Apparatus for non-contact cleaning a paint spray tip

a technology of spray tip and cleaning apparatus, which is applied in the direction of cleaning using liquids, burners, combustion types, etc., can solve the problems of uneven spraying of paint, dripping paint, other aesthetic defects, etc., and achieve the effect of fast drying and complete spraying tip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

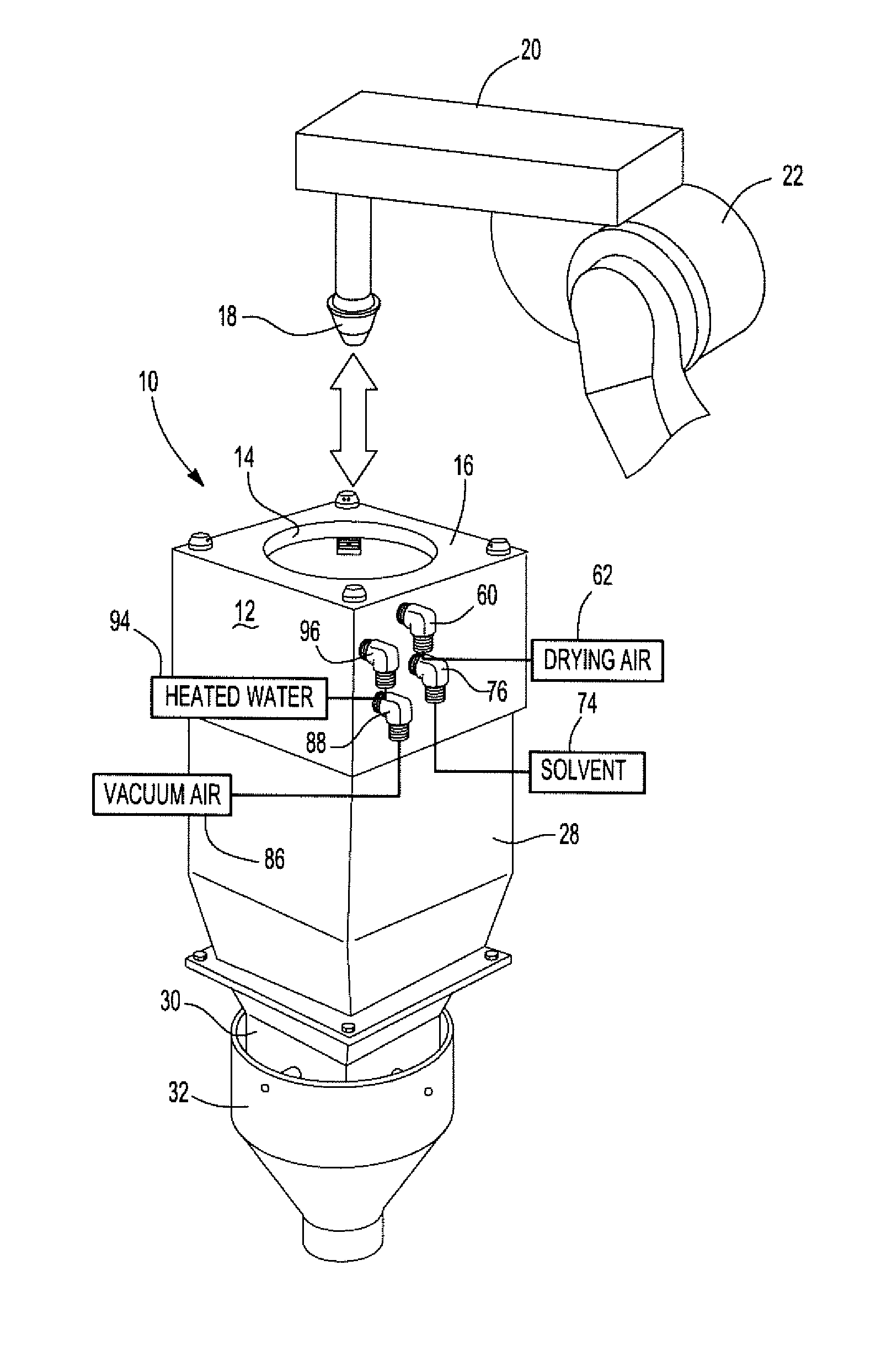

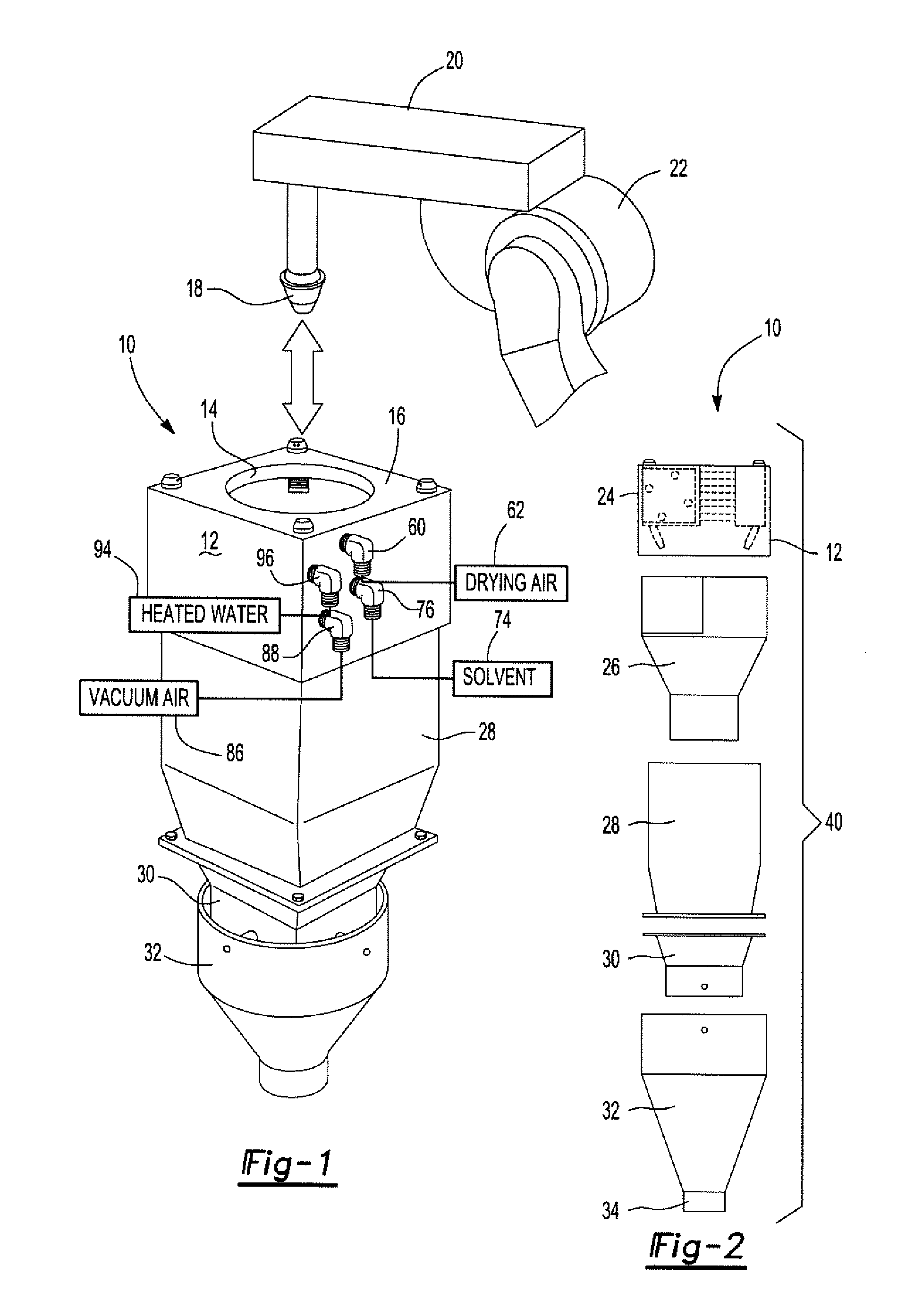

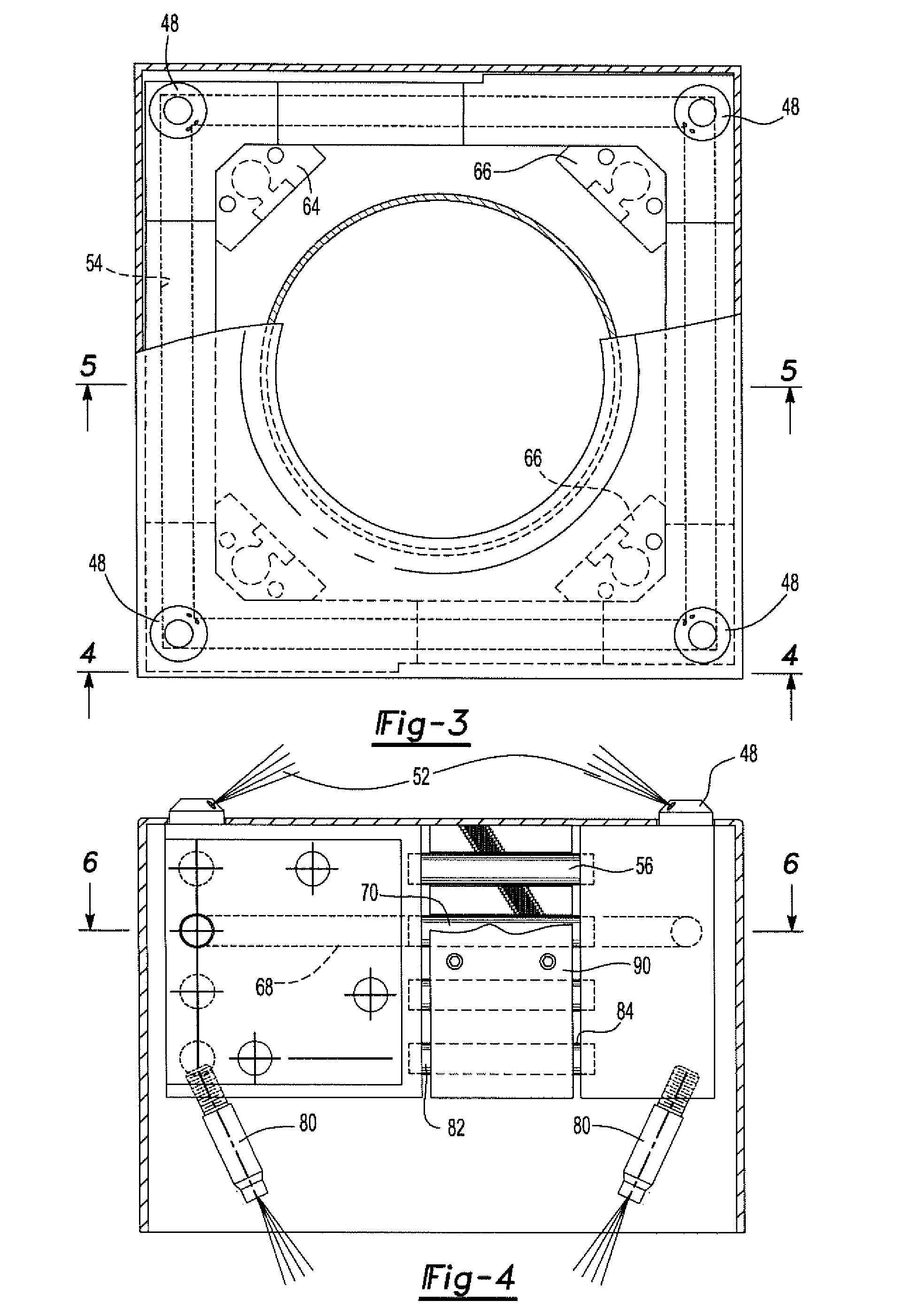

[0023]With reference first to FIGS. 1 and 2, a preferred embodiment of a non-contact cleaning apparatus 10 according to the present invention is shown. The apparatus 10 includes a housing 12 which is constructed from any appropriate material, such as sheet metal. The housing 12 includes a generally circular opening 14 in its top 16. This opening 14, furthermore, is dimensioned to receive a spray tip 18 of a paint spray gun 20, typically manipulated by a robot 22 (only partially illustrated).

[0024]Still referring to FIGS. 1 and 2, the housing 12 preferably includes a plurality of housing sections, including a top section 24 as well as lower housing sections 26, 28, 30, and 32. These housing sections 24-32 are secured together in any appropriate fashion, such as by bolts. In addition, the housing sections 24-32 all include a vertically open passageway so that the solvent may be collected and recycled or disposed of. The air flows through the opening 14 in the top housing section 24, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com