Preparation method of shock-resistant STF (shear thickening fluid) gel

An anti-shock and liquid technology, which is applied in the preparation of anti-shock shear thickening liquid gel and the field of material preparation, can solve the problem of easy sedimentation and instability of shear thickening liquid, and achieve good shear thickening effect, Improved stability, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method for impact-resistant shear thickening liquid gel, comprising the steps of:

[0021] (1) Weigh 0.5g of acrylic acid, add 4.5g of β-hydroxyethyl acrylate into a 100ml beaker and stir well.

[0022] (2) Weigh 20g of STF liquid (such as polyethylene glycol suspension containing nano-silica particles), add it to the mixture of acrylic acid and β-hydroxyethyl acrylate, and stir evenly.

[0023] (3) Add 0.06g of dibenzoyl peroxide and 0.02g of N,N-dimethylaniline into the above mixture, stir evenly, and control the reaction temperature at 20°C.

[0024] (4) Stand still until the reaction mixture stops flowing, and STF gel is formed after about half an hour.

[0025] (5) A uniformly dispersed shear-thickening gel can be prepared by the above method.

Embodiment 2

[0027] A preparation method for impact-resistant shear thickening liquid gel, comprising the steps of:

[0028] (1) Weigh 0.5 g of polyethylene glycol (400) diacrylate, add 5 g of isooctyl acrylate into a 100 ml beaker and stir evenly.

[0029] (2) Weigh 20g of STF liquid (such as polyethylene glycol suspension containing nano-silica particles), add it to the mixture of acrylic acid and β-hydroxyethyl acrylate, and stir evenly.

[0030] (3) Add 0.07 g of benzoyl peroxide into the above mixture, stir evenly, and control the reaction temperature at 40°C.

[0031] (4) Stand still until the reaction mixture no longer flows to form STF gel.

[0032] (5) A uniformly dispersed shear-thickening gel can be prepared by the above method.

Embodiment 3

[0034] A preparation method for impact-resistant shear thickening liquid gel, comprising the steps of:

[0035] (1) Weigh 0.7 g of acrylic acid, 4.4 g of a mixture of equal weights of β-hydroxyethyl acrylate and isooctyl acrylate, add it into a 100 ml beaker and stir evenly.

[0036] (2) Weigh 22g of STF liquid (such as polyethylene glycol suspension containing nano-silica particles), add it to the mixture of acrylic acid and β-hydroxyethyl acrylate, and stir evenly.

[0037] (3) Add 0.06 g of azobisisobutyronitrile into the above mixture, stir evenly, and control the reaction temperature at 30°C.

[0038] (4) Stand still until the reaction mixture no longer flows to form STF gel.

[0039] (5) A uniformly dispersed shear-thickening gel can be prepared by the above method.

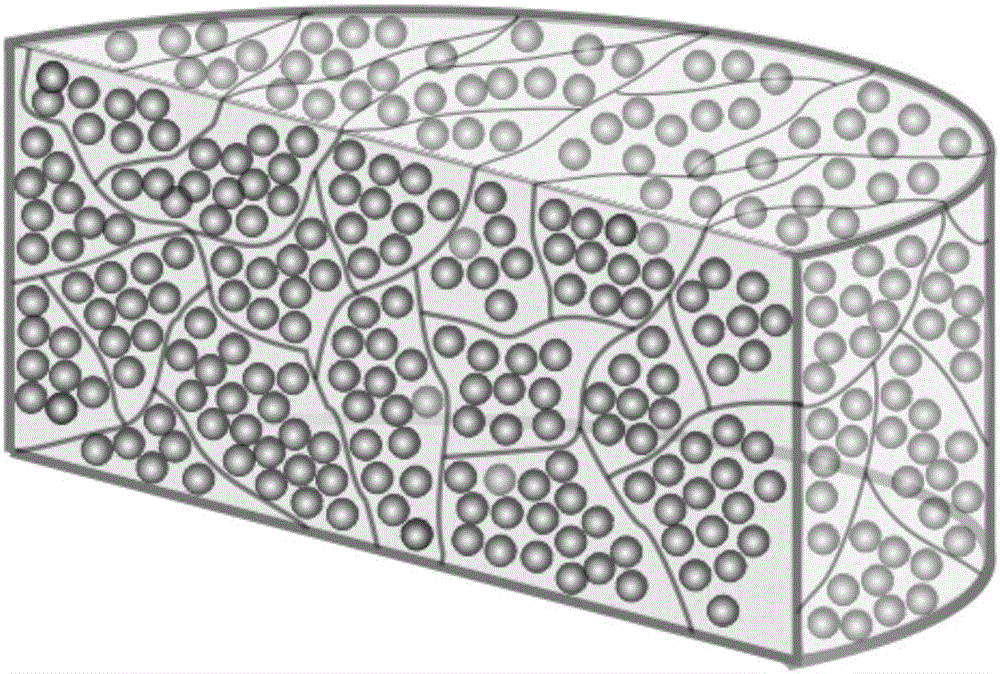

[0040] The schematic diagram of the STF gel structure prepared by the embodiment of the present invention is as attached figure 1 shown, from the attached figure 1 It can be seen that the shear-thickeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com