Patents

Literature

131results about How to "Disruption of regularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

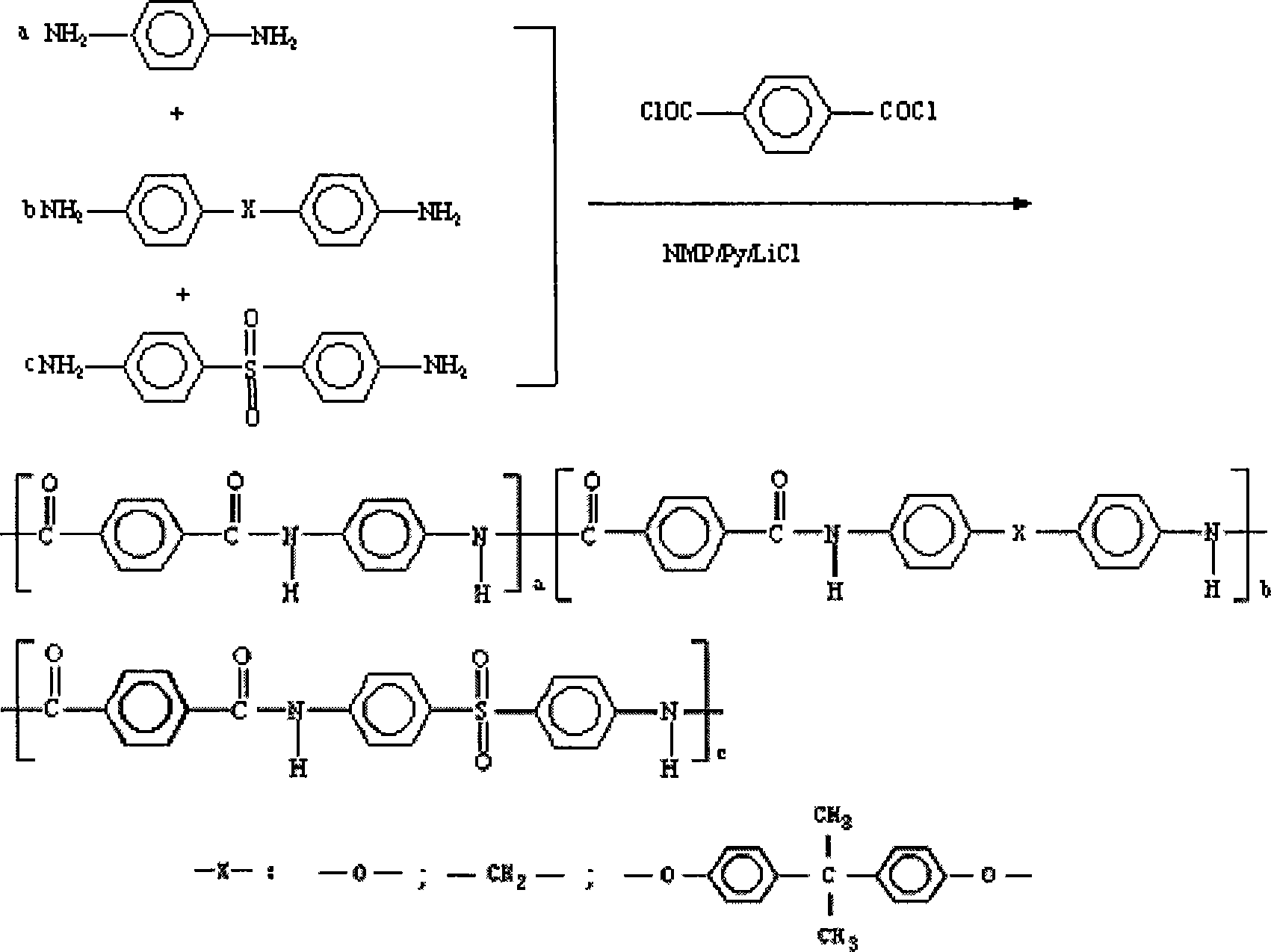

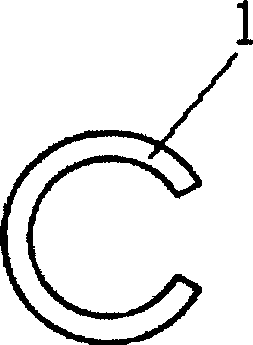

Random copolymerization polysulfonamide spinning liquid and preparation method thereof

InactiveCN101235552ADisruption of regularityImprove flexibilityMonocomponent copolyamides artificial filamentSpinning solutions preparationMetal chlorideMechanical property

The invention relates to random copolymerization poly-sulfone amide spinning fluid which is composited by three species aromatic diamine and terephthaloyl chloride and a method for preparing the random copolymerization poly-sulfone amide spinning fluid, wherein the spinning fluid takes the N-methyl-2pyrrolidone NMP as the dissolvent, monomer and the mole percent which are adopted by the method are as following: the aromatic diamine 40%-60%, the terephthaloyl chloride 60%-40%, taking the above total monomer 100% as a benchmark, further adding 1.0%-4.0% alkali chloride as the solvent. Since the method takes the manifold aromatic diamine as the monomer of the poly-reaction, which properly damages the regularity of the main chain, however, which has no effect to arrange the original crystal lattice, increasing the flexibility of the chain at various degree, the method is beneficial for orienting and crystallizing of the entire molecular chain and for improving the mechanical property of the material. The method has the advantages of simple technology, condition optimized, high operability, convenient manufacture and low cost.

Owner:SHANGHAI UNIV

Method for preparing complete water soluble low molecular weight chitosan/chitooligosaccharace

The disclosed preparation method for chitose / chitosan oligosaccharide with low molecular weight as 0.18-15mega and well water-solubility comprises: preparing water-soluble chitosan by acetylization; degrading the product with non-specific hydrolase while controlling the enzyme dosage and reaction time; adjusting the degraded product pH value to 8-9 with KOH or NaOH solution; depositing with ethanol, cleaning, and vacuum drying the final product with free amidogen that can promote wound healing, restrains tumor cell growth and improves human immunity. Compared with prior art, this invention is convenient to control for wide application.

Owner:WUHAN UNIV

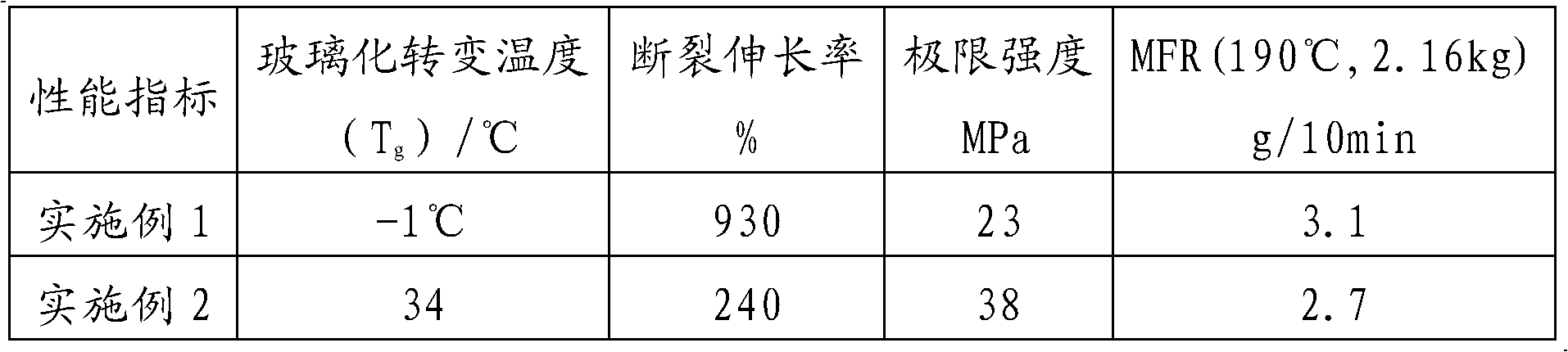

Thermoplastic block copolyether ester elastomer and preparation method thereof

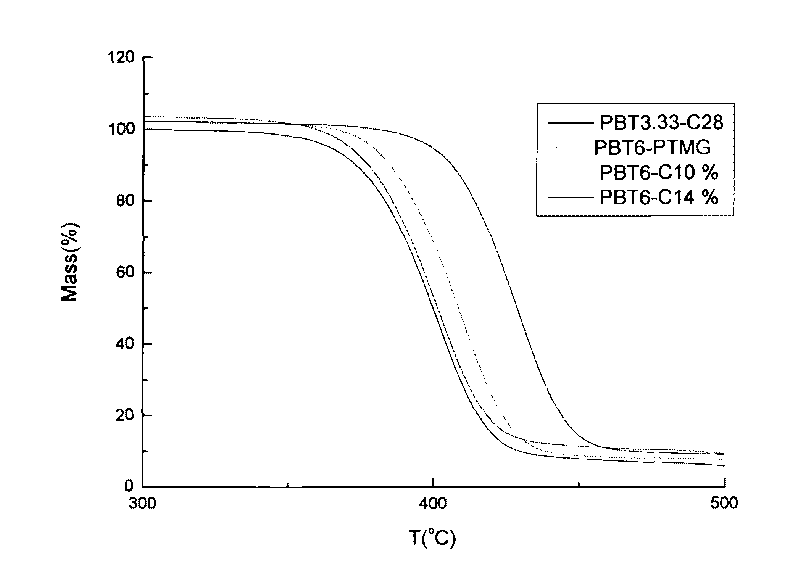

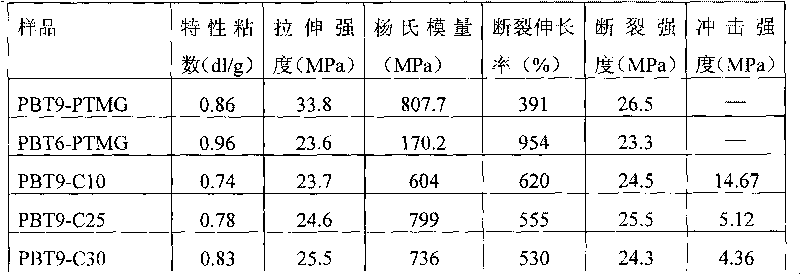

This invention relates to a thermoplastic block copolyether ester elastomer and a preparation method thereof, wherein the aromatic dicarboxylic acid and mixing divalent alcohol are reacted at 180-265 DEG C in the mol ratio of 1: 1.2-2.2; the titanium compound, the mixture of titanium compound and zinc compound or the mixture of titanium compound and magnesium compound is used as catalyst; the copolyether ester contains 15-90ppm of titanium element, 10-200ppm of zinc or magnesium, and 300-4000ppm of antioxidant; the obtained matter is reacted under pressure lower than 150Pa to distil out 1,4-butanediol and 1,4-cyclohexanedimethanol; the final temperature of the reaction is at 260-290 DEG C; in terms of total weight of the copolyether ester, the content of the hard segment is 50-92wt%; the inherent viscosity is 0.65-1.85dl / g; the melting point is at 160-220 degrees centigrade; the elongation at break is 500-1400% and the thermal decomposition temperature is 360 to 450 DEG C.

Owner:PETROCHINA CO LTD +1

Aliphatic-polyamide-modified copolyester, aliphatic-polyamide-modified copolyester fiber, and preparation methods thereof

ActiveCN103232596ALower crystallization properties and glass transition temperatureDisruption of regularitySpinning head liquid feederMonocomponent synthetic polymer artificial filamentPolyamideDiethylene glycol

The invention discloses aliphatic-polyamide-modified copolyester, aliphatic-polyamide-modified copolyester fiber, and preparation methods thereof. Preparation materials of the aliphatic-polyamide-modified copolyester comprise: terephthalic acid, ethylene glycol with an amount of 105-200mol% of the terephthalic acid, diethylene glycol isophthalate-5-alkali metal sulfonate with an amount of 1-10mol% of the terephthalic acid, and aliphatic polyamide with an amount of 1-40wt% of terephthalic acid. According to the aliphatic-polyamide-modified copolyester, flexible aliphatic polyamide chain segments are introduced into polyester macromolecular chains, such that macromolecular chain regularity is broken, and copolyester crystallinity and glass transition temperature are reduced. Aliphatic-polyamide-modified copolyester fiber prepared by using the aliphatic-polyamide-modified copolyester has soft texture. Also, when sulfonate groups are introduced into polyester macromolecular chains, flexible aliphatic polyamide chain segments are introduced, such that the copolyester fiber can be dyed by using cationic dyes under normal temperature and normal pressure.

Owner:CHINESE TEXTILE ACAD

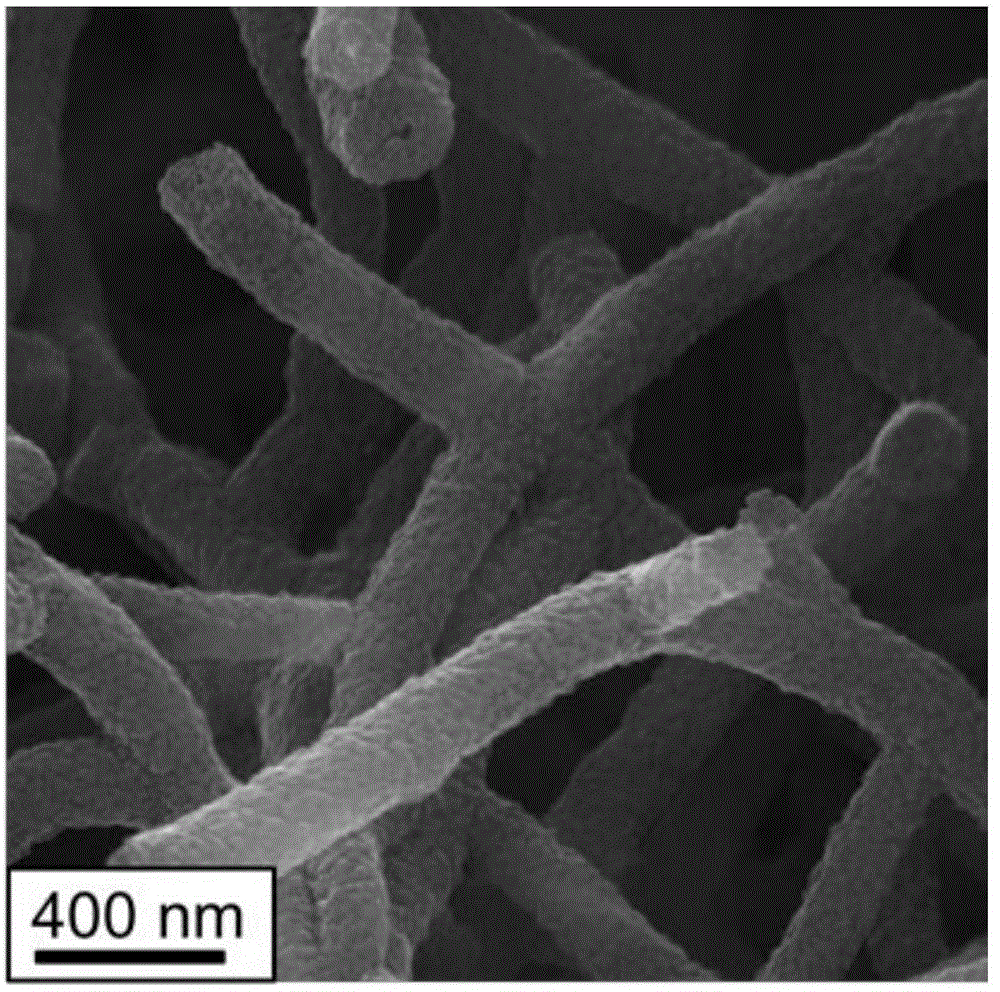

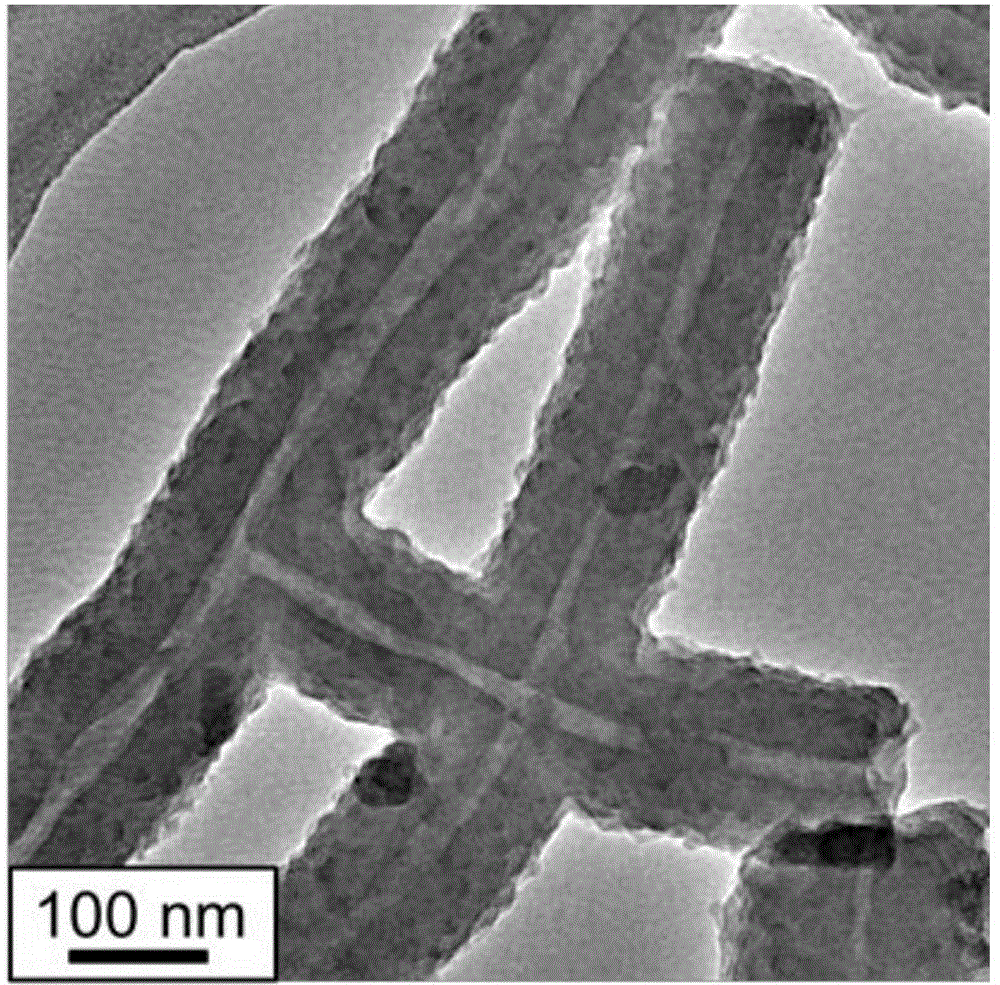

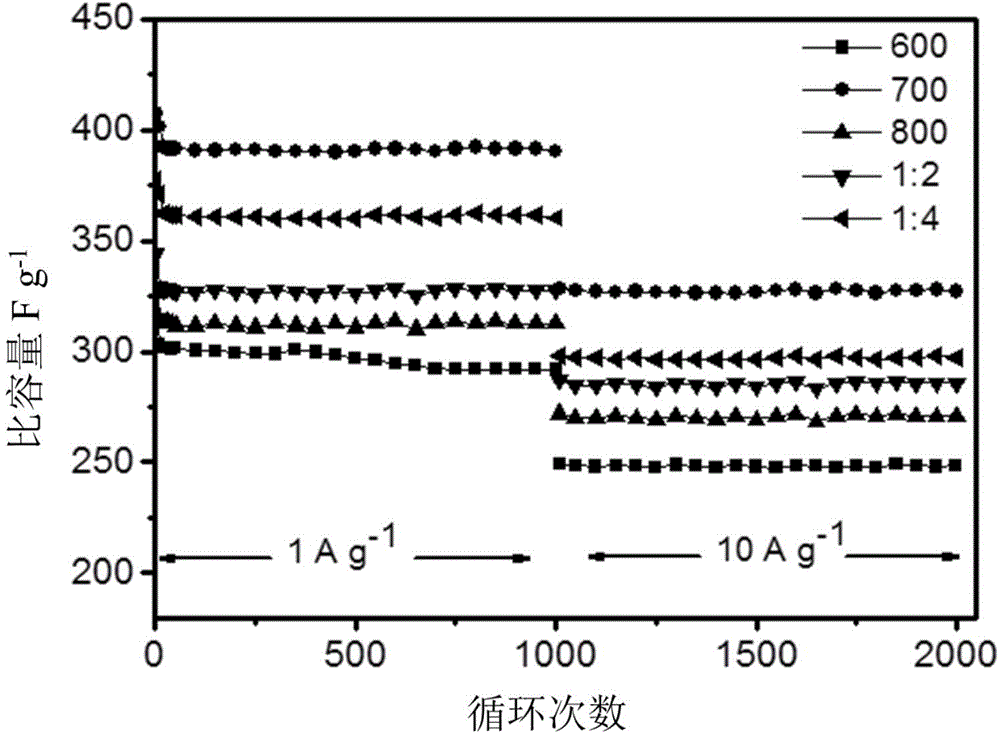

Nitrogen-doped porous carbon nanotube material and its preparation method and use in super capacitor electrode

InactiveCN105314614AImprove electrochemical performanceDisruption of regularityMaterial nanotechnologyHybrid capacitor electrodesPorous carbonNitrogen atmosphere

The invention discloses a nitrogen-doped porous carbon nanotube material and its preparation method thereof. Polyaniline carbon nanotubes as precursors prepared from a chemical oxidation process are charred at a temperature of 600-900 DEG C in a nitrogen atmosphere to form polyaniline-based carbon nanotubes, and the polyaniline-based carbon nanotubes are activated at a temperature of 600-800 DEG C in a nitrogen atmosphere to form the nitrogen-doped porous carbon nanotubes. The nitrogen-doped porous carbon nanotube has excellent electrochemical performances, has a capacity of 392Fg<-1> after cycle 1000 times at current density of 1Ag<-1> and has a capacity of 327Fg<-1> after cycle 1000 times at current density of 10Ag<-1>.

Owner:BEIJING UNIV OF CHEM TECH

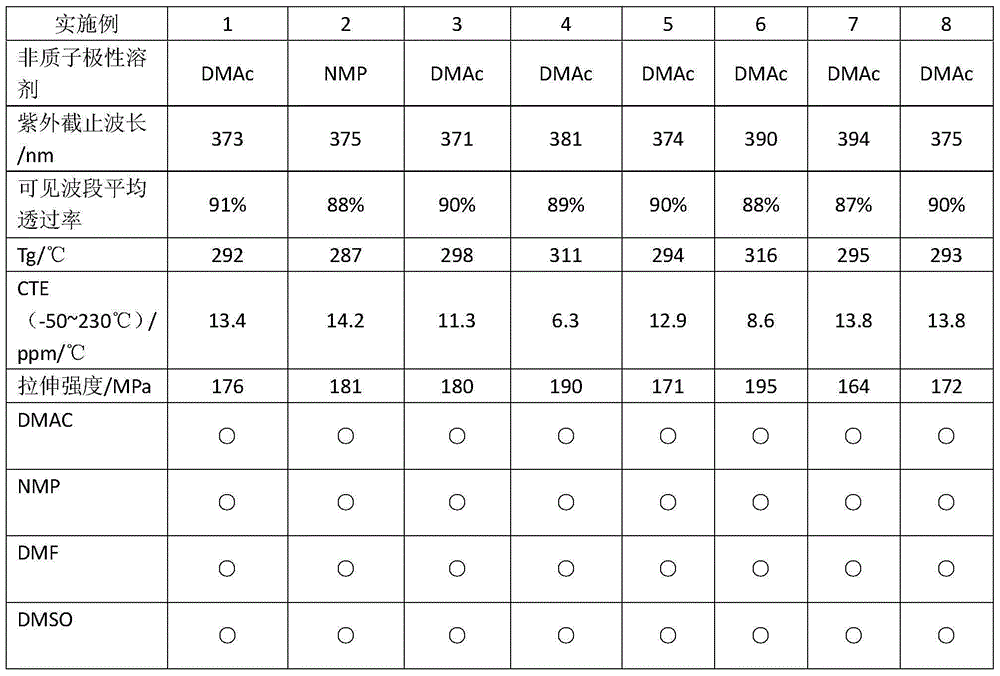

Preparation method of soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film

InactiveCN105017534AReduce the potential energy of the condensation reactionExcellent mechanicsPolymer scienceThermal expansion

The invention discloses a preparation method of a soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film. According to the prepared film, fluorine-containing diamine monomers serve as diamine monomers, trimellitic anhydride acid chloride serves as anhydride monomers, and the polyamide imide film is further prepared through a trimethylchlorosilane activation mechanism under a simple and moderate synthesis condition. The prepared polyamide imide film has high dimensional stability (the CTE is 5-15 ppm / DEG C or so) and good temperature resistance (Tg is 300 DEG C or so), the transmittance of visible light wavebands is 90% or so, the prepared polyamide imide film can be dissolved in an aprotic polar solvent and is convenient to machine and process, and the comprehensive performance of the prepared polyamide imide film meets the material performance requirement of a part of devices in the microelectronics and optoelectronics field.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

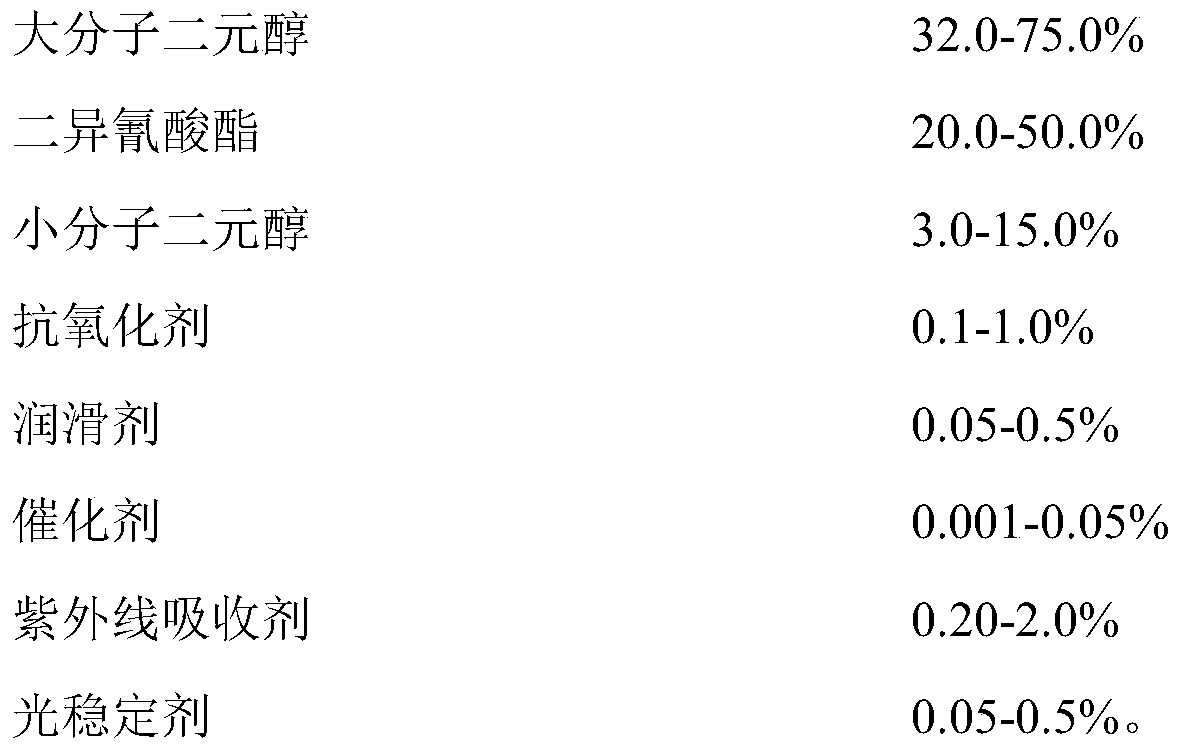

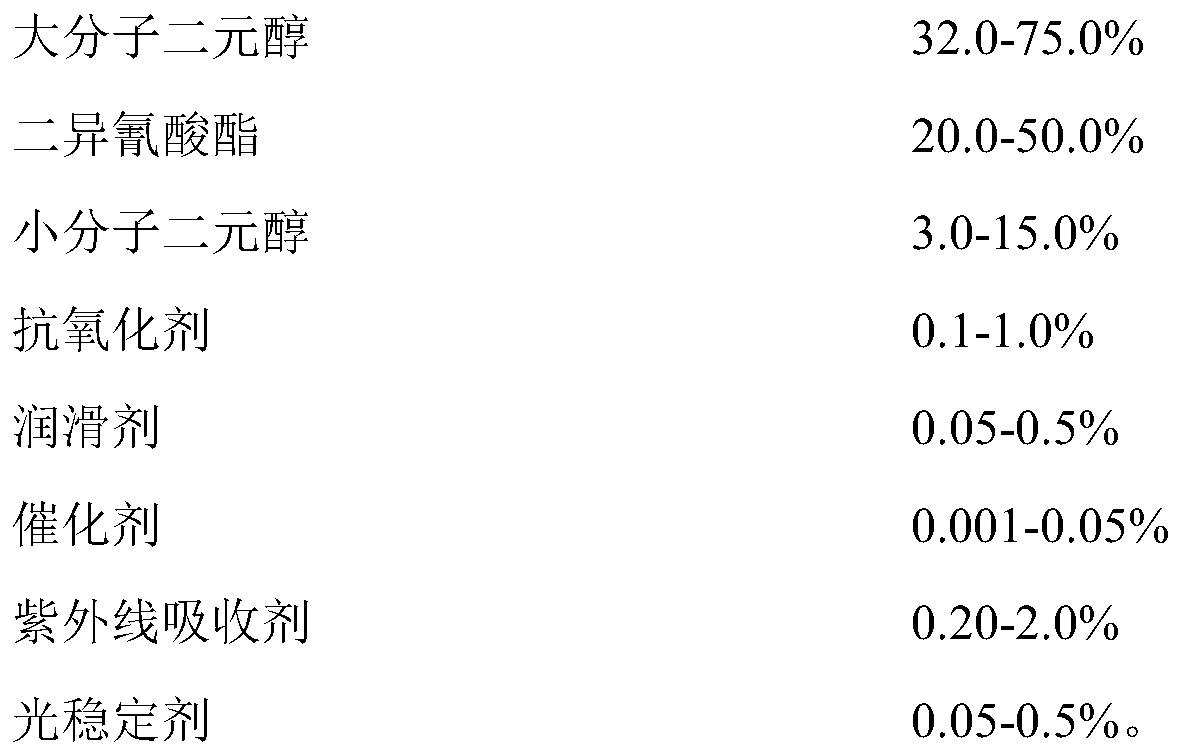

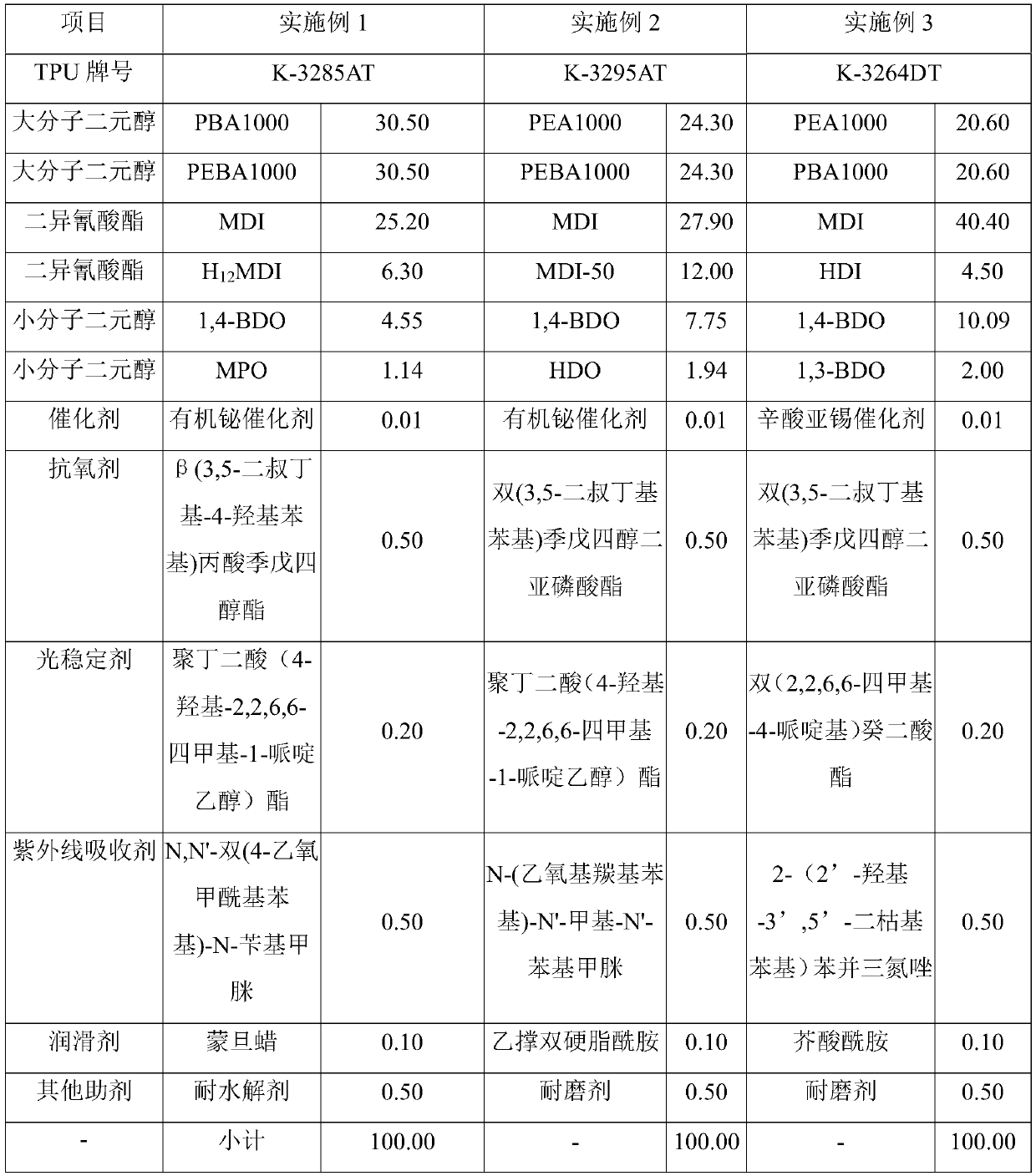

High-weather-resistance ultra-transparent thermoplastic polyurethane elastomer and preparation method thereof

The invention belongs to the technical field of polyurethane, and particularly relates to a high-weather-resistance ultra-transparent thermoplastic polyurethane elastomer and a preparation method thereof. The thermoplastic polyurethane elastomer comprises the following raw materials: macromolecular diol, diisocyanate micromolecular diol, an antioxidant, a lubricant, a catalyst, an ultraviolet light absorber and a light stabilizer. The preparation method comprises the following steps: mixing the raw materials, pouring the mixture into a co-rotating twin-screw reactive extruder, carrying out polymerization reaction to obtain a high-molecular polymer; and carrying out underwater granulation, dehydration, drying, packaging and curing treatment to obtain the finished product. The thermoplasticpolyurethane elastomer product disclosed by the invention has ultrahigh transparency, excellent weather resistance and high hardness, wherein the transparency of the polyester type thermoplastic polyurethane elastomer can reach that the turbidity of a 4mm test piece is less than or equal to 2.0% and the turbidity of a 6mm test piece is less than or equal to 5.0%; the transparency of the polyethertype thermoplastic polyurethane elastomer can reach that the turbidity of a 6mm test piece is less than or equal to 2.0% and the turbidity of an 8mm test piece is less than or equal to 5.0%.

Owner:山东科力美实业有限公司

Polyimide film and preparation method and applications thereof

ActiveCN102167824AHigh transparencyReduced solar absorption and emission ratioDiphenyl etherOptical transparency

The invention discloses a polyimide film and a preparation method and applications thereof. The compound forming the polyimide film is the compound of which structural general formula is shown in the formula I. The preparation method of polyimide is as follows: aromatic dianhydride 2,3,3',4'-diphenyl ether tetracarboxylic acid dianhydride (aODPA) and a series of aromatic diamine monomers are used as raw materials to prepare polyimide resin through chemical imidization. The polyimide film prepared by the technology has good optical transparency, low solar absorptivity-emissivity ratio and good thermal stability, and can be used to prepare the thermal protection device of the spacecraft, the solar cell array substrate and the antenna reflector / collector or solar sail and have important application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

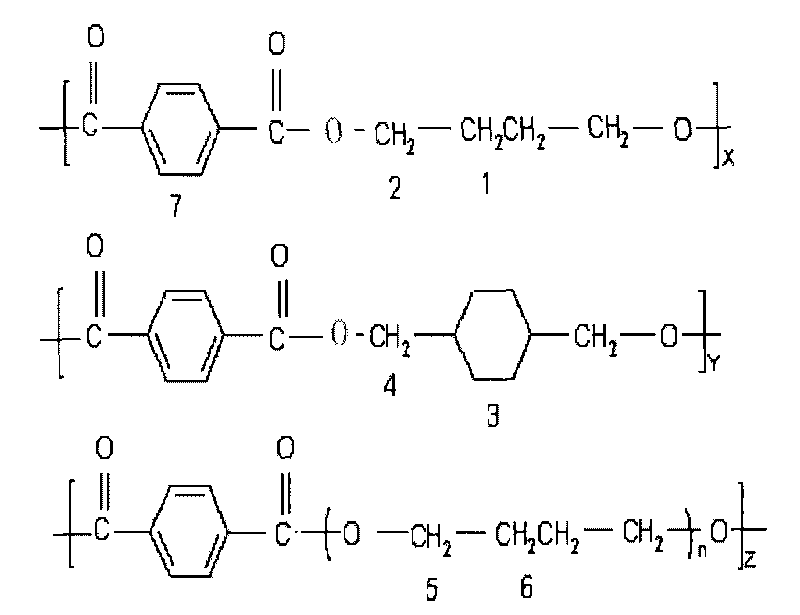

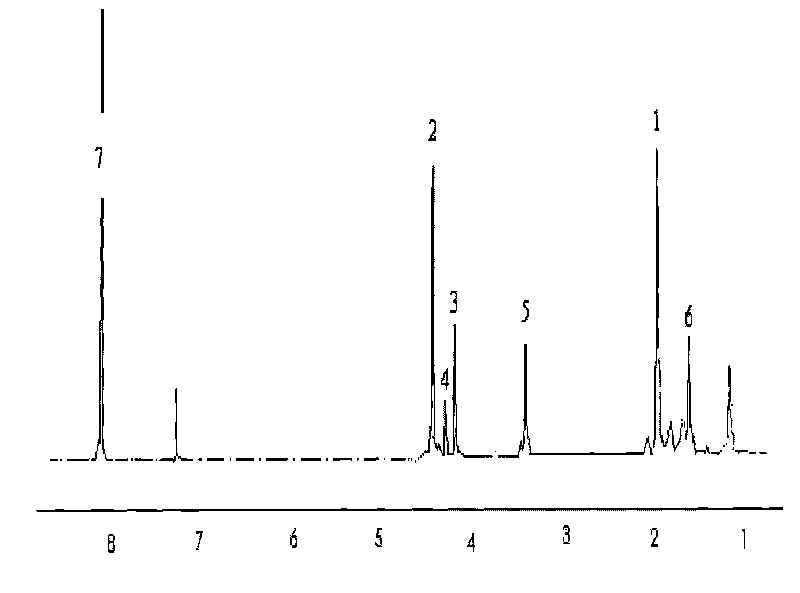

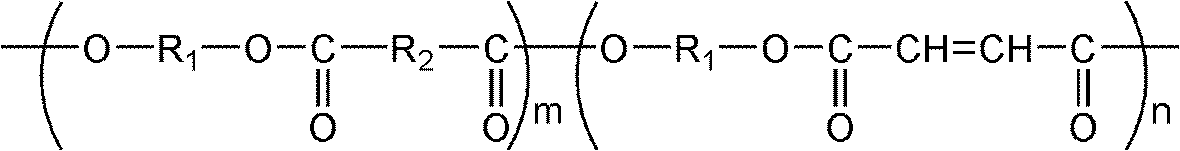

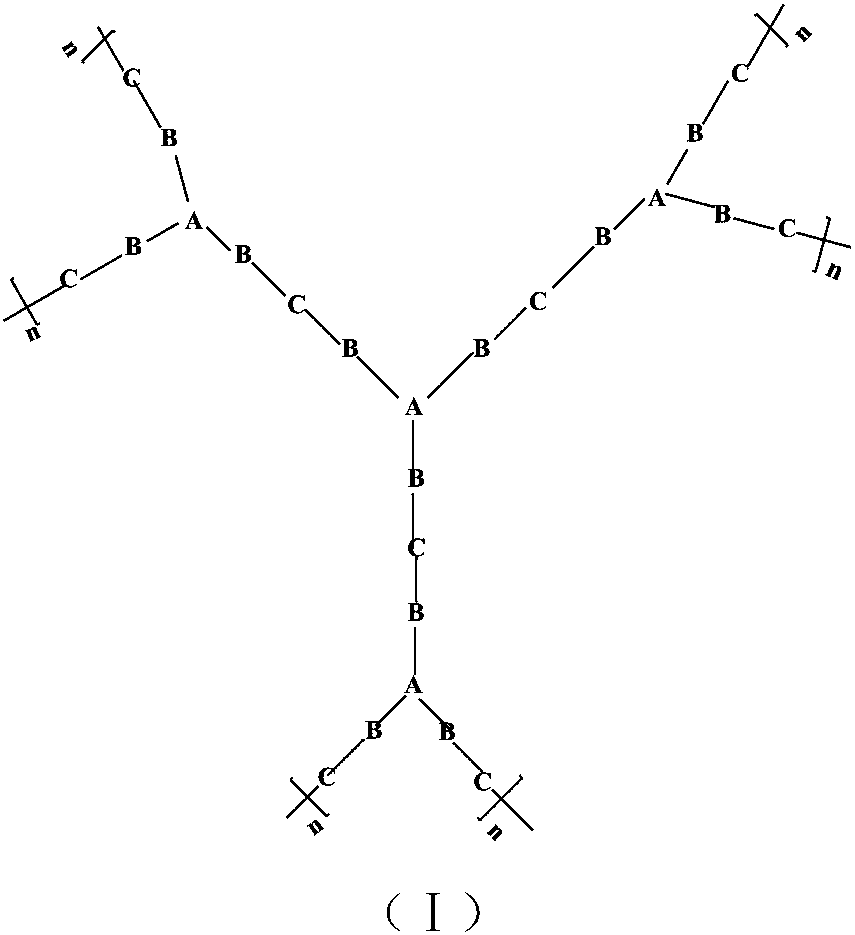

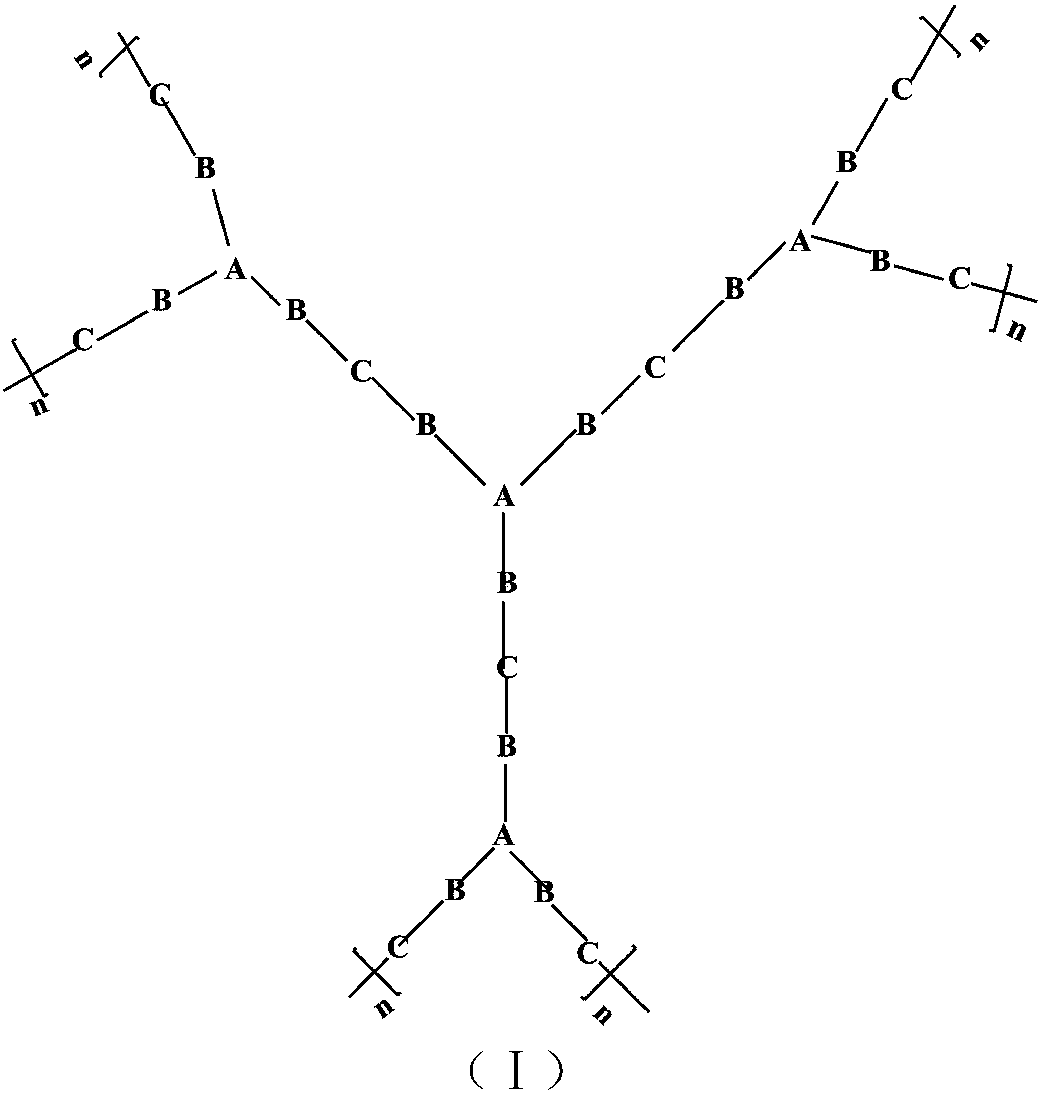

Preparation method of copolyether ester

The invention relates to a preparation method of copolyether ester, belonging to the field of thermoplastic block copolyether ester elastomers. The copolyether ester contains a short-chain polyester hard segment and a long-chain polyether ester soft segment, wherein the short-chain polyester hard segment comprises repeating units of a dicarboxylic acid component and a dihydric alcohol component, and the long-chain polyether ester soft segment comprises repeating units of a dicarboxylic acid component and a poly alkylene ether glycol component. The polyester hard segment comprises a polyester segment (A) and a polyester segment (B), wherein the polyester segment (A) comprises repeating units of an aromatic dicarboxylic acid component and a 1,4-butanediol component, and the polyester segment (B) comprises repeating units of an aromatic dicarboxylic acid component and a 1,4-cyclohexanedimethanol component; and the polyether ester soft segment is a polyether ester segment (C) which comprises repeating units of an aromatic dicarboxylic acid component and a poly alkylene ether glycol component. The product has excellent comprehensive performance, the melting point is 160-220 DEG C, the elongation at break is 500-1400%, and the thermal decomposition temperature is 360-450 DEG C.

Owner:BEIJING UNIV OF TECH

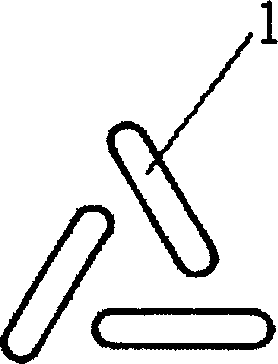

Preparation method of high-elongation spandex fiber

ActiveCN106757485AHigh elongationDisruption of regularityMonocomponent synthetic polymer artificial filamentDry spinning methodsFiberMaterials preparation

The invention discloses a preparation method of a high-elongation spandex fiber, and belongs to the technical field of high polymer material preparation. The method is especially suitable for high-speed spinning of the spandex fiber. The method comprises the following steps of (1) taking diisocyanate and oligomer dihydric alcohol as basic raw materials at a prepolymerization reaction stage to obtain an isocyanate group-terminated prepolymer; (2) dissolving the prepolymer obtained in the step (1) by using a non-protonic polar solvent to obtain a prepolymer liquid; (3) adding a mixed amine liquid prepared from a chain extender and a chain terminator to the prepolymer liquid obtained in the step (2) and carrying out prepolymerization reaction to obtain a polyurethaneurea liquid, wherein the chain extender is a mixture of polyether amine and aliphatic diamine; and (4) curing the spandex fiber prepared in the step (3) and then preparing the high-elongation spandex fiber by adopting dry spinning.

Owner:华峰重庆氨纶有限公司

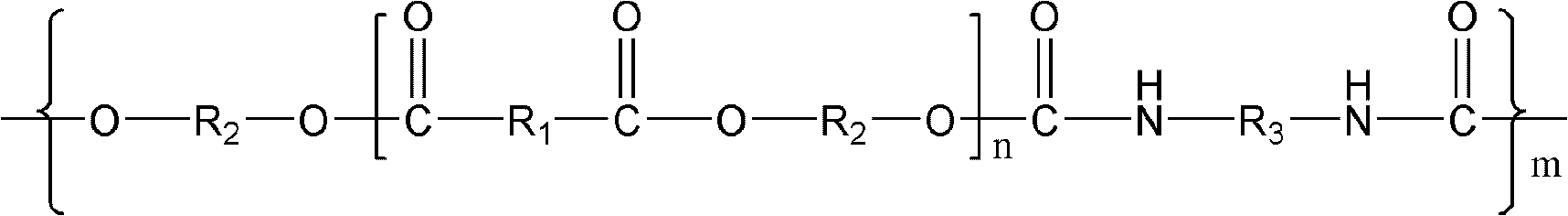

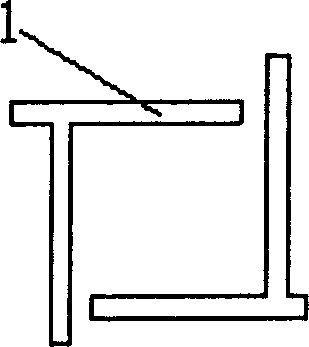

Biodegradable polyester and its preparation method

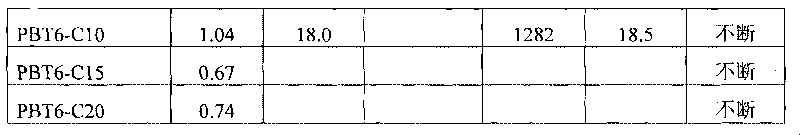

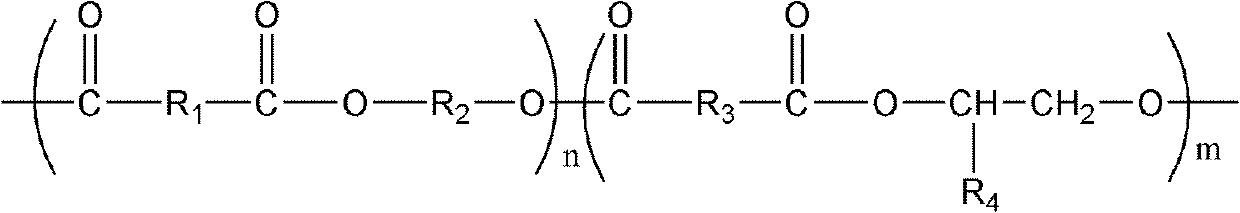

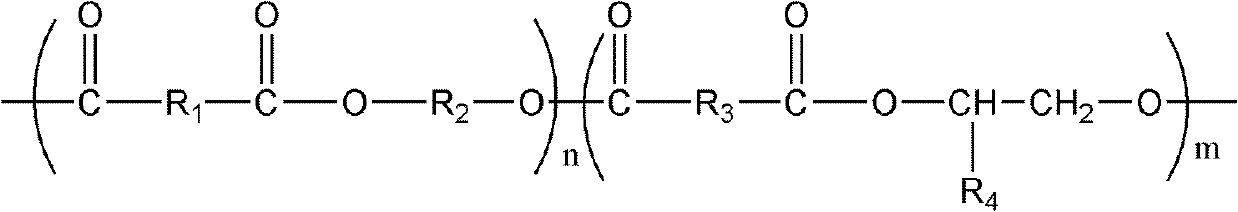

The invention belongs to the field of polymer material technology, and discloses a biodegradable polyester and its preparation method. The inventive biodegradable polyester has the following repeated unit structure, wherein n=1-1,000, M=1-1,000, o=0-11, P=2-13, q=0-11, and r=0-10. The prepared product has excellent processing performance and mechanical performance and outstanding biodegradability, and can be used to substitute for the widely used PE plastic film.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

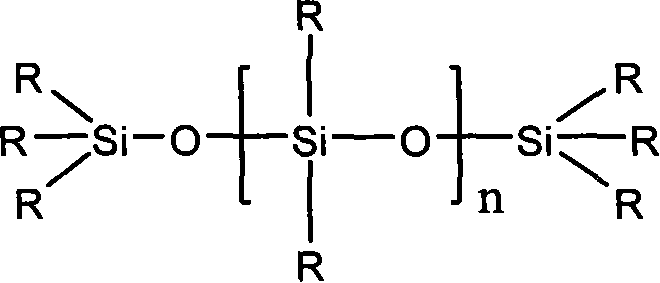

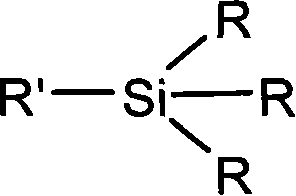

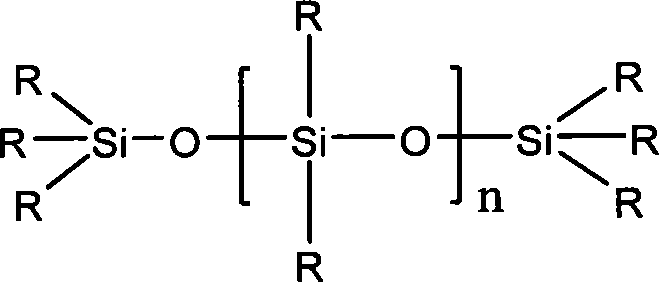

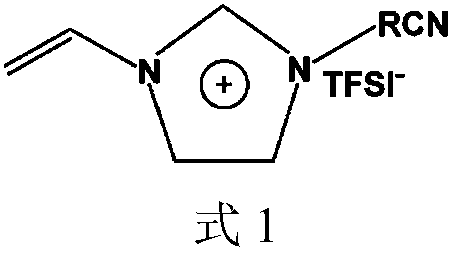

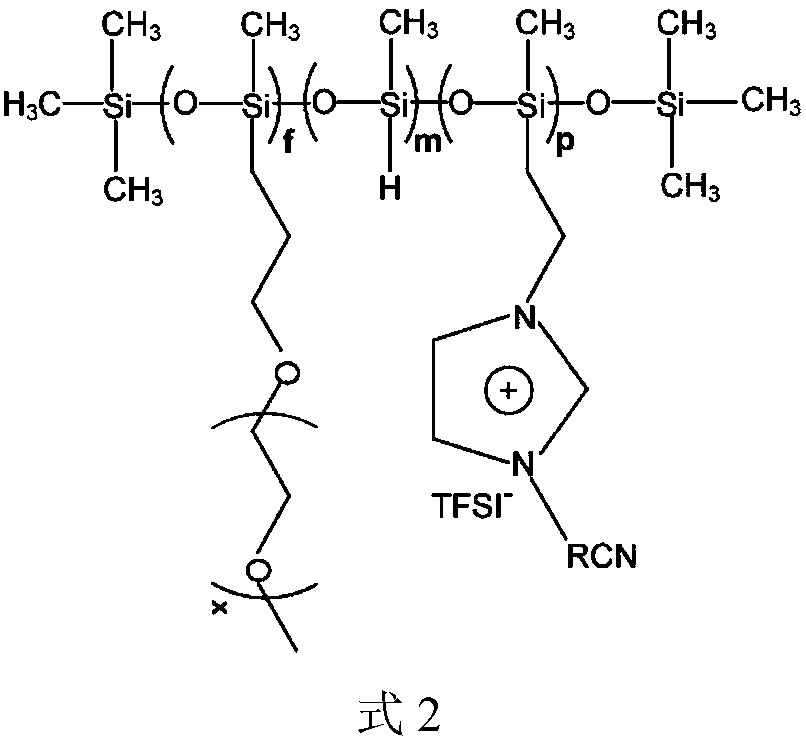

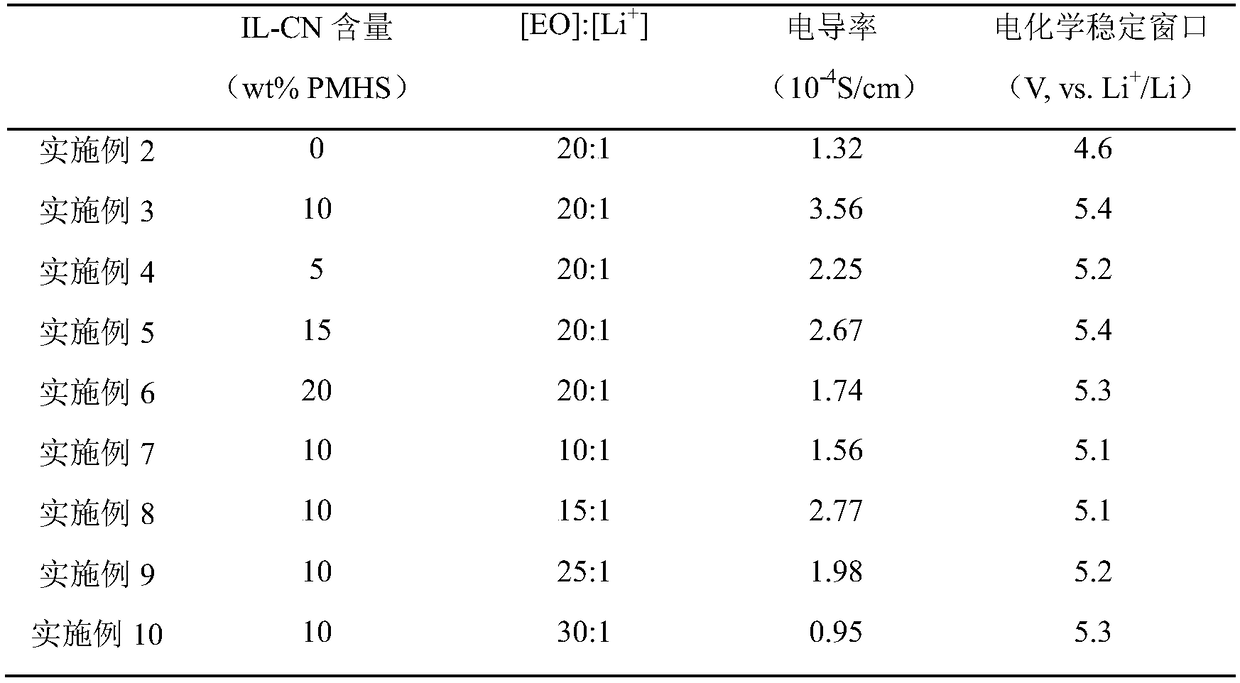

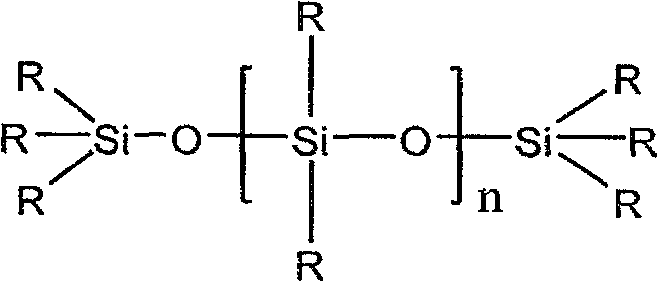

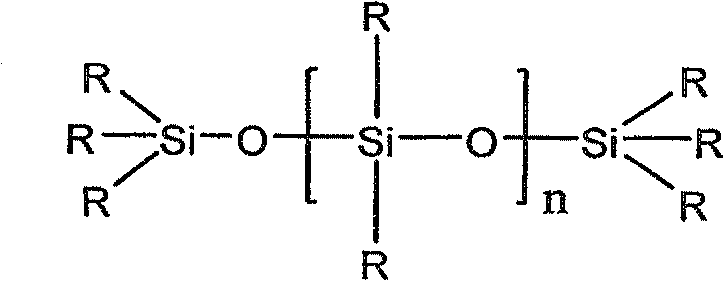

Preparation method and application of modified polysiloxane solid polymer electrolyte membrane

ActiveCN108808099ALower glass transition temperatureImprove chain movement abilitySolid electrolytesFinal product manufactureCross-linkPolymer science

The invention discloses a preparation method and application of modified polysiloxane solid polymer electrolyte membrane (SPE). The SPE is prepared from poly(methylhydrosiloxane) (PMHS), nitrile imidazole ionic liquid (IL-CN), allyl terminated polyether (PEO), lithium salt and a cross-linking agent. The preparation method comprises the following steps: 1, sufficiently mixing the PMHS, PEO and IL-CN in anhydrous toluene, adding a chloroplatinic acid catalyst, and performing reaction for a certain period of time at certain temperature; 2, mixing an appropriate amount of the lithium salt, the cross-linking agent and a catalyst into a product in the step 1 in anhydrous acetonitrile, sufficiently stirring, pouring a solution into a polytetrafluoroethylene die, and performing heating, cross-linking and solidifying in a vacuum drying oven, so as to obtain the all-solid-state polymer polymer electrolyte membrane. An obtained electrolyte has high conductivity, wide electrochemical stability window and high stability, and can be applied to lithium secondary batteries.

Owner:ZHEJIANG UNIV

High-molecular-weight polyester plastic based on 2,3-butanediol and preparation method for same

The invention discloses a high-molecular-weight polyester plastic based on 2,3-butanediol. The polyester plastic has a repetition structure unit shown in the formula, wherein R1 is defined in the specification, p is 0-11, R2 is defined in the specification, R3 is defined in the specification, n is 1-1000, and m is 1-1000. The invention further discloses a preparation method for the high-molecular-weight polyester plastic based on 2,3-butanediol. The polyester plastic is a transparent polyester plastic due to the existence of the side-chain methyl of 2,3-butanediol, as well as is high in molecular weight, excellent in mechanical property, and wide in application prospect in the aspects of injection-moulded parts, optical devices, thin films, laminated materials and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

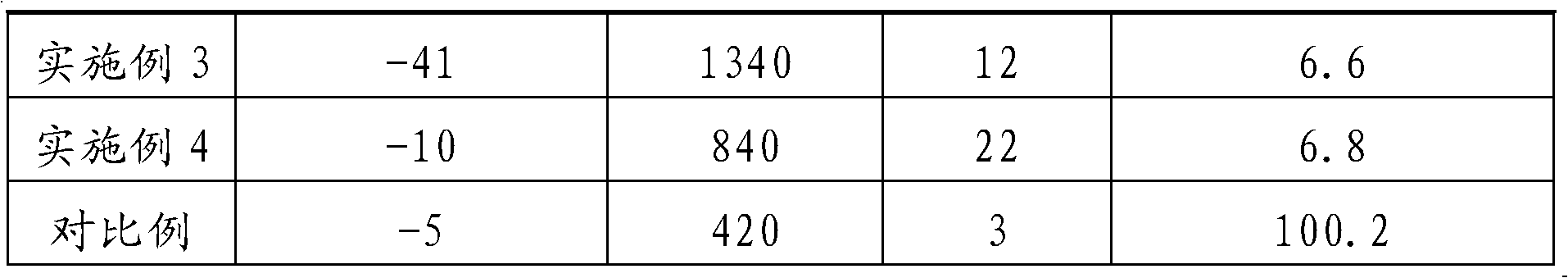

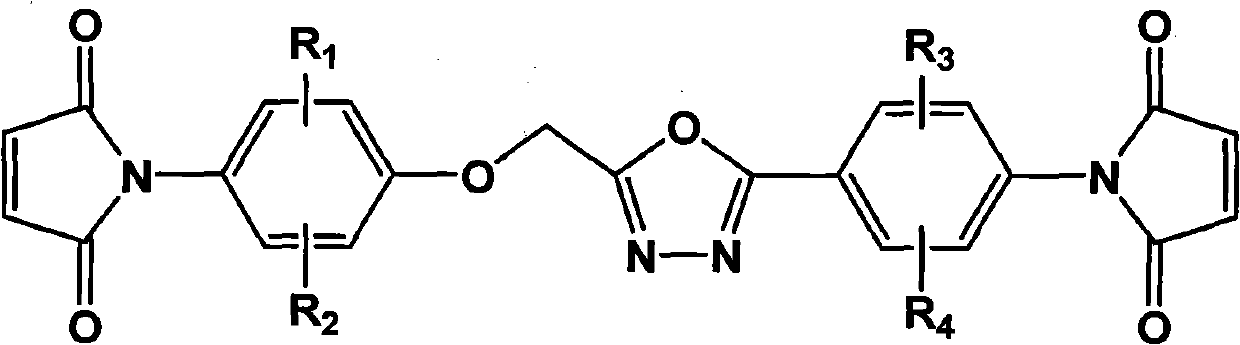

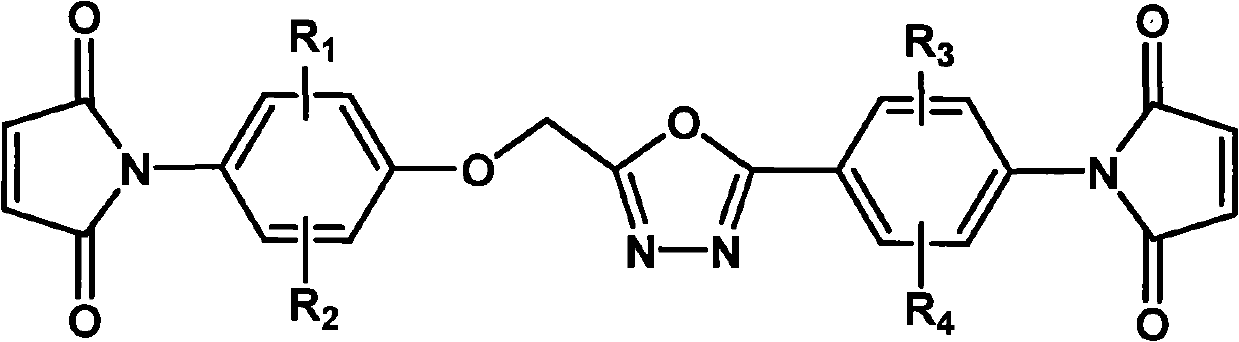

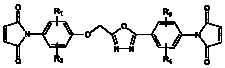

Bismaleimide containing 1,3,4-oxadiazole structure and preparation method thereof

InactiveCN101870693AImprove heat resistanceGood flexibilityOrganic chemistryAlkaneStructural formula

The invention relates to a bismaleimide containing a 1,3,4-oxadiazole structure and a preparation method thereof. In the structural formula of bismaleimide, substituents of R1 to R4 can be hydrogen atom, halogen atom, or same or different fat alkane of C1 to C20 and derivatives thereof, or same of different aromatic of C6 to C12 and derivatives thereof. The bismaleimide with a 1,3,4-oxadiazole structure is prepared by reacting diamine with a 1,3,4-oxadiazole structure with maleic anhydride to produce bismaleamic and performing imide cyclization reaction under the action of catalyst and dehydrating agent. The bismaleimide containing the1,3,4-oxadiazole structure has an asymmetric structure; and two reactive groups have different reaction activities in different chemical environments and can successively react at different curing temperatures. In addition, the cured product of the bismaleimide with a 1,3,4-oxadiazole structure has excellent heat resistance and is suitable for being used as a high-performance polymer composite matrix.

Owner:DALIAN UNIV OF TECH +1

Melting direct-spinning method of copolymerized modified low-melting-point nylon fibers

ActiveCN111304771ADisruption of regularityLow melting pointMonocomponent copolyamides artificial filamentEvaporationNylon materialCaprolactam

The present invention relates to the field of nylon materials, and discloses a melting direct-spinning method of copolymerized modified low-melting-point nylon fibers. The method comprises the steps of 1) material preparation, wherein caprolactam, a copolymerized modified component, an end-capping agent, water and a catalyst are heated and mixed; 2) ring opening, wherein a mixture is heated for ring opening; 3) pre-polycondensation, wherein a pre-polymerization reaction and devolatilization are performed; 4) final polycondensation, wherein a final polycondensation reaction and devolatilizationare performed; 5) devolatilization before spinning; and 6) spinning, wherein a product is directly conveyed to spinning threads for spinning to obtain the copolymerized modified low-melting-point nylon fibers. According to the method, the copolymerized modified component is added for destroying the regularity of nylon molecular chains and reducing the hydrogen bond density and crystallinity of the nylon molecular chains, thereby achieving the purpose of lowering the melting point of nylon; and according to different varieties and content of added copolymerized components, the melting point ofthe nylon can be controlled to be 90-200 DEG C, so that the application range of the low-melting-point nylon is greatly expanded.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Preparation method of high-molecular-weight polyethylene microporous membrane

InactiveCN103182250AHigh porositySmall apertureSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPorosityPolymer science

The invention provides a preparation method of a high-molecular-weight polyethylene microporous membrane. Polyethylene is an ultrahigh-molecular-weight copolymer of ethylene and alpha-olefin. The preparation method comprises the following steps: carrying out melt mixing, filming through extruding or mould pressing, solvent extraction, drying setting and two-way stretching on an ultrahigh-molecular-weight polyethylene copolymer to obtain the microporous membrane. The polyethylene microporous membrane, provided by the invention, is uniform in pore size distribution and high in porosity, and has better longitudinal and horizontal mechanical property. The microporous membrane can be used in fields such as water treatment, separation and purification.

Owner:BEIJING DEYUANTONG ENVIRONMENTAL PROTECTION TECH

High-elasticity composite fiber and preparation method thereof

ActiveCN107858767AIncrease elasticityFluffy goodArtificial filament heat treatmentMelt spinning methodsFiberPolyester

The invention relates to the field of textile technology, in particular to a high-elasticity composite fiber and a preparation method thereof. The composite fiber has a crimp shrinkage of 30.3-79.8%,preferably 48.6-79.8%, more preferably 65.3-79.8%, so that the composite fiber has a high crimp shrinkage; and the preparation method of the composite fiber comprises the following steps: carrying outcondensation polymerization on a polyester pre-reaction melt containing a steric hindrance monomer and an aliphatic polyamide melt to obtain polyamide ester, and then spinning the polyamide ester andthe aliphatic polyamide to prepare the composite fiber. The composite fiber provided by the invention has a three-dimensional coiled structure, excellent fluffiness and elasticity and a particularlysoft hand feeling, and can be widely used for wearing textiles.

Owner:CHINA TEXTILE ACADEMYTIANJINSCI & TECH DEV CO LTD +1

Multifunctional chromatophil copolyester fiber in high rate of retention and profile spinneret adopted

InactiveCN1563521AHigh water retentionSoft and comfortableSpinnerette packsMonocomponent polyesters artificial filamentDisperse dyeSulfonate

This invention cuts and mixes in different proportion TPA - isophthalic acid 5-sodium sulfonate glycol ester for different triod anode ion. dyes or TPA - isophthalic acid glycol ester for disperse dyes to design modified silk spray plates to spin modified hollow closed cross-section fibers and optimize the alkali process conditions to get high water reserved rate free dyed multifunction copolyester fibers.

Owner:DONGHUA UNIV

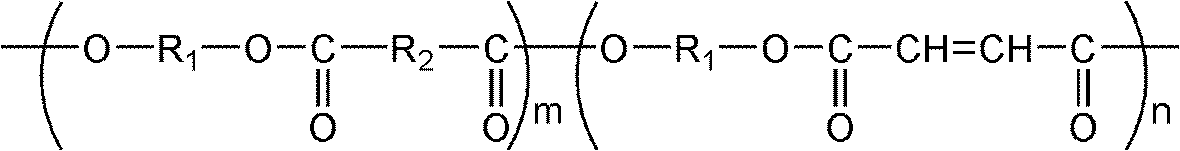

Glass fiber reinforced plastics based on 2,3-butanediol, and preparation method thereof

The invention belongs to the preparation field of glass fiber reinforced plastics, and discloses a glass fiber reinforced plastics based on 2,3-butanediol, and a preparation method thereof. The glass fiber reinforced plastics have the following repetitive structure unit defined as in the description, wherein R1 is selected from -CH(CH3)-CH(CH3)- and -(CH2)o-; R2 is selected from -(CH2)p- and ortho-position-substituted benzene; n is from 1 to 100; m is from 1 to 100; o is from 2 to 13; and p is from 0 to 11. The invention also discloses the preparation method of the glass fiber reinforced plastics based on 2,3-butanediol. Products obtained by the method have light weight, high strength, good corrosion-resistant performance, thermal performance and electrical performance, and have wide applications in aviation, rocket, spacecraft, high voltage, insulation, heat-insulation and corrosion-resistant containers, and other products required to lighten self-weight.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

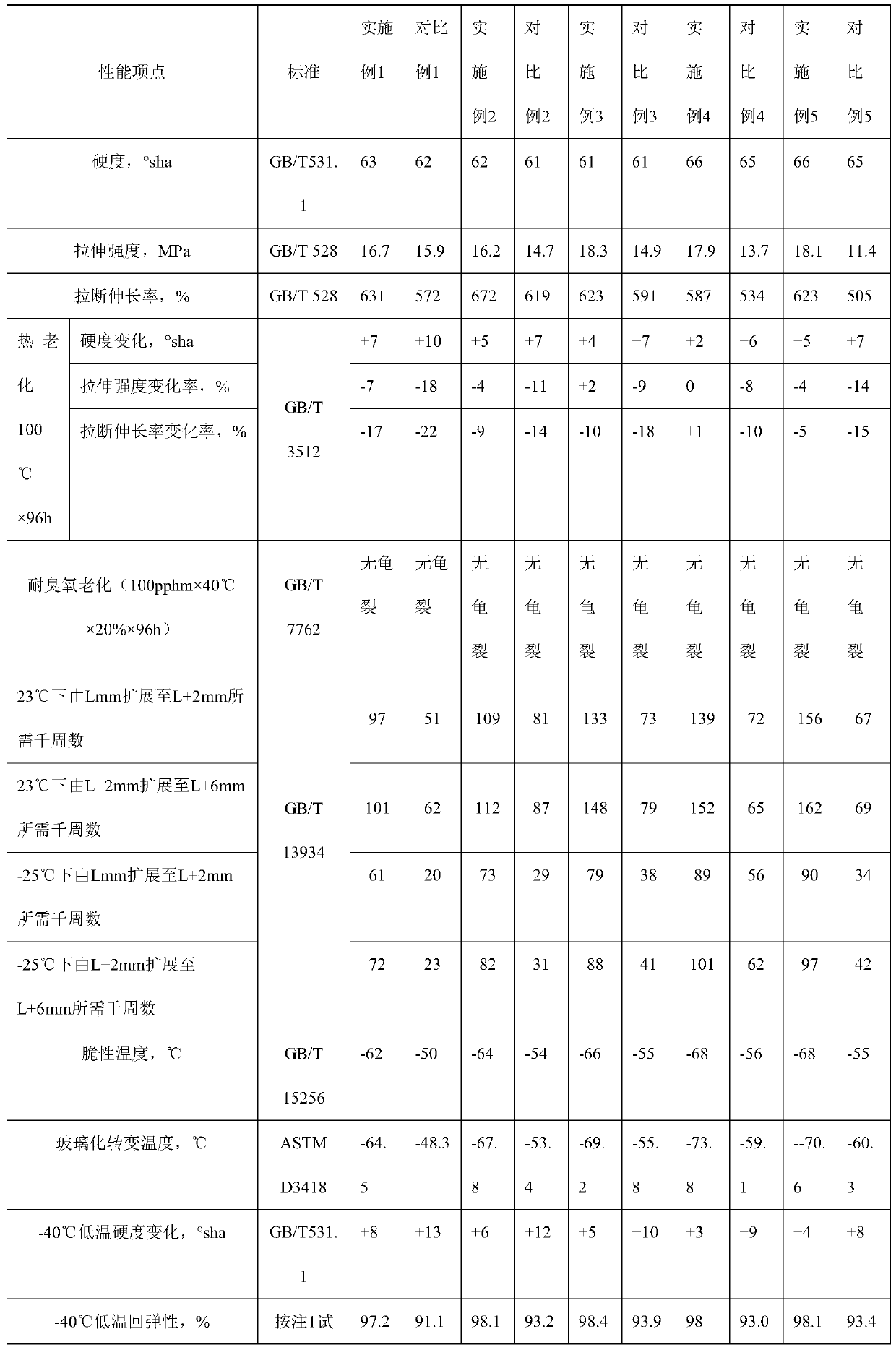

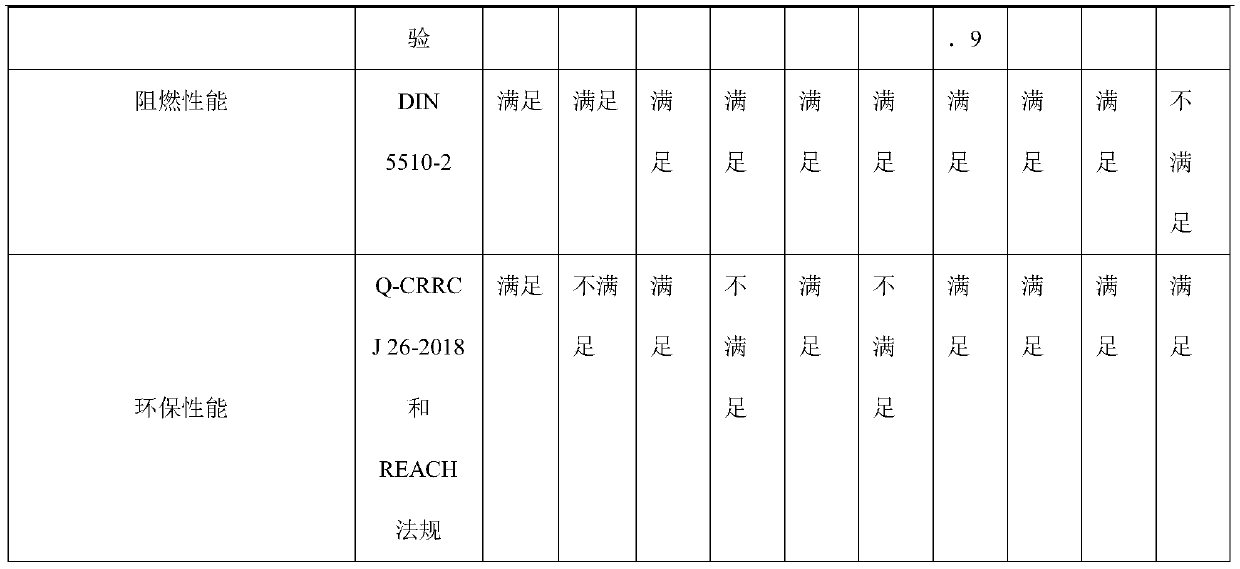

Low-temperature resistant high-resilience rubber windshield material, preparation method thereof and windshield

ActiveCN110527200AImprove low temperature toughness and low temperature elasticityReduce low temperature pressure changeMaleic anhydrideEthylene propylene rubber

The invention discloses a low-temperature resistant high-resilience rubber windshield material, a preparation method thereof and a windshield. The windshield material is prepared from the following components in parts by weight: 40-75 parts of ethylene propylene diene monomer rubber, 25-60 parts of ethylene butene diene monomer rubber, 8-12 parts of liquid ethylene propylene rubber and 5-8 parts of maleic anhydride modified polybutadiene, wherein the total weight parts of the ethylene propylene diene monomer rubber and the ethylene butene diene monomer rubber are 100 parts. The invention aimsto improve low-temperature performance and flex resistance performance of ethylene propylene diene monomer (EPDM), particularly resilience and flex crack growth resistance at low temperature. The windshield material has excellent comprehensive performance in the aspects of physical mechanical performance, low-temperature performance, flex resistance, flame retardant performance, environmental protection performance and the like, and can meet technical requirements of windshield products.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

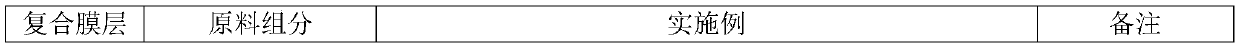

Antibacterial high-oxygen barrier PE composite film and preparation method thereof

The invention belongs to the field of packaging materials, and particularly relates to an antibacterial high-oxygen barrier PE composite film and a preparation method thereof. The antibacterial high-oxygen barrier PE composite film sequentially comprises a PE film layer, a PVA film layer and a PE film layer from outside to inside and is prepared through three-layer co-extrusion compounding. The antibacterial high-oxygen barrier PE composite film has excellent antibacterial and antistatic properties while effectively improving the poor moisture resistance, oxygen barrier property and film interlayer binding force of an existing PE composite film, has the advantage of good comprehensive performance, has wide application space, and is especially suitable for food packaging and medical treatment.

Owner:山东亚新塑料包装有限公司

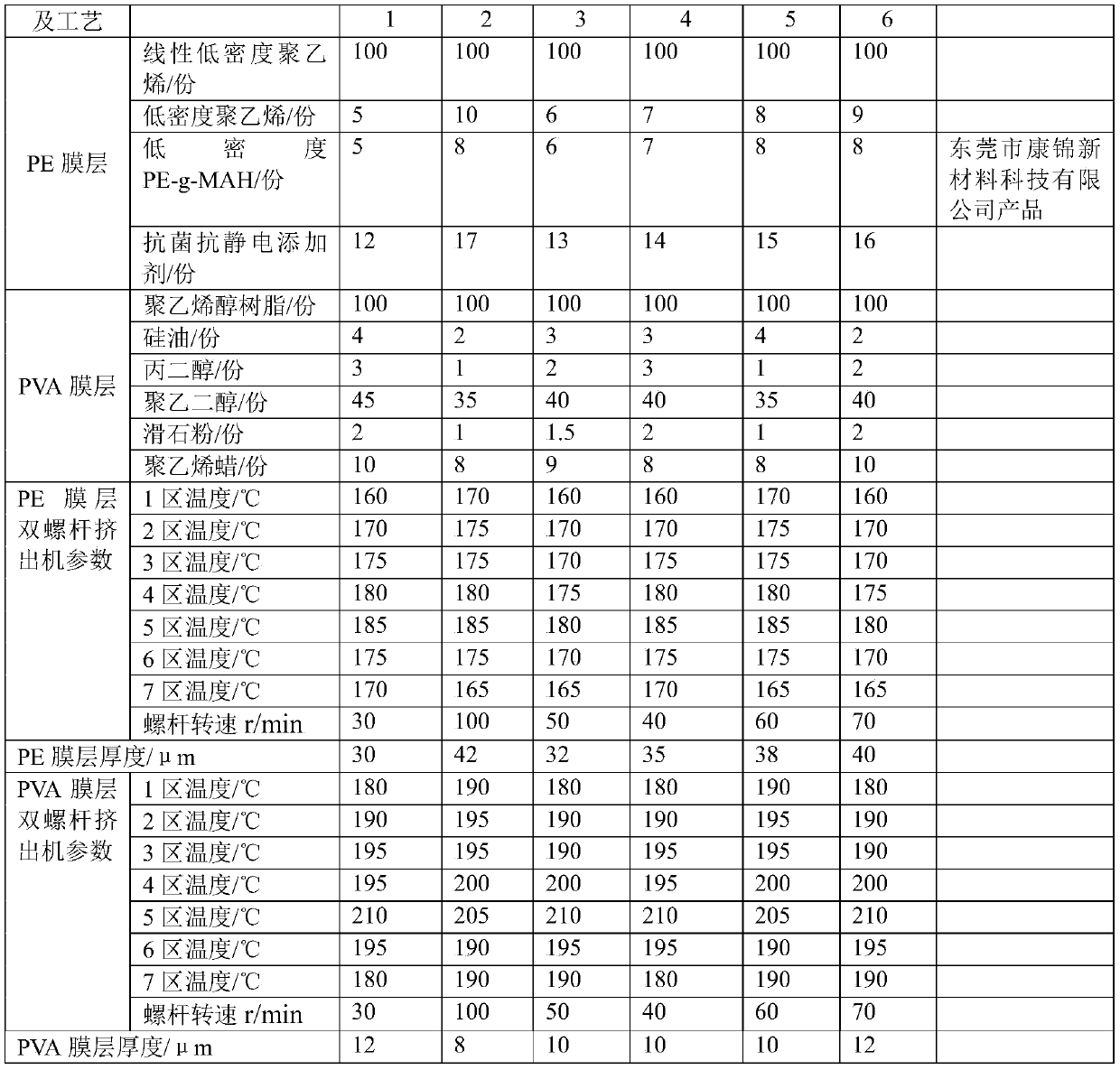

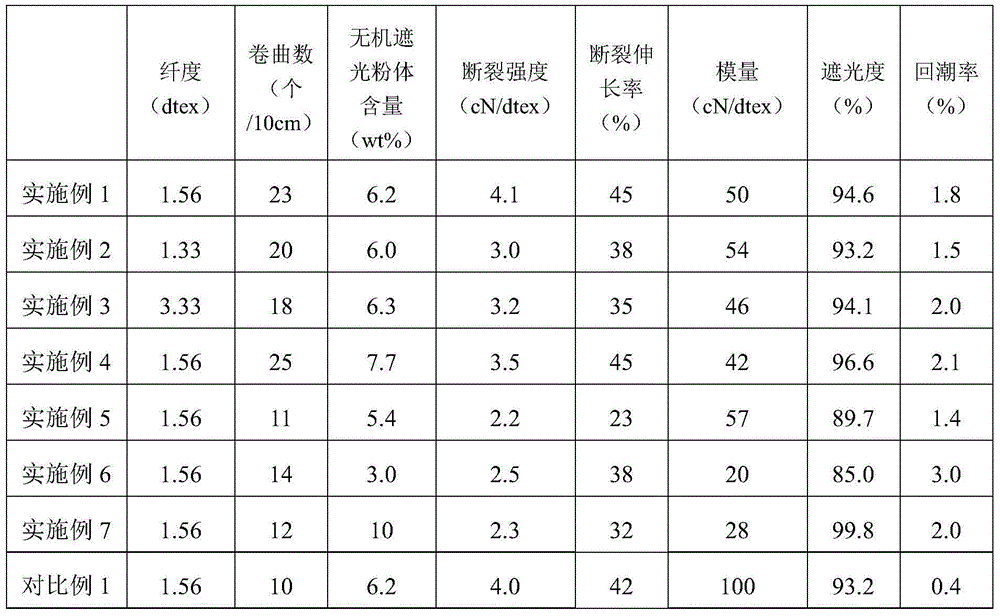

Light-masking hydrophilic fiber and preparation method thereof

ActiveCN104451936AImprove hydrophilicityExcellent hydrophobic propertiesMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolyester

The invention provides a light-masking hydrophilic fiber and a preparation method thereof. The preparation method comprises the following steps: A1, dividing inorganic light-masking powder into a first part and a second part, blending the first part of powder, aromatic dibasic acid and aliphatic diol into mixed slurry, and performing esterification reaction on the mixed slurry, so as to form a pre-reaction melt; A2, adding aliphatic polyamide into the pre-reaction melt, performing polycondensation reaction, and cooling, so as to form a modified polyester material; A3, coating the surface of the second part of powder with a resin coating, so as to form composite master batch; A4, blending and melting the modified polyester material and the composite master batch, so as to obtain a hydrophilic group modified polyester melt containing the inorganic light-masking powder; A5, spinning and drafting the hydrophilic group modified polyester melt containing the inorganic light-masking powder, so as to obtain the light-masking hydrophilic fiber. The fiber prepared by the preparation method has good internal reflection light absorption effect, and high refractive index and hydrophilicity, and the prepared textiles have good visual masking effect and good skin adaptability.

Owner:CHINESE TEXTILE ACAD

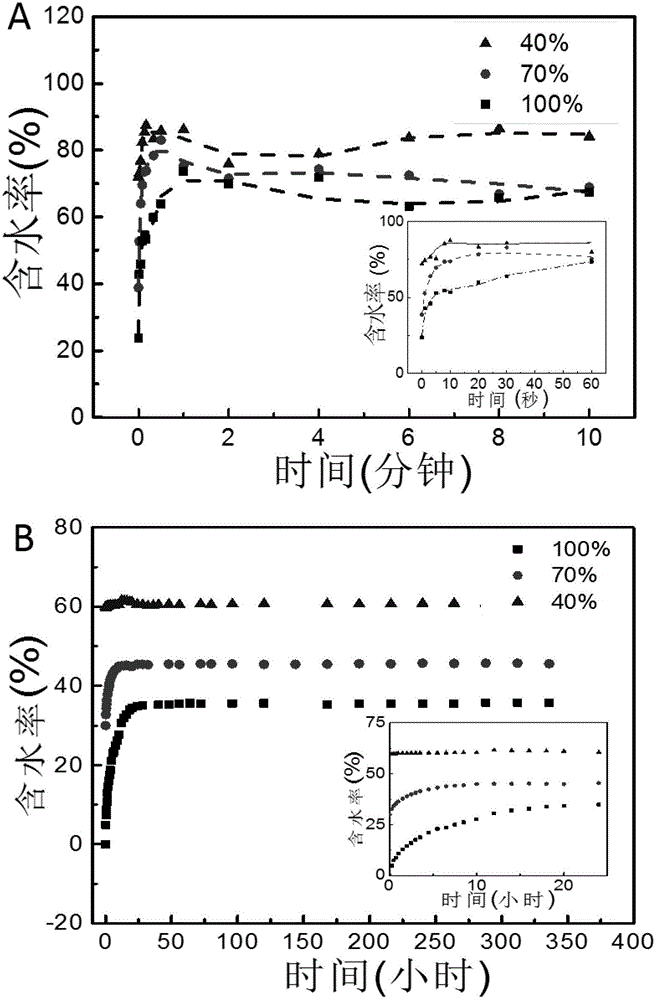

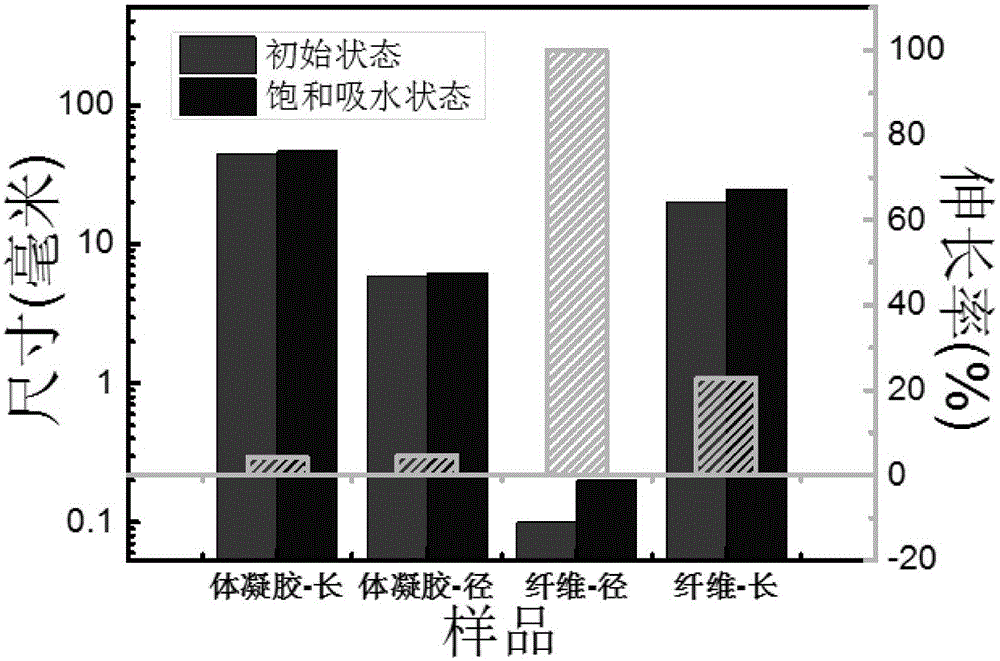

Preparation method of PEGMA/PEGDA hydrogel fiber having ultrafast-anisotropically water-absorption performance

ActiveCN105133065AStable structureImprove water absorptionArtificial filament physical treatmentWet spinning methodsWater bathsFiber

The invention relates to a preparation method of PEGMA / PEGDA hydrogel fibers having an ultrafast-anisotropically water-absorption performance. The preparation method comprises following steps: 1) preparing PEGMA through a polymerization reaction at room temperature; 2) preparing a polymer water solution from the PEGMA and the PEGDA, adding a photo-initiator, performing ultrasound dispersion, stirring the mixture until the photo-initiator is dissolved completely to obtain a PEDMA / PEGDA spinning solution; 3) at room temperature, feeding the spinning solution into a water bath through a spinning spray head by a metering pump, setting an ultraviolet point light source to enable a free radical polymerization reaction of the PEDGA in the spinning solution for preparing primary PEGMA / PEGDA hydrogel fibers; and 4) drafting the primary PEGMA / PEGDA hydrogel fibers to obtain the PEGMA / PEGDA hydrogel fibers. The PEGMA / PEGDA hydrogel fibers are stable in structure and good in water absorption performance. The preparation method has very important significance on development, application and post-processing of hydrogel materials.

Owner:DONGHUA UNIV

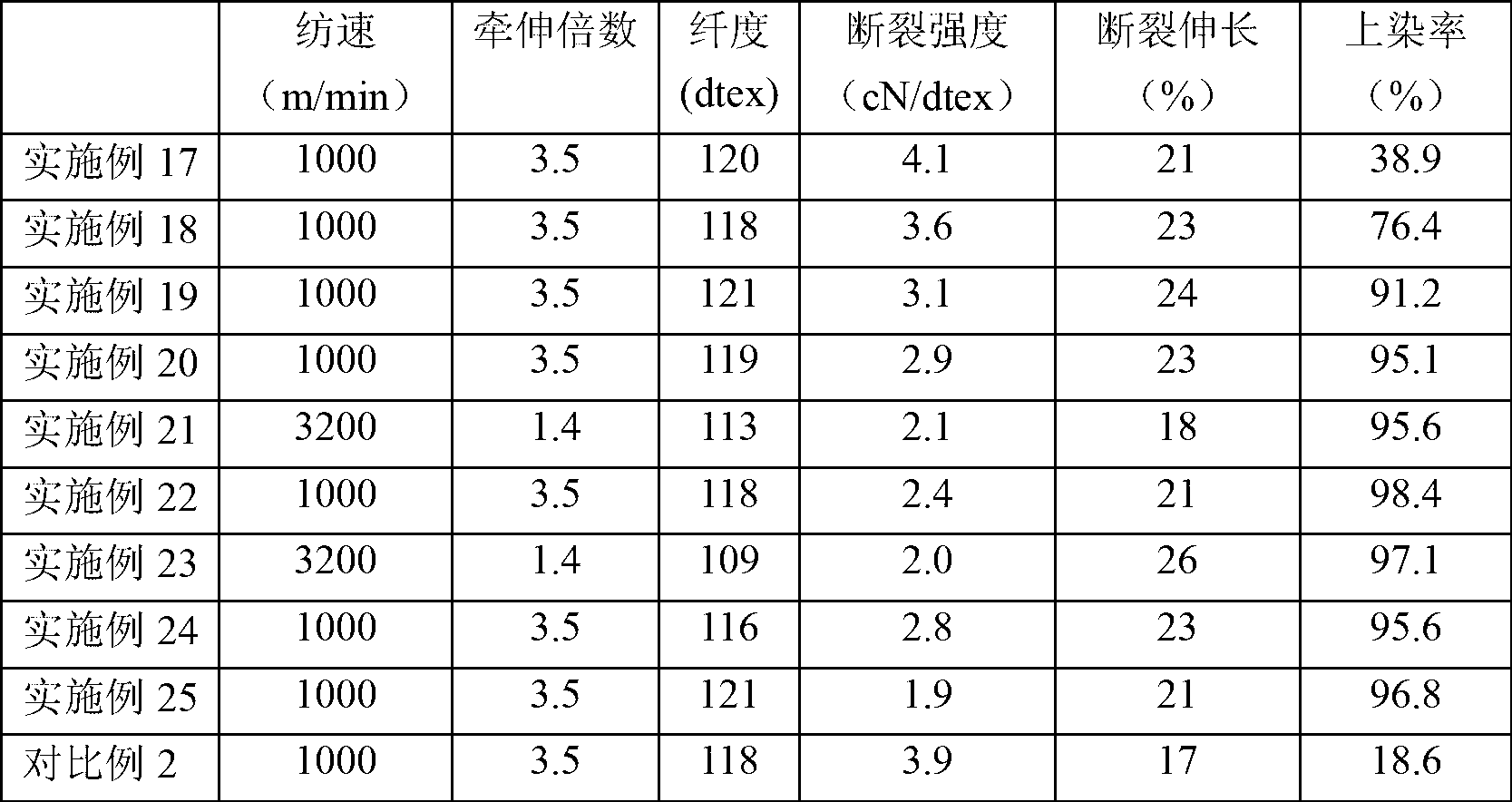

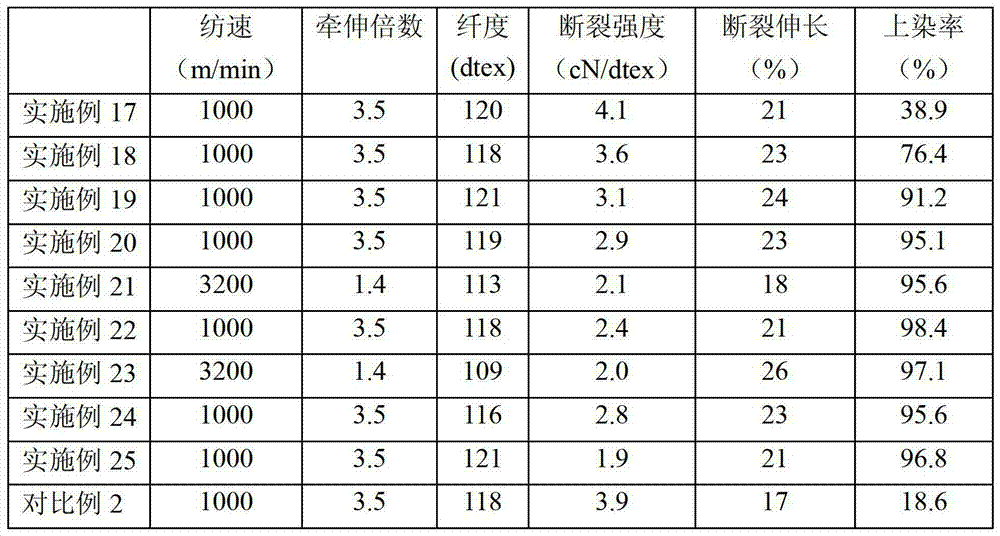

Aliphatic-polyamide-modified copolyester, aliphatic-polyamide-modified copolyester fiber, and preparation methods thereof

ActiveCN103232596BReduce crystallinityLower glass transition temperatureSpinning head liquid feederMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses aliphatic-polyamide-modified copolyester, aliphatic-polyamide-modified copolyester fiber, and preparation methods thereof. Preparation materials of the aliphatic-polyamide-modified copolyester comprise: terephthalic acid, ethylene glycol with an amount of 105-200mol% of the terephthalic acid, diethylene glycol isophthalate-5-alkali metal sulfonate with an amount of 1-10mol% of the terephthalic acid, and aliphatic polyamide with an amount of 1-40wt% of terephthalic acid. According to the aliphatic-polyamide-modified copolyester, flexible aliphatic polyamide chain segments are introduced into polyester macromolecular chains, such that macromolecular chain regularity is broken, and copolyester crystallinity and glass transition temperature are reduced. Aliphatic-polyamide-modified copolyester fiber prepared by using the aliphatic-polyamide-modified copolyester has soft texture. Also, when sulfonate groups are introduced into polyester macromolecular chains, flexible aliphatic polyamide chain segments are introduced, such that the copolyester fiber can be dyed by using cationic dyes under normal temperature and normal pressure.

Owner:CHINESE TEXTILE ACAD

High heat conduction organosilicon filling and sealing gum

InactiveCN100575443CImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING TECH UNIV

Preparation method of polyurethane modified aramid fiber pulp

InactiveCN107354532ADisruption of regularityLarge specific surface areaFibre typesElectro-spinningRubber materialPolymer science

The invention discloses a preparation method of polyurethane modified aramid fiber pulp. A polyurethane spinning solution is added to an aramid fiber spinning solution, and the obtained mixed spinning solution is spun. Polyurethane has a high elasticity and a high strength, so the modified aramid fiber pulp has enough strength and toughness; and spinning fibers are treated with an aqueous LiCl solution, and the treated spinning fibers are complexed with carbonyl groups in the molecular chain of aramid fibers in order to destroy the regularity of the molecular chain of the aramid fibers and etch the surface of the aramid fibers, so the surface roughness of the aramid fibers is increased, the specific surface area of the modified aramid fiber pulp obtained after beating treatment is increased, and the adsorption capability to resin and rubber materials is improved.

Owner:CHUZHOU SANHE FIBER MFG

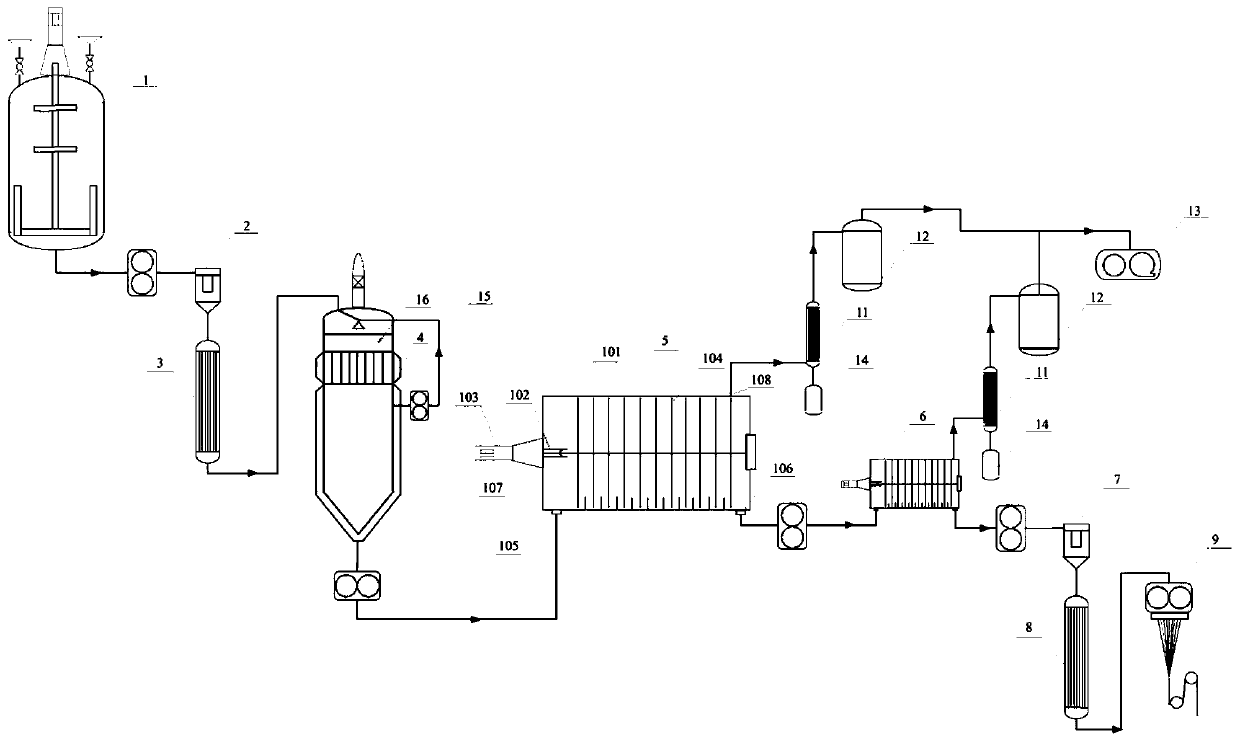

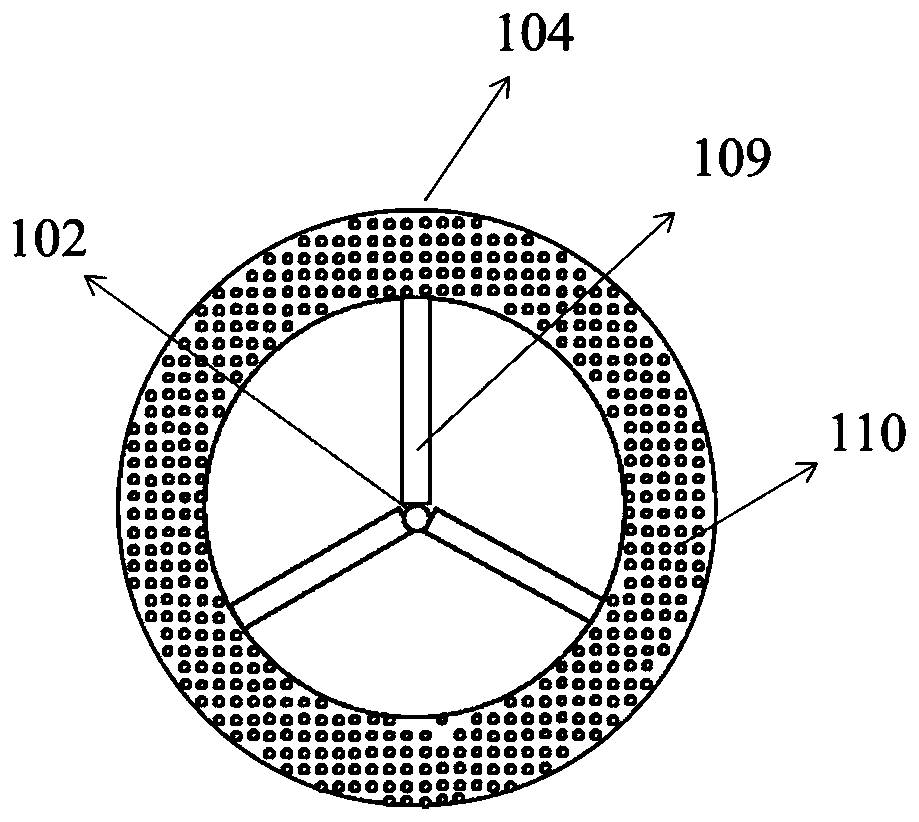

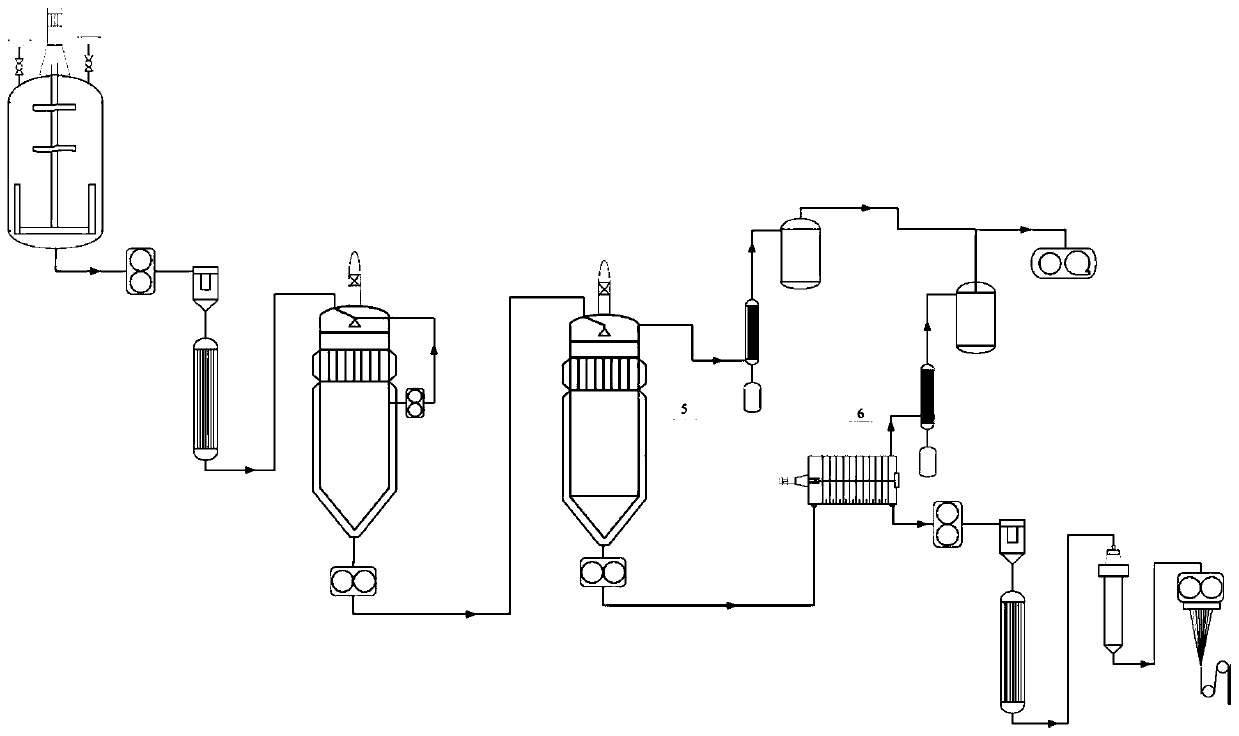

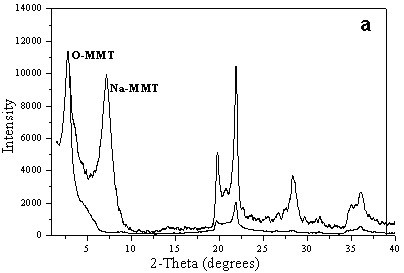

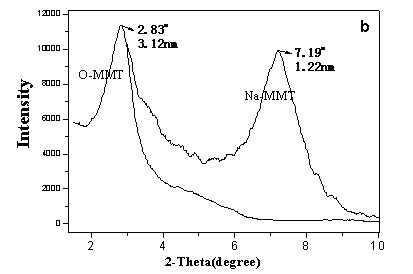

Preparation method of high barrier light-proof, preservative and environment-friendly polyester material

The invention relates to a preparation method of high barrier light-proof, preservative and environment-friendly polyester material. The method comprises the following technical processes: 1) performing preliminary modification of montmorillonite to obtain organized montmorillonite loaded with main titanic type catalyst; 2) selecting proper branching agent; 3) performing esterification; 4) performing polycondensation, wherein firstly the expanded montmorillonite loaded with titanium and stable other metal composite catalyst and branching agent are separately dissolved in ethanediol to obtain additives, the additives are injected through an additive nozzle, polyphosphoric acid is injected through another nozzle, the dosage is subject to the content in polyester, a gear pump is used to inject the esterified oligopolymer along with the above additives in the pipeline in a prepolymerizer; the prepolymerizer is an upflow bubble tower; and when reaching the top of the prepolymerizer, the material flows to a final polycondensation autoclave, and the product is filtered by a melt filter and then pulled to a pelleter to prepare polyester slices; and 5) tackifying solid phase. The method of the invention can provide the high barrier light-proof, preservative and environment-friendly polyester material.

Owner:JIANGSU XINGYE PLASTIC +1

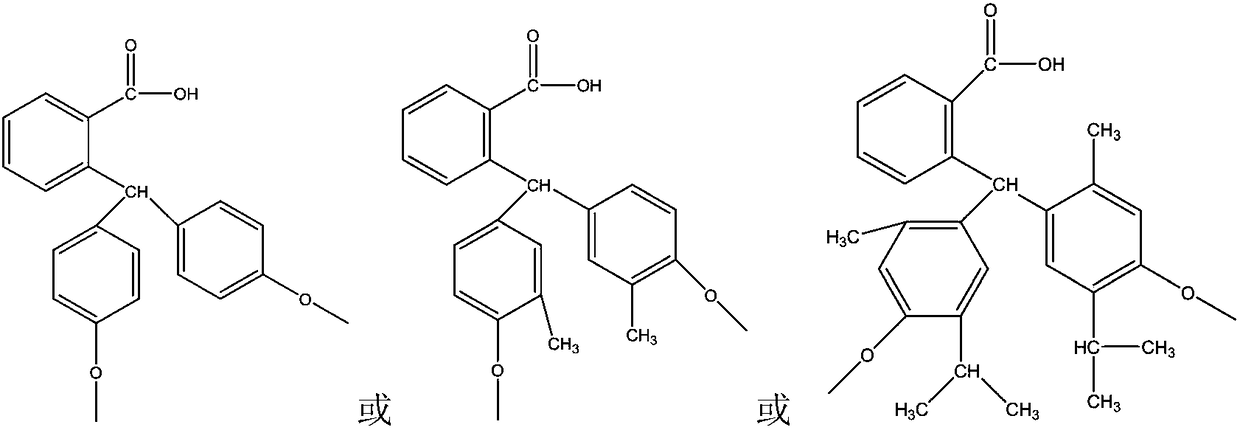

Solidified and modified epoxy resin composition containing side carboxyl hyperbranched polyarylether copolymer, preparation method and application thereof

The invention provides a solidified and modified epoxy resin composition containing a side carboxyl hyperbranched polyarylether copolymer. The epoxy resin composition mainly comprises the side carboxyl hyperbranched polyarylether copolymer, epoxy resin, a curing agent and a curing accelerator. The invention also provides a preparation method and the application of the epoxy resin composition. Thepreparation method comprises the following steps: mixing the side carboxyl hyperbranched polyarylether copolymer, epoxy resin, a curing agent and a curing accelerator, adding the mixture into an organic solvent, stirring and heating, carrying out procedural warming, mixing the obtained epoxy resin composition with the inorganic matter, and carrying out solidification and mould pressing to preparethe epoxy resin matrix composite material. The tenacity of the epoxy resin composition prepared by using the method is obviously improved, the modulus, heat resistance and insulativity are obviously improved, and the epoxy resin composition has broad applications in the fields of aerospace special type electronic insulation materials, high temperature resistant coatings, laminated boards and advanced composite materials.

Owner:DALIAN UNIV OF TECH

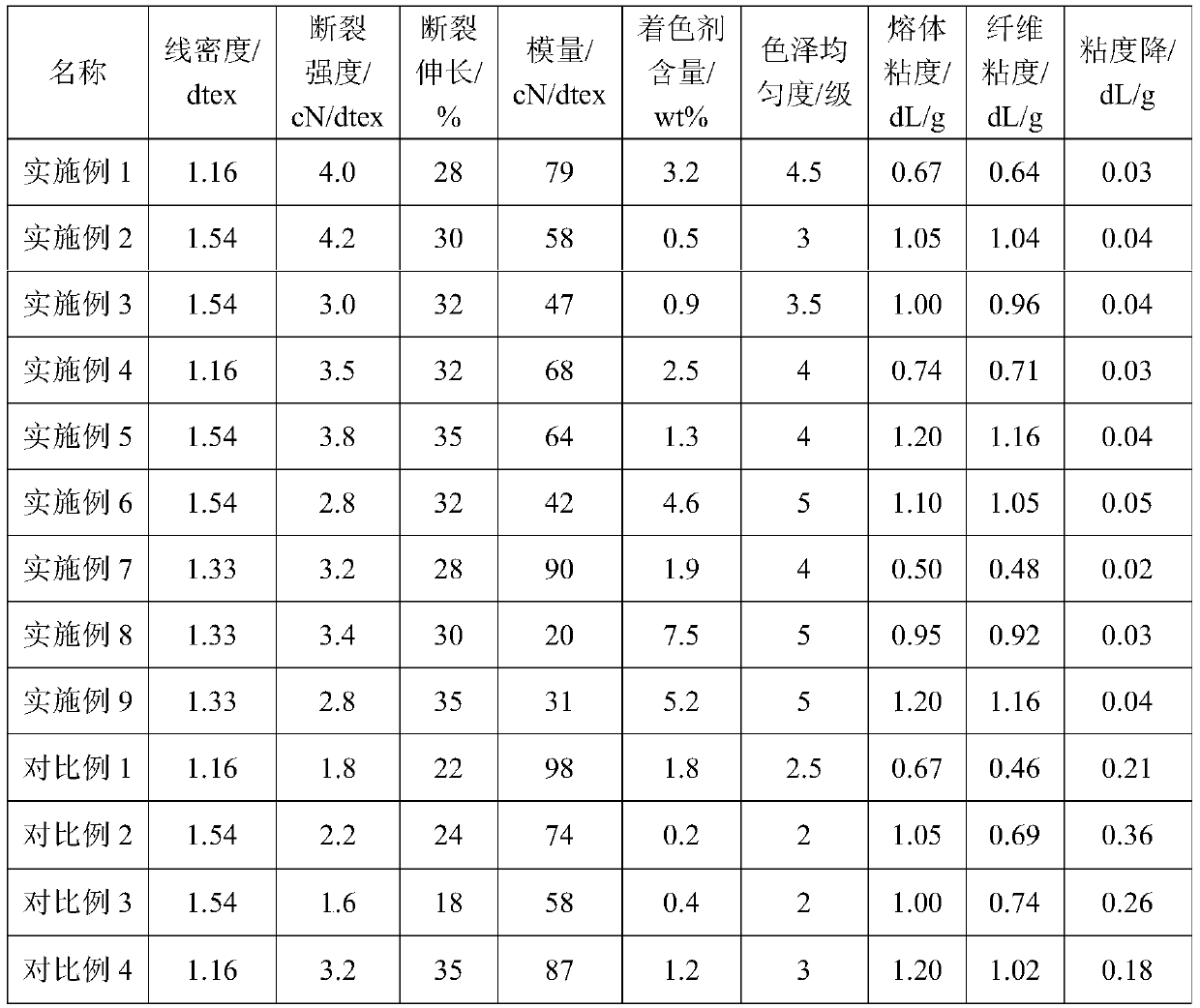

A kind of dope dyed polyester fiber and its preparation method

ActiveCN107723831BAchieve preparationSpeed up preparationPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention belongs to the technical field of textiles, and particularly relates to a stock solution coloring polyester fiber and a preparation method thereof. The preparation method comprises the following steps: (1) adding a coloring agent into carrier polyester polyhydric alcohols, and preparing into uniform coloring mother solution; (2) adding the coloring mother solution into a polyester oligomer, uniformly mixing, and successively carrying out pre-condensation reaction and final condensation reaction in a condensation system to obtain coloring polyester melt; and (3) spinning and stretching the obtained coloring polyester melt, and obtaining the stock solution coloring polymeter fiber. The coloring agent is uniformly scattered in a polyester component, so that the compatibility problem of the polyester component and the coloring agent carrier can be effectively solved, the influence of the coloring agent and a carrier thereof on the spinning performance of the coloring polyester melt can be eliminated, and the prepared stock solution coloring polyester fiber is high in content of coloring agent, stable in quality, free from color difference, soft in hand touching, and goodin mechanical performance.

Owner:CHINESE TEXTILE ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com