Patents

Literature

1093 results about "N-butyl acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In rodent models, butyl acrylate is metabolized by carboxylesterase or reactions with glutathione; this detoxification produces acrylic acid, butanol, and mercapturic acid waste, which is excreted in the urine, feces, and as carbon dioxide.

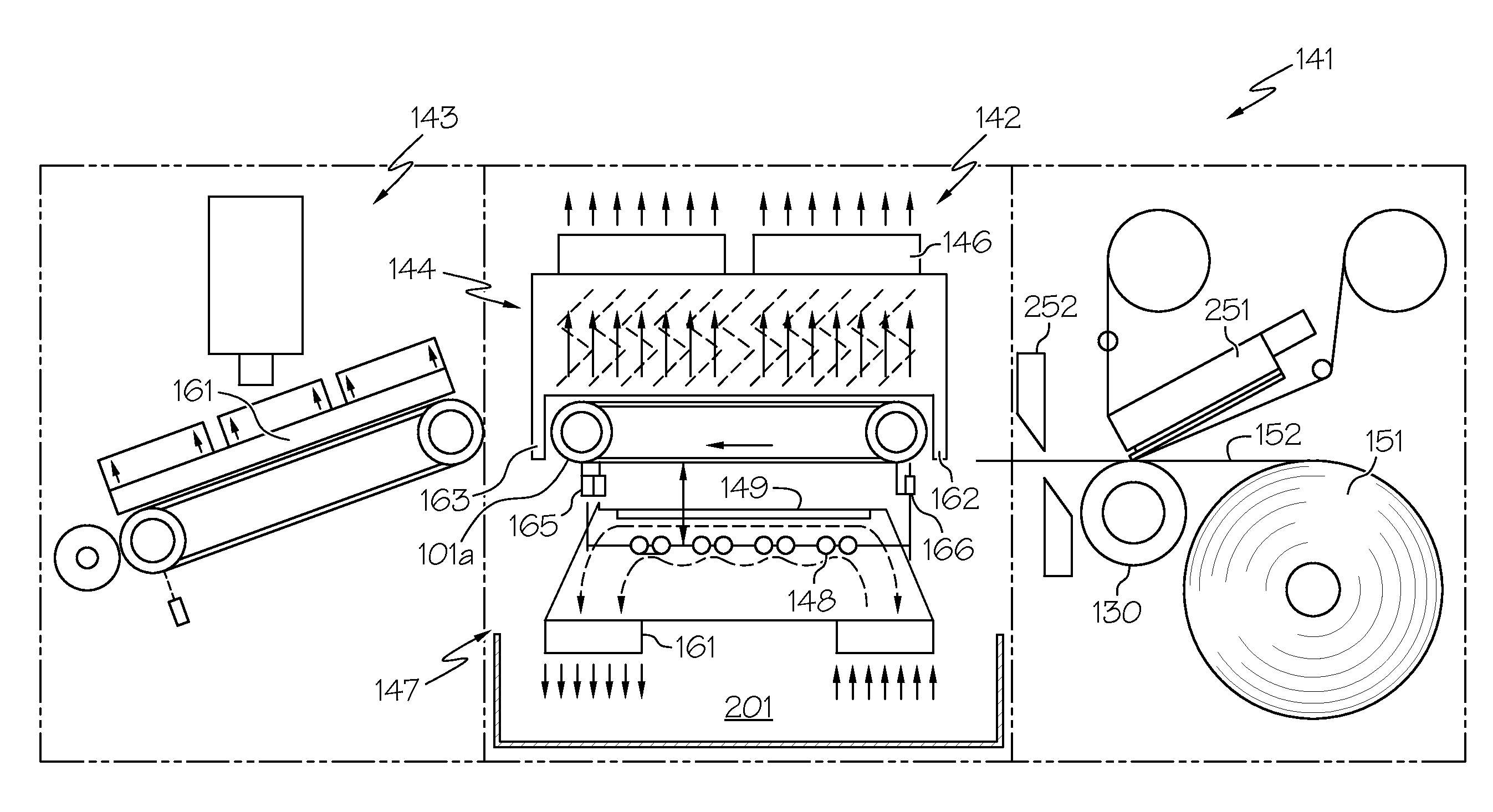

Linerless labels and activatable adhesives, systems, machines and methods therefor

InactiveUS20130133532A1Improve securityEasy to operateStampsRecord information storagePlasticizerAdhesive

A system is disclosed for printing, activating and applying a flow of linerless activatable labels to a flow of items to be labeled. An activatable adhesive is formulated to readily absorb energy from a given radiation source, an activatable adhesive linerless label incorporates such the activatable adhesive. Related methods and uses are described. The activatable adhesive includes a plasticizer, a tackifier, and an adhesive base polymer that includes butyl acrylate, styrene, methyl methacrylate, methacrylic acid, and acrylic acid.

Owner:AVERY DENNISON CORP

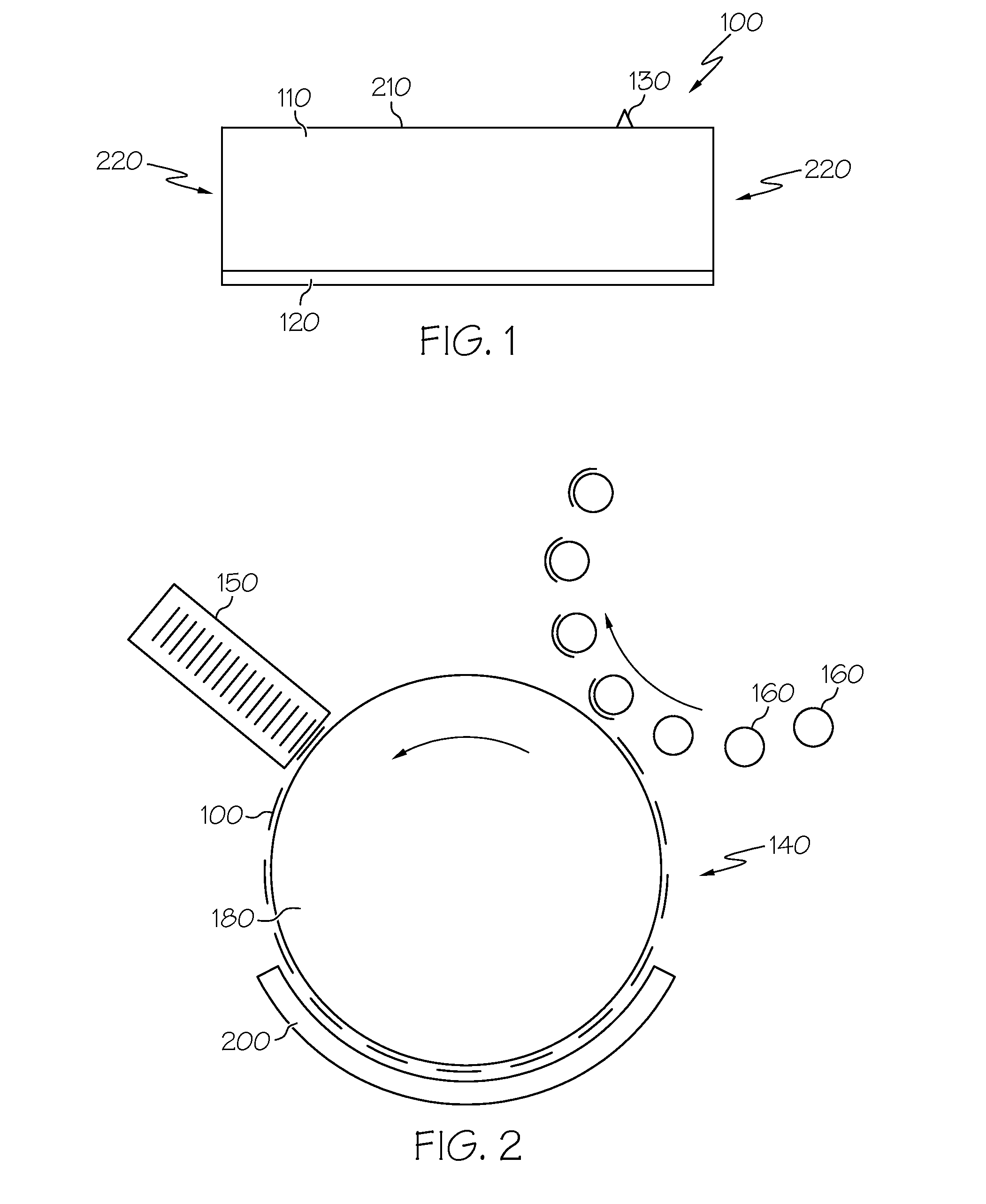

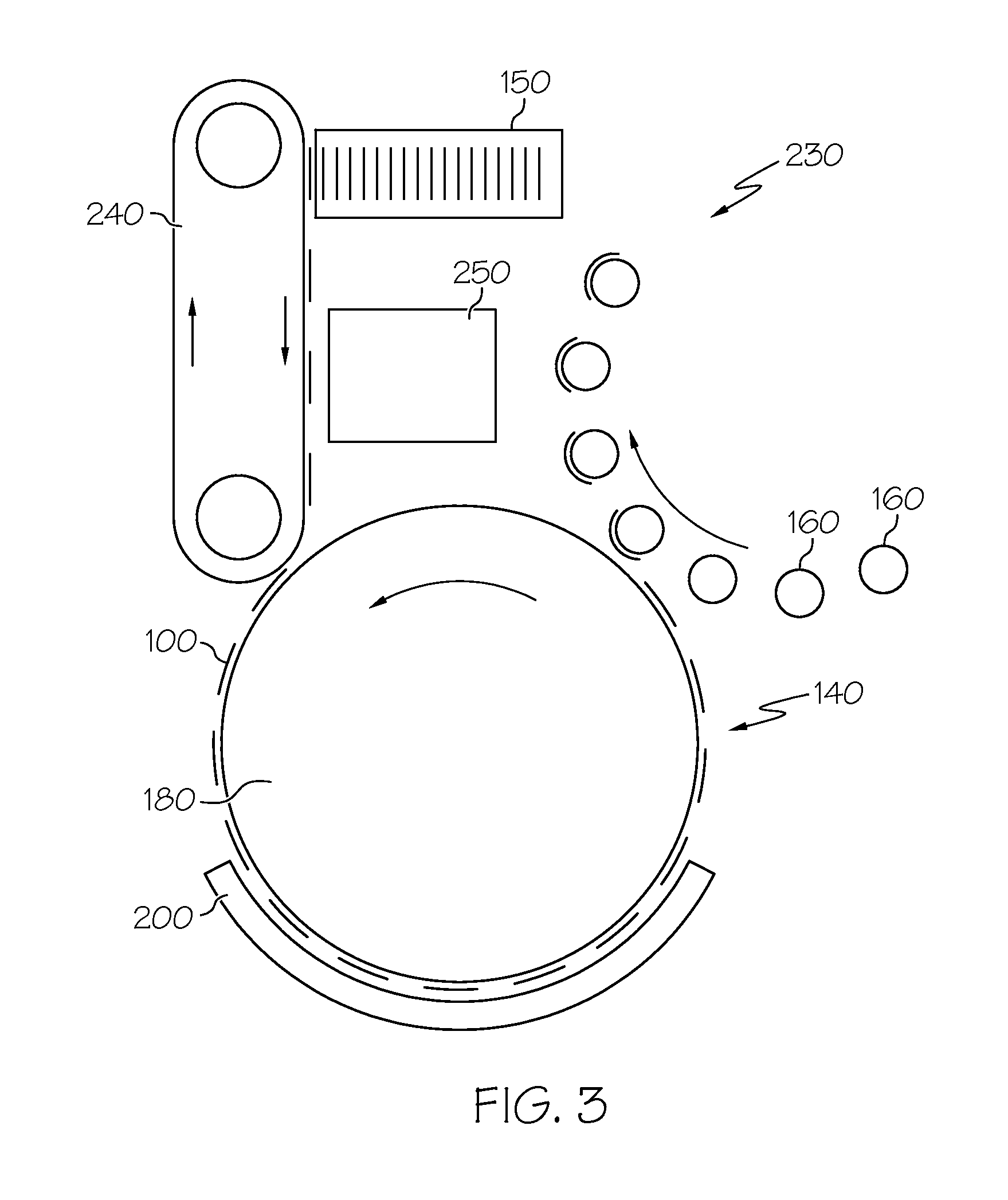

Encapsulant compositions, methods of manufacture and uses thereof

ActiveUS20100295091A1Increased durabilityIncreased moisture protectionSpecial tyresLaminationMeth-Sealant

An encapsulant composition containing about 15 to about 50 wt % of an ethylene / ethyl acrylate / maleic anhydride copolymer containing about 20 to about 40 wt % of an ethylene / glycidyl (meth)acrylate copolymer; about 2 to about 30 wt % of an ethylene / butyl acrylate / maleic anhydride copolymer; about 5 to about 50 wt % of polyethylene, about 0.05 to about 5 wt % of an adhesion promoter; and optionally about 0.01 to about 2 wt % of at least one additive. The composition is useful for encapsulating thin film devices. The disclosure also relates to a method of encapsulating thin film devices with the composition and to devices produced by the method.

Owner:SK GEO CENTRIC CO LTD

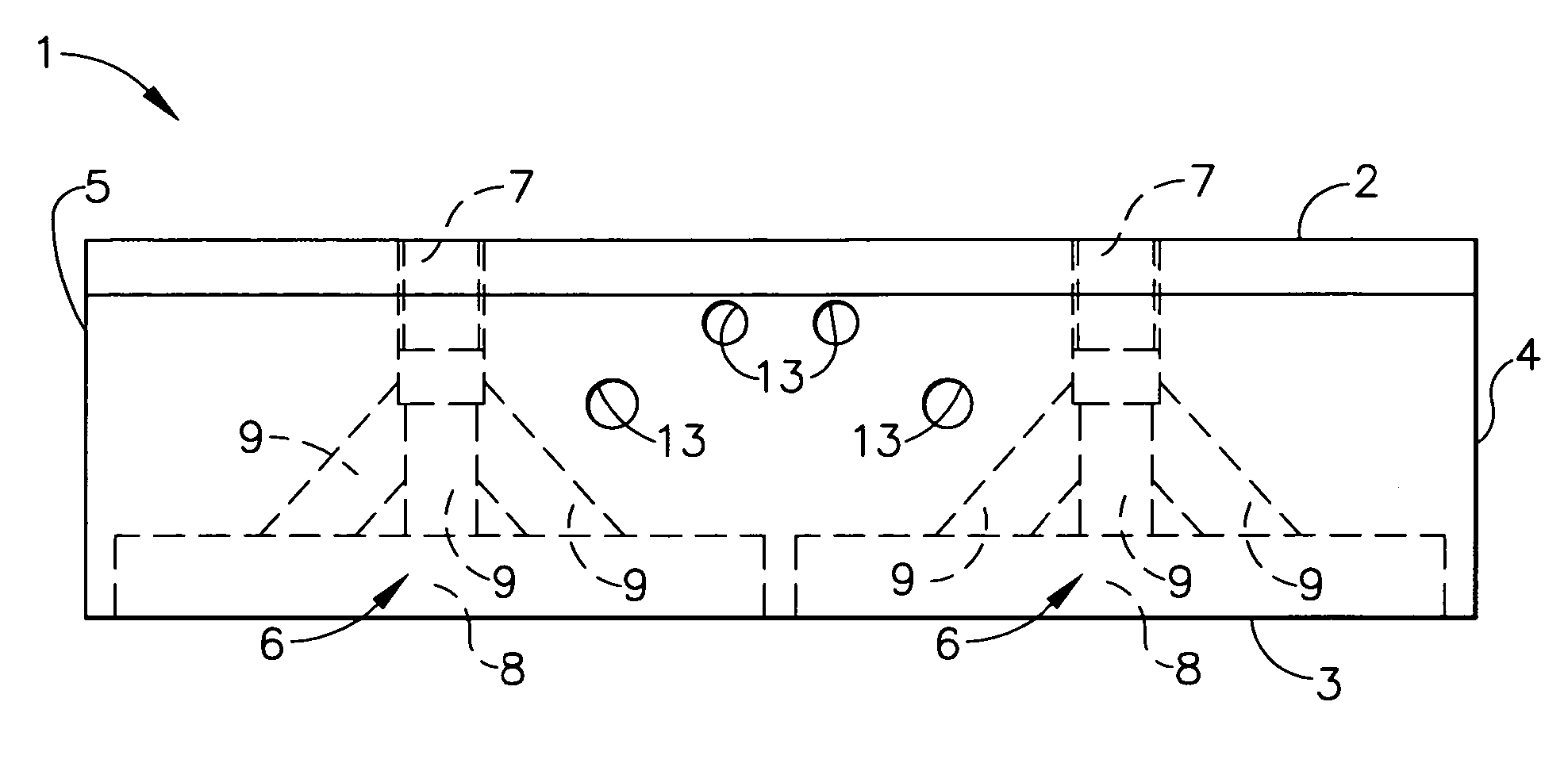

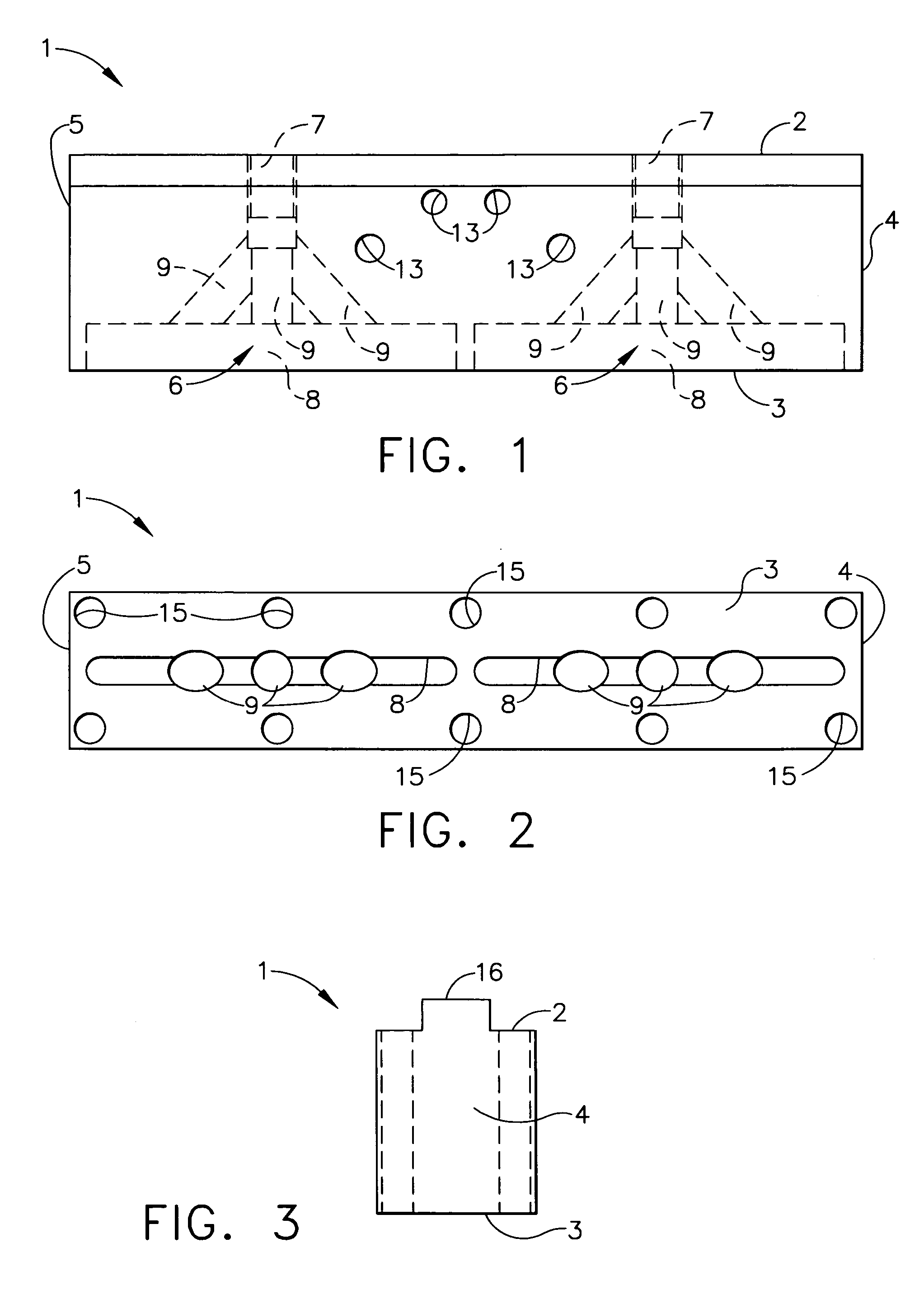

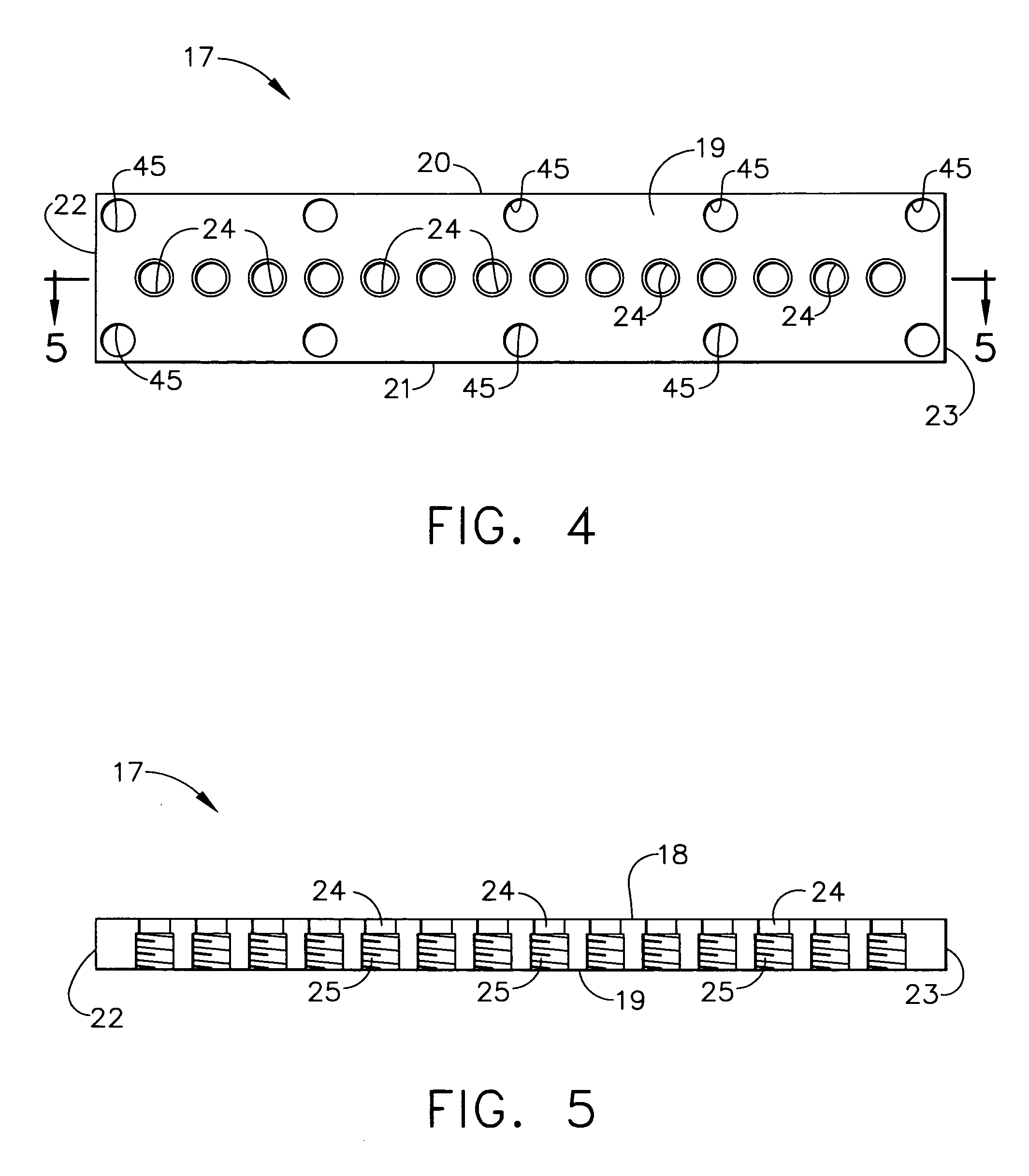

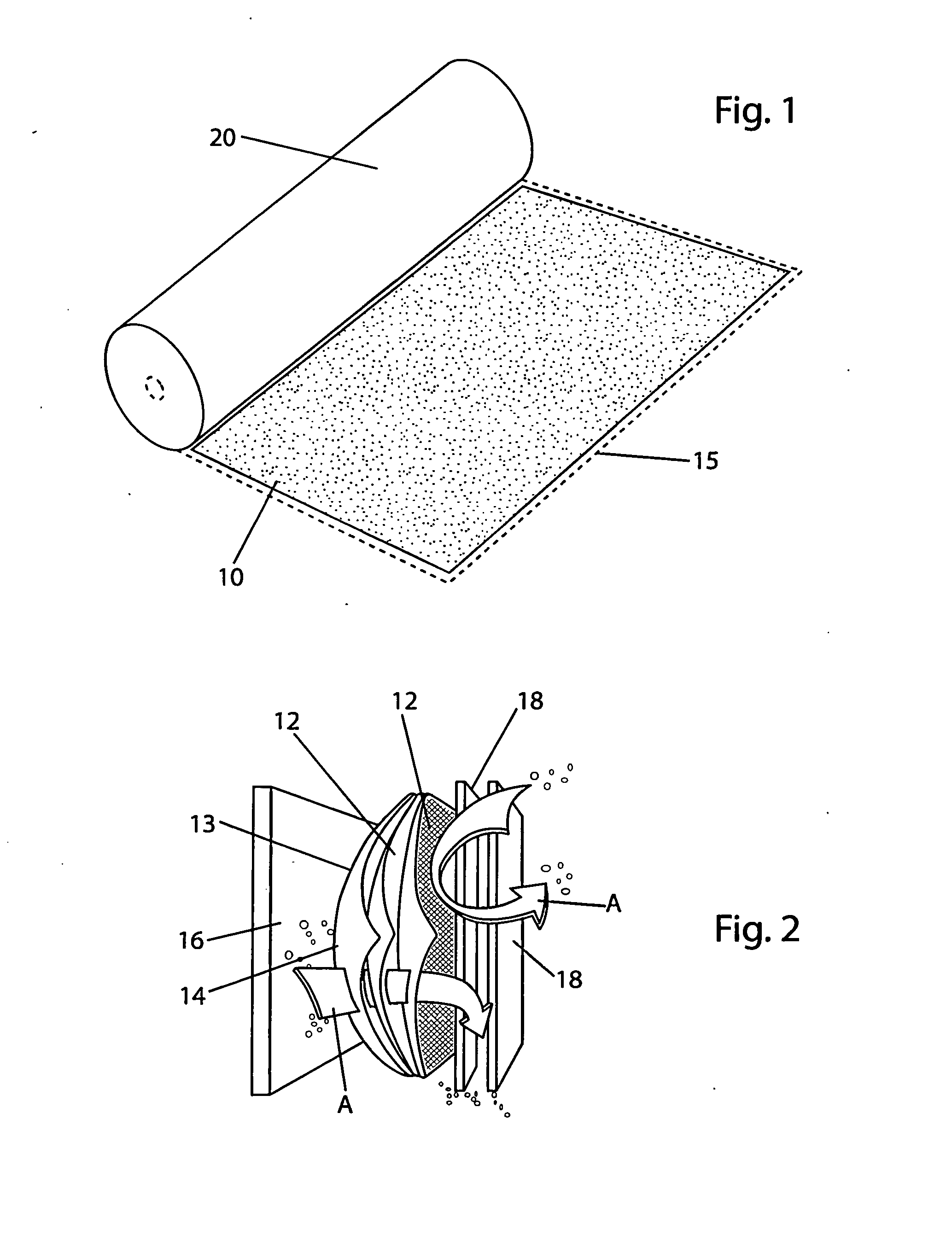

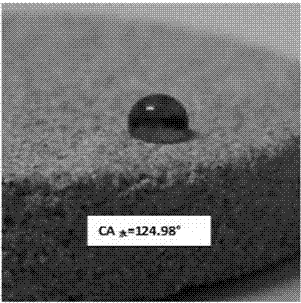

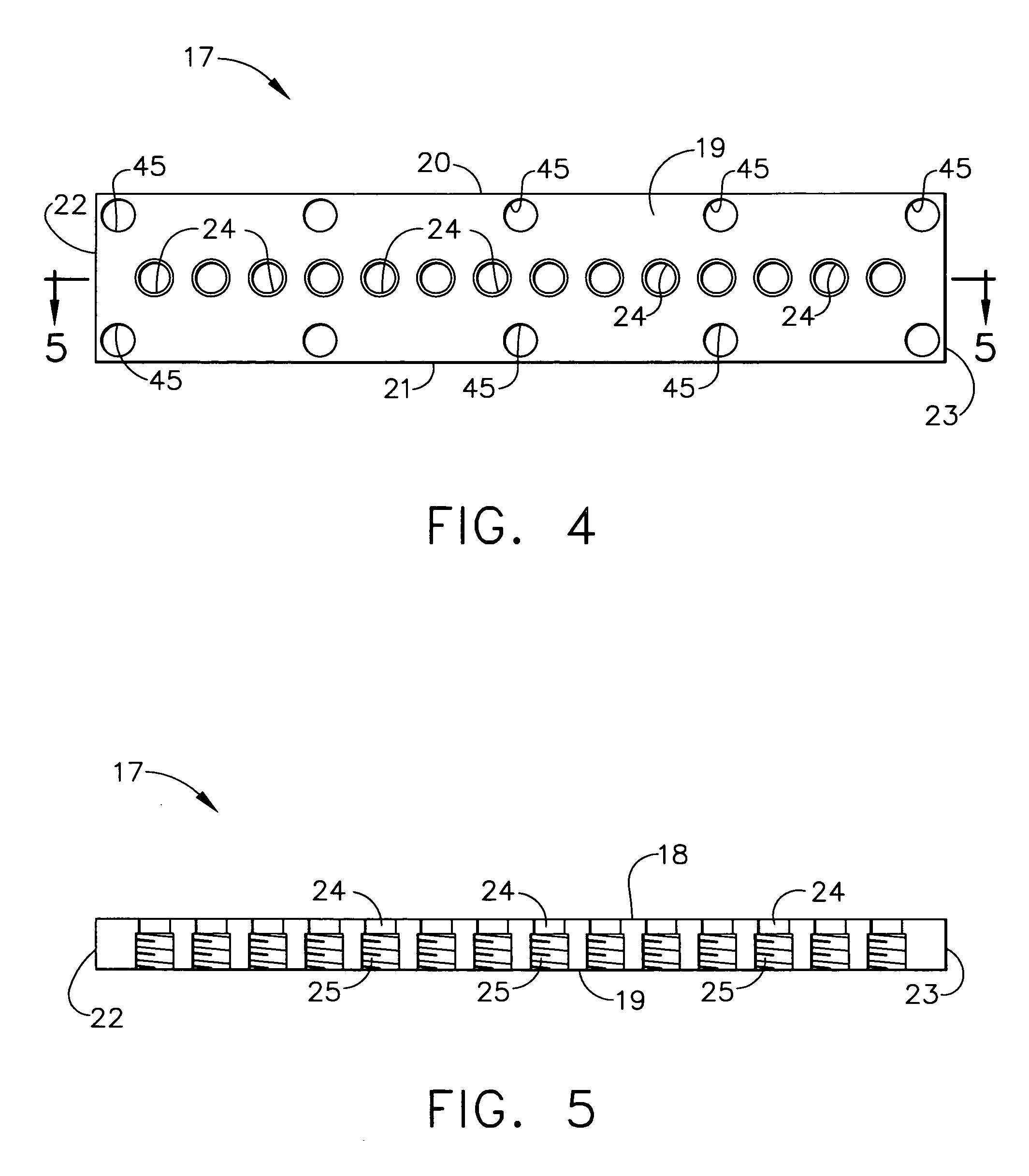

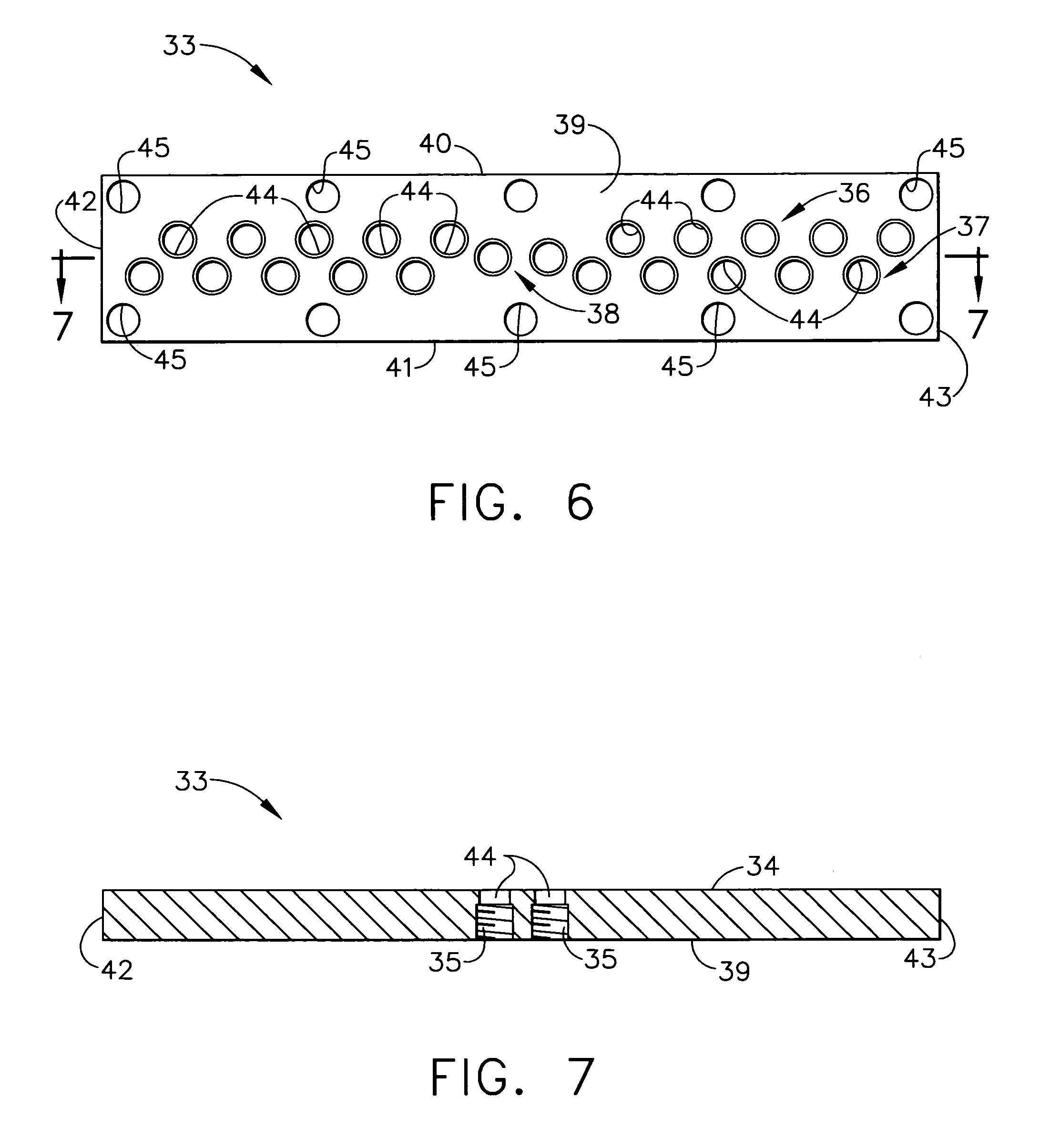

Applicator head for applying fluid material to substrate

InactiveUS20050189442A1Improve sound insulationGood curative effectMovable spraying apparatusSpray nozzlesControl mannerAcrylonitrile

An applicator head for connection to a robotic device, and useful for applying a fluid material to a substrate. The applicator head comprises: (a) a body portion; (b) at least one material delivery system comprising an inlet, a fluid delivery cavity, and two or more passageways connecting the inlet to the fluid delivery cavity; and (c) a nozzle plate attached to the bottom surface of the body portion, and having a plurality of openings communicating with the fluid delivery cavity. In one embodiment, the applicator head comprises a nozzle inserted in each of the plurality of openings in the nozzle plate, with each nozzle adapted to apply a bead of a fluid material to a substrate, with the beads spaced less than about 2 mm apart. Also disclosed is a sound-damping composition comprising: (a) n-butyl acrylate-acrylonitrile-styrene copolymer; (b) at least about 0.5% by weight of a low-density glass bead filler; (c) at least one additional filler; and (d) at least one rheological modifier; and having a density of from about 1 to about 2 g / cc. Methods for applying the sound-damping composition by extruding it onto a substrate and baking it to exhaust water in a controlled manner, and methods for increasing the sound-damping efficacy of an aqueous polymeric composition, are also disclosed.

Owner:EFTEC NORTH AMERICA

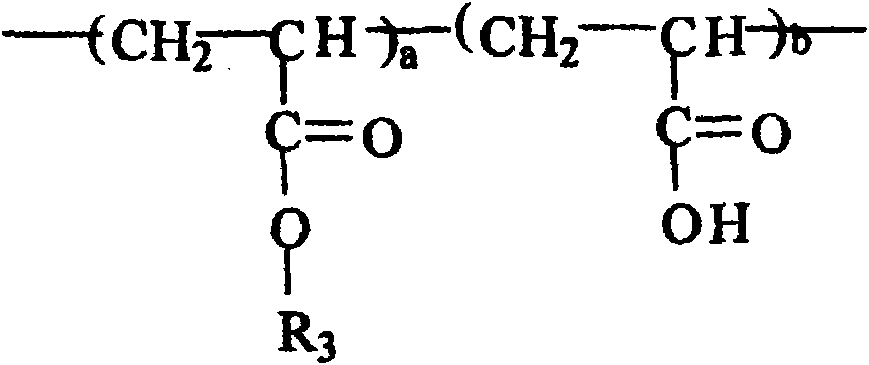

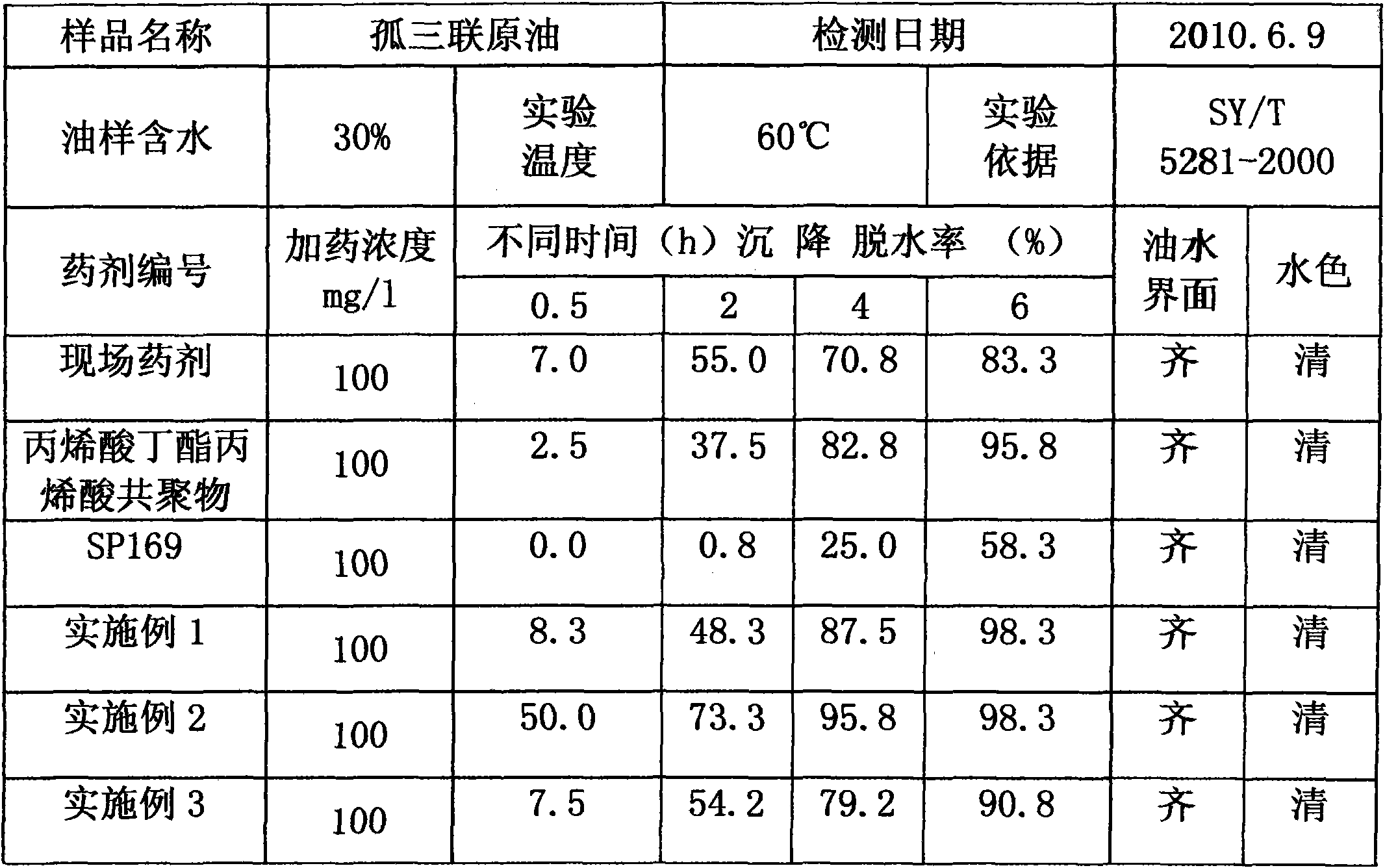

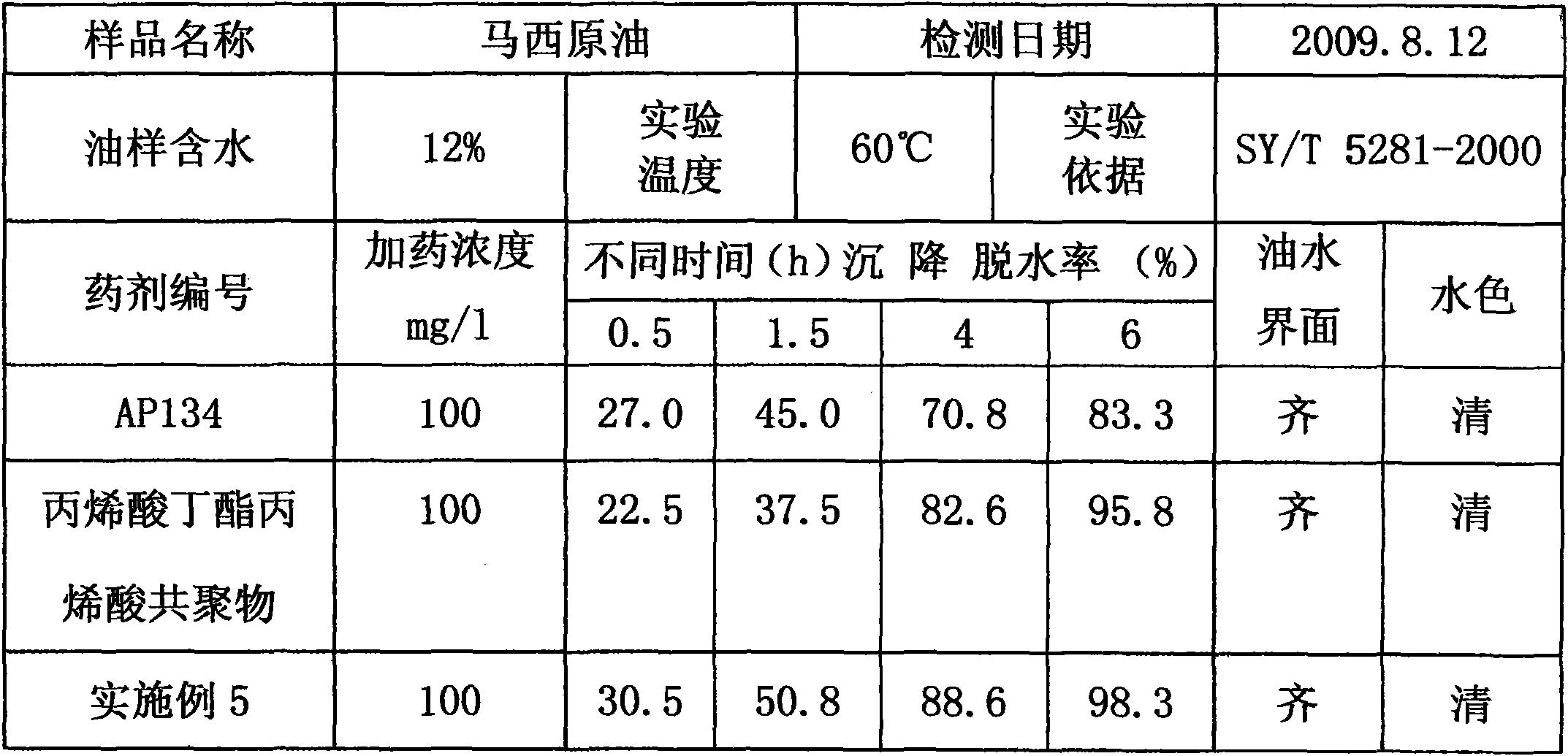

Novel crude oil demulsifier and preparation method thereof

InactiveCN102399576AGood demulsification effectDewatering/demulsification with chemical meansDemulsifierHydroquinone Compound

The invention relates to a novel crude oil demulsifier and a preparation method thereof. The novel crude oil demulsifier is prepared from esterified butyl acrylate acrylic acid copolymer and polyether demulsifier. Calculated according to a total weight of the butyl acrylate acrylic acid copolymer and the polyether demulsifier as 100%, the novel crude oil demulsifier comprises components of, by weight: 10-95% of the butyl acrylate acrylic acid copolymer, 5-90% of the polyether demulsifier, 0.1-3% of an acidic catalyst, 0.1-0.2% of a polymerization inhibitor of hydroquinone, and a solvent which is a good solvent for the butyl acrylate acrylic acid copolymer and the polyether demulsifier. According to the novel crude oil demulsifier and the preparation method thereof, the butyl acrylate acrylic acid copolymer and the polyether demulsifier with demulsification functions are subject to an esterification reaction. The prepared demulsifier provides a good demulsification effect upon crude oil emulsion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-whitening emulsion pressure sensitive adhesives

InactiveCN1284106ALow hazeAdhesiveNon-macromolecular adhesive additivesEster polymer adhesivesMethacrylateEmulsion

Water resistant, low haze acrylic emulsion pressure sensitive adhesive compositions for use in decorative, light management or optical articles are disclosed. These emulsion pressure sensitive adhesives comprise (a) 50-90% by weight n-butyl acrylate, and (b) 10-50% by weight 2-hydroxy ethyl acrylate, or 2-hydroxy ethyl methacrylate, hydroxy propyl acrylate monomer, or mixtures thereof. These emulsion pressure sensitive adhesives can be used in wet lamination processes, and exhibit less than 2% increase in haze, less than 2% increase in opacity and greater than 95% transmittance after the wet lamination process.

Owner:3M CO

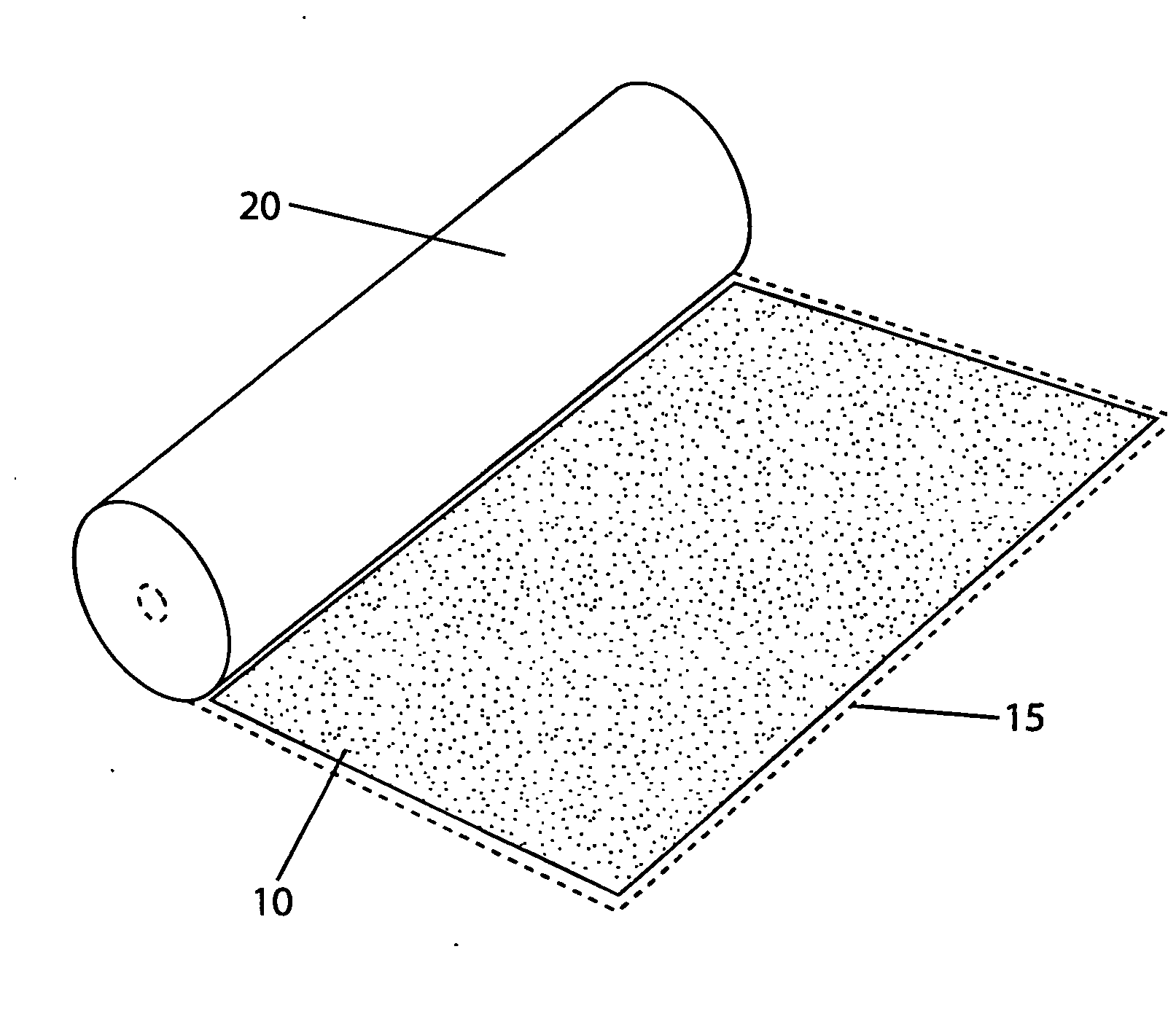

Building membrane with porous pressure sensitive adhesive

A breathable multilayer spun bonded polypropylene membrane having a coated pressure sensitive adhesive capable of allowing air and moisture vapor to pass through it. The adhesive is formed of a copolymer comprising a backbone of n-butyl acrylate, 2-ethylhexyl acrylate, and vinyl acetate which is mixed with a surfactant and emulsified to produce bubbles which form pores when the copolymer is set with about 80% to about 90% of the pore sizes ranging from about 200 microns to about 300 microns and a pore density in the cured pressure sensitive adhesive ranging from about 4200 per inch2 to about 4600 per inch 2, said pores being uniformly distributed to form a flow path through the adhesive.

Owner:VAPROSHIELD

Cleaning implement comprising a modified open-cell foam

A cleaning implement comprises a modified open-cell foam with a density in the range from about 5 to about 1,000 kg / m3 and with an average pore diameter in the range from about 1 μm to about 1 mm, comprising an amount in the range from about 1 to about 2,500% by weight, based on the weight of the unmodified open-cell foam, of at least about one water-insoluble polymer (b), selected from polystyrene, styrene copolymers, polybutadiene, butadiene copolymers, polyvinylesters, polyvinylethers, copolymers from (meth)acrylic acid with at least one (meth)acrylate, and polyurethanes, with the proviso that styrene-acrylonitrile-C1-C10-alkyl (meth)acrylate terpolymers, styrene-butadiene-n-butyl acrylate terpolymers, and styrene-maleic anhydride copolymers are excluded.

Owner:THE PROCTER & GAMBLE COMPANY

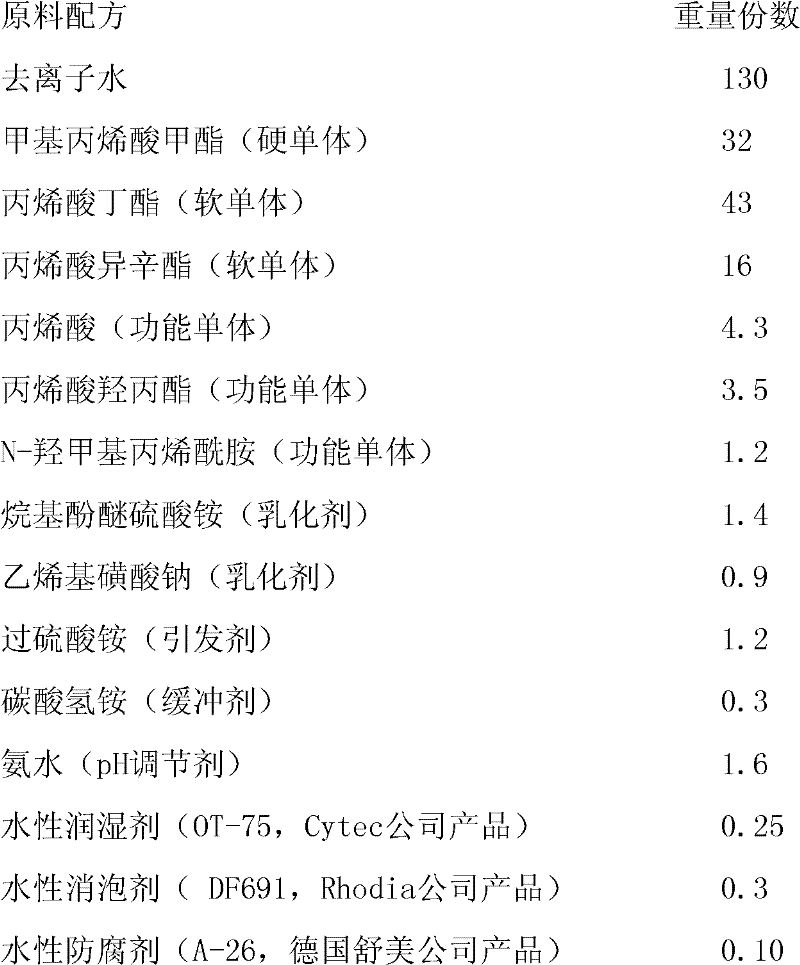

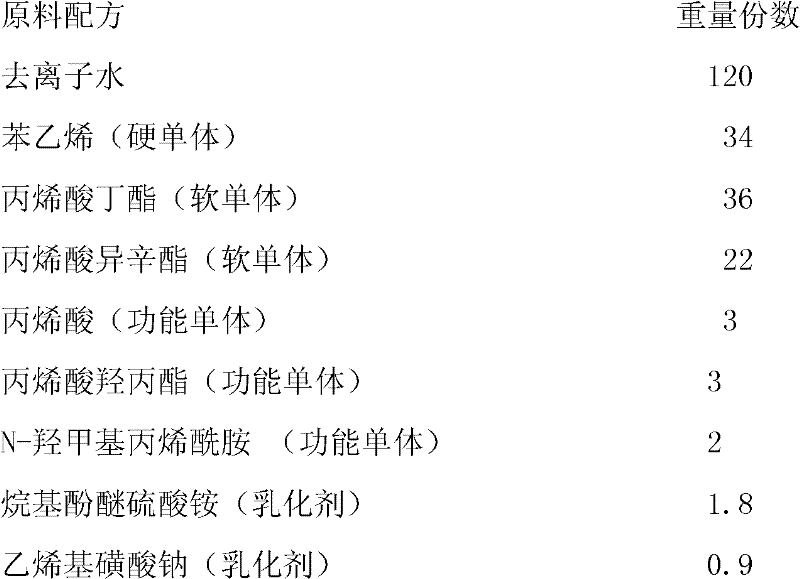

Aqueous adhesive for non-woven fabric composite membrane and preparation method of aqueous adhesive

InactiveCN102443367AImprove stabilityGood adhesionEster polymer adhesivesHydrocarbon polymer adhesivesIsooctyl acrylateFunctional monomer

The invention discloses an aqueous adhesive for a non-woven fabric composite membrane and a preparation method of the aqueous adhesive, belonging to the field of manufacturing of adhesives. The adhesive comprises the following components of: deionized water, monomers, a composite emulsifier, an initiator, a buffering agent, a pH regulator and an aqueous addition agent, and the solid content of the adhesive is 40-50%. The monomers in the components of the adhesive comprise a hard monomer, soft monomers and functional monomers, wherein the hard monomer is styrene or methyl methacrylate, the soft monomers are butyl acrylate and iso-octyl acrylate, and the functional monomers are composed of crylic acid, hydroxy-propyl acrylate and N-methylol acrylamide. The monomers comprise the following components in percentage by mass: 20-40% of styrene or methyl methacrylate, 10-30% of iso-octyl acrylate, 30-50% of butyl acrylate, 1-5% of crylic acid, 1-5% of hydroxy-propyl acrylate and 1-5% of N-methylol acrylamide. The aqueous adhesive has the advantages of effectively improving wetting and flatting properties on the surface of a plastic film, ensuring that the plastic film has a better wettingproperty with the non-woven fabric, and enhancing the peeling strength.

Owner:NANTONG GAOMENG NEW MATERIAL

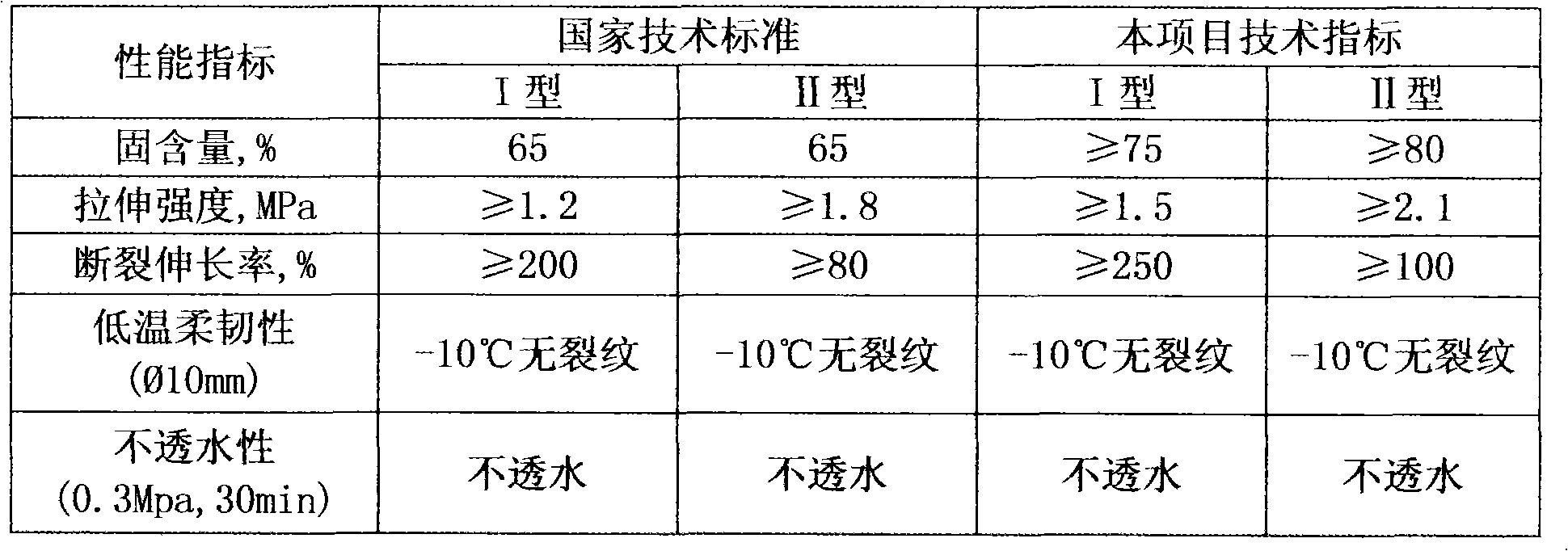

Elastic styrene acrylic emulsion for polymer cement waterproof coating and preparation method thereof

InactiveCN101891859AReduce dosageImprove stabilityAntifouling/underwater paintsPaints with biocidesHydrophilic monomerFatty alcohol

The invention relates to elastic styrene acrylic and elastic acrylate emulsions and a polymerization method thereof, in particular to an elastic styrene acrylic emulsion for a polymer cement waterproof coating and a preparation method thereof. The prepared emulation comprises the components of fatty alcohol polyoxyethylene ether sulfate, fatty alcohol polyoxyethylene ether (methyl) acrylate, n-butyl acrylate, styrene, N-methyl methacrylate, AMPS and N-hydroxymethyl acrylamide. Different from a common waterproof emulsion, the emulsion has the advantages of remarkably reducing the using amount of an emulsifier and a hydrophilic monomer, improving the stability of the polymer emulsion, and improving the membrane formation property of the polymer emulsion and the toughness, strength and waterproof property of a coating.

Owner:成都科杰高新技术发展有限公司

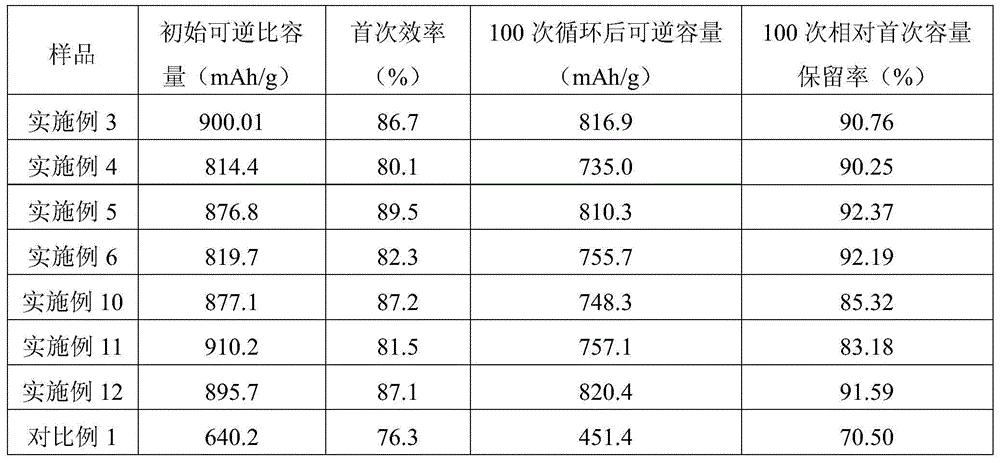

High-performance binder for silicon materials for lithium ion batteries and preparation method thereof

ActiveCN104538635AImprove conductivityImprove microscopic compositionCell electrodesCyclic processAcrylonitrile

The invention provides a high-performance binder for silicon materials for lithium ion batteries, which is a polyacrylonitrile copolymer, a polymeric monomer of the copolymer comprises acrylonitrile, also comprises a second monomer and / or a third monomer; and the second monomer is a monobutyl itaconate monomer, and the third monomer is selected from a mixture of one or more of an itaconic acid, sodium allylsulfonate, acrylamide, amino, a pyridyl or acylamino monomer, n-butyl acrylate or methyl acrylate. The invention also provides a preparation method of the binder. Compared with existing binders, the binder disclosed by the invention has better binding power, can effectively improve the expansion of silicon materials in the processes of charging and discharging, and can improve the performance of a silicon electrode in the process of cycling. Meanwhile, the binder is simple in preparation method, low in cost and good in repeatability, and can achieve the practical need of mass production.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

Curable Composition

The invention has its object to provide a curable composition having improved compatibility of a high-molecular-weight polyether polymer and a vinyl polymer and excellent in mechanical properties. The invention uses a curable composition which comprises a polyether polymer (I) having at least one crosslinkable functional group and a number average molecular weight of 10,000 or higher, and a vinyl polymer (II) having at least one crosslinkable functional group at a polymer terminus and compatible with the polyether polymer (I). As the vinyl polymer (II), a poly(n-butyl acrylate / ethyl acrylate / octadecyl acrylate) copolymer may be mentioned, for example.

Owner:KANEKA CORP

Environment-friendly type white emulsion glue

InactiveCN101265398AImprove water resistanceImprove heat resistanceMonocarboxylic acid ester polymer adhesivesSodium bicarbonateSodium acetate

Owner:江苏德华兔宝宝装饰新材有限公司

Water-based electrode binding agent and preparation method thereof

ActiveCN106281147AImprove mechanical propertiesGood compatibilityCell electrodesGraft polymer adhesivesWater basedPollution

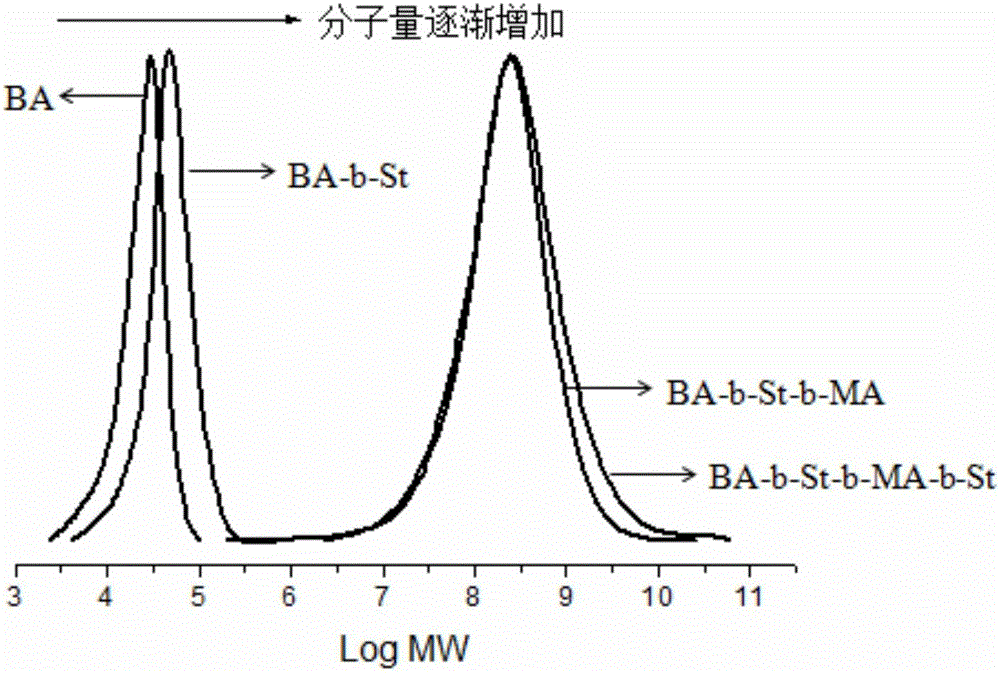

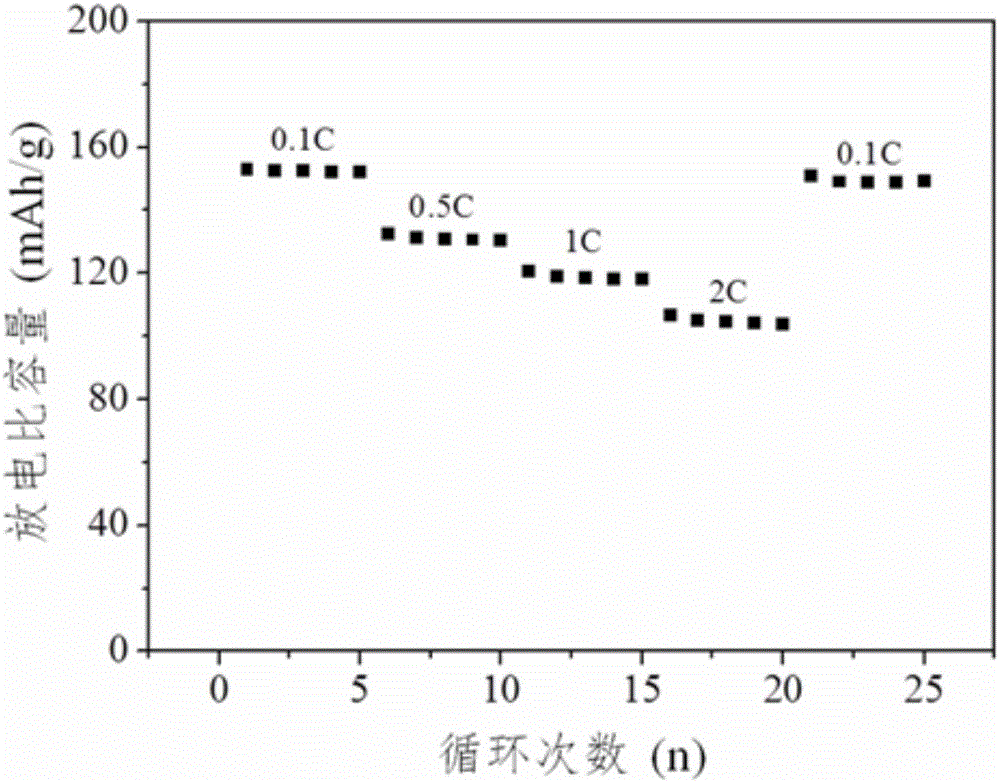

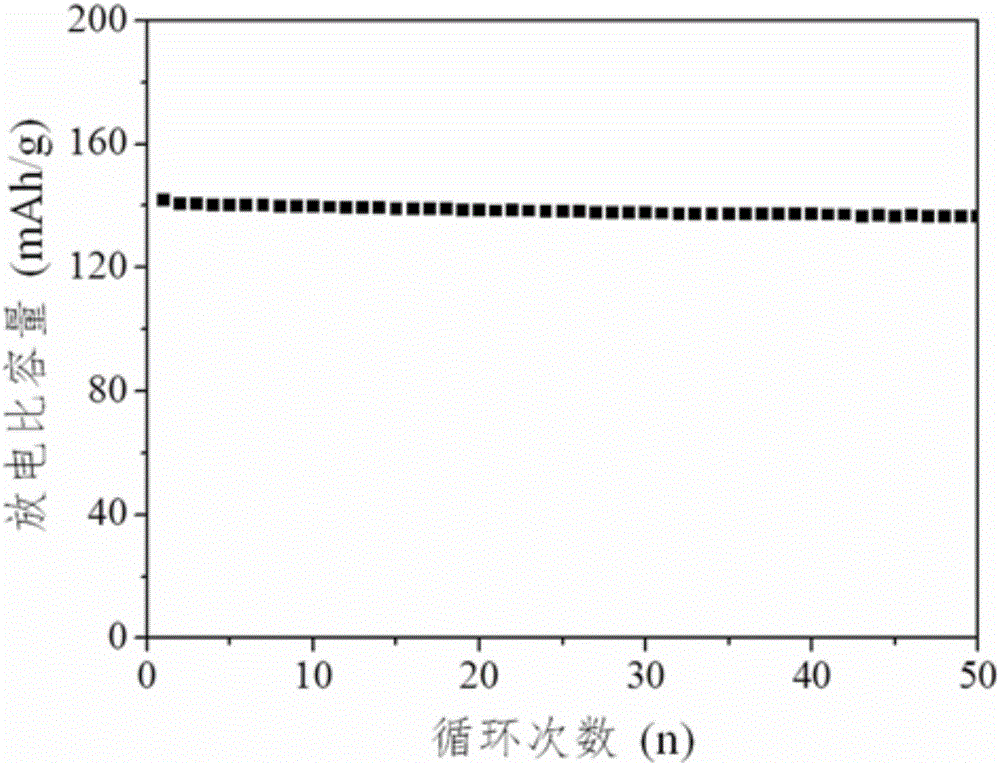

The invention discloses a water-based electrode binding agent and a preparation method thereof. According to the water-based electrode binding agent, an emulsion polymerization system is adopted, and a reversible addition-fragmentation chain transfer free-radical polymerization technology is used for preparing butyl acrylate / styrene / methyl acrylate block copolymer latex which is used as the electrode binding agent. A preparation process has the advantages of energy saving and environment protection; compared with a traditional binding agent polyvinylidene fluoride, the water-based electrode binding agent has the advantages of low price, simple process, no pollution and the like; the discharge specific capacity of a used electrode in a lithium iron phosphate electrode can reach 153.4mAh / g, and the discharge specific capacity in a graphite electrode can reach 358.6mAh / g; and therefore, the water-based electrode binding agent has great application prospects.

Owner:浙江杰特维新材料有限公司

Electrode binding agent of novel lithium ion battery and preparation method of electrode binding agent

ActiveCN108417836AReduce electrode polarizationHigh discharge specific capacityCell electrodesSecondary cellsCyclic processInterface impedance

The invention discloses an electrode binding agent of a novel lithium ion battery. The electrode binding agent is an ABA-type three-block polymer, wherein polyacrylic acid blocks are arranged at two ends, a polyacrylate block is arranged at a middle part, each polyacrylic acid block is formed by polymerizing a methacrylic acid monomer and / or an acrylic acid monomer, and the polyacrylate block is formed by polymerizing one or more of methyl acrylate, butyl acrylate, hydroxyethyl acrylate and hydroxypropyl acrylate. The invention also discloses a preparation method for the electrode binding agent of the novel lithium ion battery. The block copolymer binding agent provided by the invention is small in electrode polarization and high in discharging specific capacity, the capacity retention ratio during the circulation process is high, and the binding agent is small in interface impedance, can be simultaneously applicable to a positive electrode and a negative electrode and has huge application prospect in the field of the lithium ion battery.

Owner:MINNAN NORMAL UNIV

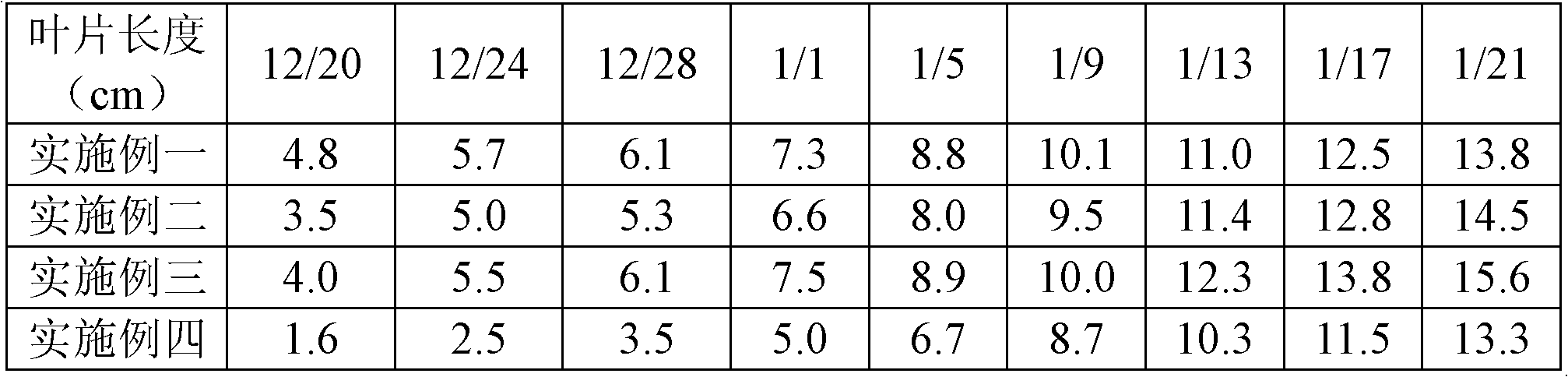

Method for producing lycoris by plant tissue culture

InactiveCN102144554ALarge amount of reproductionGuaranteed qualityHorticulture methodsPlant tissue cultureVaccinationLycoris radiata

The invention relates to a method for producing the lycoris by plant tissue culture, which comprises the steps of: (1) taking an MS (mass spectrometry) culture medium as a basic culture medium, and taking a 2, 4-D, IAA (indo acetic acid), NAA (naphthyl acetic acid), 6-BA (butyl acrylate) and IBA (iso butyl alcohol) as a regulated and controlled growth hormone preparation culture medium; (2) taking the bulb of the lycoris as an explant, and sterilizing; (3) vaccinating the explant of the bulb on a bulb inducing culture medium to culture in an inducing way so as to grow bulbils; (4) transferring the bulbils into a rooting culture medium to culture in a rooting way, so that the bulbils can independently absorb the nutrient elements from the soil and the matrix; (5) transferring the bulbils into the culture medium to culture; (6) opening an opening of a vaccination bottle to refine the seedling; withdrawing the bulbils, and transferring the bulbils into a nutrient cup which takes the vermiculite, the pearlite and the nutrient soil as the mixed matrix; and transferring the bulbils into a large tent, so that the survival rate reaches 94%-96%. The method is less in material taking, and economical in culturing; the culture condition can be manually controlled and is not influenced by the natural condition; the method is short in growing period, and high in propagation rate; and the quality of lycoris is guaranteed.

Owner:江苏九久环境科技有限公司

Self-crosslinking aqueous laminating adhesive and preparation method thereof

PendingCN101955742ALow costGood adhesionMonocarboxylic acid ester polymer adhesivesPolymer scienceFunctional monomer

The invention discloses a self-crosslinking aqueous laminating adhesive and a preparation method thereof, and belongs to the field of adhesive manufacture. The laminating adhesive is a laminating adhesive with 40 to 50 percent of solid content, which is prepared from a monomer, an emulsifier, an initiator, a buffer, deionized water, a pH adjuster and an aqueous aid serving as raw materials by the steps of pre-emulsification, seed reaction, polymerization and compounding, wherein the monomer comprises a hard monomer, a soft monomer and a functional monomer, wherein the hard monomer is vinyl acetate; the soft monomer is composed of butyl acrylate and ethyl acrylate; and the functional monomer is composed of one of acrylic acid and methacrylic acid, one of hydroxyethyl acrylate and hydroxypropyl acrylate, and N-hydroxymethyl acrylamide; and the emulsifier is composed of ammonium alkyl ether sulfate and alkylphenol polyoxyethylene ether according to a weight ratio of 2:1. The laminating adhesive is prepared from the monomer vinyl acetate with low cost serving as a raw material, has low cost, and has the advantages of large bonding force and peel strength and high environmental protection.

Owner:BEIJING COMENS NEW MATERIALS

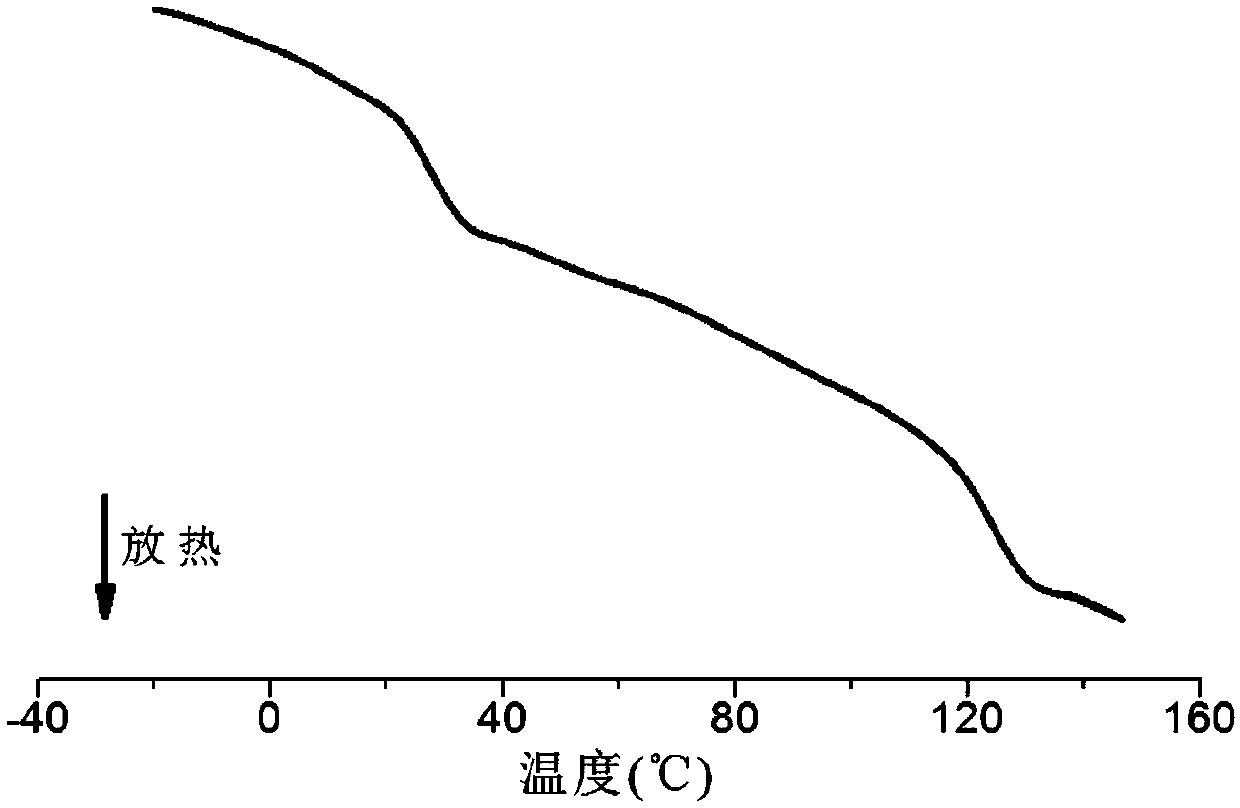

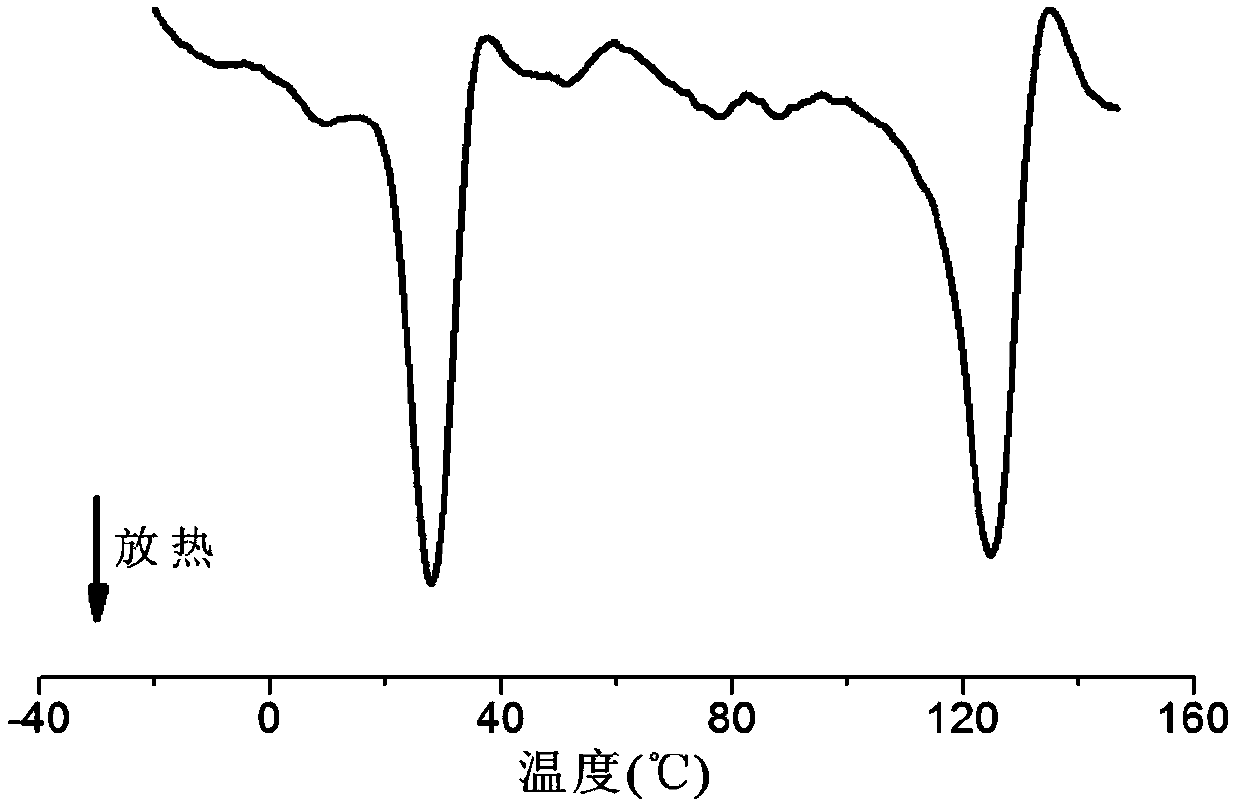

Preparation method for nanometer TiO2 modified composite phase change microcapsule

ActiveCN105056854AHigh phase change enthalpyConstant phase transition temperatureMicroballoon preparationMicrocapsule preparationAlkaneCross-link

The invention discloses a preparation method for a nanometer TiO2 modified composite phase change microcapsule. The preparation method comprises the following steps: preparing a core material from n-alkane and alkyl stearate, preparing a wall material from methyl methacrylate, butyl acrylate, ethyl acrylate, a cross-linking agent and nanometer TiO2 and mixing the core material with the wall material so as to obtain an oil phase A; dissolving a reactive emulsifier in deionized water so as to prepare a water phase B; adding the oil phase A into the water phase B and carrying out ultrasonic dispersion so as to form an O / W pre-emulsion; heating the O / W pre-emulsion and adding an initiator into the O / W pre-emulsion so as to prepare a nanometer TiO2 modified composite phase change microcapsule emulsion; and subjecting the nanometer TiO2 modified composite phase change microcapsule emulsion to standing and carrying out filtering, washing and drying so as to obtain the nanometer TiO2 modified composite phase change microcapsule. According to the preparation method, under the condition of usage of reactive emulsifier, nanometer TiO2 is used to modify the wall material, so the phase change microcapsule with a small and uniform size is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

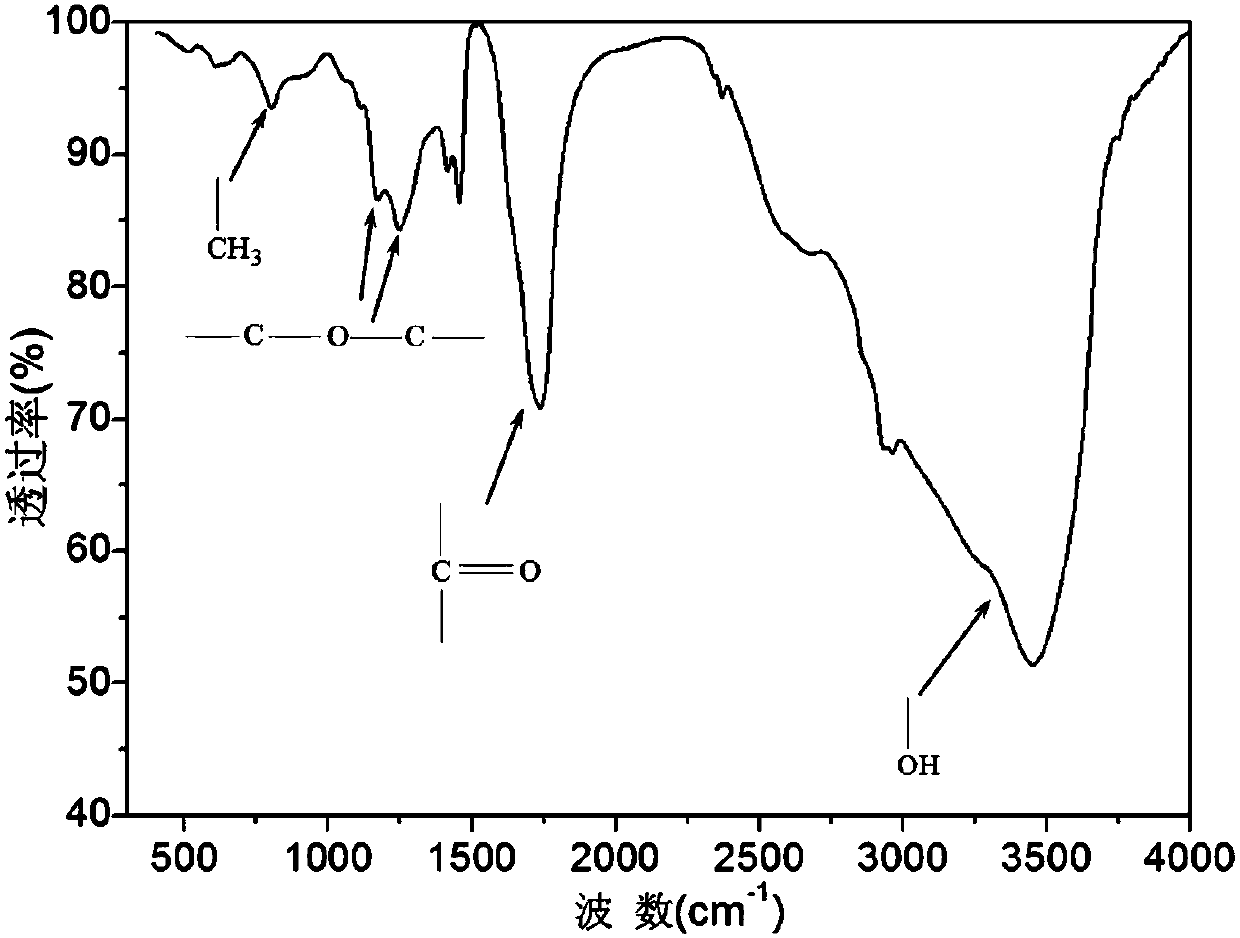

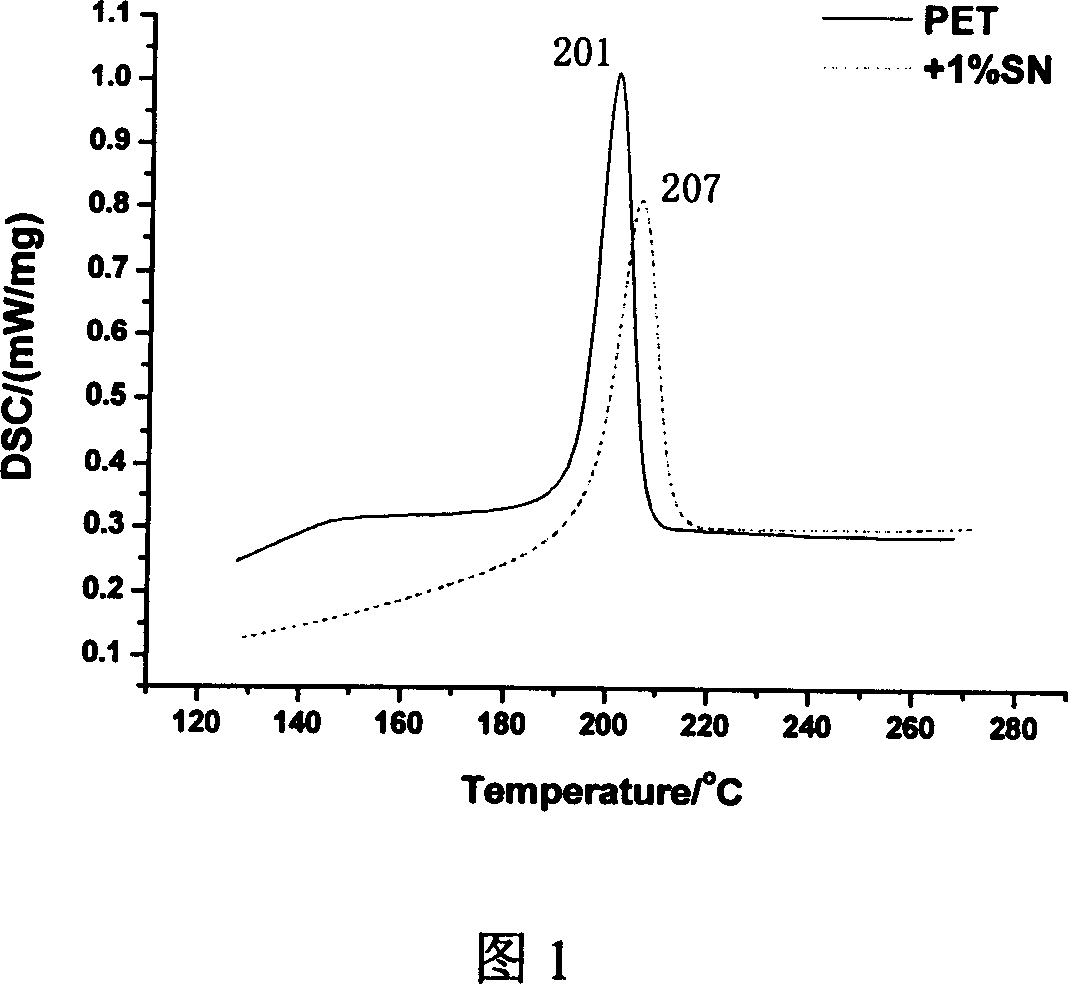

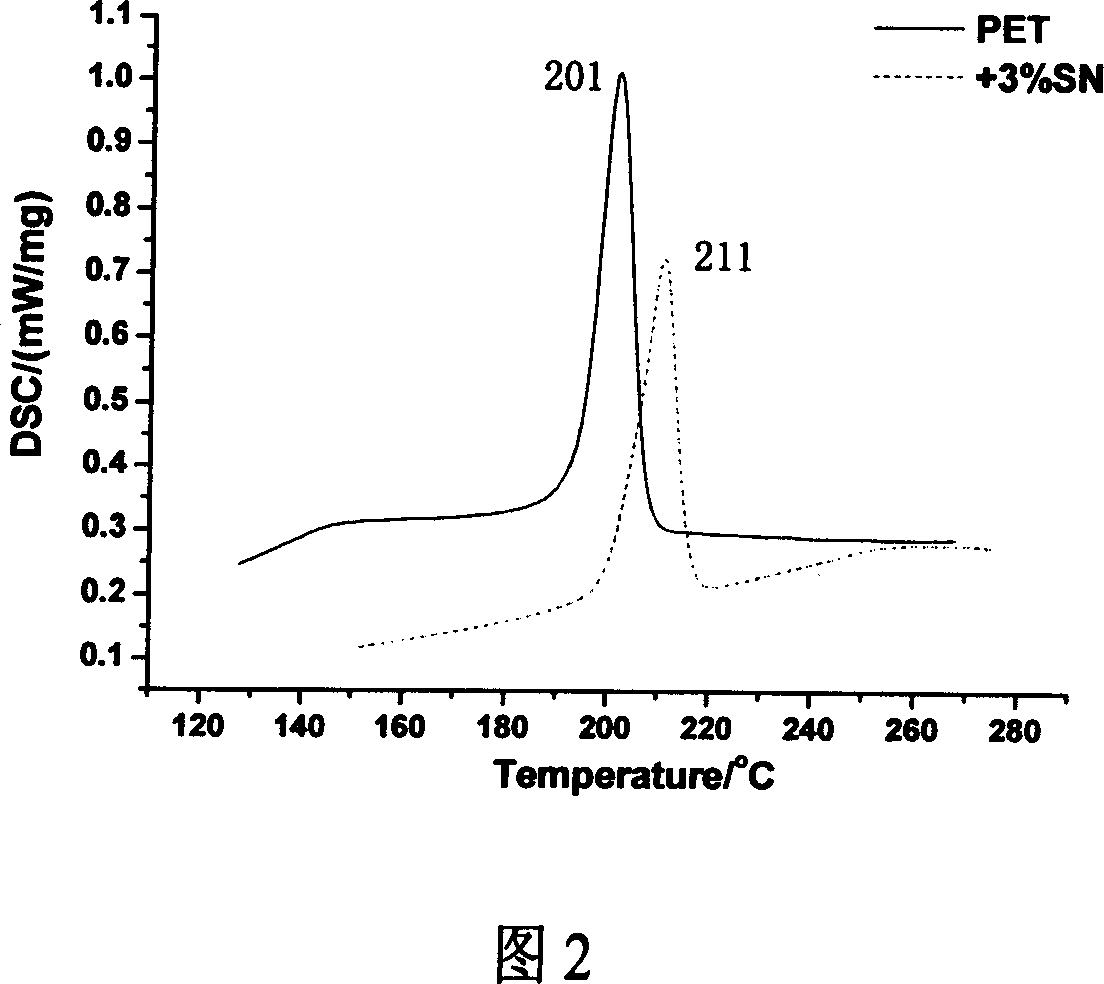

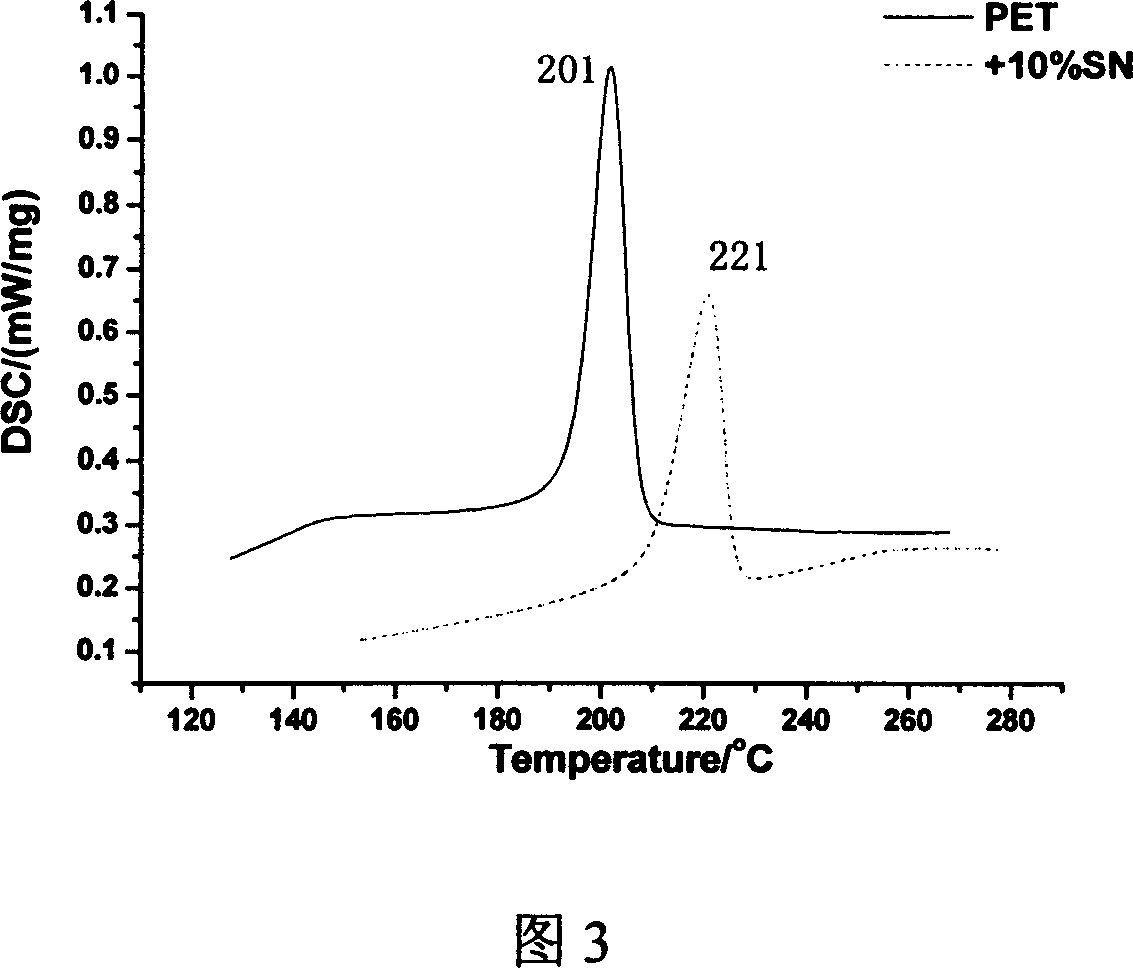

Core-shell structure ionomer for PET resin toughening crystallization and method for making same

InactiveCN1990514AGuaranteed price advantageSignificantly toughenedEngineering plasticPolymer chemistry

The invention relates to a core-shell ionomer that is used to intensify the crystallization for PET resin and the method for preparing the same. In the beginning, the ionomer employs (methyl) acrylic acid monomer with glass- transition temperature of contained butyl acrylate far lower than room temperature for part polymerization and nucleation, employs monomer with glass- transition temperature of contained methyl methacrylate higher than room temperature and a plurality of unstaratured aliphatic acids containing methacrylic acid for polymerization and nucleation, then forms soft core / hard shell core-shell construction; then, neutralizing with base liquid to establish core-shell ionomer. The invention employs cheap monomer and substance, forms core-shell ionomer through emulsion polymerization, and applies it to the forming and extrusion for PET resin, which toughes and promotes the crystallization for PET, and widens its application in engineering plastic field with lower cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Acrylic pressure-sensitive adhesive tape or sheet and process for producing the same

InactiveUS20100112346A1Improve adhesionBroaden applicationFilm/foil adhesivesAcid polymer adhesivesPolymer scienceMeth-

Provided is an acrylic pressure-sensitive adhesive tape or sheet highly adhesive to hard-to-adhere adherends such as coatings having the surface control agent bleeding thereon.The acrylic pressure-sensitive adhesive tape or sheet, according to the present invention, having a viscoelastic layer (X) containing microspheres and an acrylic polymer containing an alkyl (meth)acrylate as the principal monomer component as the base polymer and a pressure-sensitive adhesive layer (Y) formed at least on one side of the viscoelastic layer (X) by irradiation of an acrylic monomer mixture or a prepolymer of the acrylic monomer mixture with active energy ray, wherein the amount of acrylic acid in the acrylic monomer mixture for the pressure-sensitive adhesive layer (Y) or a prepolymer of the acrylic monomer mixture is 6 to 12 wt % with respect to all monomer components and the amount of n-butyl acrylate is 35 to 65 wt % with respect to the total amount of 2-ethylhexyl acrylate and n-butyl acrylate.

Owner:NITTO DENKO CORP

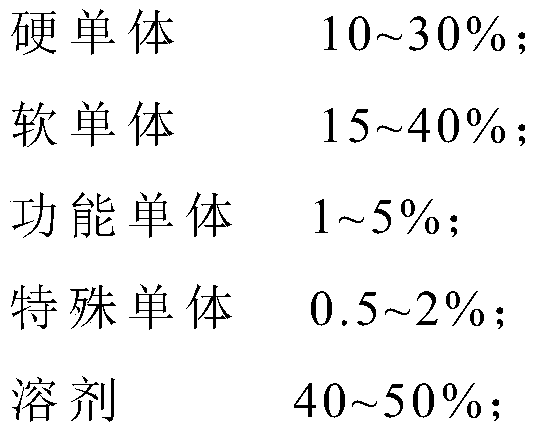

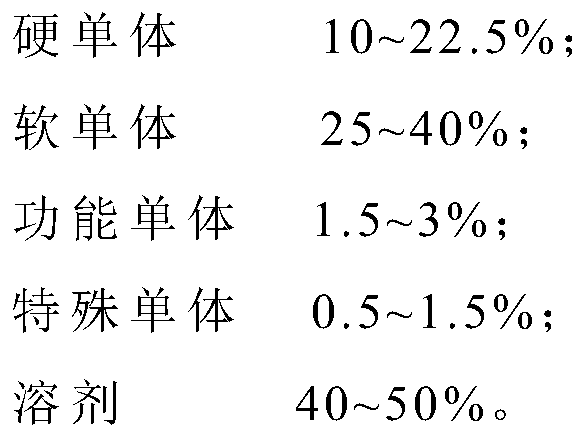

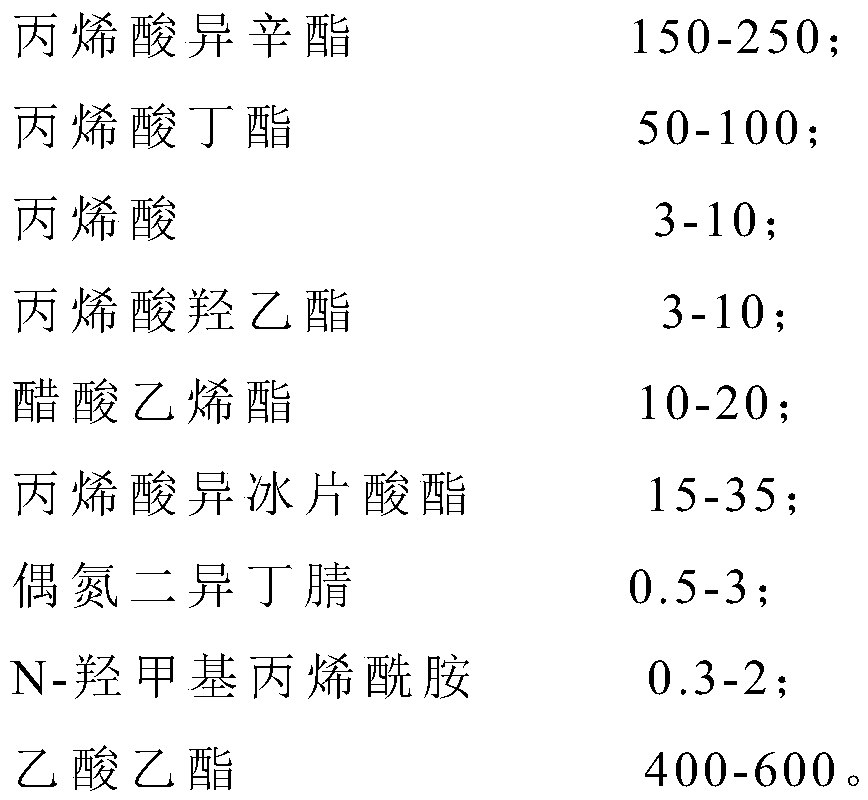

Polyacrylate, pressure-sensitive adhesive and preparation method

ActiveCN109762097AThe polymerization process is simpleHigh temperature resistance and good adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylateGlycidyl methacrylate

The invention relates to polyacrylate. Polyacrylate is synthesized from raw materials in percentage by mass as follows: 10%-30% of a hard monomer, 15%-40% of a soft monomer, 1%-5% of a functional monomer, 0.5%-2% of a special monomer and 40%-50% of a solvent, wherein the hard monomer comprises one or more of methyl acrylate, methyl methacrylate, vinyl acetate, acrylonitrile and isobornyl methacrylate; the soft monomer comprises one or more of ethyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate and n-propyl acrylate; the functional monomer comprises one or more of hydroxyethyl acrylate, acrylic acid, methacrylic acid, hydroxypropyl acrylate and 2-hydroxyethyl methacrylate; the special monomer comprises one or more of methacrylamido ethyl ethylene urea, hydroxyethyl methacrylate phosphate and glycidyl methacrylate. A pressure-sensitive adhesive has good high-temperature-resistant adhesive property, does no squeeze out, has no residue, has low cost and can be applied to masking tapesused in capacitor taping in the electronics industry as well as certain high-temperature-resistant adhesive tapes.

Owner:CYBRID TECHNOLOGIES INC

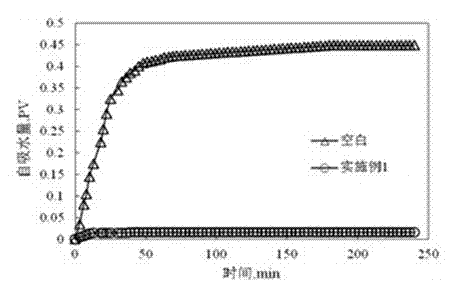

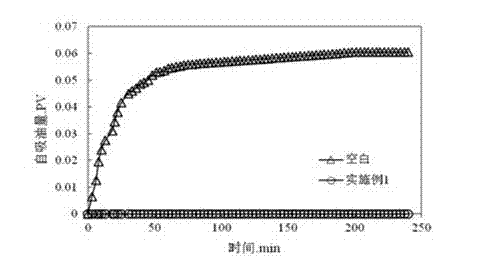

Anti-water-blocking agent for drilling fluid and preparation method thereof

ActiveCN102887974AGood weather resistanceImprove performanceDrilling compositionGas phaseWater block

The invention relates to an anti-water-blocking agent for drilling fluid and a preparation method thereof. The anti-water-blocking agent is a polymer containing a butyl acrylate (BA) monomer, a methyl methacrylate (MMA) monomer, a methacrylic acid (MAA) monomer, an acrylamide (AM) monomer and a 2-(perfluorohexyl)ethyl methacrylate (G06B) monomer, wherein the mol percent of a is 35.8-36.5%, the mol percent of b is 27.0-30.5%, the mol percent of c is 7.5-9.0% and the mol percent of d is 7.5-9.0%. According to the invention, the anti-water-blocking agent effectively reduces filtrate surface tension and oil-water interfacial tension, improves gas-phase relative permeability, has a good invading fluid draining effect and is beneficial to driving away resident fluid in near wellbore formations in a draining manner so as to better relieve the water blocking effect. The preparation method of the anti-water-blocking agent is safe and economic and has a high conversion rate; and a batch feeding method is used, so that the requirements for low dosage and high performance are met.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Cable semiconductive shield compositions

InactiveUS6706791B2Special tyresPower cables with screens/conductive layersAliphatic unsaturated hydrocarbonGram

A composition comprising:(a) one or more copolymers selected from the group consisting of (I) a copolymer of ethylene and vinyl acetate containing about 10 to about 50 percent by weight vinyl acetate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; (II) a copolymer of ethylene and ethyl acrylate containing about 10 to about 50 percent by weight ethyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; and (III) a copolymer of ethylene and butyl acrylate containing about 10 to about 50 percent by weight butyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes, and based upon 100 parts by weight of component (a):(b) about 55 to about 200 parts by weight of a linear copolymer of ethylene and an alpha-olefin having 3 to 12 carbon atoms, the copolymer having a melt mass flow rate of about 0.1 to about 30 grams per 10 minutes and a density of 0.870 to 0.944 gram per cubic centimeter;(c) about 5 to about 50 parts by weight of polypropylene having a melt mass flow rate of about 0.5 to about 30 grams per 10 minutes and a density of 0.900 to 0.920 gram per cubic centimeter;(d) about 2 to about 50 parts by weight of an organopolysiloxane having the following formula: R<1>xR<2>ySiO(4-a-b) / 2wherein R<1 >is an aliphatic unsaturated hydrocarbon group; R<2 >is an unsubstituted or substituted monovalent hydrocarbon group excluding aliphatic unsaturated hydrocarbon groups; x is equal to or greater than 0 but less than 1; y is greater than 0.5 but less than 3; x+y is greater than 1 but less than 3; a is greater than 0 but equal to or less than 1; and b is equal to or greater than 0.5 but equal to or less than 3;(e) about 10 to about 350 parts by weight of carbon black; and(f) optionally, up to about 2 parts by weight of an organic peroxide.

Owner:NIPPON YUNIKAA

Sound damping compositions and methods for applying and baking same onto substrates

InactiveUS7253218B2Good curative effectMovable spraying apparatusPretreated surfacesControl mannerAcrylonitrile

Owner:EFTEC NORTH AMERICA

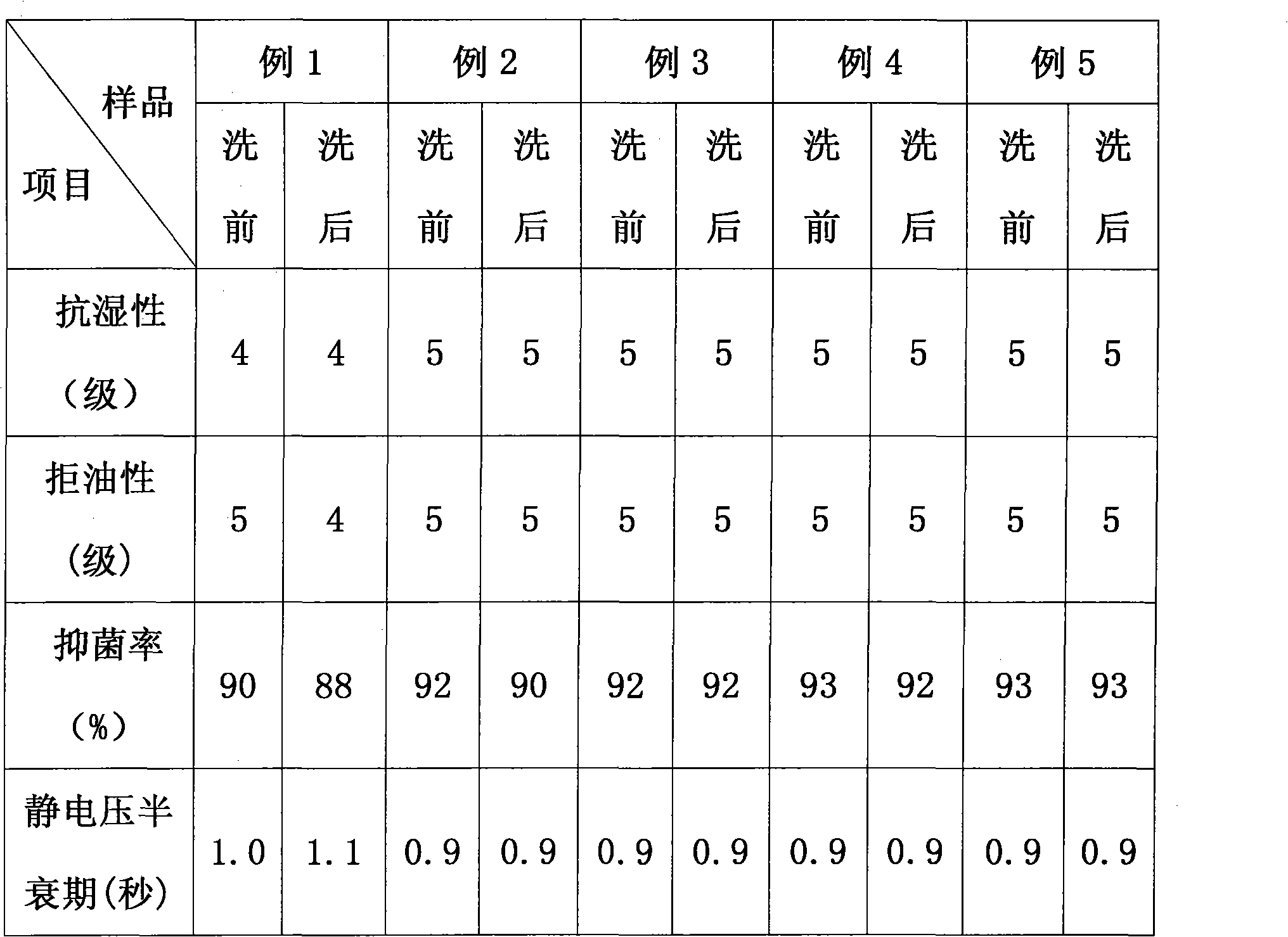

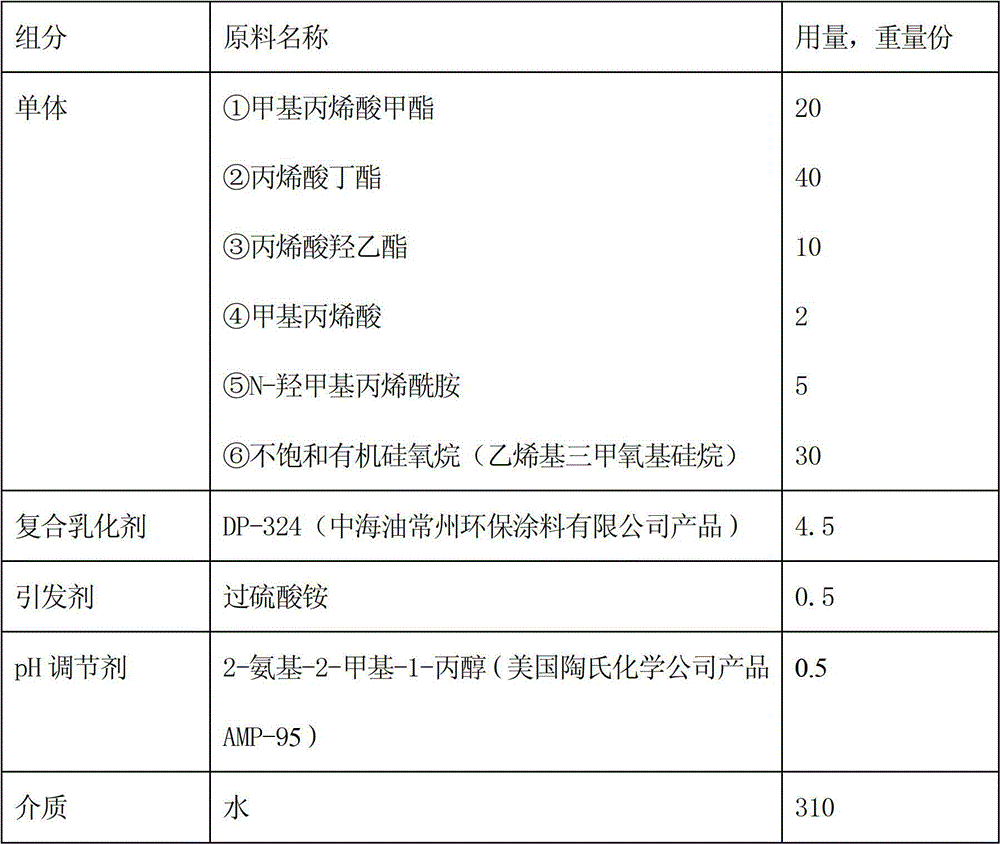

Durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and preparation method

ActiveCN102108638AImprove washing resistanceGood film fastnessFibre treatmentGlycidyl methacrylateAdhesive

The invention provides a durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and a preparation method. The coating adhesive is prepared from methyl acrylate, n-butyl acrylate, glycidyl methacrylate, allyl methacrylate, 2,2,2-trifluoroethyl methacrylate, acryloyloxyethyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether XL90, hexadecyl trimethyl ammonium chloride, 2,2-azobis(2-methylpropionamidine)hydrochloride, deionized water and an associative polyurethane levelling and rheological agent WT-203 through the processes of emulsification, initiated polymerization and thickening.

Owner:DANDONG UNIK TEXTILE

Hot melt adhesive

InactiveCN101659841AImprove adhesionReduce manufacturing costMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesTackifierChemistry

The invention relates to a hot melt adhesive which comprises substances based on the parts by weight: 10-20 parts of 501-800g / 10mins of MI containing 26-30% of vinyl acetate monomer EVA, 10-20 parts of 301-500g / 10mins of MI containing 22-25% of vinyl acetate monomer EVA, 10-20 parts of 150-300g / 10mins of MI containing 18-21% of vinyl acetate monomer EVA, 15-30 parts of 701-900g / 10mins of MI containing 30-33% of N-butyl acrylate monomer EBA, and 15-30 parts of 500-700g / 10mins of MI containing 25-28% of N-butyl acrylate monomer EBA; meanwhile, softening point of the EBA and the EVA is 100-110 DEG C; furthermore, the hot melt adhesive also comprises 20-30 parts of tackifier which has the softening point of 100-110 DEG C and can be pentaerythritol abietate, ester gum, hydrogenated abietate, terpene-phenolic abietate, terpene-phenolic resin or gum rosin, 10-15 parts of wax having the molecular weight of 2000-5000 and the melting point of 60-90 DEG C, 10-25 parts of filler and 0.5-1 part ofstabilizing agent.

Owner:陈铁旦

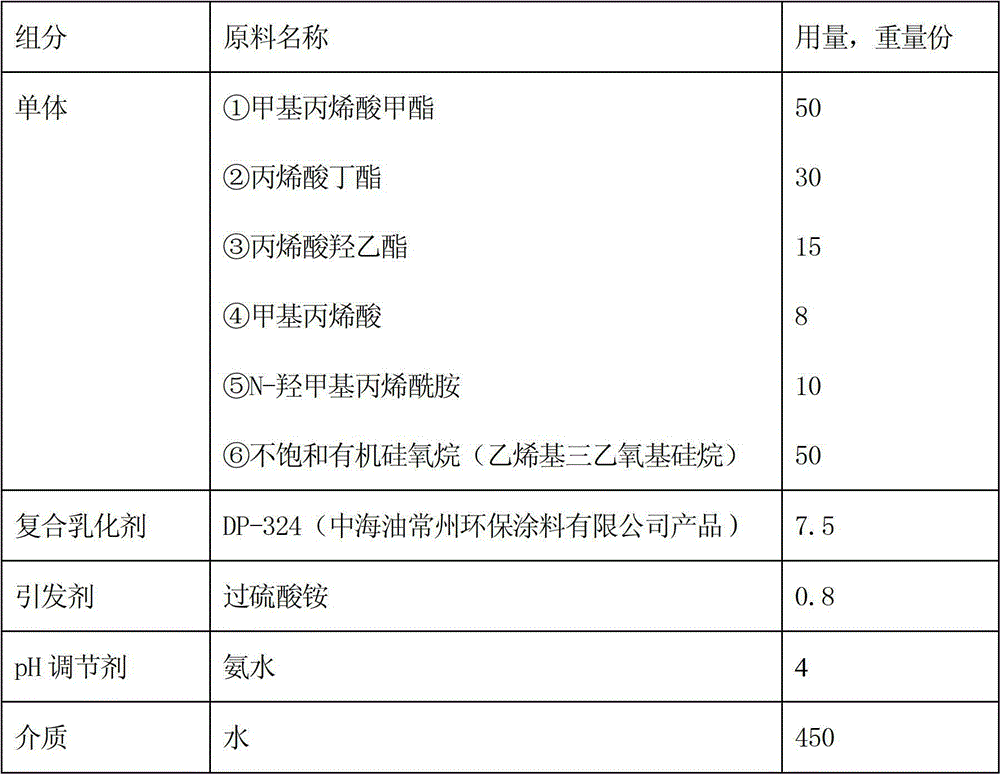

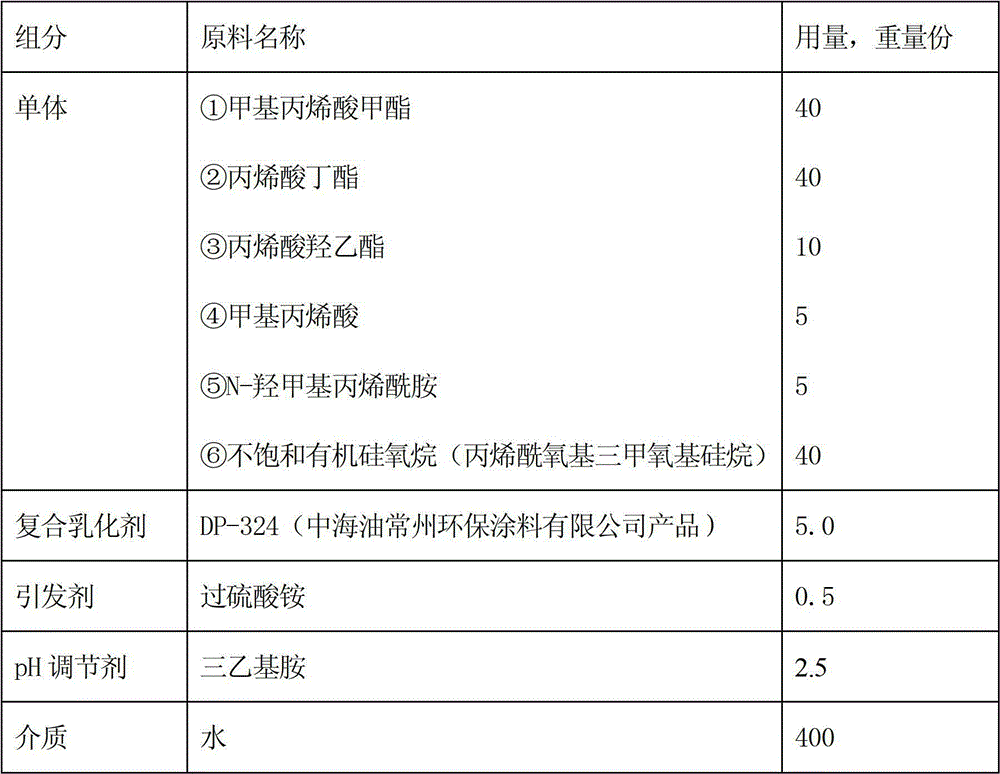

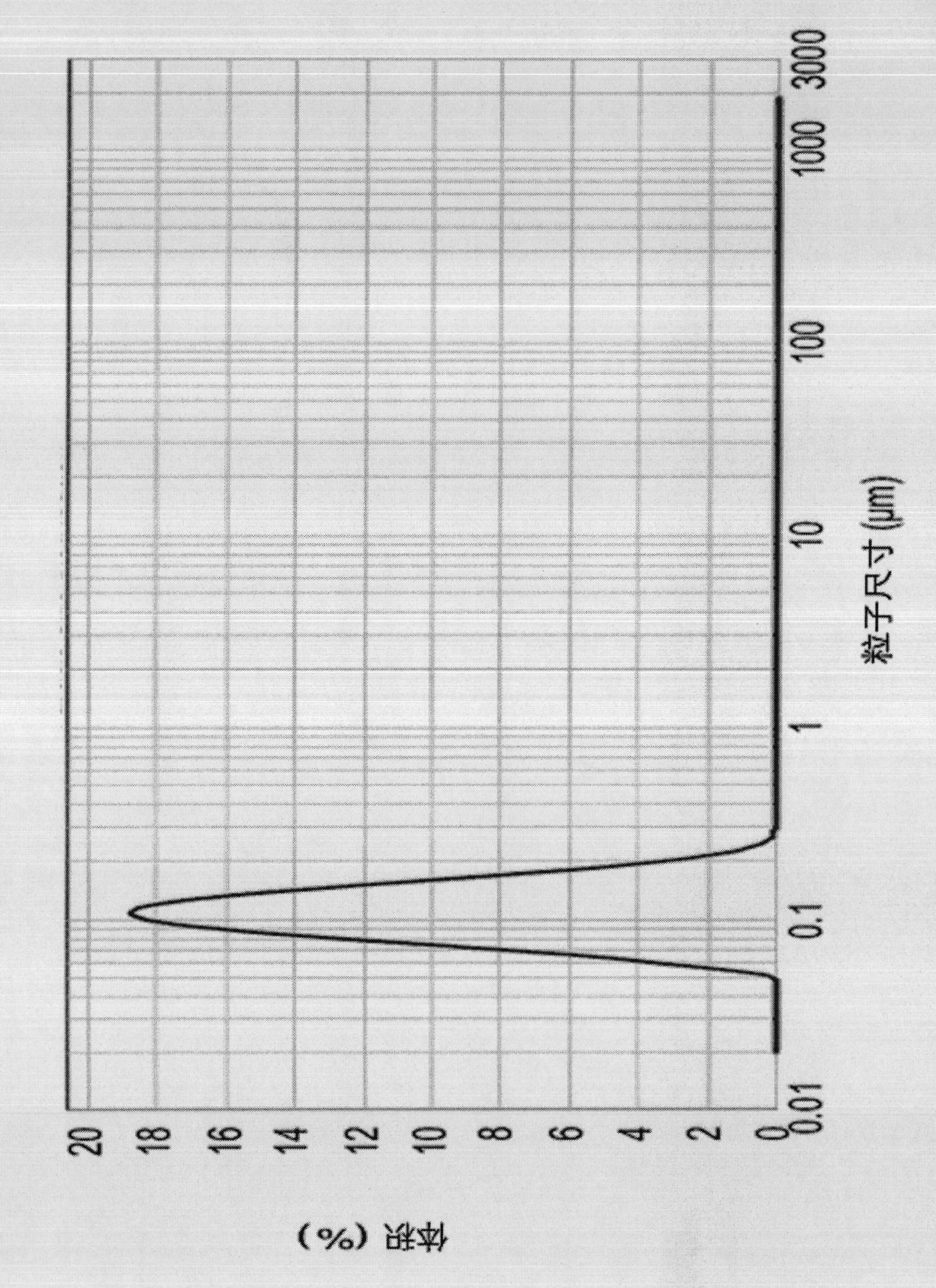

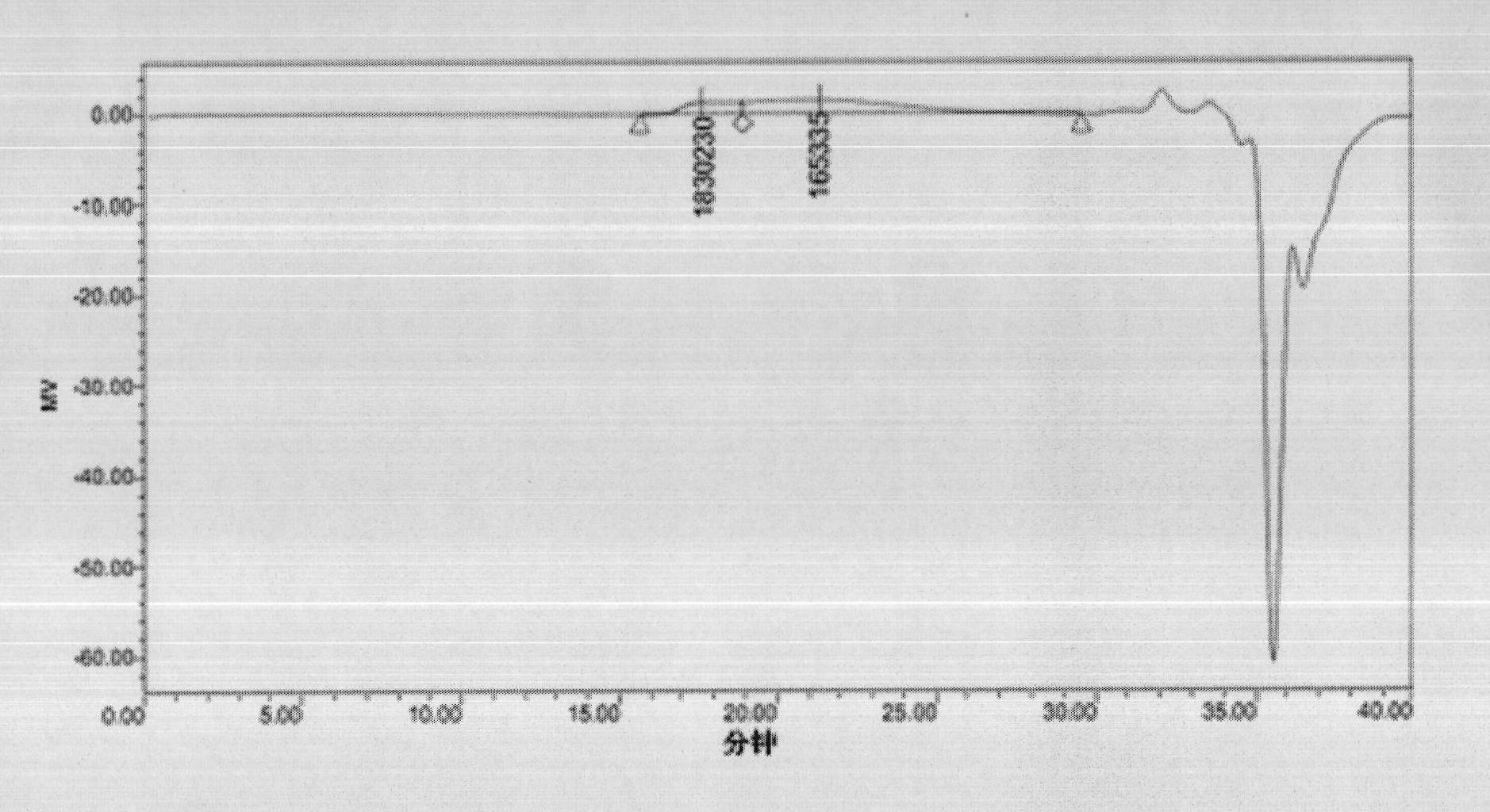

Organic-inorganic composite hydrophilic coating

The invention relates to an organic-inorganic composite hydrophilic coating which is composed of, by weight, 5-10 parts of a silicon hydroxyl contained acrylic ester emulsion, 10-40 parts of silica sol, 0.5-5 parts of a hydrophilic modified additive, 0-5 parts of other additives and 30-50 parts of deionized water. The silicon hydroxyl contained acrylic ester emulsion is formed by subjecting raw materials of methyl methacrylate, butyl acrylate, hydroxyethyl acrylate, methacrylic acid, N- hydroxymethyl acrylamide, unsaturation organo-siloxane, a compound emulsifier, a ammonium persulfate initiator, water and a potential of hydrogen (PH) conditioning agent to emulsion polymerization. Compared with paint films of conventional water-based dual-component finishing varnish and solvent type fluorocarbon finishing varnish, the pain film of the organic-inorganic composite hydrophilic coating has a super-hydrophilicity performance and a hydrophilic self-cleaning effect and is safe, environment-friendly, obvious in contamination resistant effect, and capable of well protecting the wall surface of a building and reducing maintenance expenses.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Process for treating skin with a tetrapolymer

The present invention relates to a treatment process for human skin, comprising the topical application to said skin of a composition comprising, in a physiologically acceptable medium, a tetrapolymer of methacrylic acid, methyl methacrylate, butyl acrylate and C16-C20 alkyl (meth)acrylates, said composition being devoid of sunscreen agents. The invention likewise relates to the use of a tetrapolymer of methacrylic acid, methyl methacrylate, butyl acrylate and C16-C20 alkyl (meth)acrylates.

Owner:LOREAL SA

Composite toughening modifier for plastics and preparation method thereof

ActiveCN102464839AGood toughening effectReduce energy consumptionPigment treatment with macromolecular organic compoundsElastomerMethacrylate

The invention provides a composite toughening modifier for plastics and a preparation method thereof. The composite toughening modifier for plastics comprises nanometer calcium carbonate and polyacrylate elastomer coated on the nanometer calcium carbonate, wherein, the polyacrylate elastomer is formed by using a soft monomer and a hard monomer through polymerization, the soft monomer comprises one or more of acrylic acid butyl ester, isobutyl acrylate, octyl acylate, or octyl methacrylate, and the hard monomer comprises one or more of methyl methacrylate, styrene or vinyl acetate. The composite toughening modifier can be used as a filling material of a rubber and plastic material, can be used for toughening toughening cooperating with CPE to increase the impact strength of the material by more than 5 times, and the impact strength of the toughened material is increased by over more than 10 times more than that of untoughened PVC, the application range of nanometer calcium carbonate is greatly enlarged, and the cost of rubber and plastic products can be greatly reduced.

Owner:SHANGHAI HUAMING HI TECH GRP

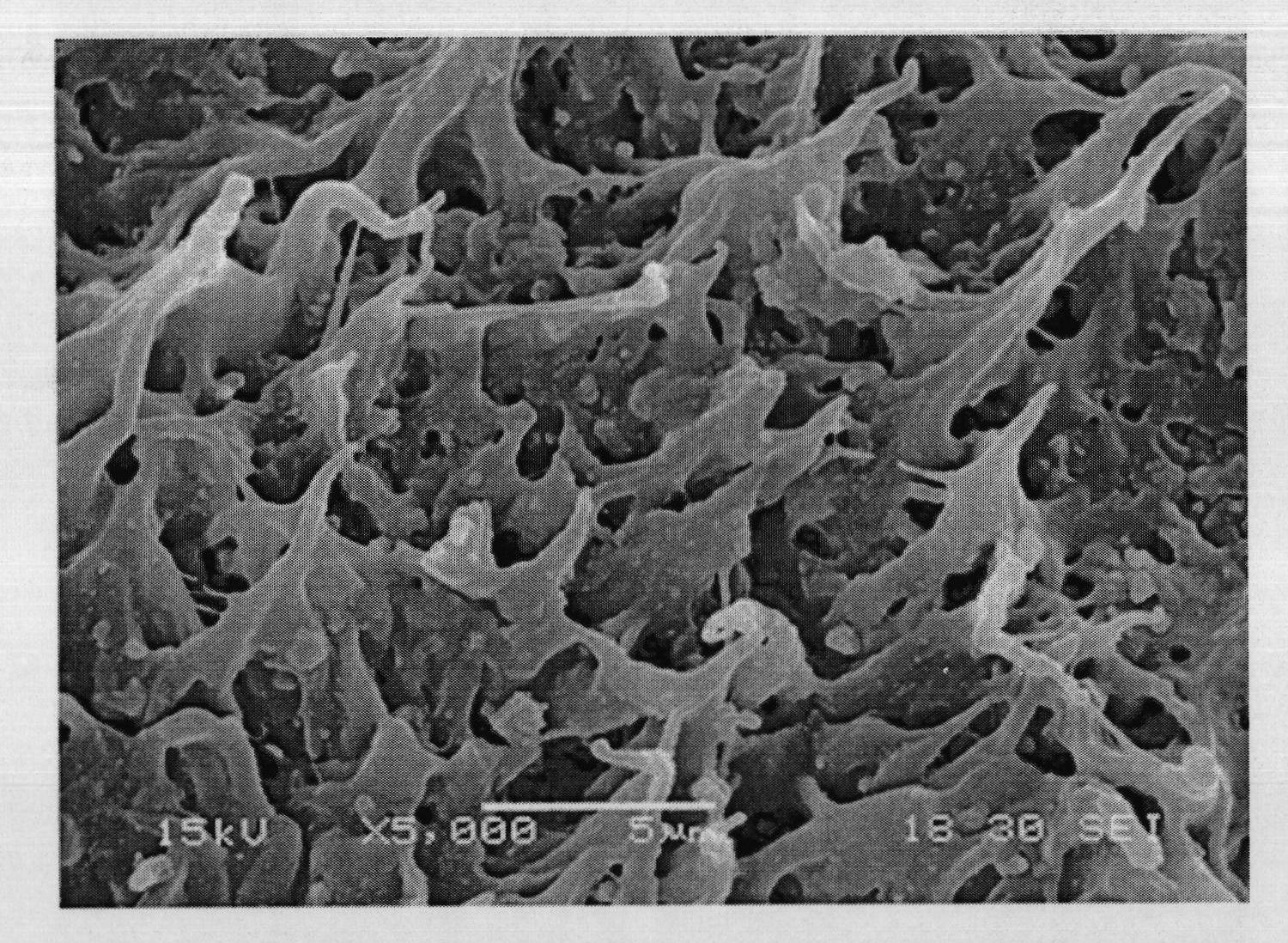

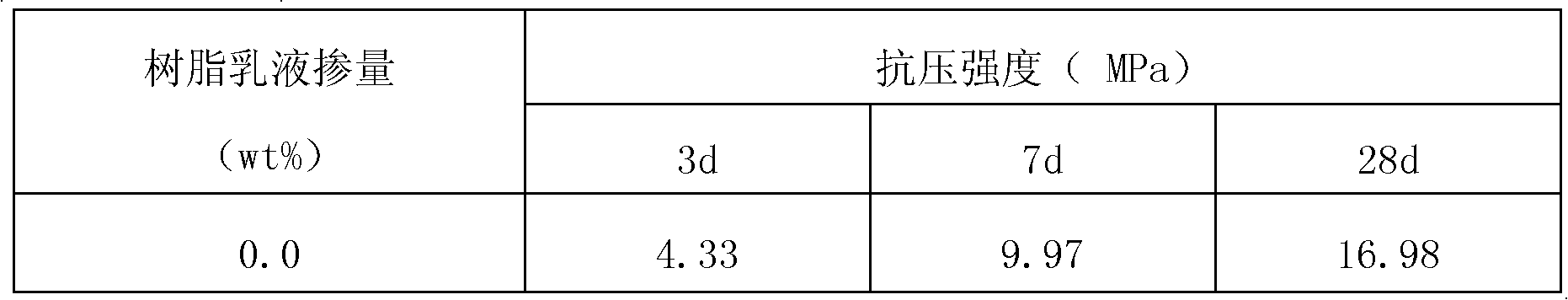

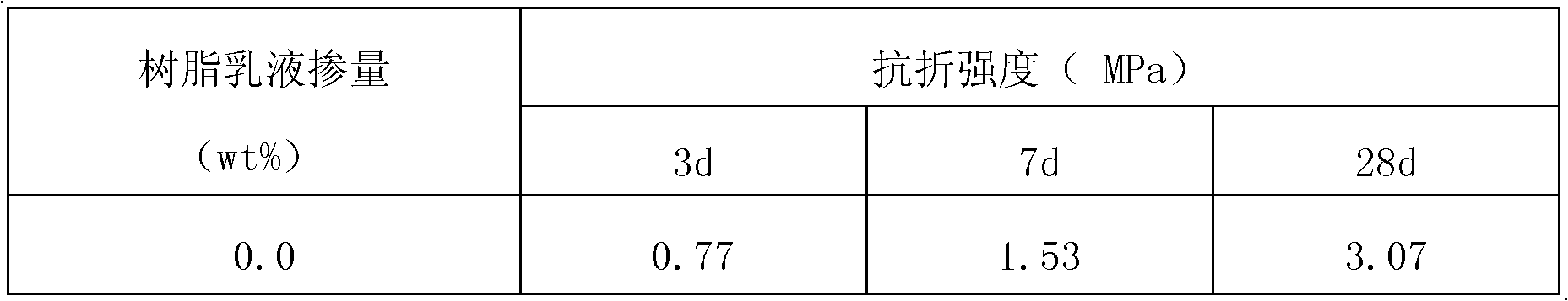

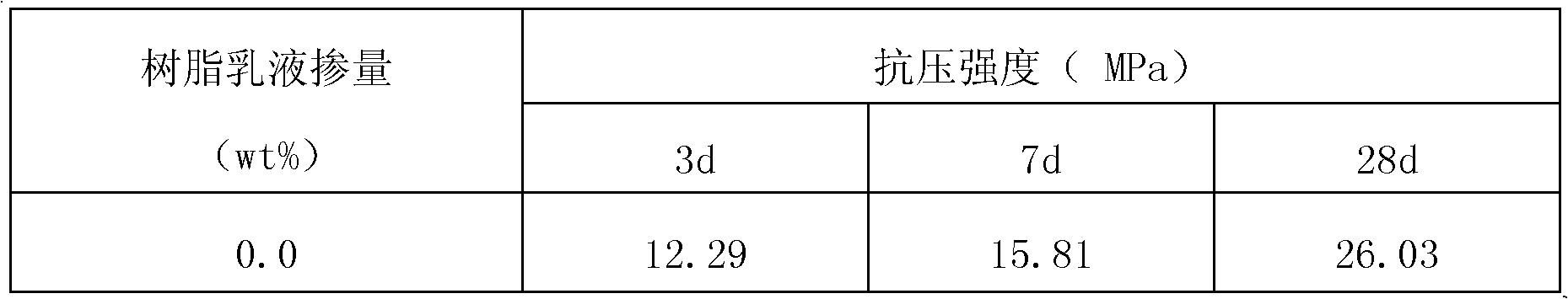

Fly ash-based inorganic polymer composite cementitious material and preparation method thereof

InactiveCN101792275AEfficient circular economyNo waste dischargeSolid waste managementCement productionAcrylic resinFlexural strength

The invention relates to a fly ash-based inorganic polymer composite cementitious material and a preparation method thereof, and the fly ash-based inorganic polymer composite cementitious material comprises the following raw materials: 1350g of fly ash, 150g of silicon powder, 225 or 300g of sodium silicate and 307 or 264g of water (water + crystal water in Na2SiO29H2O: fly ash and silicon powder is equal to 0.29), wherein the doping amount of butyl acrylate-acrylic resin emulsion is 0.5%-3% of the weight of the fly ash and the silicon powder. The fly ash-based inorganic polymer composite cementitious material is prepared by using the sodium silicate for exciting the binary complex fly ash and the silicon powder at room temperature or doping the butyl acrylate-acrylic resin emulsion into the binary complex fly ash and the silicon powder excited by the sodium silicate at the room temperature. The optimal compressive strength at the age of 28 days is improved by 10.43MPa in comparison with a binary complex fly ash-based inorganic polymer, and the flexural strength at the age of 28 days is improved by 2.52MPa. The doping of the butyl acrylate-acrylic resin emulsion can significantly improve the compressive strength and the flexural strength of the fly ash-based inorganic polymer composite cementitious material; and the preparation process is carried out under normal temperature and normal pressure and has the advantages of zero emission, greenness and environmental protection.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

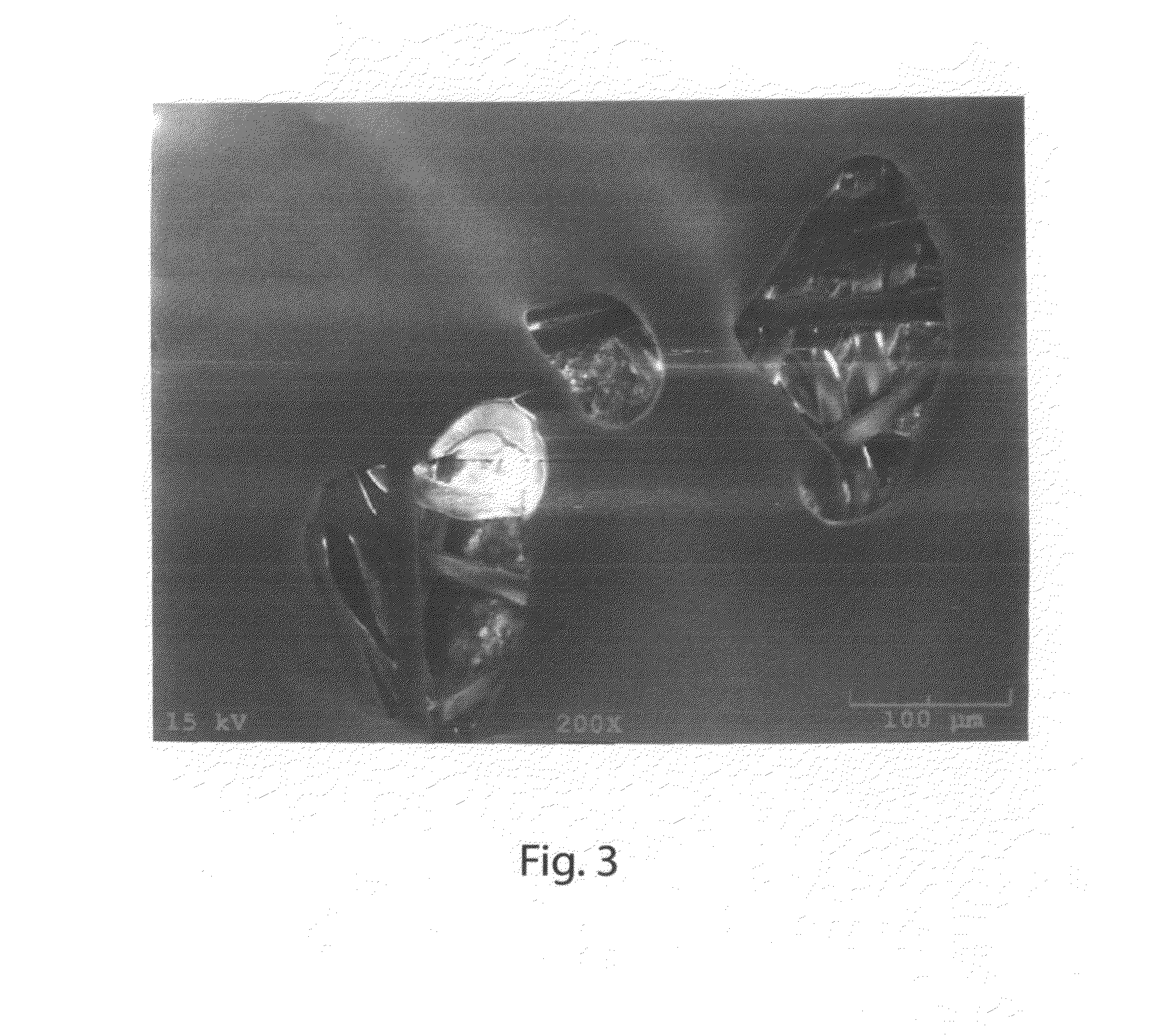

Preparation method of hydrophobic modified cationic polyacrylamide flocculant

ActiveCN103319652AReduce hydrophilicitySettling fastWater/sewage treatment by flocculation/precipitationSuspended particlesColloidal particle

A preparation method of hydrophobic modified cationic polyacrylamide flocculant comprises the following steps: weighing and mixing acrylamide, acryloyloxyethyl trimethyl ammonium chloride, butyl acrylate, perfluorinated octyl ethyl acrylate and a surfactant, obtaining polymer monomer aqueous solution by adding deionized water and mixing well by stirring, and then adding a plurality of additives; adding a compound initiator for polymerization and then adding a photoinitiator for polymerization; after the polymerization reaction, taking out colloidal particles for prilling, drying, crushing, and sifting, so that the hydrophobic modified cationic polyacrylamide flocculant is obtained. The flocculant provided by the present invention is able to improve the adsorption capacity of polymers to suspended particles, especially organic matters in water, by introducing lyophobic group into the macromolecule of the flocculant. Meanwhile, the flocculant possesses the properties of hydrophobic associating polymer, which is beneficial to the interaction between macromolecules, reducing the hydrophilic performance of the floc body, increasing the settling velocity of the floc body, and improving intensity of the flocs and water separation capability of the filter cake.

Owner:格润化学(东营)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com