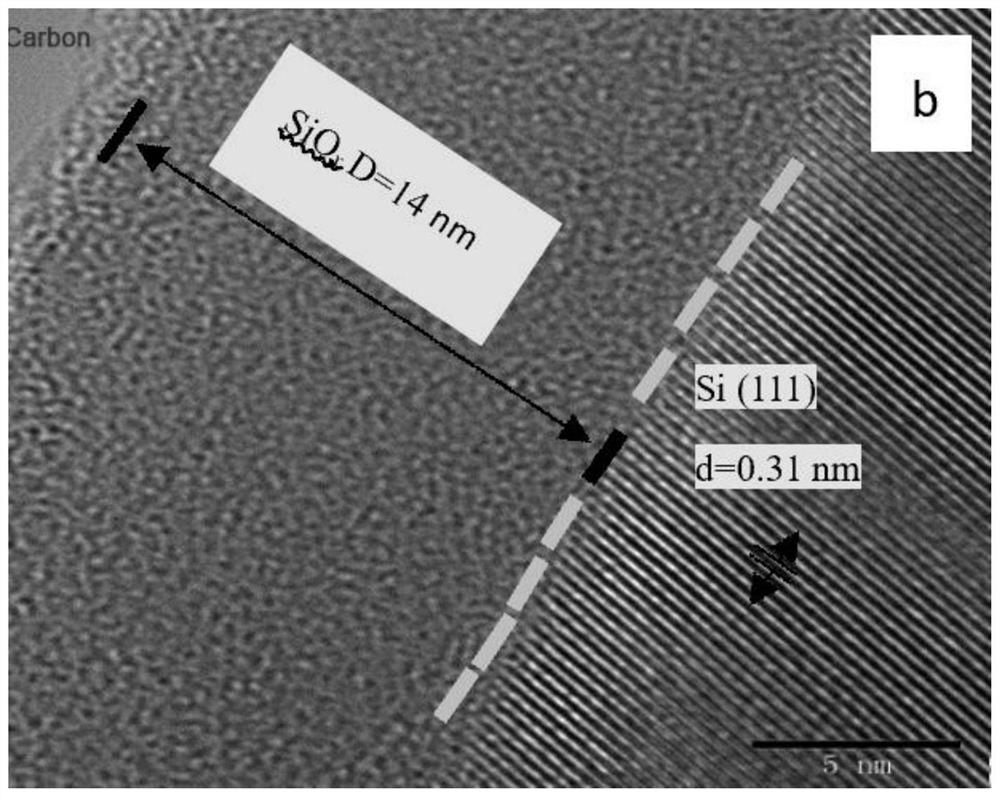

Silicon/oxidative silicon nuclear-shell structured nano-composite material, its preparation and use

InactiveCN1895999AReunion won't happenImprove cycle stabilityNanostructure manufactureElectrode manufacturing processesNanometreLithium ion intercalation

A silicon / monox core-shell structured nanometer-composite material, its production and use are disclosed. The process is carried out by building in and removing lithium ion by sol-gel method. Its advantages include stable crystal structure, better reversible capacity and circulation performance, better operability, repeatability and quality. It can be used in production of lithium-ion battery.

Owner:FUDAN UNIV

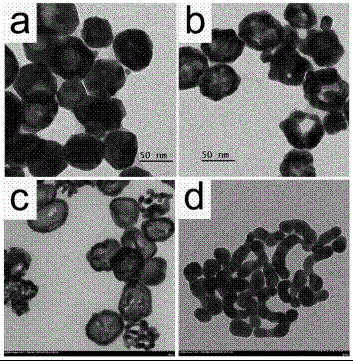

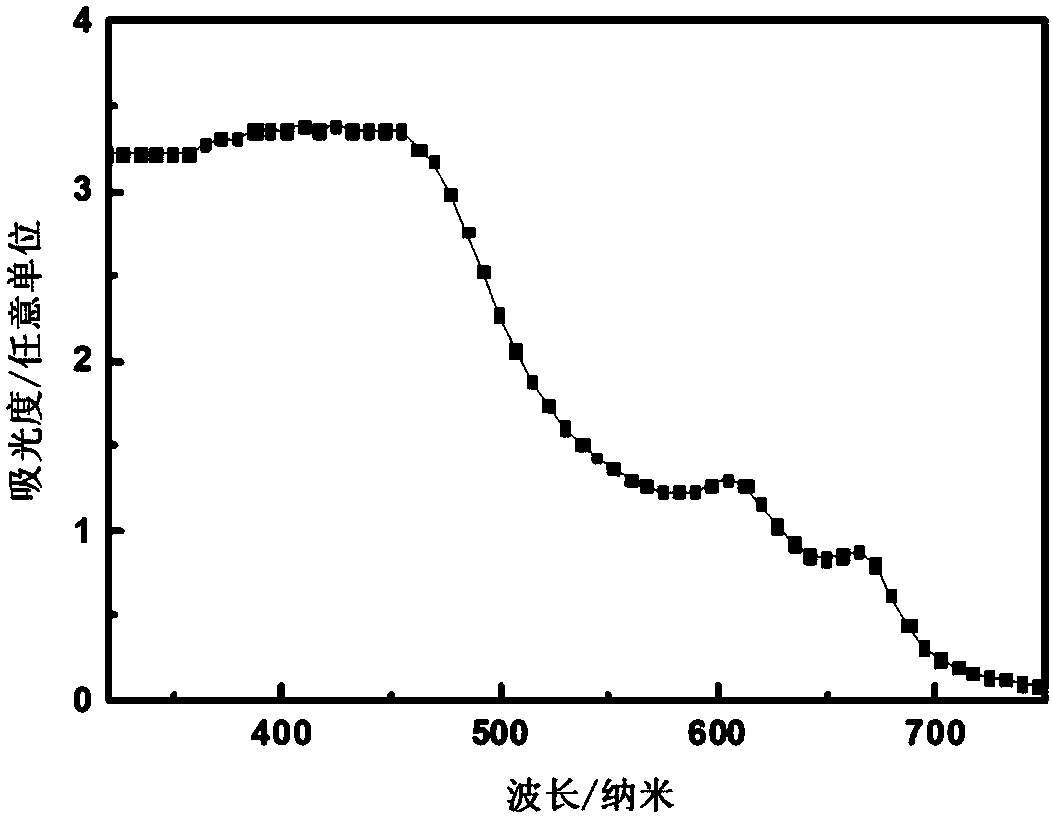

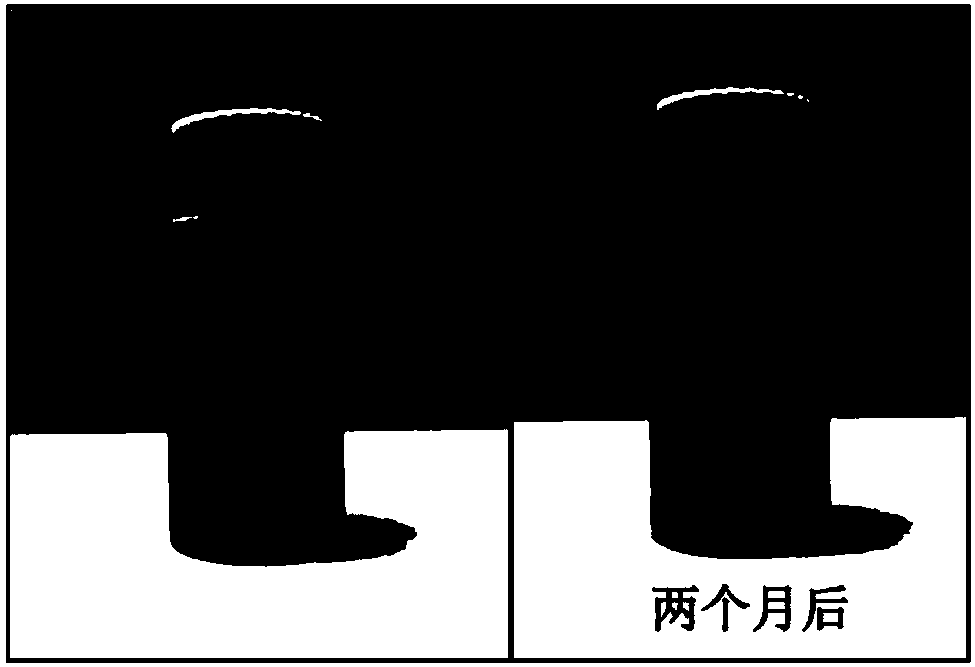

Preparation method for porous hollow gold-silver nano-alloy particles

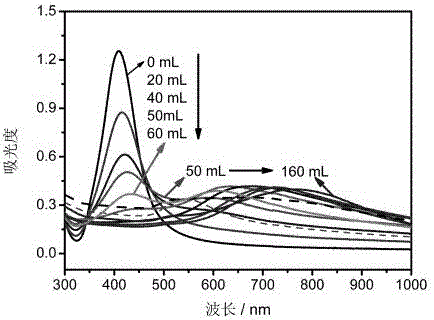

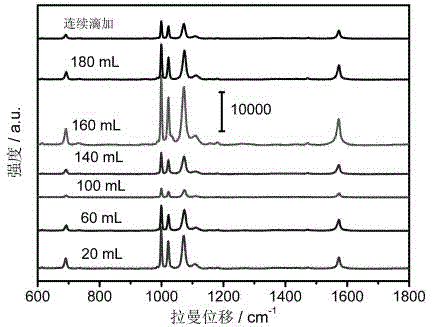

ActiveCN105710385AExcellent SERS enhancement effectGood SERS enhancement effectMaterial nanotechnologyTransportation and packagingAqueous solutionChlorauric acid

Provided is a preparation method for porous hollow gold-silver nano-alloy particles. The method includes the following steps that 200 ml of tri-distilled water is added into a reaction vessel and heated to 60-70 DEG C, 30-40 mg of silver nitrate is added, heating is continued until the temperature reaches 90-95 DEG C, afterward, 4 mL of a sodium citrate aqueous solution with the concentration being 10-30 mg / mL is added, a reaction is performed for 5-10 minutes, and the reaction is performed for 30-60 minutes by keeping the temperature at 85-90 DEG C; the reaction temperature is adjusted to 60-90 DEG C, 20-240 mL of a chloroauric acid aqueous solution with the concentration being 1.0*10<-4> mol / L is added dropwise at the speed of 20-30 drops / minute, and the drop addition quantity is determined according to different requirements; and prepared porous hollow gold-silver nano-alloy particles are subjected to centrifugal separation and dispersed in tri-distilled water again, and the porous hollow gold-silver nano-alloy particles can be obtained. By means of the method, tuning of the localized surface plasmon resonance (LSPR) absorption peak of the porous hollow gold-silver nano-alloy particles in a full visible light region can be realized.

Owner:NANTONG NTEC MONOFILAMENT TECH CO LTD

Nanometer microsphere of temozolomide polylactic acid and its preparation and preparing method therefor

InactiveCN100998566AGood sustained release performanceGood slow releaseOrganic active ingredientsPharmaceutical non-active ingredientsFreeze dryMicrosphere

A nanoball of temozolomide-sodium polylactate is proportionally prepared from temozolomide and sodium polylactate. Its product may be injection, freeze-dried powder injection, slow-release micropills, tablets, or membrane for treating cancer, especially the cerebral glioma. Its preparing process is also disclosed.

Owner:南京伍盛纳米科技有限公司

Method for preparing lithium ion battery negative electrode material from photovoltaic industry wastes

InactiveCN107732200AReduce manufacturing costEfficient Development StrategyCell electrodesPhotovoltaic industrySolvent

The invention discloses a method for preparing a lithium ion battery negative electrode material from photovoltaic industry wastes. The method comprises 1) pretreating photovoltaic industry wastes toobtain silicon powder, and 2) preparing a lithium ion battery negative electrode material through 2.1), adding the prepared silicon powder and a dispersant into a solvent according to a mass ratio of4 to 1 and carrying out dispersion to obtain uniformly dispersed nano-silicon particles, 2.2), adding an initiator ammonium persulfate into the solution obtained by the step 2.1) and carrying out ultrasonic dispersion, 2.3), acidifying the solution and adjusting the pH of the solution to 1-3, 2.4), then dropwisely adding monomers into the silicon particles for coating and stirring the mixture fora reaction in an ice bath for 8-12h, and 2.5) after the reaction, centrifuging the liquid, washing the liquid to pH of 7, then carrying out vacuum drying and carrying out grinding to obtain the lithium ion battery negative electrode material. Through treatment on photovoltaic industry wastes, the silicon raw material is modified through the simple and easy industrial use method and the commercialapplication of the silicon negative electrode is promoted.

Owner:XI AN JIAOTONG UNIV

Nano-silver aqueous solution and application method for applying nano-silver aqueous solution to technical wood

ActiveCN103817348AImprove stabilityGood dispersionWood treatment detailsNanotechnologyMicrowave frequency rangeAcrylic resin

The invention relates to the field of nano materials, in particular to a nano-silver aqueous solution and an application method for applying the nano-silver aqueous solution to technical wood. According to the aqueous solution, deionized water is used as a solvent, nano-silver is used as a solute and dissolves in the deionized water, acrylic resin is used as a complexing agent and a stabilizing agent and dissolves in the deionized water, meanwhile a dispersing agent and a first reducing agent are added to the deionized water, and then the solution is formed, wherein the dispersing agent is triethanolamine, the first reducing agent is a hydrous ammonia aqueous solution, the concentration of nano-silver ranges from 50 ppm to 150 ppm, and the mass content of acrylic resin in the solution ranges from 1% to 10%. The application method includes the steps that the technical wood is fed to a vacuum tank filled with the nano-silver aqueous solution, and the vacuum tank is pumped until the vacuum degree ranges from -0.05 MPa to -0.01 MPa for 15 min to 20 min; pressure application is conducted, and pressure is applied to 0.2 MPa to 0.5 MPa for 18 min to 28 min; eventually, microwave processing is conducted for 1 min to 3 min, the microwave frequency ranges from 300 MHz to 950 MHz, and then the technical wood is taken out for drying. The nano-silver aqueous solution is good in stability and dispersibility, nano-silver can be more effectively permeated into the technical wood, and mold is fully defended.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Method for preparing industrial ultra-fine activated calcium carbonate from carbide slag

The invention discloses a method for preparing industrial ultra-fine activated calcium carbonate from a carbide slag, and particularly relates to preparation of employing O / W-type microemulsion. The technology disclosed by the invention comprises the steps of extracting calcium in the carbide slag by saturated ammonium chloride solution, and separating undissolved impurities to filter and obtain calcium chloride solution; reacting fatty acid and alkyl alcohol with sodium hydroxide solution, and adding petroleum ether to form microemulsion; fining microemulsion particles by ultrasound, slowly dripping the obtained calcium chloride solution under an agitation condition, dripping carbonate or bicarbonate solution after dripping, thereby respectively obtaining an upper layer of oil phase, a middle layer of opaque oil phase containing calcium carbonate sediment, and a lower layer of water phase after reaction and delivery are finished; and centrifugally separating, washing and drying the middle layer to obtain industrial ultra-fine activated calcium carbonate, wherein the oil phase and the water phase can be recovered to apply mechanically. By adopting the method, the processing problem of the carbide slag can be well solved; the obtained oil phase and water phase can be recycled; the cost is saved; the prepared light calcium carbonate surface is coated with a layer of fatty acid; the dispersibility is good; the problem that the product is easily gathered is solved; and the method has economical, social and environment-friendly concepts.

Owner:ANHUI YOUSHENGMEI NEW MATERIAL TECH CO LTD

Material mixing method of graphite negative electrode slurry

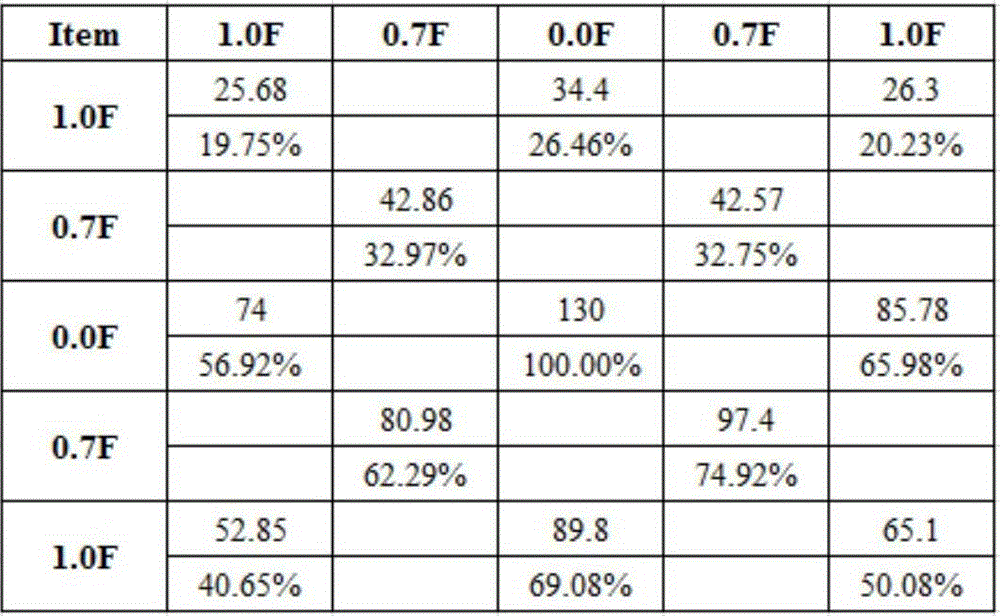

ActiveCN109904430ASmooth mixingReunion won't happenCell electrodesSecondary cellsGraphiteEquilibrium constant

The invention provides a material mixing method of graphite negative electrode slurry. The graphite negative electrode slurry comprises a first graphite material, a second graphite material and a third graphite material, wherein the average grain diameter of the first graphite material is d1, the average grain diameter of the second graphite material is d2, and the average grain diameter of the third graphite material is d3, wherein d1 is smaller than d2 which is smaller than d3, and d2 is equal to k*(d1+d3); k is equal to a*(c1+c3) / (c2+0.5), wherein a is an equilibrium constant, and a is greater than or equal to 1.1 and less than or equal to 1.3; c1, c2 and c3 represent percentages of the first graphite material, the second graphite material and the third graphite material; and c1+ c2 +c3is equal to 1, and c1+c2 is less than or equal to c3. The material mixing method comprises the following steps of carrying out mixing on the first graphite material, the second graphite material andthe third graphite material to obtain three slurry materials respectively, and then enabling the three slurry materials to be mixed according to a specific sequence to obtain the graphite negative electrode slurry with high dispersion degree. The graphite negative electrode slurry disclosed by the invention is high in graphite dispersion degree, free of agglomeration, free of sedimentation, high in storage stability, high in energy density and high in rate performance.

Owner:山东中信迪生电源有限公司

Photochromic fiber making method

InactiveCN104047069AExtended drying timeTo achieve slice drying effectFilament forming substance formingMelt spinning methodsMasterbatchYarn

The invention discloses a photochromic fiber making method which is realized by the following steps: (1) under vacuum conditions, drying light nylon slices with a low melting point, cooling to the room temperature, and excluding vacuum to discharge; (2) taking a certain quality of the dried nylon slices obtained by the step (1), adding a photochromic agent, a dispersing agent, a coupling agent, a heat stabilizer and an antioxidant, melting at 165 to 180 DEG C to prepare masterbatch; (3) taking the following raw materials by mass to mix: 70-90% of the nylon slices obtained by the step (1) and 10-20% of the masterbatch obtained by the step (2), and preparing photochromic POY (pre-oriented yarn) by melt spinning; and (4) drawing the photochromic POY to obtain the photochromic FDY (fully drawn yarn). The photochromic fiber is good in color changing effect, good in comprehensive application performance and low in production cost.

Owner:YIXING ZHENGTAI CHEM FIBER +1

LED fluorescent glue and packaging method for improving luminescence uniformity, and LED

InactiveCN105845812AGood dispersionLarge specific surface areaSolid-state devicesSemiconductor devicesFluorescenceWavelength

The invention discloses an LED fluorescent glue that improves the uniformity of light emission. In parts by weight, the fluorescent glue consists of 1 part of packaging glue, 0.01-1 part of fluorescent powder, 0.01-0.1 part of silica-based inorganic nanoparticles, 0.01 part of ‑1 part silicone granules. Inorganic nanomaterials and silicone particles are mixed in the encapsulation glue, which reduces the sedimentation rate of the phosphor in the encapsulation glue, improves the uniformity of the phosphor distribution in the colloid, makes the white light spot more uniform, and improves the light diffusivity and transmittance. The light rate is maximized, and by changing the propagation path of the light, the light of various wavelengths is more fully mixed, and the spatial color uniformity of the light is further improved. It also provides an LED packaging method and LED that improve the uniformity of light emission, which improves the consistency of products, reduces the probability of uneven color distribution in space due to uneven distribution of phosphor powder, and improves product yield and product production. efficiency.

Owner:SHENZHEN JUFEI OPTOELECTRONICS CO LTD

Nano silver decoration laminated board

ActiveCN103832205AEffective penetrationImprove stabilitySpecial ornamental structuresPolymer sciencePolyolefin

The invention relates to the field of nano materials, and particularly relates to a nano silver decoration laminated board. The nano silver decoration laminated board is formed by bonding a decoration single board and a base material by a bonding agent layer; the decoration single board and the base material are formed by impregnating by a nanometer aqueous solution; the bonding agent layer contains a nanometer silver substance; the decoration single board and the base material are engineering wood; the nanometer silver aqueous solution is formed by taking deionized water as a solvent, dissolving nanometer silver as solute into the deionized water, taking acrylic resin as a complexing agent and dissolving a stabilizing agent into the deionized water, and meanwhile adding a dispersion agent and a first reducing agent; the concentration of nanometer silver in the bonding agent is 75-150ppm; the mass content of flour in the solution is 18-45%; environment-friendly glue comprises 40-80 parts solid with 40-55%bacrylic resin emulsion, 20-40 parts of acrylic resin powder, 5-20 parts of solid with 40-60%EVA emulsion as well as 7-13 parts of chlorinated polypropylene or polyolefin substrate adhesion promoter. The nano silver decoration laminated board provided by the invention is good in stability and dispersion, and can fully resist mildew.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

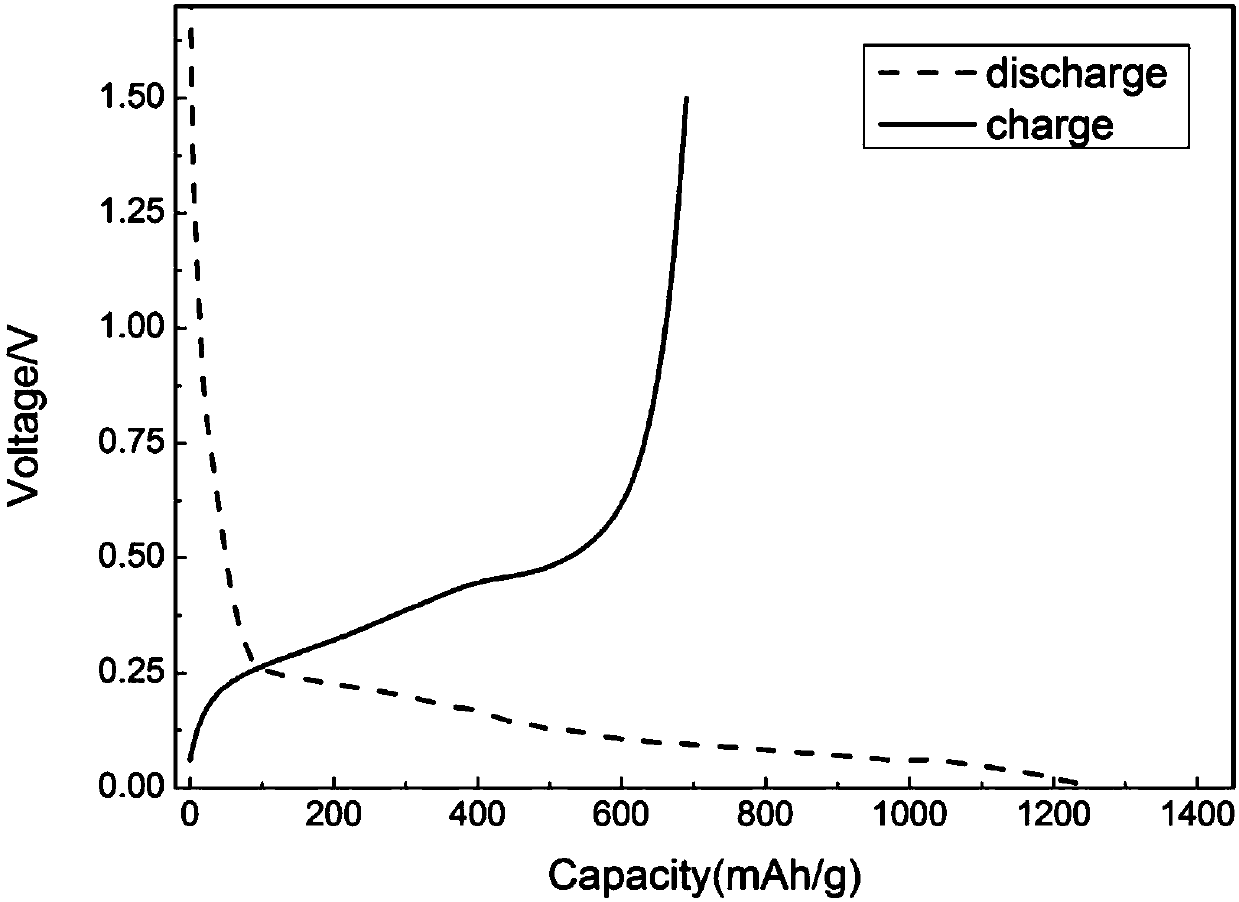

Silicon/silicon oxide/carbon composite negative electrode material for lithium ion battery and preparation method of silicon/silicon oxide/carbon composite negative electrode material

ActiveCN112366301AHigh specific capacityImprove Coulombic efficiencyMaterial nanotechnologyNegative electrodesCarbon compositesSilicon oxide

The invention relates to a negative electrode material for a lithium ion battery, a preparation method of the negative electrode material and the battery, and discloses a preparation method of a silicon / silicon oxide / carbon composite negative electrode material for the lithium ion battery, the silicon / silicon oxide / carbon composite negative electrode material and the battery. The silicon-carbon composite negative electrode material prepared by adopting an in-situ oxidation method and a high-temperature pyrolysis method has a core-shell structure, and the obtained shell structure is stable andfirm in structure. According to the invention, a lithium storage active phase SiOx and an amorphous pyrolytic carbon coating layer are generated on the surface of the nano-silicon through the dual-core shell structure, volume expansion in the charging and discharging process of the nano-silicon can be well buffered on the premise that the capacity is not remarkably reduced, the high conductivity and stability of the pyrolytic carbon coating layer are helpful for enhancing the stability of the Si@SiOx and electrolyte interface SEI film, so that the composite material has high capacity, excellent rate capability and cycle performance.

Owner:博尔特新材料(银川)有限公司

Preparation method of environment-friendly adhesive

ActiveCN104231980AInhibit sheddingImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDi-tert-butyl peroxideMethyl carbonate

The invention relates to adhesives, particularly to a preparation method of an environment-friendly adhesive. The environment-friendly adhesive is composed of the following raw materials including, by weight parts, 70-95 parts of phthalic anhydride, furfuryl alcohol extracted from natural plant, triethylene glycol, pentanediol, butantriol, zinc oxide, magnesium oxide, chloroprene rubber and elastic rubber, 2-3 parts of softening oil, 20-30 parts of dimethyl carbonate, benzoyl peroxide, ethyl acetate, emulsifier and flour, 5*10-5-9*10-5 parts of nano silver, and fire retardant, wherein the elastic rubber is composed of first elastic rubber and second elastic fiber which are mixed at a weight ratio of 1-3:1. The preparation method of the second elastic rubber comprises heating polyvinyl alcohol solution and waterborne polyurethane water solution, cooling the mixture to 30-50 DEG C and then adding acrylate into the mixture; then adding potassium hydroxide into the mixture and heating the mixture; then adding cementum protein, abietin and plant phenols extracted from natural plant for reaction; then adding sodium benzoate, di-tert-butyl peroxide and the ethyl acetate and mixing the reactants to obtain the environment-friendly adhesive. The environment-friendly adhesive is good in bactericidal activity and high in stability, dispersibility and adhesiveness.

Owner:安吉竹印象家居用品有限公司

Preparation method of shock-resistant STF (shear thickening fluid) gel

ActiveCN106674421AOvercome the disadvantage of easy settlementReunion won't happenN-butyl acrylatePolyethylene glycol

The invention discloses a preparation method of shock-resistant STF (shear thickening fluid) gel. 1-10 parts by weight of any one or a mixture of several of acrylic acid, polyethylene glycol (400) diacrylate, and polyethylene glycol (600) methacrylate, 10-15 by weight of any one or a mixture of several of beta-hydroxyl ethyl acrylate, iso-octyl acrylate and butyl acrylate as well as 30-90 by weight of an STF are mixed in a reaction container; an initiator with the weight accounting for 0.15%-2% of the total weight of the mixture is added to initiate a reaction, the reaction temperature is controlled within 10-80 DEG C, and uniform mixing and defoaming are performed; standing is performed, and the uniform and stable STF gel is obtained after a curing reaction. The prepared STF gel is uniformly dispersed, cannot settle easily and has a good shear thickening effect. Besides, the preparation process is good in stability and can realize industrial production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

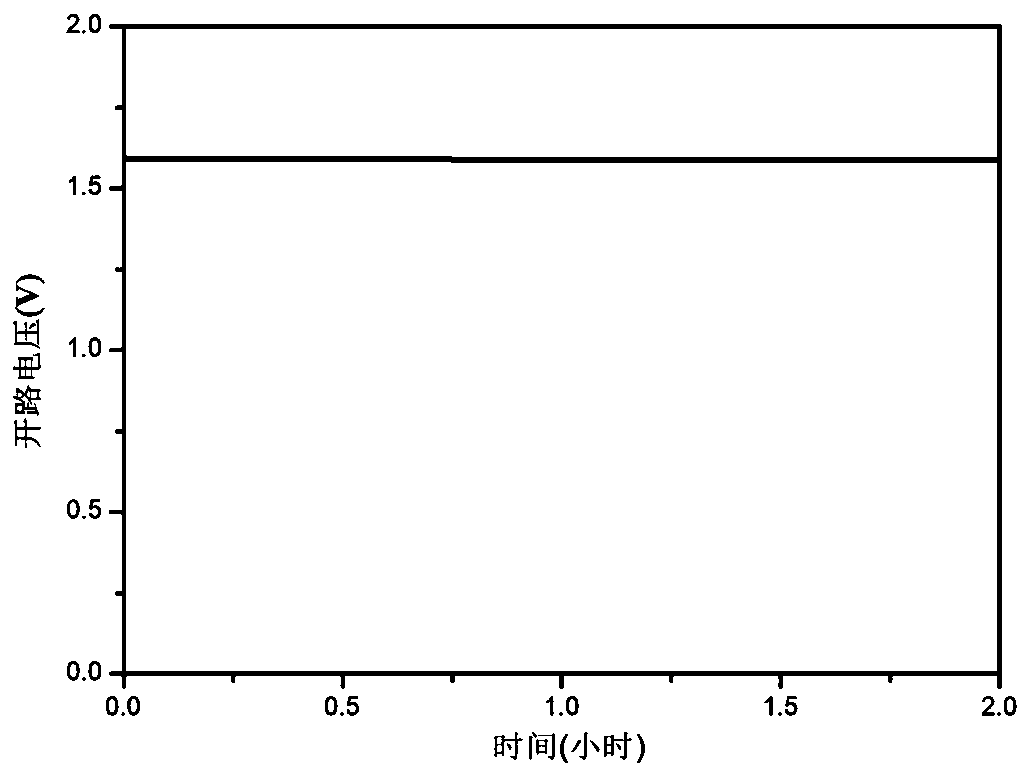

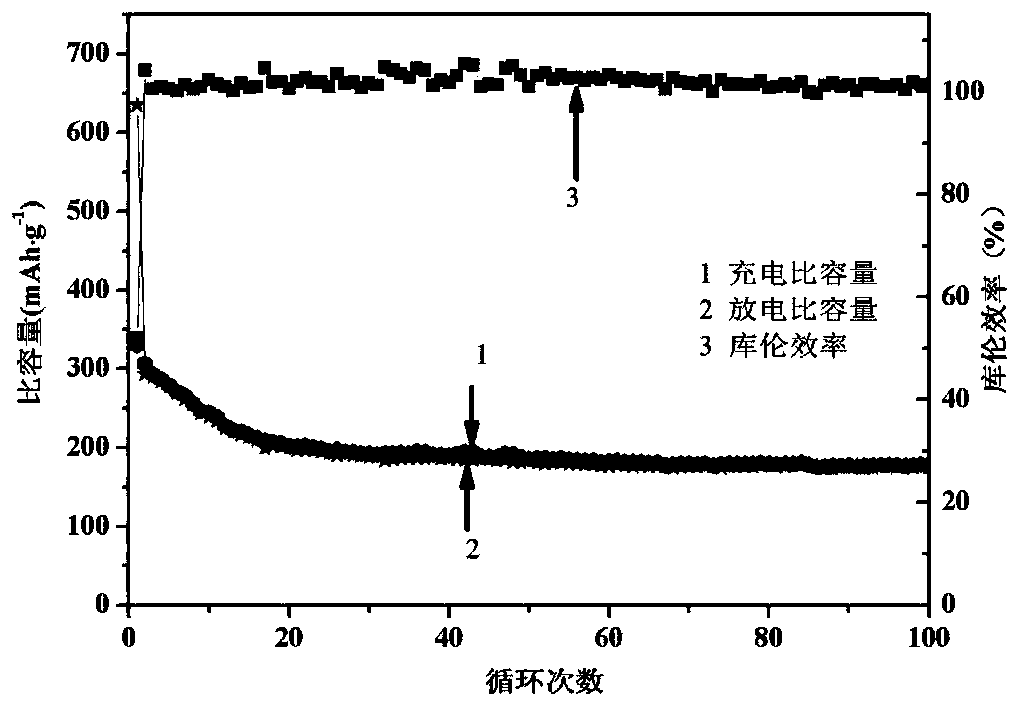

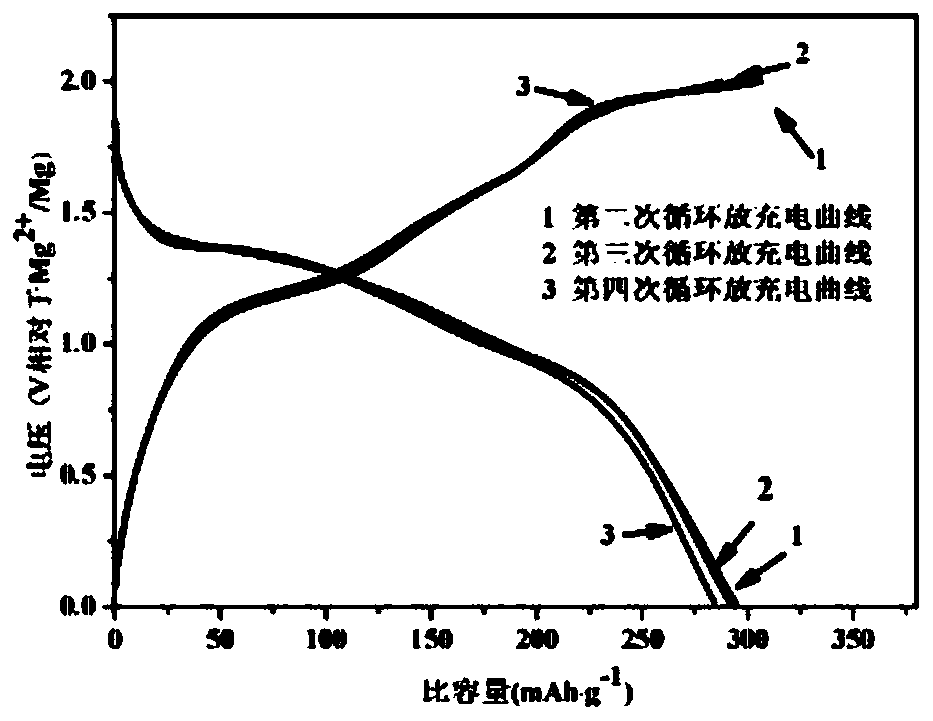

Magnesium-lithium double-ion battery composite cathode material, preparation method and application thereof, and battery system

ActiveCN109755553ASimple structureComplete structureMaterial nanotechnologyCell electrodesElectrochemical responseHigh current density

The invention provides a magnesium-lithium double-ion battery composite cathode material, a preparation method and application thereof, and a battery system, and belongs to the field of magnesium ionbatteries. In the magnesium-lithium double-ion battery composite cathode material, a polyaniline layer has a protective effect on the composite cathode material, and PANI-coated VS4 / rGO is higher in conductivity and of a more complete structure, which is favorable for achieving charging and discharging under a large current density; a PANI conductive layer does not participate in electrochemical reaction, and coats the surface of VS4 to improve the conductivity of VS4, and can well adapt to the charging and discharging process under the high current density; meanwhile, the PANI layer reduces the loss of active substances in the core VS4 during charging and discharging, thus maintaining the structural integrity; and the PANI layer allows VS4 to better adapt to the volume change caused by the intercalation and deintercalation of Mg<2+> and Li<+>, and reduces the loss of the active substances on a current collector, thereby significantly increasing the stable cycle capacity of the cathodematerial.

Owner:BEIHANG UNIV

Functional nanocellulose-boron nitride composite film and preparation method thereof

ActiveCN109971020AReduce the number of layersImprove thermal conductivityCoatingsComposite filmFiltration

The invention discloses a functional nanocellulose-boron nitride composite film. A deposition layer is formed after suction filtration of a nanocellulose / boron nitride dispersion liquid on a mixed cellulose ester micro-porous filter membrane, and the deposition layer is hot-pressed and dried to form the inner layer of the composite film; and the inner layer of the composite film is a nanocellulose-boron nitride composite monolayer structure containing 1-7 wt% of boron nitride. The invention also discloses a preparation method of the composite film. The preparation method comprises: (1) mixing,stirring and ultrasonically crushing a nanocellulose dispersion and a boron nitride dispersion to obtain the nanocellulose-boron nitride dispersion; and (2) placing the obtained dispersion on the mixed cellulose ester filter membrane, carrying out vacuum suction filtration to form the deposition layer, removing the mixed cellulose ester filter membrane, and hot-pressing and drying the depositionlayer to obtain the inner layer of the composite film. The composite film provided by the invention has a high heat conduction coefficient and a high hydrophobic insulation performance, and can be widely used in the fields of electronic devices and biomaterials.

Owner:SHANGHAI UNIV

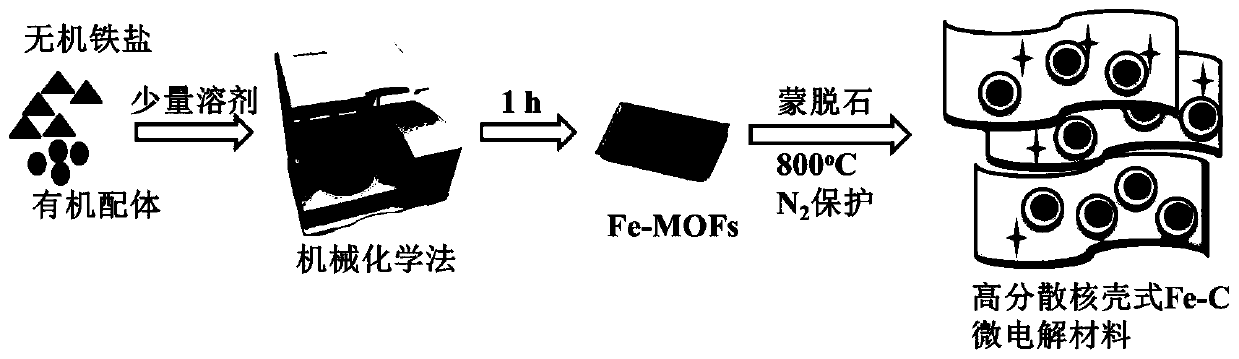

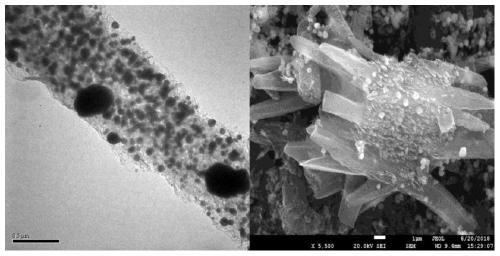

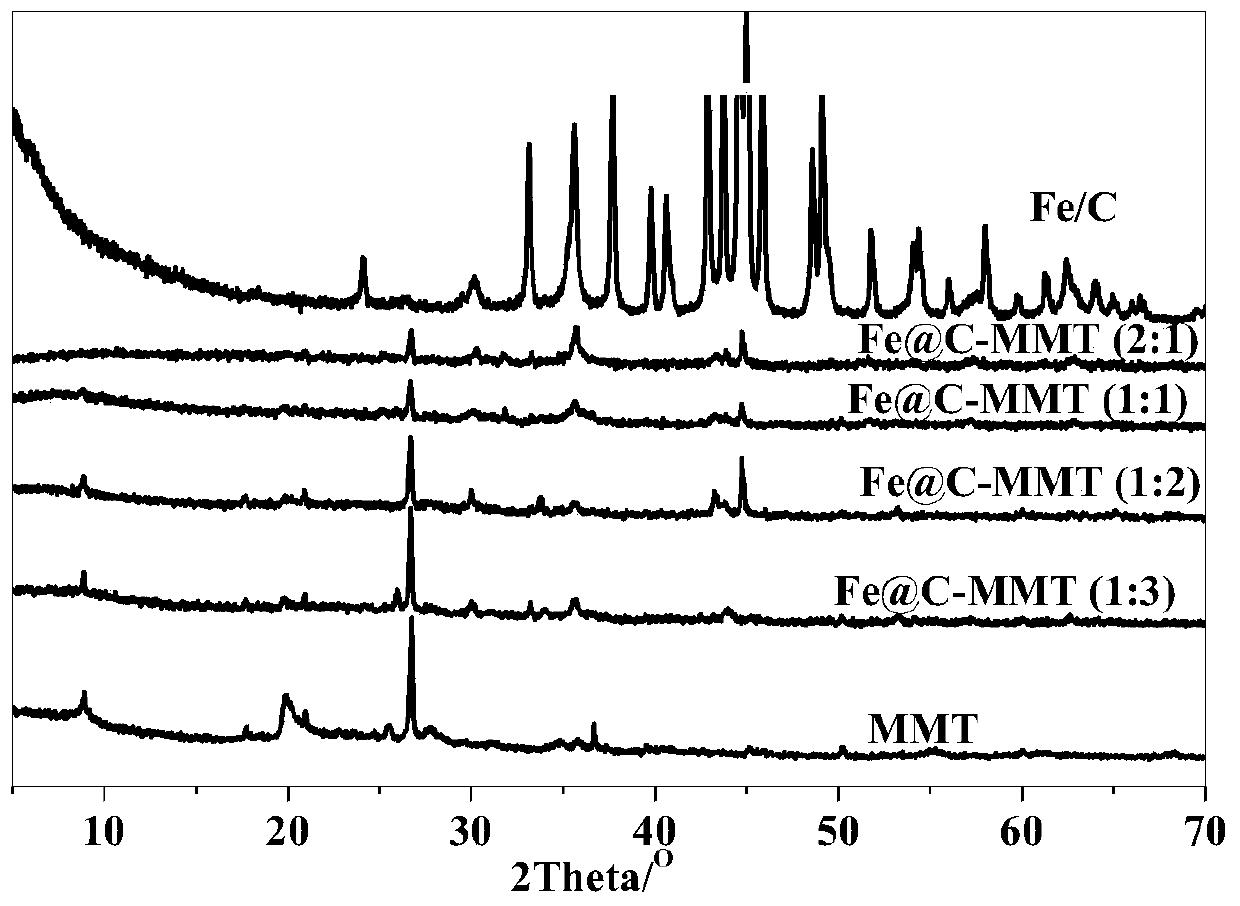

Preparation method and applications of iron-carbon micro-electrolysis material for maintaining long-term catalytic activity of Fenton system

ActiveCN110252305AIncrease profitIncrease loadMaterial nanotechnologyWater treatment compoundsElectrolysisDecomposition

The invention provides a preparation method and applications of an iron-carbon micro-electrolysis material for maintaining the long-term catalytic activity of a Fenton system. According to the present invention, the catalyst is derived from an iron metal organic framework (Fe-MOFs) and montmorillonite; after Fe-MOFs prepared by a mechanochemical method are mixed with montmorillonite, high temperature carbonizing is performed to form a core-shell type iron-carbon filler micro-electrolysis material (Fe@C-MMT) dispersed between the montmorillonite sheet structures; the inefficient decomposition of hydrogen peroxide can be delayed by highly dispersing the Fe@C-MMT material in the water sample, and the hydroxyl radicals are selectively generated, such that the hydrogen peroxide in the system has long-term oxidation ability; the catalyst has a certain pH value adjustment ability, wherein organic pollutants can be efficiently degraded when the initial pH value is 3-6.5; and the catalyst has good stability, can be reused multiple times, and is suitable for removing refractory organic pollutants such as phenol, methyl orange and the like in environmental water samples by advanced oxidation technology Fenton reactions.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

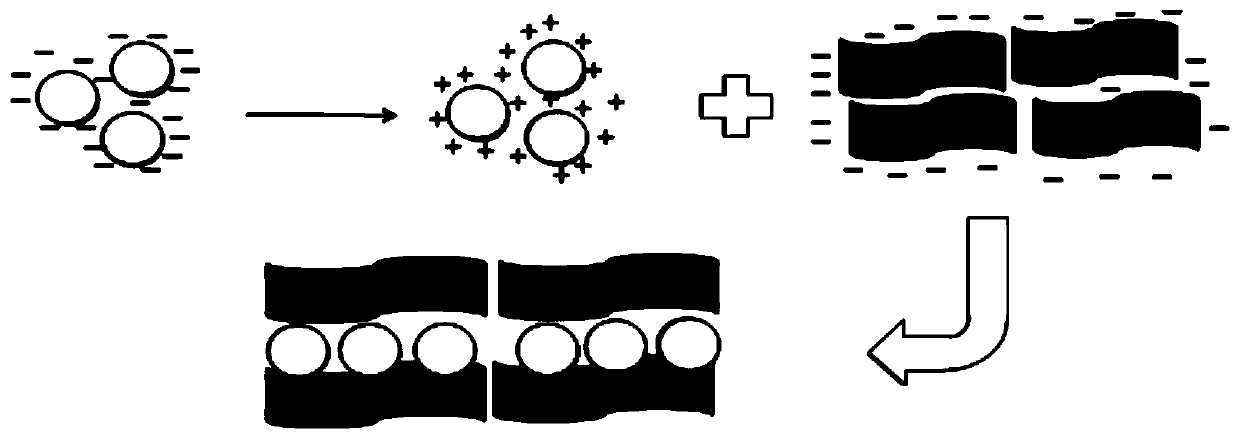

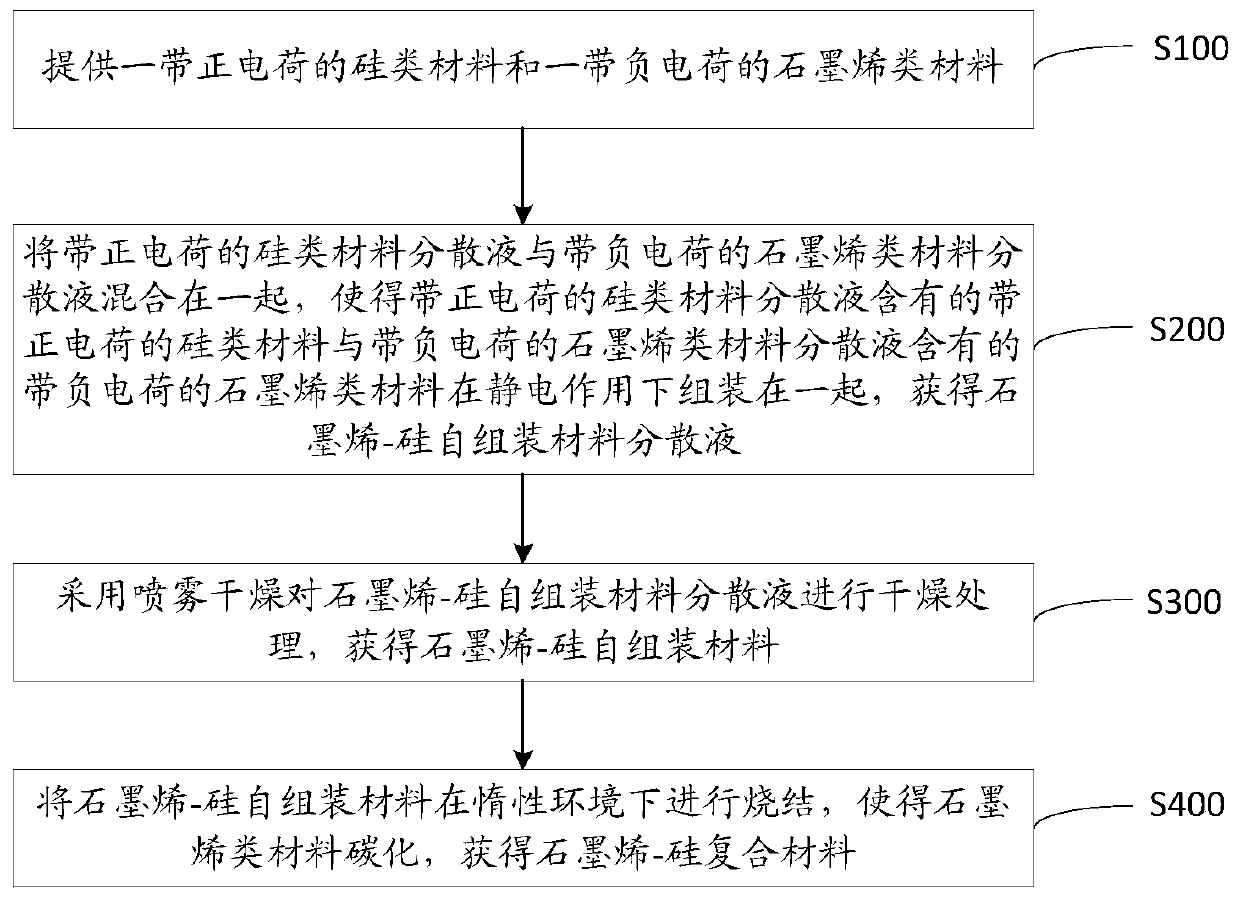

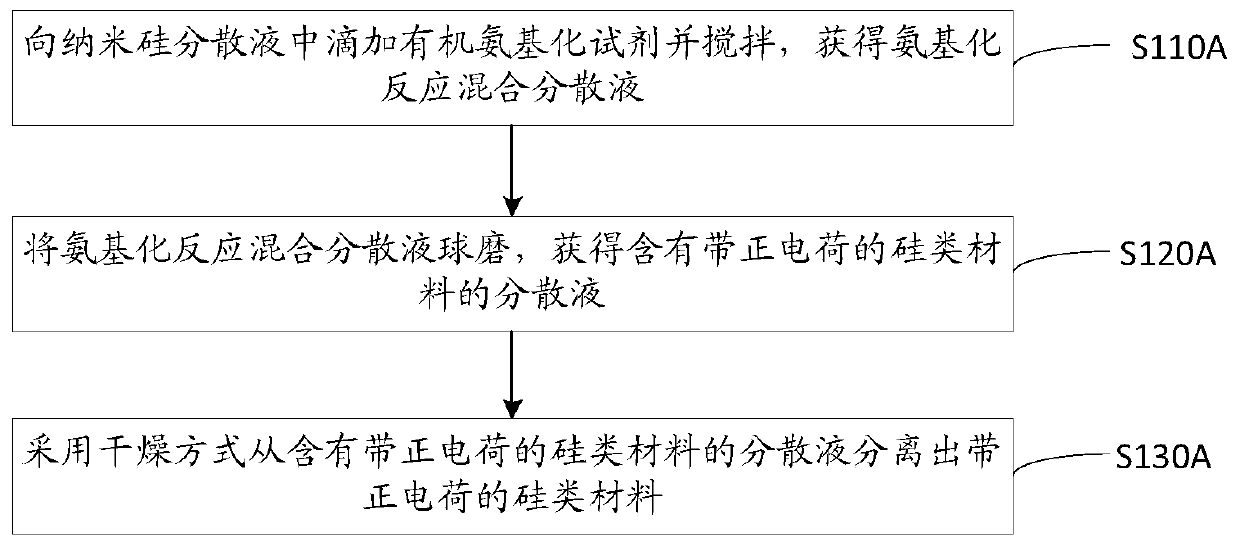

Graphene-silicon composite material, preparation method thereof, electrode material and battery

ActiveCN110112408AImprove structural strengthFast evaporationMaterial nanotechnologyNegative electrodesCvd grapheneStructural stability

The invention discloses a graphene-silicon composite material, a preparation method thereof, an electrode material and a battery and relates to the technical field of batteries so as to improve the structural stability of an electrode containing a silicon-based material, and therefore, the cycle performance of the battery is ensured. The preparation method of the graphene-silicon composite material comprises a step of mixing positively-charged silicon-based material dispersion liquid with a negatively-charged graphene-based material dispersion liquid such that a positively-charged silicon-based material and a negatively-charged graphene-based material are assembled together to obtain a graphene-silicon self-assembled material dispersion liquid, a step of drying the a graphene-silicon self-assembled material dispersion liquid by using spray drying to obtain a graphene-silicon self-assembled material, and a step of sintering the graphene-silicon self-assembled material in an inert environment to obtain the graphene-silicon composite material. The graphene-silicon composite material is prepared by the above preparation method. The graphene-silicon composite material provided by the invention is applied to the battery.

Owner:内蒙古信敏惠纳米科技有限公司

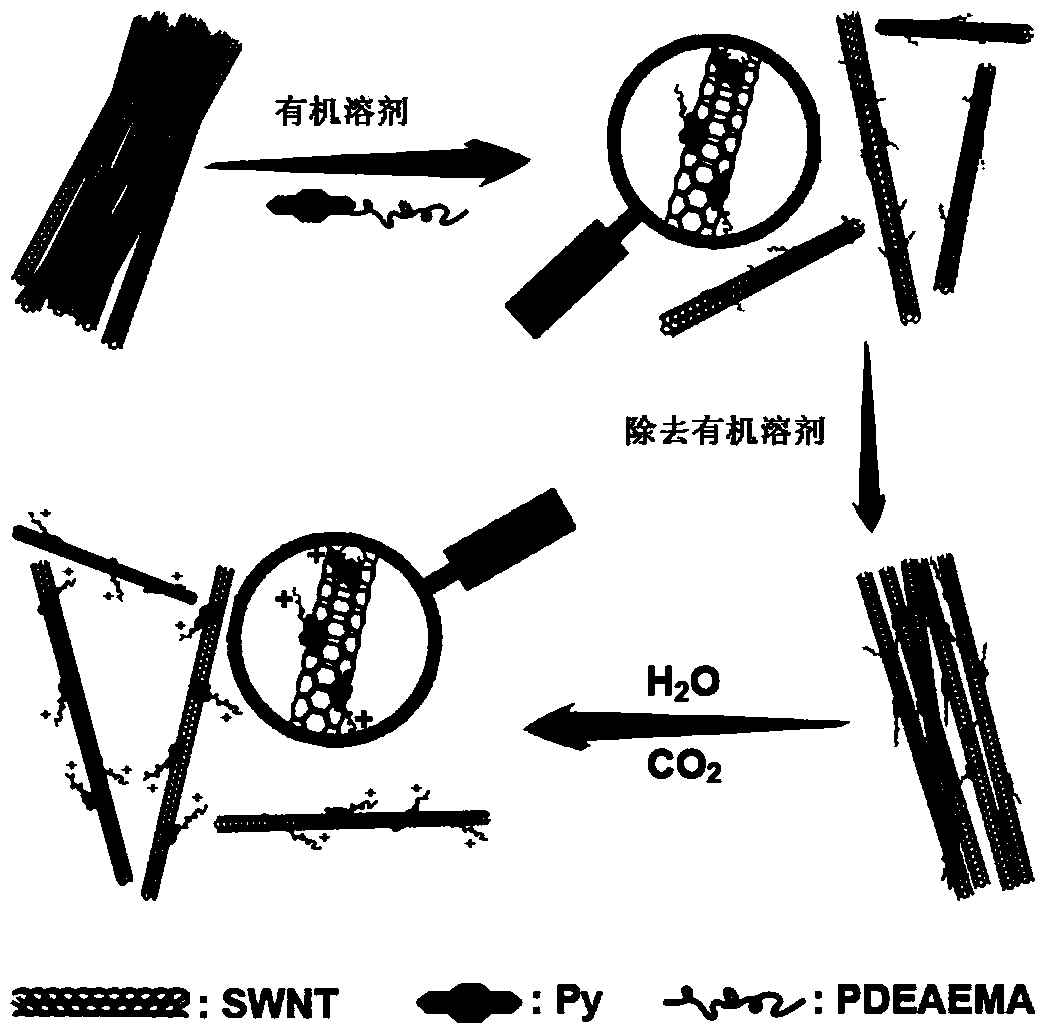

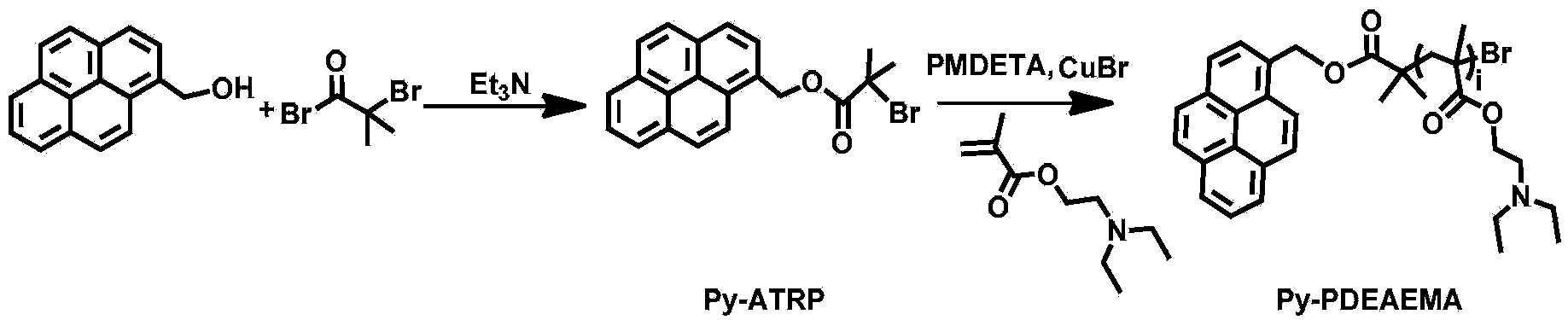

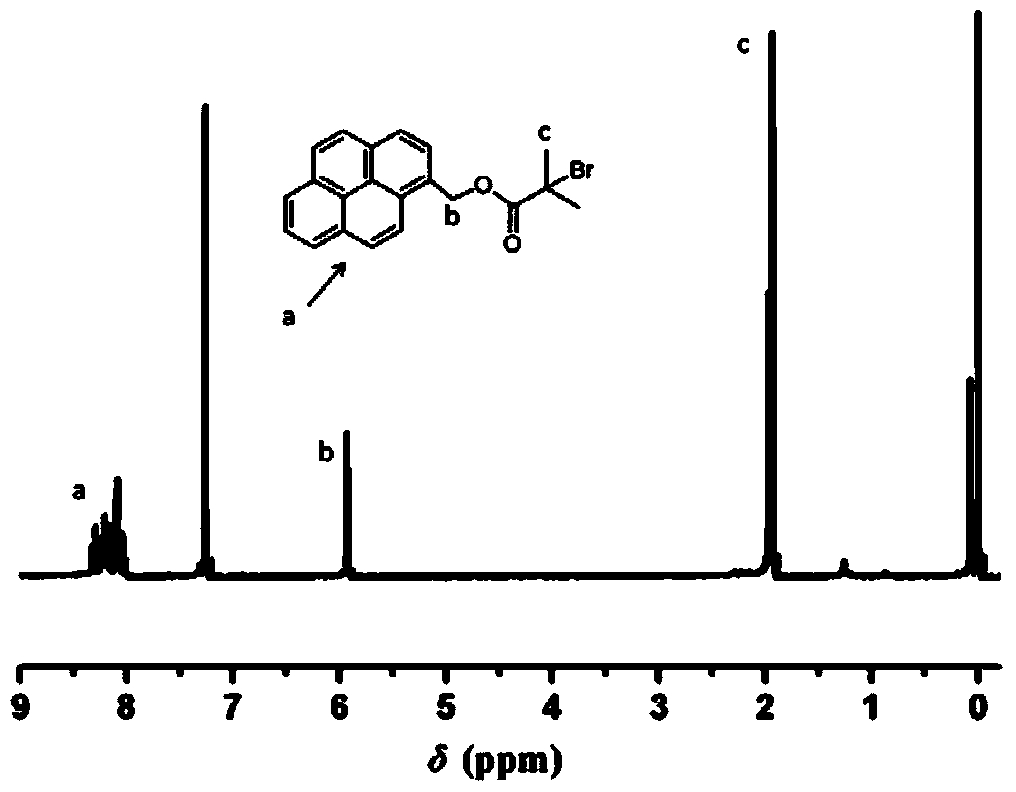

Dispersion method of single-walled carbon nanotube

InactiveCN104140483AEffective dispersionSimple methodMaterial nanotechnologyPolymer scienceOrganic solvent

The invention discloses a dispersion method of a single-walled carbon nanotube. The invention provides a polymer shown in the formula I, and a preparation method of the polymer. In the formula I, i is a natural number between 20 and 150. The dispersion of the single-walled carbon nanotube in an organic solvent can be realized by mixing the polymer shown in the formula I and the single-walled carbon nanotube in an organic solvent. On the basis, a complex of the polymer shown in the formula I and the single-walled carbon nanotube can be obtained after the organic solvent is removed, and the dispersion of the single-walled nanotub in water can be realized by adding the complex into water and introducing CO2 gas. A polymer chain can be ensured to take effect with only one carbon tube by using a pyrene group-containing ATRP initiator (a compound shown in the formula II); the single-walled carbon nanotube can be dispersed by utilizing the polymer shown in the formula I and CO2, so that the carbon tube can be dispersed into the organic solvent and water; and the method is simple, convenient and easy, and mild in conditions; the SWNT dispersed by utilizing the method cannot be agglomerated, can be evenly dispersed, and can be used for further functionalization or industrial processing.

Owner:TSINGHUA UNIV

Modified adhesive

ActiveCN104293248AInhibit sheddingImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesBenzoyl peroxideGlutaric acid

The invention discloses an adhesive and particularly relates to a modified adhesive. The modified adhesive consists of the following raw materials in parts by weight: 70-95 parts of elastic rubber, 25-35 parts of phthalic anhydride, 7-11 parts of furfuryl alcohol extracted from natural plant, 10-12 parts of triethylene glycol, 15-18 parts of glutaric acid, 8-10 parts of butantriol, 5-7 parts of zinc oxide powder, 3-5 parts of magnesium oxide, 15-25 parts of chloroprene rubber, 2-3 parts of softening oil, 15-20 parts of dimethyl carbonate, 1-3 parts of benzoyl peroxide, 4-8 parts of ethyl acetate, 1-4 parts of an emulsifier, 20-30 parts of flour, 5*10<-5>-9*10<-5> parts of nano sliver, 1-3 parts of a flame retardant, 0.8-2.5 parts of a catalyst, 3-7 parts of a bamboo vinegar aqueous liquid, 6-13 parts of bamboo carbon powder with grain size of 0.01-0.06mm, wherein the bamboo vinegar aqueous liquid is a mixed liquid of bamboo vinegar, a chelating agent and water in a weight ratio of 1 to (0.1-0.2) to (60-100); the bamboo carbon powder is prepared by the steps such as raw material pre-treatment, primary carbon preparation, activation treatment and pelletizing; the elastic rubber comprises first elastic rubber and second elastic rubber mixed in a weight ratio of (1-3) to 1. The adhesive has good antibacterial activity, stability and adhesion property.

Owner:安吉竹印象家居用品有限公司

Wool, cashmere/bamboo charcoal fiber blended fabric manufacturing method

InactiveCN104695109AIntensify the effect of warmingReduce churnFibre treatmentWoven fabricsPolyesterPolymer science

The invention discloses a wool, cashmere / bamboo charcoal fiber blended fabric manufacturing method. The method includes: selecting warp and weft materials comprising, by weight, 15-20 parts of tencel, 30-50 parts of wool, 20-30 parts of cashmere, 15-20 parts of ceiba, 20-30 parts of vegetable protein regenerated cellulose fibers, 10-18 parts of modal fibers, 40-90 parts of viscose, 8-15 parts of bamboo charcoal fibers, 60-95 parts of cotton fibers and 8-18 parts of super-fine denier polyester. The weaving process includes: warping, boiling to be finalized, slashing, after finishing and jet operating. For after finishing, fabric is subjected to after finishing by a working solution containing 20-40g / L capsicum tincture extract finishing agents, 15-20g / L nonionic organic silicon softeners and 30-60g / L nano ceramic powder dispersion agents, and an after-finishing method refers to a dipping treatment method or an impregnation method.

Owner:SUZHOU CHENHENG WEAVING

High-concentration high-stability transitional metal chalcogen compound printing ink for ink jet printing and preparation method of printing ink

InactiveCN108410265AInhibition of agglomerationReunion won't happenInksHigh concentrationPrinting ink

The invention belongs to the technical field of two-dimensional material preparation, and particularly relates to high-concentration high-stability transitional metal chalcogen compound printing ink for ink jet printing and a preparation method of the printing ink. Specific to the problem that as current transitional metal chalcogen compound nano sheet printing ink is low in concentration and poorin stability, the use and storage are inconvenient, the technical scheme of the invention is characterized in that the preparation method comprises the following steps: [1] selecting two kinds of stripping solvents, and preparing a binary good solvent system; [2] adding a water-soluble high-molecular compound into the binary good solvent system to obtain a mixed solvent; [3] stripping a nano sheet of a transitional metal chalcogen compound from transitional metal chalcogen compound powder by using an ultrasound stripping method; [4] performing centrifugal separation, and taking supernate, i.e., transitional metal chalcogen compound nano sheet dispersion liquid; and [5] adding a conditioning agent with a physical property to obtain the transitional metal chalcogen compound printing ink. The transitional metal chalcogen compound printing ink is suitable for the ink jet printing of a transitional metal chalcogen compound two-dimensional material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com