LED fluorescent glue and packaging method for improving luminescence uniformity, and LED

A technology of uniform light emission and packaging method, which is applied to LED. It can solve the problems of poor density between phosphor and colloid, uneven dispersion of phosphor, and poor product performance, and achieve good chemical stability, uniform white light spot, and small specific gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

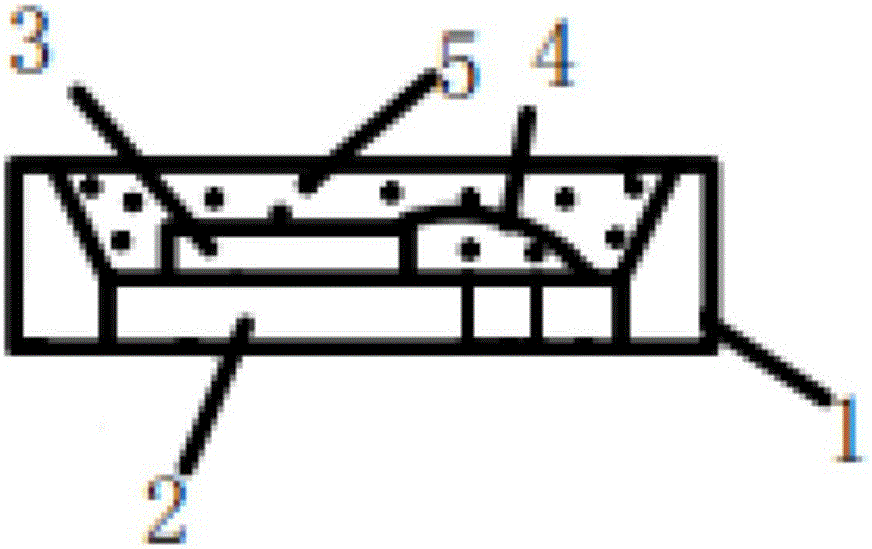

Image

Examples

Embodiment 1

[0029] This embodiment provides a LED fluorescent glue that improves the uniformity of light emission. In parts by weight, the fluorescent glue consists of 1 part of packaging glue, 0.01 part of phosphor powder, 0.01 part of silica-based inorganic nanoparticles, and 0.01 part of organic silicon particles. composition, wherein the fluorescent powder is a silicate fluorescent powder, the silica-based inorganic nanoparticles are fumed silica with a particle diameter of 5nm, and the organosilicon particles are polysiloxane-based organosilicon particles. The example is methyl silicone resin, the particle size is micron order, and the refractive index is less than 1.45.

[0030] This embodiment also provides an LED packaging method for improving luminous uniformity, comprising the following steps:

[0031] a. Solid crystal, fix the light-emitting chip on the bottom of the package cavity of the LED bracket with the crystal-bonding material silver glue, and then perform wire bonding t...

Embodiment 2

[0037] This embodiment provides a LED fluorescent glue that improves the uniformity of light emission. In parts by weight, the fluorescent glue consists of 1 part of packaging glue, 0.5 part of phosphor powder, 0.06 part of silica-based inorganic nanoparticles, and 0.5 part of organic silicon particles. composition, wherein the fluorescent powder is aluminate fluorescent powder, the silica-based inorganic nanoparticles are fumed silica with a particle diameter of 25nm, and the organosilicon particles are polysiloxane-based organosilicon particles. The example is low phenylmethyl silicone resin, the particle size is micron order, and the refractive index is less than 1.45.

[0038] This embodiment also provides an LED packaging method for improving luminous uniformity, comprising the following steps:

[0039] a. Die-bonding, fix the light-emitting chip on the bottom of the package cavity of the LED bracket with the solder paste of the crystal-bonding material, and then perform ...

Embodiment 3

[0045] This embodiment provides a LED fluorescent glue that improves the uniformity of light emission. In parts by weight, the fluorescent glue consists of 1 part of packaging glue, 1 part of phosphor powder, 0.1 part of silica-based inorganic nanoparticles, and 1 part of organic silicon particles. Composition, wherein the fluorescent powder is a mixture of nitride fluorescent powder and nitrogen oxide fluorescent powder, the silica-based inorganic nanoparticles are fumed silica with a particle size of 50nm, and the organosilicon particles are polysiloxane The silicone-like particles, in this embodiment, are low-phenylmethyl silicone resins, the particle size is micron order, and the refractive index is less than 1.45.

[0046] This embodiment also provides an LED packaging method for improving luminous uniformity, comprising the following steps:

[0047] a. Die-bonding, the flip-chip light-emitting chip is fixed on the bottom of the package cavity of the LED bracket with sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com