A kind of preparation method and application of phosphorus-nitrogen synergistic flame retardant polymer polyol

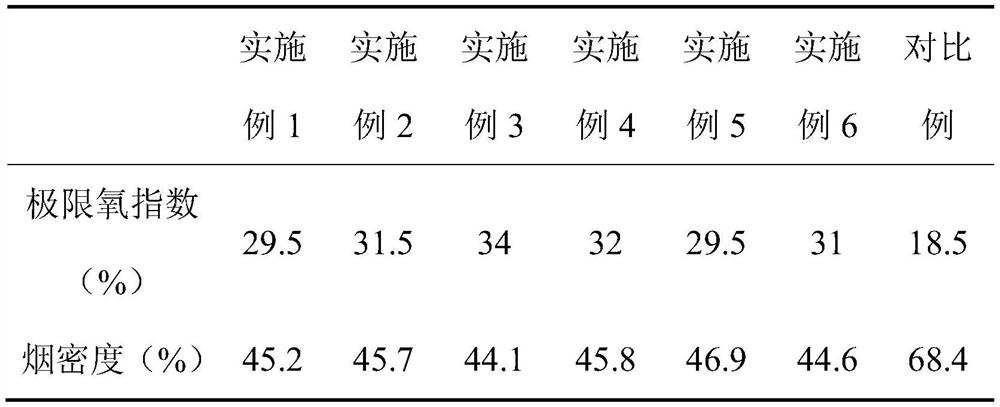

A technology of synergistic flame retardant and polymer, which is applied in the preparation of phosphorus-nitrogen synergistic flame retardant polymer polyol and the application field of polyurethane foam synthesis, which can solve the problems of uneven distribution of flame retardants, poor flame retardant effect and easy loss. , to achieve the effect of good flame retardant effect, overcoming easy sedimentation and low smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Under a nitrogen atmosphere, 115.8g of hexachlorocyclotriphosphazene was dissolved in 579g of tetrahydrofuran, 201g of triethylamine and 78g of n-propylamine were added to the above solution, and the reaction was carried out at -50°C for 10h; then 40g of ethylenediamine was added Into the solution, react at 50°C for 10h, finally filter to obtain a colorless and transparent solution, and distill at high temperature to obtain a white solid phosphazene compound.

[0037] 157g of phosphazene compound and 43g of terephthalaldehyde were added to 800g of polyether polyol 1, and the reaction was carried out at 80 °C for 5 hours; then the pressure was -0.098MPa~-0.08MPa, and the temperature was 110 °C under the conditions of vacuum removal Residual monomers were used to obtain a phosphorus-nitrogen synergistic flame retardant polymer polyol with a viscosity of 1953 mP·s / 25°C.

Embodiment 2

[0039] Under a nitrogen atmosphere, 156.7g of hexachlorocyclotriphosphazene was dissolved in 784g of dioxane, 213g of pyridine and 98g of n-butylamine were added to the above solution, and the reaction was performed at -20°C for 5h; then 100g of 1, 3-Propanediamine was added to the solution, reacted at 30 °C for 20 h, and finally filtered to obtain a colorless and transparent solution, which was distilled at high temperature to obtain a white solid phosphazene compound.

[0040] 231g of phosphazene compound and 69g of adipaldehyde were added to 700g of polyether polyol 1, and the reaction was carried out at 100 °C for 3 hours; then the pressure was -0.098MPa~-0.08MPa, and the temperature was 110 °C under the conditions of vacuum to remove the residual Monomer to obtain a phosphorus-nitrogen synergistic flame retardant polymer polyol with a viscosity of 2371 mP·s / 25°C.

Embodiment 3

[0042] Under a nitrogen atmosphere, 245.5g of hexachlorocyclotriphosphazene was dissolved in 1227g of acetone, 427.5g of triethylamine and 127g of dimethylamine were added to the above solution, and reacted at -10°C for 4h; then 124g of 1, 4-Butanediamine was added to the solution, reacted at 50°C for 10 hours, and finally filtered to obtain a colorless and transparent solution, which was distilled at high temperature to obtain a white solid phosphazene compound.

[0043] 332g of phosphazene compound and 68g of glutaraldehyde were added to 600g of polyether polyol 2, and the reaction was carried out at 50 °C for 10 h; then the residual pressure was removed by vacuuming under the conditions of -0.098MPa ~ -0.08MPa and temperature of 120 °C. Monomers were used to obtain a phosphorus-nitrogen synergistic flame retardant polymer polyol with a viscosity of 5830 mP·s / 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com