A kind of preparation method of anti-shock thickening liquid gel

An impact-resistant and liquid-resistant technology, which is applied in the preparation of materials and the preparation of impact-resistant shear-thickening liquid gels, can solve the problems of easy sedimentation and instability of shear-thickening liquids, and achieve good shear-thickening effects, Improved stability and good stability of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method for impact-resistant shear thickening liquid gel, comprising the steps of:

[0021] (1) Weigh 0.5g of acrylic acid, add 4.5g of β-hydroxyethyl acrylate into a 100ml beaker and stir well.

[0022] (2) Weigh 20g of STF liquid (such as polyethylene glycol suspension containing nano-silica particles), add it to the mixture of acrylic acid and β-hydroxyethyl acrylate, and stir evenly.

[0023] (3) Add 0.06g of dibenzoyl peroxide and 0.02g of N,N-dimethylaniline into the above mixture, stir evenly, and control the reaction temperature at 20°C.

[0024] (4) Stand still until the reaction mixture stops flowing, and STF gel is formed after about half an hour.

[0025] (5) A uniformly dispersed shear-thickening gel can be prepared by the above method.

Embodiment 2

[0027] A preparation method for impact-resistant shear thickening liquid gel, comprising the steps of:

[0028] (1) Weigh 0.5 g of polyethylene glycol (400) diacrylate, add 5 g of isooctyl acrylate into a 100 ml beaker and stir evenly.

[0029] (2) Weigh 20g of STF liquid (such as polyethylene glycol suspension containing nano-silica particles), add it to the mixture of acrylic acid and β-hydroxyethyl acrylate, and stir evenly.

[0030] (3) Add 0.07 g of benzoyl peroxide into the above mixture, stir evenly, and control the reaction temperature at 40°C.

[0031] (4) Stand still until the reaction mixture no longer flows to form STF gel.

[0032] (5) A uniformly dispersed shear-thickening gel can be prepared by the above method.

Embodiment 3

[0034] A preparation method for impact-resistant shear thickening liquid gel, comprising the steps of:

[0035] (1) Weigh 0.7 g of acrylic acid, 4.4 g of a mixture of equal weights of β-hydroxyethyl acrylate and isooctyl acrylate, add it into a 100 ml beaker and stir evenly.

[0036] (2) Weigh 22g of STF liquid (such as polyethylene glycol suspension containing nano-silica particles), add it to the mixture of acrylic acid and β-hydroxyethyl acrylate, and stir evenly.

[0037] (3) Add 0.06 g of azobisisobutyronitrile into the above mixture, stir evenly, and control the reaction temperature at 30°C.

[0038] (4) Stand still until the reaction mixture no longer flows to form STF gel.

[0039] (5) A uniformly dispersed shear-thickening gel can be prepared by the above method.

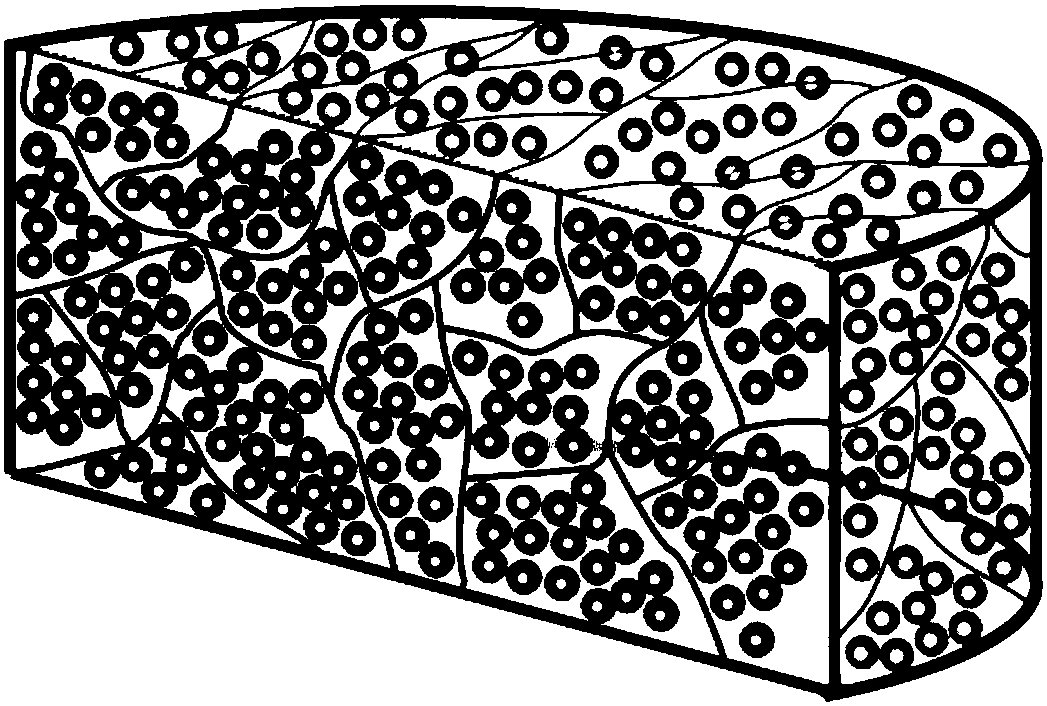

[0040] The schematic diagram of the STF gel structure prepared by the embodiment of the present invention is as attached figure 1 shown, from the attached figure 1 It can be seen that the shear-thickeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com