Polyacrylate, pressure-sensitive adhesive and preparation method

A technology of polyacrylate and methyl methacrylate, applied in the field of pressure-sensitive adhesives, can solve the problems of different molecular weights and their distributions, and achieve the effects of low cost, simplified polymerization process, and good high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

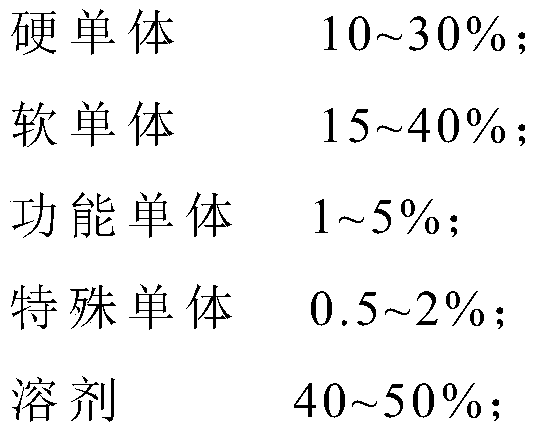

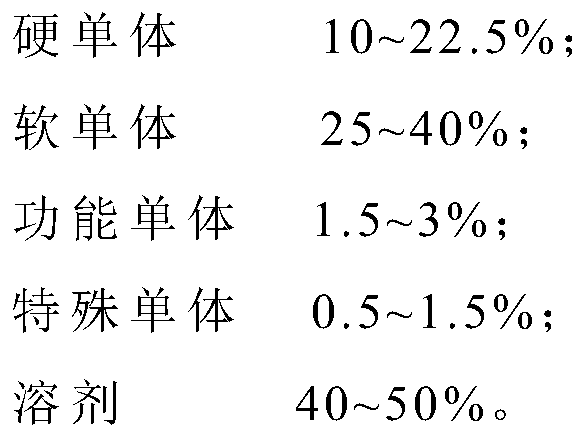

Method used

Image

Examples

Embodiment 1

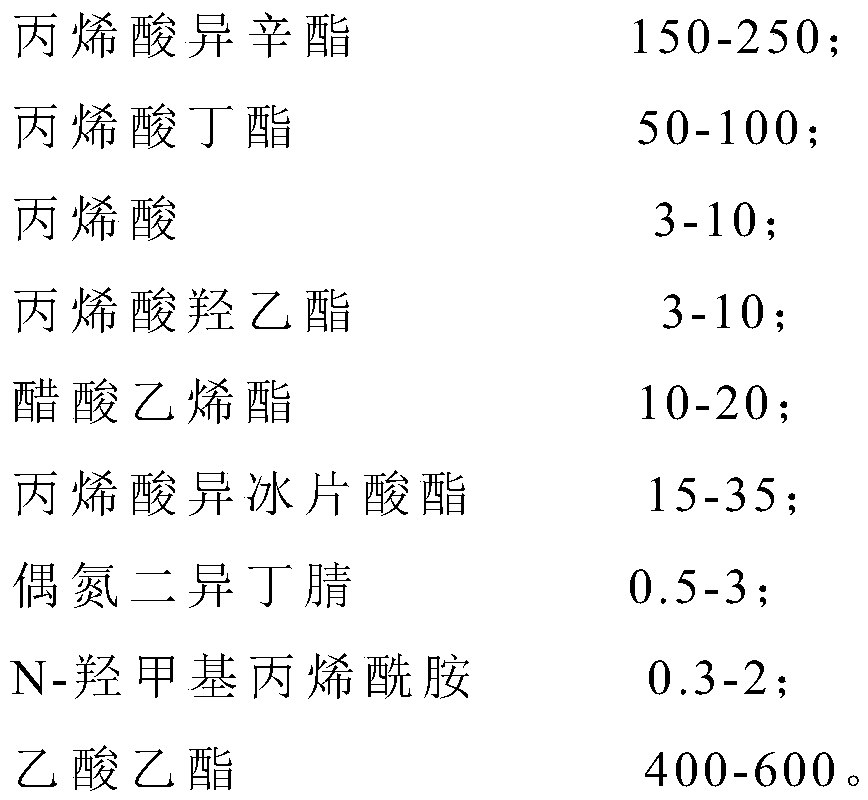

[0052] Weighing initiator 1.753g, ethyl acetate 18g mixed to obtain initiator solution.

[0053] Weigh 100g of methyl acrylate, 200g of isooctyl acrylate, 15.06g of acrylic acid, 0.5g of hydroxyethyl acrylate, 300g of ethyl acetate, 30g of vinyl acetate, and 5g of glycidyl methacrylate into the reactor, mix well and pass nitrogen gas Protect for about 30 minutes. After the temperature in the reactor rises to 65-68°C and stabilizes, add 40% initiator solution. When the temperature rises, the reaction starts timing. The reaction temperature is maintained at 65-68°C for 120 minutes, and then the second Add 40% initiator solution for the first time, continue to insulate for 60 minutes, add remaining initiator solution for the third time and insulate for 180 minutes; add 40g ethyl acetate to dilute and discharge when the insulation finishes.

Embodiment 2

[0055] Weighing initiator 1.753g, ethyl acetate 18g mixed to obtain initiator solution.

[0056]Weigh 90g of methyl acrylate, 240g of isooctyl acrylate, 15.06g of acrylic acid, 0.5g of hydroxyethyl acrylate, 300g of ethyl acetate, 30g of vinyl acetate, and 5g of glycidyl methacrylate into the reactor, mix well and pass nitrogen gas Protect for about 30 minutes. After the temperature in the reactor rises to 65-68°C and stabilizes, add 40% initiator solution. When the temperature rises, the reaction starts timing. The reaction temperature is maintained at 65-68°C for 120 minutes, and then the second Add 40% initiator solution for the first time, continue to insulate for 60 minutes, add remaining initiator solution for the third time and insulate for 180 minutes; add 50g ethyl acetate to dilute and discharge when the insulation finishes.

Embodiment 3

[0058] Weighing initiator 1.753g, ethyl acetate 18g mixed to obtain initiator solution.

[0059] Weigh 80g of methyl acrylate, 190g of isooctyl acrylate, 15.06g of acrylic acid, 2g of hydroxyethyl acrylate, 300g of ethyl acetate, 30g of vinyl acetate, 5g of hydroxyethyl methacrylate phosphate into the reactor, mix well and pass into Nitrogen protection for about 30 minutes, when the temperature in the reactor rises to 65-68°C and stabilizes, add 35% initiator solution, when the temperature rises, the reaction starts timing, the reaction temperature is maintained at 65-68°C for 120 minutes, and then Add 40% initiator solution for the second time, continue to insulate for 60 minutes, add remaining initiator solution for the third time and insulate for 180 minutes; add 50g ethyl acetate to dilute and discharge when the insulation finishes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com