Patents

Literature

219 results about "Solvent flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle formation

InactiveUS20030109421A1Risk minimizationPeptide/protein ingredientsGranulation by liquid drop formationAnti solventEngineering

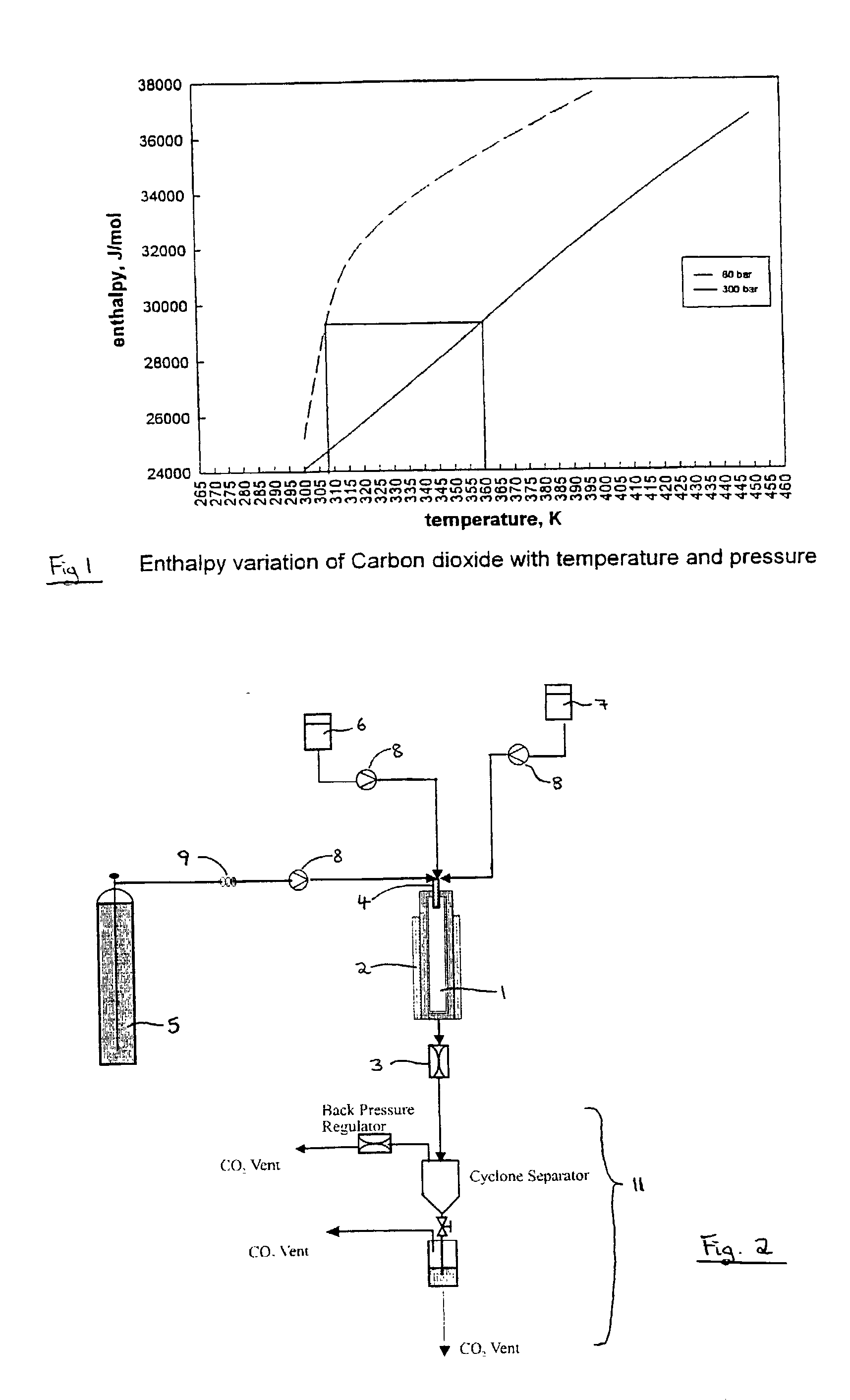

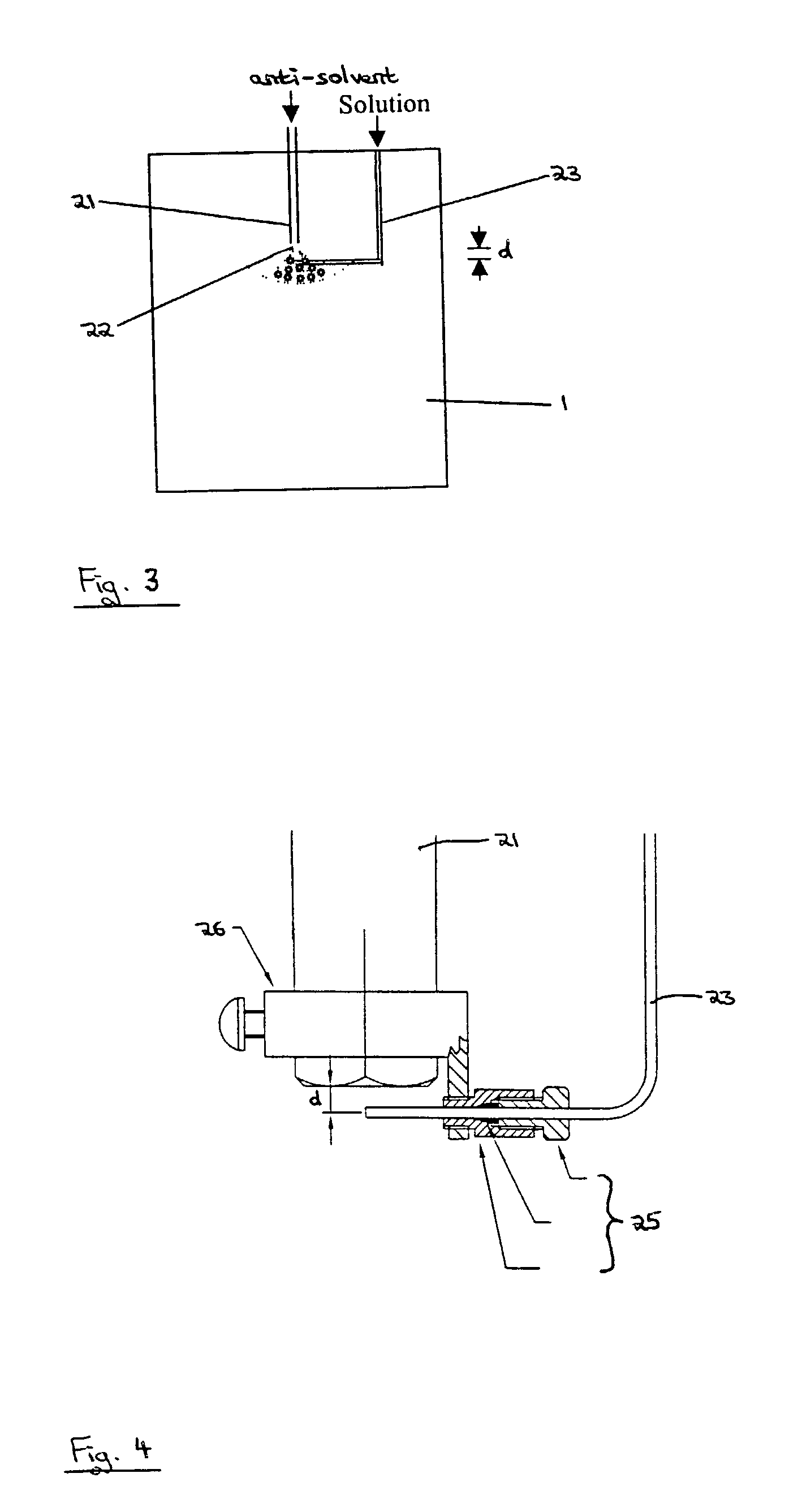

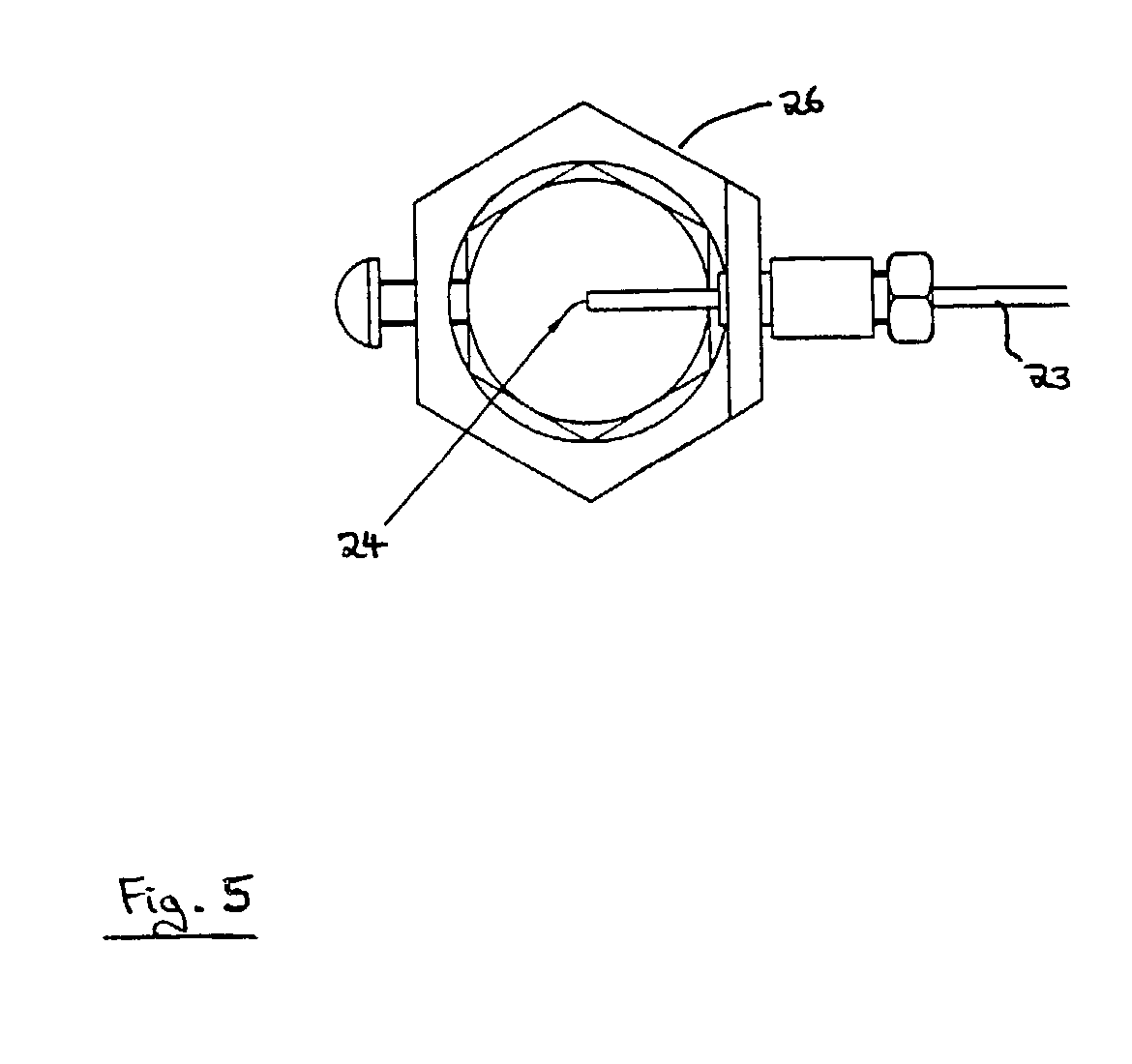

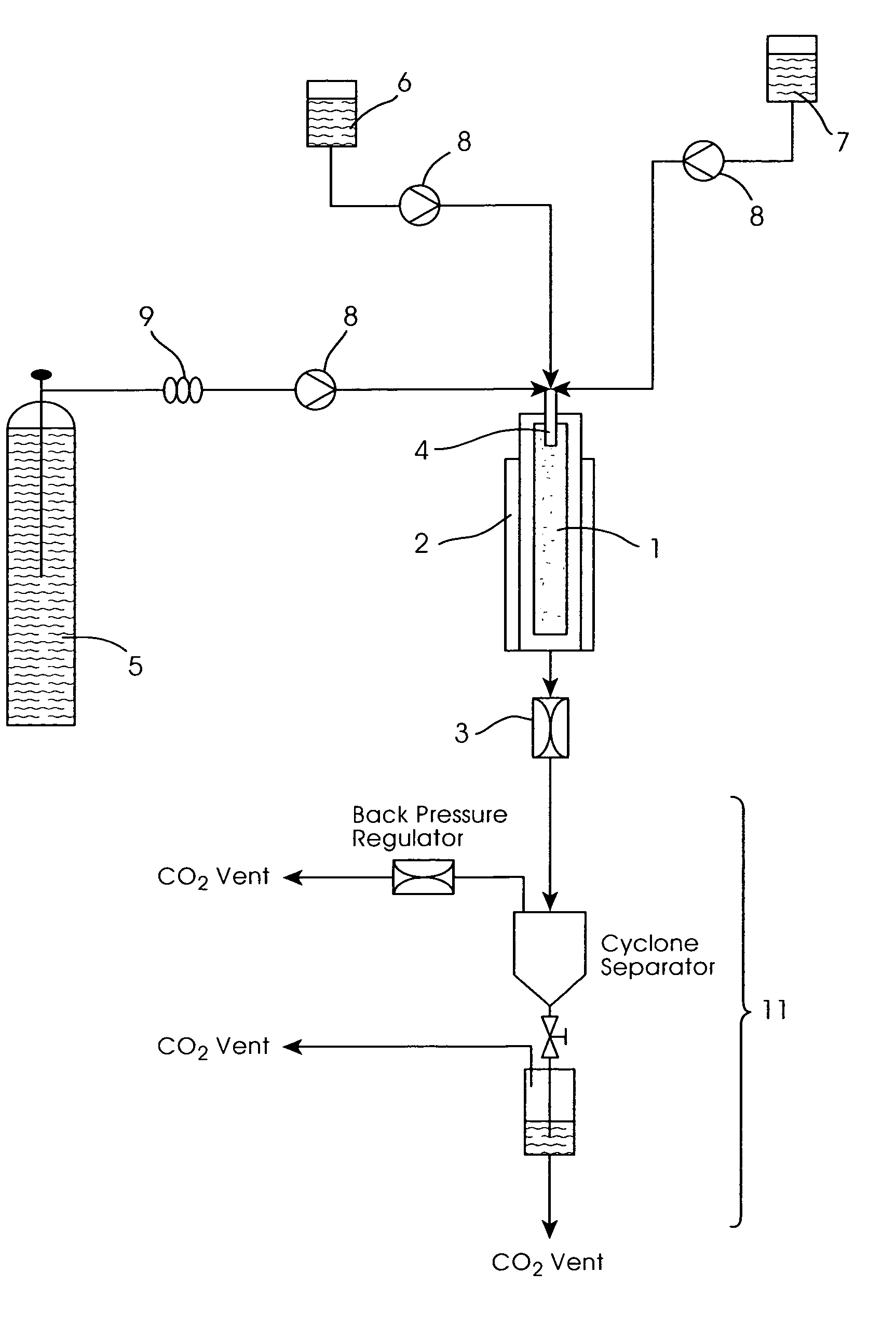

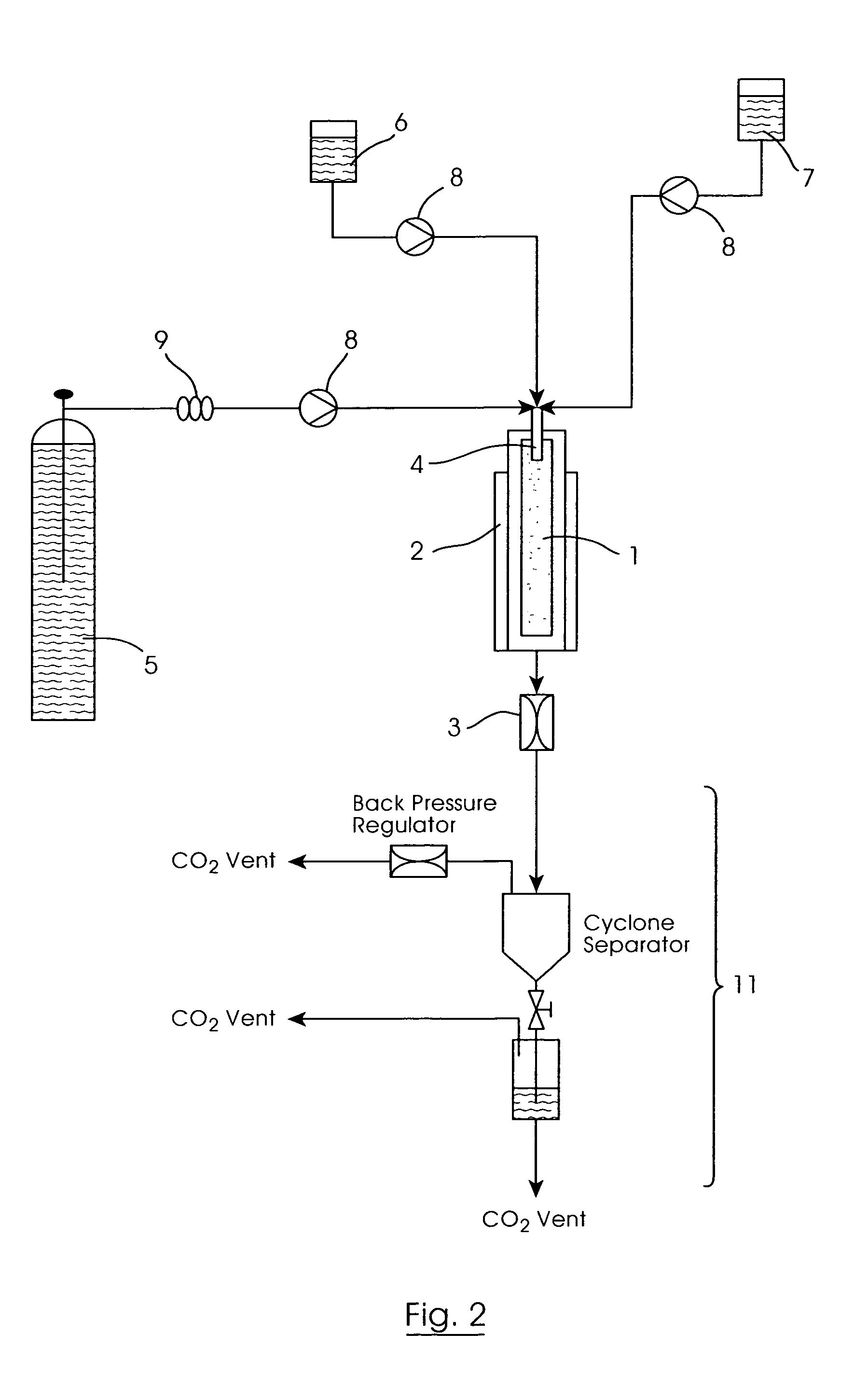

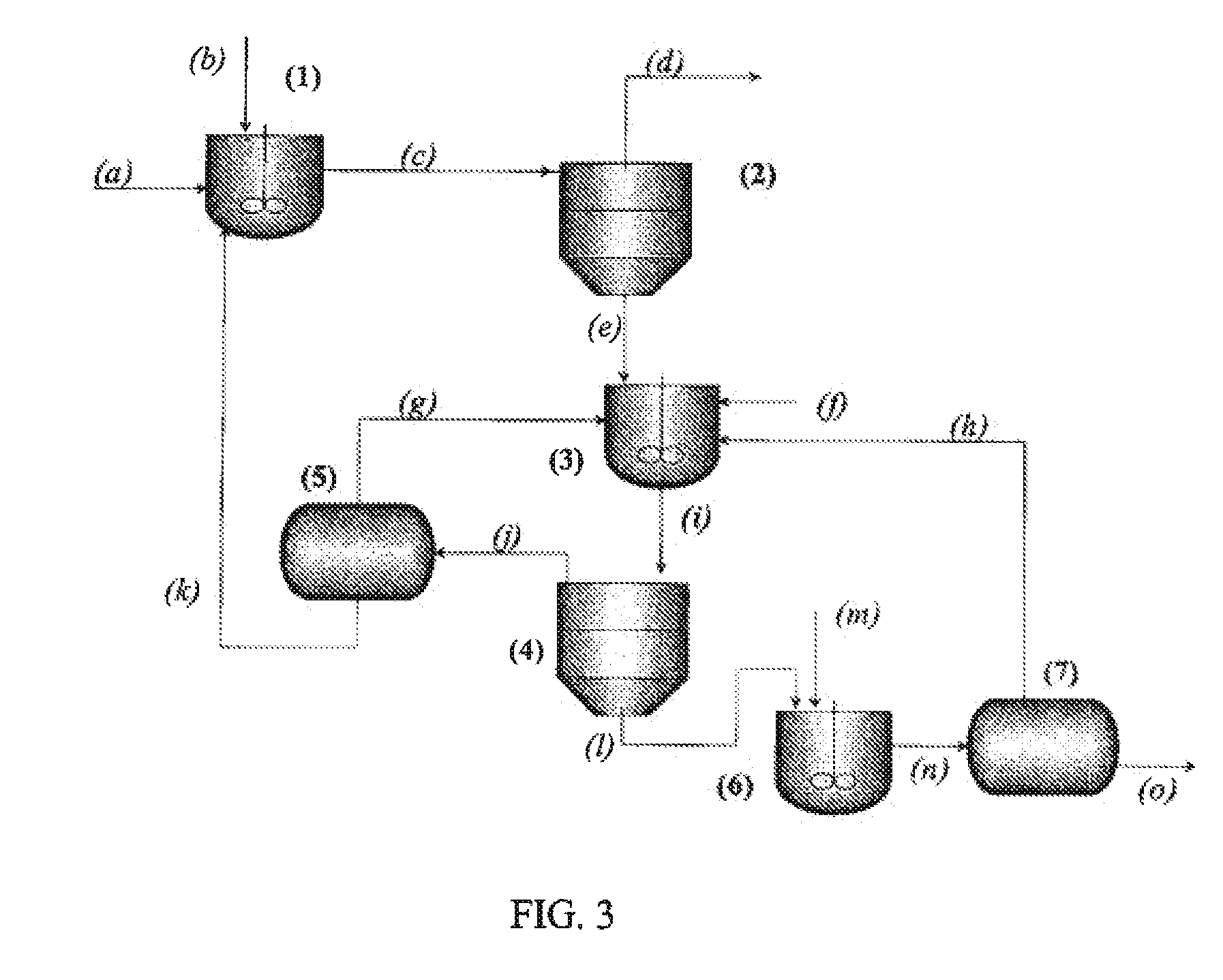

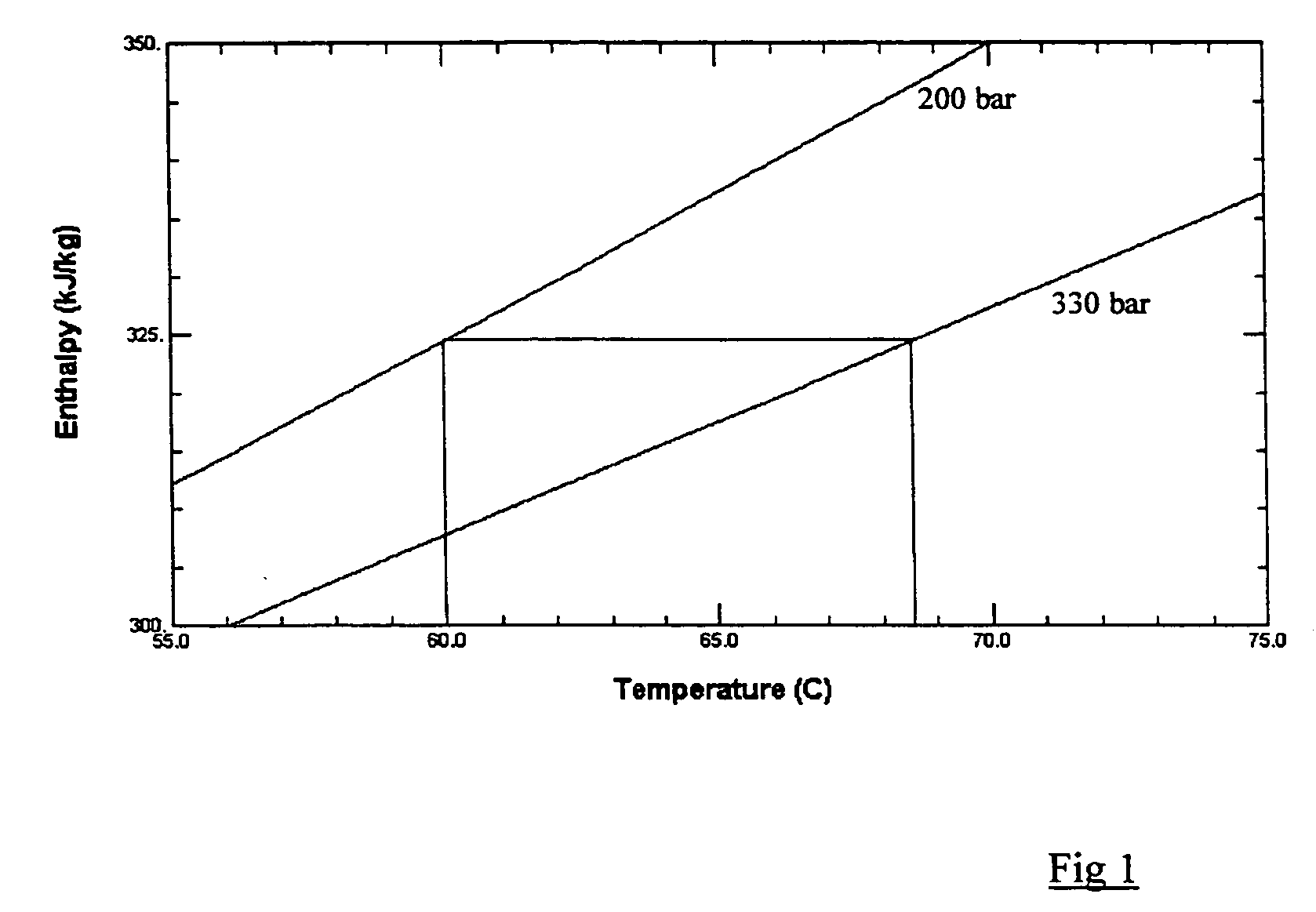

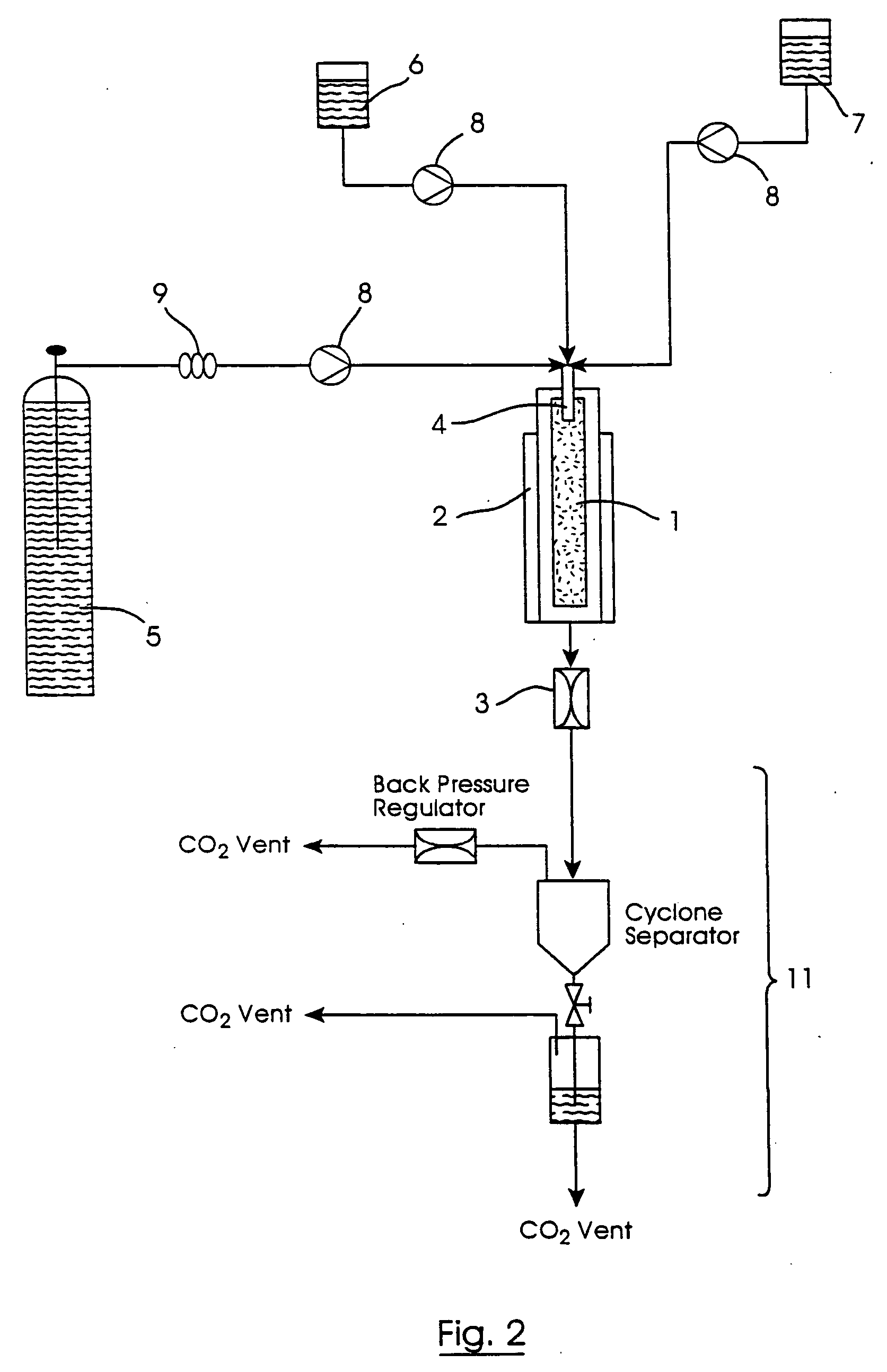

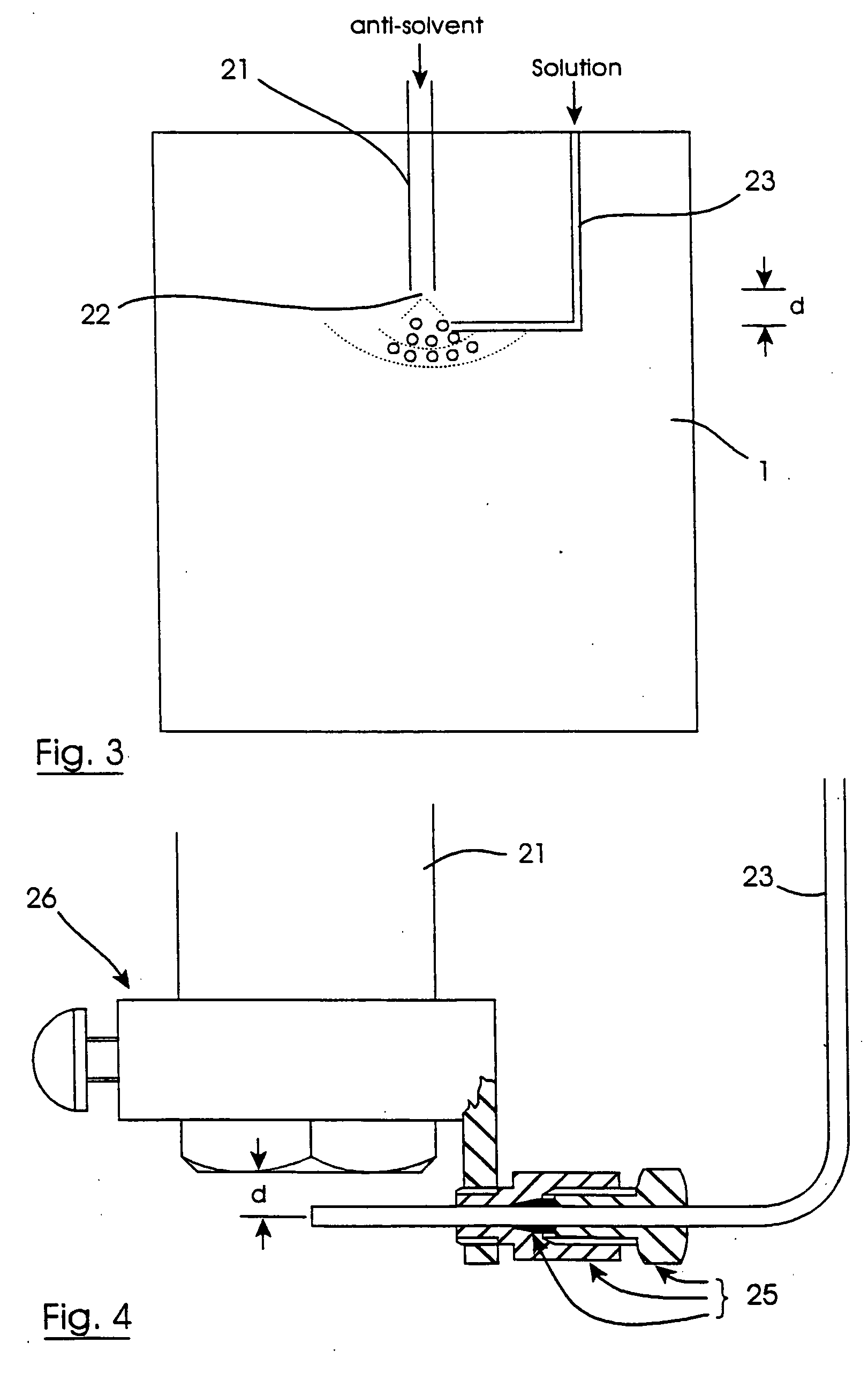

Method for preparing a target substance in particulate form, comprising introducing into a particle formation vessel, through separate first and second fluid inlets respectively, (a) a "target solution / suspension" of the substance in a fluid vehicle and (b) a compressed fluid anti-solvent, and allowing the anti-solvent to extract the vehicle so as to form particles of the substance, wherein the anti-solvent fluid has a sonic, near-sonic or supersonic velocity as it enters the vessel, and wherein the anti-solvent and the target solution / suspension enter the vessel at different locations and meet downstream (in the direction of anti-solvent flow) of the second fluid inlet. Also provided is apparatus for use in such a method.

Owner:NEKTAR THERAPEUTICS INC

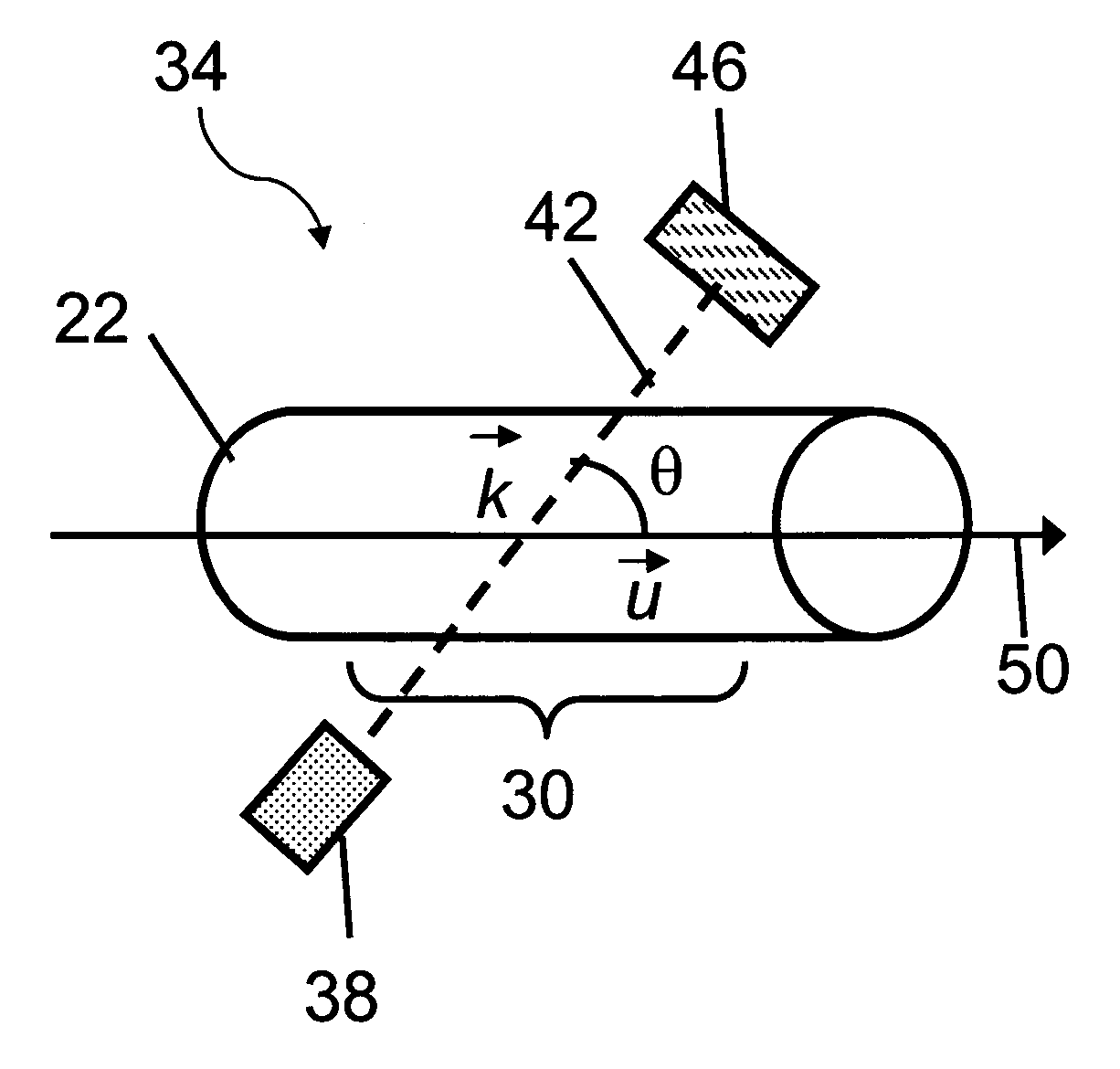

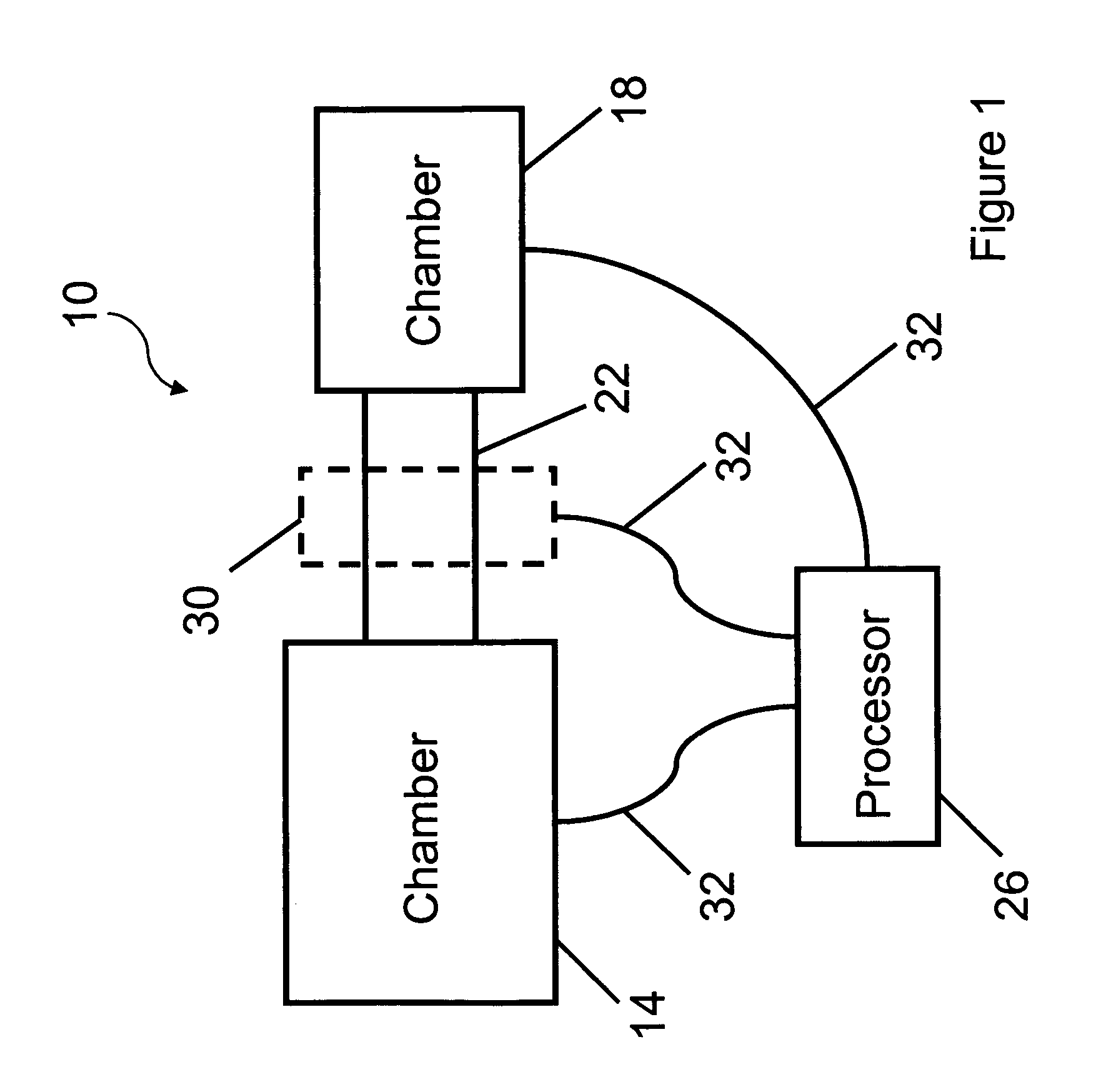

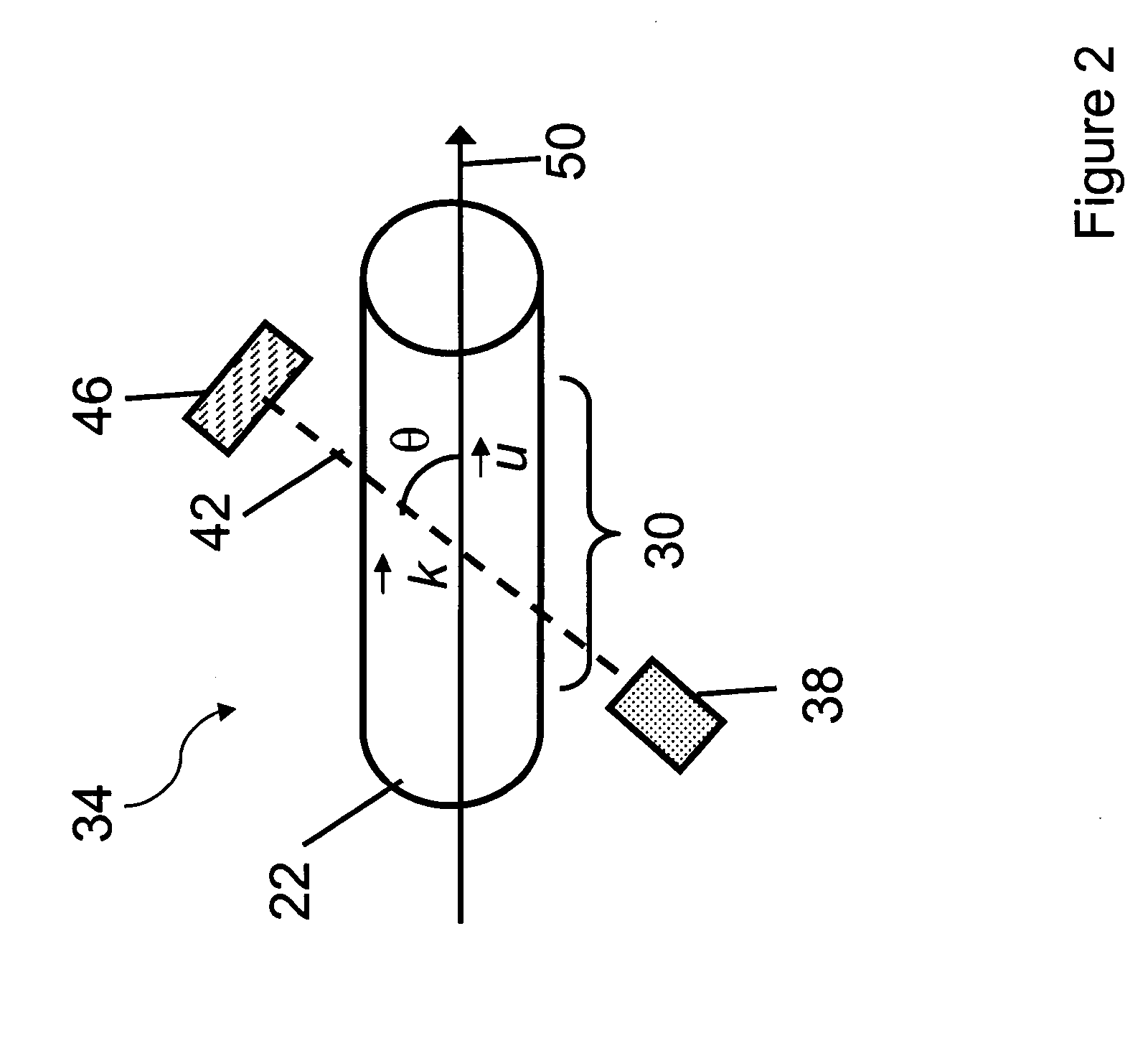

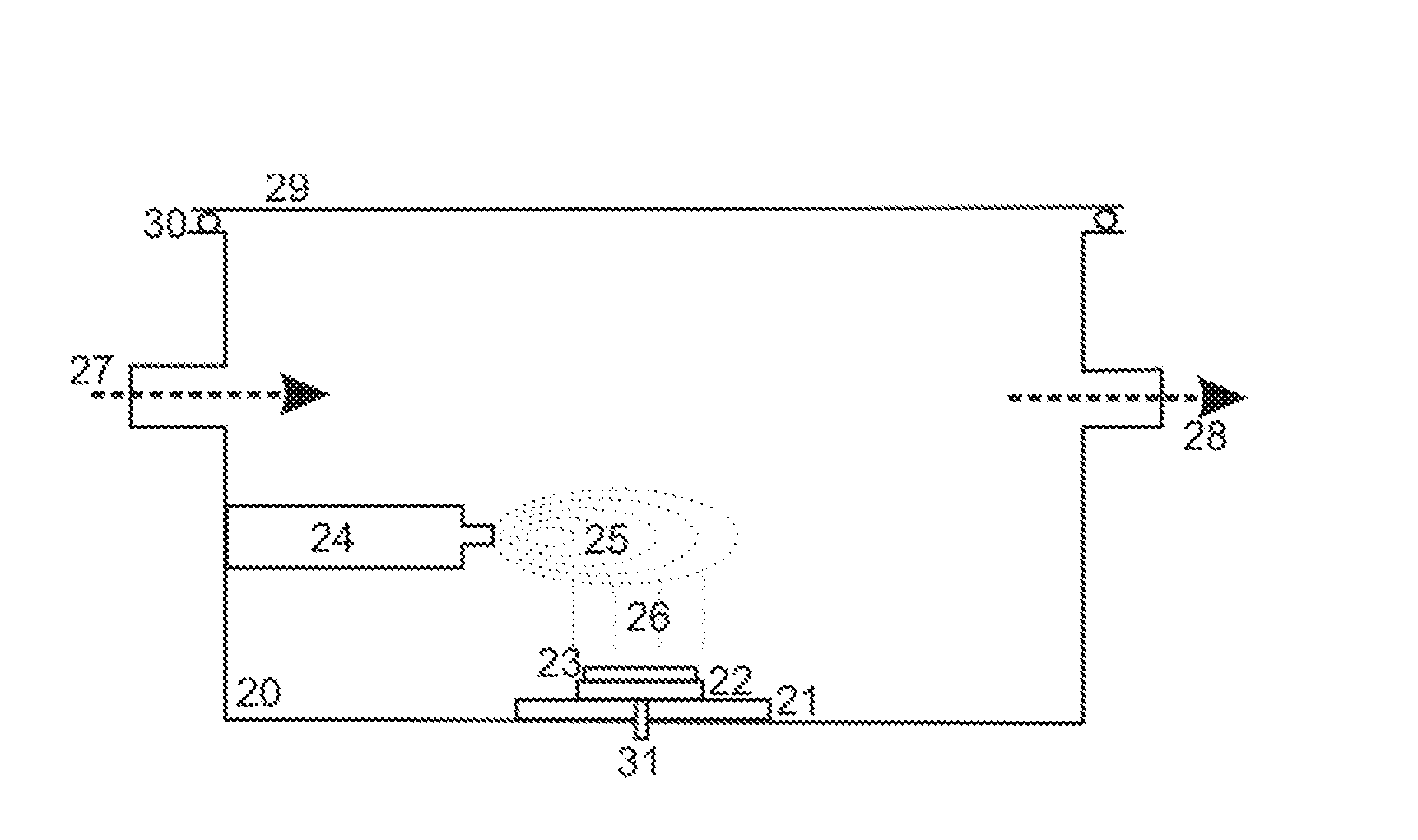

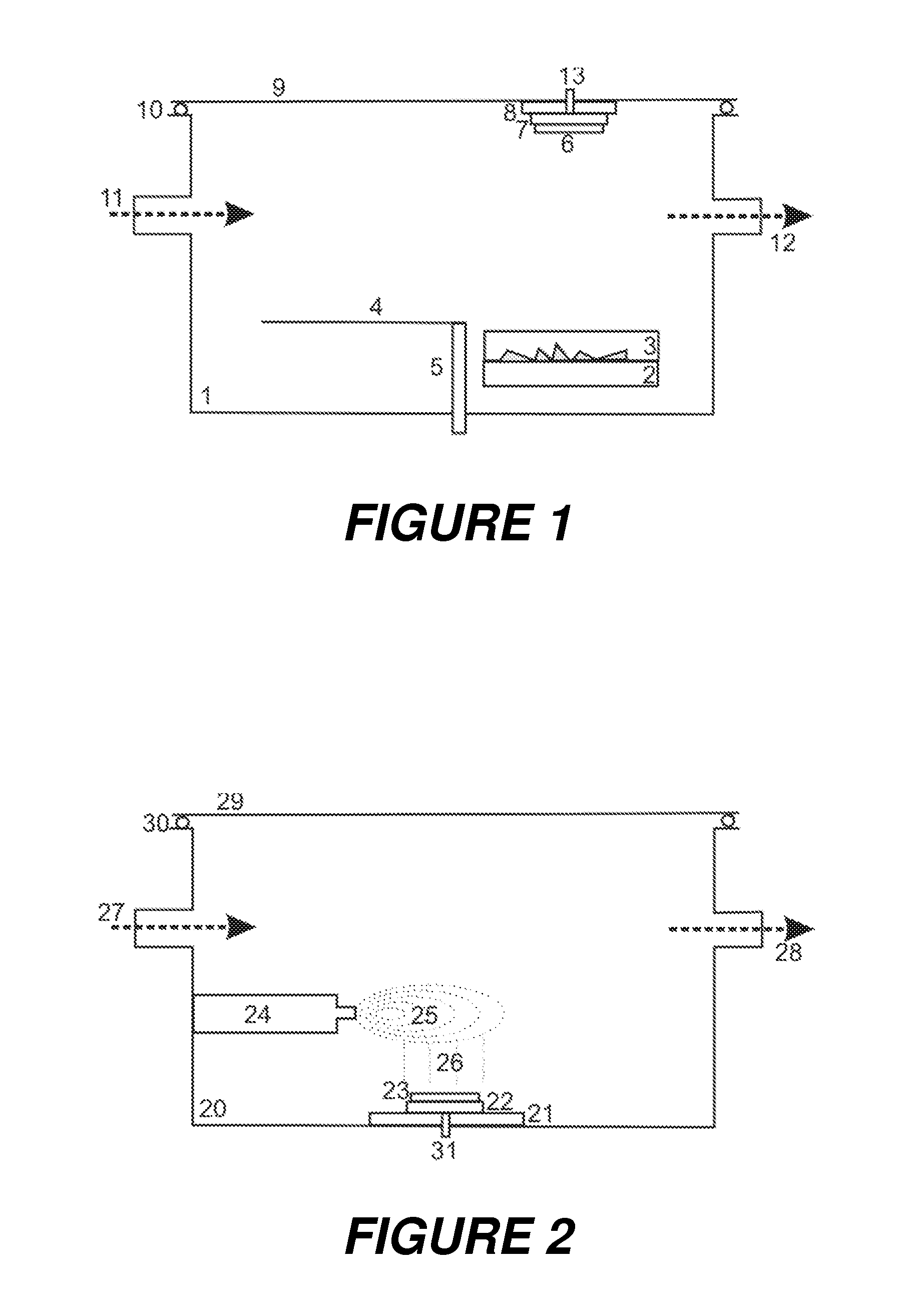

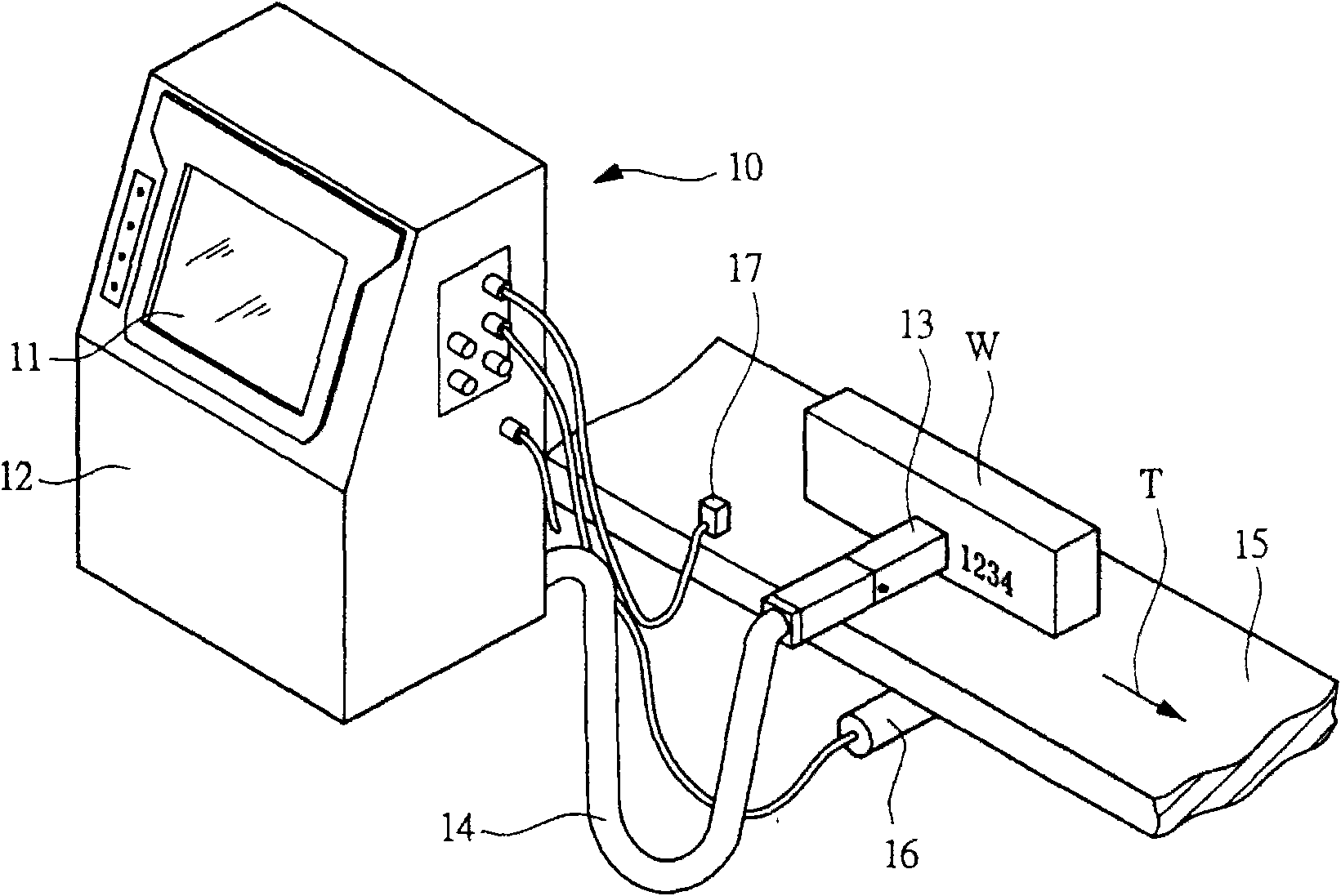

System for monitoring a drying process

InactiveUS20060208191A1Shorten the timeImprove efficiencyRadiation pyrometryDrying solid materials without heatLight beamMass flux

An apparatus for monitoring a parameter of a solvent during a drying process is described. The apparatus includes a light source providing at least one light beam and a detection system receiving a signal corresponding to the at least one light beam transmitted through a vapor of the solvent flowing through a diagnostic region. A processor can determine from the signal at least one solvent parameter associated with the vapor of the solvent, and the processor can determine from the at least one solvent parameter the instantaneous mass flux of the vapor of the solvent.

Owner:PHYSICAL SCI

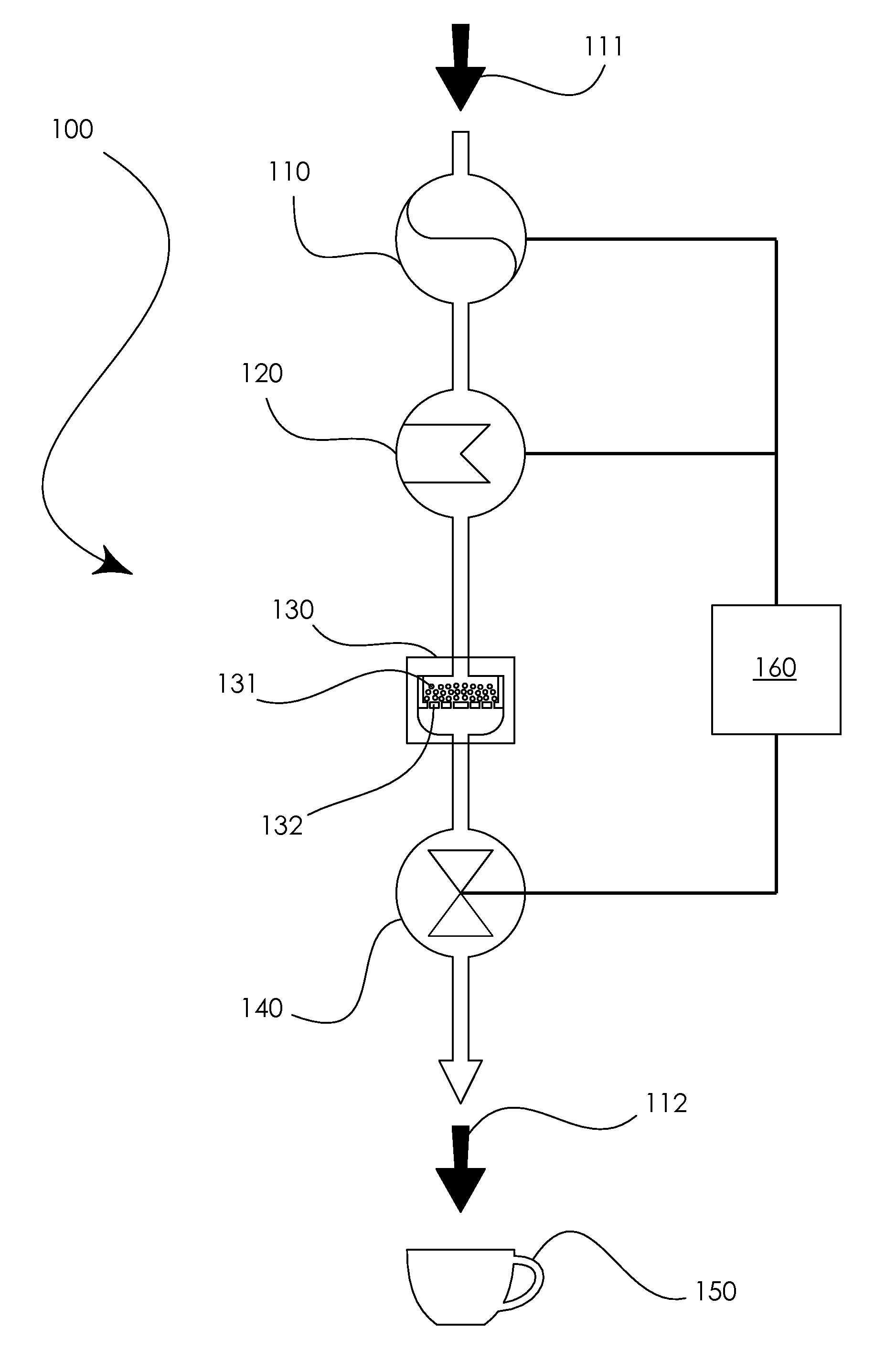

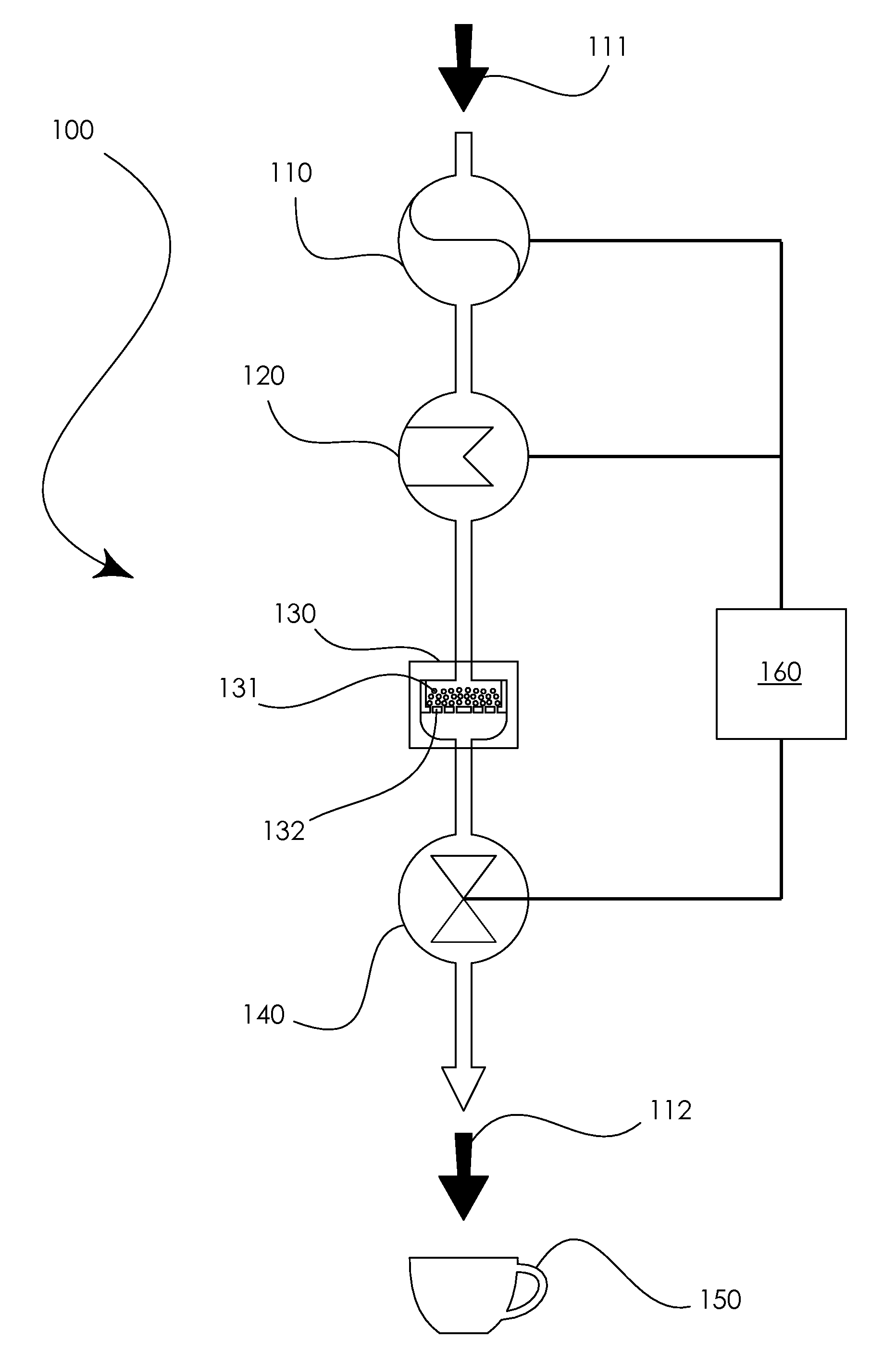

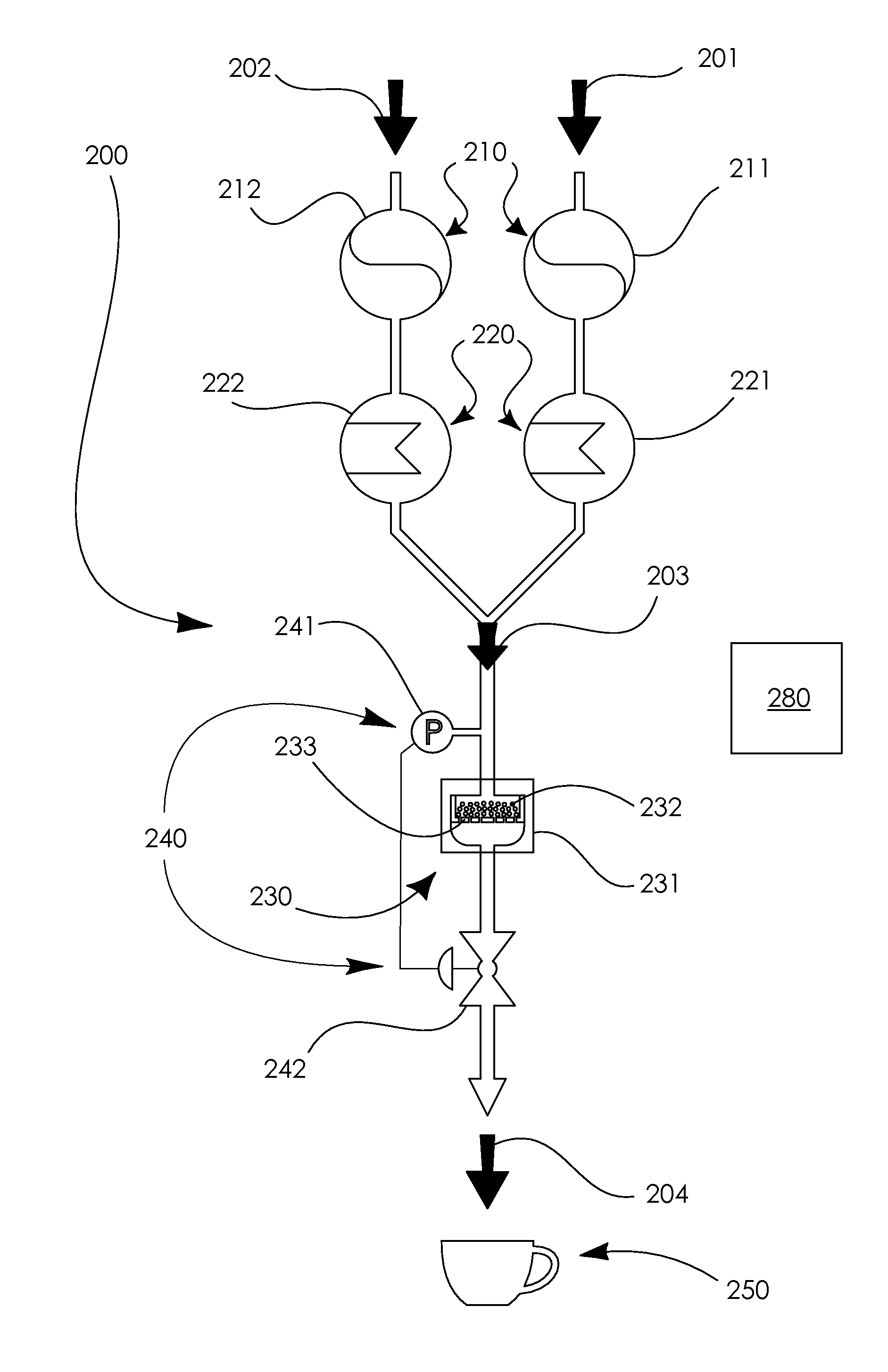

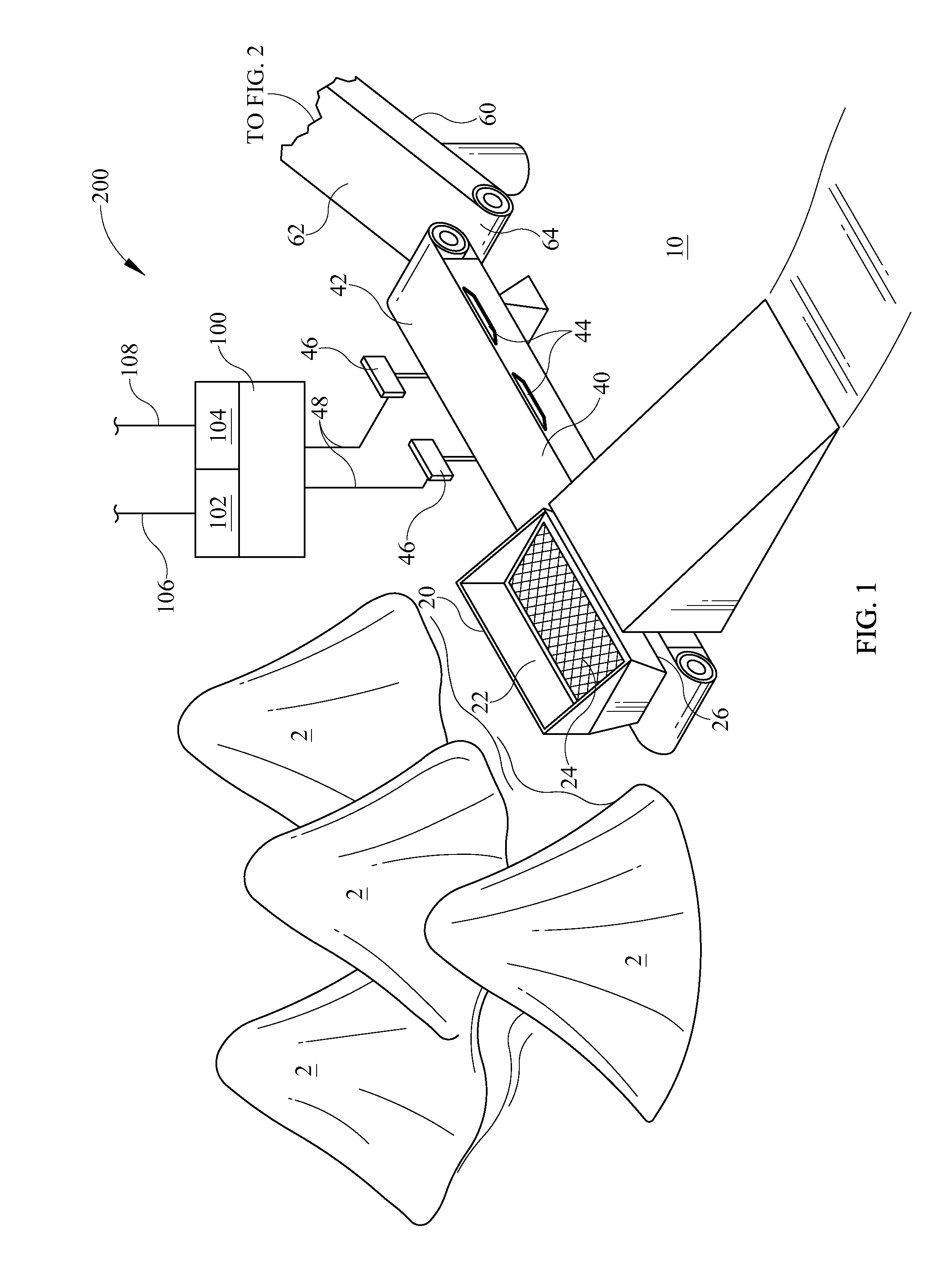

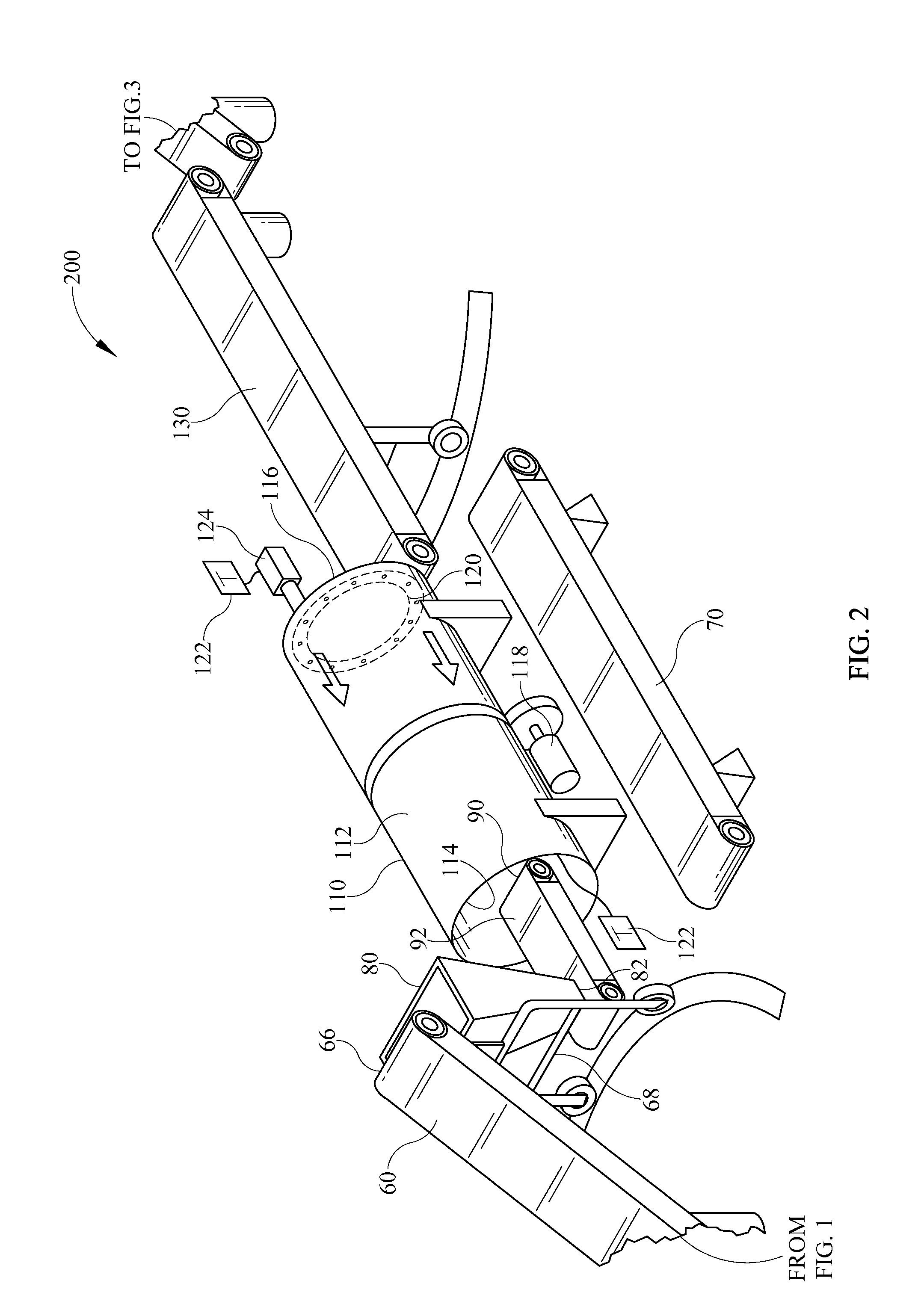

Device and system for brewing infused beverages

An infused beverage brewing assembly that includes a solvent flow management system operable to receive and convey a solvent, a solvent temperature management system in fluid communication with the solvent flow management system and operable to modulate the temperature of the solvent, a brewing chamber for housing a solute disposed to receive the solvent to produce an infused beverage resulting from an infusion process, an infusion pressure regulation system with at least one pressure regulation component located downstream of the brewing chamber, operable to selectively and dynamically modify an infusion process pressure greater than a pressure created upstream in the brewing chamber caused by a flow of the solvent through the solute, and operable such that the flow of the solvent through the solute is not singularly contingent on a pressure differential across the at least one pressure regulation component, and an outlet for discharging the infused beverage.

Owner:DUVALL GIDEON

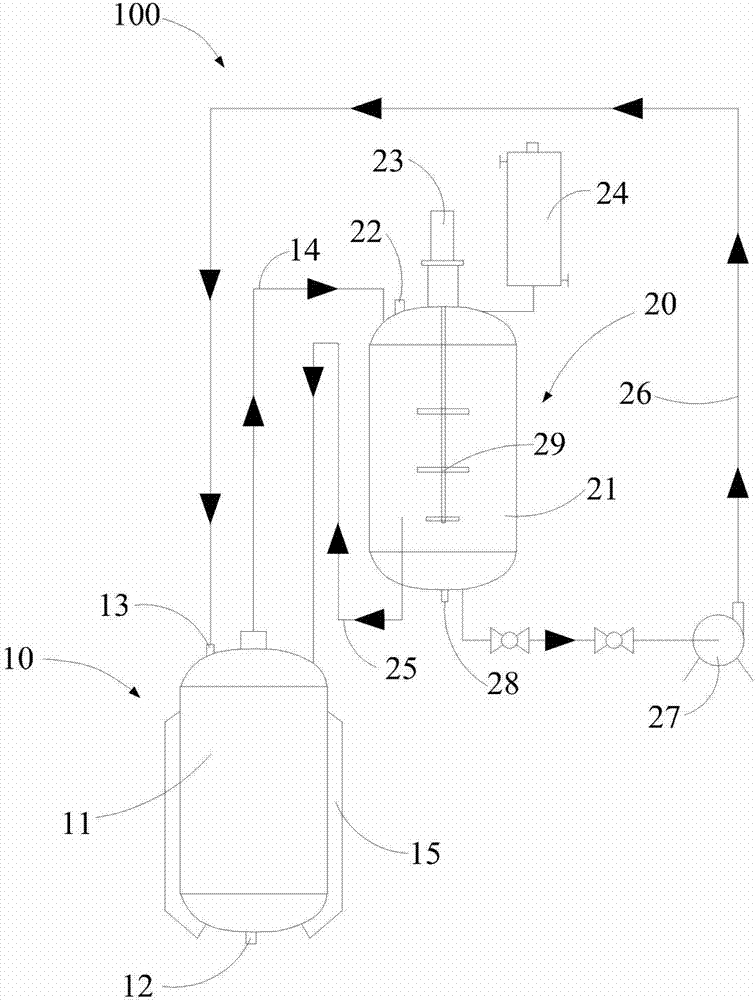

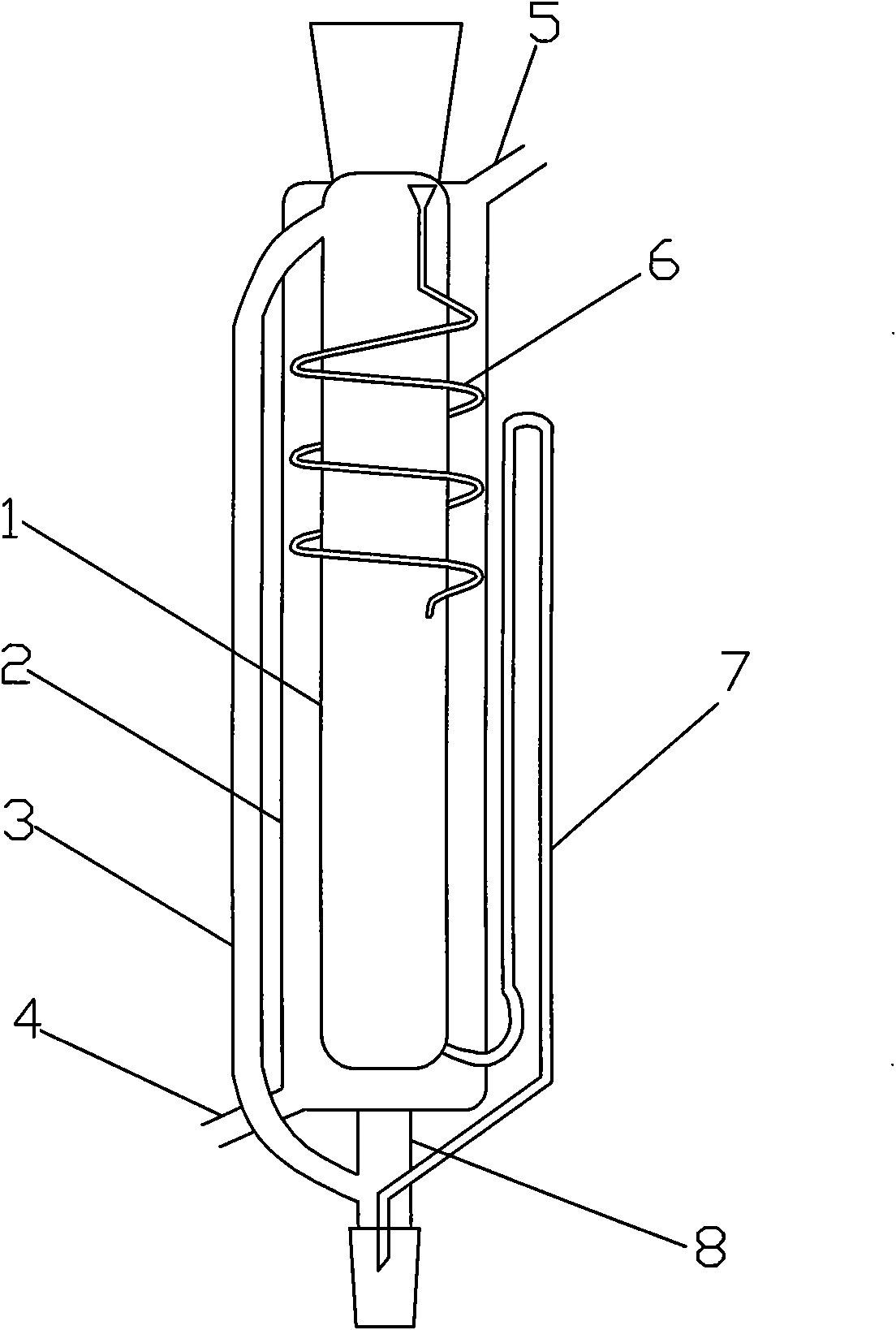

Polymer purification device and purification method

InactiveCN102786681ASimple structureWon't mix inChemical/physical/physico-chemical stationary reactorsFeed devicesSiphonPurification methods

The invention discloses a polymer purification device and a purification method. The purification device comprises a solvent supply system and a washing system, wherein the solvent supply system comprises a solvent kettle, a solvent circulation pipe and a heater, one end of the solvent circulation pipe is connected with the solvent kettle, the other end of the solvent circulation pipe is connected with the washing kettle, the heater is used for heating washing solvents in the solvent kettle so that the washing solvents flow into the washing kettle through the solvent circulation pipe, the washing system comprises a washing kettle, a motor, a condenser and a siphon, the motor and the condenser are respectively arranged at the top of the washing kettle, one end of the siphon is connected with the washing kettle, the other end of the siphon is connected with the solvent kettle, and washing solvents in the washing kettle flow back into the solvent kettle through the siphon. The polymer purification device provided by the invention has the advantage that the structure is simple, and the purification method adopting the purification device has the advantages that the energy consumption is low, the purification effect is good, and the automation can be realized.

Owner:KINGFA SCI & TECH CO LTD +2

Method for preparing lactide

The invention refers to a method for producing lactide. The character lies in: under the protection of inert gas, the invention uses instillation to eliminate the water in lactic acid, then uses an azeotropic solvent which can make the condensation reaction advantage to generate lactide, the solvent is good solvent to lactide and the bad solvent to lactic acid polymer, the solvent flows back in the protection of inert gas continuously, make the lactic acid is condensed into lactide, then decompression distillation is carried on, through recrystallization there gets the high purity lactide.

Owner:上海高分子材料研究开发中心

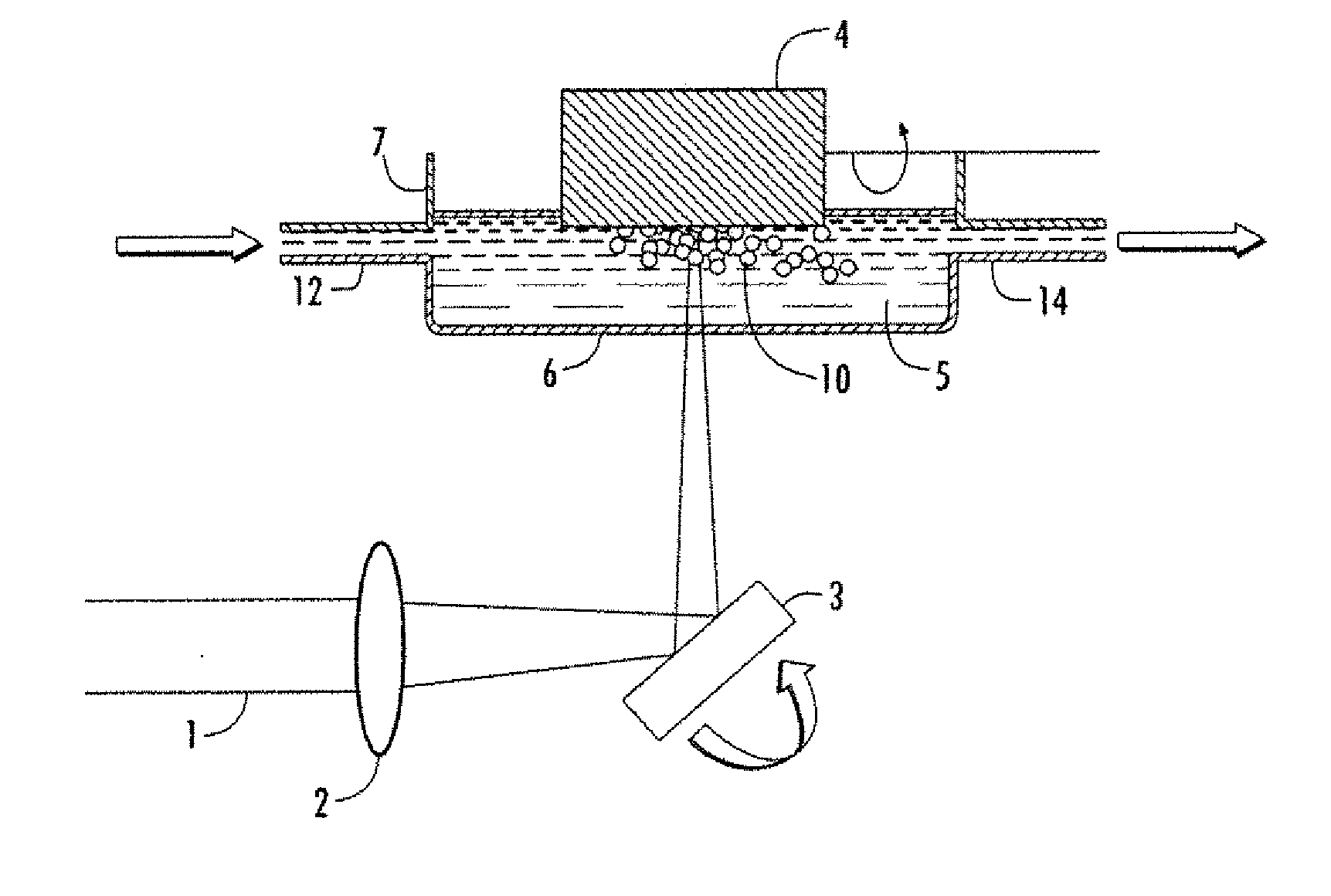

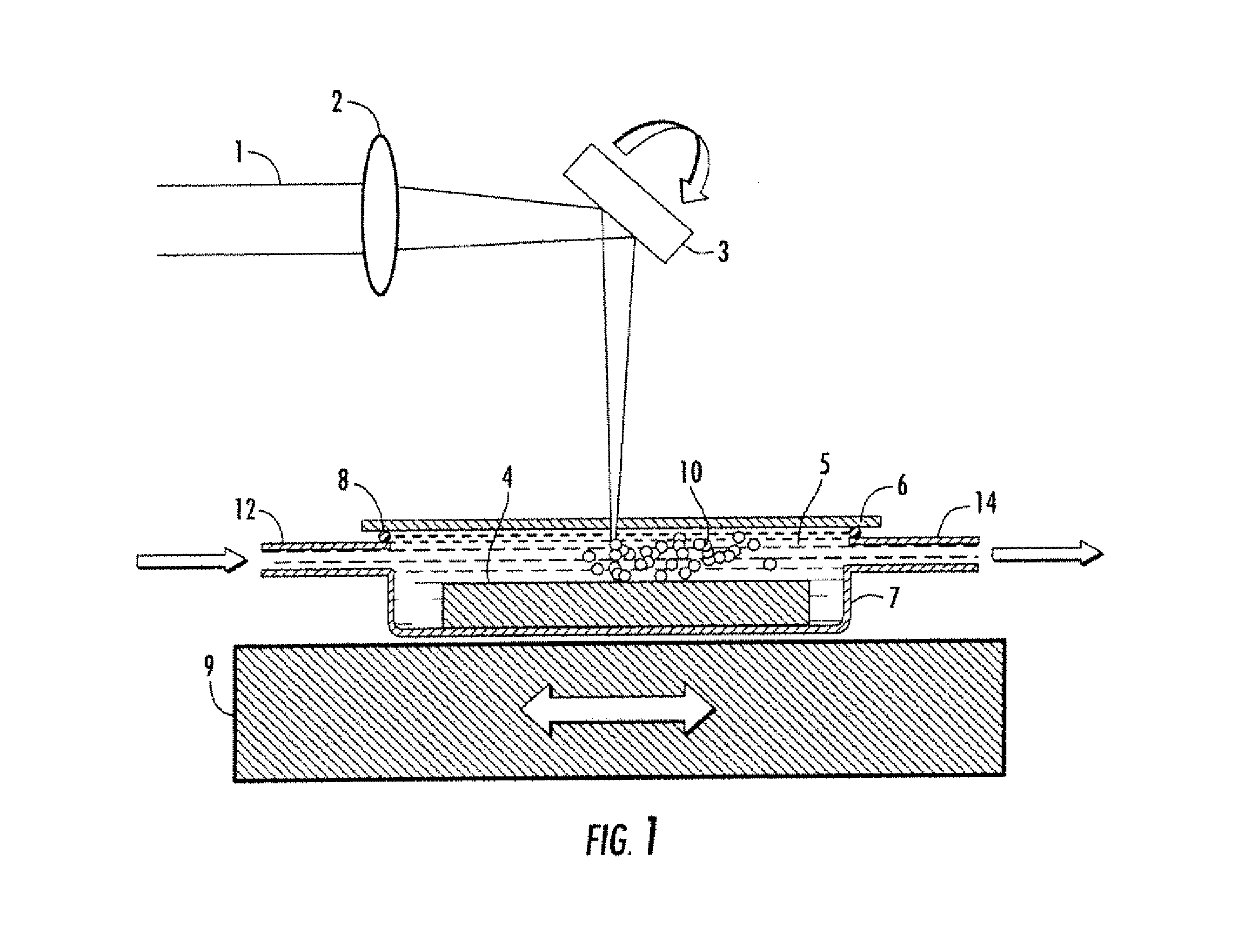

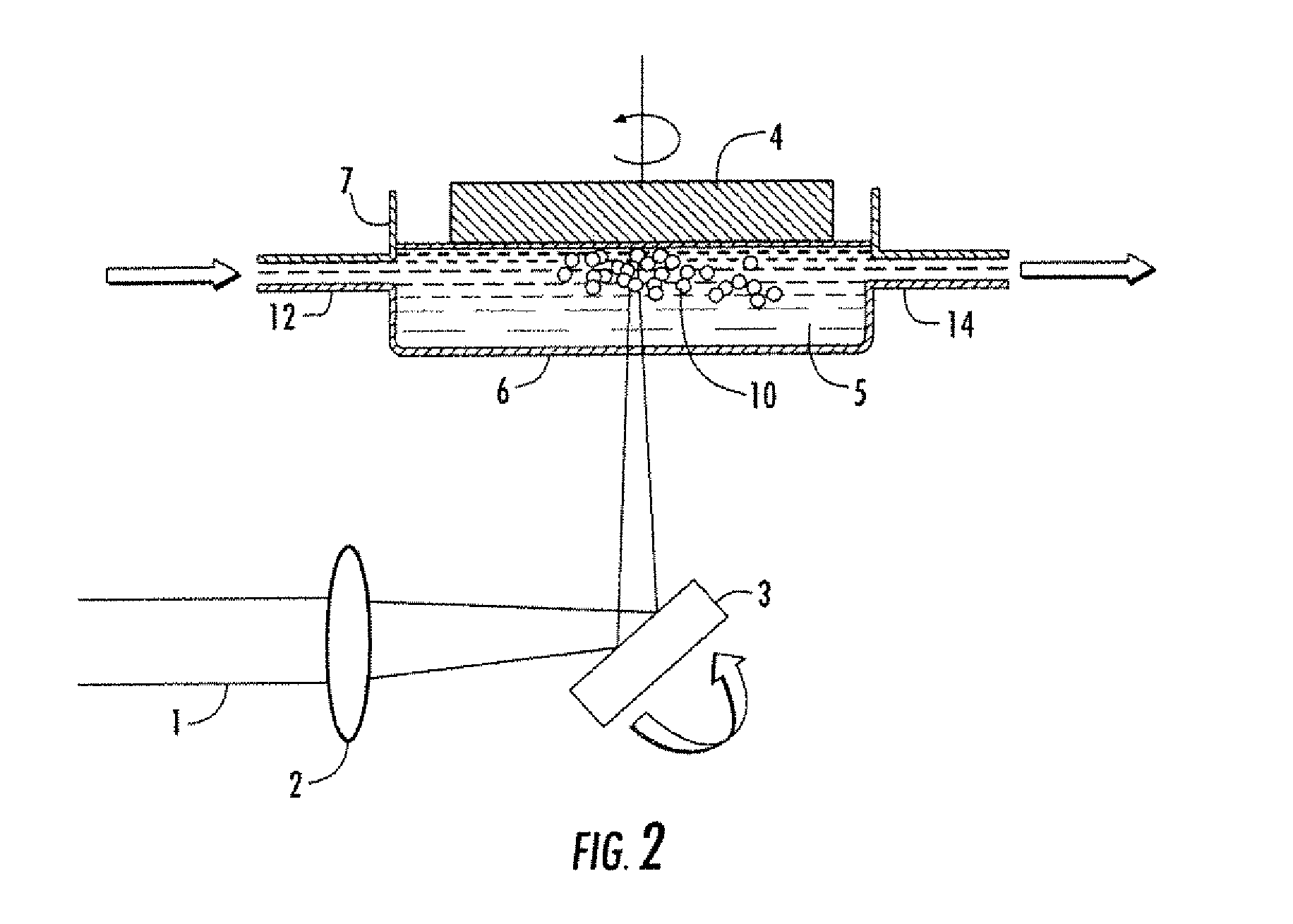

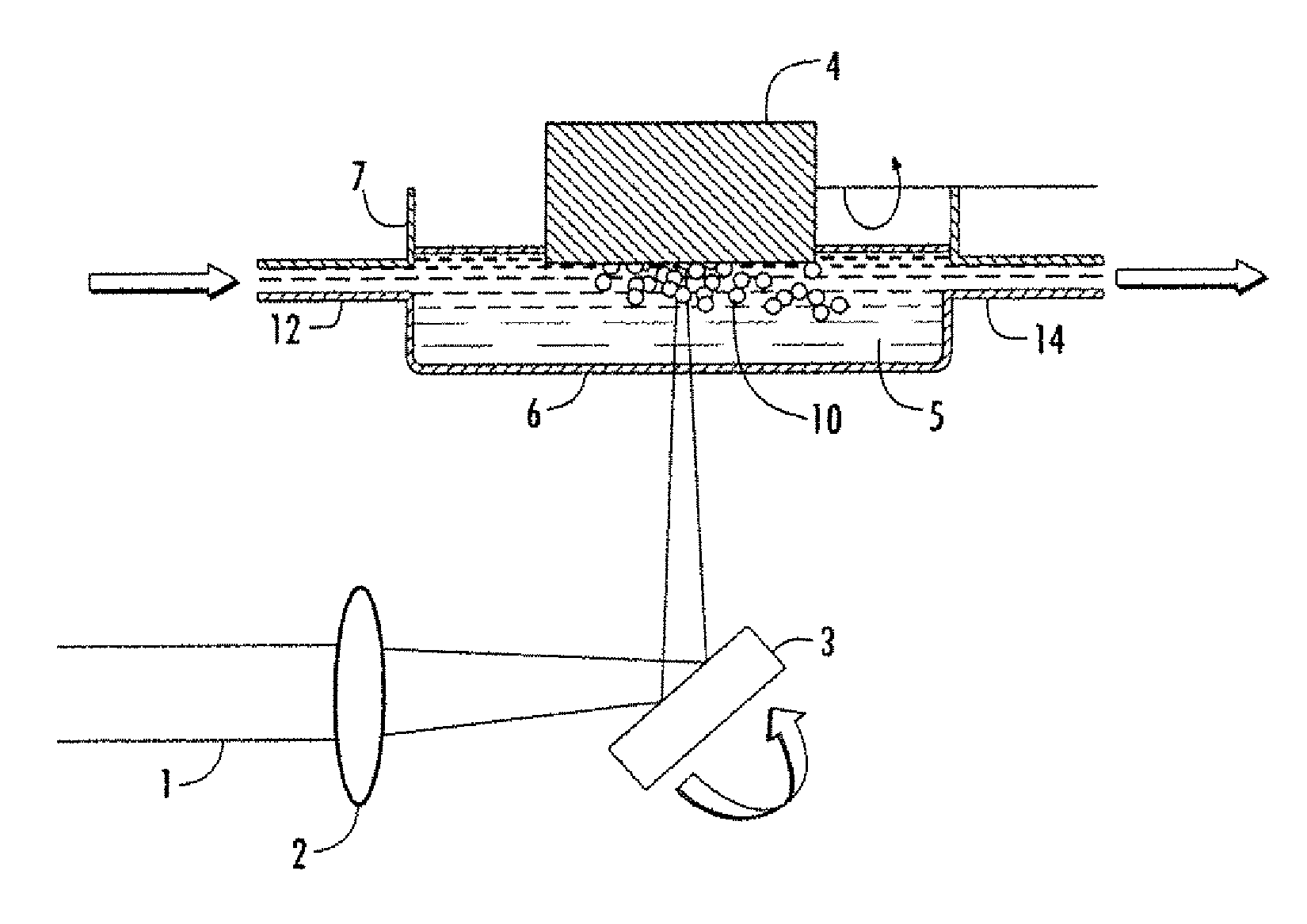

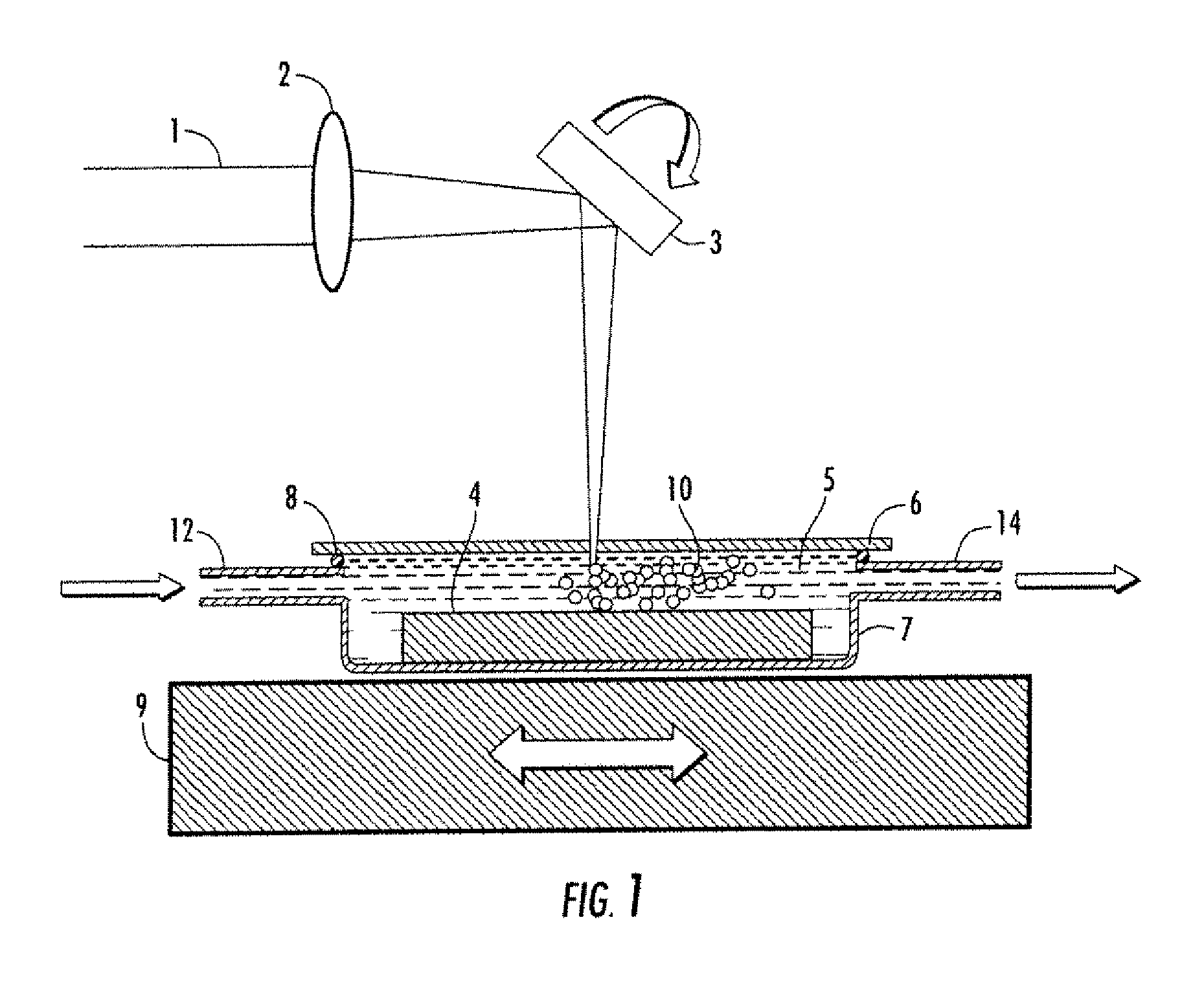

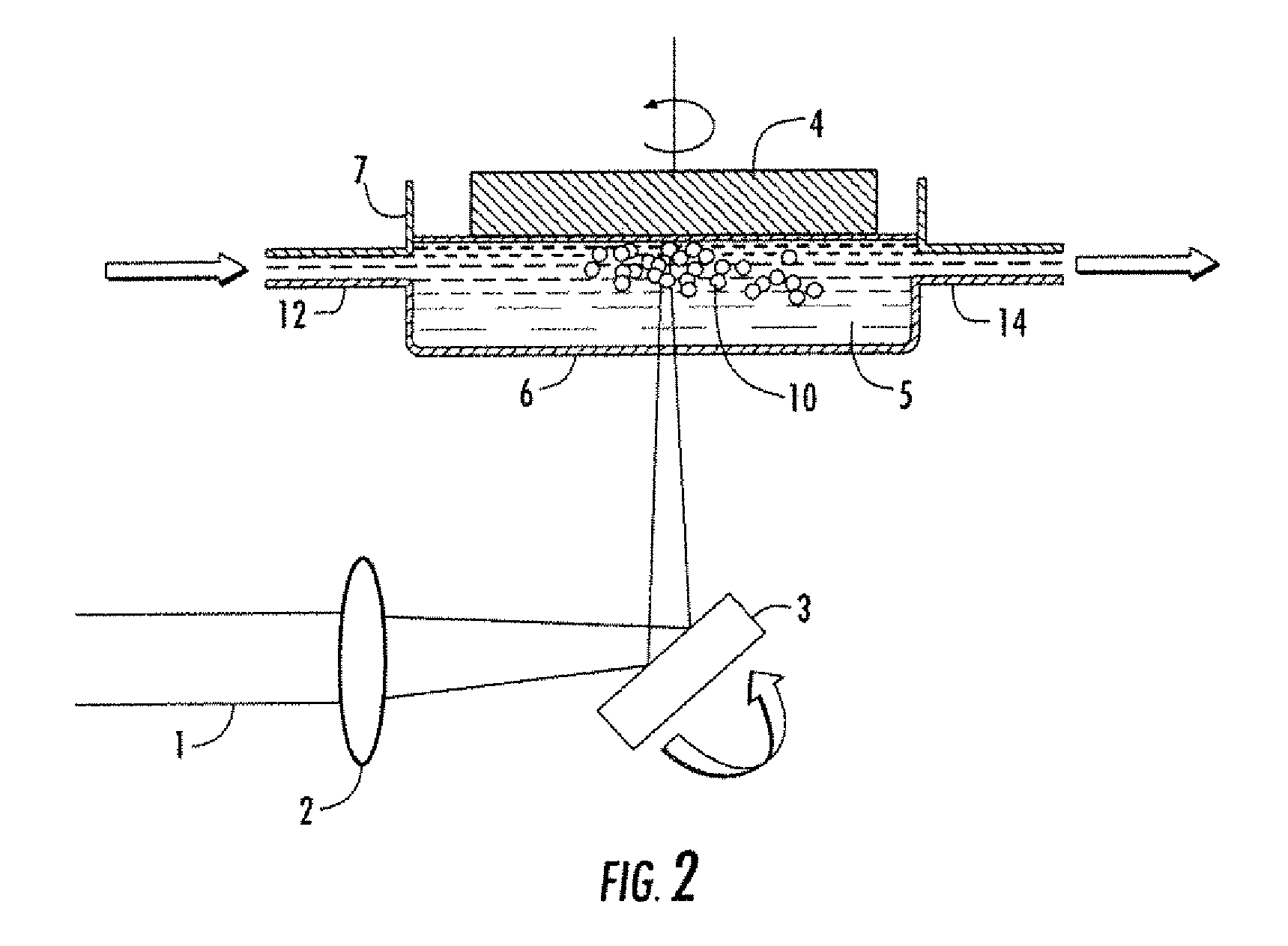

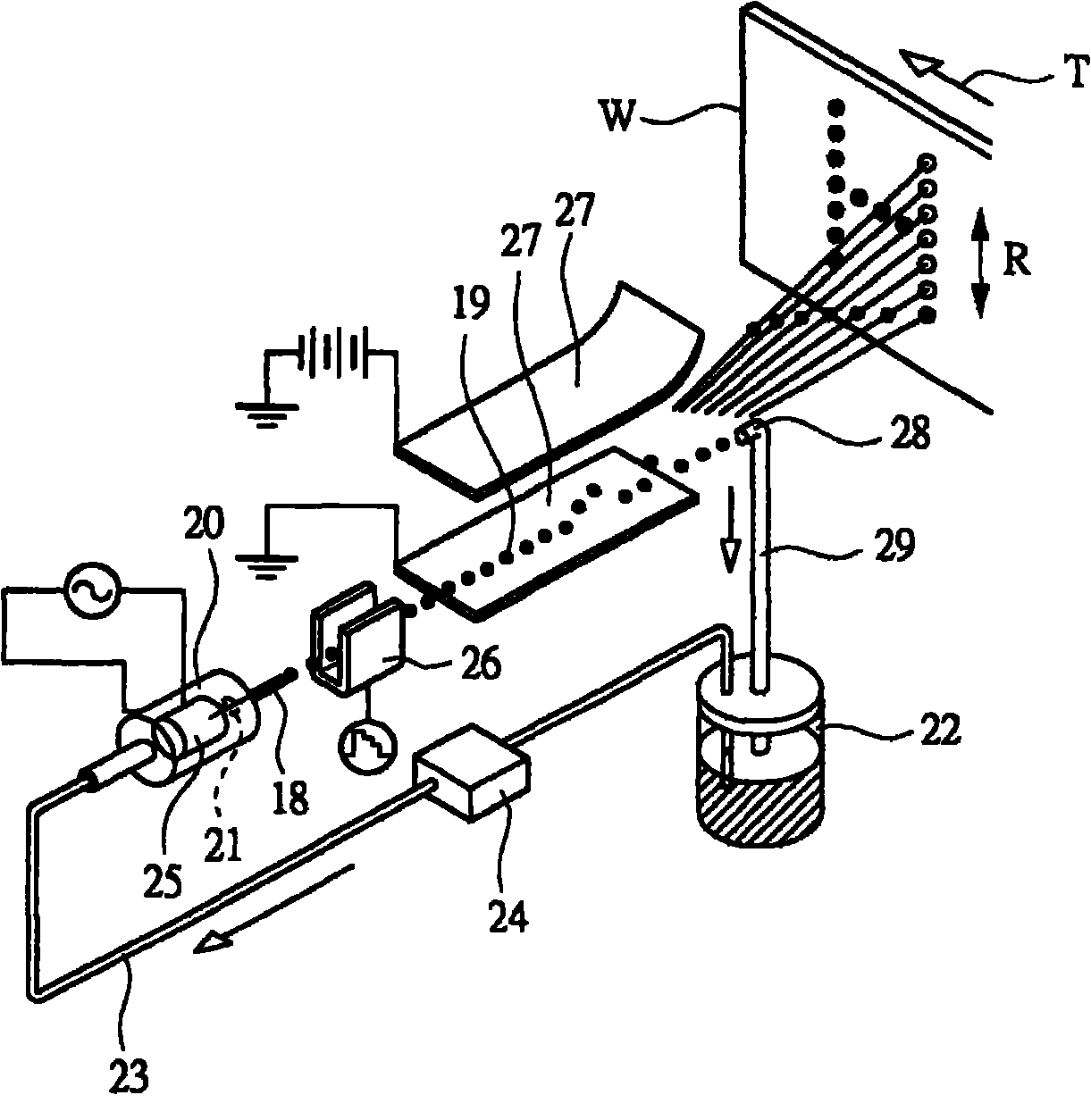

Production of organic compound nanoparticles with high repetition rate ultrafast pulsed laser ablation in liquids

InactiveUS20110196044A1High repetition rateImprove efficiencyBiocidePowder deliveryUltrashort laserOrganic compound

Disclosed is a method of producing a chemically pure and stably dispersed organic nanoparticle colloidal suspension using an ultrafast pulsed laser ablation process. The method comprises irradiating a target of an organic compound material in contact with a poor solvent with ultrashort laser pulses at a high repetition rate and collecting the nanoparticles of the organic compound produced. The method may be implemented with a high repetition rate ultrafast pulsed laser source, an optical system for focusing and moving the pulsed laser beam, an organic compound target in contact with a poor solvent, and a solvent circulating system to cool the laser focal volume and collect the produced nanoparticle products. By controlling various laser parameters, and with optional poor solvent flow movement, the method provides stable colloids of dispersed organic nanoparticles in the poor solvent in the absence of any stabilizing agents.

Owner:IMRA AMERICA

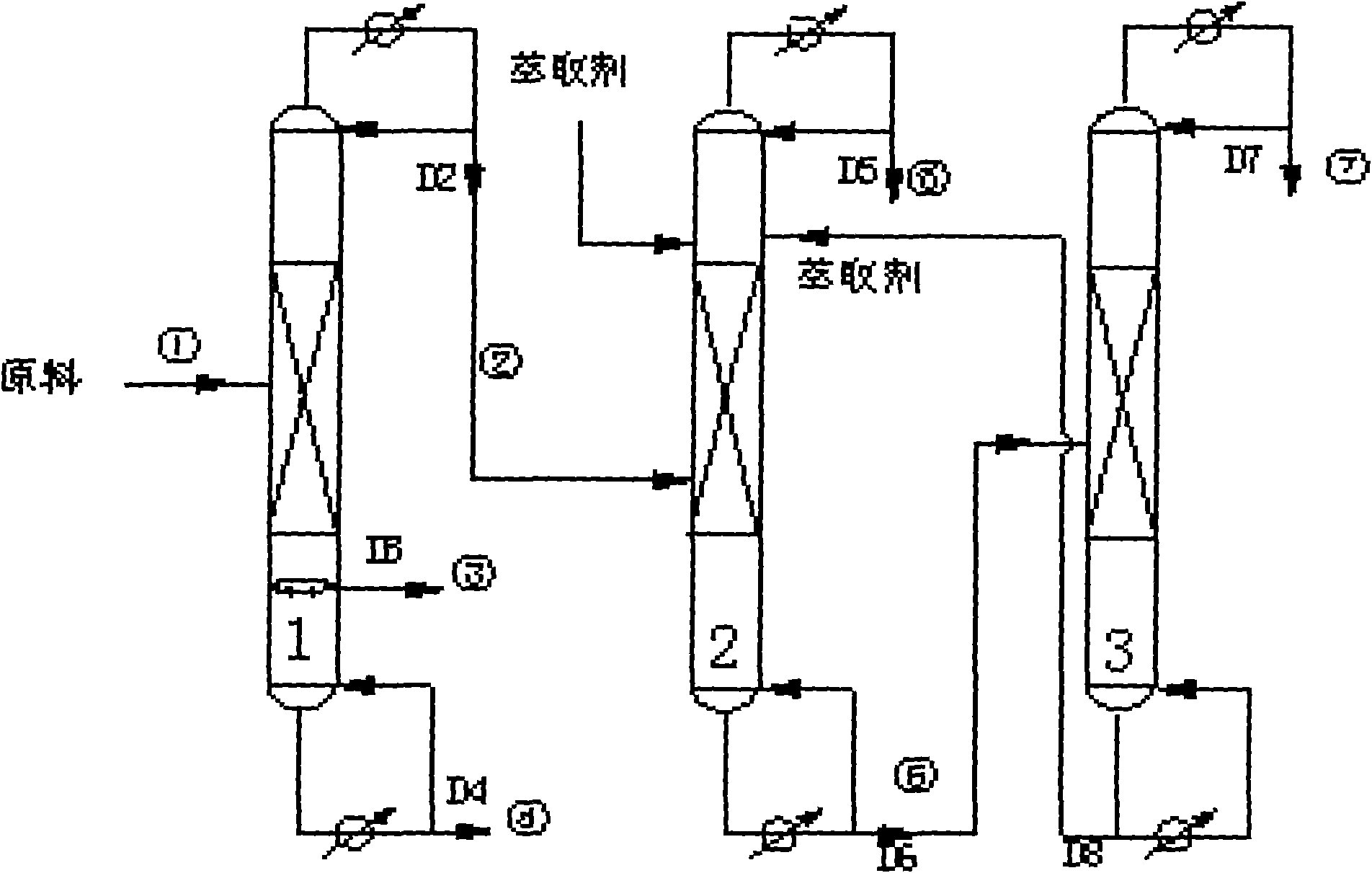

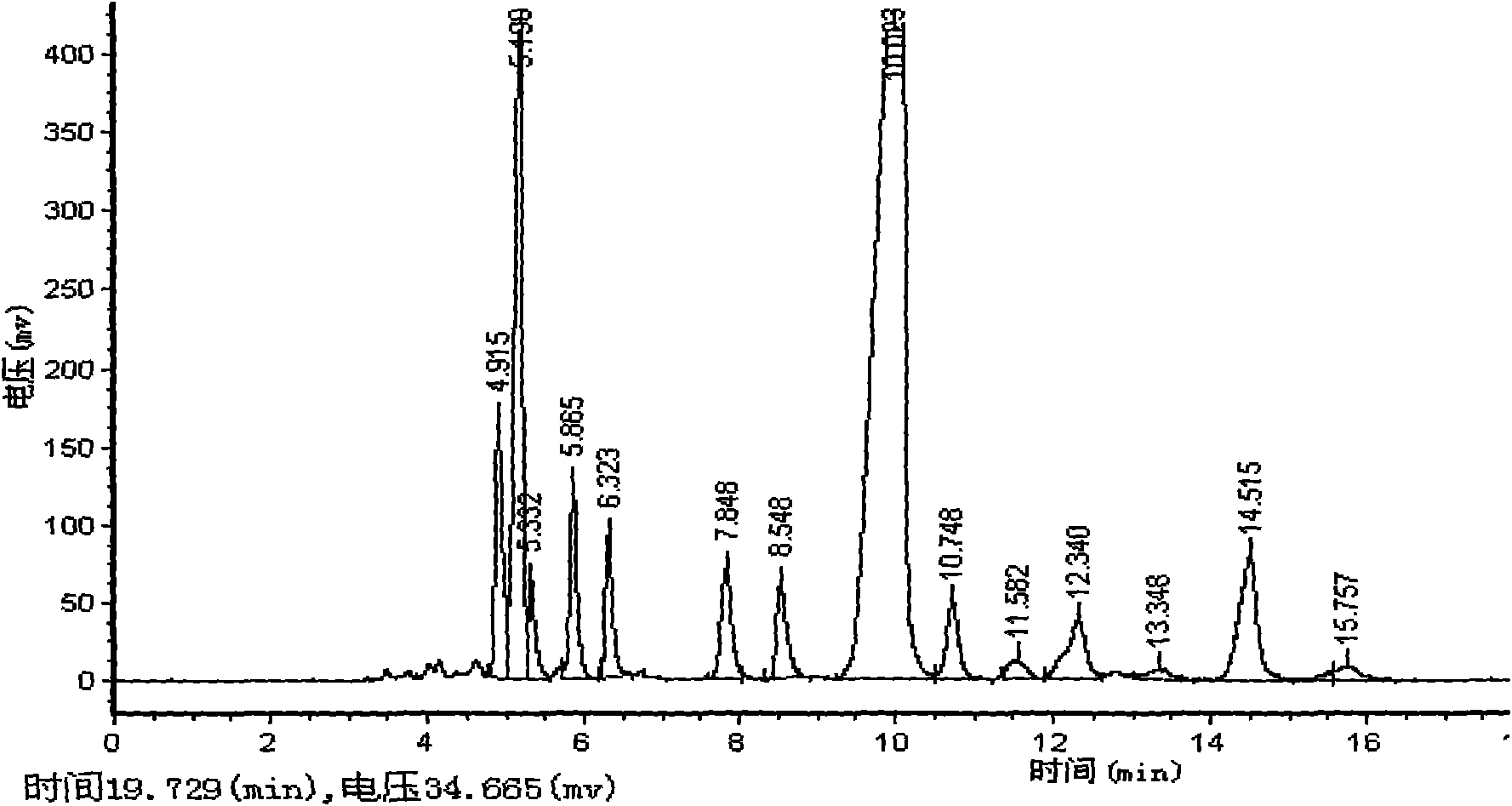

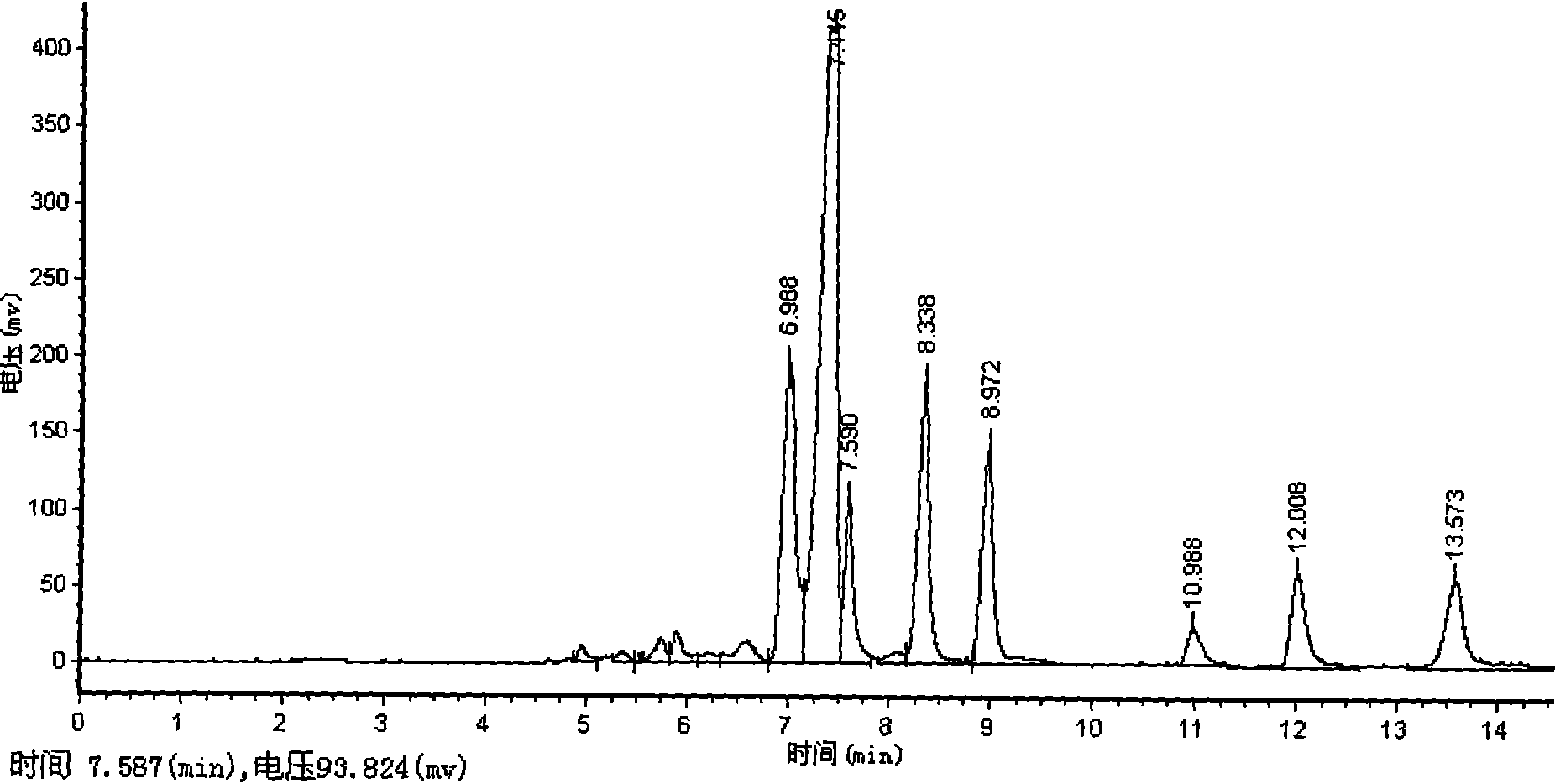

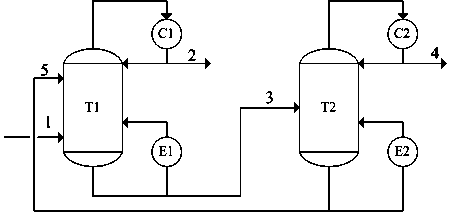

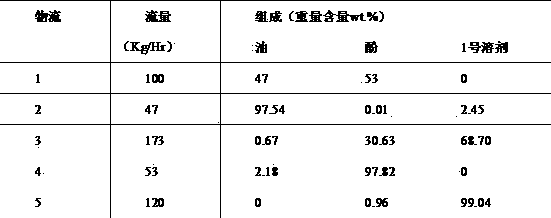

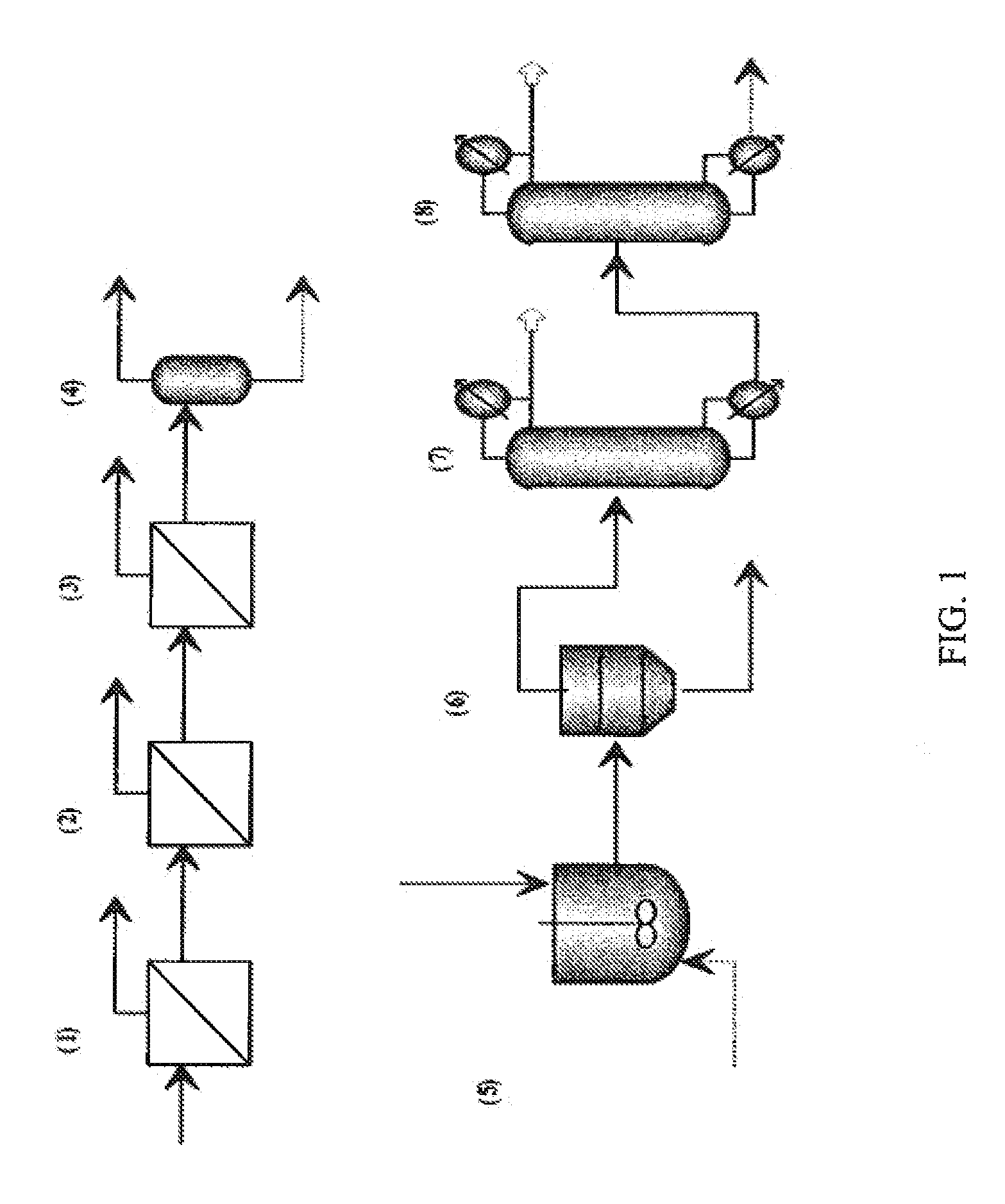

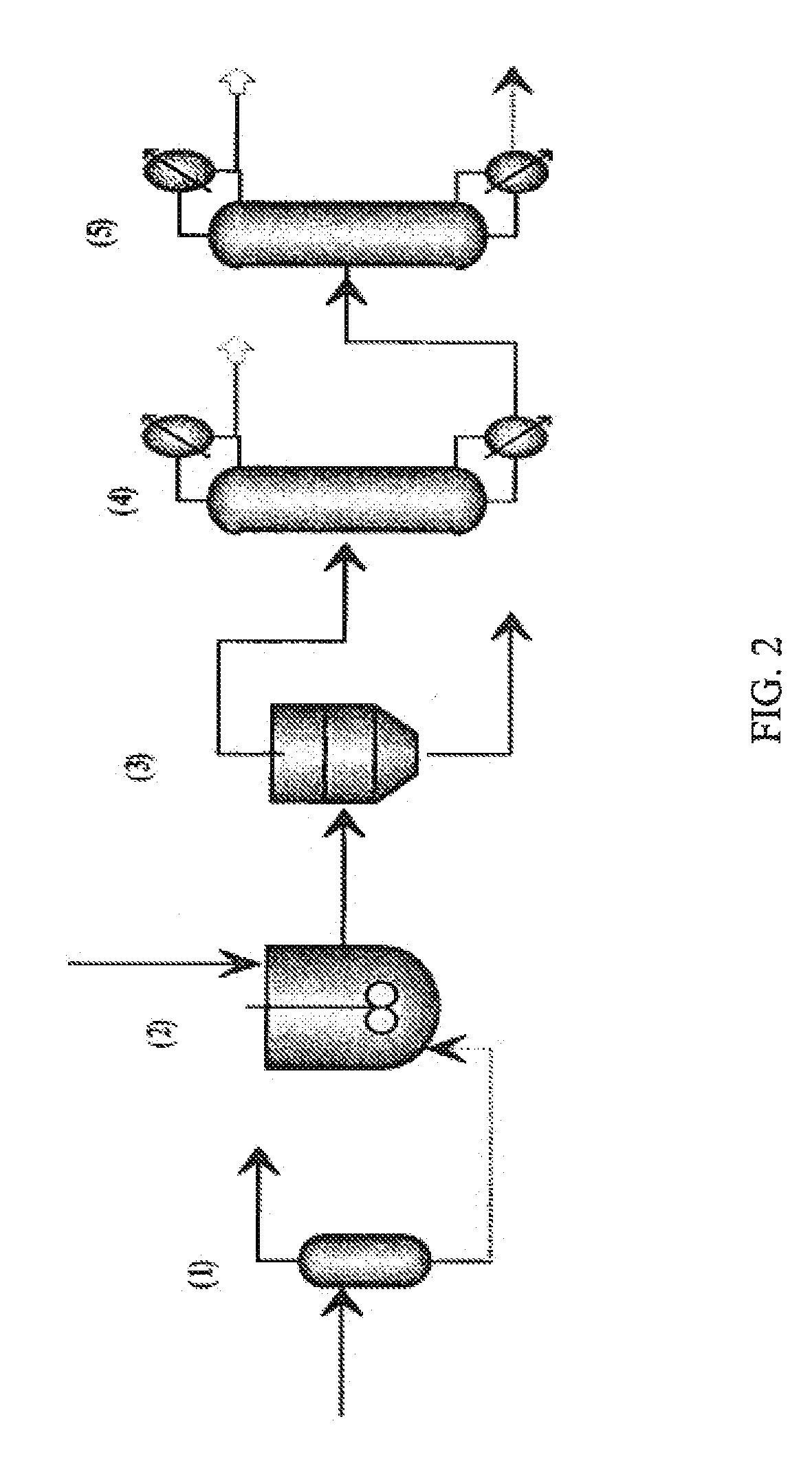

Method for extracting mesitylene fraction rich in hydrocracking C 9 by combination of continuous lateral line distillation and extractive distillation

InactiveCN101538185AIncrease contentImprove separation efficiencyDistillation purification/separationExtractive distillationTower

The invention discloses a method for extracting mesitylene fractions rich in hydrocracking C 9 by combination of continuous lateral line distillation and extractive distillation, comprising the following steps: (1) material hydrocracking C 9 aromatic is added into a continuous lateral line distillation tower, the tower bottom is heated, fractions 2 with a boiling range of 155 DEG C to 170 DEG C, fractions 3 with a boiling range of 170 DEG C to 190 DEG C and fractions 4 with a boiling range of 190 DEG C to 210 DEG C are obtained at the same time after pretreatment, content of mesitylene in the fractions 2 achieves above 90 percent, and a little mesitylene and a great deal of heavy aromatic are contained in the fractions 3 and the fractions 4; (2) the fractions 2 enter an extractive distillation tower, content of mesitylene fractions on the top 5 of the extractive distillation tower achieves above 98 percent, and fractions 6 containing a great deal of extraction solvent and heavy aromatic hydrocarbon are left at the tower bottom; (3) the fractions 6 are treated through a solvent recovery tower, heavy aromatic fractions 7 are left on the top of the solvent recovery tower, a tower reactor extracts solvent, and the solvent flows into the extractive distillation tower for recycling use. The invention only needs one distillation tower, obviously improves the efficiency, and lowers the energy consumption and the cost.

Owner:SINOPEC YANGZI PETROCHEM

Method and device for purifying graphene oxide/graphite solution

ActiveCN102626591ARapid purificationPromote migrationCosmetic preparationsToilet preparationsCvd grapheneDialysis

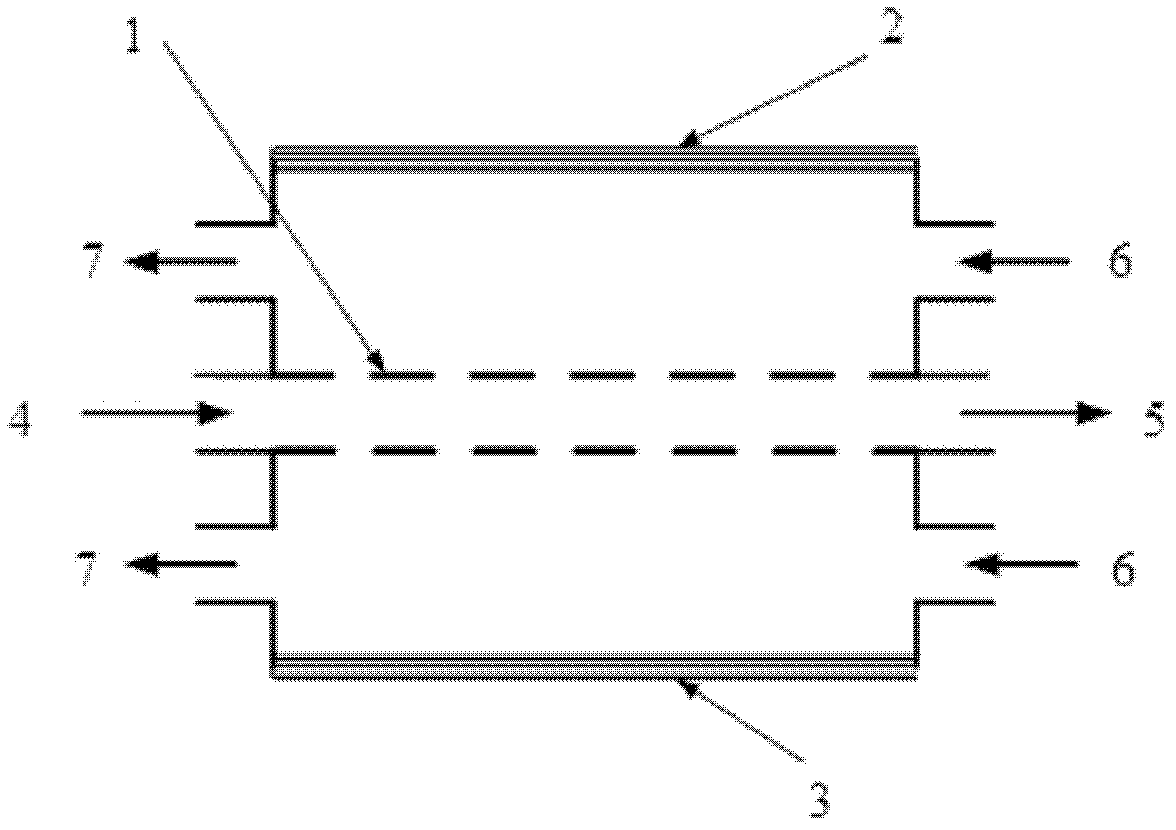

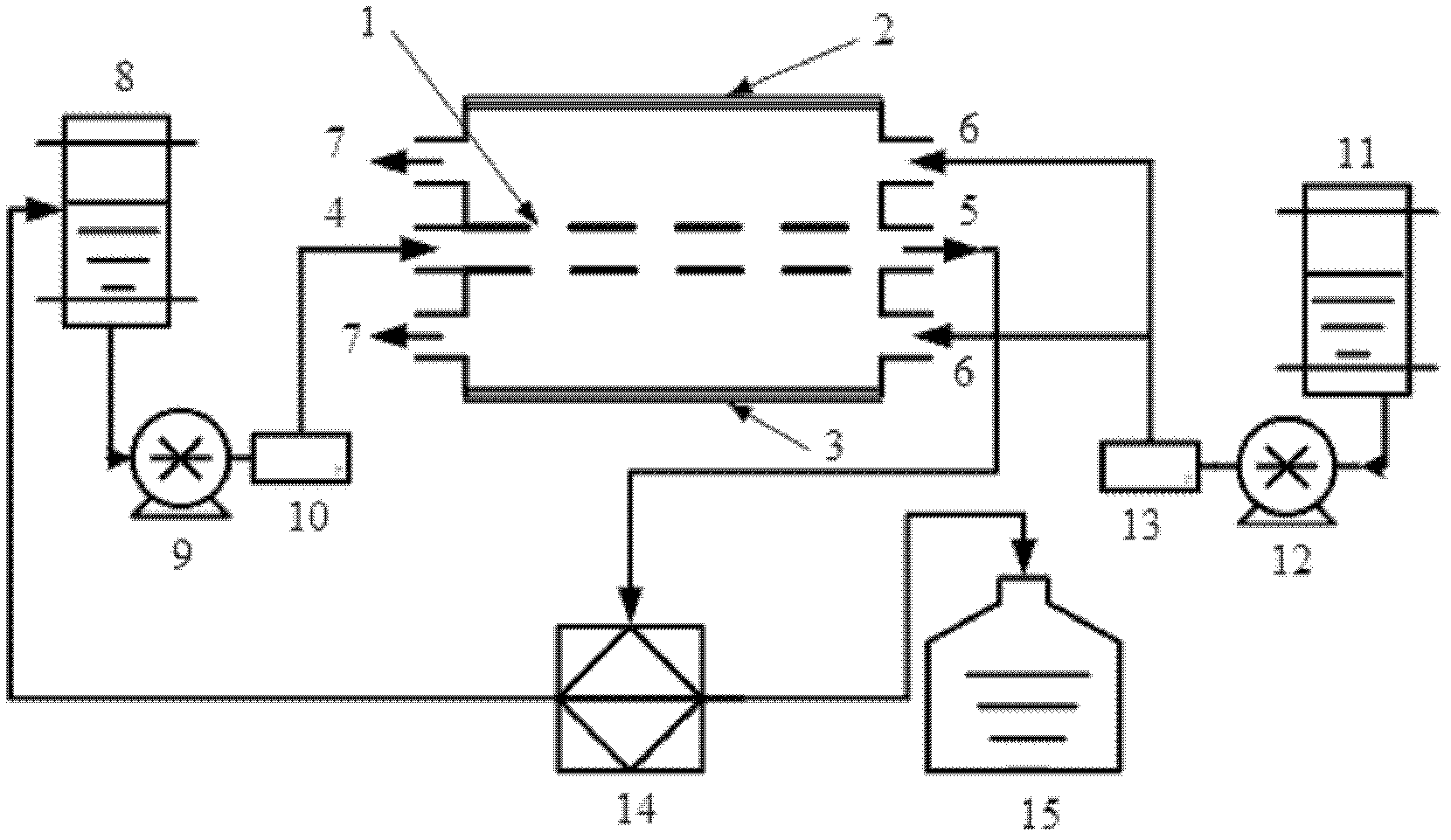

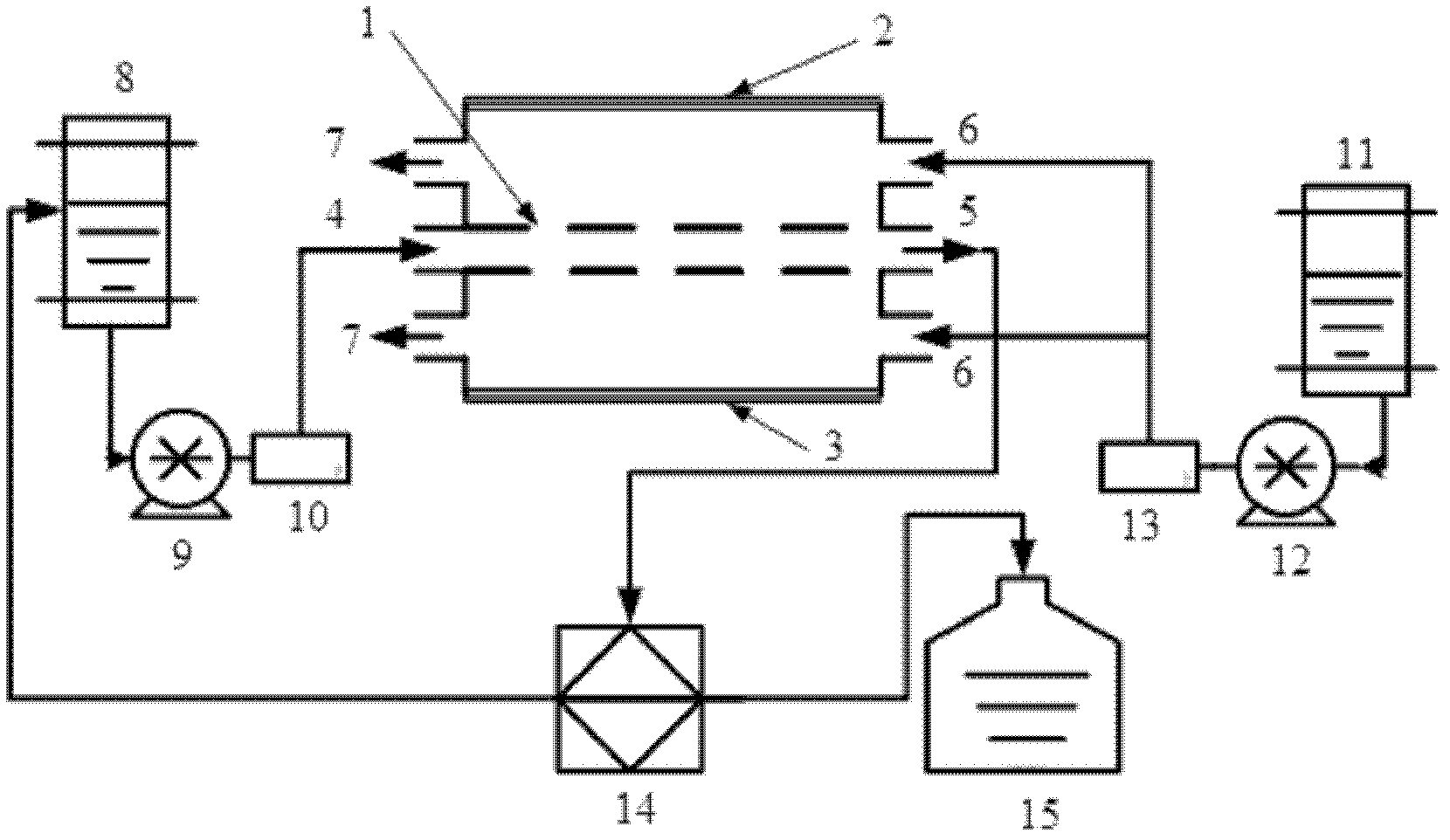

The invention relates to a method and a device for purifying a graphene oxide / graphene solution. According to the method, the graphene oxide / graphene solution to be purified is introduced into a dialysis cavity, wherein the dialysis cavity is located between a cathode and an anode, a channel for the graphene oxide / graphene solution is located in the middle of the dialysis cavity, and solvent flowing channels are formed between the dialysis cavity and the cathode as well as between the dialysis cavity and the anode; the graphene oxide / graphene solution to be purified enters the dialysis cavity from one end of the dialysis cavity and is exposed to the action of an electric field between the cathode and the anode; ions and charge particles in the graphene oxide / graphene solution to be purified migrate to the electrodes with opposite charges by respectively transmitting through the wall of the dialysis cavity and then are taken way by solvent flows; and the residual purified graphene oxide / graphene solution flows out form the dialysis cavity. Compared with the prior art, the method and the device have the advantages of low cost, high efficiency, suitability for mass production and the like.

Owner:上海碳源汇谷新材料科技有限公司

Particle formation

InactiveUS7087197B2Risk minimizationGranulation by liquid drop formationLiposomal deliveryAnti solventMechanical engineering

Owner:NEKTAR THERAPEUTICS INC

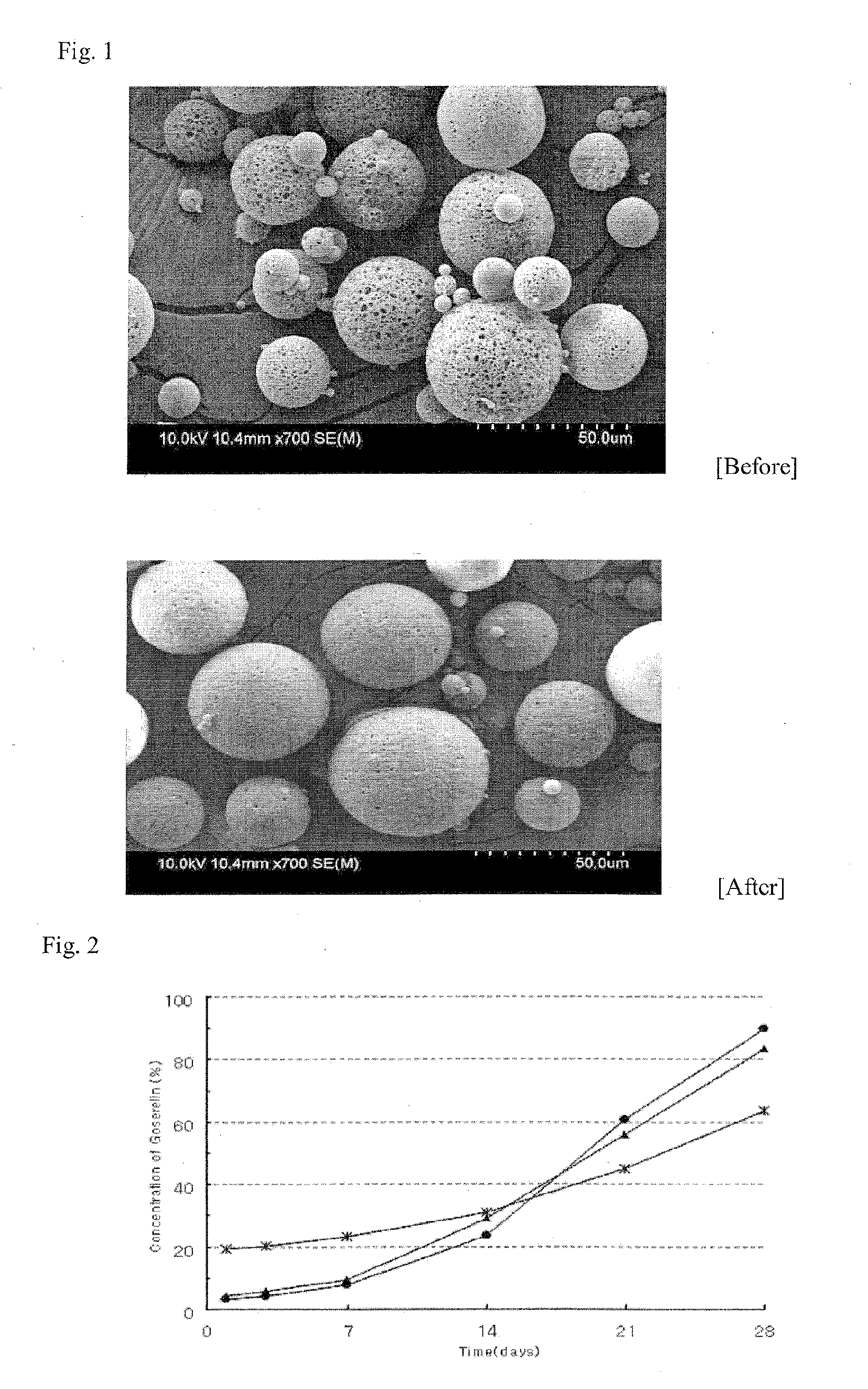

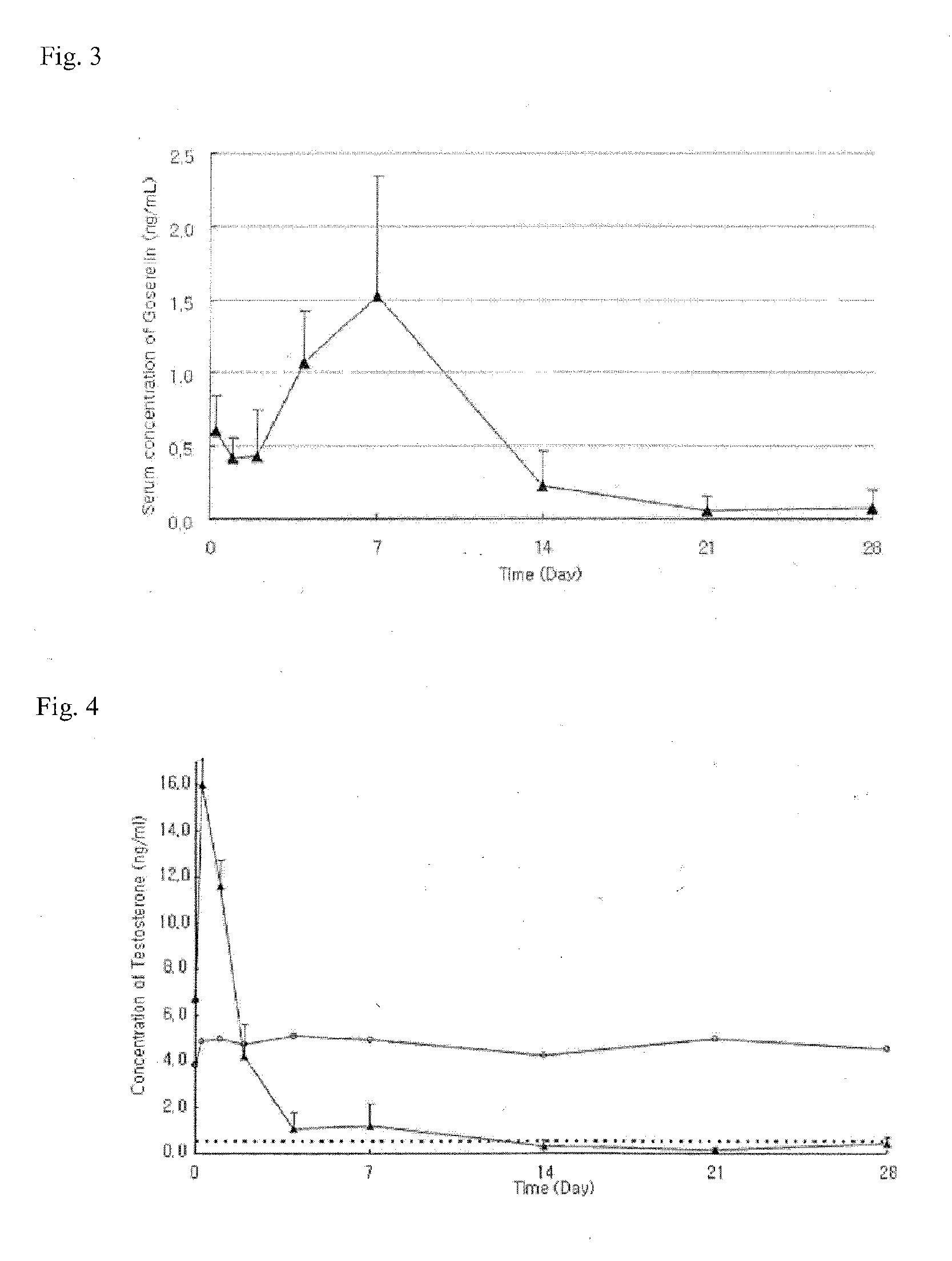

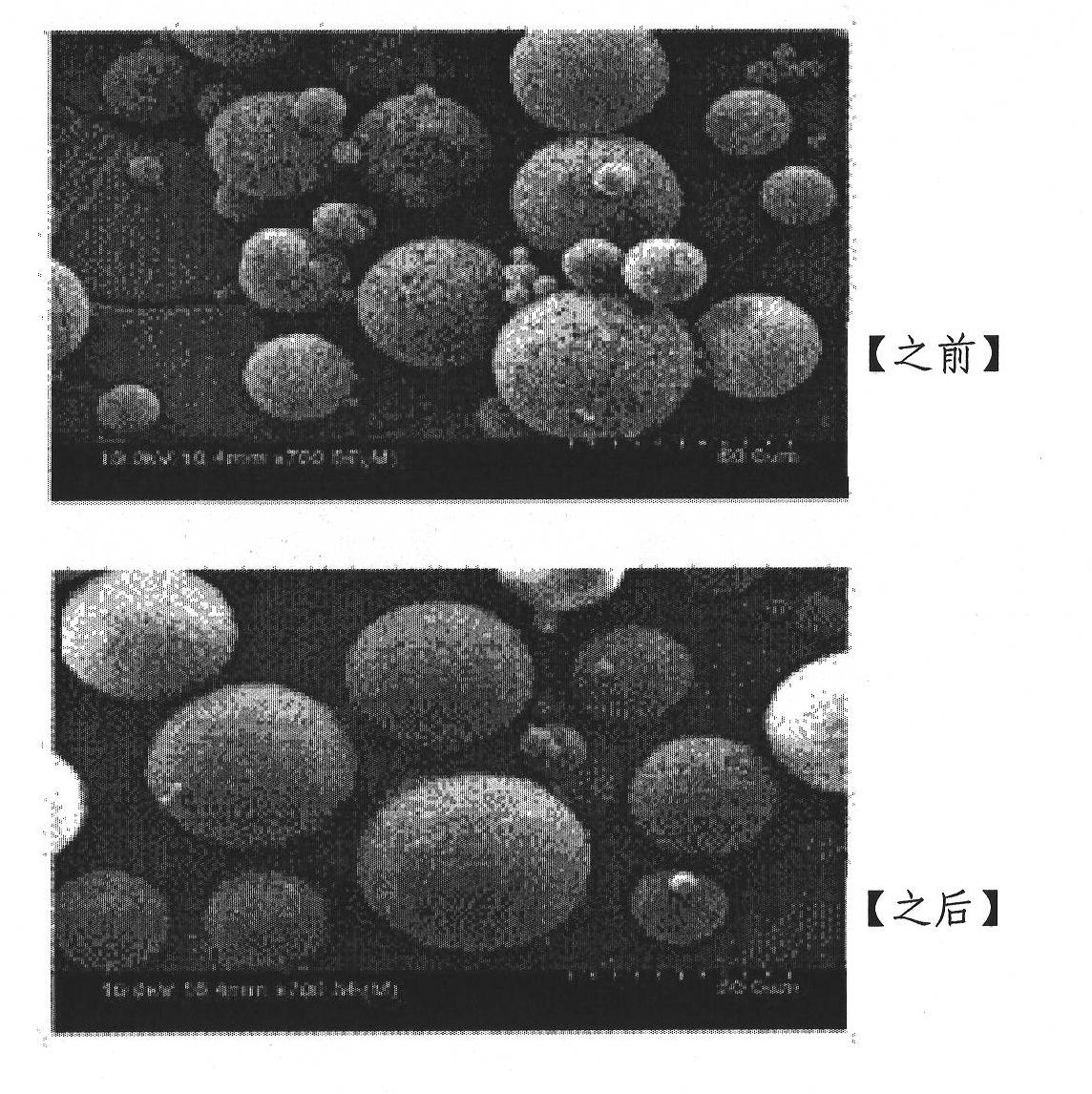

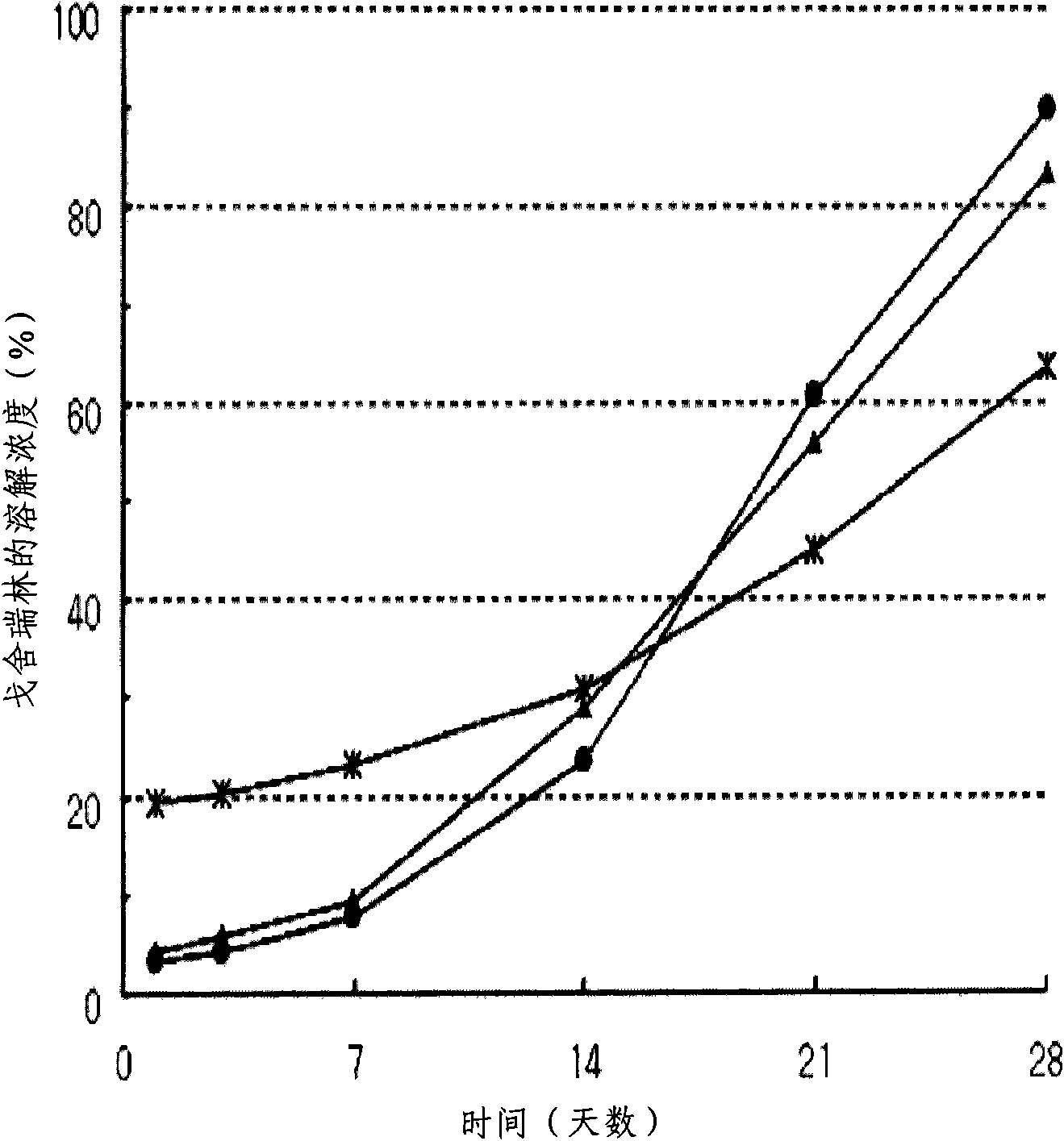

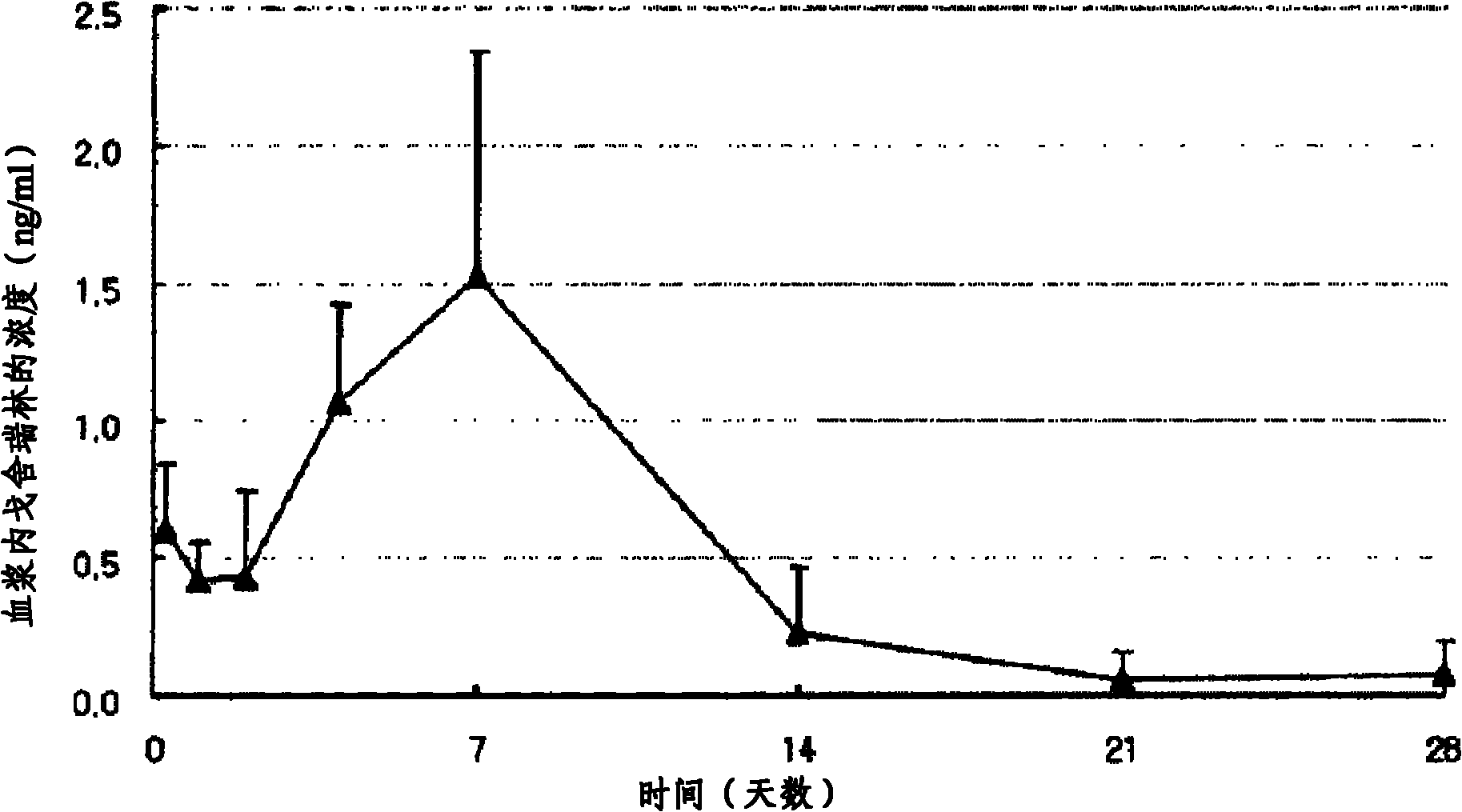

Method for manufacturing sustained release microsphere by solvent flow evaporation method

InactiveUS20110200679A1Eliminate the effects ofSuppresses burst releasePowder deliveryPeptide/protein ingredientsMicrospherePharmaceutical Substances

The present invention relates to a method for preparing a sustained-release microsphere which can control the long-term release of a drug. More particularly, as the preparation of a microsphere in which a drug is loaded in a carrier comprising a biodegradable polymer, the present invention relates to a method for preparing a sustained-release microsphere wherein a solvent intra-exchange evaporation method by means of co-solvent is used for suppressing the initial burst release of physiologically active substance, to release the physiologically active substance in the body continuously and uniformly.

Owner:DONG KOOK PHARMA CO LTD

Method for extracting phenol compounds from direct coal liquefied oil through extractive distillation

ActiveCN103896739AHigh recovery rateIncrease relative volatilityOrganic chemistryOrganic compound preparationSulfolaneExtractive distillation

The invention relates to a method for extracting phenol compounds from direct coal liquefied oil through extractive distillation. An extractive distillation solvent (hereinafter referred to as solvent) adopted in the method is glyceryl triacetate and / or sulfolane, or a mixed solvent formed by mixing glyceryl triacetate and / or sulfolane and one or more selected from glycerol, triethanolamine, triethylene glycol, tetraethylene glycol, dimethyl sulfoxide and diethanol amine according to any proportion. The method is used for extracting phenol compounds from direct coal liquefied oil in an extraction distillation tower by using the solvent, then, a solvent flow rich in the phenol compounds enters a recovery tower and is separated, the phenol compounds discharged from the top of the recovery tower are recovered after being cooled to obtain phenol products, and the solvent is recycled after being discharged from the bottom of the recovery tower. The method has the characteristics of high product purity, low system energy consumption, no wastewater generation, no acid and alkaline waste and no corrosion to equipment.

Owner:TAIYUAN UNIV OF TECH

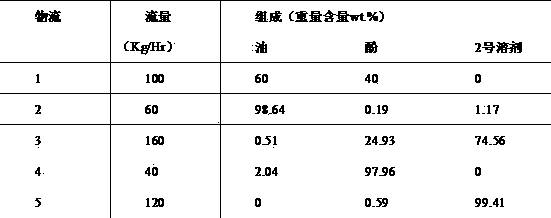

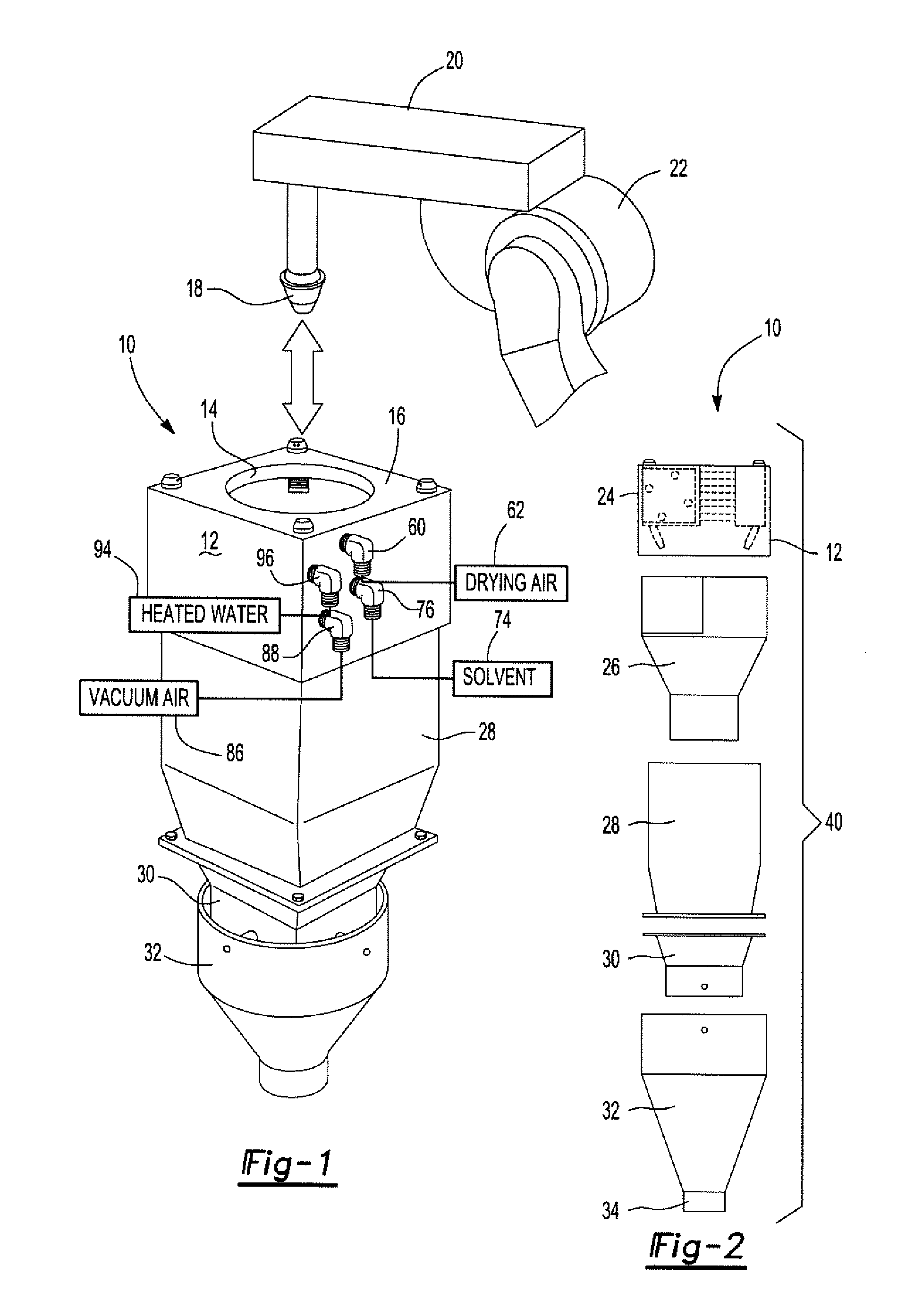

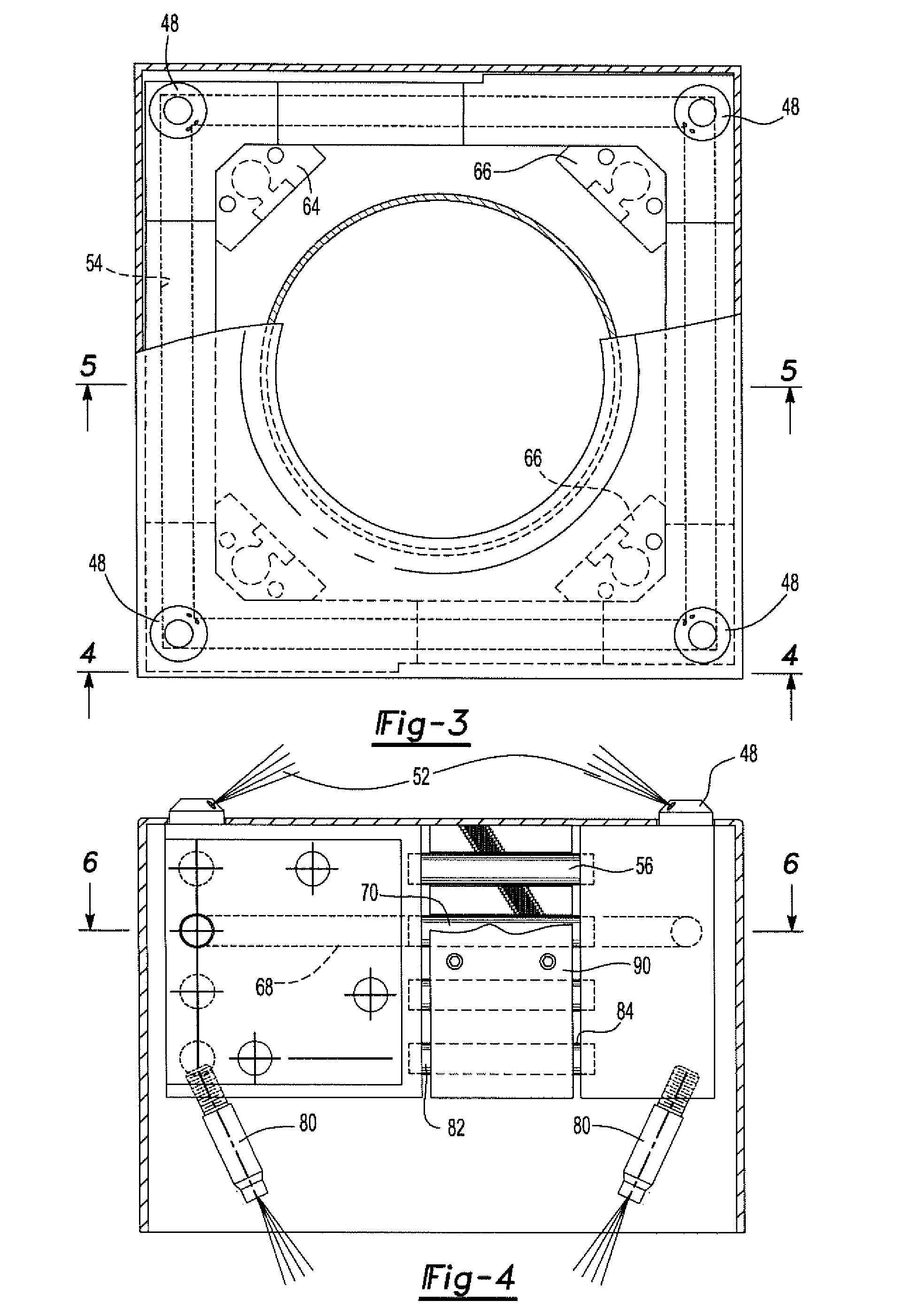

Apparatus for non-contact cleaning a paint spray tip

InactiveUS20150097051A1Facilitates fasterFacilitates complete dryingLiquid spraying apparatusCleaning using liquidsEngineeringAirflow

An apparatus for non-contact cleaning a paint spray tip of a spray gun. The apparatus includes a housing with a top and an opening formed in the top to receive the spray tip. At least one drier nozzle is fluidly connected to a source of compressed air so that discharge from the nozzle impinges upon and dries the spray tip. Similarly, at least one solvent nozzle is also attached to the housing around the opening and discharges solvent on the spray tip when positioned in the housing opening. One or more down flow nozzles are also mounted to the housing to create a downdraft through the housing opening to facilitate cleaning and drying of the spray gun spray tip. A heated fluid also flows through the housing in close proximity to the fluid passageways for the drier nozzle and solvent nozzle in order to heat both the drier nozzle air flow and solvent flow to facilitate cleaning of the spray tip.

Owner:JESSUP PHILIP +1

Production of organic compound nanoparticles with high repetition rate ultrafast pulsed laser ablation in liquids

InactiveUS8992815B2Improve efficiencyHigh repetition rateBiocidePowder deliveryUltrashort laserOrganic compound

Disclosed is a method of producing a chemically pure and stably dispersed organic nanoparticle colloidal suspension using an ultrafast pulsed laser ablation process. The method comprises irradiating a target of an organic compound material in contact with a poor solvent with ultrashort laser pulses at a high repetition rate and collecting the nanoparticles of the organic compound produced. The method may be implemented with a high repetition rate ultrafast pulsed laser source, an optical system for focusing and moving the pulsed laser beam, an organic compound target in contact with a poor solvent, and a solvent circulating system to cool the laser focal volume and collect the produced nanoparticle products. By controlling various laser parameters, and with optional poor solvent flow movement, the method provides stable colloids of dispersed organic nanoparticles in the poor solvent in the absence of any stabilizing agents.

Owner:IMRA AMERICA

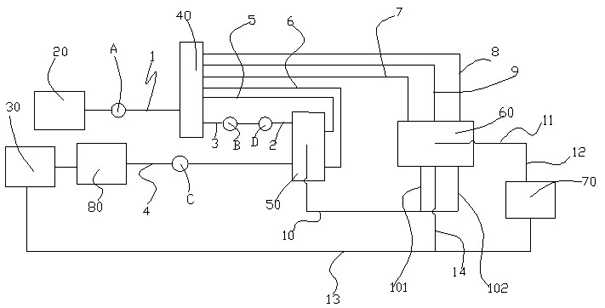

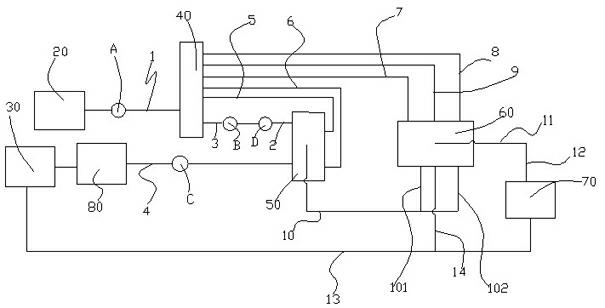

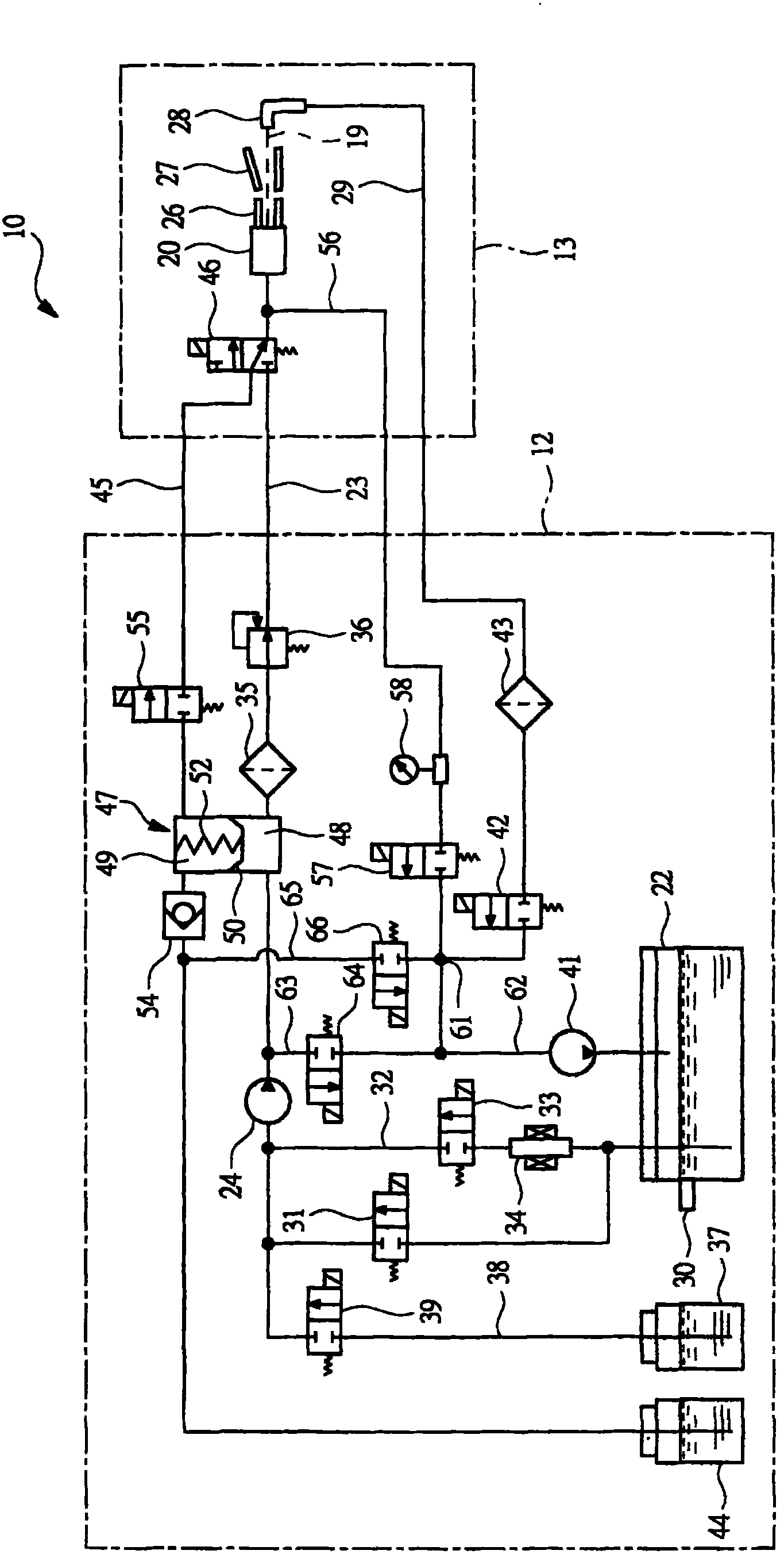

Flushing and detecting system of triple valve, solvent valve and spray gun of automata

ActiveCN102069081AAvoid secondary failureImprove flushing effectMachine part testingDetection of fluid at leakage pointDiaphragm pumpEngineering

The invention relates to a flushing and detecting system of a triple valve, a solvent valve and a spray gun of an automata, which comprises a compressed air supply device, a solvent supply device, a diaphragm pump and a plurality of pipelines, wherein the diaphragm pump is connected with the solvent supply device to pump out solvents in the solvent supply device with certain pressure; the pipelines are correspondingly connected to make the solvents and compressed air enter the solvent valve, the triple valve and the spray gun so as to clean the solvent valve, the triple valve and the spray gun, and after cleaning, the solvents flow back to the solvent supply device through a backflow pipe so as to be recycled. The flushing and detecting system of the solvent valve, the triple valve and the spray gun of the automata simulates the working principle of the automata to mix the solvents and the compressed air with certain pressure and further clean the valves and the spray gun with a good cleaning effect, and simultaneously whether a valve core is damaged or shifted or not is judged through observing the movement situation and the leakage condition of the valve core in air control.

Owner:GUANGQI HONDA

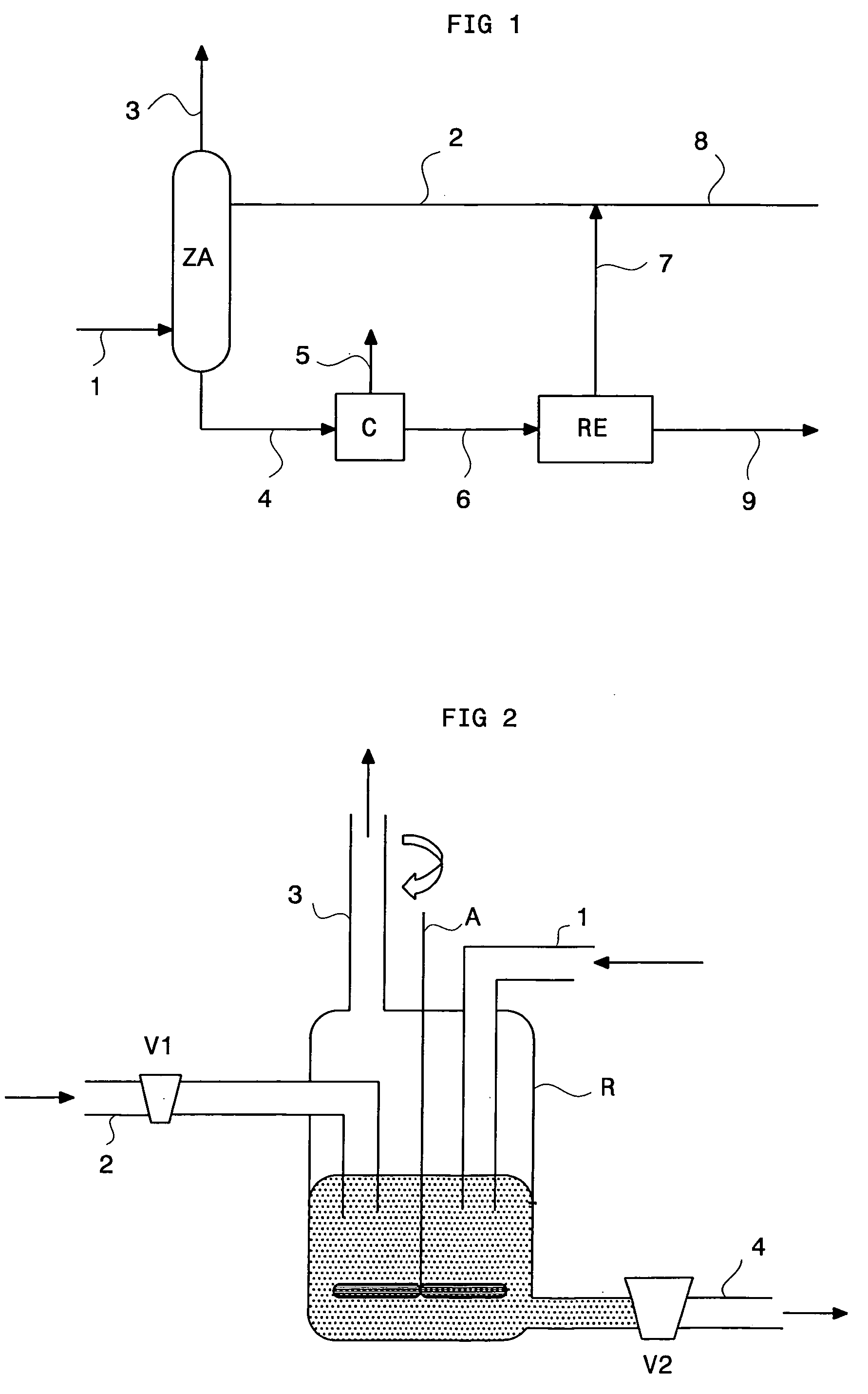

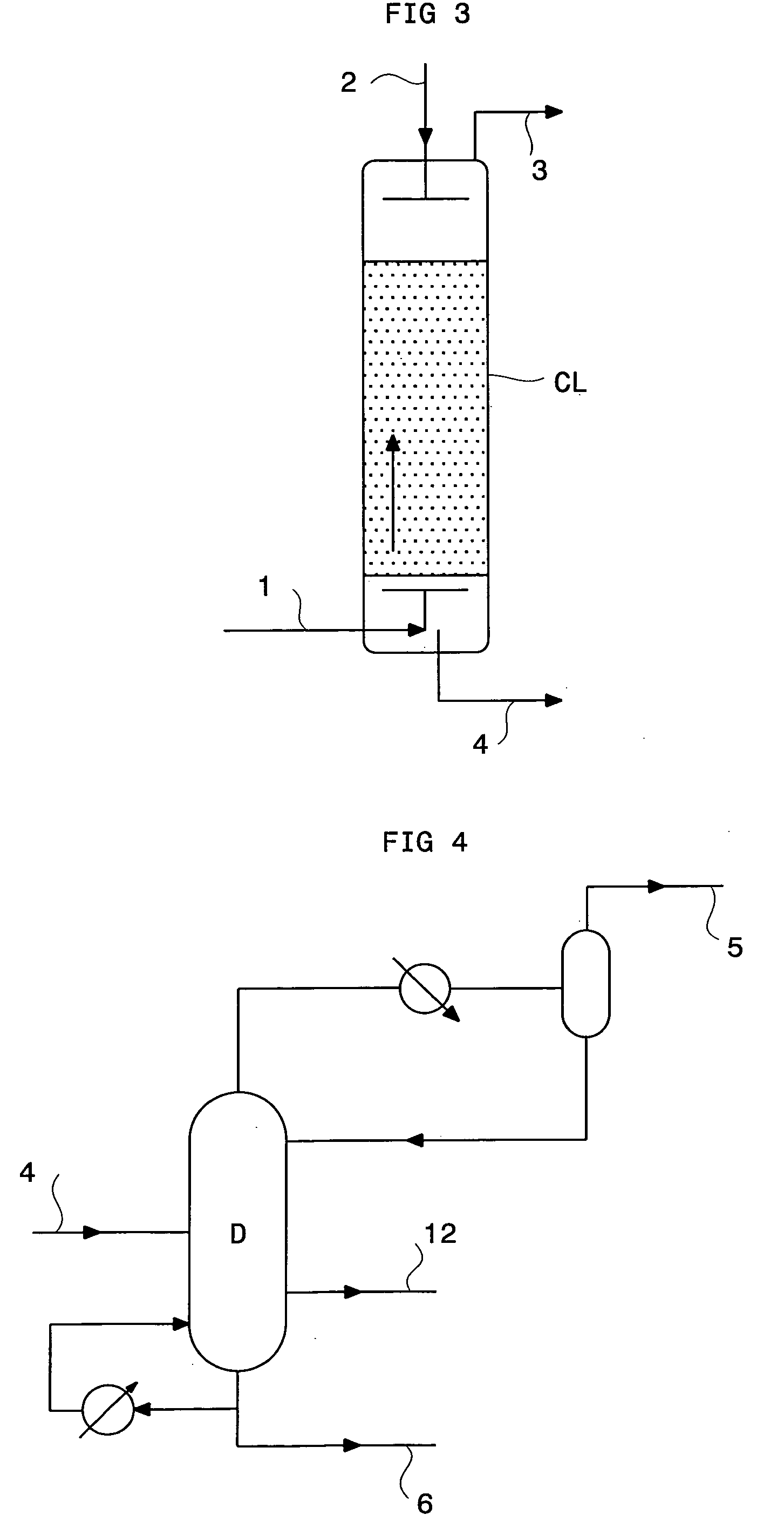

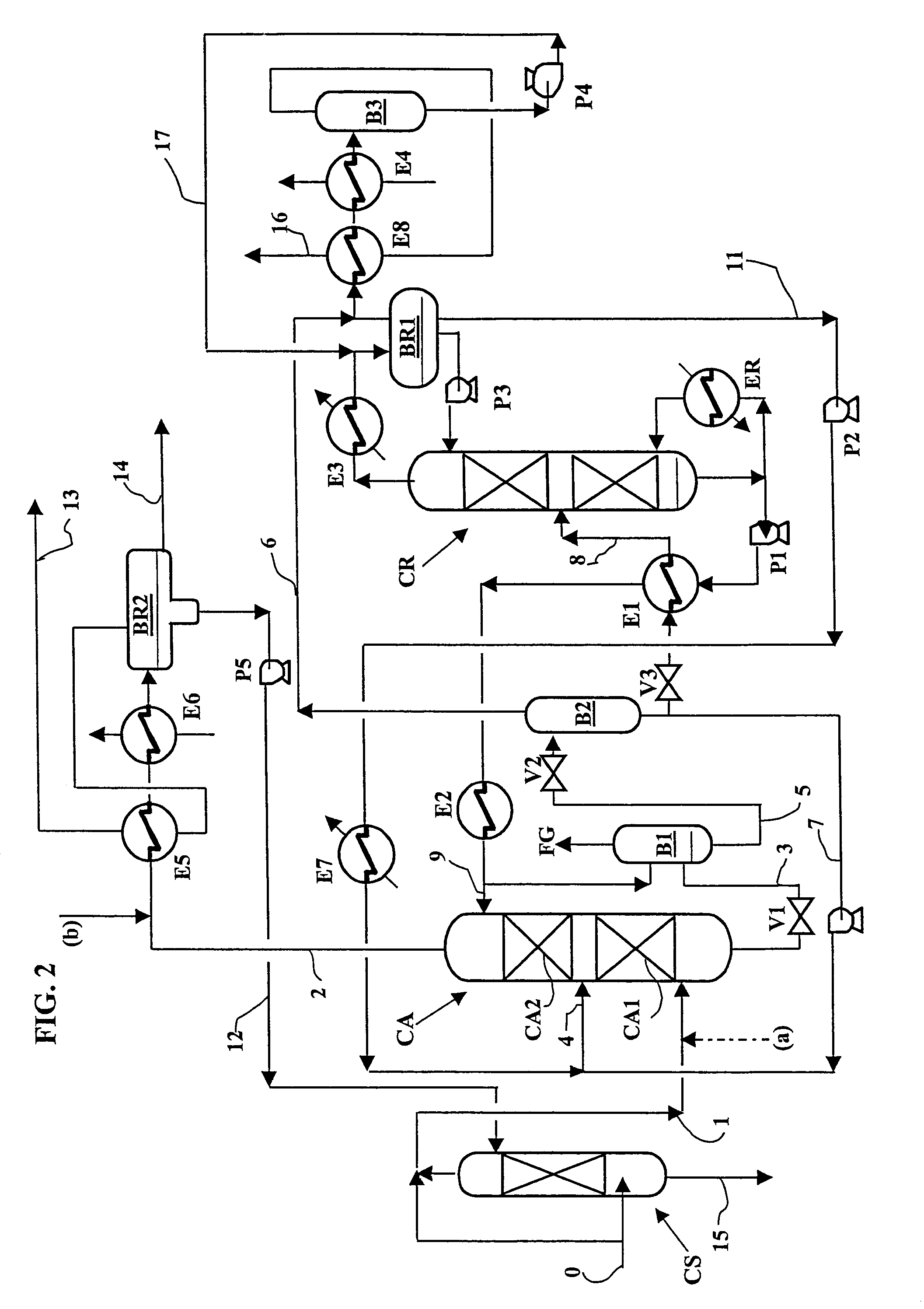

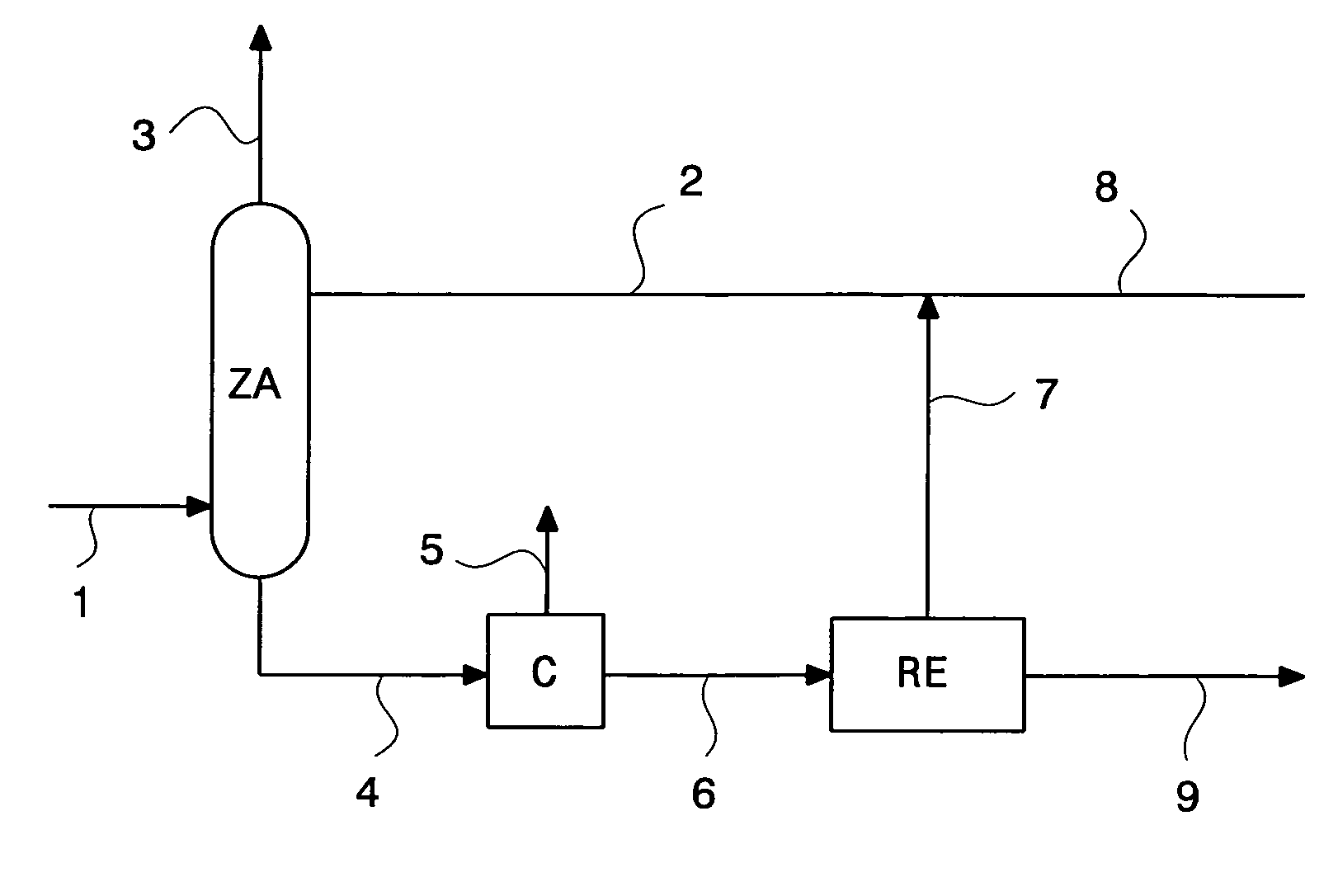

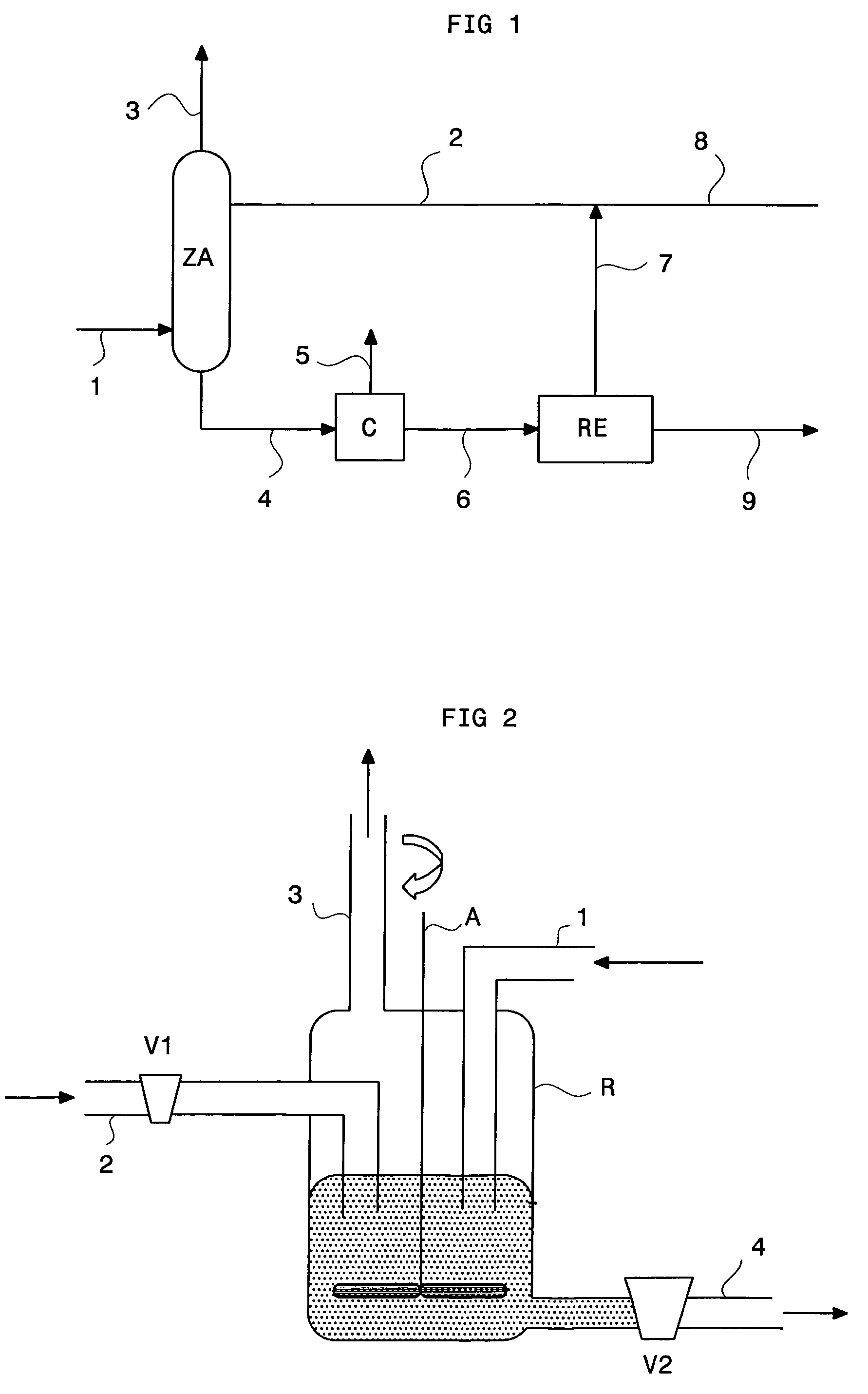

Method of collecting mercaptans contained in a gaseous feed

The gaseous feed flowing in through line 1 is contacted in contacting zone ZA with a liquid solvent flowing in through line 2. The solvent comprises between 0.001% and 100% by weight of a liquid olefin. Contacting in zone ZA is carried out in the presence of an acid catalyst. The purified gaseous feed is discharged from zone ZA through line 3. The sulfide-laden solvent is discharged through line 4, then regenerated in unit RE. The regenerated solvent is recycled through lines 7 and 2 to zone ZA.

Owner:INST FR DU PETROLE

Method for purifying an alcohol from a fermentation broth using a falling film, a wiped film, a thin film or a short path evaporator

ActiveUS20110257441A1Increase productionSemi-permeable membranesFermented solutions distillation/rectificationAlcoholThin membrane

Method for purifying an alcohol from a fermentation broth comprising adding a heavy solvent, evaporating the alcohol to be purified, and mechanically drawing out of the crystallized salts by heavy solvent flow and scrapping on a falling film evaporator, a wiped film evaporator, a thin film evaporator or a short path evaporator.

Owner:METABOLIC EXPLORER

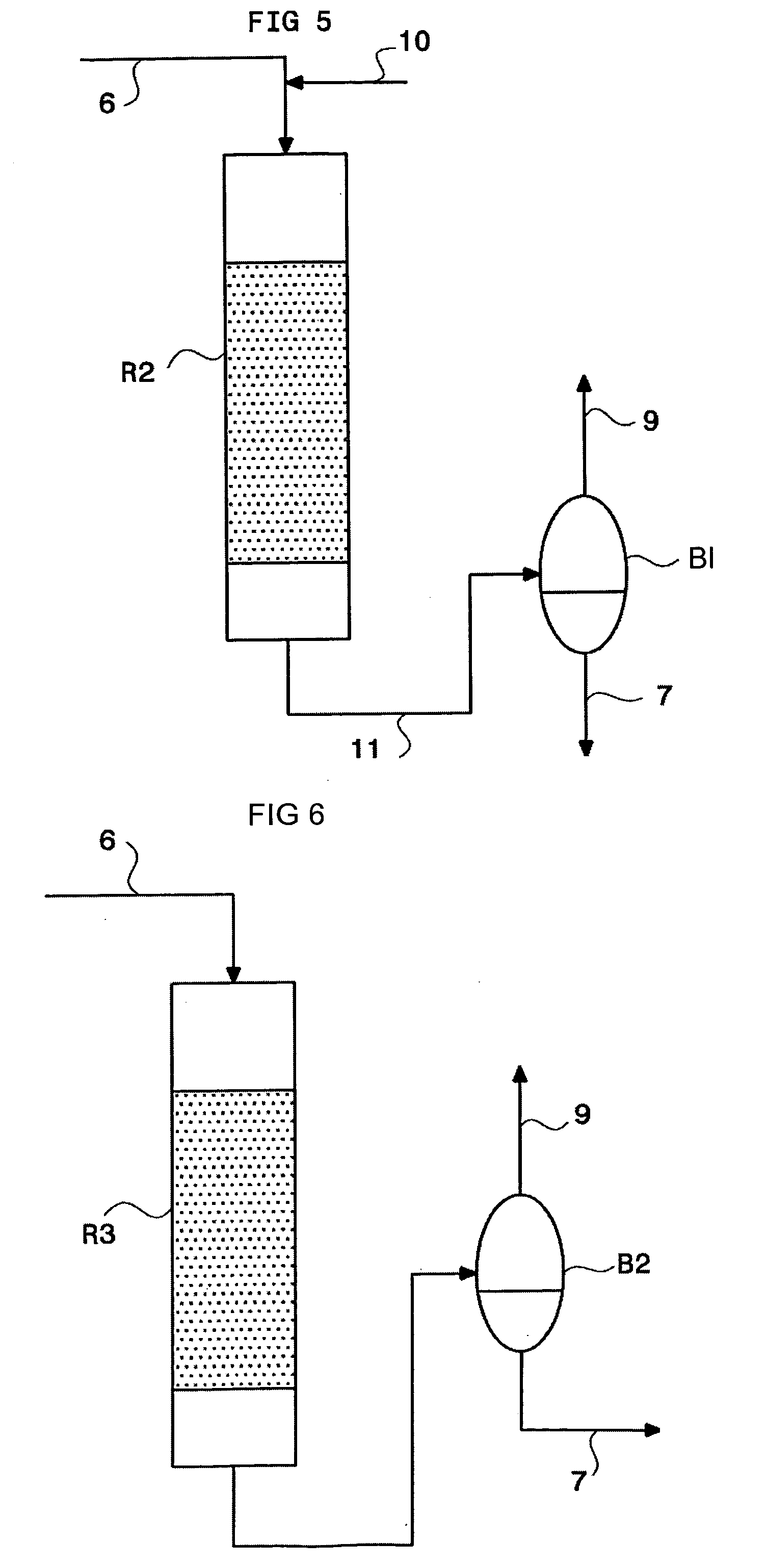

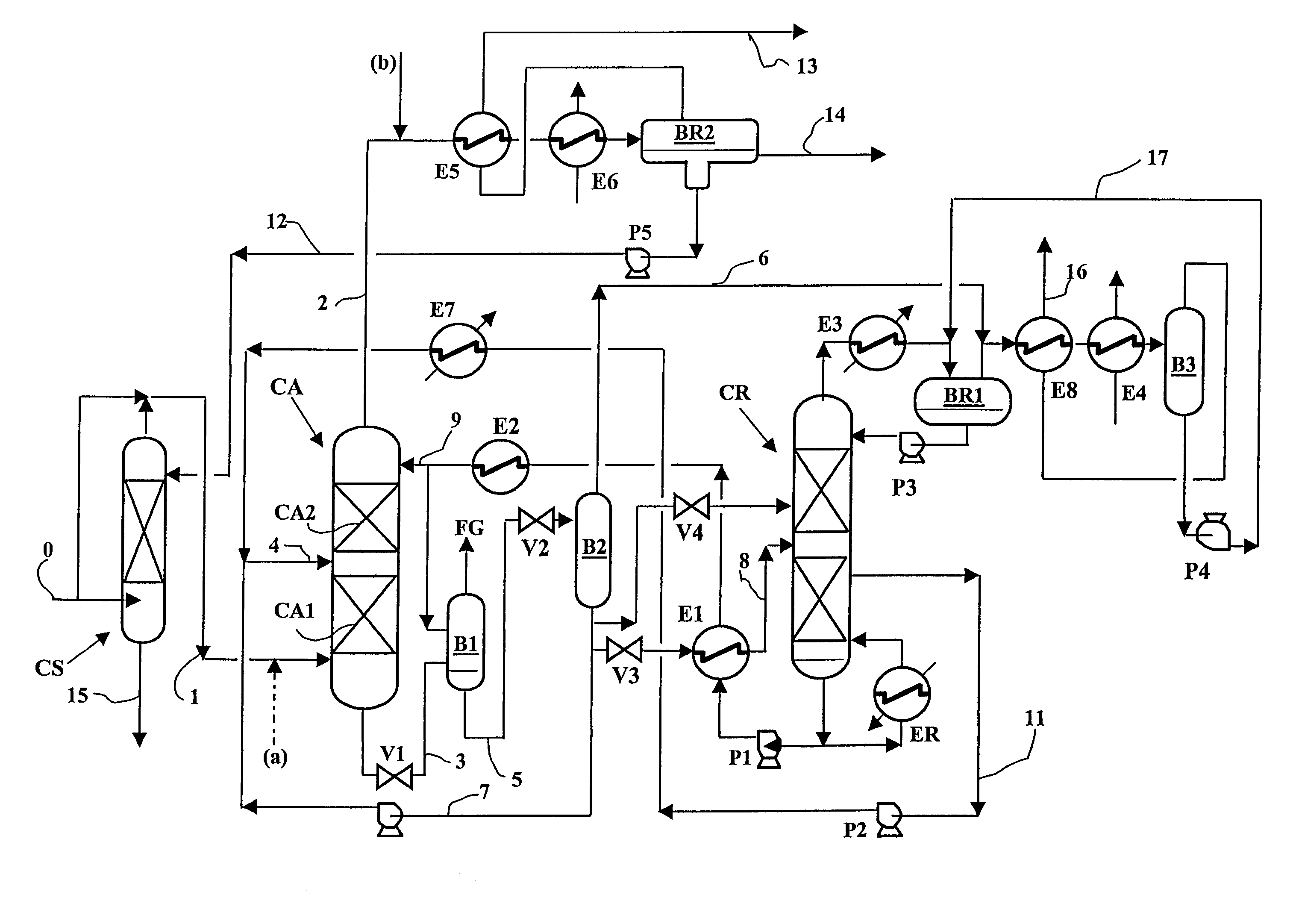

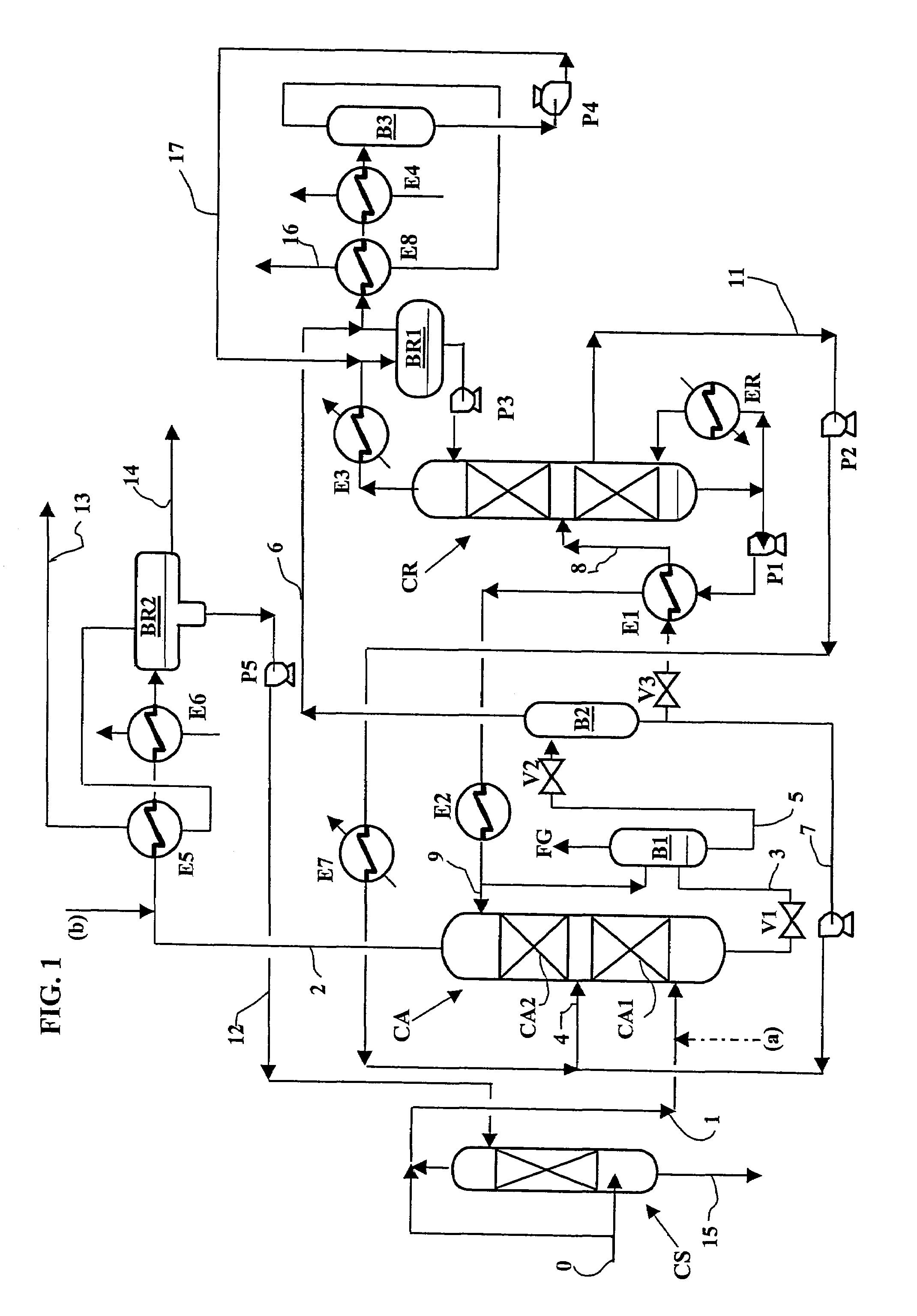

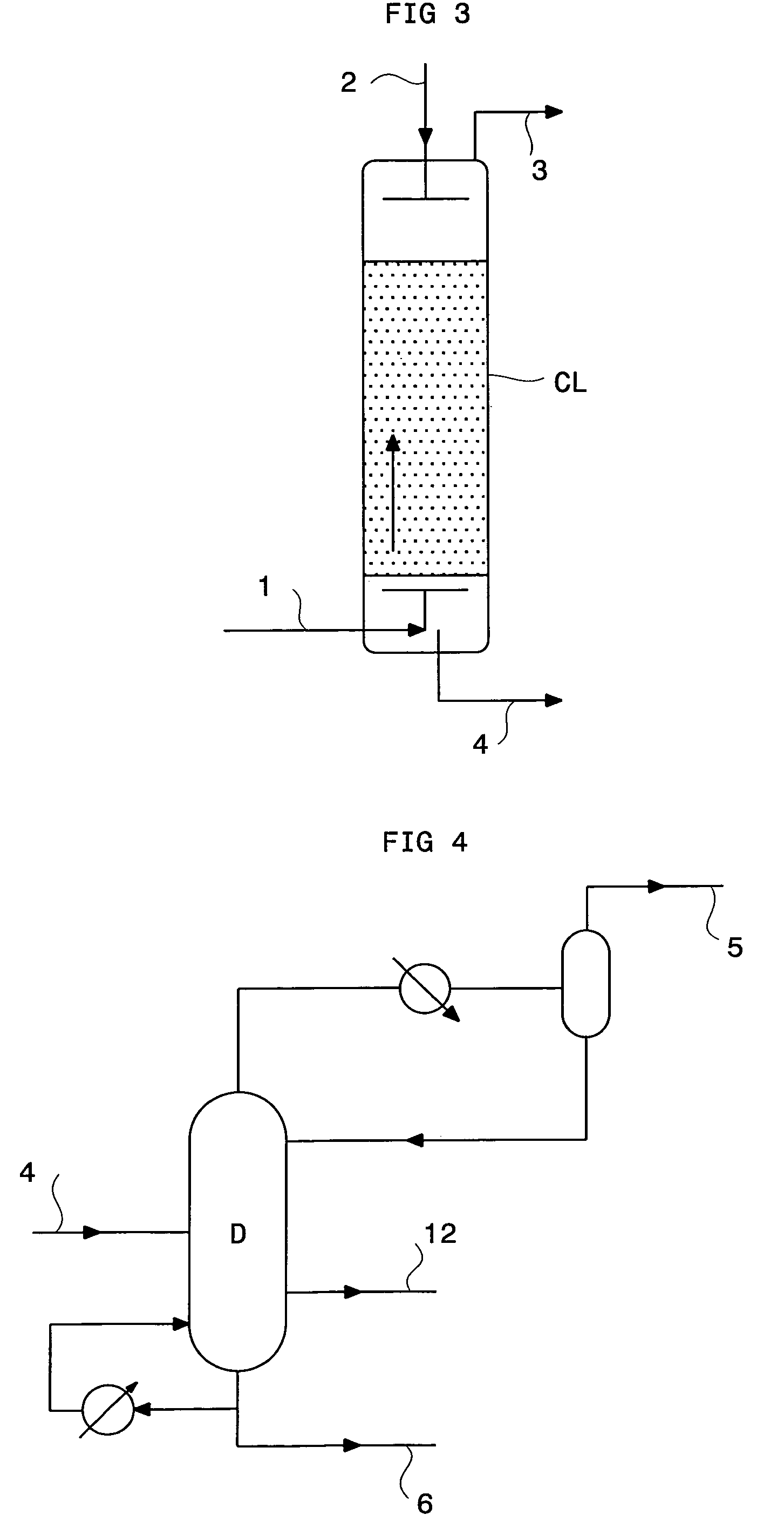

Natural gas deacidizing method

The natural gas is successively contacted in column CA with a relatively methanol-rich solvent flowing in through line 4, then with a relatively poor solvent flowing in through line 9. The acid gas-containing solvent recovered through line 3 at the bottom of column CA is expanded through valves V1 and V2 to release acid gases through line 6. A fraction of the expanded solvent is distilled in column CR. The regenerated solvent obtained at the bottom of column CR is sent to the top of column CA through line 9. A second fraction of the expanded solvent is mixed with a solvent drawn off from column CR at an intermediate point between the bottom and the top of this column. This mixture of solvents is sent through line 4 into column CA.

Owner:INST FR DU PETROLE

Method for manufacturing sustained release microsphere by solvent flow evaporation method

InactiveCN102137657AInhibition of excess releaseInhibition of initial excess releasePill deliveryGranular deliveryMedicineMicrosphere

The present invention relates to a method for manufacturing a sustained release microsphere which is able to continuously control the release of a drug. More specifically, the present invention relates to a method for manufacturing a sustained release microsphere through a solvent flow evaporation method using a cosolvent when manufacturing a microsphere in which a drug is sealed in a carrier comprising biodegradable polymers. Thus, early excessive release of a physiologically active substance is suppressed so the physiologically active substance can be continuously and uniformly released in the body.

Owner:DONG KOOK PHARMA CO LTD

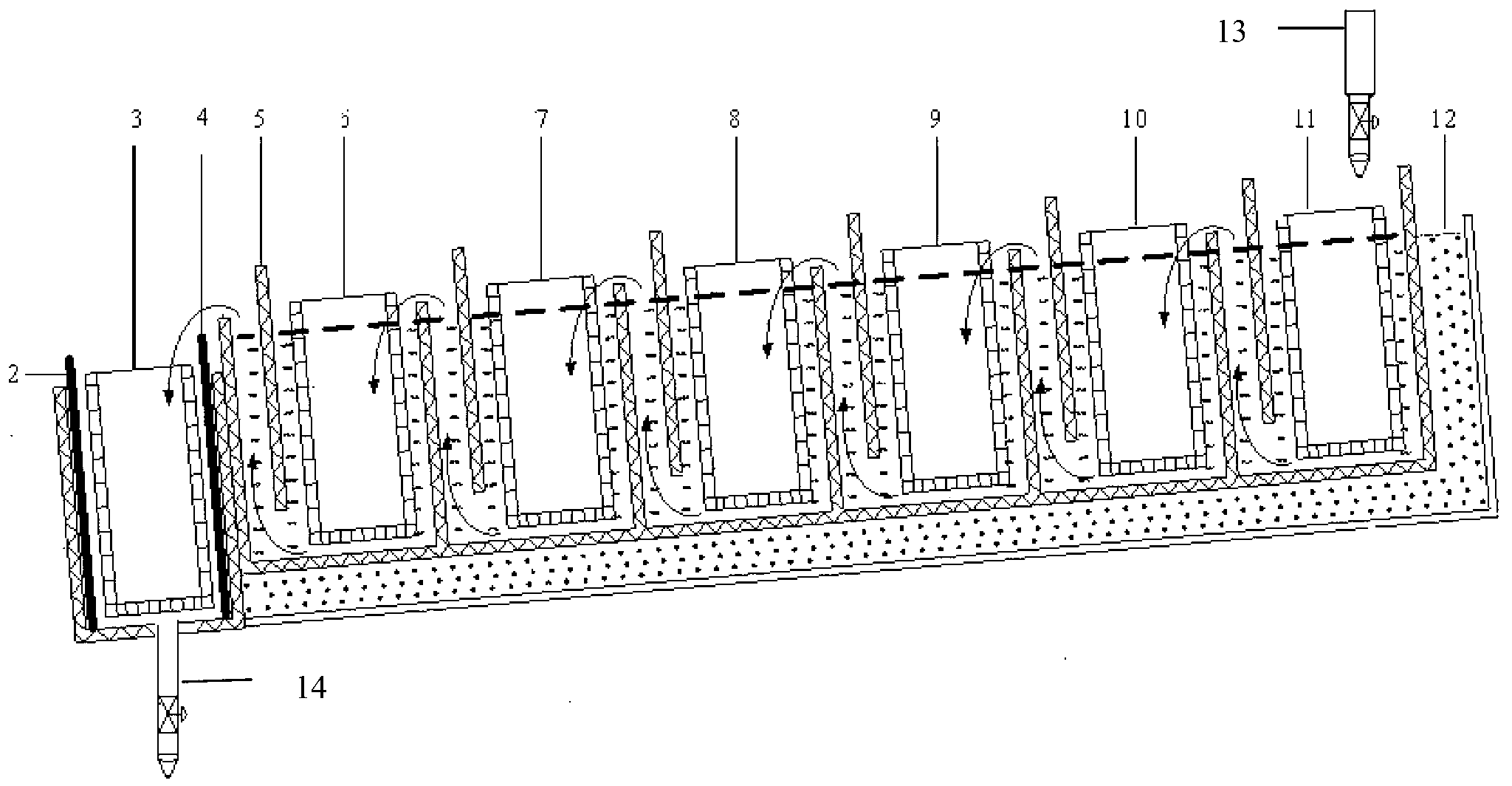

Apparatus and method for pulsed electric field-assisted countercurrent extraction of grape skin residue polyphenol

InactiveCN103223261AHigh extraction rateIncrease economic value addedOrganic chemistryEnergy based chemical/physical/physico-chemical processesPolyphenolTime-Consuming

The invention discloses an apparatus for extracting grape skin residue polyphenol by pulsed electric field auxiliary counter current, which comprises a pulsed treatment pool and N extraction units, and N is no less than 1; the pulsed treatment pool and N extraction units are arranged in order; a solvent inlet is arranged above the N extraction units, and the lower part of the pulsed treatment pool is provided with an extract outlet. During work, firstly, the solvent is injected into the Nth extraction unit, and the solvent flows from the filled extraction unit into the next extraction unit, and finally the solvent flows from the first extraction unit into the pulsed treatment pool. The invention also discloses a method for realizing extraction of grape skin residue polyphenol by pulsed electric field auxiliary counter current according to the apparatus. The invention solves the problems of long time consuming, low extraction efficiency and complex operation technology when extracting grape skin residue polyphenol by the present traditional method.

Owner:SOUTH CHINA UNIV OF TECH

Particle formation

InactiveUS20050085409A1Avoiding undue agglomeration of particleMaximize efficiencyPeptide/protein ingredientsGranulation by liquid drop formationEngineeringMechanical engineering

Method for preparing a target substance in particulate form, by introducing into a particle formation vessel, through separate first and second fluid inlets respectively, (a) a solution or suspension of the target substance in a fluid vehicle (the “target solution / suspension”) and (b) a compressed fluid anti-solvent for the substance, and allowing the anti-solvent to extract the vehicle from the target solution / suspension so as to form particles of the target substance, wherein the target solution / suspension enters the vessel downstream of the point of entry of the anti-solvent and at a point which lies on or close to the main axis of anti-solvent flow, and wherein the anti-solvent has a sub-sonic velocity as it enters the particle formation vessel.

Owner:NEKTAR THERAPEUTICS UK LTD

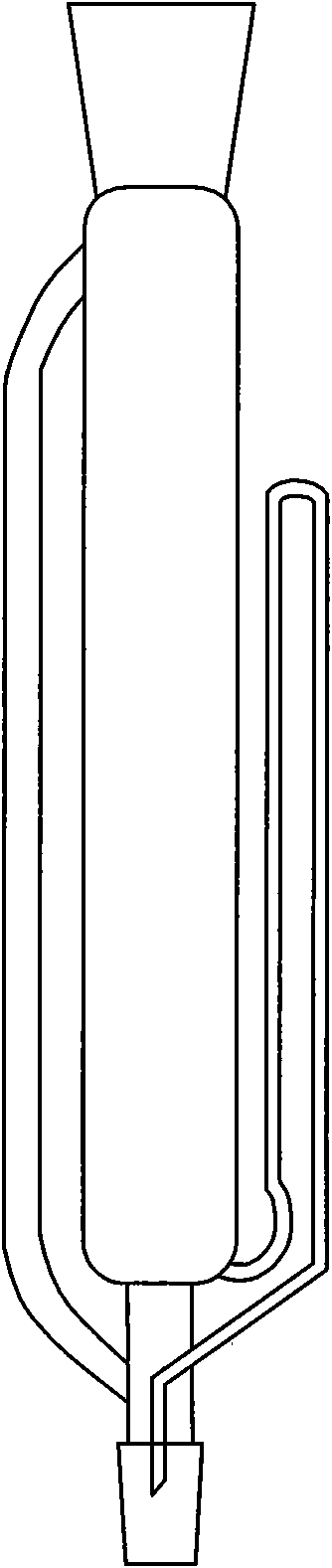

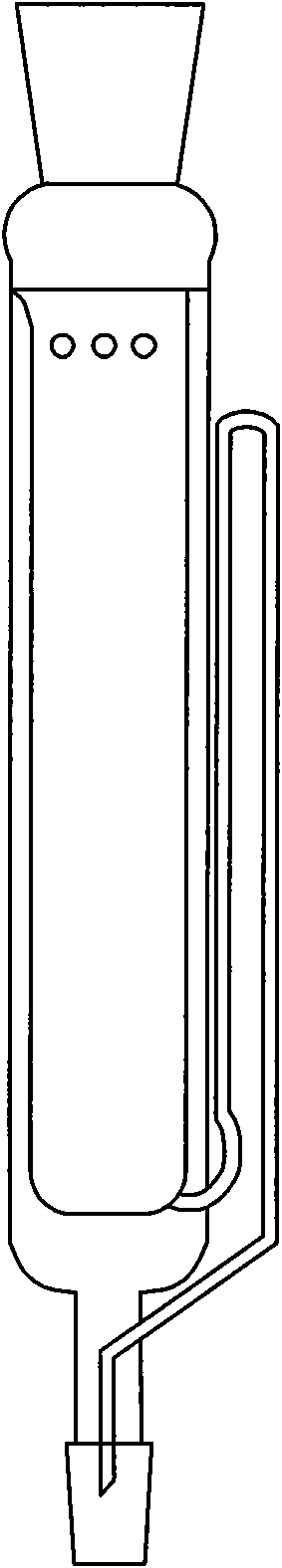

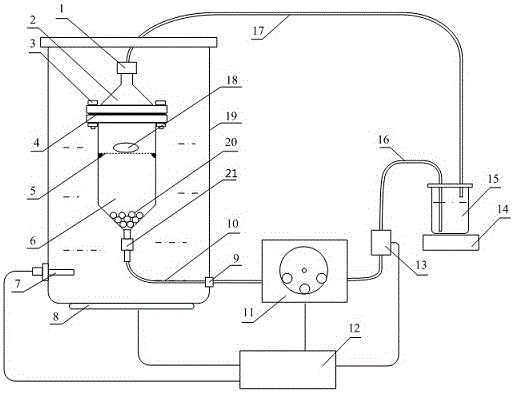

Temperature controlled Soxhlet extractor

ActiveCN101940849ATemperature controlGuaranteed stabilitySolid solvent extractionTemperature controlSoxhlet extractor

The invention relates to a Soxhlet extractor, particularly relating to a temperature controlled Soxhlet extractor. The temperature controlled Soxhlet extractor comprises an external pipe and an internal pipe which are arranged in a sheathing manner; one end of the external pipe is provided with a temperature control liquid inlet; the other end of the external pipe is provided with a temperature control liquid inlet; a ground connecting end is arranged at the lower part of the external pipe; a branch pipe is arranged between the upper part of the internal pipe and the ground connecting end; a syphon pipe is arranged at the bottom of the internal pipe; a coiled pipe is arranged between the external pipe and the internal pipe; and the pipe body of the coiled pipe is positioned in the interlayer between the external pipe and the internal pipe. In the invention, the internal pipe is sheathed in the external pipe; the temperature control liquid circulates in the interlayer between the external pipe and the internal pipe to lead the internal pipe to keep a certain temperature; the coiled pipe is arranged between the external pipe and the internal pipe; the pipe body of the coiled pipe is arranged in the interlayer between the external pipe and the internal pipe; the condensed and refluxed solvent flows into the internal pipe after passing through the coiled pipe, thus the condensed solvent is controlled at a certain temperature through the temperature control liquid, so as to lead the extracting process to be performed at the required temperature.

Owner:CHINA TOBACCO HENAN IND

Preparation of thin tissue sections for imaging mass spectrometry

ActiveUS20150093780A1Efficient measurementParticle separator tubesPreparing sample for investigationMass Spectrometry-Mass SpectrometryMass spectrometry imaging

The invention relates to the preparation of thin tissue sections for mass spectrometric (MALDI) imaging, and proposes a method wherein a microcrystalline layer of the matrix material is produced on the surface of the thin tissue sections, and soluble analyte molecules are transported orthogonally through the thin tissue section to the matrix layer, without substantial lateral diffusion, by means of a solvent flow with alternating or constant direction, and are then deposited in the matrix layer and, if possible, embedded in the matrix crystals. A solvent flow which alternates in direction can be produced by successive, alternating phases of swelling and drying, brought about by periodic changes to the thin tissue section temperature and / or the partial pressures of the solvents. A continuous solvent flow can be generated by applying the thin tissue section onto a porous support which supplies solvent to the rear surface of the thin tissue section.

Owner:BRUKER DALTONIK GMBH & CO KG

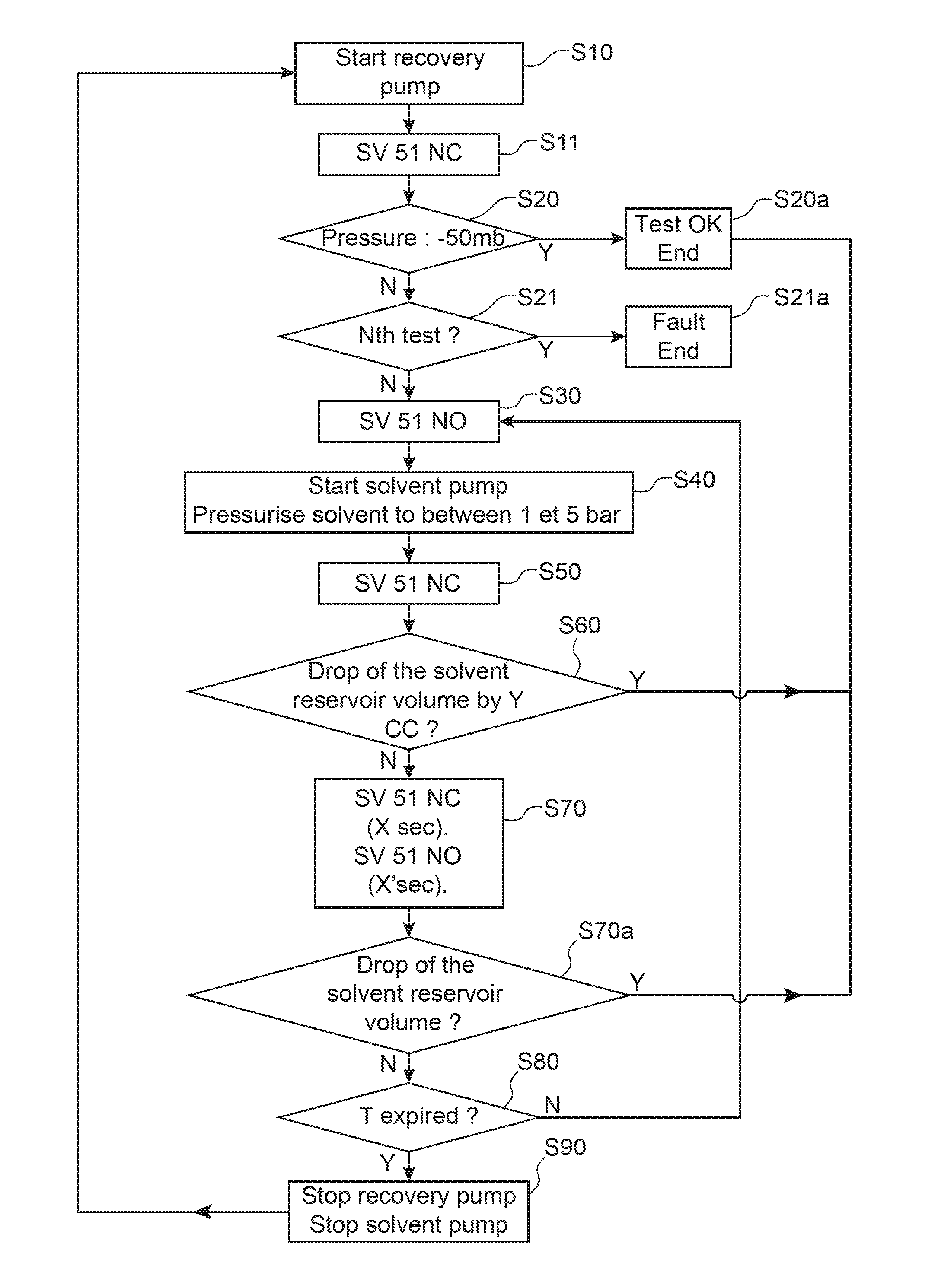

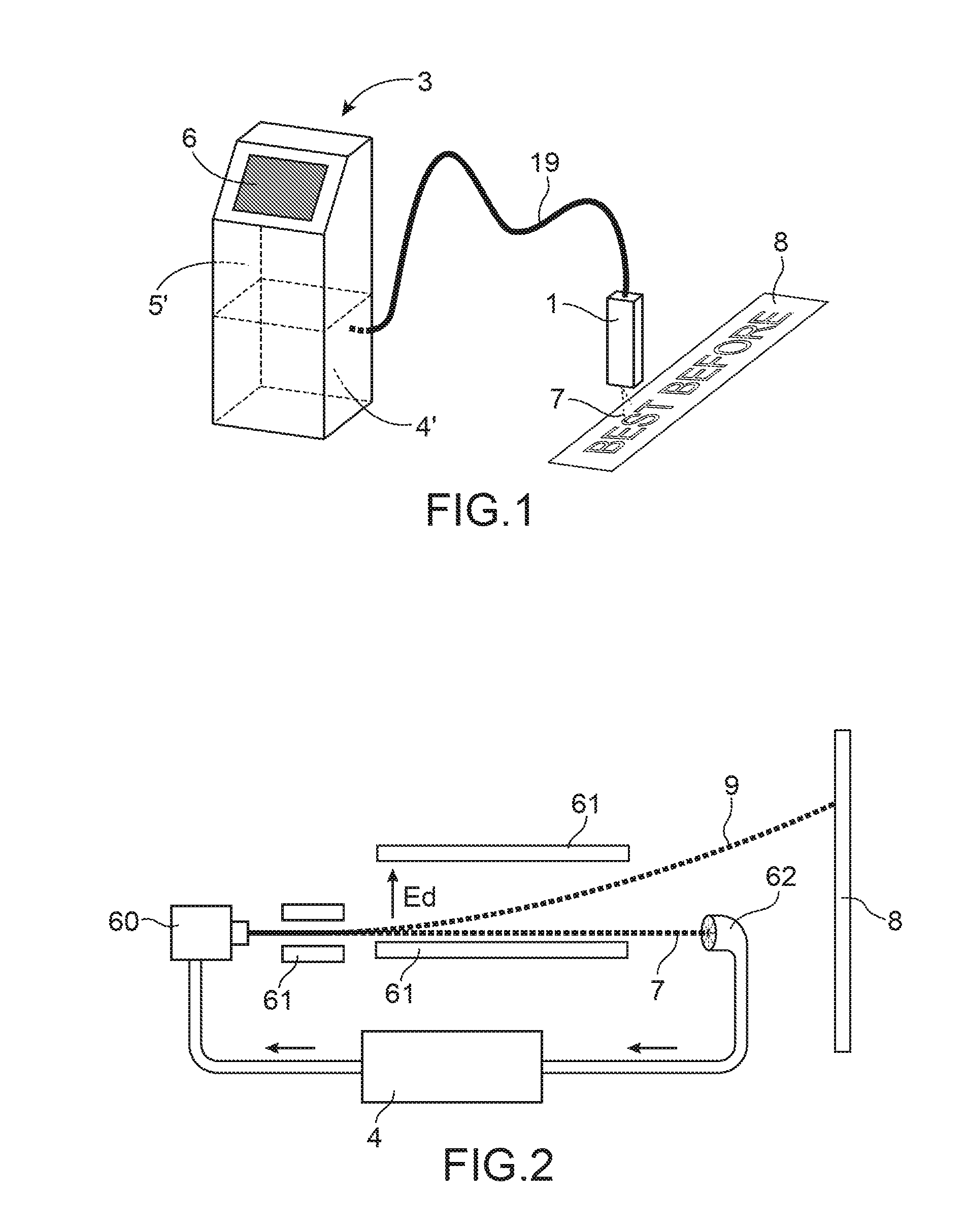

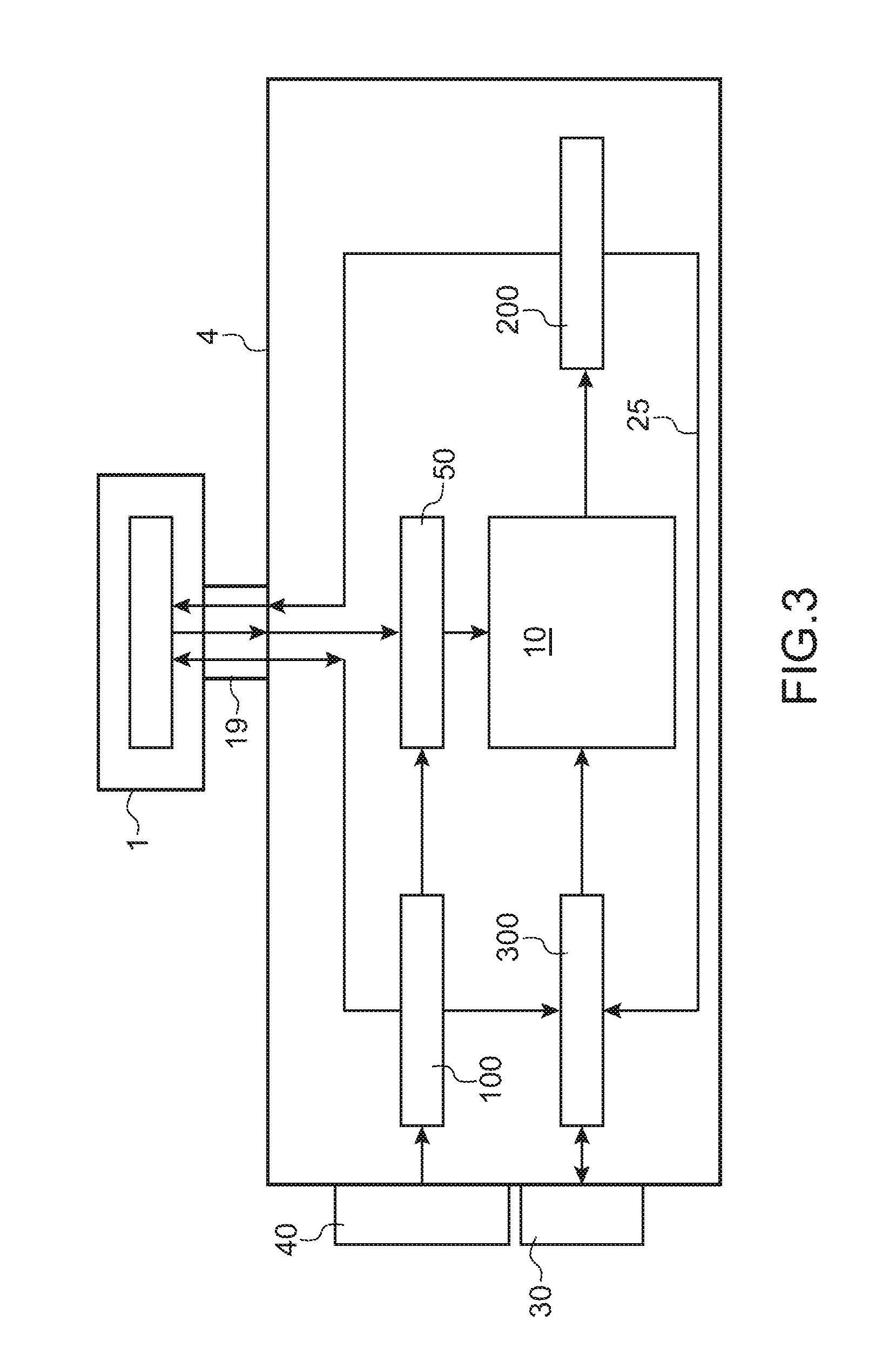

Method and device for partial maintenance of a hydraulic circuit

The invention relates to a method of cleaning a fluid circuit in an inkjet printer that comprises a print head connected to the fluid circuit through an umbilical (19), and also comprises means (50) of recovering fluid from the print head (1), this method comprising at least sending solvent to said fluid recovery means (50), without making this solvent flow in the umbilical or in the print head.

Owner:DOVER EURO SARL

Simple type test device for dissolution rate of flowing pool

InactiveCN105784952ASimple structureEasy to operateTesting medicinal preparationsPeristaltic pumpMicrosphere

The invention discloses a simple type test device for a dissolution rate of a flowing pool. The simple type test device comprises the flowing pool, a filter, a multichannel peristaltic pump, a heating pool, a solvent storage bottle and a controller, wherein an upper opening of the flowing pool is in sealing connection with one opening of the filter; the other opening of the filter is communicated with the solvent storage bottle through a hose a; a lower opening of the flowing pool is connected with one end of a hose b; the other end of the hose b is connected with an outlet of the multichannel peristaltic pump; an inlet of the multichannel peristaltic pump is communicated with the solvent storage bottle through a hose c; the flowing pool is arranged in the heating pool. The simple type test device can work in an open or closed form; the heating temperature and the solvent flow rate are controlled; the simple type test device has the characteristics of simple structure, convenience in operation, low cost, and the like and is fit for determining the releasing rate of various drug sustained-release preparations, such as drug release brackets, implants, microspheres, microchips, lipidosome, of institutions of colleges, research institutions, pharmaceutical factory, and the like.

Owner:YANBIAN UNIV

Method for catalytically preparing chromene pyrimido indazolone derivative serving as drug intermediate

ActiveCN111484499AReduce usageHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystOrganic synthesis

The invention belongs to the field of organic synthesis, and discloses a method for catalytically preparing a drug intermediate chromene pyrimido indazolone derivative, which comprises the following steps: adding an ethanol water solution into a reaction container, adding aromatic aldehyde, 1H-indazole-3-amine and 4-hydroxycoumarin, stirring at room temperature, uniformly mixing, and finally adding an acidic ionic liquid catalyst; heating until the solvent flows back, keeping the temperature until the raw material point disappears, and stopping stirring after the reaction is finished; coolingthe reaction solution to room temperature, grinding the precipitated solid, performing standing, and carrying out suction filtration to obtain filter residues; washing the filter residue with ethanol,and carrying out vacuum drying to obtain a product; and adding reaction raw materials into the filtrate after suction filtration to carry out the next round of reaction. According to the method, thenew acidic ionic liquid catalyst is utilized, and the ethanol aqueous solution is used as a reaction solvent, so that the catalytic reaction efficiency can be effectively improved, the adding amount of the catalyst is reduced, the ethanol aqueous solution can effectively play a role of a recrystallization solvent, and the purification process is simplified.

Owner:东营睿港管道工程有限责任公司

Method of collecting mercaptans contained in a gaseous feed

The gaseous feed flowing in through line 1 is contacted in contacting zone ZA with a liquid solvent flowing in through line 2. The solvent comprises between 0.001% and 100% by weight of a liquid olefin. Contacting in zone ZA is carried out in the presence of an acid catalyst. The purified gaseous feed is discharged from zone ZA through line 3. The sulfide-laden solvent is discharged through line 4, then regenerated in unit RE. The regenerated solvent is recycled through lines 7 and 2 to zone ZA.

Owner:INST FR DU PETROLE

Stop treatment method for ink-jet recording apparatus

The invention provides a stop treatment method for an ink-jet recording apparatus, and aims to carry out stop treatment for the ink-jet recording apparatus through a small amount of solvent. During the process from printing state of injecting ink by a nozzle (20) to state of stopping supplying ink to the nozzle (20), solvent is supplied to the nozzle (20) from a solvent supply flow path (45), the solvent flowed through the nozzle (20) is supplied to a recovery flow path (29) to clean the recovery flow path (29), then solvent is supplied to an attraction flow path (56) from the solvent supply flow path (45) to clean the attraction flow path (56), outer gas is supplied to the attraction flow path (56) from the nozzle (20), and after the solvent is changed to air, the solvent is supplied to the attraction flow path (56) again to fine clean. By carrying out residual liquid removing for the attraction flow path (56) and residual liquid removing for the recovery flow path (29) alternatively and repeatedly, liquid in the recovery flow path (29) and the attraction flow path (56) are supplied to an ink container.

Owner:HITACHI IND EQUIP SYST CO LTD

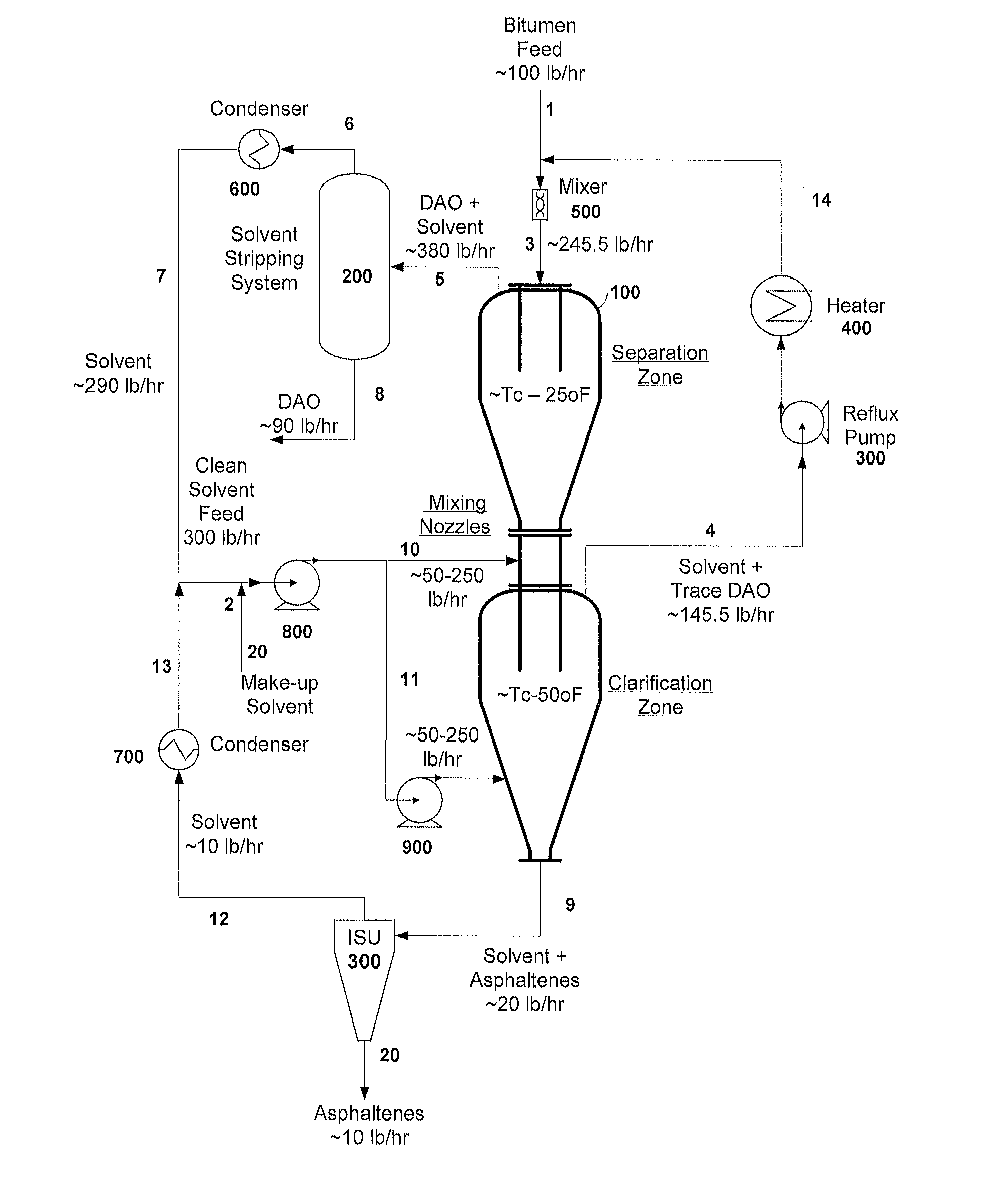

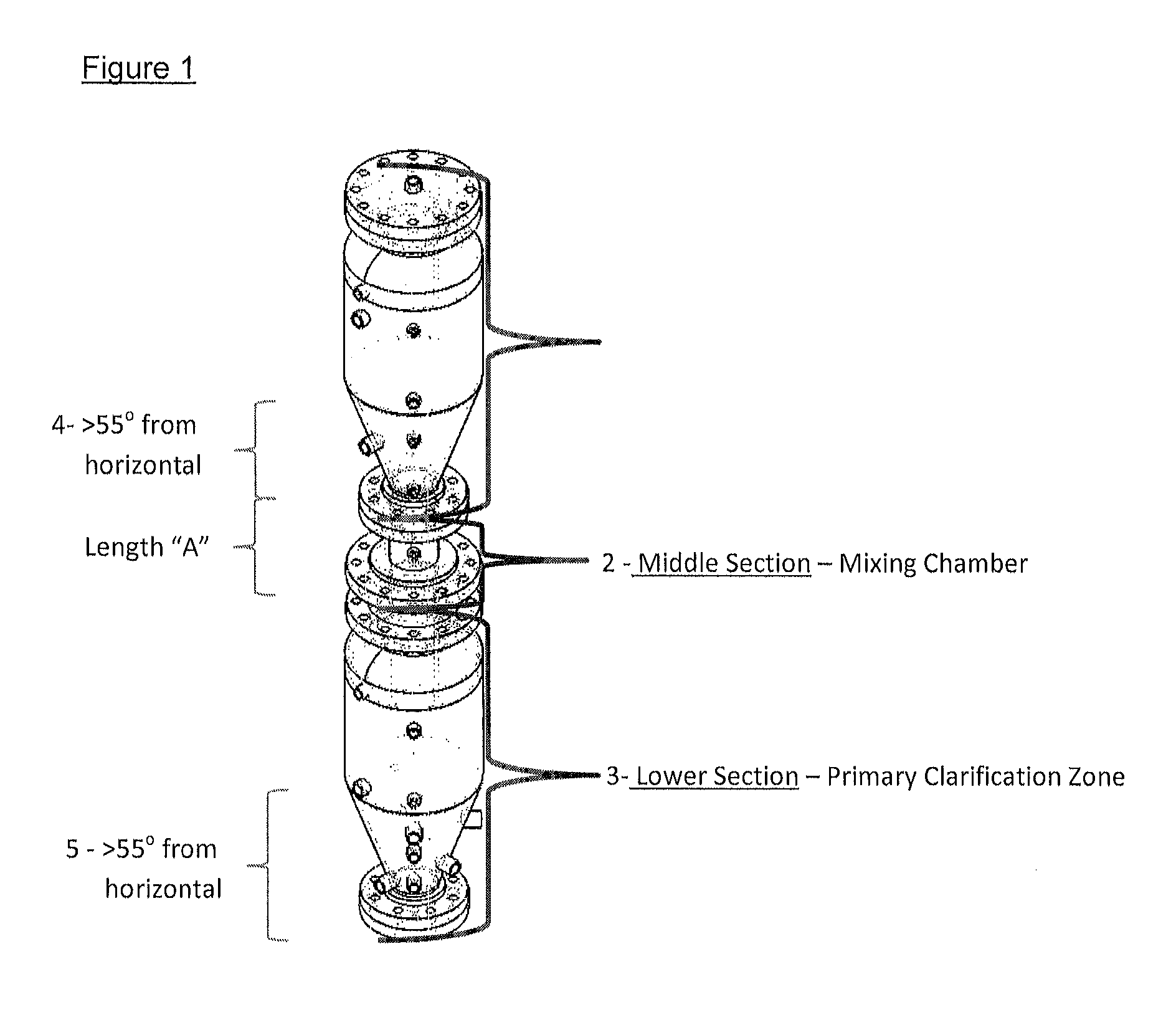

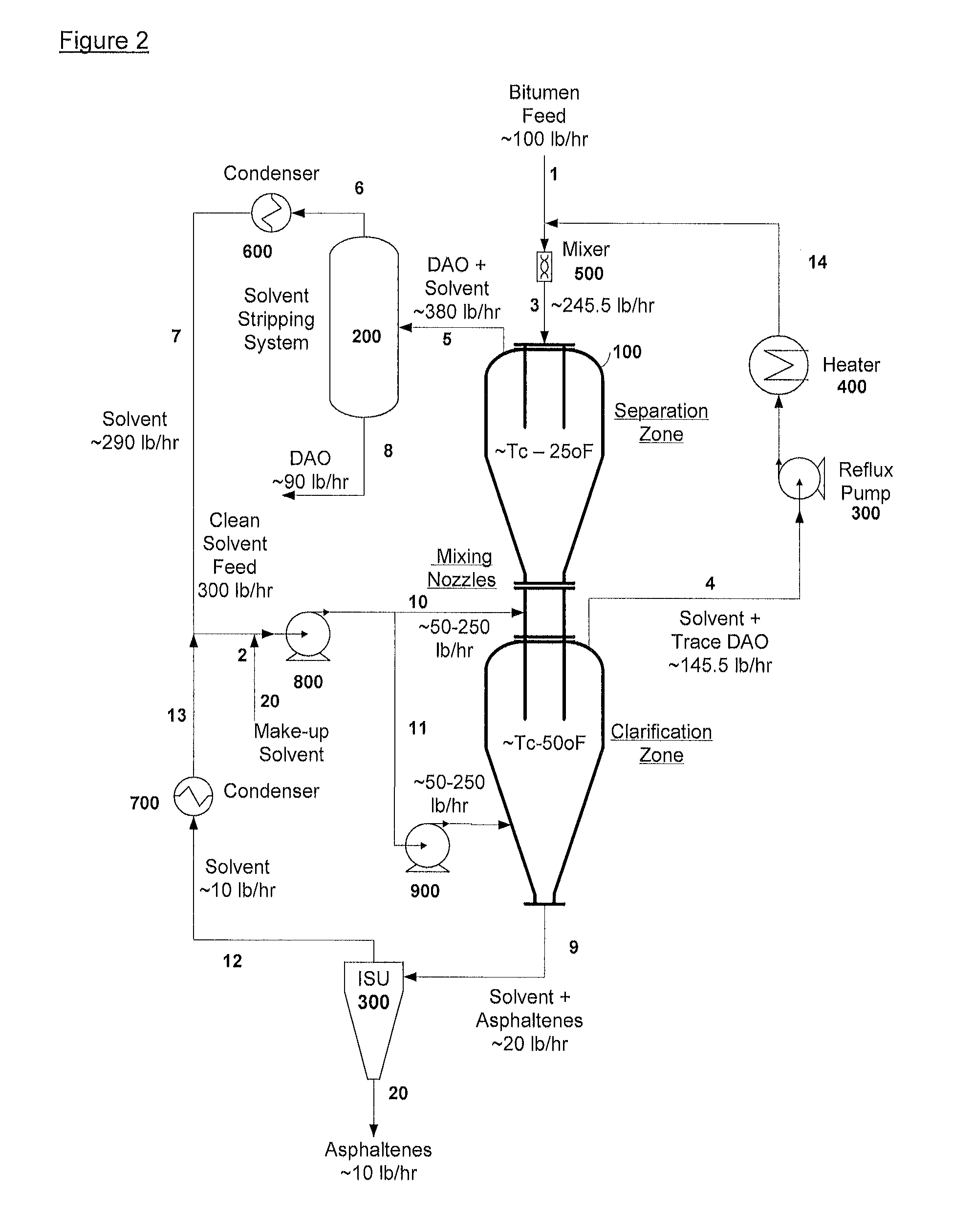

Separation of solid asphaltenes from heavy liquid hydrocarbons using novel apparatus and process ("ias")

ActiveUS20140246357A1Reduce pluggingMitigate settlingWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionLiquid hydrocarbonsEngineering

An apparatus and process is provided for improved asphaltene separation from heavy hydrocarbon or bitumen with low process complexity through mass transfer using solvent and counter-current flows, with three sections: an upper DAO / solid-asphaltene separation zone, a middle solvent mixing and segregation zone, and a bottom clarification zone. Solvent mixed with heavy hydrocarbon forms a process feed introduced to the process vessel's upper zone and exposed to counter-current solvent removing DAO from solid asphaltene particles in the feed, the particles fall through the middle zone and are mixed with introduced solvent, which introduced solvent segregates DAO-rich solution in the upper zone (for extraction from that zone) from solvent-rich mixtures in the middle mixing and lower clarification zones. Solvent flows and precipitate movement are controlled to optimize mass transfer in process, resulting in high DAO recovery and dry, solid asphaltene product.

Owner:SUNCOR ENERGY INC

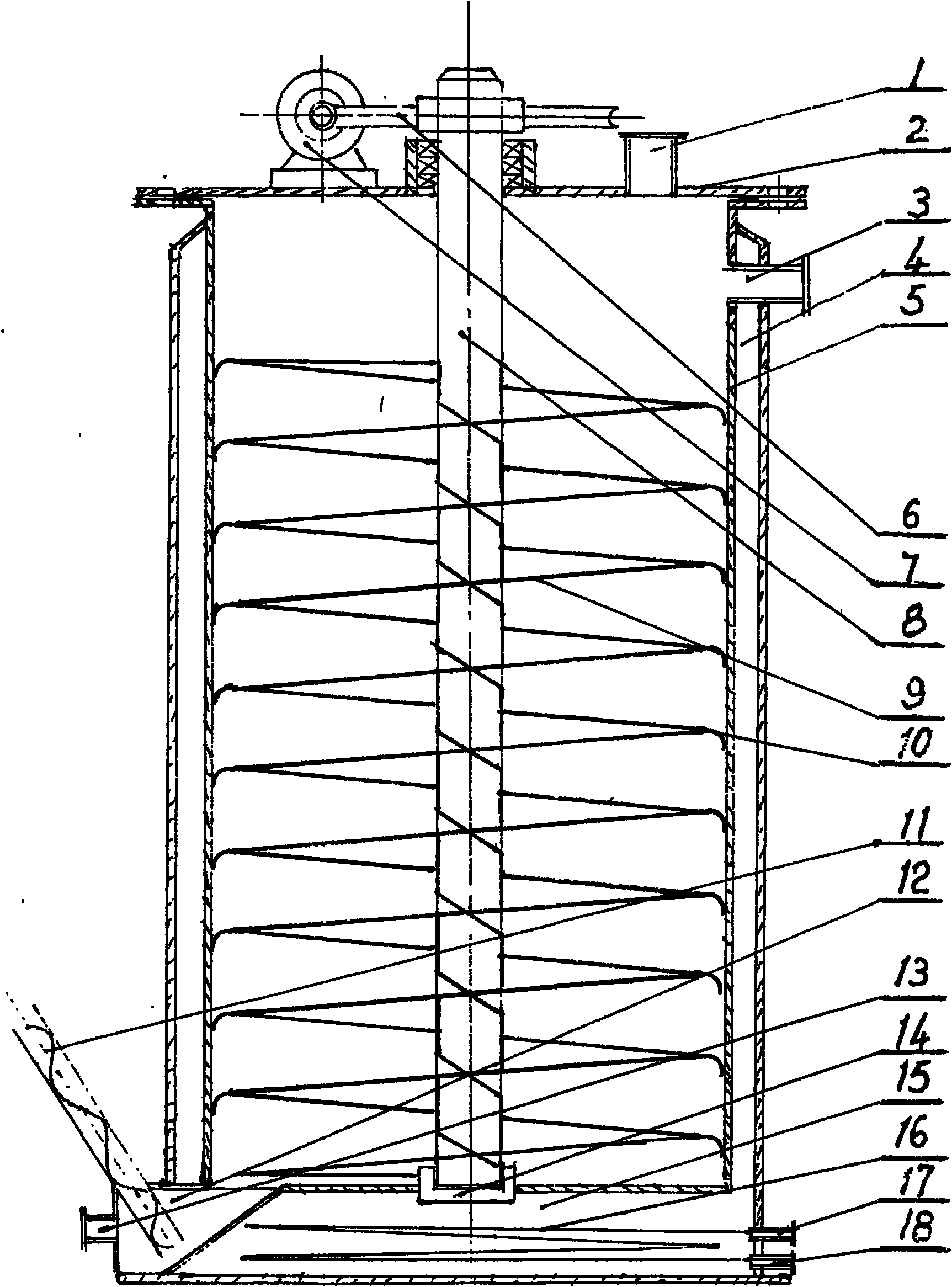

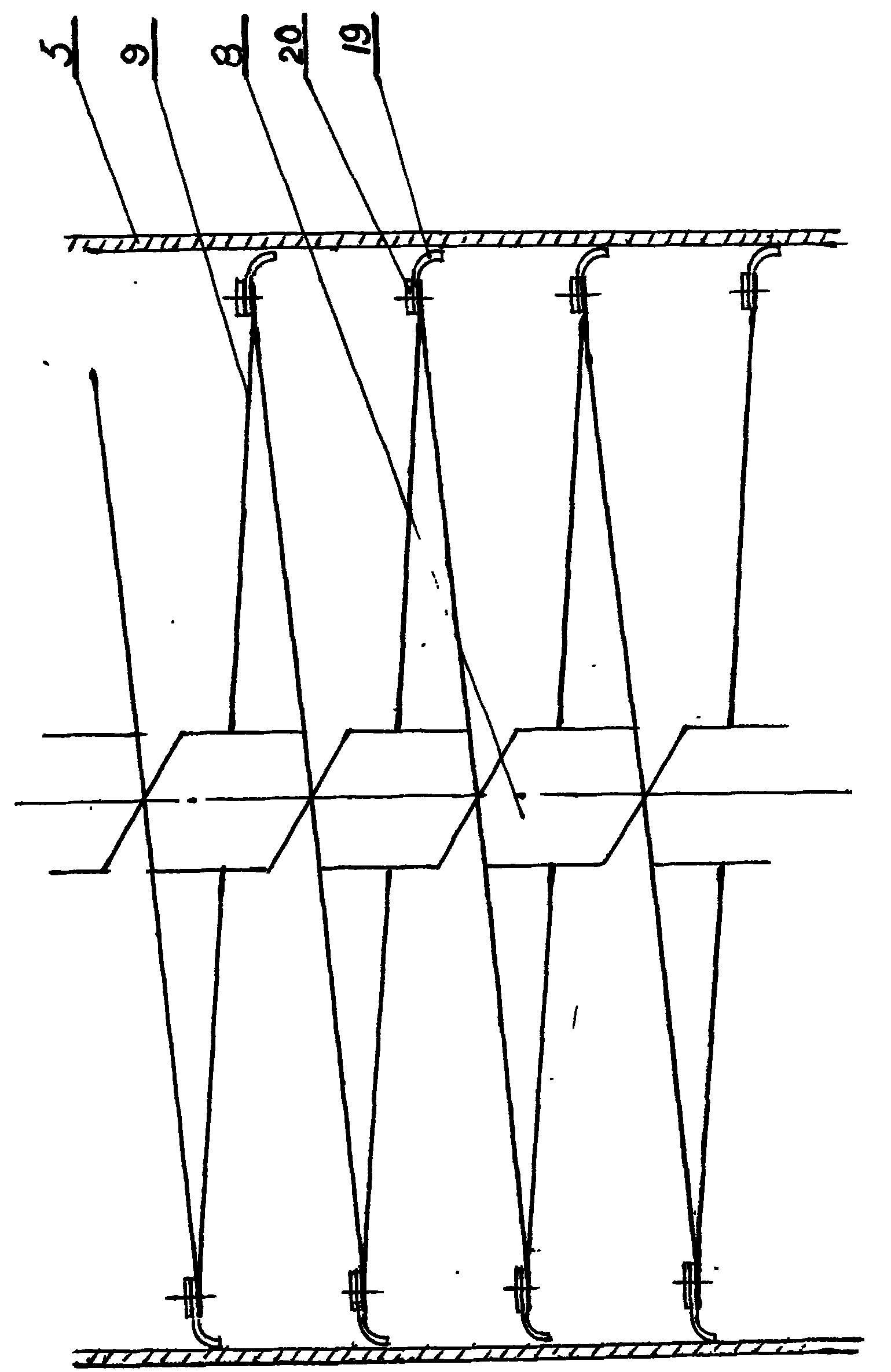

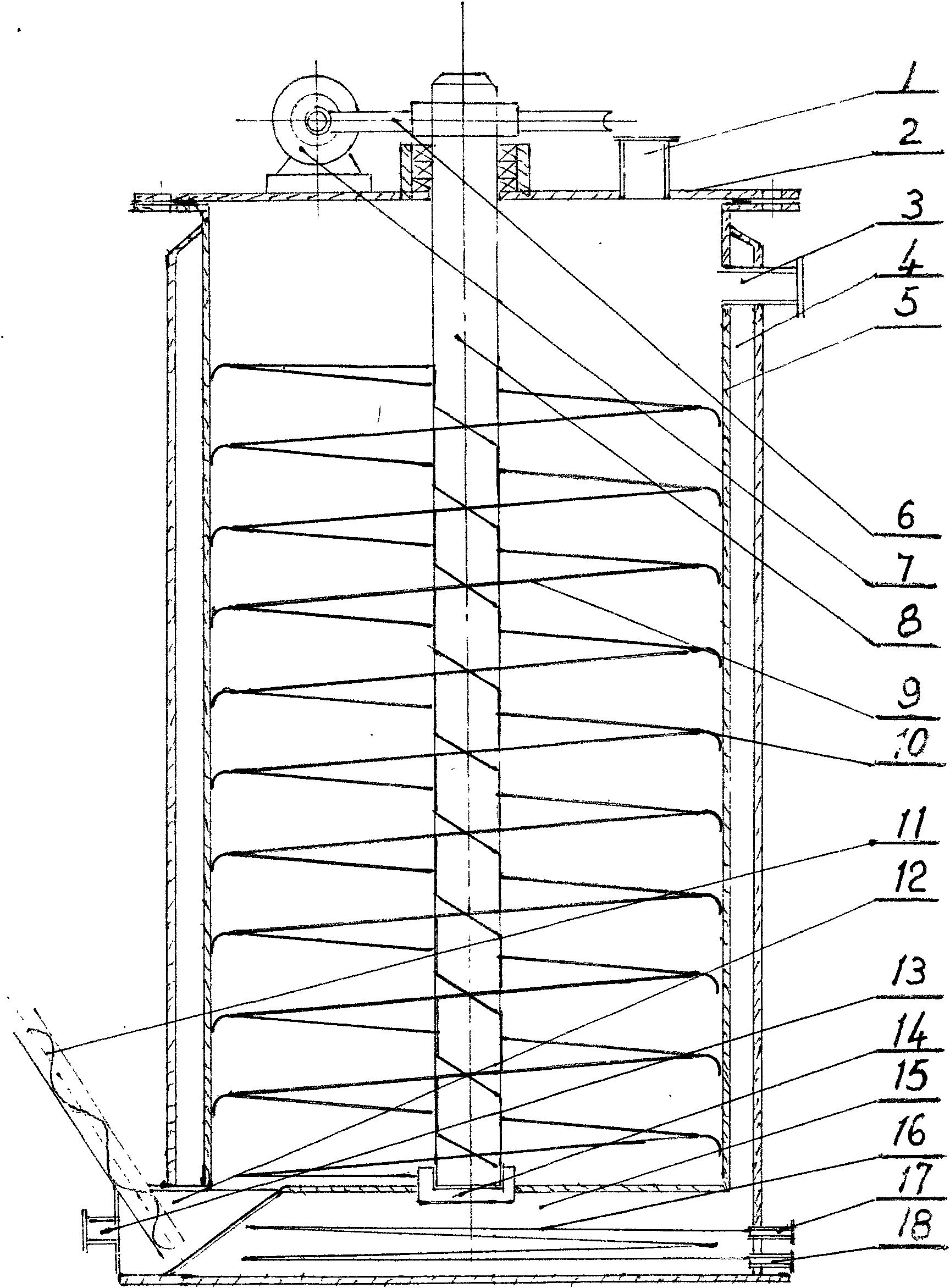

Continuous countercurrent extracting tank

InactiveCN102008835ACompact structureReduce unit consumptionSolid solvent extractionHigh energyEngineering

The invention relates to a continuous countercurrent extracting tank for extracting traditional Chinese medicines, comprising a tank body, a material pushing spiral conveyor, a driver, a medicinal material inlet, an extracting solution overflowing outlet, a solvent inlet, a decoction dreg slot, a spiral dreg discharging machine and the like, wherein the driver drives the material pushing spiral conveyor to rotate towards one direction and push medicines to move from top to bottom along the spiral conveyor, a solvent flows opposite to the medicinal materials from the bottom, decoction dregs are airtightly discharged out of a chamber by the spiral dreg discharging machine, the outer edge of the material pushing spiral conveyor is provided with a flexible non-return seal, and the volume of the tank body is partitioned into a continuous and long spiral strip-shaped space by the material pushing spiral conveyor, thereby creating conditions for the better uniform fluidity, diffusion and osmosis of an extracting solution and the medicines. The technology in the invention can be used for reforming an out-dated multifunctional extracting tank, the material pushing spiral conveyor and corresponding components are additionally arranged in the inane multifunctional extracting tank so that the multifunctional extracting tank with low yield and high energy consumption is reformed into a continuous countercurrent extracting tank with doubly increased yield and greatly reduced energy consumption, thereby playing a better role for the production of the traditional Chinese medicines after the reformation.

Owner:沈善明

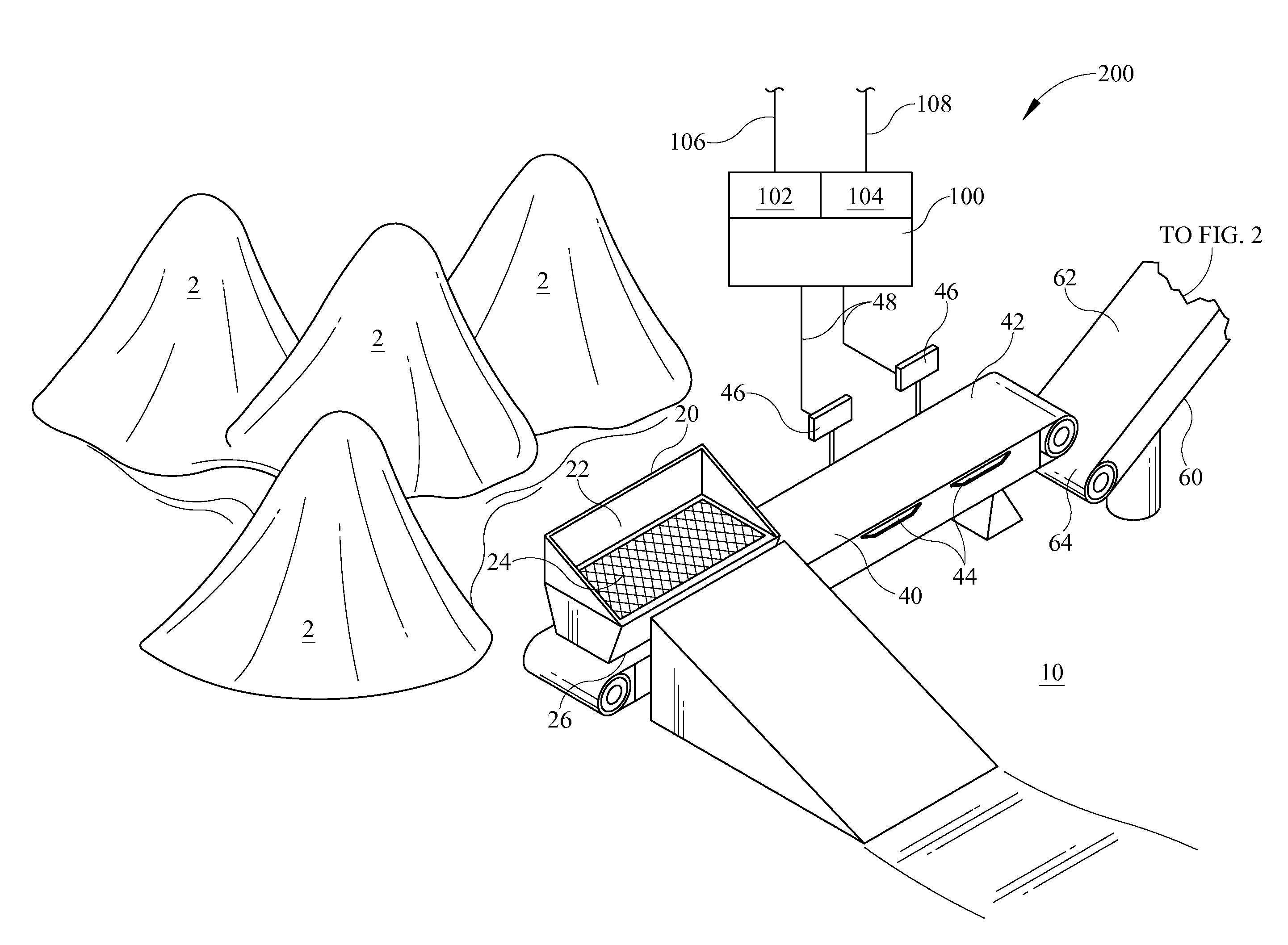

System and method for extracting bitumen from tar sand

InactiveUS20100236991A1Efficient and cost-effective processMinimal contaminationWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionTarEngineering

An improved system for removing bitumen from tar sands comprises a pre-treatment system utilizing a vibratory load hopper for classifying and sizing said tar sand particles communicating with a dryer for heating and drying said tar sand particles to a predetermined temperature thereby controlling the moisture content of said tar sands. An extraction system is also included for accepting said tar sands from the dryer comprising a plurality of extraction vessels arranged in series for transporting said tar sands from a first extraction vessel to a final extraction vessel. Furthermore, a solvent system for supplying a predetermined volume of solvent flow through said extraction vessels is employed, whereby solvent is supplied to the last extraction vessel and a solvent and bitumen mixture is withdrawn from the first extraction vessel.

Owner:CHAN LILA HAU YUK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com