Preparation method of polycaprolactone

A technology for polycaprolactone and caprolactone is applied in the field of preparing polycaprolactone, which can solve the problems of difficulty in degrading polymer materials, aggravating pollution, and restricting the rapid development of polymer materials, and achieves controllable molecular weight and metal residues. Less, the effect of various catalyst structure changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

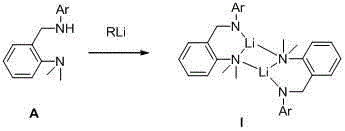

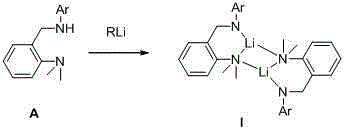

[0043] The structural formula of the ligand used is the above formula (A), where Ar is 4-methylphenyl, and the reaction process is as follows: under a nitrogen atmosphere, dissolve 0.51 g of the ligand in 10 mL of dry n-hexane, add at -10°C, etc. The molar amount of n-butyllithium was slowly raised to room temperature to react for 3 hours, filtered and washed with dry n-hexane, collected and dried to weigh 0.49 g solid, yield 94%.

[0044] The NMR information of the obtained product is as follows. It can be seen from the NMR information that the lithium compound whose Ar is 4-methylphenyl was successfully synthesized.

[0045] 1 H NMR (400 MHz, CDCl 3 ) δ 7.40 (d, J = 7.5 Hz, 2 H, Ph- H ), 7.24–6.91 (m, 10 H, Ph- H ), 6.62 (d, J = 7.6 Hz, 2 H, Ph- H ), 4.40 (s, 4H, C H 2 N), 2.72 (s, 12 H, NC H 3 ), 2.20 (s, 6 H, C H 3 ).

[0046] 13C NMR (100 MHz, CDCl 3 ) δ 152.45, 146.61, 134.27, 129.81, 128.23, 127.98, 126.66, 124.17, 116.34, 114.34, 48.86, 45.46, 20...

Embodiment 2

[0048] The structural formula of the ligand used is the above formula (A), where Ar is 2,6-dimethylphenyl, and the reaction process is as follows: under a nitrogen atmosphere, dissolve 0.47 g of the ligand in 10 mL of dry cyclohexane, at 0 °C Add 1.05 times the molar amount of n-butyllithium, slowly rise to room temperature and react for 6 hours, filter and wash the filter cake with dry n-hexane, collect and dry and weigh to obtain 0.46 g solid, yield 95%.

[0049] The NMR information of the obtained product is as follows. It can be seen from the NMR information that the lithium compound whose Ar is 2,6-dimethylphenyl was successfully synthesized.

[0050] 1 H NMR (400 MHz, CDCl 3 ) δ 7.42 (dd, J = 6.2, 1.3 Hz, 2H, Ph- H ), 7.28-7.25 (m, 2H, Ph- H ), 7.17 (dd, J = 7.0, 1.0 Hz, 2H, Ph- H ), 7.06 (td, J = 7.4, 1.2 Hz, 2H), 7.00 (d, J = 7.4 Hz, 4H), 6.83 (t, J = 7.5 Hz, 2H), 4.17 (s, 4H, NC H 2 Ph), 2.73 (s, 12H, NC H 3 ), 2.31 (s, 12H, PhC H 3 ).

[0051]...

Embodiment 3

[0053] The structural formula of the ligand used is the above formula (A), where Ar is 2,6-diethylphenyl, and the reaction process is as follows: under a nitrogen atmosphere, dissolve 0.34 g of the ligand in 5 mL of dry toluene, and at -10°C Add 1.1 times the molar amount of methyllithium, rise to room temperature and react for 1 hour, filter and wash the filter cake with dry n-hexane, collect, dry and weigh to obtain 0.32 g, yield 91%.

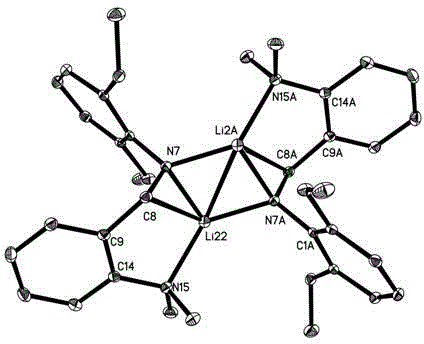

[0054] The crystal structure of the obtained product is shown in figure 1 As shown, the NMR information is as follows, it can be seen that the lithium compound whose Ar is 2,6-diethylphenyl was successfully synthesized.

[0055] 1 H NMR (400 MHz, CDCl 3 ) δ 7.48–7.45 (m, 2H, Ph- H ), 7.29 (dd, J = 7.8, 1.5 Hz, 2H, Ph- H ), 7.19 (dd, J = 8.0, 1.1 Hz, 2H, Ph- H ), 7.13 (d, J = 7.9 Hz, 2H, Ph- H ), 7.09 (m, 4H, Ph- H ), 6.97 (dd, J = 8.1, 6.9 Hz, 2H, Ph- H ), 4.12 (s, 4H, NC H 2 Ph), 2.73 (s, 12H, NC H 3 ), 2.52 (q, J =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com