Polysiloxane with side chain containing vinyl and quaternary ammonium salt, synthesis method of polysiloxane and application thereof in preparation of antibacterial silicone rubber

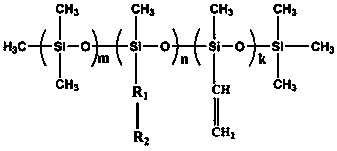

A technology of polysiloxane and quaternary ammonium salt, applied in the field of organic silicon polymer materials, can solve the problems of difficulty in preparing high molecular weight polysiloxane containing quaternary ammonium salt, low product yield, difficult industrialization, etc., and achieve high yield High, long-lasting antibacterial performance, molecular weight controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In a single-necked flask equipped with a spherical condenser and a magnet, add 4.22g of chloropropylmethyldiethoxysilane, 3.15g of N,N-dimethyl n-octylamine and 6ml of ethanol in sequence, and stir to make them evenly mixed. Nitrogen protection, reflux at 80°C, react for 48 hours, after the reaction, distill off the low boilers under reduced pressure to obtain a yellow transparent oily liquid, wash the product with petroleum ether three times, and dry it in vacuum for 24 hours, which is methyldiethoxysilane quaternary Ammonium salt monomer (i), yield 97%.

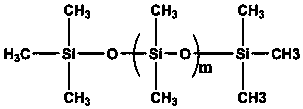

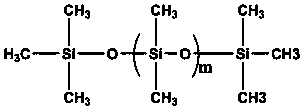

[0039] In a three-necked flask equipped with a spherical condenser, thermometer, and stirrer, add 2.00g of methyldiethoxysilane quaternary ammonium salt monomer (i), 0.48g of vinylmethyldiethoxysilane, 20.10g Hydroxy-terminated polydimethylsiloxane, 0.08g octamethyltrisiloxane and 0.23g tetramethylammonium hydroxide silicon alkoxide, stir to mix evenly, nitrogen protection, slowly raise the temperature to 70°C and keep...

Embodiment 2

[0041] In a single-necked flask equipped with a spherical condenser and a magnet, add 3.09g of chloromethylmethyldimethoxysilane, 3.15g of N,N-dimethyl n-octylamine and 6ml of ethanol in sequence, and stir to make them evenly mixed. Nitrogen protection, reflux at 80°C, and react for 48 hours. After the reaction, remove the low boilers by distillation under reduced pressure to obtain a yellow transparent oily liquid, wash the product with petroleum ether three times, and dry it in vacuum for 24 hours, which is methyldimethoxysilane quaternary Ammonium salt monomer (ii), yield 99%.

[0042] In a three-necked flask equipped with a spherical condenser, thermometer, and stirrer, add 3.00g of methyldimethoxysilane quaternary ammonium salt monomer (ii), 0.32g of vinylmethyldimethoxysilane, 25.12g Hydroxyl-terminated polydimethylsiloxane, 0.13g octamethyltrisiloxane and 0.28g tetramethylammonium hydroxide silicon alkoxide, stir to mix evenly, nitrogen protection, slowly raise the temp...

Embodiment 3

[0044] As described in Example 1, the difference is that the N,N-dimethyl n-octylamine used in the quaternization reaction was changed to imidazole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com