Patents

Literature

336 results about "Terephthaloyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

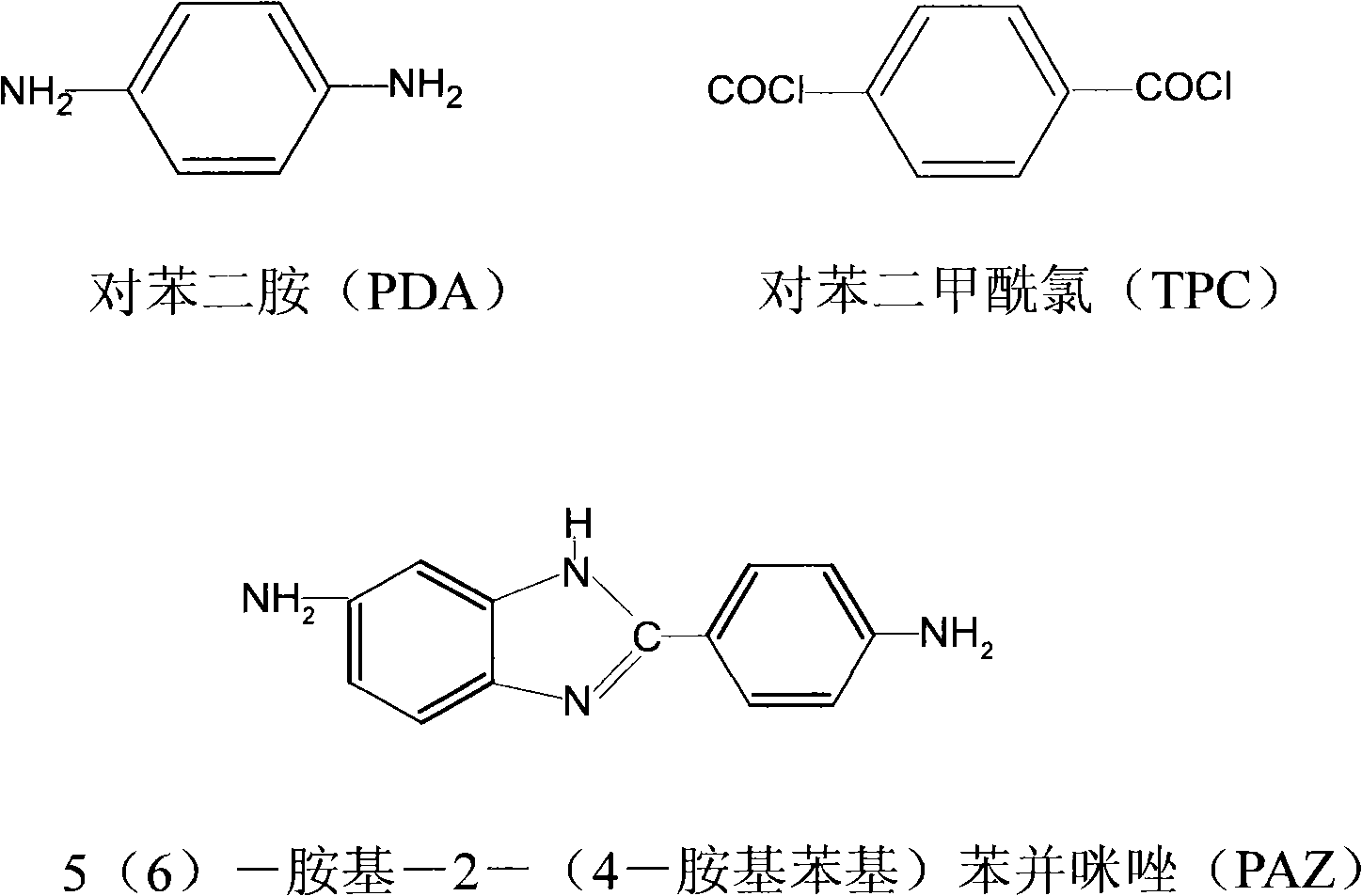

Terephthaloyl chloride (TCL, 1,4-benzenedicarbonyl chloride) is the acid chloride of terephthalic acid and is one of two monomers used to make Kevlar(R), the other being p-phenylenediamine. TCL is used as a key component in performance polymers and aramid fibers, where it imparts flame resistance, chemical resistance, temperature stability, light weight, and very high strength. TCL is also an effective water scavenger, used to stabilize isocyanates and urethane prepolymers.

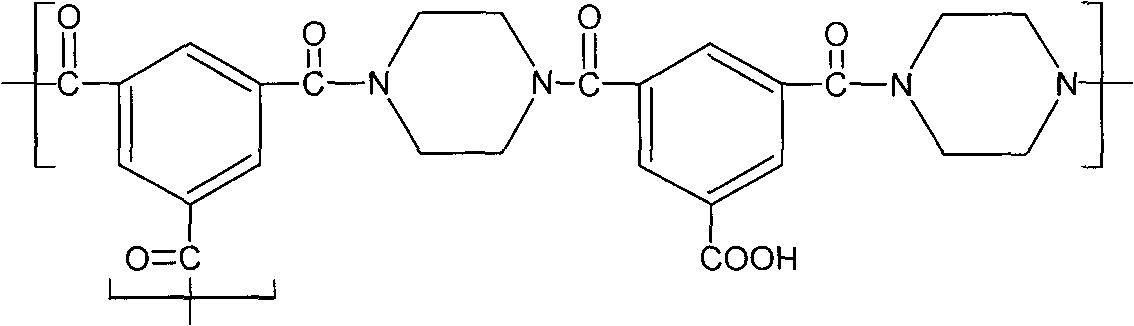

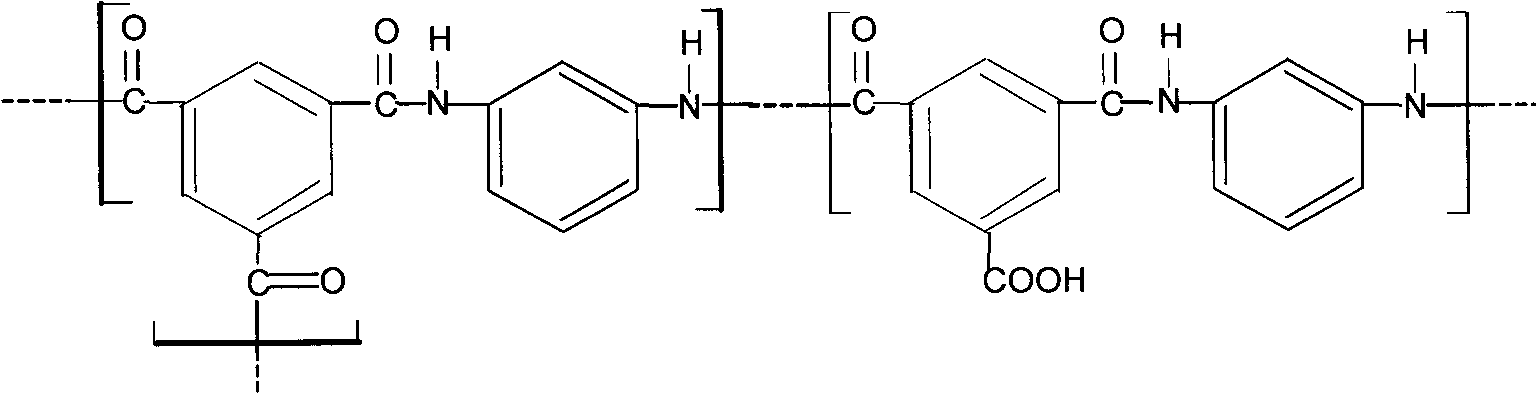

Method for preparing polyaramide resin modified by aromatic heterocycle and chloromonomer

InactiveCN101165078AGood molecular weightHigh molecular weightPolyamide coatingsMonocomponent polyamides artificial filamentTwo stepMonomer

The present invention discloses process of producing aromatic heterocycle and chlorated monomer modified polyaramide resin. Monomers including paraphthaloyl chloride and p-phenylene diamine in the calculated equivalents and 2-(4-aminophenyl)-5(6) aminophenyl benzimidazole in 20-80 % the calculated equivalent are synthesized inside NMP / CaCl2 solvent system into high molecular weight resin through one two-step process including the first reaction between partial paraphthaloyl chloride and all the p-phenylene diamine to form amido group terminated low molecular weight oligomer and the subsequent reaction between the rest paraphthaloyl chloride and the amido group terminated low molecular weight oligomer to form the high molecular weight resin. The aromatic heterocycle and chlorated monomer modified polyaramide resin has the advantages of high fireproof performance, high mechanical strength and low cost.

Owner:四川华通特种工程塑料研究中心有限公司

Random copolymerization polysulfonamide spinning liquid and preparation method thereof

InactiveCN101235552ADisruption of regularityImprove flexibilityMonocomponent copolyamides artificial filamentSpinning solutions preparationMetal chlorideMechanical property

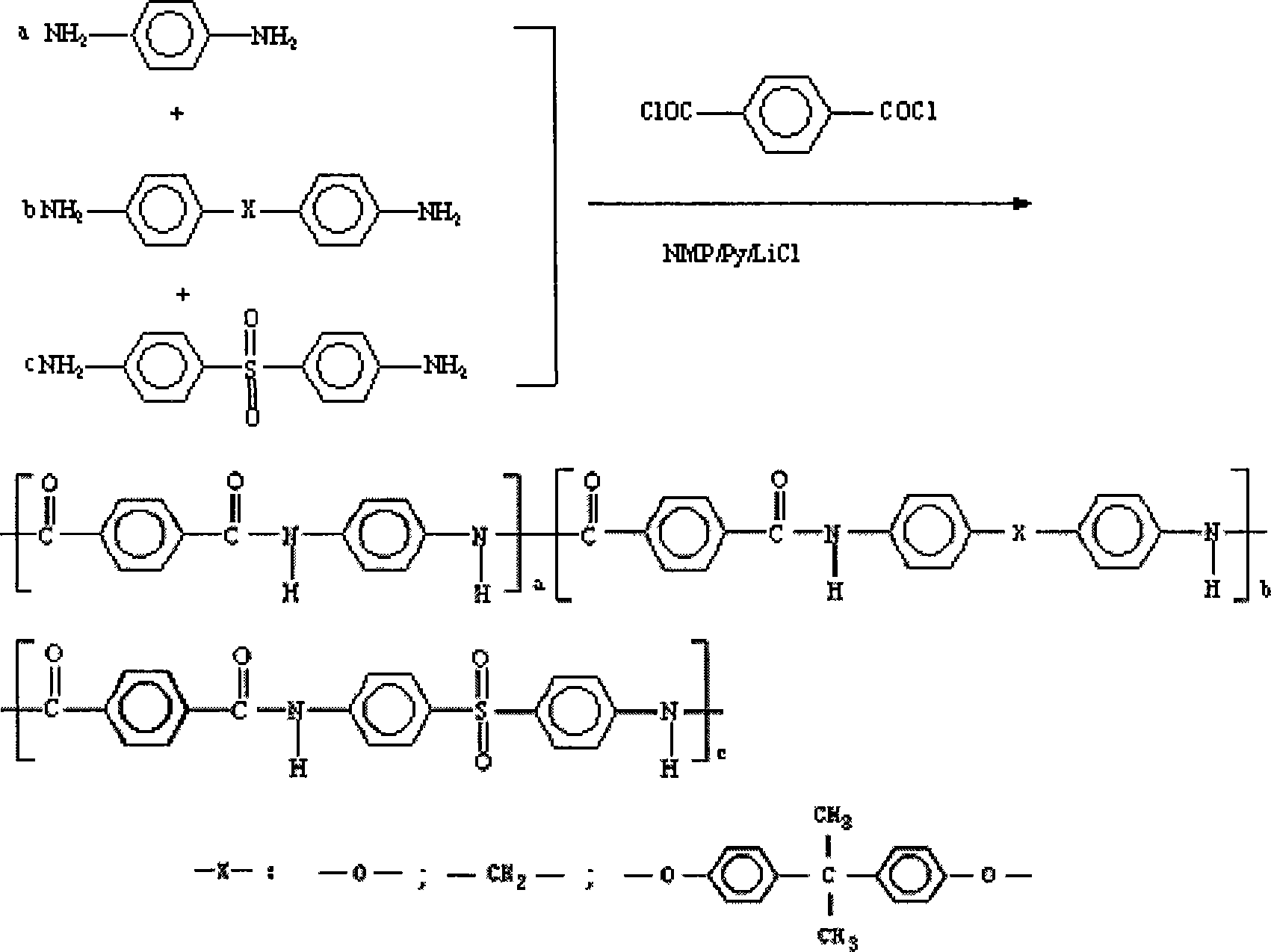

The invention relates to random copolymerization poly-sulfone amide spinning fluid which is composited by three species aromatic diamine and terephthaloyl chloride and a method for preparing the random copolymerization poly-sulfone amide spinning fluid, wherein the spinning fluid takes the N-methyl-2pyrrolidone NMP as the dissolvent, monomer and the mole percent which are adopted by the method are as following: the aromatic diamine 40%-60%, the terephthaloyl chloride 60%-40%, taking the above total monomer 100% as a benchmark, further adding 1.0%-4.0% alkali chloride as the solvent. Since the method takes the manifold aromatic diamine as the monomer of the poly-reaction, which properly damages the regularity of the main chain, however, which has no effect to arrange the original crystal lattice, increasing the flexibility of the chain at various degree, the method is beneficial for orienting and crystallizing of the entire molecular chain and for improving the mechanical property of the material. The method has the advantages of simple technology, condition optimized, high operability, convenient manufacture and low cost.

Owner:SHANGHAI UNIV

Method for preparing aramid IIII fiber

InactiveCN101851809AImprove spinning efficiencyLow investment costMonocomponent copolyamides artificial filamentDry spinning methodsYarnLithium chloride

The invention relates to a method for preparing an aramid IIII fiber, which comprises the following steps of: (1) synthesizing a spinning stock solution, carrying out low-temperature copolymerization by adopting three monomers of p-phenylenediamine, paraphthaloyl chloride and 5(6)-amido-2-(4-amidophenyl)benzimidazole as raw materials and adopting dimethylacetylamide / lithium chloride as a solvent; (2) spinning by adopting a dry method spinning process, i.e. leading the spinning stock solution obtained in the previous step to pass through a spinneret and directly enter a hot inert gas channel and evaporating and removing the solvent in the spinning stock solution by utilizing a hot inert gas to obtain cured raw yarn; and (3) carrying out water washing and heat treatment on the raw yarn and winding to obtain the aramid IIII fiber. The method has high solid content of the spinning stock solution, high spinning speed, great improvement of spinning efficiency, obvious reduction of fiber manufacturing cost, improved mechanical performance of the manufactured aramid IIII fiber and wide application prospect.

Owner:SINOSELEN HI TECH

Semi-continuous preparation method of poly p-phenylene terephthalamide resin

The invention discloses a semi-continuous preparation method of poly p-phenylene terephthalamide resin which comprises the steps of, proceeding pre-polycondensation to p-phenylene diamine and part of the paraphthaloyl chloride into the dissolvent architecture of solvent and assisting solvent, charging in pre-polymerization member and the remaining paraphthaloyl chloride powder into double bolt extrusion machine, letting in dried liquid ammonia to neutralize the hydrogen chloride gas produced in the reaction, and charging macromolecular addictive polyvinylpyrrolidone into the double bolt extrusion machine to obtain the polymer.

Owner:DONGHUA UNIV +1

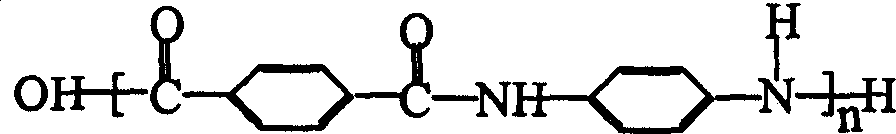

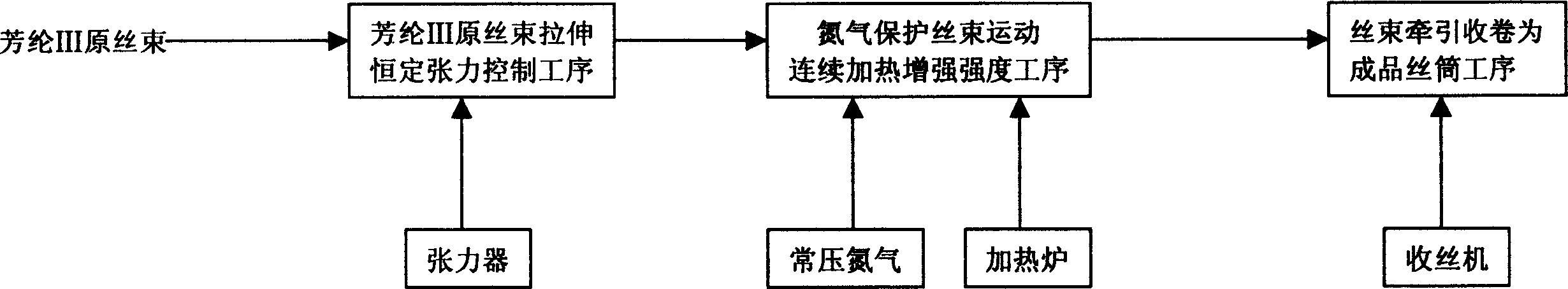

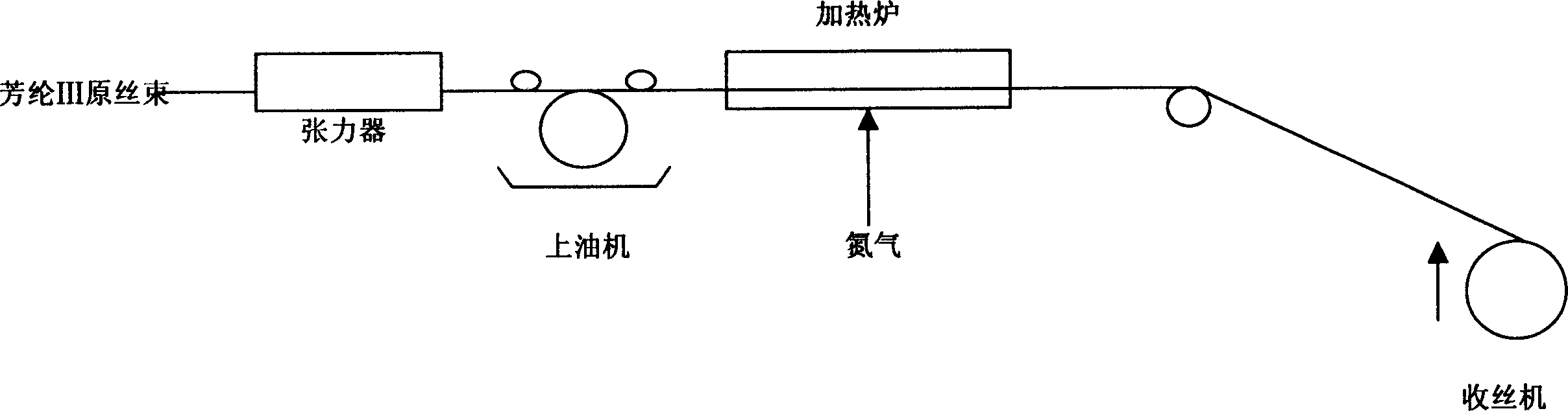

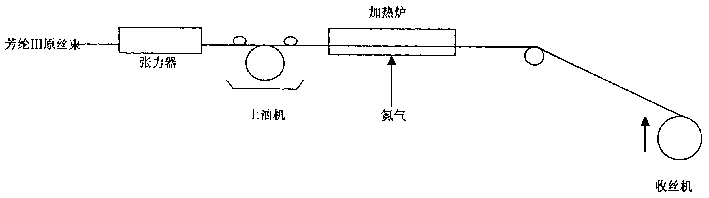

Post-treatment new process for aramid fibre III raw tow

InactiveCN1473969AGuaranteed uniformityImprove yieldArtificial filament heat treatmentMonocomponent polyamides artificial filamentNitrogen gasSolvent

The aramid III fiber as a new kind of high-strength material has wide application. Aramid III liquid is prepared with the materials including p-phenlenediamine, terephthalyl chloride and 5(6)-amino-2-(3-aminophenyl) benzimidazole and through low temperature copolymerization in dimethyl acetamide solvent; and is produced into aramid III fiber through serial spinning steps. The present invention provides the post-treatment technological process to raise the strength of aramid III fiber from 1.5 GPa to 4.5 GPa. The post-treatment process includes the treatment in the apparatus comprising tensioner, oiling machine, heating furnace and winding machine with the tension controlled in 0.2-1.0 CN / tex, temperature inside the nitrogen protected furnace 320-500 deg.c, and heating time 0.5-5 min. The raw tow is heated under motion inside the furnace homogeneously.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Polyamide-imide copolymer film and method of preparing polyamide-imide copolymer

ActiveUS20140243482A1Improve mechanical propertiesExcellent optical propertiesNon-linear opticsPolymer sciencePolyamide-imide

Disclosed herein is a polyamide-imide copolymer film, comprising a copolymer resin in which a unit structure derived from TFDB (2,2′-bistrifluoromethyl-4,4′-biphenyl diamine), a unit structure derived from 6FDA (4,4′-(hexa-fluoroisopropylidene)diphthalic anhydride), a unit structure derived from BPDA (3,3′,4,4′-biphenyltetracarboxylic dianhydride) and a unit structure derived from TPC (terephthaloyl chloride or 1,4-benzenedicarbonyl chloride) are copolymerized, wherein the copolymer resin has a weight average molecular weight of 10,000˜400,000.

Owner:KOLON IND INC

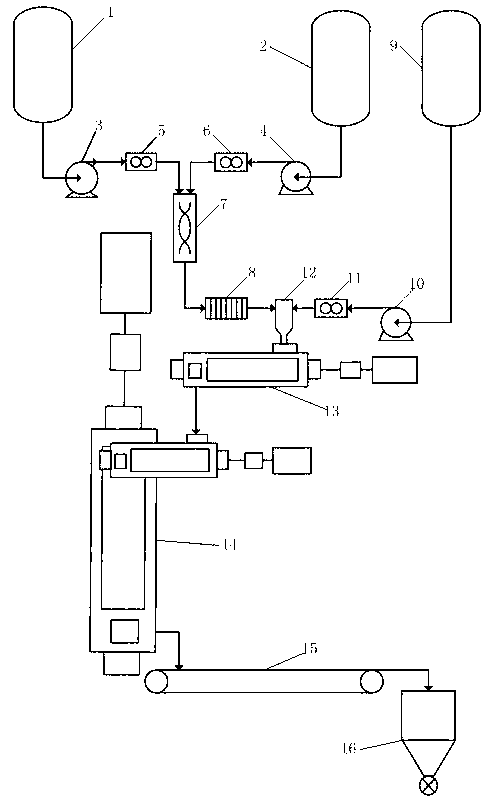

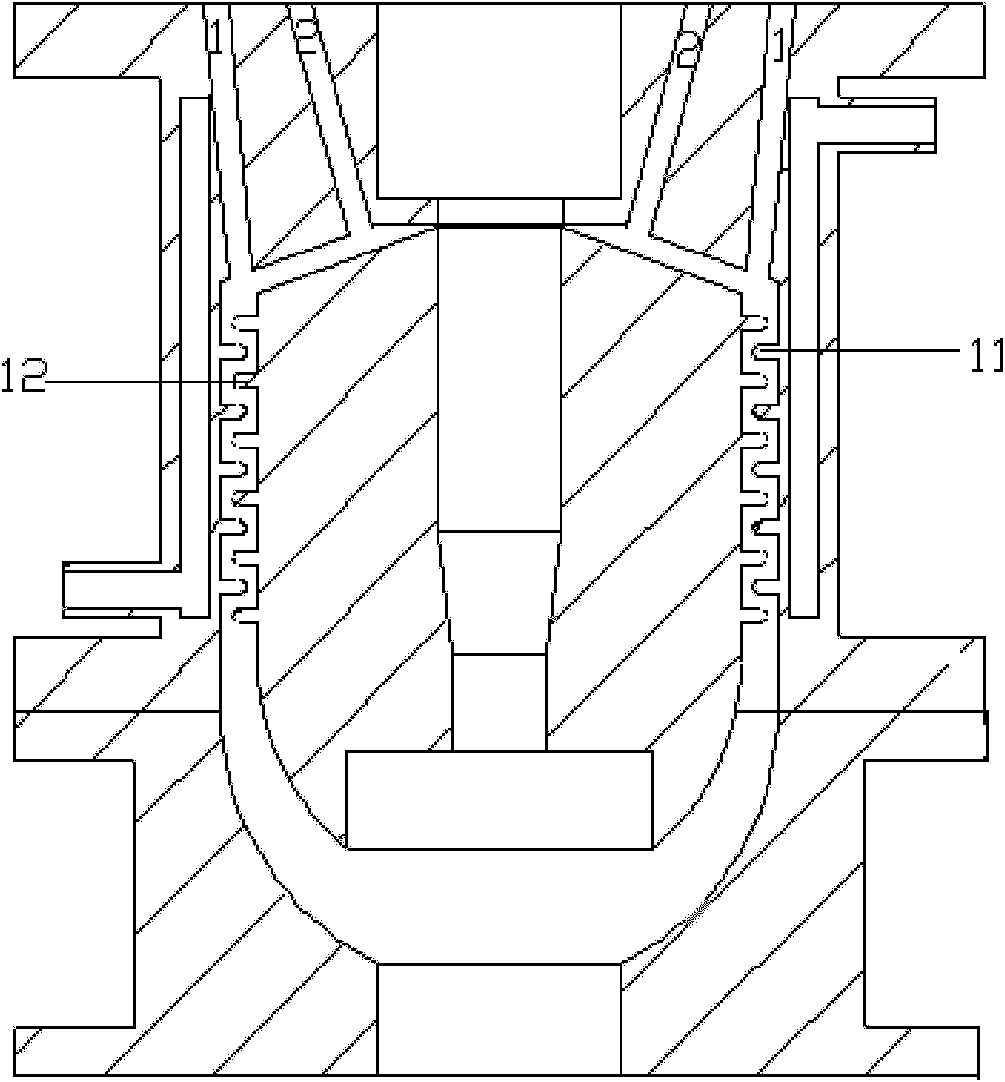

Continuous production device for poly-p-phenylene terephthamide resin

ActiveCN102838744AReduce continuous metering errorsQuality improvementContinuous measurementPolymer science

The invention provides a continuous production device for a poly-p-phenylene terephthamide resin, which belongs to the field of high molecular materials and relates to a high molecular material manufacturing technology. The continuous production device is characterized by comprising a p-phenylenediamine melt and solvent mixing and cooling device, a pre-polycondensation double-screw reactor, a combined second-order polycondensation double-screw reactor and a water washing device. After the continuous production device provided by the invention is used, the p-phenylenediamine and paraphthaloyl chloride are both fed as melts, so that continuous measurement errors are reduced and degrees of influences of flow fluctuation and solvent concentration on the mol ratio of the p-phenylenediamine and the paraphthaloyl chloride are reduced; and the obtained poly-p-phenylene terephthamide resin has the advantages of stable mass, narrow molecular weight distribution and low ash content and is suitable for industrially and continuously preparing the poly-p-phenylene terephthamide resin on a large-scale.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

Method for preparing high molecular weight poly(p-phenyleneterephthalamide) and products

ActiveCN101456950AReduce generationHigh molecular weightMonocomponent polyamides artificial filamentReaction temperatureHigh molecular mass

A preparation method for the p-phenylene terephthalamide p-phenylenediamine with high molecular weight, which comprises the following steps: adding anhydrous calcium chloride and N-methylpyrrolidone (NMP) to a reactor according to the weight proportion of 4-20: 100; adding proper amount of p-phenylenediamine (PPD), starting stirring, stirring for 30min at room temperature; inletting cooling medium to the reactor jacket to reduce temperature; reducing the system temperature to 0-15 DEG C below zero; adding the first batch of terephthaloyl chloride (TPC), continually stirring for 30min; reducing the temperature to 0-15 DEG C below zero again; adding the second batch of TPC; stirring quickly; stopping reaction after the system occurs pole-climbing and gel and is stirred to prepare the p-phenylene terephthalamide p-phenylenediamine. By adding the reactant TPC by two batches, the method of the invention can effectively control the reaction temperature; by cooling and reducing the temperature of the system, the method reduces the occurrence of side reaction and prepares the p-phenylene terephthalamide p-phenylenediamine with higher molecular weight and better color and luster.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Method for synthesizing high-viscosity polyphenylene terephthalamide

The invention relates to a method for synthesizing high-viscosity polyphenylene terephthalamide, and belongs to the technical field of polymer synthesis. The method comprises the following steps of: adding dissolution-helping salt into N-methyl pyrrolidone first, adding p-phenylenediamine for dissolution, adding paraphthaloyl chloride for polymerization, and washing and drying an obtained reaction product to obtain the polyphenylene terephthalamide. An acid absorbent used by the synthesis method is calcium hydride, the calcium hydride can react with hydrogen chloride produced in a polymerization reaction, and generated calcium chloride is a cosolvent in a solvent system and is favorable for the stability of a reaction system; and the calcium hydride can remove trace water in the reaction system, so that the influence of water on polyphenylene terephthalamide (PPTA) polymerization is eliminated. Moreover, the unreacted calcium hydride can be easily removed in the subsequent washing step after the PPTA polymerization is finished.

Owner:TSINGHUA UNIV

Polyamide-imide copolymer film and method of preparing polyamide-imide copolymer

ActiveUS9018343B2Maintain good propertiesHigh glass transition temperatureNon-linear opticsPolymer sciencePolyamide-imide

Owner:KOLON IND INC

Continuous large-scale production method for p-aramid nanofiber dispersion liquid

ActiveCN106750265AThe polymerization process went wellForm evenlyMonocomponent polyamides artificial filamentNanofiberChloride

The invention relates to a continuous large-scale production method for p-aramid nanofiber dispersion liquid, and belongs to the technical field of novel polymer materials. A proper aid is added in a process of generating poly-p-phenylene terephthamide (PPTA) through a reaction of p-phenylenediamine and paraphthaloyl chloride, so that the PPTA can directly generate nanofiber instead of random particles under control. Double screws are taken as a main reactor of PPTA polymerization, and an aid damaging molecular molecular aggregation of the PPTA is added into a PPTA polymerization system, so that successful proceeding of a PPTA polymerization process can be ensured on the one hand, interaction between the aid and the PPTA can be accelerated under the strong shear stirring action of a screw element on the other hand, and uniform nanofiber is formed instead of random particles by the PPTA. Moreover, a dispersing process of the nanofiber is finished directly in the screws under the shearing action of the double screws. The method is simple in equipment and is urgent in production links, major reaction and dispersion processes are finished in the double screws, and the production stability and continuity are enhanced greatly.

Owner:山东聚芳新材料股份有限公司

Production technology of poly (p-phenytene terephthalamide) resin

The invention relates to a production technology of poly (p-phenytene terephthalamide) resin, including the steps that: (1) p-phenylenediamine and 50-95% of paraphthaloyl chloride are subject to condensation polymerization at the temperature of minus 15 to 10 DEG C in solvent system containing cosolvent, so as to obtain precursor polymer; (2) the rest 5-50% of paraphthaloyl chloride and the precursor polymer are pumped into a first screw extruder for carrying out condensation polymerization, so as to obtain prepolymer; (3) the prepolymer is extruded into a second screw extruder for carrying out condensation polymerization, so as to obtain polymer, wherein the middle piece position and nose position of the second screw extruder are connected with an air extractor, so that at least 50% of hydrogen chloride produced in the condensation polymerization can be removed from the second screw extruder; (4) the obtained polymer is sequentially subject to washing at the temperature of minus 10 to 10 DEG C, dewatering and drying, thus obtaining the poly (p-phenytene terephthalamide) resin. The invention does not require to add acid absorbent, production environment is friendly, technology is simple, and reaction is stable.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD

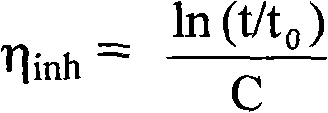

Preparation of high viscosity Poly(p-phenyleneterephthalamide) resin

The invention discloses a method for preparing poly p-phenylene terephtha-lamide resin with high viscosity. Firstly, para-phenylene diamine is fully dissolved and added into a prereactor, then paraphthaloyl chloride is added into the prereactor for prepolycondensation, then a prepolymer is added into a double screw extruder, a pyridine acid absorbent and a remained paraphthaloyl chloride low-temperature solution are respectively and synchronously added for a final polycondensation reaction through a liquid metering pump, and the extrusion is performed; and a polymer is kept stand, washed, dehydrated and dried. The inherent viscosity of the poly p-phenylene terephtha-lamide resin prepared by the method is between 6.5 and 9.5dl / g, the resin has good spinnability, and the spun fiber has good color and luster, high strength, and stable performance.

Owner:SINOPEC YIZHENG CHEM FIBER

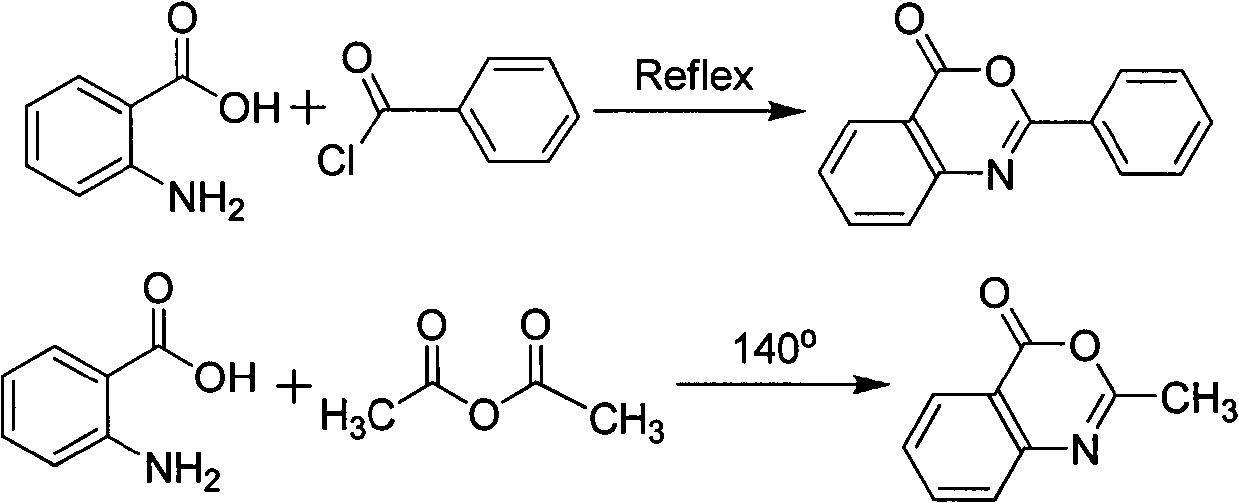

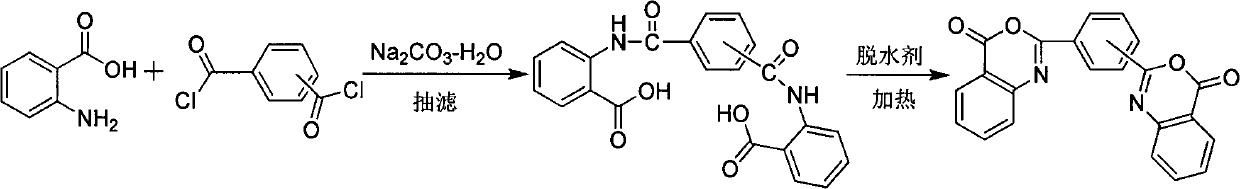

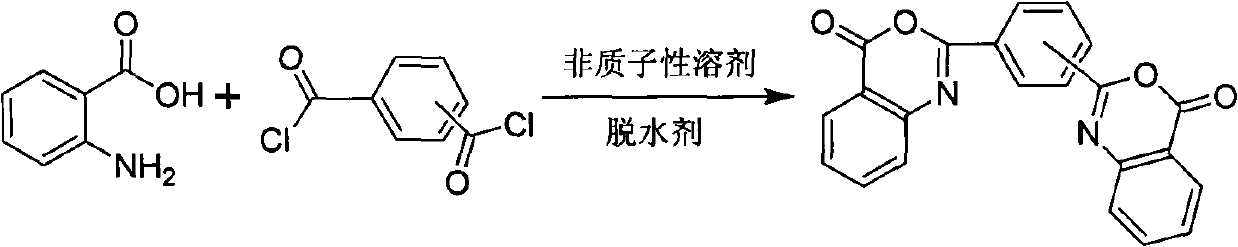

Novel synthetic method of bis-benzoxazine ketone ultraviolet absorbent

The invention provides a novel synthetic method of a bis-benzoxazine ketone ultraviolet absorbent, and belongs to the technical field of fine chemical engineering. The method comprises the following steps: A, stirring, anhydrides, used as raw materials, of o-aminobenzoic acid and (o-, m-, p-) phthaloyl dichloride or (o-, m-, p-)phthalic acid for a certain time in a non-polar solvent; B, adding chemical dehydrating agent or physical dehydrating agent in a reaction system without separating, slowly heating and refluxing for a certain time to obtain (o-, m-, p-)substituted bis-benzoxazine ketone ultraviolet absorbent; wherein the stirring time in the step A is not less than 1 hour, the refluxing time is 5-10 hours in the step B, the chemical dehydrating agent used in the step B is various dehydrating agents reacted with the water, including but not limited to alkaline calcium oxide, soda lime, acidic concentrated sulfuric acid, concentrated phosphoric acid, polyphosphoric acid, phosphorus pentoxide, thionyl chloride, acetic anhydride and the like, neutral molecular sieve, water-absorbent, anhydrous cupric sulfate and the like; the physical dehydrating agent comprises but not limited to non-protonic solvent such as benzene, methylbenzene, xylene and the like. The method provided by the invention has the advantages of being simple in operation flow, low in cost, simple in equipment, and suitable for the scale industrial production.

Owner:SHANDONG UNIV OF SCI & TECH

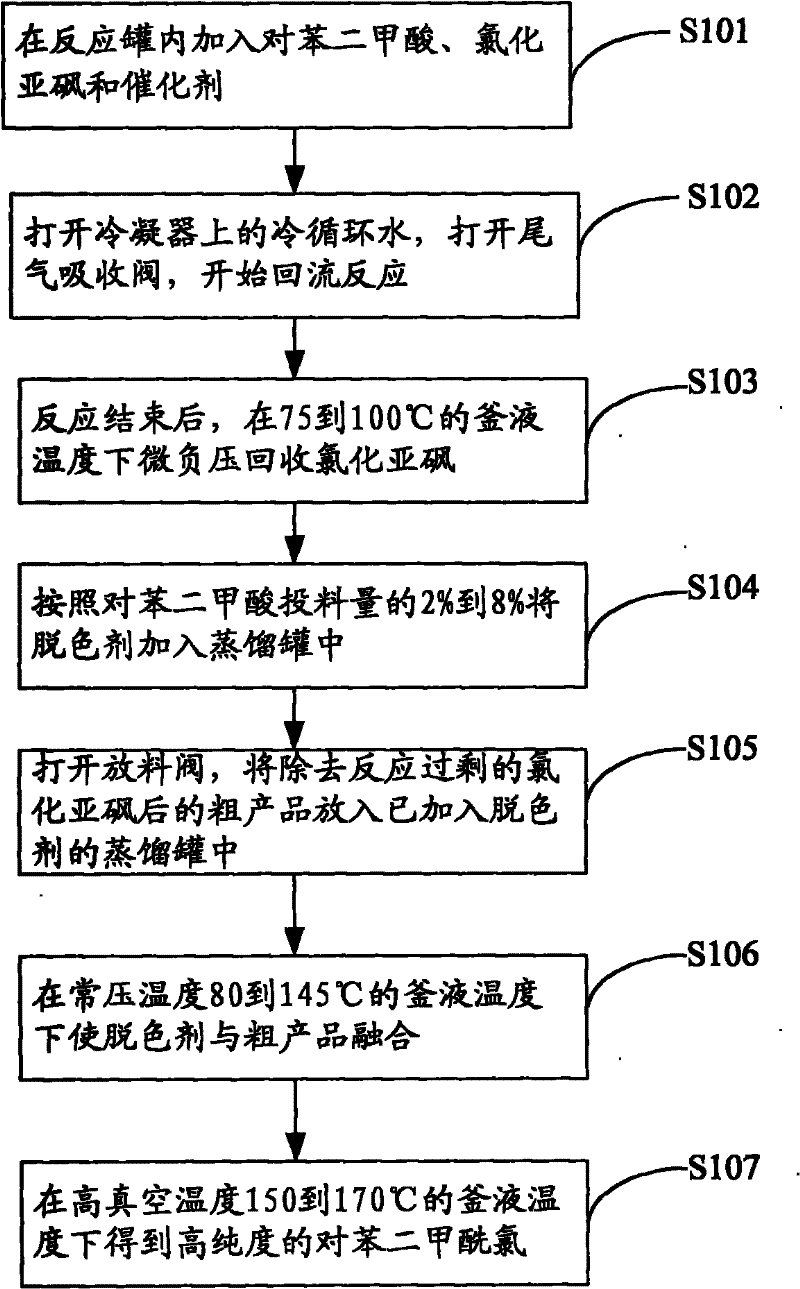

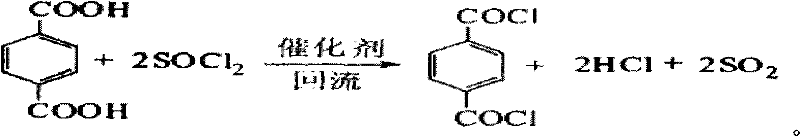

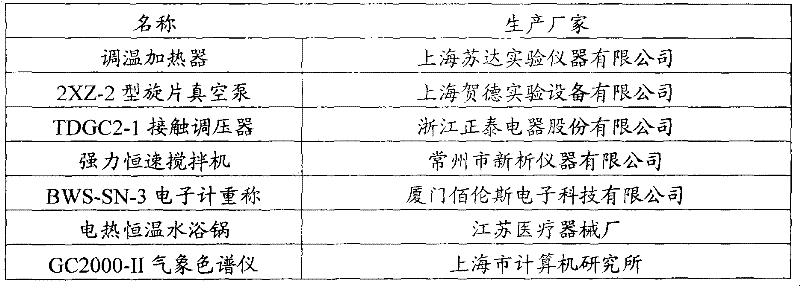

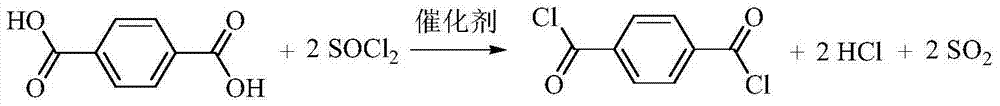

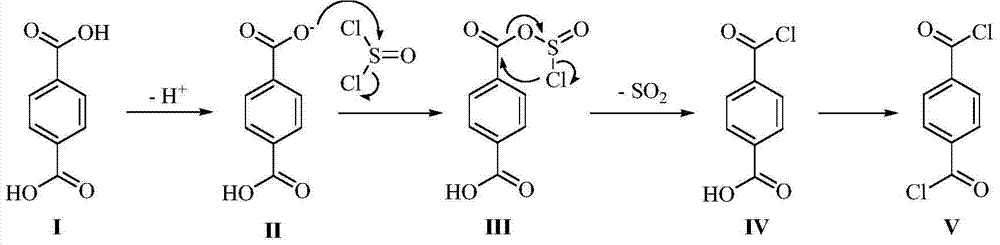

Preparation method of terephthaloyl chloride

InactiveCN102225895ASatisfy the requirement of aggregationHigh yieldOrganic compound preparationCarboxylic compound preparationLiquid temperatureAlembic

The invention is suitable for the field of terephthaloyl chloride preparation, and provides a preparation method of terephthaloyl chloride. The method comprises the following steps that: terephthalic acid, thionyl chloride and a catalyst are added into a reaction tank; a cold circulating water switch on a condenser is switched on, and a tail gas absorption valve is turned on, such that a reflux reaction is started; after the reaction, thionyl chloride is recovered under a kettle liquid temperature of 75 to 100 DEG C; a decolorant with a volume of 2% to 8% of the added terephthalic acid volume is added to an alembic; a feeding valve is opened, a crude product with excess thionyl chloride removed is added to the alembic with the decolorant added; the decolorant is fused with the crude product under a kettle liquid temperature of 80 to 145 DEG C; high purity terephthaloyl chloride is obtained under a high vacuum condition under a kettle liquid temperature of 150 to 170 DEG C. With the method provided by the present invention, the recovery rate of the product reaches 90 to 95%, the product content reaches 99.95% or above after one distilling process, such that energy consumption is reduced. The inner core crystal of the product turns from light red or light yellow to yellowish white or pure white, such that the requirement of aramid fiber 1414 polymerization can be satisfied.

Owner:YIZHENG HUANA TECH

Method for preparing graphene oxide grafted with thermotropic liquid crystal compound with end group containing epoxy group

InactiveCN102766265AWide variety of sourcesEasy to operateLiquid crystal compositionsEpoxyPtru catalyst

The invention discloses a method for preparing graphene oxide grafted with a thermotropic liquid crystal compound with an end group containing an epoxy group. P-phthanoyl chloride, p-hydroxybenzoic acid, thionyl chloride, diethylene glycol and glycidol are used as raw materials to react to obtain the thermotropic liquid crystal compound with the end group containing the epoxy group with pyridine and lauric acid butyltin as catalyst; thionyl chloride is added into graphene oxide mixed liquid formed by ultrasonic dispersion to react to obtain acyl chlorination graphene oxide; and acyl chlorination graphene oxide and thermotropic liquid crystal compound with the end group containing the epoxy group are used as raw materials and react with pyridine as catalyst to obtain graphene oxide grafted with the thermotropic liquid crystal compound with the end group containing the epoxy group. The graphite oxide is obtained by using Hummers oxidation method with chemical pure crystalline flake graphite as a raw material. Other chemical solvents are analytically pure. The raw materials are wide in source, simple in preparation process, free of pollution, low in cost and favorable for industrial large-scale production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for preparing polyamide-imide copolymer fibers

ActiveCN105239188ASimple processImprove efficiencyArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a method for preparing polyamide-imide copolymer fibers. The method comprises the steps that diamine monomers are added to an aprotic polar solvent, stirring is carried out at the temperature of -5 DEG C to 100 DEG C under nitrogen protection, dianhydride monomers are added for reacting, then paraphthaloyl chloride is added at the temperature of -10 DEG C to 20 DEG C, and reacting is carried out to obtain polyamide-polyamide acid polymer spinning solution; the spinning solution stands still for deaeration, and enters an inert gas channel of 140 DEG C to 380 DEG C after passing through a filtering and spinning assembly, cured raw yarn is obtained, and partially-cyclized precursor nascent fibers are obtained through winding; the nascent fibers are cyclized and drafted through the process of cyclizing and drafting integration. The method for preparing the polyamide-imide copolymer fibers is simple in process and high in efficiency, the obtained polyamide-imide copolymer fibers have the advantages of being high in strength and modulus, and resistant to irradiation and high temperature, and a new thought is provided for preparation of polyamideimide fibers.

Owner:DONGHUA UNIV

Preparation method for aromatic copolyamide fibers

InactiveCN102926022AMonocomponent copolyamides artificial filamentArtificial filament heat treatmentFiberFiltration

The present invention relates to a preparation method for aromatic copolyamide fibers. According to the preparation method, p-phenylenediamine, one or two diamine monomers and terephthaloyl chloride are adopted to carry out a low temperature solution polymerization reaction in a cosolvent-containing amide solvent system to prepare an aromatic copolyamide solution with a solid content of 2-10%, and the solution is sequentially subjected to deaeration, filtration, spinning, water washing, drying and oiling to prepare the newborn aromatic copolyamide fibers, wherein a breaking strength is 9-16 cN / detx, an elastic modulus is 300-450 cN / detx, and after the newborn aromatic copolyamide fibers are subjected to a heat treatment for 20-60 min at a temperature of 300-500 DEG C under a vacuum condition, the obtained fibers have a breaking strength of 25-35 cN / detx and an elastic modulus of 950-1350 cN / detx.

Owner:曹煜彤 +4

Method for preparing poly(p-phenylene terephthalamide) (PPTA) resin

The invention relates to a method for preparing poly(p-phenylene terephthalamide) (PPTA) resin. The method comprises the following steps of: (1) introducing inert gas, adding p-phenylenediamine into cosolvent-containing N-methyl pyrrolidone (NMP) to obtain mixed liquid, adding 50 to 85 percent of the total amount of terephthaloyl chloride after the p-phenylenediamine is completely dissolved, and performing pre-polycondensation to obtain prepolymer; and (2) adding the prepolymer and the rest terephthaloyl chloride into a double-screw extruder simultaneously, introducing inert gas, performing final polycondensation reaction, and extruding after the reaction is completely performed; and standing the extruded polymer, washing, dehydrating, and drying. An acid-acceptor is not required to be added during preparation, environment-friendly production is performed, and a few impurities are introduced; and the PPTA resin has small average particle size, large specific surface area, high molecular weight, low ash content and high logarithmic viscosity number, and is easy to clean.

Owner:DONGHUA UNIV +1

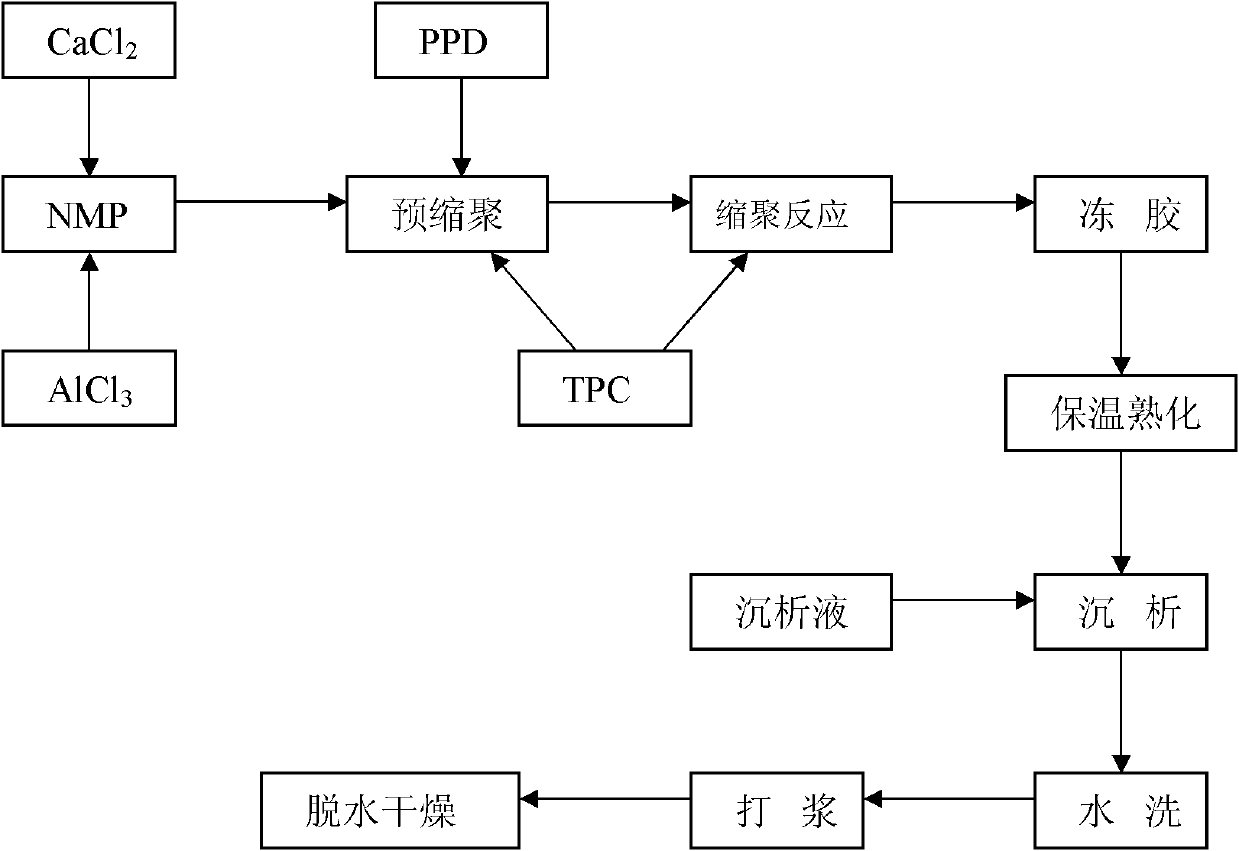

One-step preparation method of para aramid fibrids

ActiveCN102560737APrecipitate evenlyAvoid cloggingConjugated synthetic polymer artificial filamentsNitrogenColloid

The invention discloses a one-step preparation method of para-aramid fibrids, comprising the following steps: mixing NMP, CaCl2 and AlCl3 to prepare an NMP-CaCl2-AlCl3 solvent, adding p-phenylenediamine under the protection of nitrogen for dissolving, adding p-phthaloyl chloride at 5 DEG C for pre-polycondensation reaction, wherein the molar ratio of p-phenylenediamine to p-phthaloyl chloride is 1:0.6; after finishing the pre-polycondensation reaction, adding p-phenylenediamine with dramatically stirring for polycondensation reaction, wherein the molar ratio of the p-phenylenediamine added in the polycondensation reaction to the p-phenylenediamine added in the pre-polycondensation reaction os 1:0.4; stopping stirring when colloid generates in the reaction, and curing in the presence of nitrogen at 50-80 DEG C; letting the cured colloid solution and a para aramid pulp suspension respectively enter a precipitation device with a rotating speed of 1000-3000 rpm through a feeding inlet for precipitation, after the precipitation, washing with water, pulping, dehydrating and drying to obtain the para aramid fibrids. The invention has the advantages of easy preparation of the para aramid fibrids, precise control of precipitation speed and fiber size of the fibrids, and prevention of fibers from bonding into blocks.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Preparation method of polyphenylene terephthalamide copolymer adopting dimethylacetamide direct spinning

InactiveCN102070781AInhibit aggregationGet rid of the bondageMonocomponent copolyamides artificial filamentPolymer scienceDiaminodiphenyl ether

The invention discloses a preparation method of polyphenylene terephthalamide (PPTA) copolymer adopting dimethylacetamide (DMAC) direct spinning. The method comprises the following steps: 4,4'-diaminodiphenylsulfide or 4,4'-diaminodiphenyl ether is used as third monomer, m-phthaloyl chloride is introduced as fourth monomer to perform copolymerization with p-phthaloyl chloride and p-phenylenediamine in a solvent system and prepare uniform, transparent and thick PPTA copolymer size, and the concentration of the polymer is adjusted to perform dope spinning. The method of the invention effectively avoids of adopting the complicated production equipment to perform the polymerization of PPTA; cheap 4,4'-diaminodiphenylsulfide or 4,4'-diaminodiphenyl ether is used as the third monomer and the fourth monomer with a meta-structure is introduced to prepare the PPTA copolymer which can be directly dissolved in DMAC, thus avoiding of using concentrated sulfuric acid as spinning solvent; and the spinning solvent is consistent to the polymerization solvent, the concentration of the polymer is adjusted to perform dope spinning with DMAC and the production process can be greatly simplified.

Owner:CHANGCHUN UNIV OF TECH

Continuous polymerization method of high-viscosity poly-p-phenylene terephthamide

The invention provides a continuous polymerization method of high-viscosity poly-p-phenylene terephthamide. Based on the design of the polymerization formula, and the design and use of a novel mixing device and a hydrogen chloride discharge device matched with the design of the polymerization formula, continuity of the PPTA (poly-p-phenylene terephthamide) polymerization is guaranteed, and the molecular weight of the obtained PPTA is high. The method is characterized by comprising the following steps of: preparing materials, namely dissolving hydrotropy salt and PPD (p-Phenylenediamine) at a low temperature; keeping the TPC (paraphthaloyl chloride) in molten state; mixing, by combination of a Venturi jet mixer and a dynamic or static mixer, ensuring even mixing of the TCP and the PPD solution; and polymerization, finishing the polymerization of the PPD and the TPC by a double-screw reactor, and eliminating the hydrogen chloride released by some reaction. The continuous polymerization method has the advantages of improving the stability of the PPD and TCP reaction, ensuring the continuity and the stability of the production, and facilitating the high-efficiency separation of the hydrogen chloride; by the continuous polymerization method provided by the invention, polymerization production of high-viscosity PPTA can be realized steadily and continuously.

Owner:AFCHINA CORP CO LTD +1

Polyamide composite nanofiltration membrane

ActiveCN102133506ANo low separabilityNot low permeabilitySemi-permeable membranesToluene diisocyanateChloride

The invention relates to a polymer separation membrane, in particular to a high-performance polyamide composite membrane. In the invention, an ultra-thin active separating layer is compounded on a porous supporting membrane through interfacial polycondensation between an aqueous solution containing aliphatic macromolecular polyamine and an organic solution containing a dyadic aromatic reaction monomer; the aliphatic macromolecular polyamine is polyvinylamine; the dyadic aromatic reaction monomer is phthaloyl chloride or paraphthaloyl chloride or 2,4-toluene diisocyanate; and the thickness of the active separating layer is 0.02-0.5 mum. The invention has the advantage that a novel high-performance composite nanofiltration membrane which is made of raw materials easy to obtain and has low cost and excellent preferential segregation performance is provided. The high-performance composite nanofiltration membrane provided by the invention has multiple purposes and a simple manufacturing method.

Owner:浙江易膜新材料科技有限公司

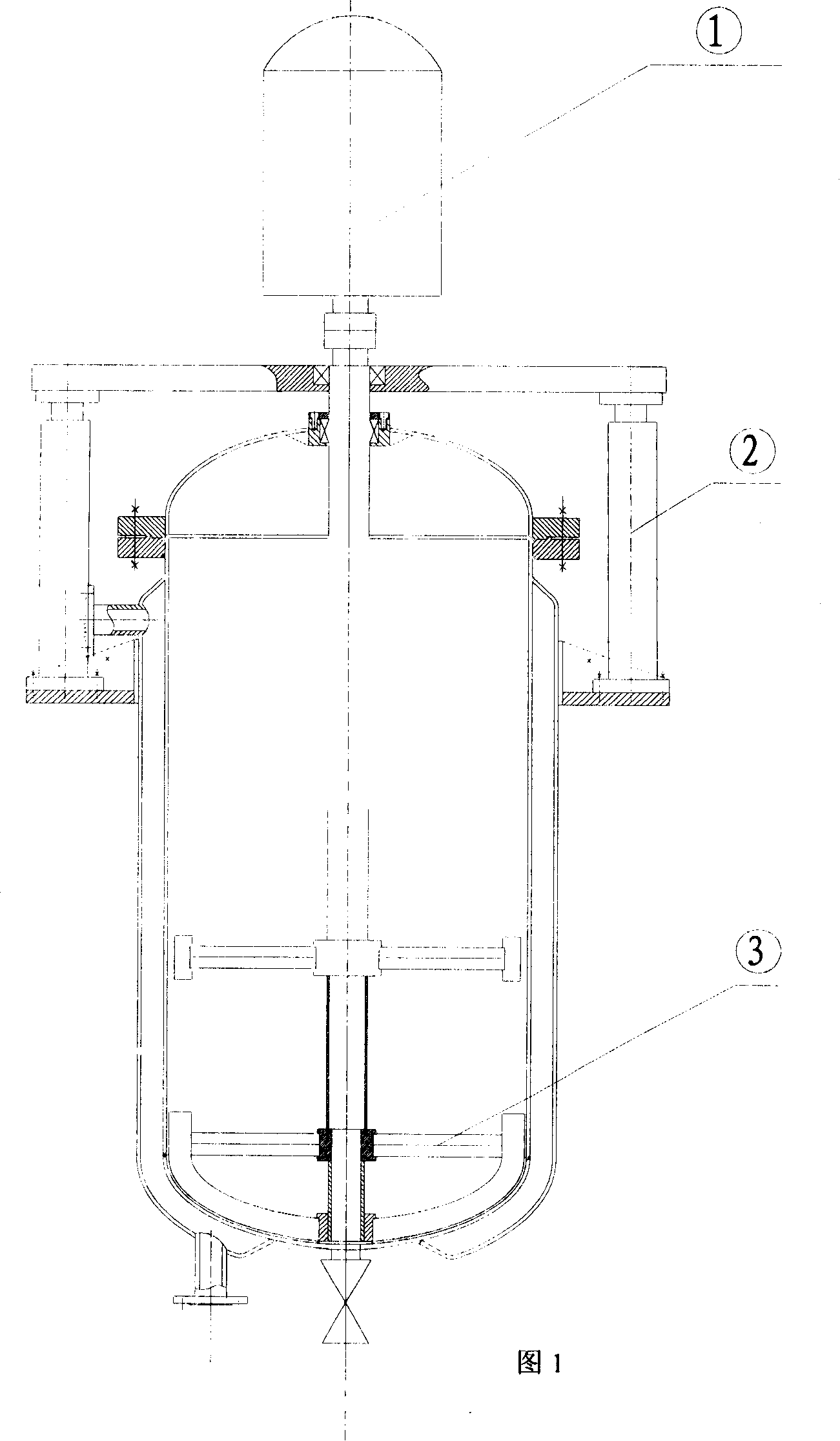

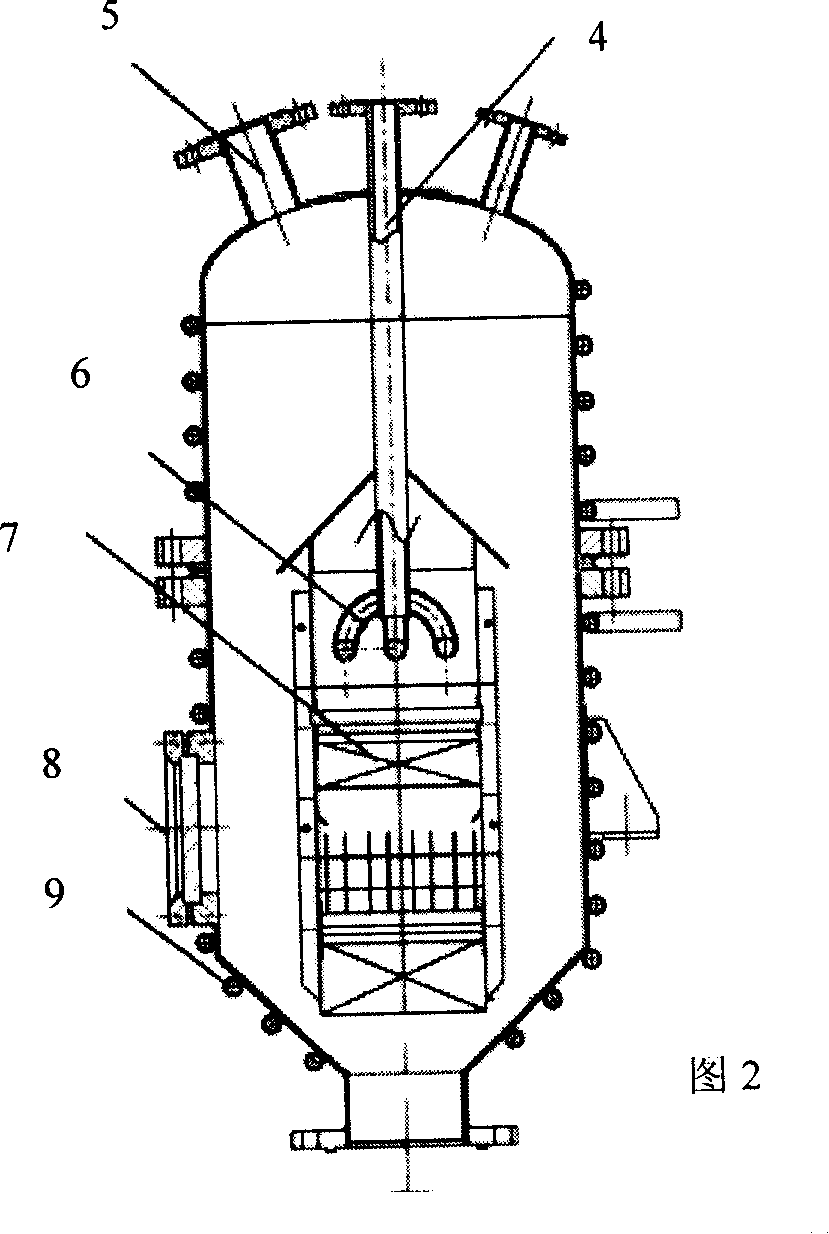

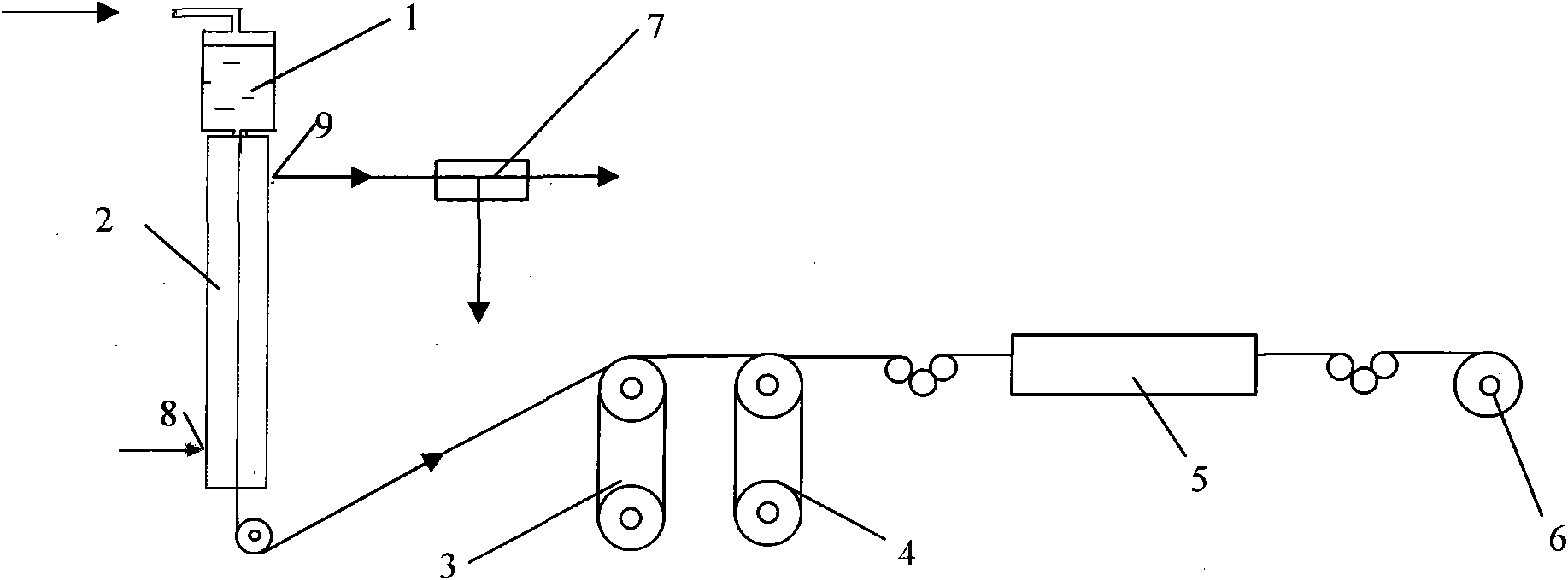

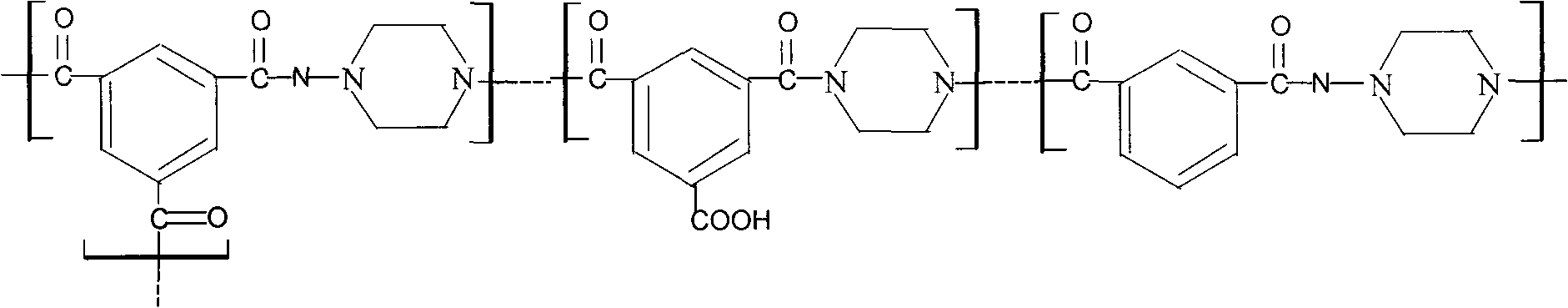

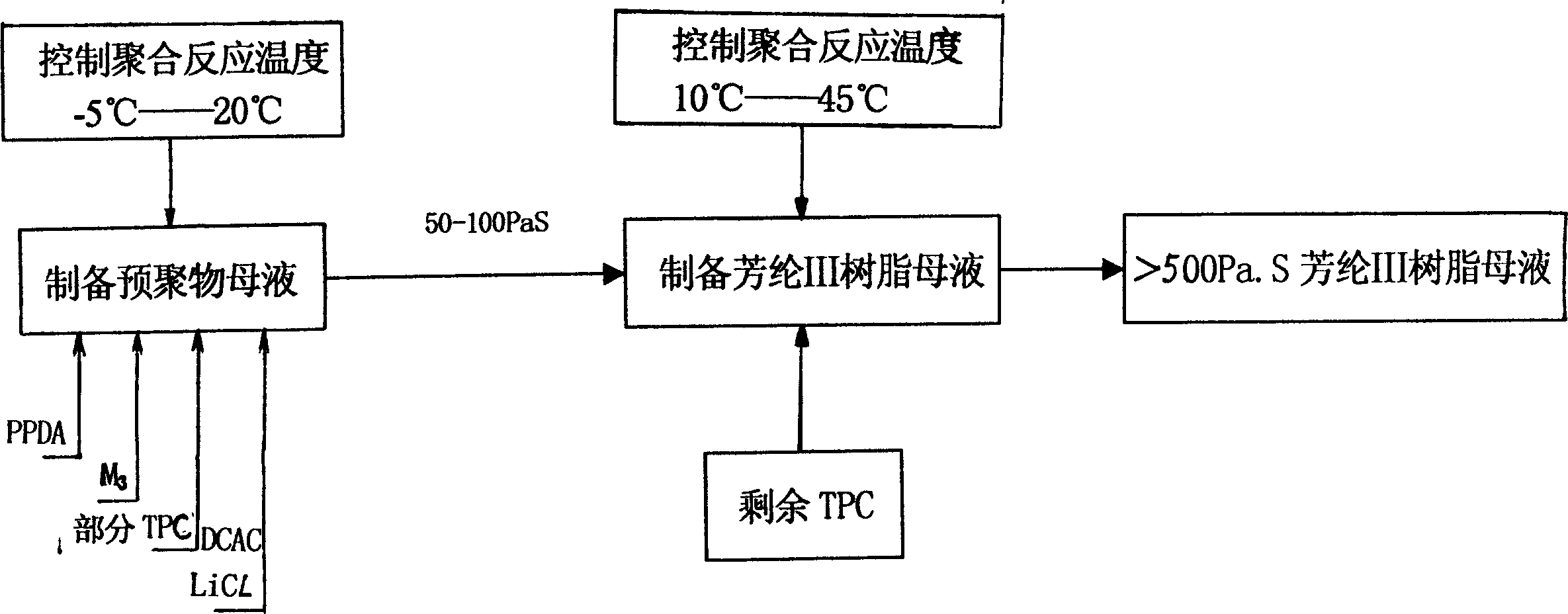

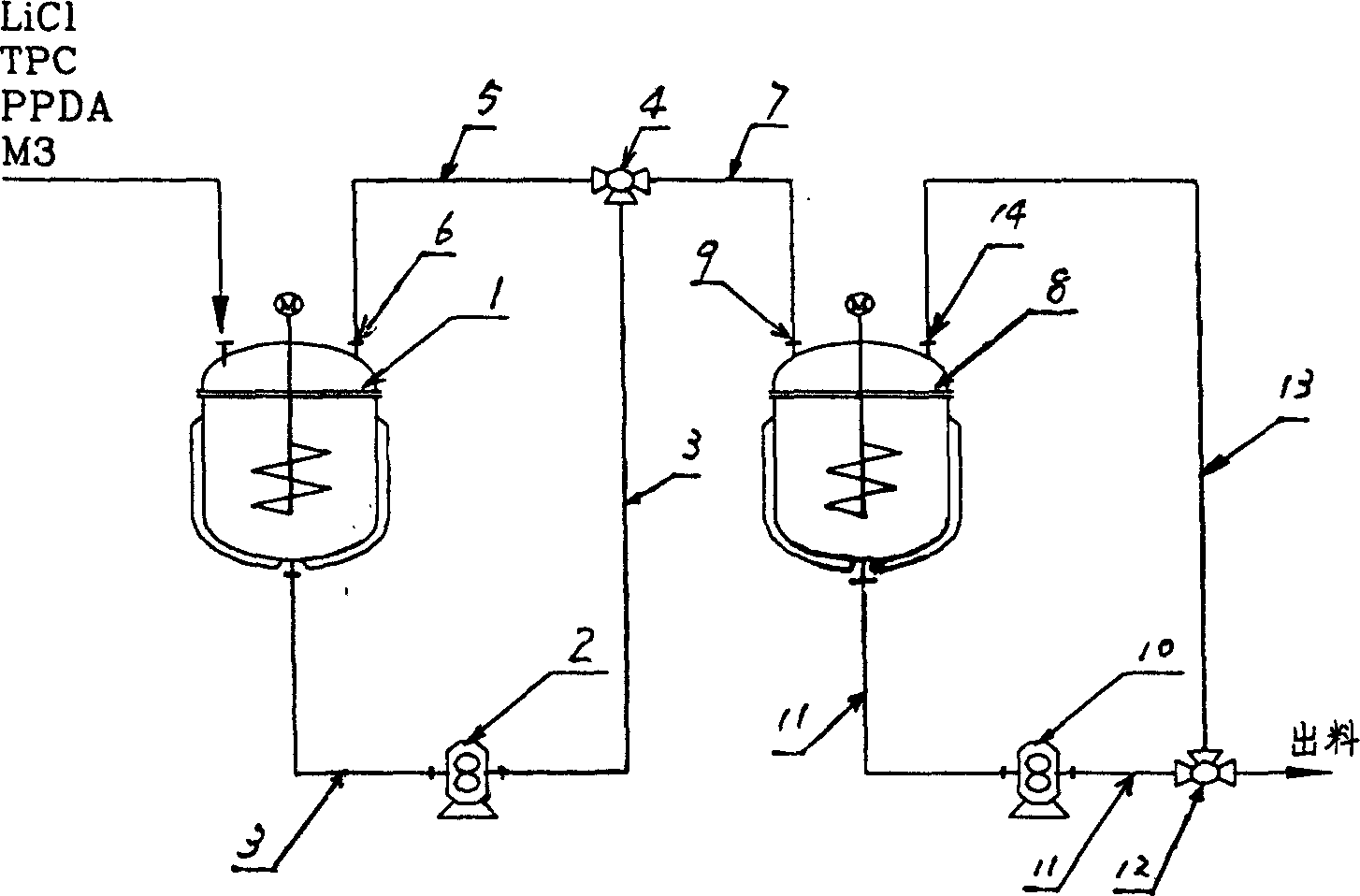

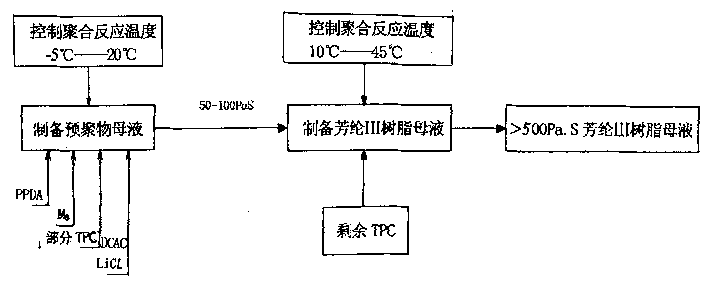

Technique method for preparing mother liquor of fullbodied aramid fiber III resin and preparation equipment

A process for preparing high-viscosity aramid fibre C resin includes reaction between p-phenyldiamine, M3 monomer and part of p-phenyl diformly chloride in N, N diformylacetylamine in which lithium chloride is dissolved to obtain the mother liquid of prepolymer, and reaction between said mother liquid and rest of p-phenyl diformly chloride. Its apparatus is composed of prepolymerizing reactor, polymerizing reactor, delivery pump and pipelines. Its advantage is high hot mass transfer effect.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Preparation method of poly-p-phenylene terephthamide resin

The invention relates to a preparation method of poly-p-phenylene terephthamide resin. The preparation method is characterized by comprising the following steps: (1) preparing a p-phenylenediamine solution; (2) preparing paraphthaloyl chloride molten mass; (3) subjecting the p-phenylenediamine solution and the paraphthaloyl chloride molten mass to a pre-polymerization reaction; (4) carrying out a condensation reaction to prepare the poly-p-phenylene terephthamide resin. The prepared poly-p-phenylene terephthamide resin powder has the advantages of high polymerization degree, uniform particle, narrow molecular weight distribution, and small repose angle. During the whole technology process, the paraphthaloyl chloride is added in a molten state, so the metering is relatively simple, the precision is high, the production stability is higher, and the production period is longer. Moreover a mixer and a pre-reactor are adopted, the thermal energy generated by the reactions can be effectively distributed to the mixer, the pre-reactor, and a double-screw reactor, thus the thermal transmission problem is solved, and the polymerization process is controllable.

Owner:SINOPEC YIZHENG CHEM FIBER +1

High strength and high modulus para-aramid fiber and preparation method thereof

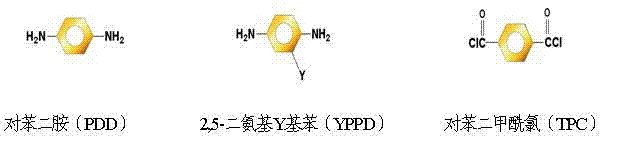

ActiveCN102383218AGood solvent resistanceHigh tensile strengthArtificial filament washing/dryingFilament/thread formingBenzenePolymer science

The invention discloses a high strength and high modulus para-aramid fiber and a preparation method thereof. The high strength and high modulus para-aramid fiber is characterized by being prepared from steps of: polymerizing 2,5-diamino Y benzene, terephthaloyl chloride or / and p-phenylenediamine monomer according to a molar ratio in a solvent system to prepare a spinning slurry, filtering the slurry, carrying out dry spray wet spinning, drying and reeling. The fiber large molecular chain infrared light spectrum has C-N bond telescoping vibration absorption peaks at wave number of 2230 cm<-1> and 1406 cm <-1> and has amide bond absorption peaks at 1662 cm<-1> and 3500-3300 cm<-1>. Specific indexes of the fiber are as below: tensile strength of 24-28g / d, initial modulus of 700-900g / d, fracture elongation of 2.5-3.5%, filament number of 1-2 D and yarn fineness of 300-3000 D. The invention is easily controlled and environment-friendly and reduces corrosion of apparatus, thereby reducingindustrialization cost and spinning cost relatively.

Owner:南充易安新材料有限公司

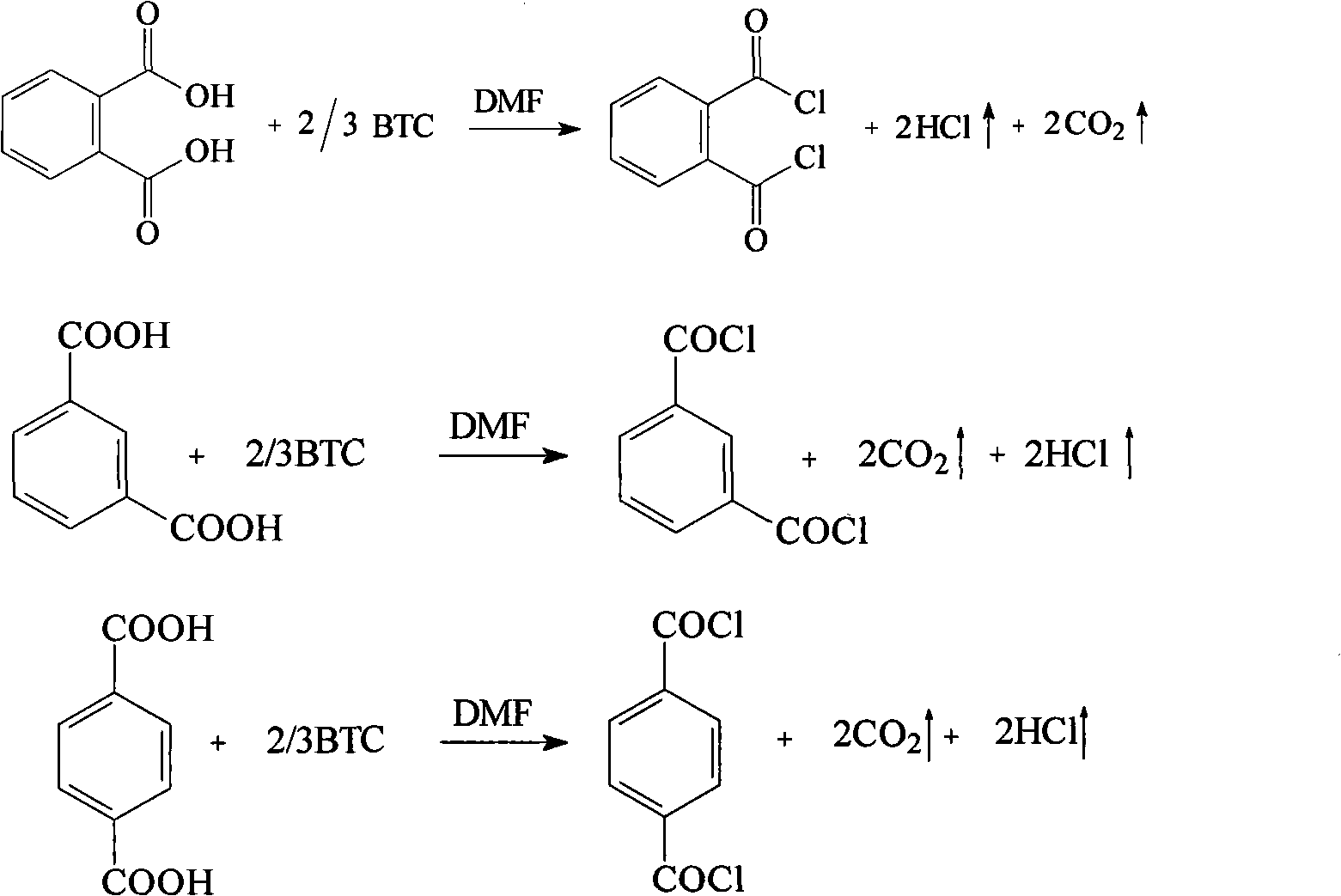

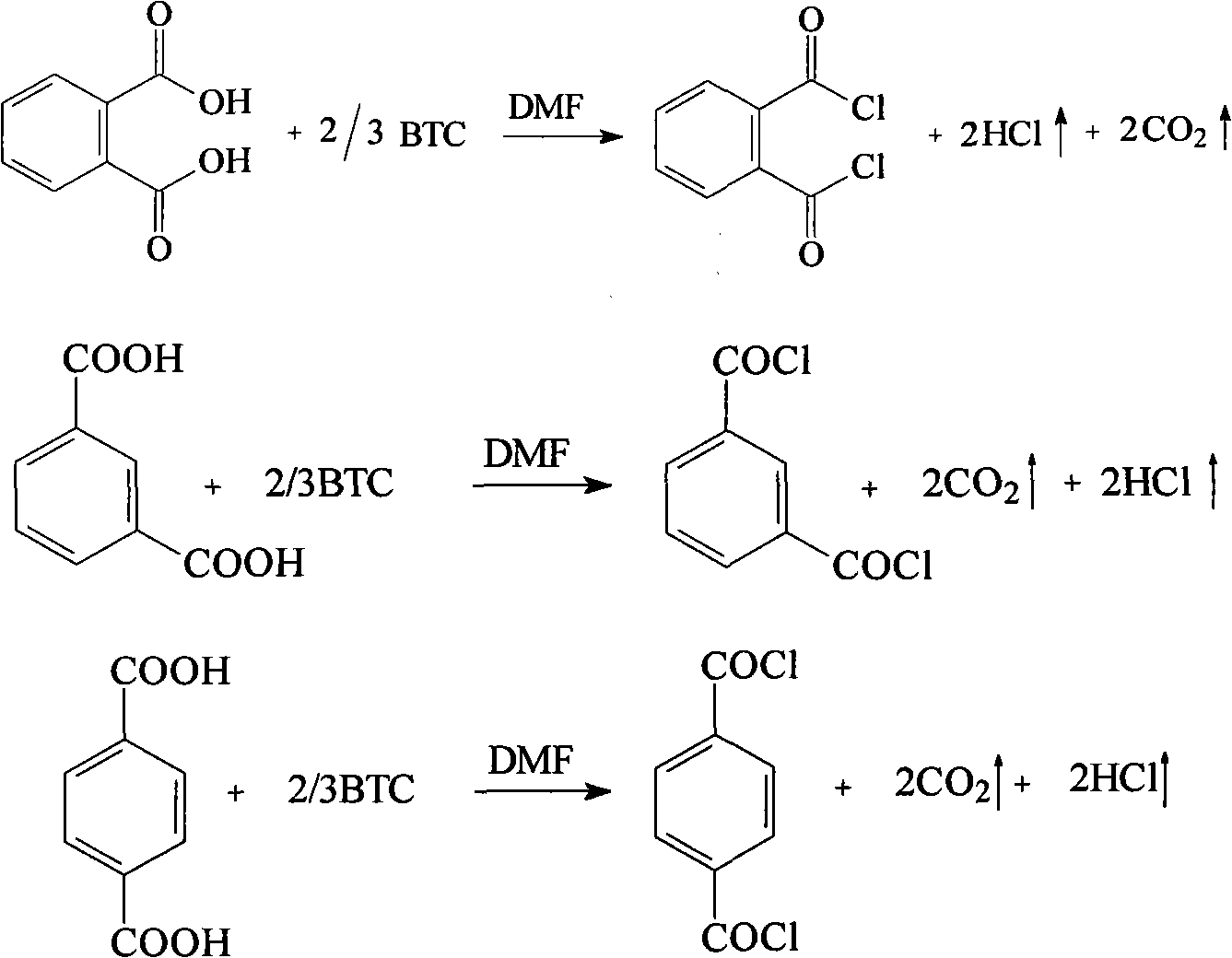

Preparation method for phthalyl chloride, m-phthaloyl chloride and paraphthaloyl chloride

InactiveCN101805257AReduce usageReasonable process conditionsOrganic compound preparationCarboxylic compound preparationReaction temperatureEthane Dichloride

The invention relates to a preparation method for phthalyl chloride, m-phthaloyl chloride and paraphthaloyl chloride. In the method, benzene dicarboxylic acid and triphosgene are taken as raw materials and mixed for catalytic reaction in an organic solvent of 1, 2-dichloroethane, the mol ratio for the catalytic reaction is 0.5-0.9, the catalyst is N, the dosage of N-dimethyl formamide is 0.1-0.6 time of the weight of the raw material benzene dicarboxylic acid, the catalytic reaction lasts for 2-5 hours, and the reaction temperature is the reflux temperature of the solvent 1, 2-dichloroethane. Compared with the prior art, the invention avoids using toxic and hazardous thionyl chloride, phosphorus oxychloride and phosgene and the like. Therefore, the invention has the advantages of reasonable process conditions, simple and safe operation, high reaction yield, low manufacture cost and easy realization of industrial production, and has high implementation value, social benefit, economic benefit and environmental benefit.

Owner:TAIYUAN UNIV OF TECH

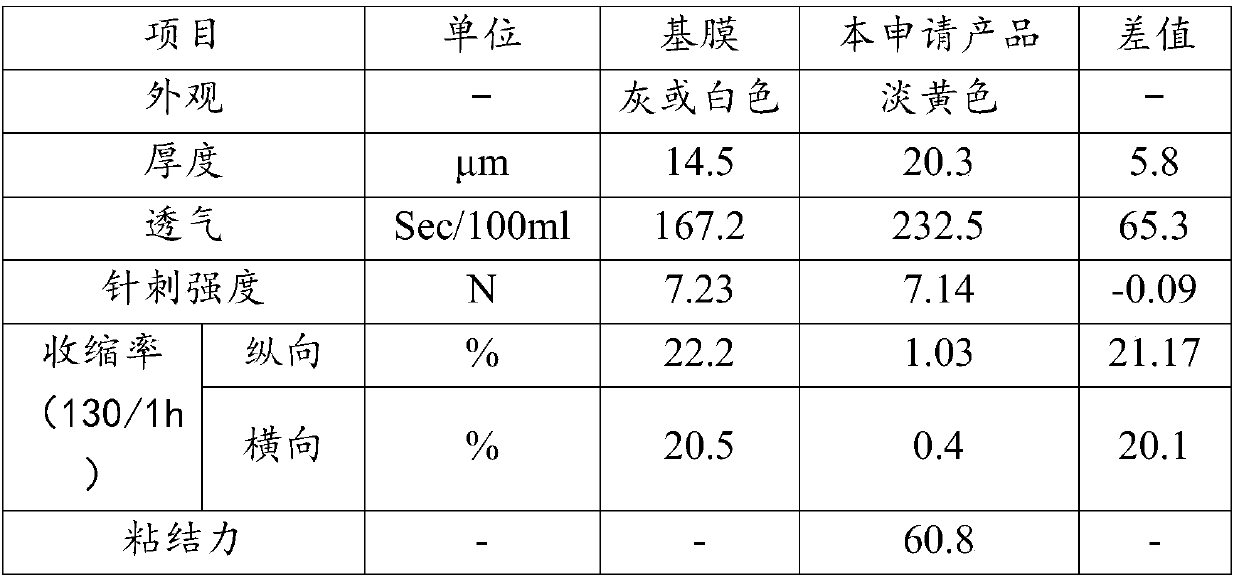

Membrane coating liquid and water-based nano-para-aramid coated membrane

ActiveCN109546056ANothing producedReduce usageMaterial nanotechnologyCell component detailsWater basedCoated membrane

The invention provides membrane coating liquid and a water-based nano-para-aramid coated membrane. The preparation method of the membrane coating liquid comprises: adding co-solvent and polyethylene glycol into N-methyl pyrrolidone, carrying stirring and then carrying out first-time cooling, adding p-phenylenediamine and then carrying out second-time cooling, adding paraphthaloyl chloride, improving a rotating speed reaction, and carrying out temperature-rising reaction to obtain a primary polymer of para-aramid; adding N-methyl pyrrolidone, carrying out shearing at a high speed, and adding water to obtain aramid nano-fiber suspension; adding alcohol, carrying out dispersion and filtering to obtain a first solution; adding a dispersant and inorganic particles in water and carrying out dispersion and sand grinding to obtain a second solution; adding polyvinylpyrrolidone in water to obtain a third solution; mixing the first solution with the second solution, carrying out stirring, addingthe third solution, and carrying out stirring to obtain membrane coating liquid. In addition, the water-based nano-para-aramid coated membrane is prepared by using the coating liquid. According to the invention, no solvent is used for extraction; the green and environment-friendly effects are good; and the cost is low.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

High-flux composite nanofiltration membrane

InactiveCN102423643AImprove permeabilityRaw materials are easy to getSemi-permeable membranesToluene diisocyanateHigh flux

The invention relates to a macromolecular separation membrane, and in particular relates to a high-flux composite nanofiltration membrane. An ultrathin active separation layer is compounded on a porous support membrane through interfacial polycondensation between the aqueous solution containing aliphatic macromolecular polyamine and an organic solution containing aromatic polyacyl chloride; the aliphatic macromolecular polyamine is sericin with concentration of 0.2-6.0wt%; and the aromatic polyacyl chloride is trimesoyl chloride or 5-isocyanate-isophthalyl chloride or 5-oxyformyl chloride-isophthalyl chloride or phthaloyl chloride or paraphthaloyl chloride or 2,4-toluene diisocyanate, with concentration of 0.5-4.0wt%. The invention provides a novel high-flux composite nanofiltration membrane which has the advantages that: the raw materials are easily available, the cost is low, the selective separation performance is good, and the penetration flux is high. The high-flux composite nanofiltration membrane provided by the invention is widely applicable, and the manufacturing method is simple.

Owner:杭州奈诺膜环境技术有限公司

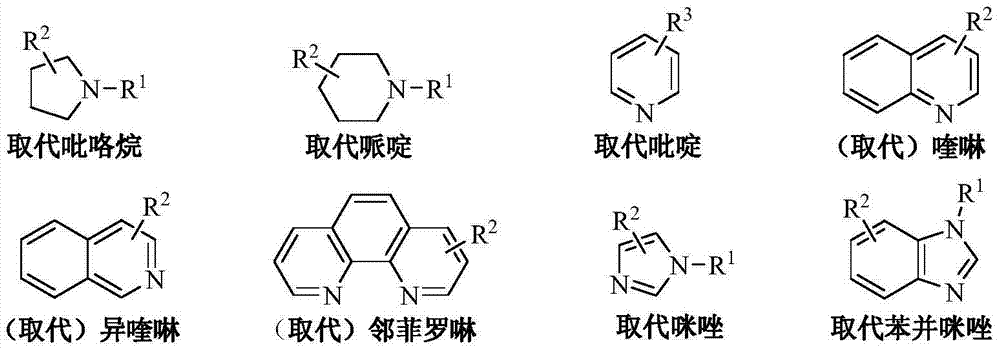

Method for preparing paraphthaloyl chloride

ActiveCN103694113AHigh yieldHigh purityOrganic compound preparationChemical recyclingPhenanthrolineQuinoline

The invention relates to a method for preparing paraphthaloyl chloride. The method comprises the following steps: mixing thionyl chloride and terephthalic acid according to the mass ratio of 2:1 to 5:1; adding one or more of nitrogen-containing organic bases such as substituted pyrrolidine, substituted piperidine, substituted pyridine, (substituted) quinoline, (substituted) isoquinoline, (substituted) phenanthroline, substituted imidazole, substituted benzimidazole and the like as a catalyst, which are 0.5-2% of mass of terephthalic acid; reacting at 70-120 DEG C for 4-16 hours; distilling and recovering excessive thionyl chloride; distilling or rectifying in vacuum to recover the catalyst, so as to obtain the product paraphthaloyl chloride by vacuum rectification, wherein the yield can be up to 96%, and the purity is higher than 99%. The method has the advantages that the catalyst is low in price and available, and can be recycled, the product is high in yield and purity, the reaction operation is simple and convenient and the like.

Owner:河南能源集团研究总院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com