Method for extracting mesitylene fraction rich in hydrocracking C 9 by combination of continuous lateral line distillation and extractive distillation

A technology of hydrocracking and extractive rectification, which is applied in the field of continuous side-line rectification and extractive rectification combined with extraction and hydrocracking of C9 rich in trimethylbenzene, can solve complex organic reactions, poor economic indicators, difficult matching of catalysts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

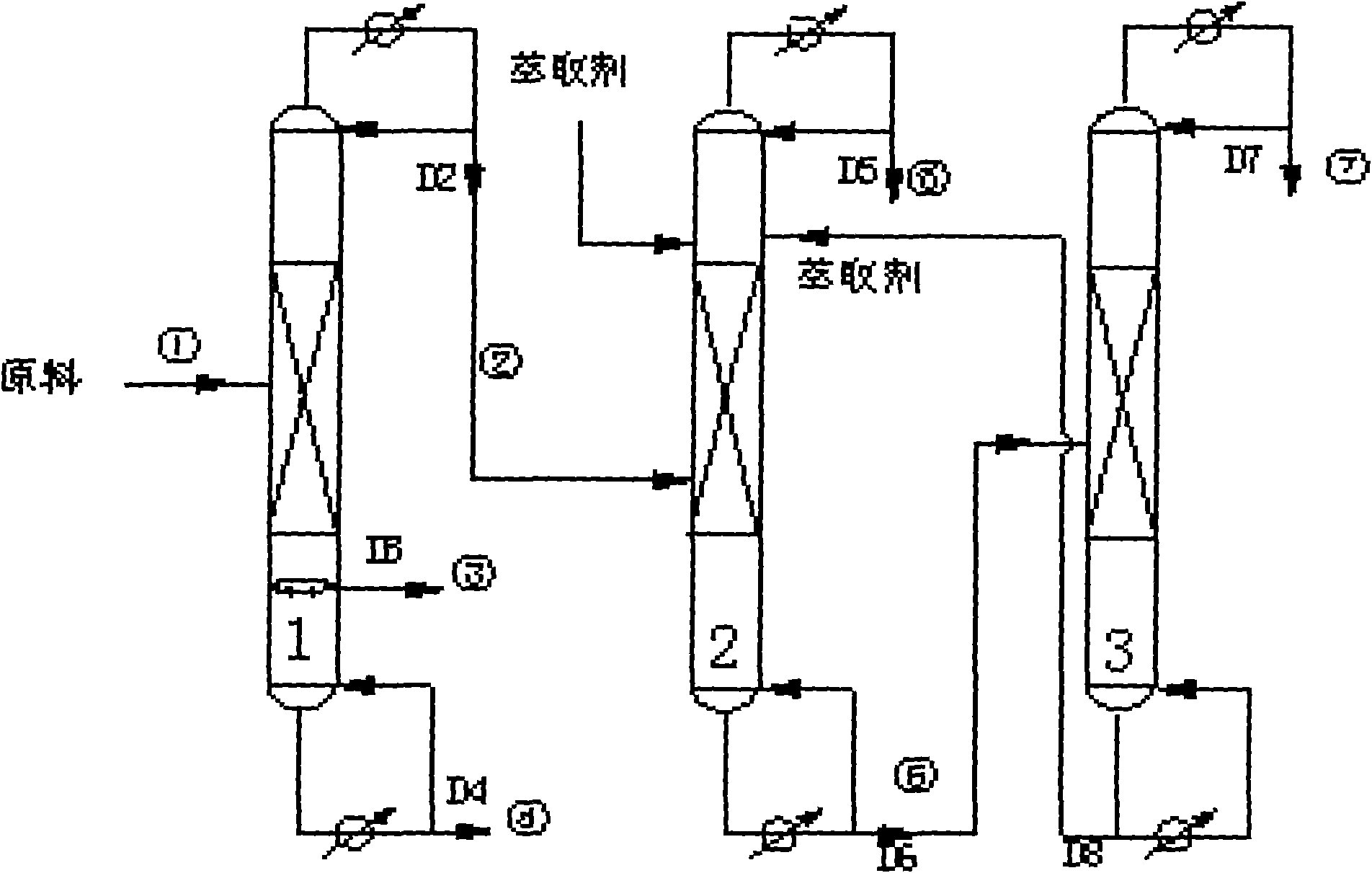

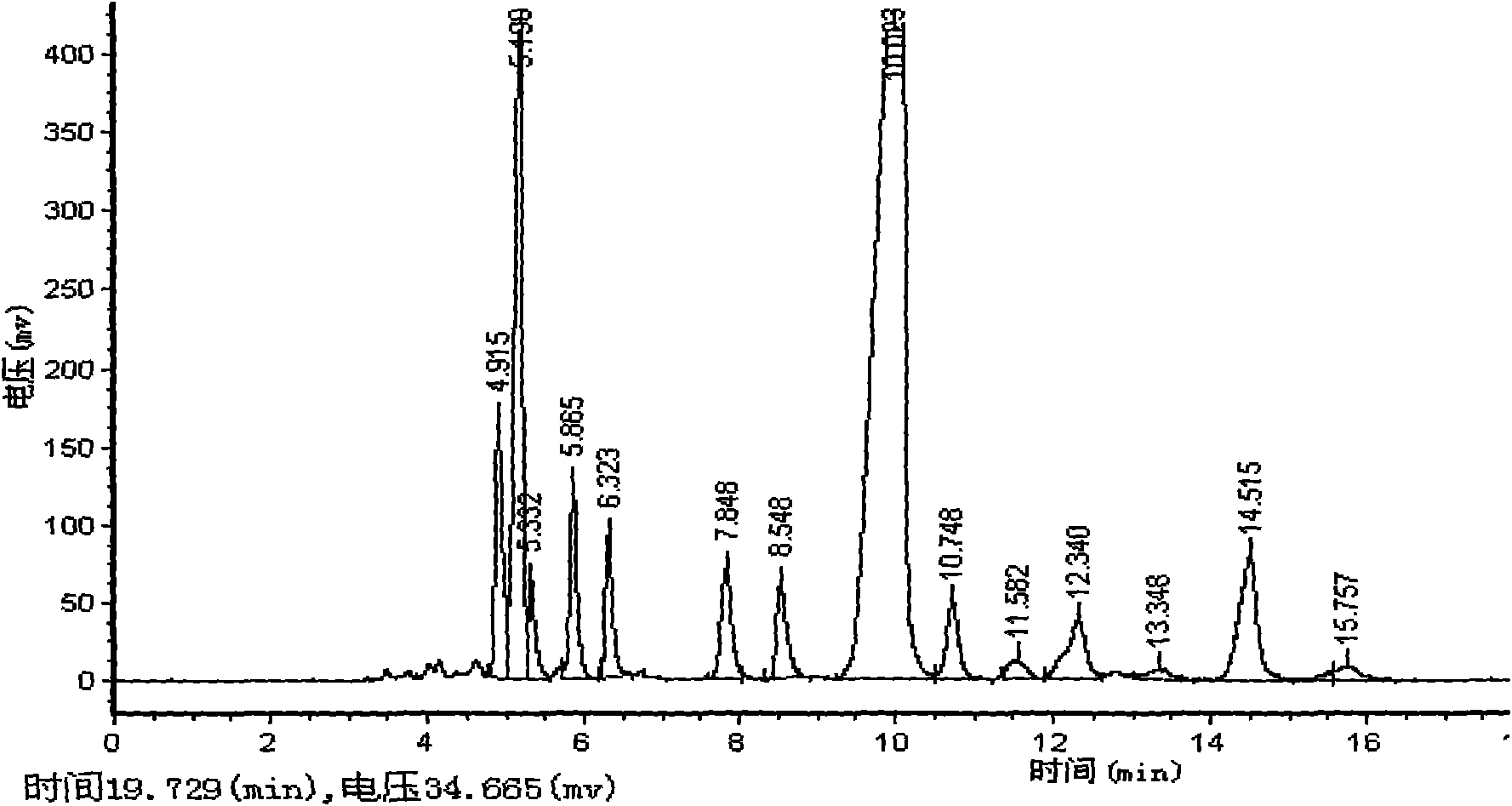

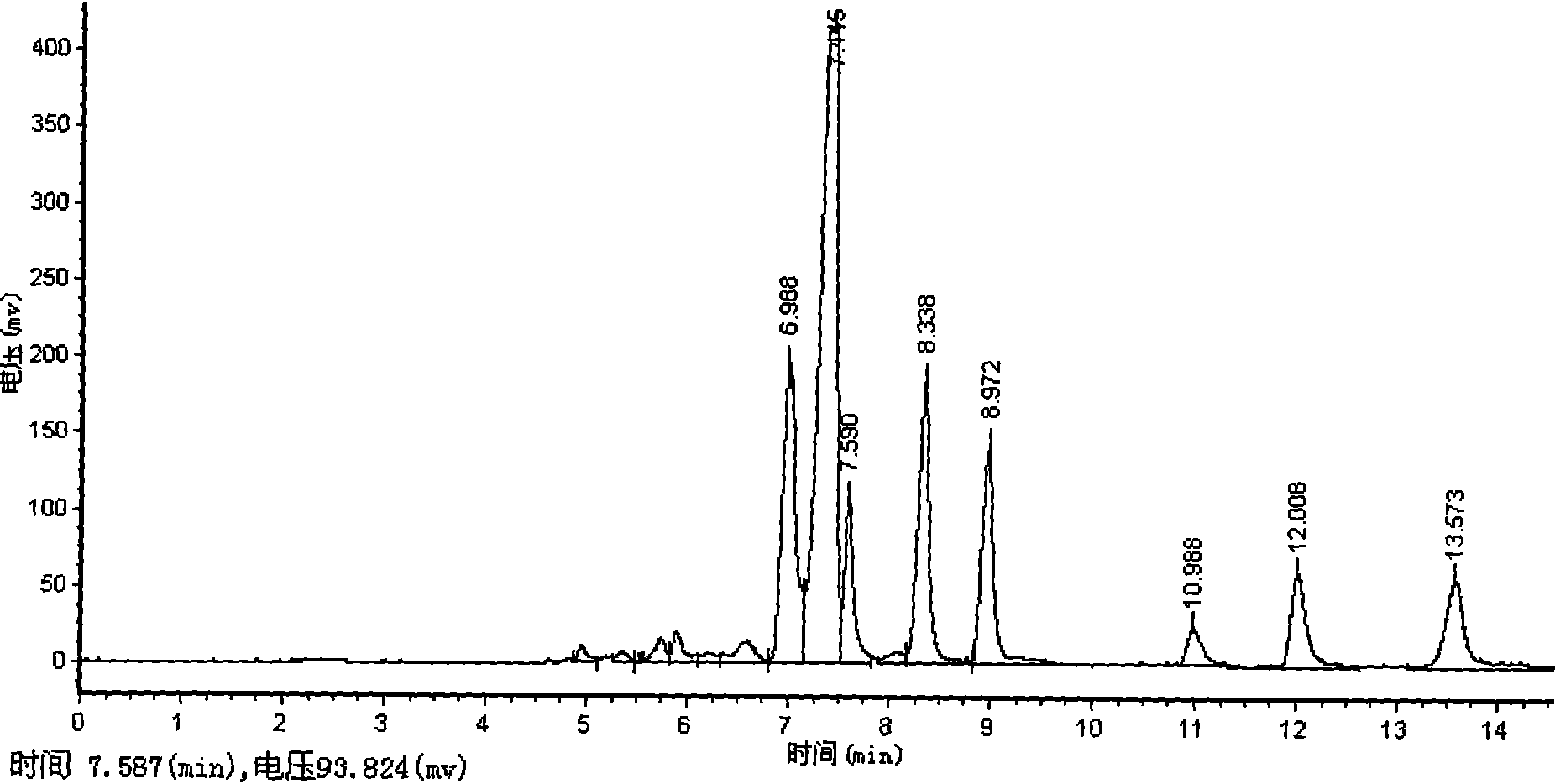

Embodiment 1

[0029] Example 1, continuous side line rectification and extractive rectification are combined to extract trimethylbenzene-rich fractions, and the inner diameter of each tower is 22cm, using Type stainless steel packing, measured by the standard system, the plate height of the packing is HETP=27mm, the tower kettle is heated by a pressure regulator to control the resistance wire, and the quantitative and qualitative analysis is carried out by gas-mass chromatography. Hydrocracking C 9 Aromatics raw material ① enters the continuous side stream rectification tower, cuts off the heavy aromatics fraction, controls the feed rate to 2ml / min, and the output volume is D 2 、D 3 and D 4 0.5ml / min, 0.5ml / min and 1.0ml / min respectively, the temperature at the top of the tower is 162.5-163.5°C, the temperature at the bottom of the tower is 200-202°C, the reflux ratio is 3-4, the number of theoretical plates is 45, and the feed The position is at 25 trays, the trimethylbenzene-rich dist...

Embodiment 2

[0030] Embodiment 2 is substantially the same as Example 1, but the extraction solvent in the (2) step is a composite extraction solvent of dibutyl phthalate and aniline, the volume ratio of dibutyl phthalate and aniline 1: 0.8; the volume ratio of the composite extraction solvent to the extractive distillation tower feedstock is 1: 0.8.

Embodiment 3

[0031] Embodiment 3 is substantially the same as Example 1, but the extraction solvent in the (2) step is a composite extraction solvent of dibutyl phthalate and aniline, the volume ratio of dibutyl phthalate and aniline It is 1: 1.2; The volume ratio of the compound extraction solvent and the raw material feed amount of the extractive distillation column is 1: 1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com