Dispersion method of single-walled carbon nanotube

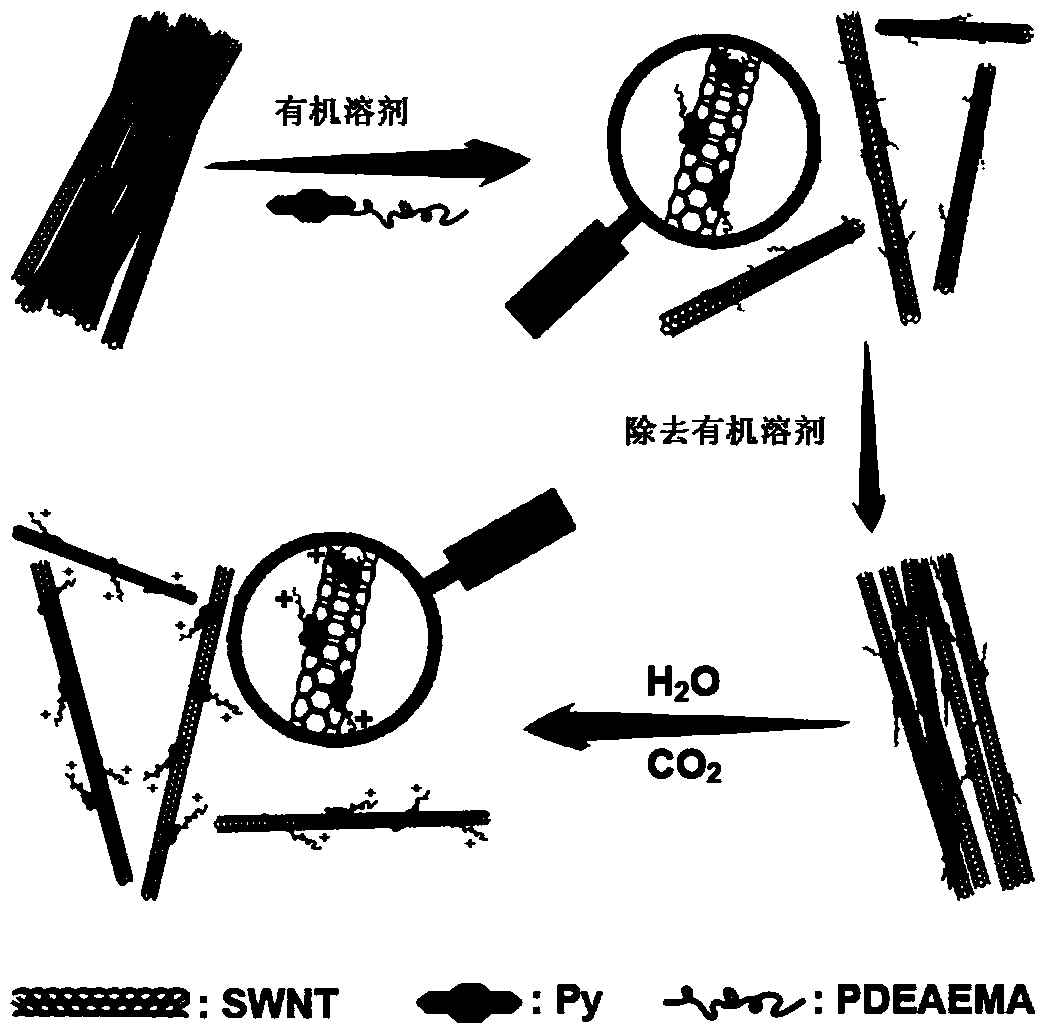

A single-walled carbon nanotube, dispersion technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of limited dispersion, limited application, poor solubility, etc., and achieve mild conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

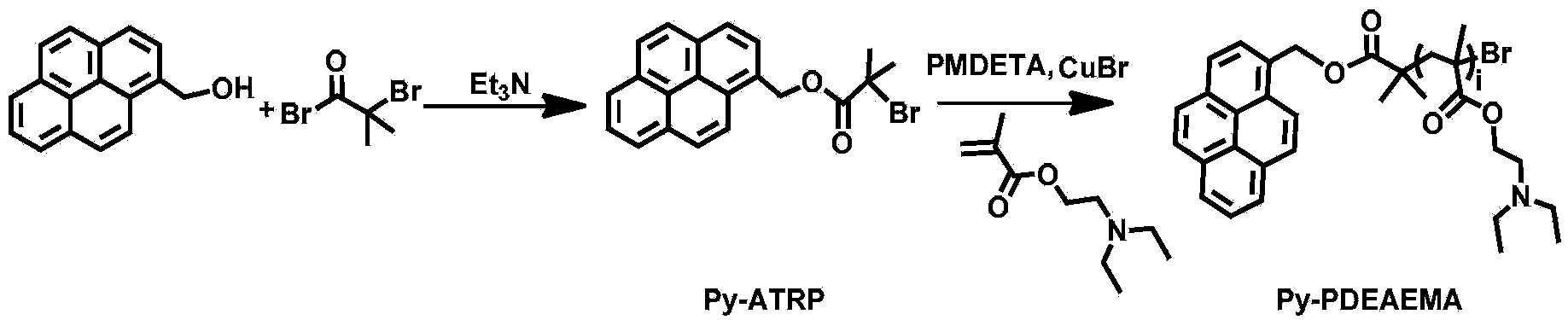

[0060] (1) Synthesis of Py-PDEAEMA

[0061] Flowchart such as figure 2 shown.

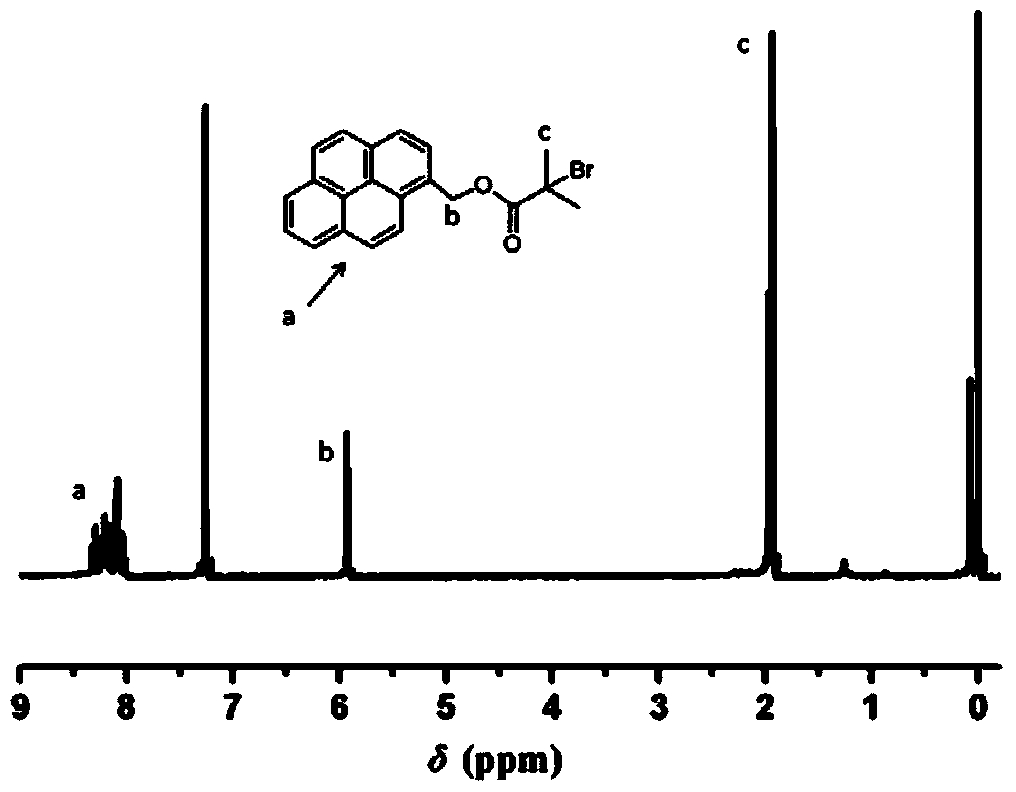

[0062] a. Put 116mg of 1-pyrene methanol into a 25mL reaction flask, add 5mL of dry THF, 152mg of triethylamine (Et 3 N), stirring to dissolve, ice bathing, dissolving 345mg of bromoisobutyryl bromide in 5mL of dry THF, putting it in the dropping funnel and adding it to the reaction system dropwise, after 20min the addition was completed, a white solid was formed, at 25°C The reaction was stirred for 1 day. After the reaction is finished, filter, transfer the filtrate to a separatory funnel, add 60mL of dichloromethane, extract with saturated ammonium chloride solution, saturated sodium bicarbonate solution and saturated sodium chloride solution respectively, separate the liquids, and wash the organic phase with anhydrous Dried over magnesium sulfate, filtered, concentrated, and column chromatographed (petroleum ether:dichloromethane=3:1, volume ratio) to obtain 0.37 g of the target product Py-A...

Embodiment 2

[0076] (1) Synthesis of Py-PDEAEMA

[0077] a and b steps are the same as in Example 1.

[0078] (2) Disperse single-walled carbon nanotubes in ethyl acetate

[0079] Put 10mg of Py-PDEAEMA into a 25mL single-necked flask, add 10mL of ethyl acetate, fully dissolve, add 1mg of SWNTs, ultrasonic 30min, SWNTs are evenly dispersed in ethyl acetate, the polymer concentration is 1mg / mL, and the concentration of SWNTs is 0.1 mg / mL SWNTs homogeneously dispersed ethyl acetate solution.

[0080] (3) Disperse single-walled carbon nanotubes in water

[0081] The ethyl acetate solution of the polymer / SWNTs composite was spin-dried and vacuum-dried to obtain a solid polymer / SWNTs composite.

[0082] The Raman spectrum of the polymer / SWNTs composite prepared in this example and the Raman spectrum of the polymer / SWNTs composite in Example 1 ( Figure 8 ) has no substantial difference, it can be known that there is a strong π-π interaction between the pyrene group in Py-PDEAEMA and SWNTs c...

Embodiment 3

[0086] (1) Synthesis of Py-PDEAEMA

[0087] a. Put 348mg of pyrenemethanol into a 50mL reaction flask, add 15mL of dry THF, 456mg of triethylamine (Et3N), stir to dissolve, put in an ice bath, dissolve 1035mg of bromoisobutyryl bromide in 15mL of dry THF, place in the drop The reaction system was added dropwise into the liquid funnel, and after 15 minutes of completion of the dropwise addition, a white solid was formed, and the reaction was stirred at room temperature for 0.5 days. After the reaction, filter, transfer the filtrate to a separatory funnel, add 150mL of dichloromethane, extract with saturated ammonium chloride solution, saturated sodium bicarbonate solution and saturated sodium chloride solution respectively, separate the liquid, and wash the organic phase with anhydrous Dried over magnesium sulfate, filtered, concentrated, and column chromatographed (petroleum ether:dichloromethane=3:1), the target product Py-ATRP was obtained 1.12g, yield: 98%.

[0088] b. Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com