Continuous production device for poly-p-phenylene terephthamide resin

A poly(p-phenylene terephthalamide) production device technology, which is applied in the field of polymer material preparation and continuous production device of poly(p-phenylene terephthalamide resin), can solve the problems of large measurement errors and blocked tubes Road, undisclosed production equipment and other problems, to achieve the effect of reducing continuous measurement errors, narrow molecular weight distribution, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

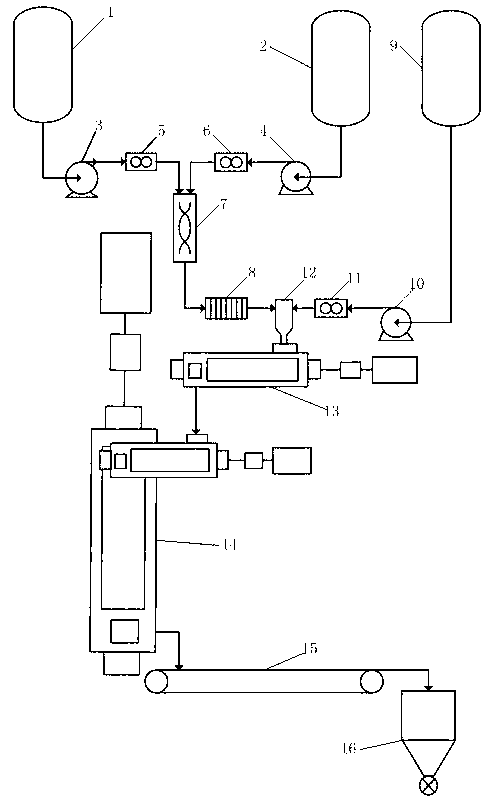

[0027] CaCl in storage tank (1) 2 - NMP solvent and PPD melt in the PPD melting storage tank (2), respectively, are transported by the gear solvent delivery pump (3) and the PPD delivery pump (4), through the mass solvent flow meter (5) and the PPD flow rate Under the metering of meter (6), at the speed of 1050.0 parts by mass / hour and 60.2 parts by mass / hour, it is continuously added to the mixer (7) for mixing, and the temperature of the mixed solution is reduced to 0 after passing through the heat exchanger (8). ℃, and 113.02 parts by mass / small TPC melt, while continuously adding to the batching mixer (12) for mixing, and then flowed into a machine with a diameter of 125mm, an aspect ratio of 7.2, a rotational speed of 300rpm, and a jacket temperature of 0℃. The pre-condensation twin-screw reactor, after reacting in the reactor for 8s, flows into the polycondensation twin-screw reactor (14), the polycondensation twin-screw reactor (14) is a combined second-stage twin-screw...

Embodiment 2

[0029] CaCl in storage tank (1) 2 - NMP solvent and PPD melt in the PPD melting storage tank (2), respectively, are transported by the gear solvent delivery pump (3) and the PPD delivery pump (4), through the mass solvent flow meter (5) and the PPD flow rate Under the metering of meter (6), at the speed of 1000.0 parts by mass / hour and 58.0 parts by mass / hour, it is continuously added to the mixer (7) for mixing, and the temperature of the mixed solution is reduced to 0 after passing through the heat exchanger (8). ℃, and 108.9 parts by mass / small TPC melt, while continuously adding to the batch mixer (12) for mixing, and then flowed into a machine with a diameter of 125mm, an aspect ratio of 7.2, a rotational speed of 250rpm, and a jacket temperature of 0℃. The pre-condensation twin-screw reactor, which flows into the polycondensation twin-screw reactor (14) after reacting in the reactor for 10s, the polycondensation twin-screw reactor (14) is a combined second-stage twin-scr...

Embodiment 3

[0031] CaCl in storage tank (1) 2 - NMP solvent and PPD melt in the PPD melting storage tank (2), respectively, are transported by the gear solvent delivery pump (3) and the PPD delivery pump (4), through the mass solvent flow meter (5) and the PPD flow rate Under the metering of meter (6), at the speed of 950.0 parts by mass / hour and 50.0 parts by mass / hour, it is continuously added to the mixer (7) for mixing, and the temperature of the mixed solution is reduced to 0 after passing through the heat exchanger (8). ℃, and 93.7 parts by mass / small TPC melt, while continuously adding to the batching mixer (12) for mixing, and then flowed into a machine with a diameter of 125mm, an aspect ratio of 7.2, a rotational speed of 200rpm, and a jacket temperature of 0℃. The pre-condensation twin-screw reactor, which flows into the polycondensation twin-screw reactor (14) after reacting in the reactor for 12s, the polycondensation twin-screw reactor (14) is a combined second-stage twin-sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com