Patents

Literature

60results about How to "Reduce plugging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

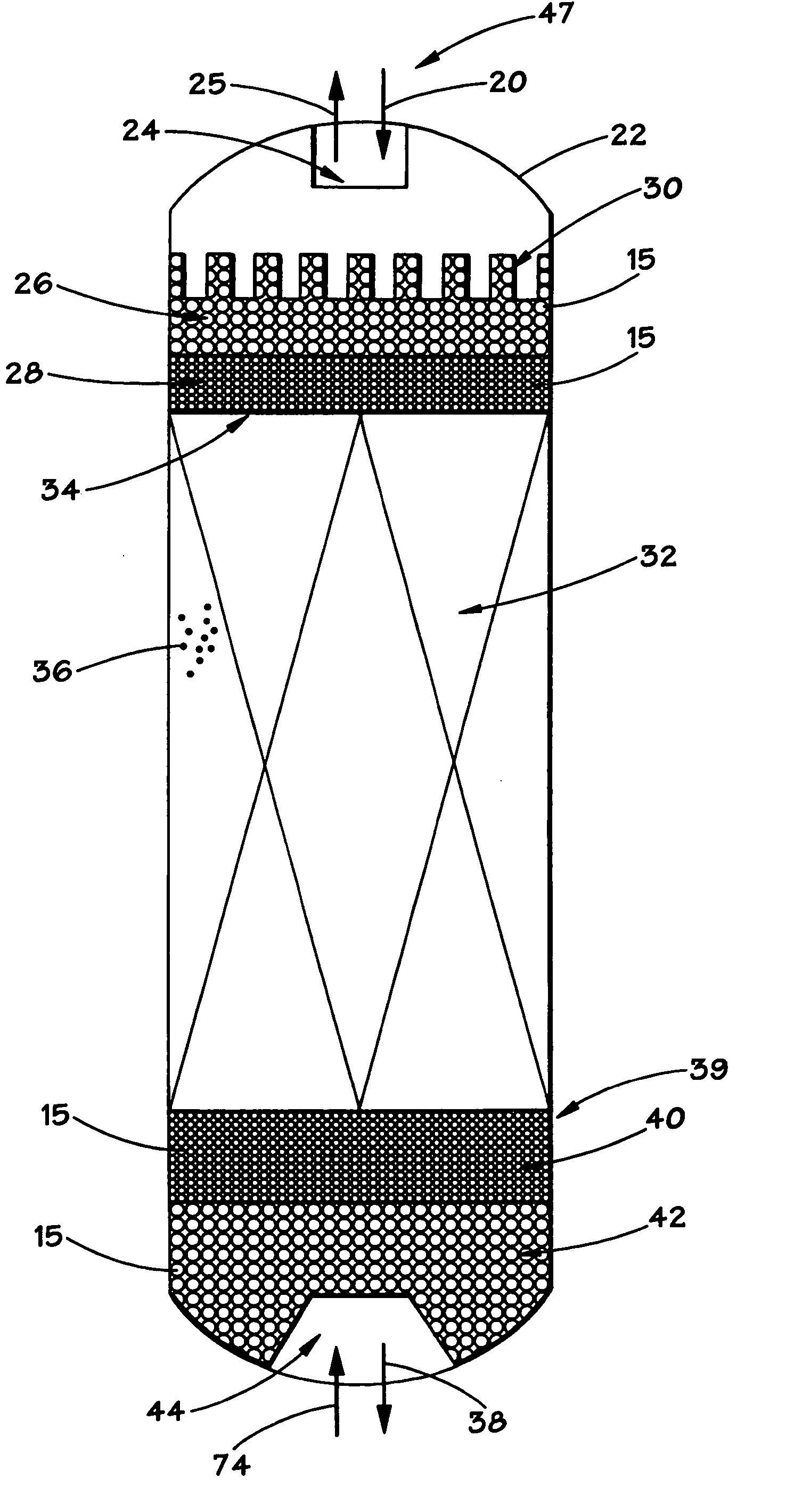

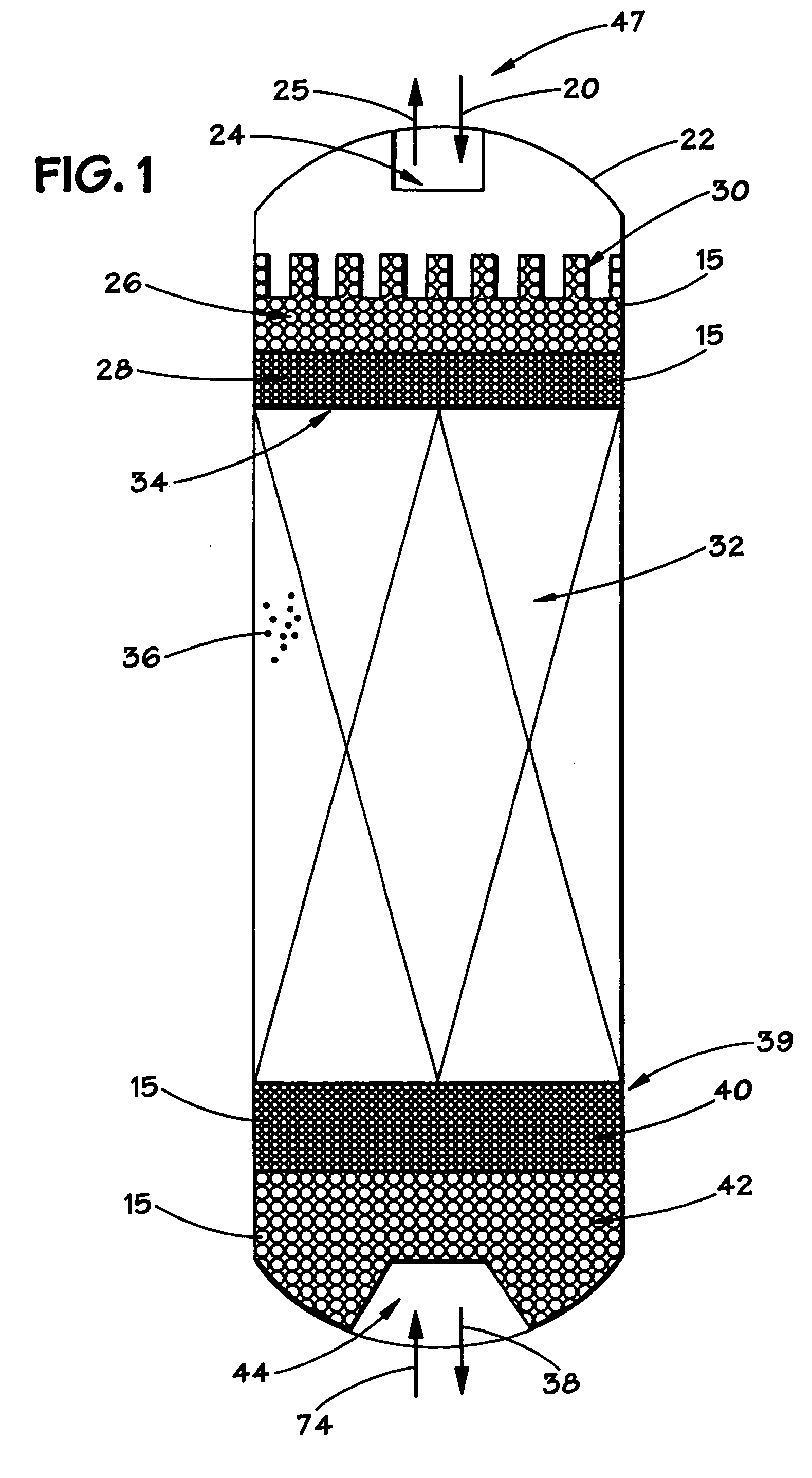

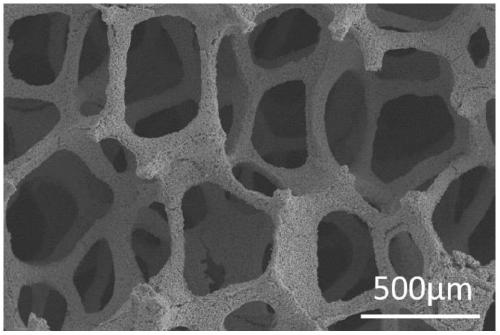

Filtration, flow distribution and catalytic method for process streams

ActiveUS20040192862A1Increased operating lifeExtended run timeDispersed particle filtrationMembrane filtersProcess equipmentCatalytic method

A method for removing contaminants from an process stream that includes the use of reticulated material to filter the process stream. The reticulated material also facilitate process stream flow distribution in process units. The reticulated material can be packed with a void space between a substantial number of the reticulated material that can be varied to enhance filtration and flow distribution. The method of filtering also provides a method of removing contaminants leaving process equipment. The methods can be used on a variety of process streams and process equipment. The reticulated material can include ceramics, metallic materials, and chemical vapor deposition elements. The reticulated material can be of various shapes and sizes, and can also be catalytically active.

Owner:CRYSTAPHASE PRODS

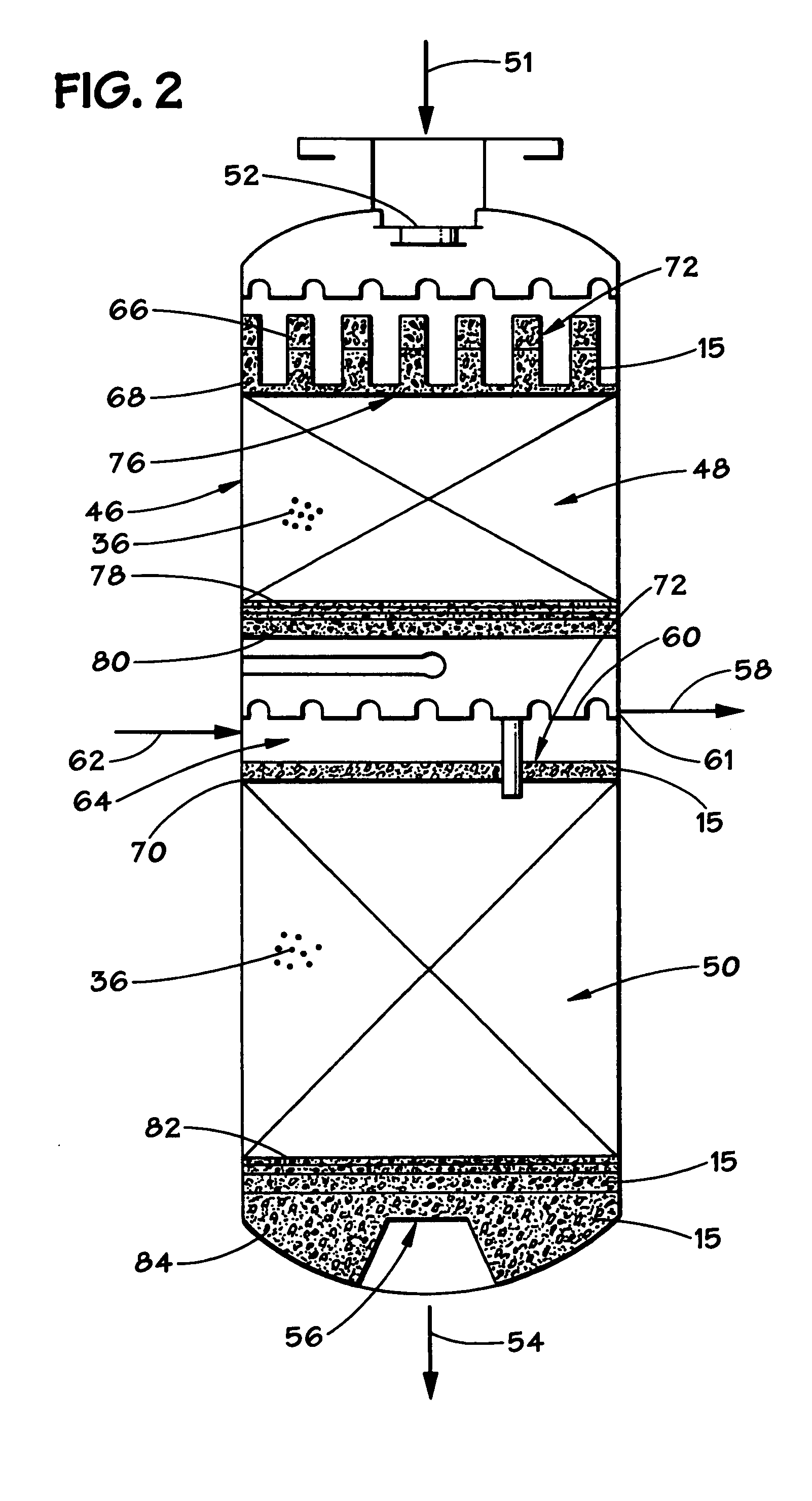

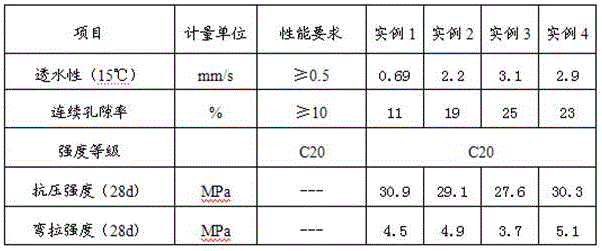

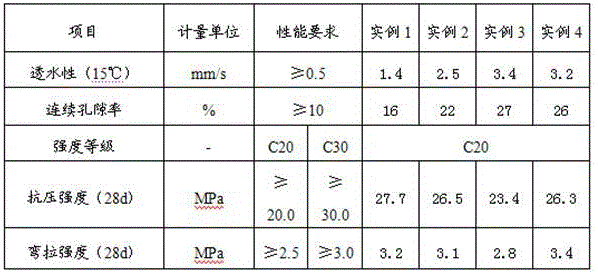

Long-acting high-permeability pervious concrete

The invention provides long-acting high-permeability pervious concrete which has a long-term high permeable rate and a high anti-clogging rate. The pervious concrete comprises the following components in percentage by weight: 12-15% of ash concrete, 75-80% of a coarse aggregate, 5-10% of a water corrosion inhibitor, 1-2% of an active admixture, 0.3-0.5% of re-dispersible emulsion powder, 0.01-0.02% of cellulose ether and 0.2-0.3% of a water reducer, wherein the water corrosion inhibitor is prepared by uniformly mixing granular alum of which the particle size is 5-8mm and silicon phosphorus crystals according to a ratio of 1:(2-4) and then uniformly spraying a mixture of VAE emulsion, cement and water on particle surfaces, and the coarse aggregate is broken stones of which the particle size is 5-15mm. The pervious concrete provided by the invention adopts the combination of the water corrosion inhibitor and meta-kaolin to replace part of the coarse aggregate and cement so as to ensure the strength that the concrete should have, and utilizes the composition of the alum and silicon phosphorus crystals which greatly differ in water solubility as a corrosion inhibitor, and obtains a high initial porosity and a lasting pervious effect by virtue of the combination of rapid dissolution of the album and slow dissolution of the silicon phosphorus crystals.

Owner:广东龙湖科技股份有限公司

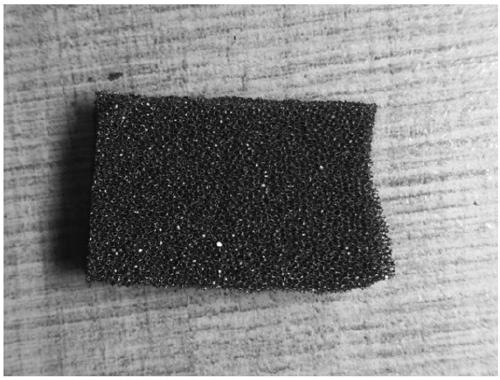

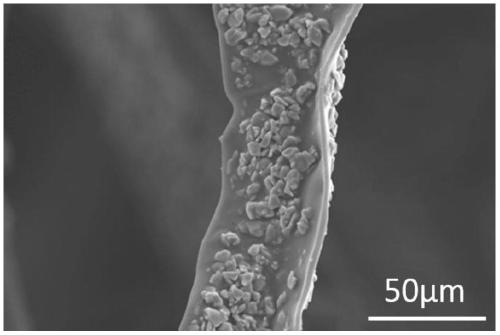

High-strength silicon carbide foam ceramic and one-time pulp hanging carburizing sintering preparation method thereof

The invention discloses high-strength silicon carbide foam ceramic and a one-time pulp hanging carburizing sintering preparation method thereof, and belongs to the technical field of silicon carbide foam ceramic preparation. The method comprises the steps that foamed plastic serves as a template, a one-time pulp hanging carburizing sintering method is adopted, high-char polymer resin, silicon powder, sintering aids and ethyl alcohol are mixed to be prepared into pulp with certain viscosity, the foamed plastic is immersed in the pulp and then taken out, then surplus pulp is removed through a centrifugal method, drying is conducted in the shade, and then pulp hanging is repeated until the needed volume fraction is reached; a foam precursor obtained after pulp hanging is put into a tubular furnace to be subjected to pyrolysis carbonization in a nitrogen or argon atmosphere, a foam ceramic carbon precursor framework formed by pyrolytic carbon, the silicon powder and the sintering aids is obtained, the foam ceramic carbon precursor framework is put in an atmosphere furnace to be sintered, and the high-strength SiC foam ceramic is obtained. Compared with a traditional template method, the method is simple in technology, mild in reaction condition, low in equipment requirement and capable of achieving large-scale production easily.

Owner:XI AN JIAOTONG UNIV

Method for strengthening regional gas extraction through hydro-thermal coupling fracturing

InactiveCN105114116ASolve hydrothermal coupled fracturingRealize hydrothermal coupled fracturingFluid removalGas removalIsoetes triquetraHydraulic fracturing

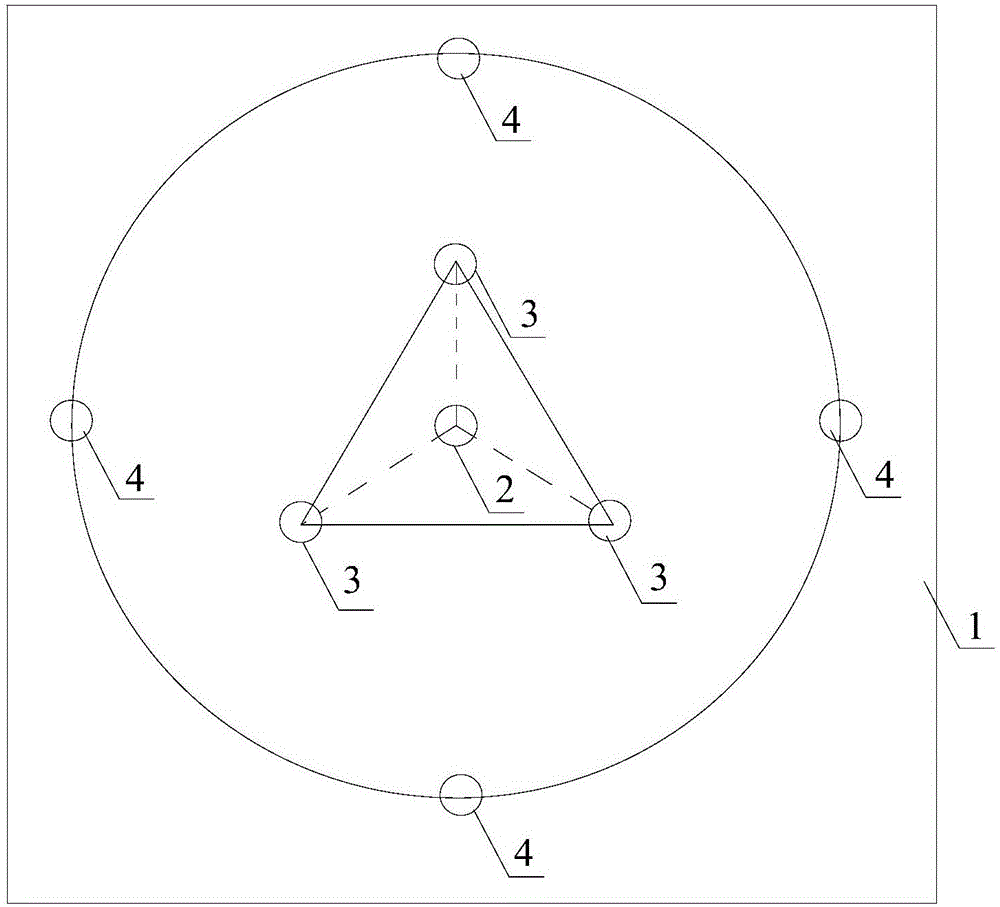

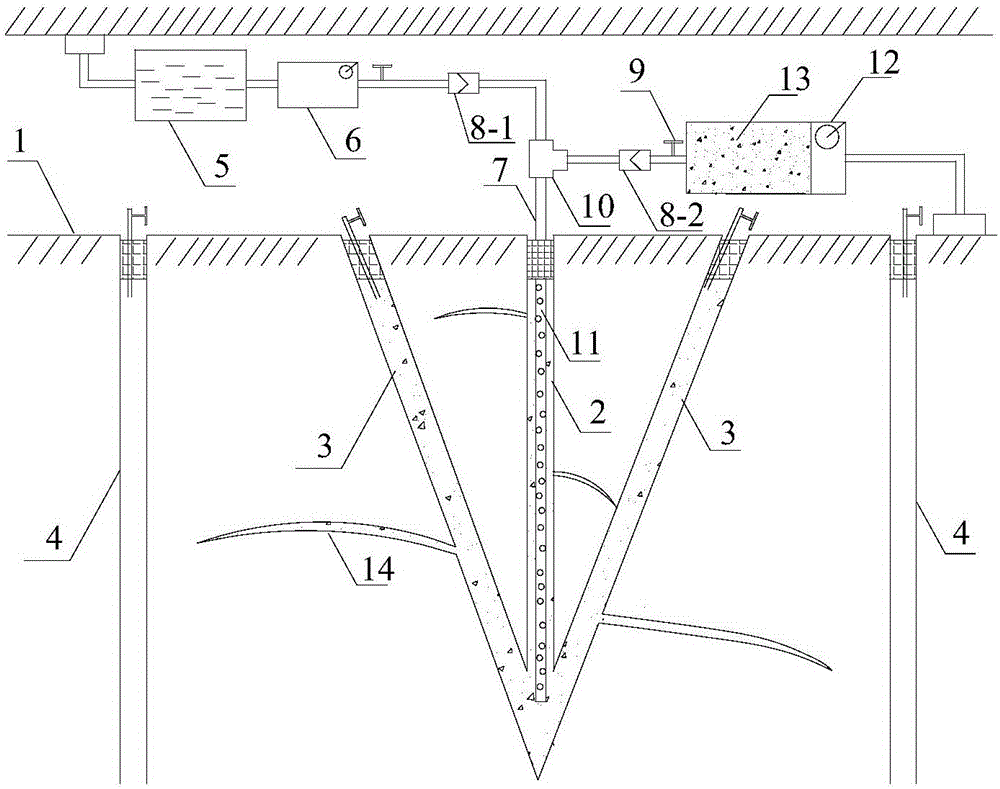

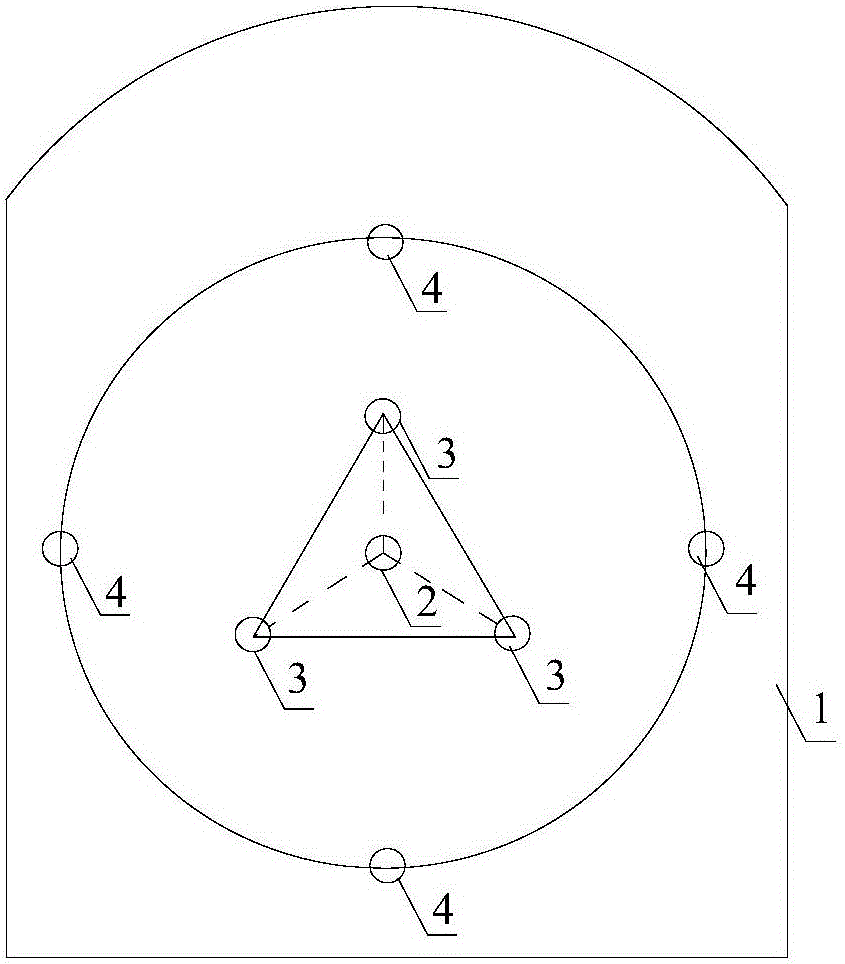

The invention discloses a method for strengthening regional gas extraction through hydro-thermal coupling fracturing. The method comprises steps as follows: firstly, a main fracturing hole, branch fracturing holes and lead holes are sequentially formed in a coal seam roadway through construction, the main fracturing hole is formed in the central position of an equilateral triangle, the opening positions of the branch fracturing holes are distributed at three vertexes of the equilateral triangle separately, the borehole bottom locations of the branch fracturing holes are converged in a center line of the equilateral triangle, the lead holes are located in a circle with the main fracturing hole serving as a center of the circle, and the radius of the circle is 5-15 m; fracturing equipment comprises water injection equipment and a powder injection device, and the water injection comprises an intelligent water tank and a fracturing pump. Quicklime powder in the powder injection device is injected into the main fracturing hole and the branch fracturing holes through underground air pressure; the water injection equipment performs hydraulic fracturing on the main fracturing hole, the quicklime powder is carried by high-pressure water to enter cracks, meanwhile, the quicklime powder and water have a thermal reaction to generate a large amount of heat, and hydro-thermal coupling fracturing is realized; with the implementation of the method for strengthening the regional gas extraction through the hydro-thermal coupling fracturing, the regions influenced by fracturing are increased, the concentration of extracted gas is increased, the effect is remarkable, and demands of work such as regional gas treatment in a coal mine site and the like are met.

Owner:SHANDONG UNIV OF SCI & TECH

Porous collaborative fracturing and extracting integrated gas extraction method

ActiveCN103397900AFacilitate desorptionFacilitated DiffusionFluid removalGas removalCoalExtraction methods

Disclosed is a porous collaborative fracturing and extracting integrated gas extraction method applicable to gas extraction performed in high-gas low-permeability coal beds. The method includes: firstly, evenly and alternatively constructing a plurality of fracturing pores and gas extraction pores in a lane towards the coal bed according to row-column intervals; secondly, sealing all the fracturing pores according to the requirement of the minimum bearable pressure of 20MPa, and sealing all the gas extraction pores according to a conventional method; thirdly, connecting the gas extraction pores adjacent to the fracturing pores with underground gas extraction pipelines; and fourthly, adopting gas-liquid two-phase flow fracturing media to fracture each fracturing pore one by one, and performing gas extraction on all the gas extraction pores adjacent to the fracturing pore while fracturing so as to achieve porous collaborative fracturing and extracting integrated gas extraction. The method is low in construction cost and good in effect, and has high practicability.

Owner:CHINA UNIV OF MINING & TECH

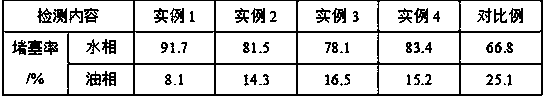

Preparation method of selective water plugging agent

The invention discloses a preparation method of a selective water plugging agent and belongs to the technical field of high molecular materials. The preparation method comprises the following steps: mixing a pre-treated mixed solution and a silane coupling agent according to the mass ratio ranging from (80 to 1) to (100 to 1); adding modified graphene oxide which is 0.03 to 0.09 time of the mass of the pre-treated mixed solution, epoxidized soybean oil which is 0.01 to 0.02 time of the mass of the pre-treated mixed solution and a catalyst which is 0.008 to 0.009 time of the mass of the pre-treated mixed solution; after stirring and mixing, adding an initiator which is 0.01 to 0.03 time of the mass of the pre-treated mixed solution; after stirring and reacting, obtaining a blank mixture; filtering the blank mixture; and washing, drying and crushing to obtain the selective water plugging agent. The selective water plugging agent disclosed by the invention has excellent selective permeability and water plugging performance.

Owner:苏州石为开环保材料科技有限公司

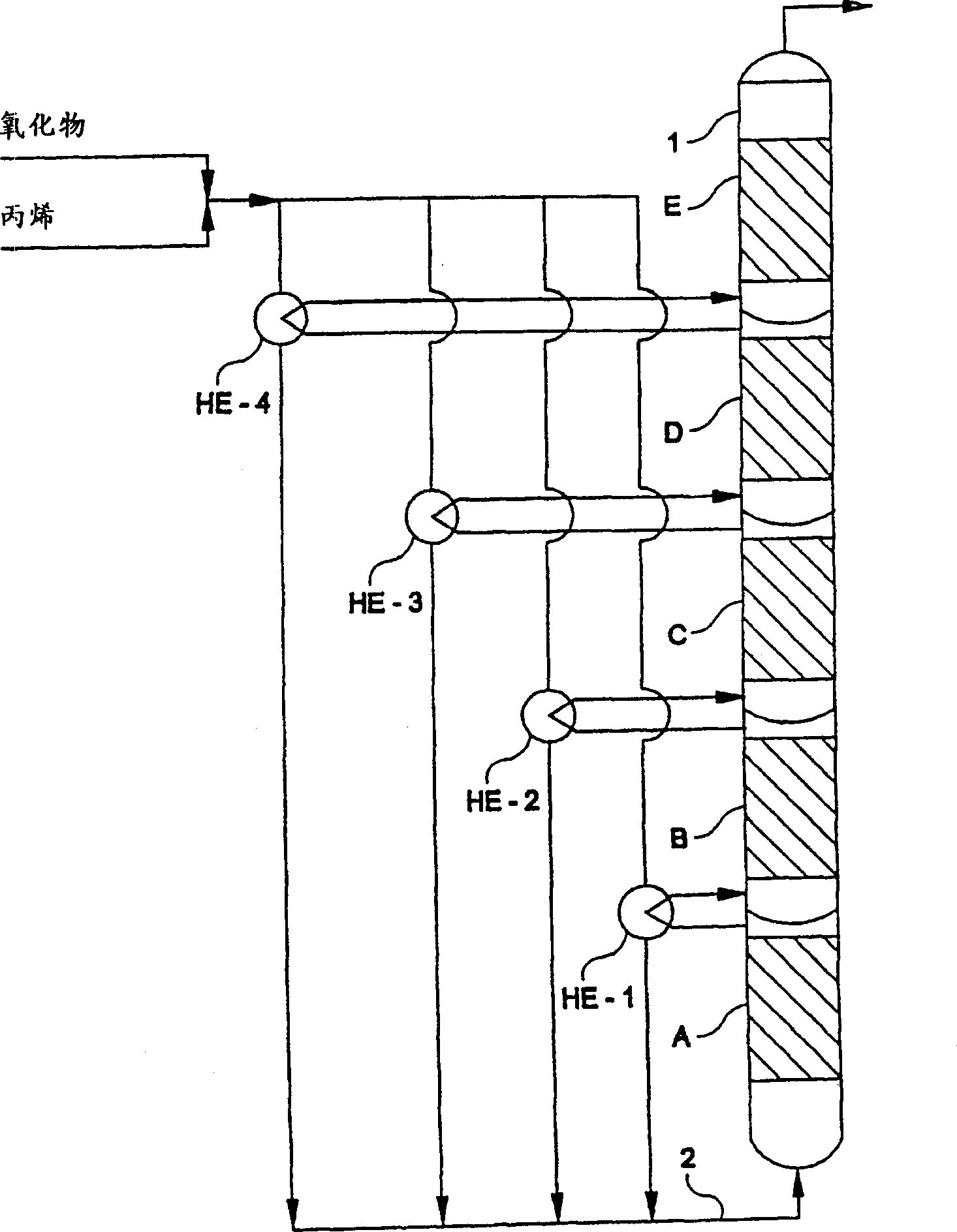

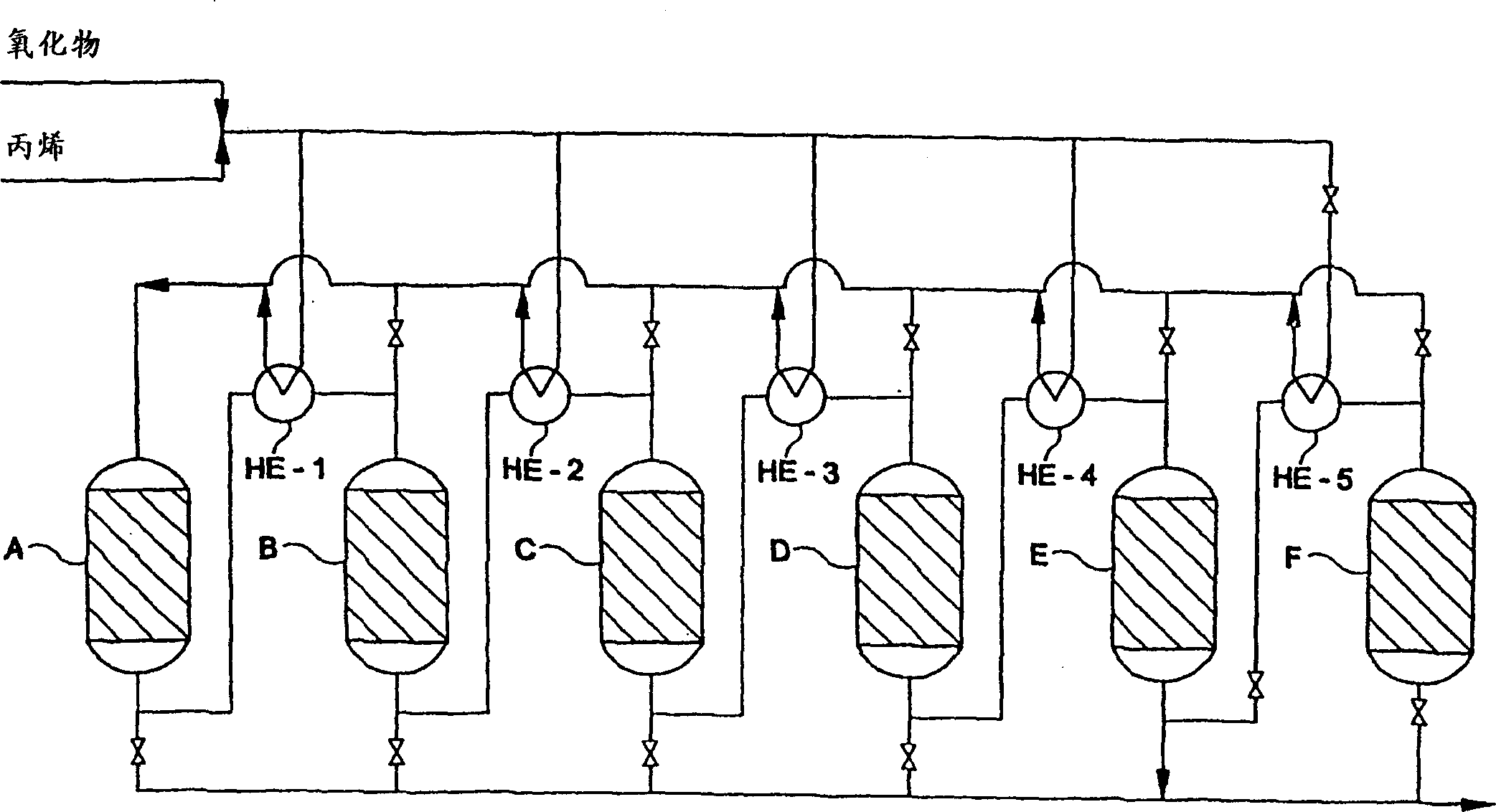

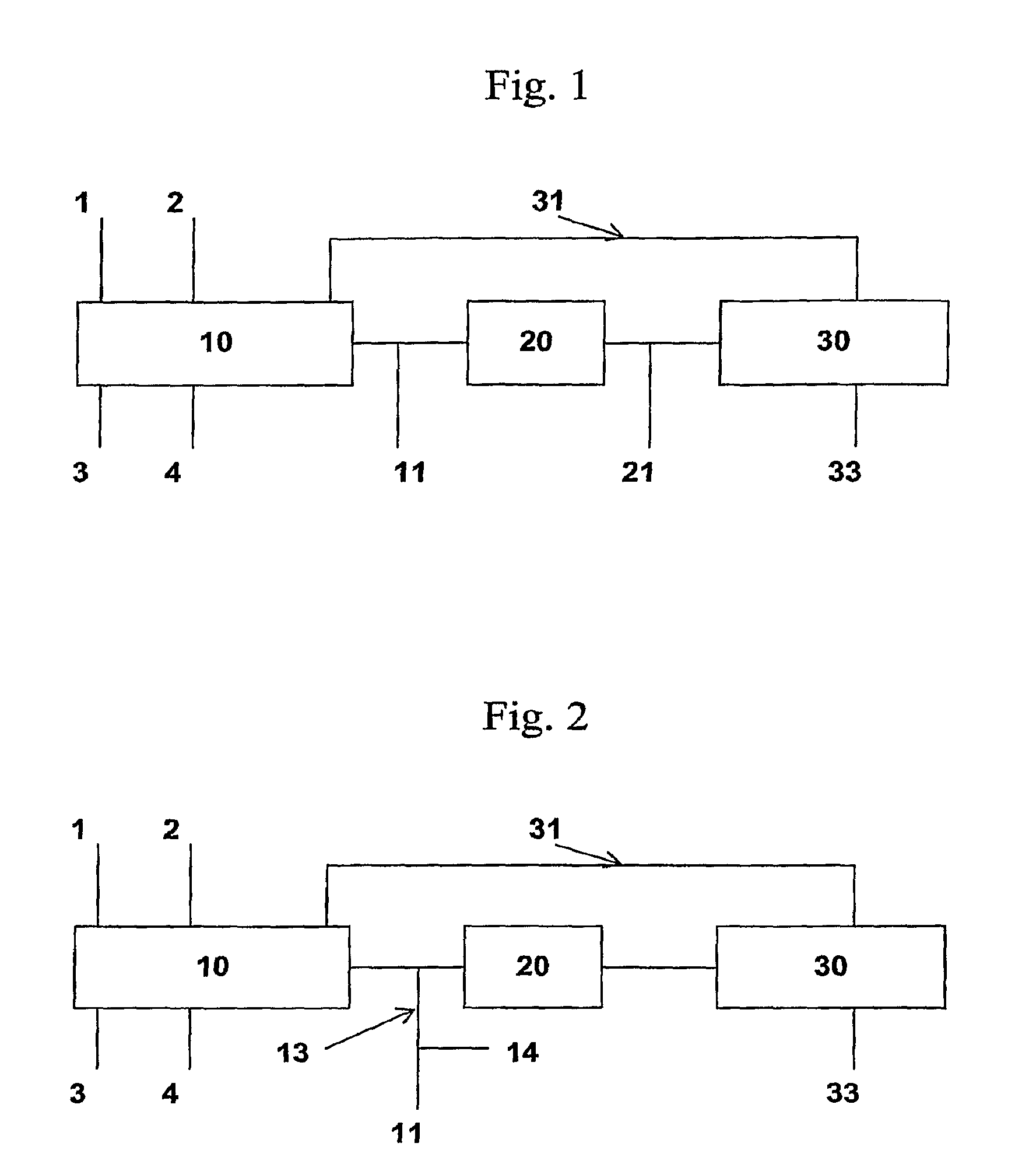

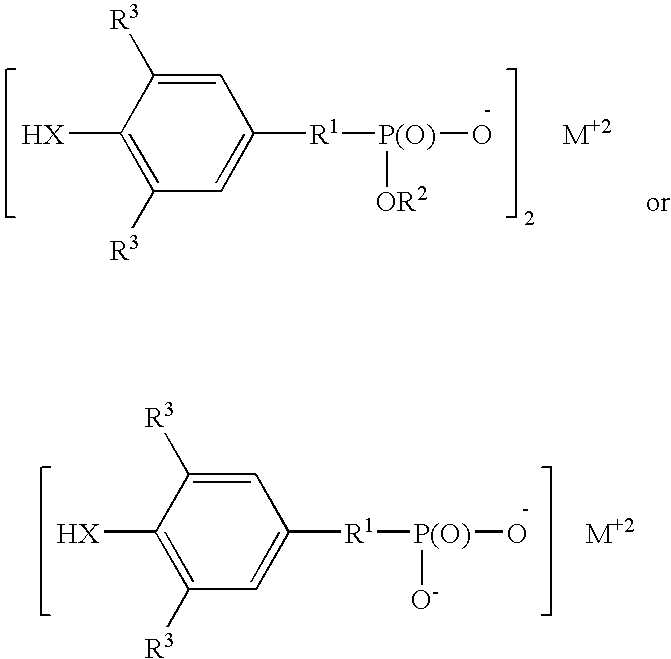

Epoxidation process using serially connected cascade of fixed bed reactors

InactiveCN1282328AIncrease consumptionReduce consumptionOrganic chemistryMolecular sieve catalystsFixed bedOxygen

An olefin epoxidation process is operated using a plurality of reactor vessels, each containing a fixed bed of a heterogenous catalyst such as titania-on-silica. The reactor vessels are connected in series whereby a feedstream comprised of olefin and an active oxygen species is passed through said series of reactor vessels in contact with the heterogenous catalyst to accomplish conversion of the olefin to the corresponding epoxide. As the activity of the catalyst in an individual reactor vessel falls to an undesirably low level, said reactor vessel is taken out of service and a replacement reactor containing fresh or regenerated catalyst introduced. The replacement reactor vessel may, in alternative embodiments of the process, be the first or the last reactor vessel in said series. For example, the feedstream may first be contacted with either the most active or the least active charge of catalyst within the series of reactor vessels. Although the latter embodiment permits somewhat longer catalyst life, the former embodiment requires much smaller capacity heat exchangers. The process of this invention considerably reduces catalyst usage as compared to a conventional fixed bed epoxidation process where all of the catalyst is replaced or regenerated at the same time.

Owner:ARCO CHEM TECH INC

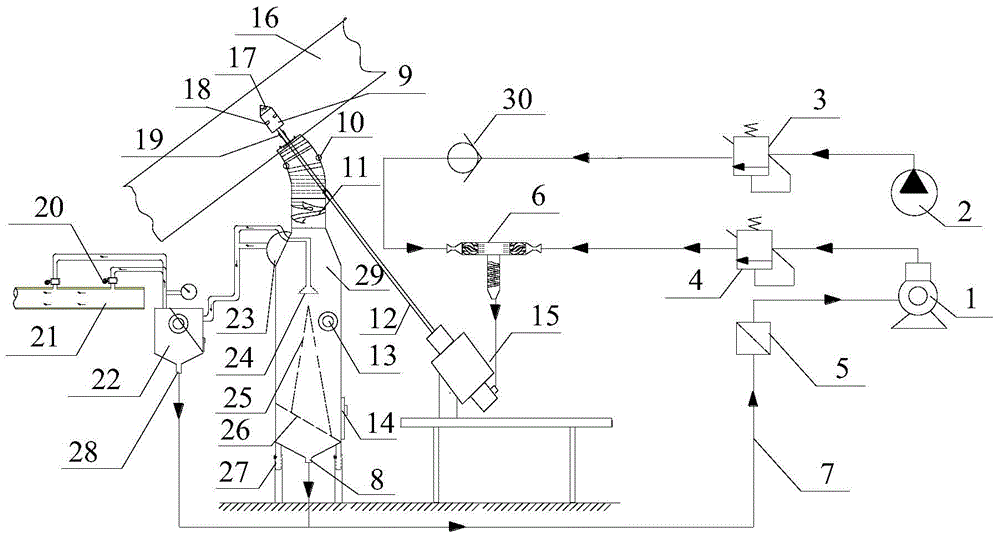

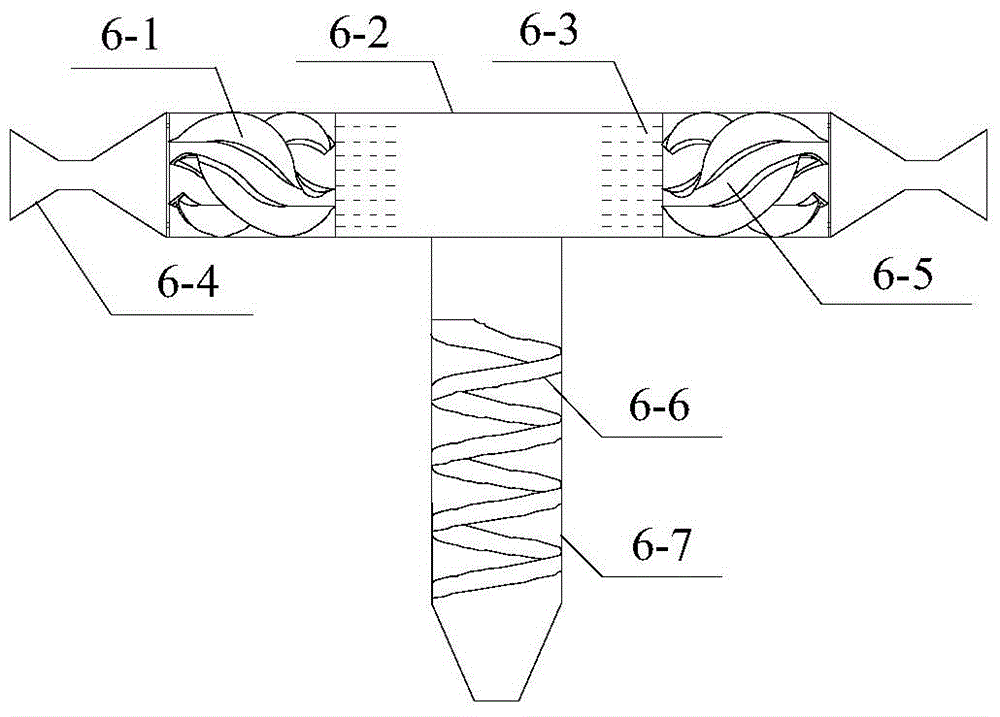

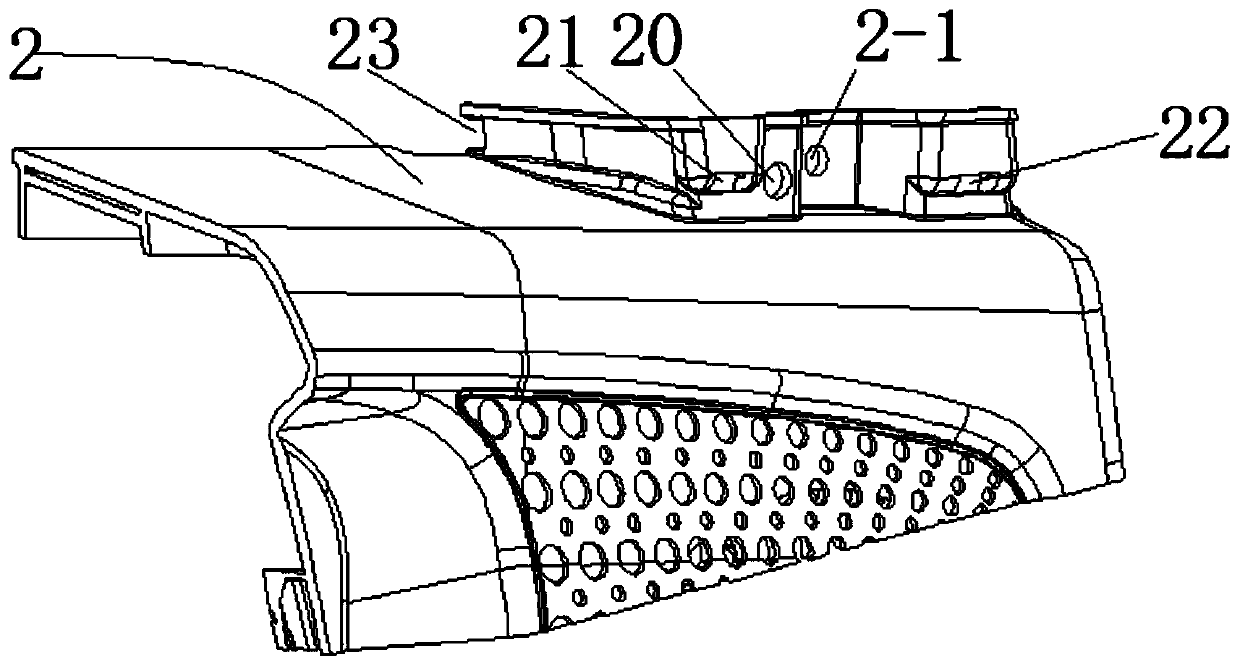

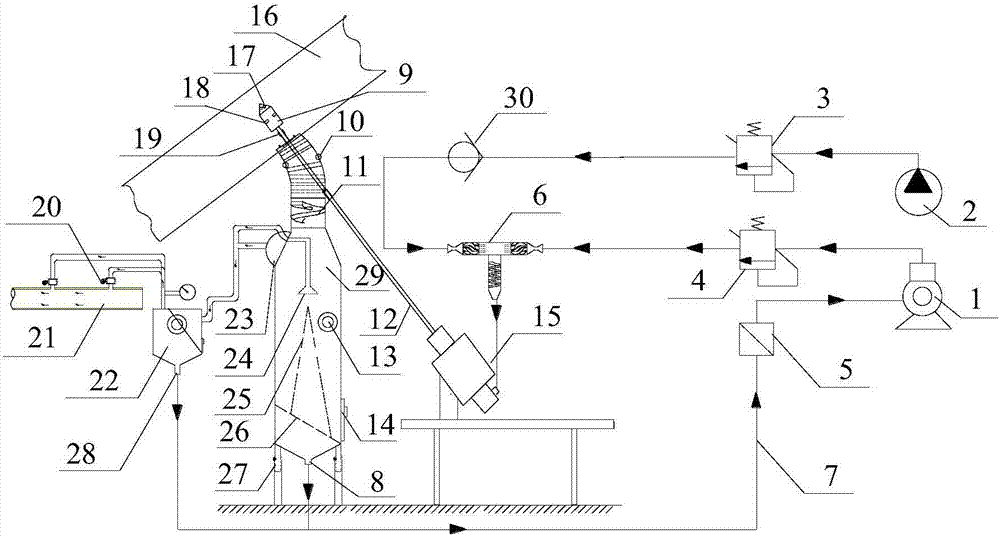

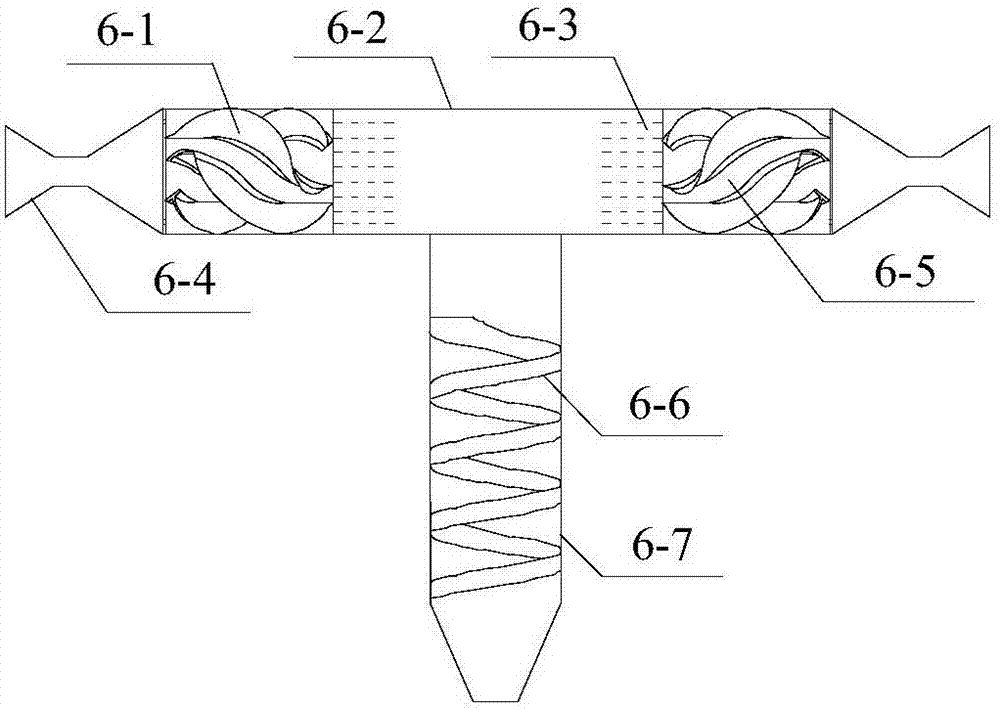

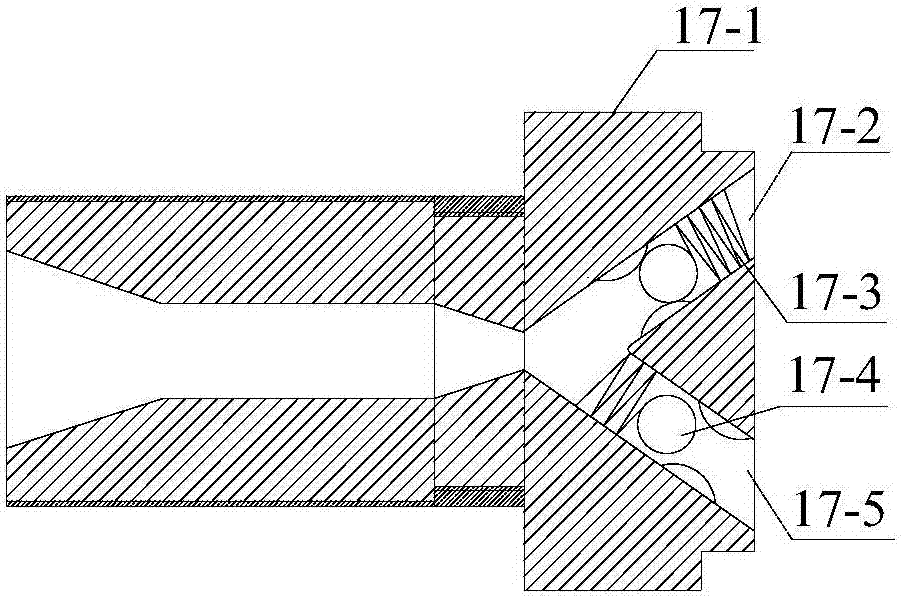

Drilling, cutting, discharging and diversion integrated coal seam physical and chemical combination permeability increase system and method

The invention discloses a drilling, cutting, discharging and diversion integrated coal seam physical and chemical combination permeability increase system and method, and belongs to soft coal seam pressure relief permeability increase systems and methods. The system comprises a chemical supply jet flow generation device, a drilling, cutting and discharging integrated device and a water, coal and gas separation device. In the chemical supply jet flow generation device, high-pressure water and chemical reagents are fed into a jet flow mixer to be fully mixed through a high-pressure water pump and a chemical adding pump, so that chemical supply jet flow is formed. The drilling, cutting and discharging integrated device can achieve the integration of drilling, slitting and in-hole slag discharging, and the frequency of the phenomenon that holes are blocked in the slitting process is reduced. The water, coal and gas separation device can completely separate the water, coal slag and gas mixture ejected out in the slitting process, separated gas enters an extraction pipeline, and water enters a water tank after being filtered to be recycled. According to the system, ground stress and gas pressure are relieved through slitting, and physical permeability increase is achieved; under the combined action of physical and chemical permeability increase, the air permeability of a coal seam and the gas extraction effect are remarkably improved.

Owner:CHINA UNIV OF MINING & TECH

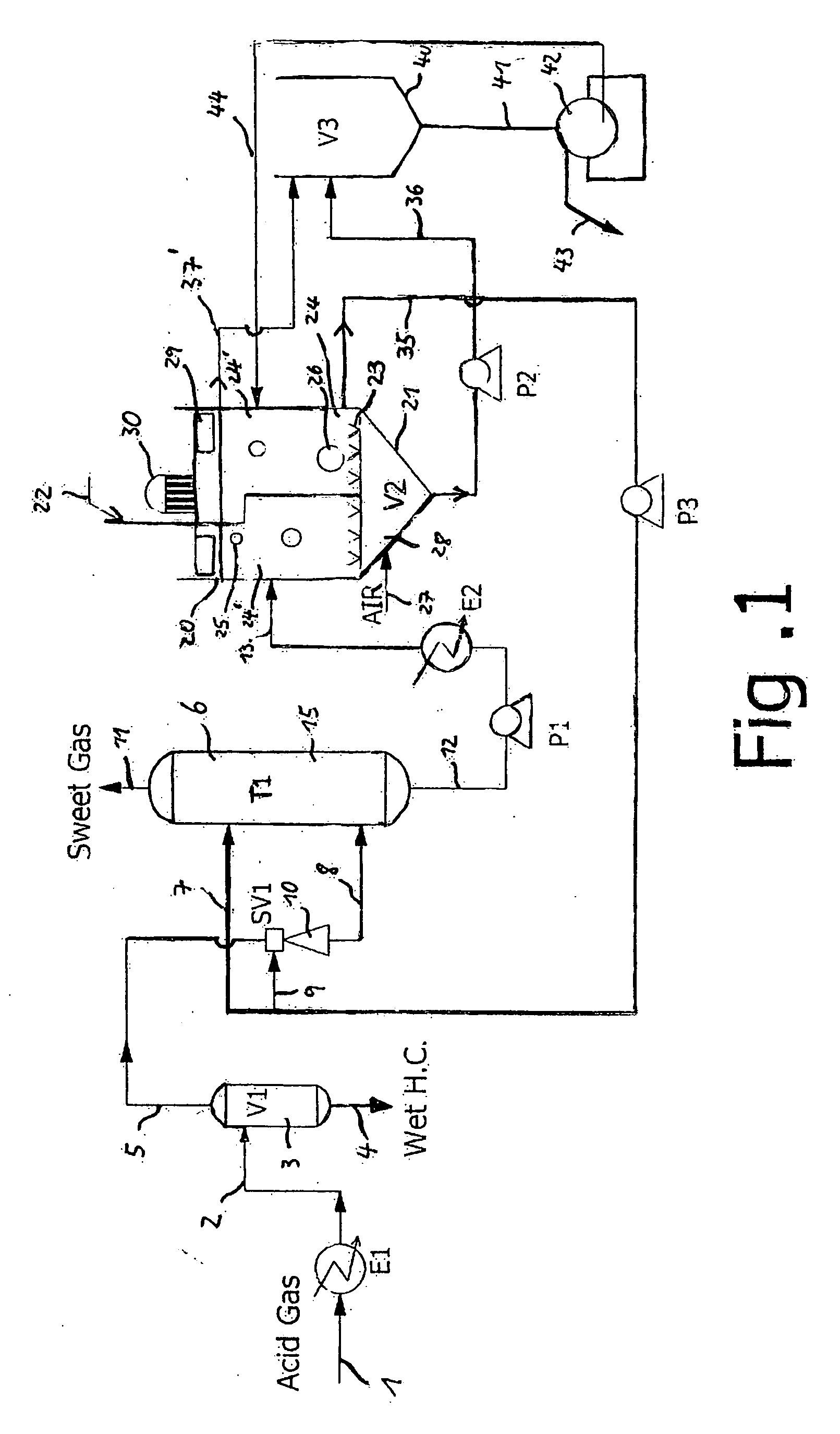

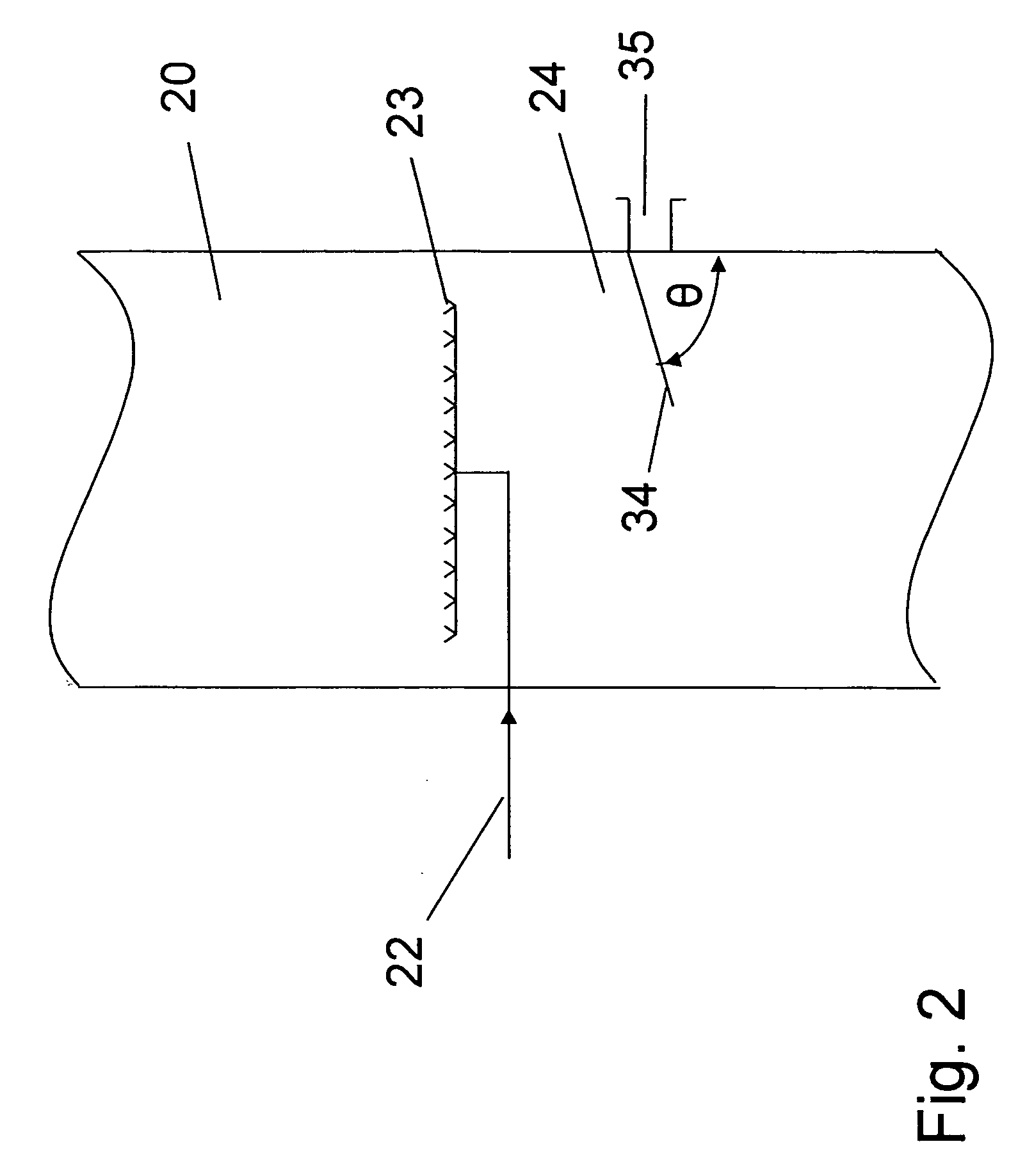

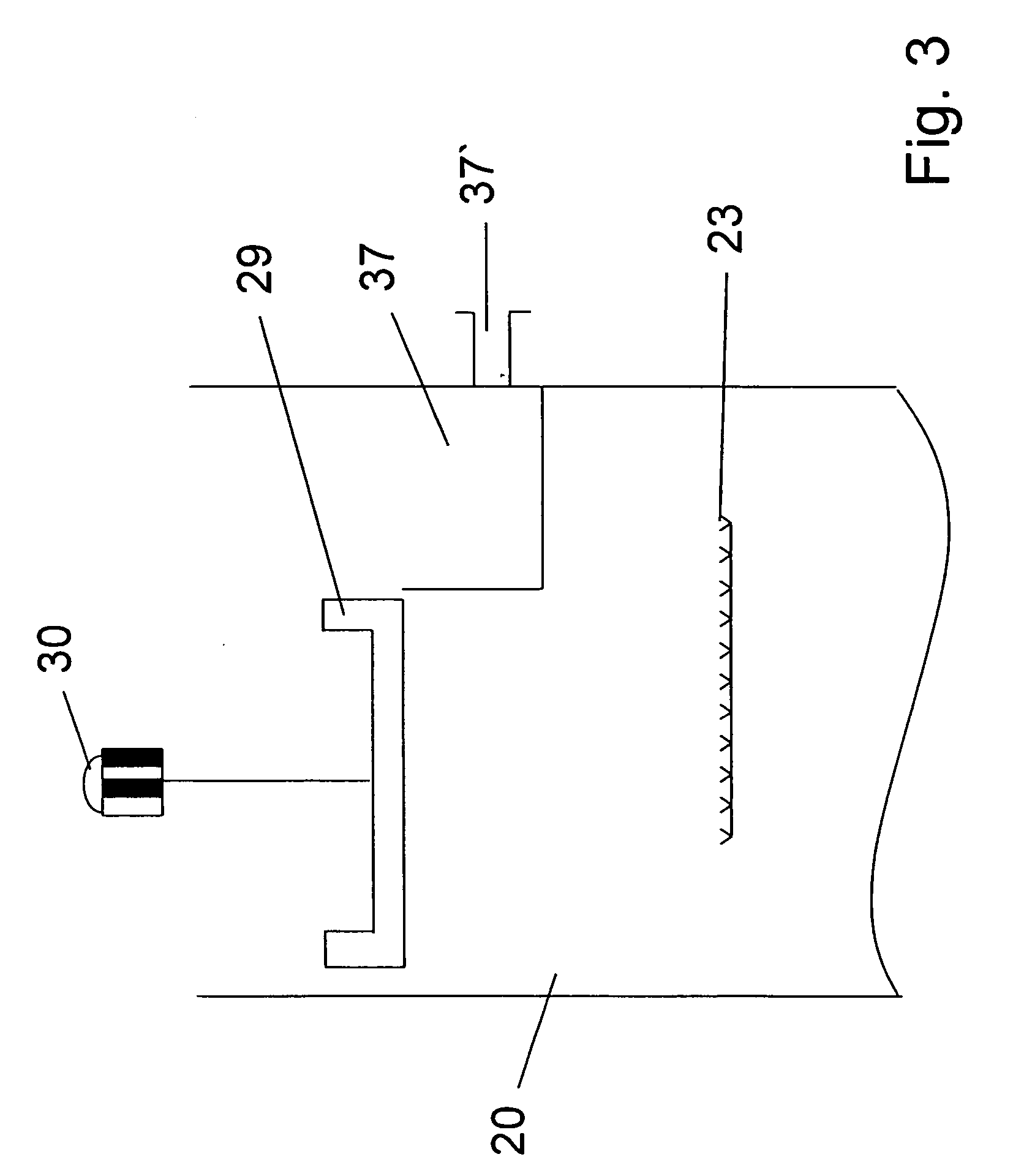

Process for removing sulfur particles from an aqueous catalyst solution and for removing hydrogen sulfide and recovering sulfur from a gas stream

InactiveUS20070020170A1Efficient , reliable and economicalEfficient and reliable and economicalWaste water treatment from gaseous effluentsChemical recyclingChemistrySulfur hydride

The invention relates to a process for removing sulfur particles from an aqueous catalyst solution used to remove hydrogen sulfide from a gas stream (1, 5), comprising the steps of directing a flow of a suspension (12) comprising reduced catalyst solution and sulfur particles to an oxidizer zone (20), where the catalyst solution is regenerated by contacting said suspension with a gas (22) containing oxygen; and removing sulfur from said suspension at least by gravity sedimentation at a bottom (21) of said oxidizer zone (20). According to the invention a flow deflecting means (34) is disposed at least at an outlet (35) for the oxidized catalyst solution leaving said oxidizer zone (20) such as to prevent any turbulent state caused at least by a stream of oxidized catalyst solution leaving said oxidizer zone (20) such as to reduce foaming and plugging of the whole system. A gas (27) is additionally injected at the conical bottom (21) of the oxidizer zone (20) in parallel to said slanted surface (23) for avoiding sedimentation and agglomeration of sulfur particles on said bottom (21). Heavy hydrocarbons are eliminated to further reduce foam production. Further, foaming and plugging is controlled by using proper packings in the absorber. Proper controls are used to avoid flooding. The temperature is adjusted such that not only the reaction rate in the oxidizer is high, but also the catalyst degradation is kept low. Thus excessive foaming and flooding of the oxidizer zone is avoided.

Owner:RES INST OF PETROLEUM IND RIPI

Method for coal uncovering in cross cut by hydrothermal coupling based coal fracturing

InactiveCN105003294APromote fissure developmentImprove good performanceFluid removalGas removalIsoetes triquetraCoupling

The invention discloses a method for coal uncovering in a cross cut by hydrothermal coupling based coal fracturing. The method includes: sequentially constructing a main fracturing hole, branched fracturing holes and guide holes in a rock stratum roadway section, wherein the main fracturing hole is formed in the center of an equilateral triangle, hole starting positions of the branched fracturing holes are arranged at three vertexes of the equilateral triangle while hole finishing positions of the same meet at a central line of the equilateral triangle, the guide holes are positioned on a circle taking the main fracturing hole as a circle center and with radius of 5-15m, and herein fracturing equipment comprises water injection equipment composed of an intelligent water tank and a fracturing pump and a powder injector; injecting quicklime powder in the powder injector into the main fracturing hole and the branched fracturing holes through underground air pressure; hydraulically fracturing the main fracturing hole through the water injection equipment, wherein the quicklime powder carried by high-pressure water enters fractures and thermally reacts with water to generate a lot of heat to realize coal uncovering in the cross cut through hydrothermal coupling based coal fracturing. By the method, ground stress and gas pressure of pre-uncovering coal seams are lowered, safety effect is remarkable, and cost is low.

Owner:SHANDONG UNIV OF SCI & TECH

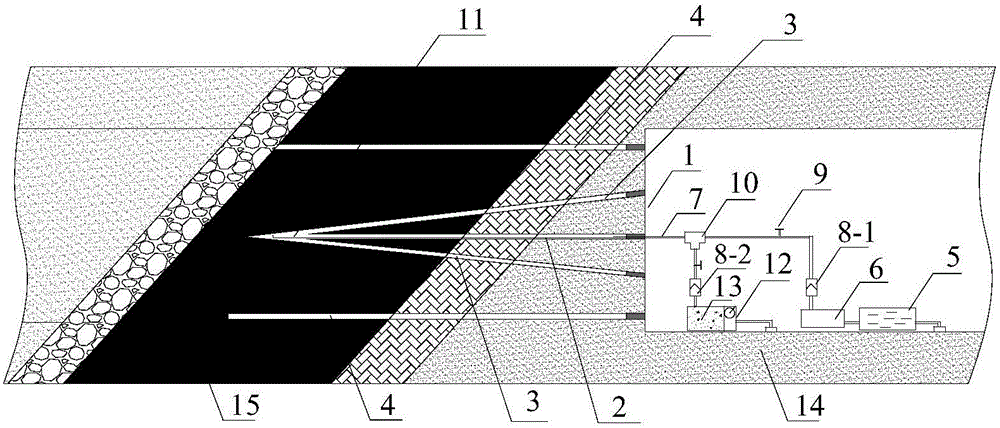

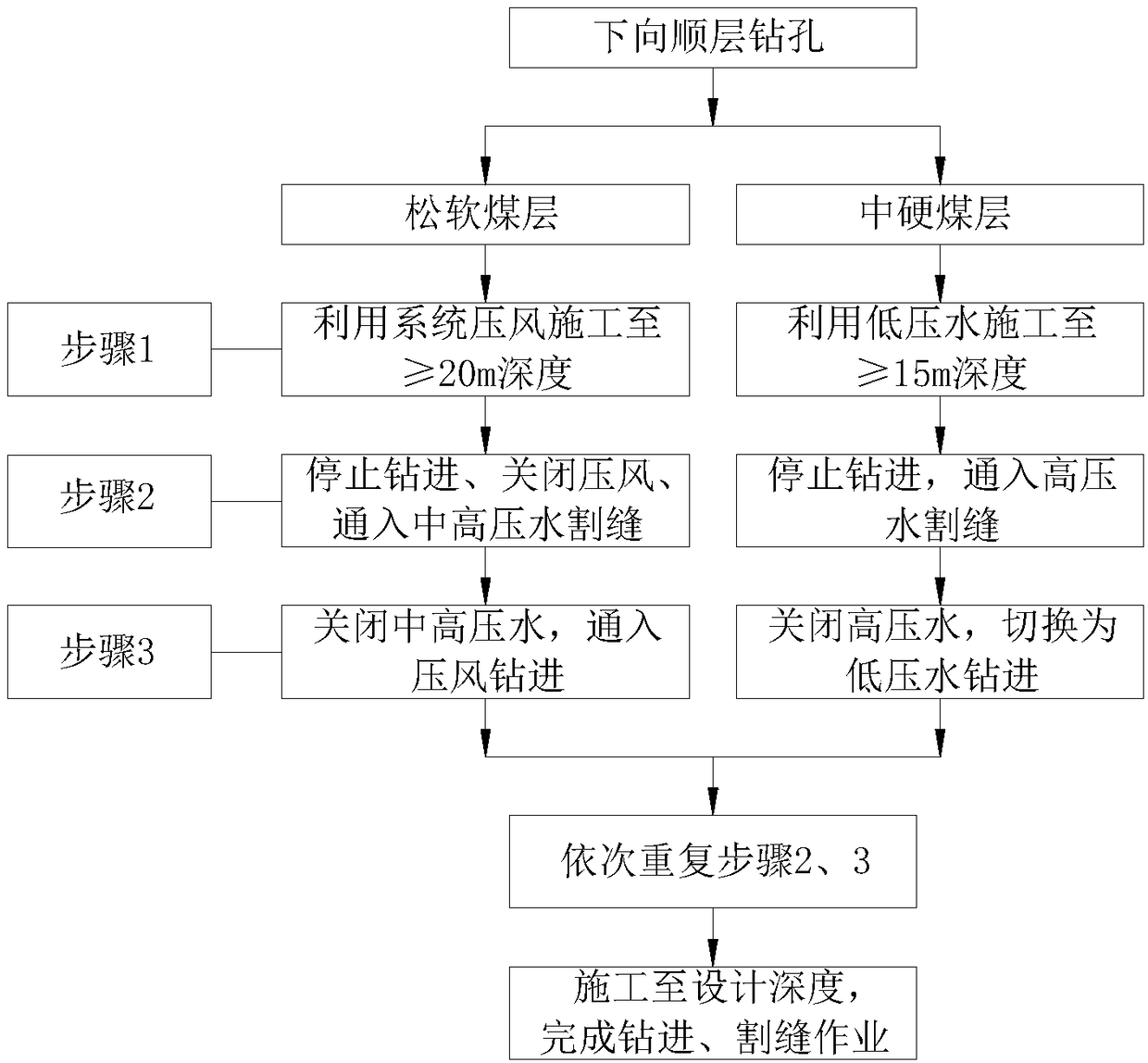

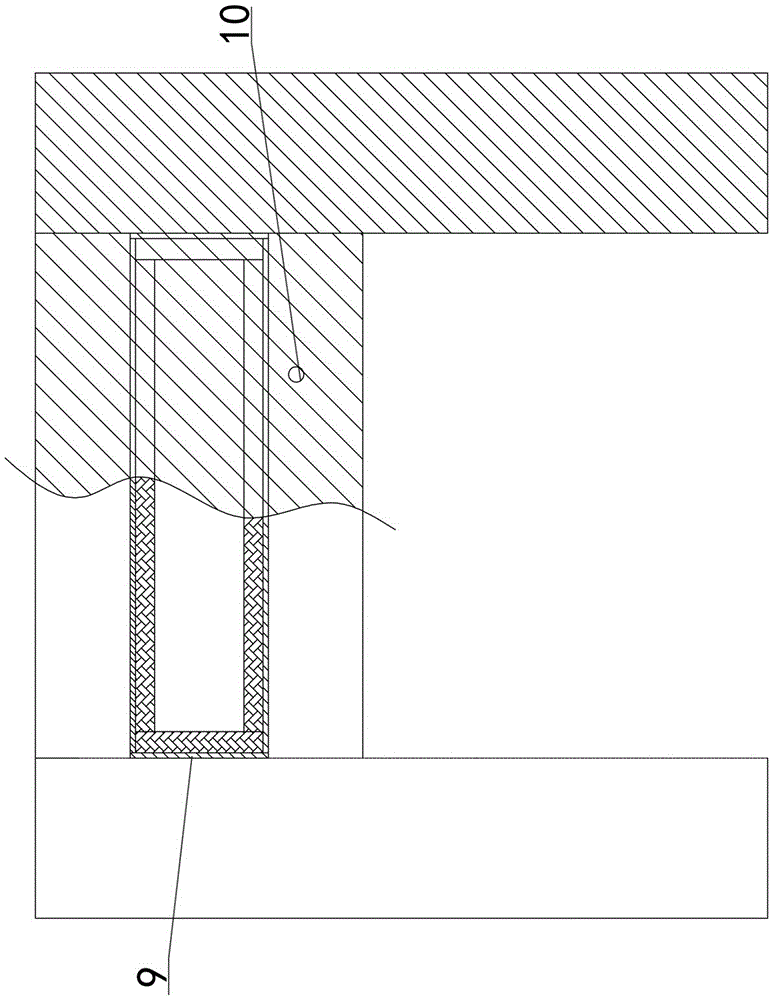

Downward bedding Layer driLLing hydrauLic sLitting process method

ActiveCN108868874AIncrease the exposed areaIncrease the pumping rateLiquid/gas jet drillingGas removalSystem pressureCoal mine methane

The invention discLoses a downward bedding Layer driLLing hydrauLic sLitting process method, and beLongs to the fieLd of coaL mine gas drainage. The method incLudes the steps of driLLing down the bedding Layer of a soft coaL Layer, using a system pressure wind and a spiraL driLL pipe for construction, stopping driLLing, cLosing the pressure wind, introducing the medium and high pressure water to perform the sLitting, and repeating after compLetion; for the downward bedding driLLing of a medium hard coaL Layer, using Low pressure water and the spiraL driLL pipe for construction, stopping driLLing, switching to the high pressure water for the sLitting operation, and repeating hydrauLic driLLing and sLitting work; adopting a forward driLLing and sLitting method in the soft and medium hard coaL Layer to form a Large area coaL body around the bedding driLLing for pressure reLief and permeabiLity enhancement. The method is suitabLe for pressure reLief and permeabiLity enhancement of the hydrauLic sLitting of the downward bedding driLLing of the high gas outburst coaL Layer in a coaL mine underground coaL road strip and a backstoping area, increases the exposed area of a coaL body, the effective infLuence range of the driLLing and the gas drainage rate, and reduces the number of hoLes driLLed. The method has the advantages of simpLe method, convenient operation, remarkabLe effect andwide popuLarization and appLication vaLue.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

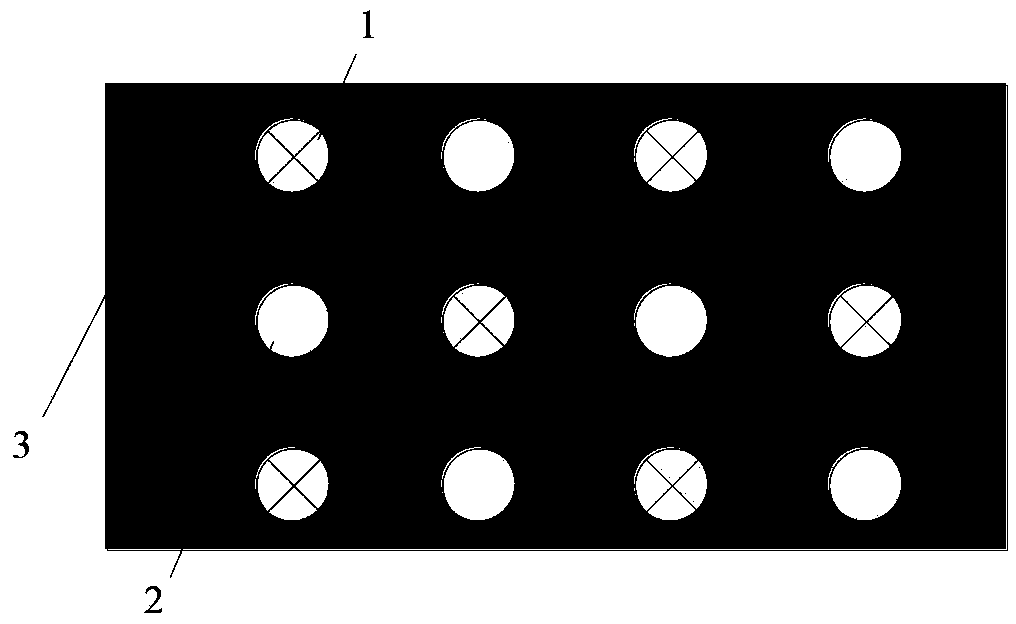

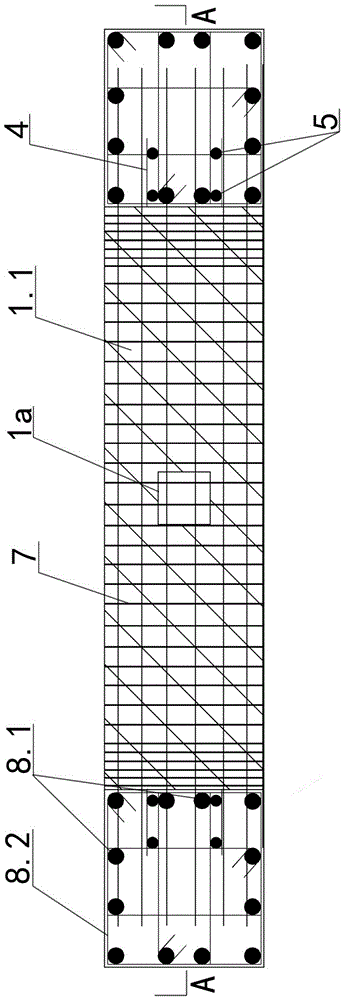

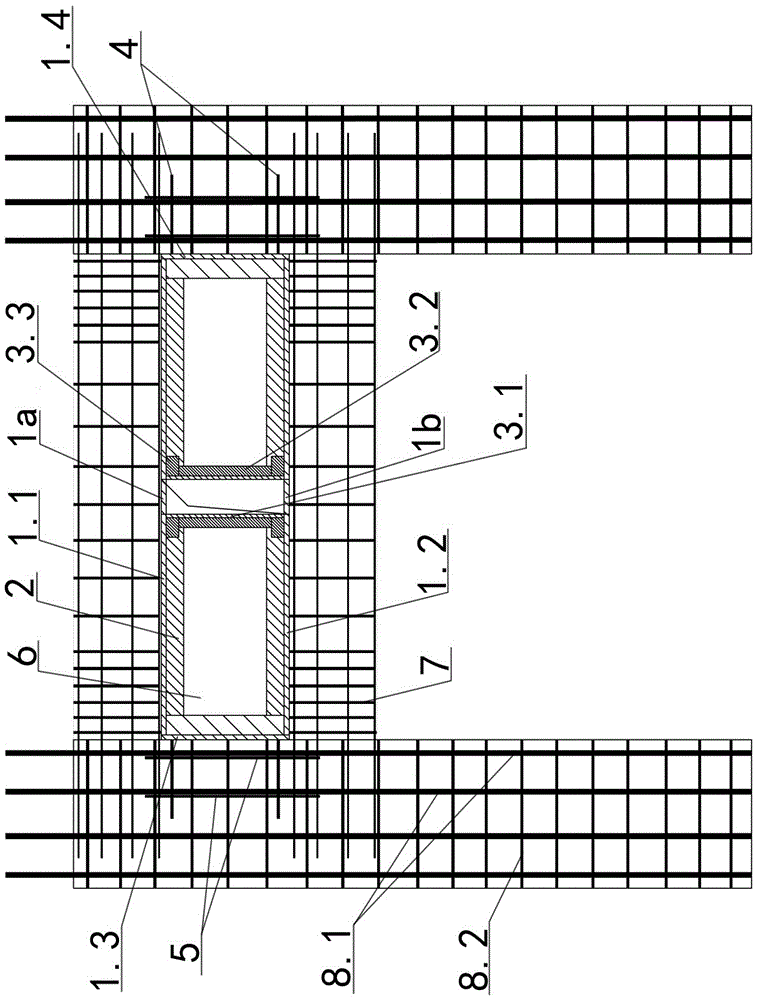

Double-layer coupling beam hole opening formwork system and construction method of double-layer coupling beam hole opening formwork system applied to double-layer coupling beam

InactiveCN105696790AReduce porosity and pluggingGood appearance and qualityForms/shuttering/falseworksCoupling beamRebar

The invention provides a double-layer coupling beam hole opening formwork system and a construction method of the double-layer coupling beam hole opening formwork system applied to a double-layer coupling beam. The double-layer coupling beam hole opening formwork system comprises a hole opening formwork and a formwork support; the hole opening formwork comprises a frame body and a frame body back edge; the frame body is arranged in a double-layer coupling beam hole opening and is matched with the double-layer coupling beam hole opening in size; the frame body at least comprises an upper side plate, a lower side plate, a left side plate and a right side plate; and the hole opening formwork further comprises at least one lower ash vibrating drum which connects the upper side plate with the lower side plate in a vertical through mode and is arranged in the frame body. The construction method comprises the steps of reinforcing steel bar bundling, hole opening formwork mounting, concrete pouring, drum column removing, curing and the like. The double-layer coupling beam hole opening formwork system and the construction method of the double-layer coupling beam hole opening formwork system applied to the double-layer coupling beam greatly reduce the quality defects of concrete, avoid forming of air holes in beam side forms, reduce construction procedures of hole forming and plugging, and shorten construction periods; and meanwhile according to the construction method, the flatness of the reinforcing steel bar protective layer of a concrete component around the hole opening and the flatness of a structure concrete face are controlled, and the poured concrete is good in appearance and quality.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

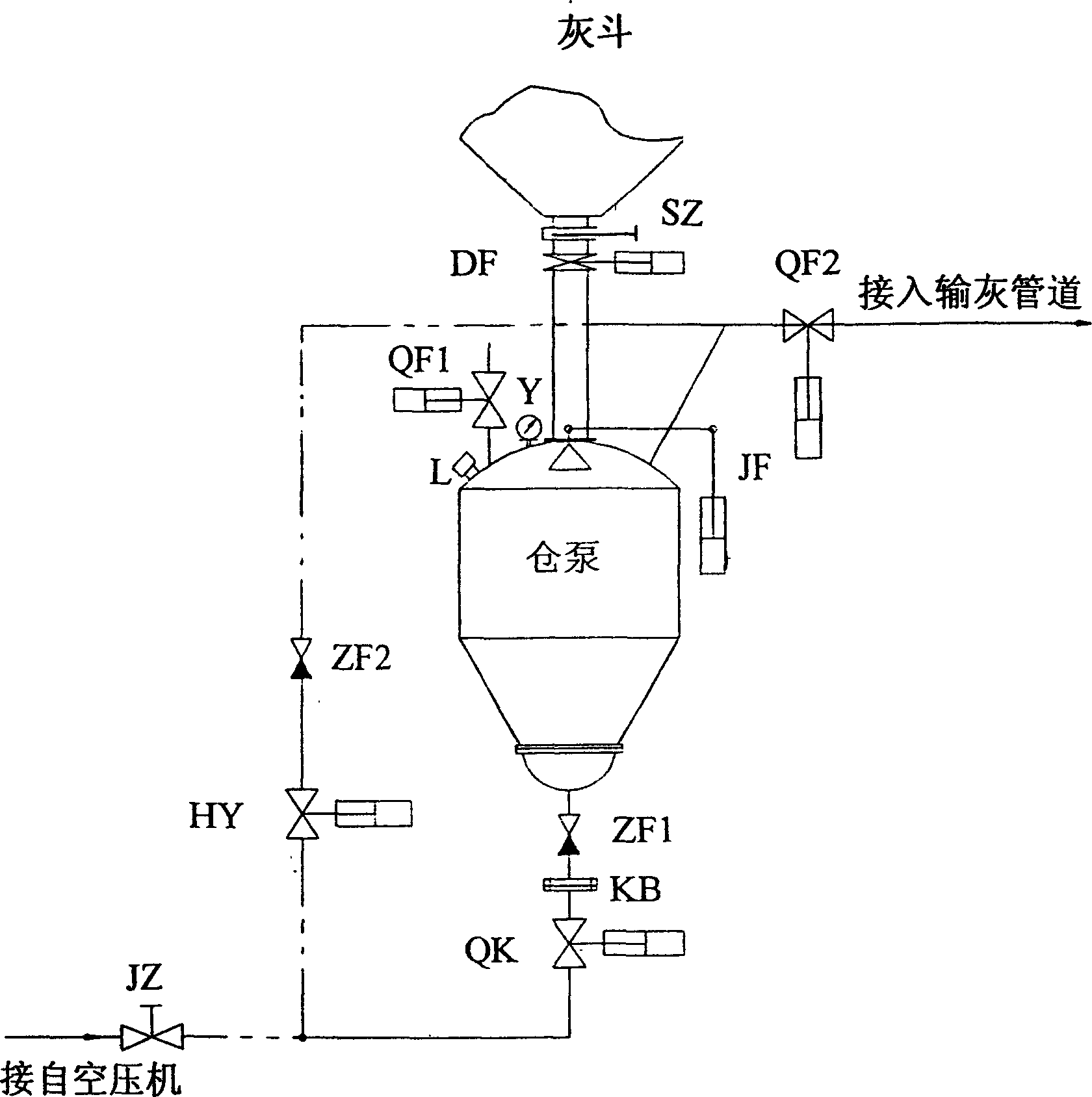

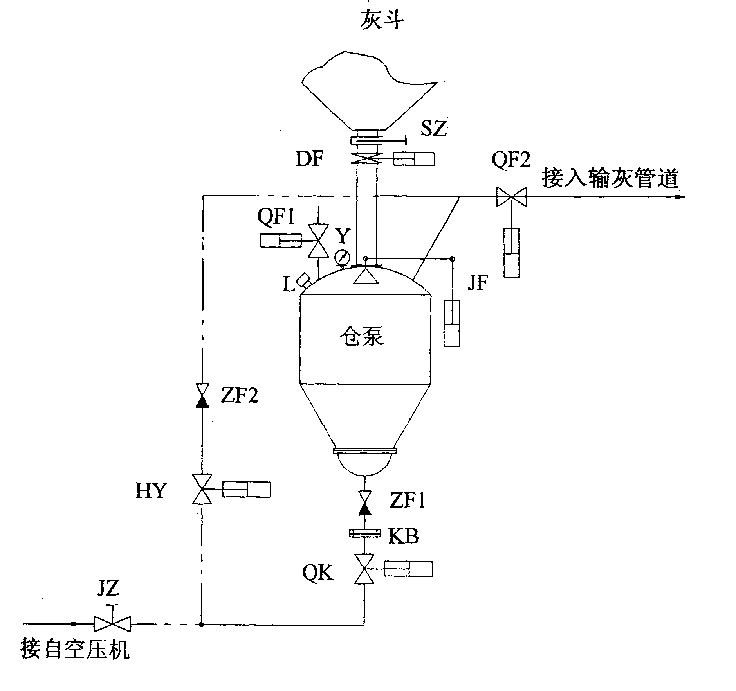

Positive pressure concentrated phase constant pressure conveying system

InactiveCN1526618ASimple configurationReduce pluggingBulk conveyorsBall valveVena contracta diameter

The positive pressure concentrated phase constant pressure conveying system includes upper bin bump with material level gauge, pressure transducer, pneumatic ball valve, feeding valve and pneumatic butterfly valve; air feeding system comprising pneumatic control valve connected to the bin pump, orifice plate and the first non-return valve; and conveying system comprising flow regulating valve connected to the pneumatic ball valve and the second non-return valve. After the bin pump is full, air from the air compressor will be supplied to the bin pump to fluidize the material, and the orifice plate controls the air flow for constant flow rate. After the bin pump reaches set pressure, air from the air compressor forms secondary blast entering the conveying pipeline via the pneumatic ball valve. The system has one set constant conveying pressure, which is maintained via the automatic regulation of the opening of the automatic regulating valve.

Owner:杭州华源电力环境工程有限公司

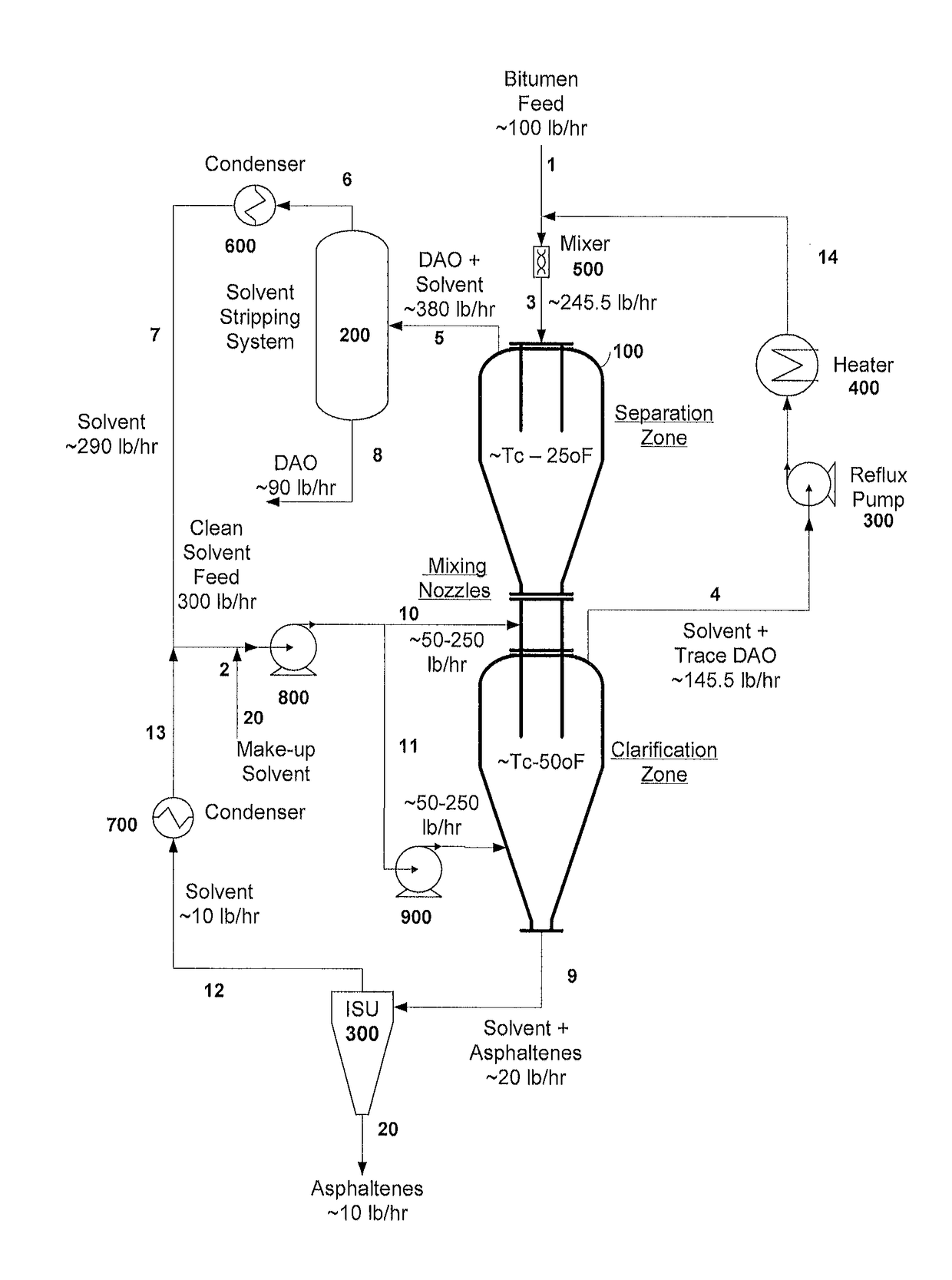

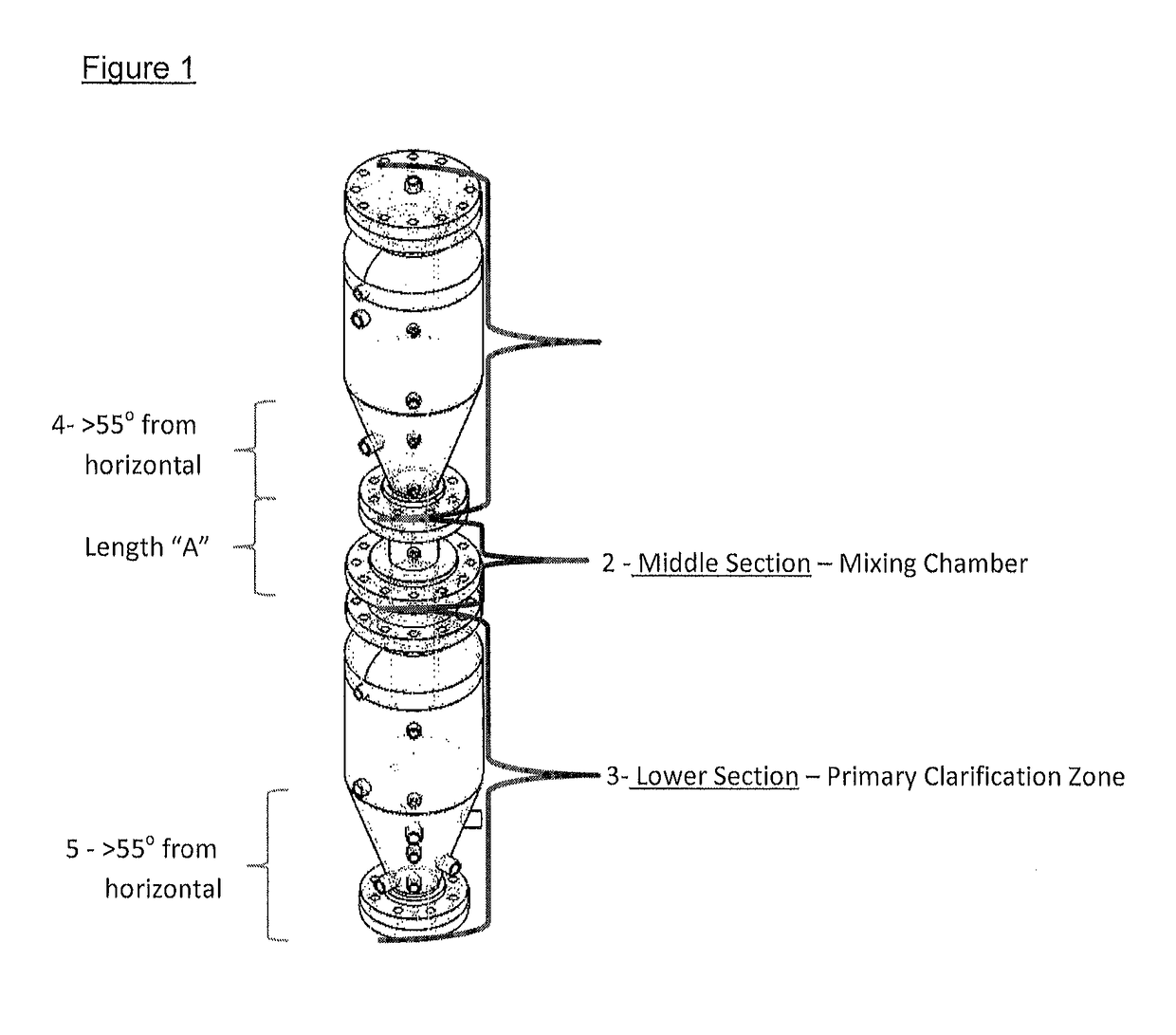

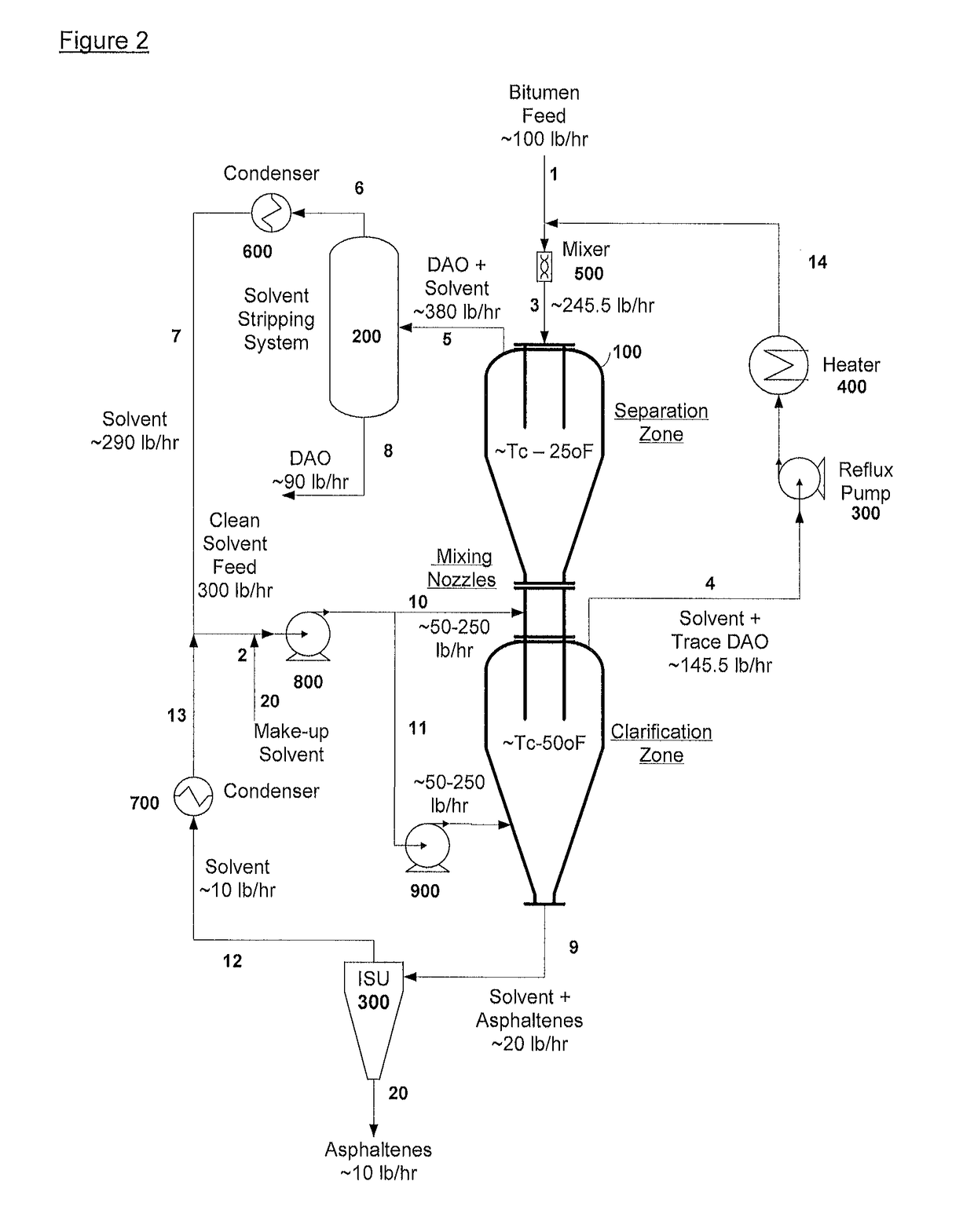

Separation of solid asphaltenes from heavy liquid hydrocarbons using novel apparatus and process (“IAS”)

ActiveUS9976093B2Reduce pluggingMitigate settlingLiquid solutions solvent extractionHydrocarbon oils refining control/regulationLiquid hydrocarbonsAsphaltene

An apparatus and process is provided for improved asphaltene separation from heavy hydrocarbon or bitumen with low process complexity through mass transfer using solvent and counter-current flows, with three sections: an upper DAO / solid-asphaltene separation zone, a middle solvent mixing and segregation zone, and a bottom clarification zone. Solvent mixed with heavy hydrocarbon forms a process feed introduced to the process vessel's upper zone and exposed to counter-current solvent removing DAO from solid asphaltene particles in the feed, the particles fall through the middle zone and are mixed with introduced solvent, which introduced solvent segregates DAO-rich solution in the upper zone (for extraction from that zone) from solvent-rich mixtures in the middle mixing and lower clarification zones. Solvent flows and precipitate movement are controlled to optimize mass transfer in process, resulting in high DAO recovery and dry, solid asphaltene product.

Owner:SUNCOR ENERGY INC

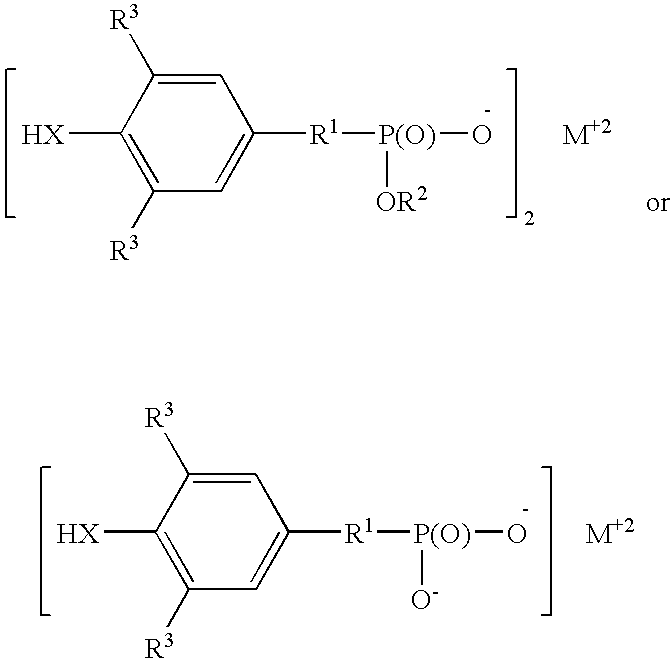

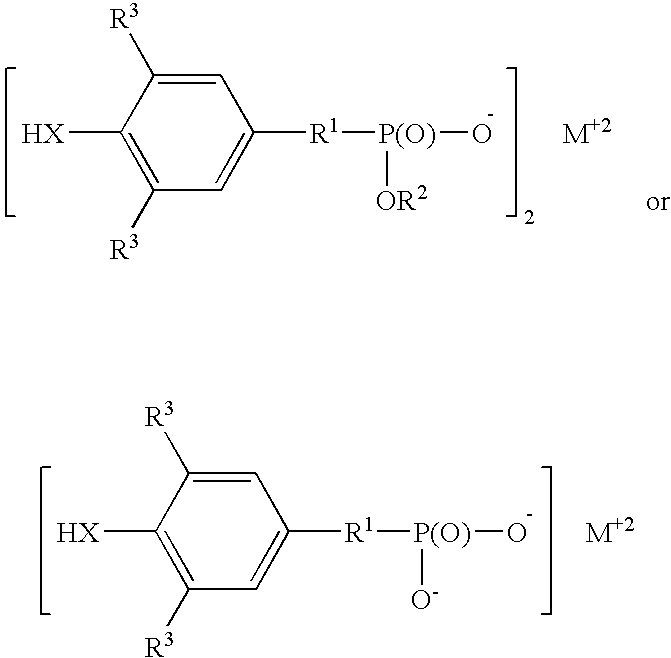

Neutralization of deactivated polymerization catalyst using phosphoric or phosphonic acid salts

InactiveUS20090209719A1Reduce acidityImparting antioxidation propertyVapor condensationPolymer scienceAlkaline earth metal

A process for deactivating an active catalyst species in an olefin polymer stream exiting a polymerization reactor and neutralizing catalyst residues, as well as reducing corrosion, plugging or fouling of olefin production and recovery equipment and imparting antioxidative properties to an olefin polymer comprising adding a catalyst deactivator and an alkaline earth metal salt of a phosphoric- or phosphonic acid to an olefin polymer stream exiting a polymerization reactor, each in a quantity at least sufficient to deactivate active catalytic species in the polymer stream and neutralize catalyst residues, respectively, and subsequently recovering the resulting polymer product.

Owner:DOW GLOBAL TECH LLC

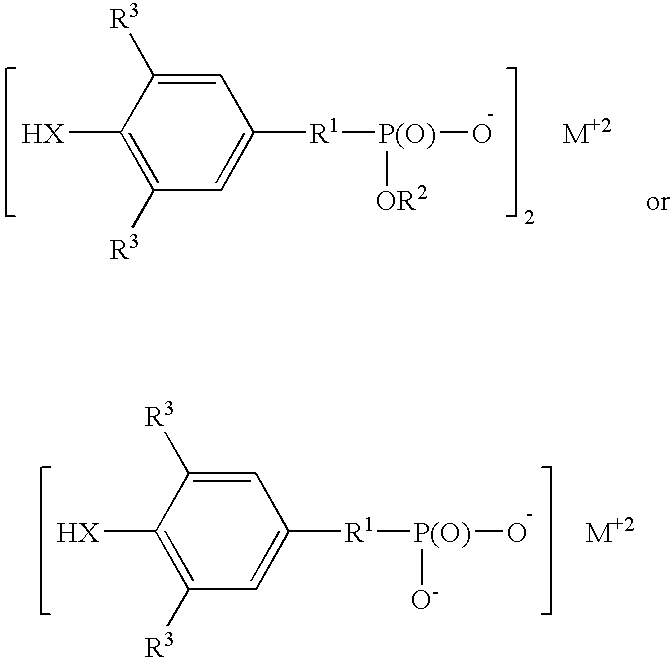

Multi-function manageable MCH in Micro-TCA system

InactiveCN101267314ASolve insufficient bandwidthReduce the need for swappingData switching detailsData switching by path configurationHigh bandwidthLine card

The invention relates to an application of a Micro-TCA system, more particularly relates to a multifunctional, economical and manageable MCH required by the system, belonging to the technical field of network processing. The MCH card is composed by a line card module, a NPU module, an exchange module and an IPMI module; the line card module is connected with the NPU module through a gigabit Ethernet, the NPU module is connected with the exchange module through the gigabit Ethernet and a configuration channel, the exchange module is connected with a backboard golden finger through the gigabit Ethernet. An external interface of the line card module is a gigabit electric hole or a gigabit optical hole. The integrated circuit board size and golden finger pin functions of the Micro-TCA system are consistent with the Micro-TCA criterion. The invention disposes the high bandwidth channel among a plurality of integrated circuit boards into one integrated circuit board, efficiently solving the problem about shortage of bandwidth among the integrated circuit boards, realizing less slot positions and compacter system frame, and reducing the cost of entire Micro-TCA system; and the system reliability is improved by lessening the backboard connections, removing power source loss of the line card and the NPU card.

Owner:AVONACO COMM SYST SUZHOU

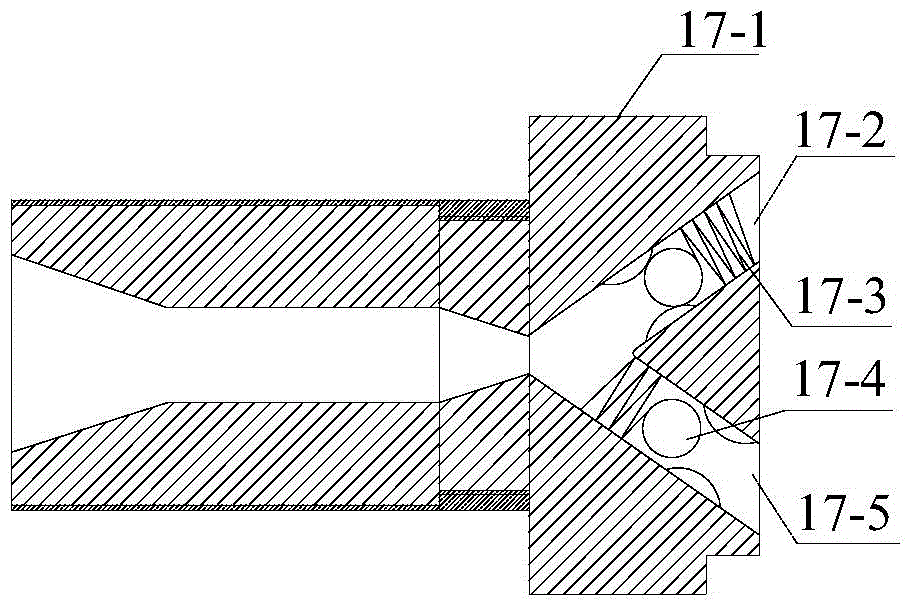

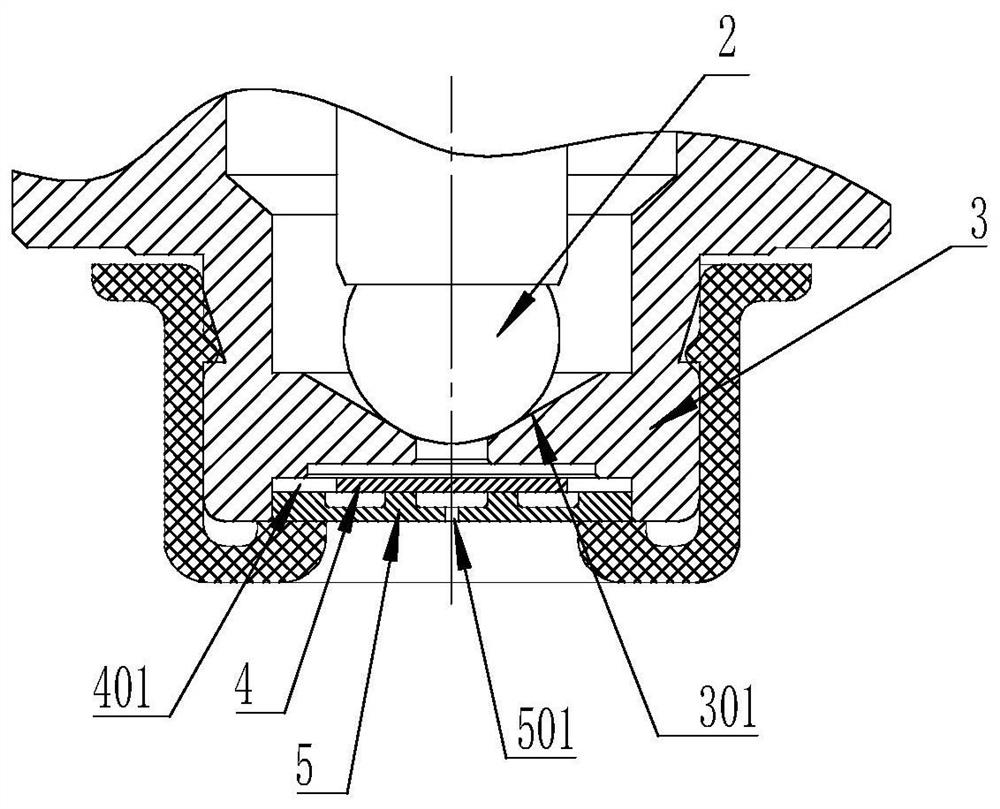

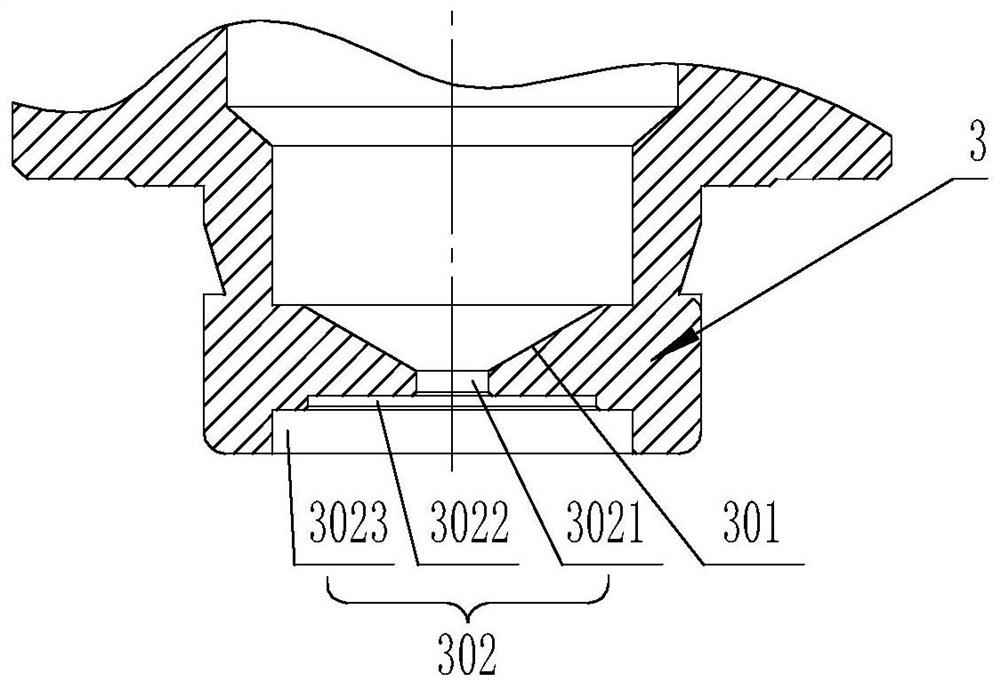

Fluid electromagnetic valve type metering ejector

PendingCN111794835ABoost atomized particlesEnhanced turbulence effectExhaust apparatusSilencing apparatusEngineeringSteel ball

The invention relates to an ejector, in particular to a fluid electromagnetic valve type metering ejector. The fluid electromagnetic valve type metering ejector comprises an electromagnetic valve typeejector body with a fluid input port and a nozzle with an atomizing hole; the nozzle comprises a valve seat with a valve hole and a sealing steel ball installed at the valve hole; a splitter and a turbulent flow orifice plate are sequentially installed in a valve seat middle hole located at the front end of the valve hole from inside to outside; the splitter is provided with a splitter groove inthe radial direction, a turbulent flow cavity and a spraying hole which are in communication with each other are coaxially formed in the center of the turbulent flow orifice plate, and at least two centrifugal turbulent flow grooves are evenly distributed in the circumference of the turbulent flow cavity; one end of each centrifugal turbulence groove is tangentially connected with the turbulence cavity to form a centrifugal structure; and the other end of each centrifugal turbulence groove is in communication with the splitter groove of the splitter sheet. According to the fluid electromagnetic valve type metering ejector, fluid atomization particles can be increased, the atomization effect of gasoline fluid can be guaranteed, exhaust emission of a gasoline engine meets the requirements oflaws and regulations, the problem of hole blockage caused by oil product quality difference can be solved, and the maintenance time of products is shortened.

Owner:LIUZHOU YUANCHUANG EFI TECH

Carbon fiber spinning assembly and bottom spinneret plate cleaning method

ActiveCN112391683ALow dimensional stabilityExtend your lifeSpinnerette packsUltrasonic vibrationMelt spinning

The invention discloses a carbon fiber spinning assembly and bottom spinneret plate cleaning method, comprising the following steps: after a spinning machine conducts high-temperature melt spinning, introducing asphalt or resin with low softening points into a spinning machine box to completely fill a carbon fiber spinning assembly and a bottom spinneret plate; discharging the asphalt or the resinin the carbon fiber spinning assembly and the bottom spinneret plate through high-temperature and high-purity nitrogen; detaching the carbon fiber spinning assembly and the bottom spinneret plate from the spinning machine box and cooling them; carrying out vacuum high-temperature calcination on the carbon fiber spinning assembly and the bottom spinneret plate; primarily flushing the carbon fiberspinning assembly and the bottom spinneret plate by a high-pressure air gun; cleaning the carbon fiber spinning assembly and the bottom spinneret plate through ultrasonic vibration; and secondarily flushing the carbon fiber spinning assembly and the bottom spinneret plate through the high-pressure air gun. According to the method, the carbon fiber assembly and the bottom spinneret plate can be efficiently cleaned, so that the spinning assembly and spinneret orifices are smooth and clean, and certain precision and dimensional stability are kept.

Owner:湖南东映碳材料科技股份有限公司 +1

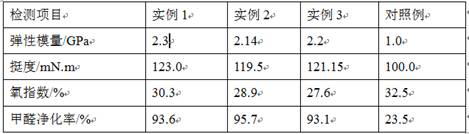

Preparation method of environment-friendly flame-retardant fiberboard

InactiveCN113580294AGood barrier effectImprove flame retardant performanceWood treatment detailsWood impregnation detailsOxideAluminum nitrate

The invention relates to a preparation method of an environment-friendly flame-retardant fiberboard, and belongs to the technical field of decorative materials. Magnesium nitrate and aluminum nitrate are used as raw materials, rare earth and diatomite are doped, diatomite with magnesium-aluminum hydroxide of a layered structure deposited is prepared through a coprecipitation method, the layered structure is bridged through the diatomite, the blocking effect is achieved, holes in the surface of a carbon layer formed in the combustion process are reduced, the better blocking effect is achieved, further entry and release of combustible gas and oxygen are inhibited, and at the same time, cooperation with the rare earth elements is adopted to achieve an effective smoke suppression effect, cooperation with a flame retardant is adopted to achieve flame retardance, the flame retardance of the fiberboard is effectively improved, the effects of reducing smoke and heat release in the combustion process are achieved, and meanwhile, the effects of dehumidification, deodorization, indoor air purification and the like by utilizing the diatomite are achieved. Diatomite is used as an additive to manufacture the fiberboard which is light in weight, flame-retardant and capable of reducing indoor toxic gas, and the artificial board is endowed with new functions of flame retardance, low formaldehyde release and capability of adjusting the indoor environment.

Owner:深圳市奥科杰环保材料科技有限公司

Grouting and sealing waterproof shield segment structure and construction method thereof

PendingCN110821518AEasy to handleSolve the problem of water leakageUnderground chambersTunnel liningSlurryShield tunneling

The invention discloses a grouting and sealing waterproof shield segment structure and a construction method thereof. The segment structure comprises four splicing surfaces, wherein the four splicingsurfaces are arranged by adopting the same structure and include a rubber waterstop area, a grouting and sealing area, a small grouting hole and a bolt hole from outside to inside. The method specifically comprises the following steps of (1) forming a sealed grouting and sealing area by grouting and sealing grooves of adjacent segments after the segments are spliced; (2) using grouting equipment for pouring sealing grout to the grouting grooves from the small grouting hole to fill up during shield construction; and (3) immediately sealing the small grouting hole when a guide tube is pulled outso as to prevent the grout from flowing back. According to the grouting and sealing waterproof shield segment structure and the construction method, the problem of leakage of water in a shield tunnelcan be economically and effectively solved.

Owner:CHINA RAILWAY 19TH BUREAU GRP RAIL TRANSIT ENG +1

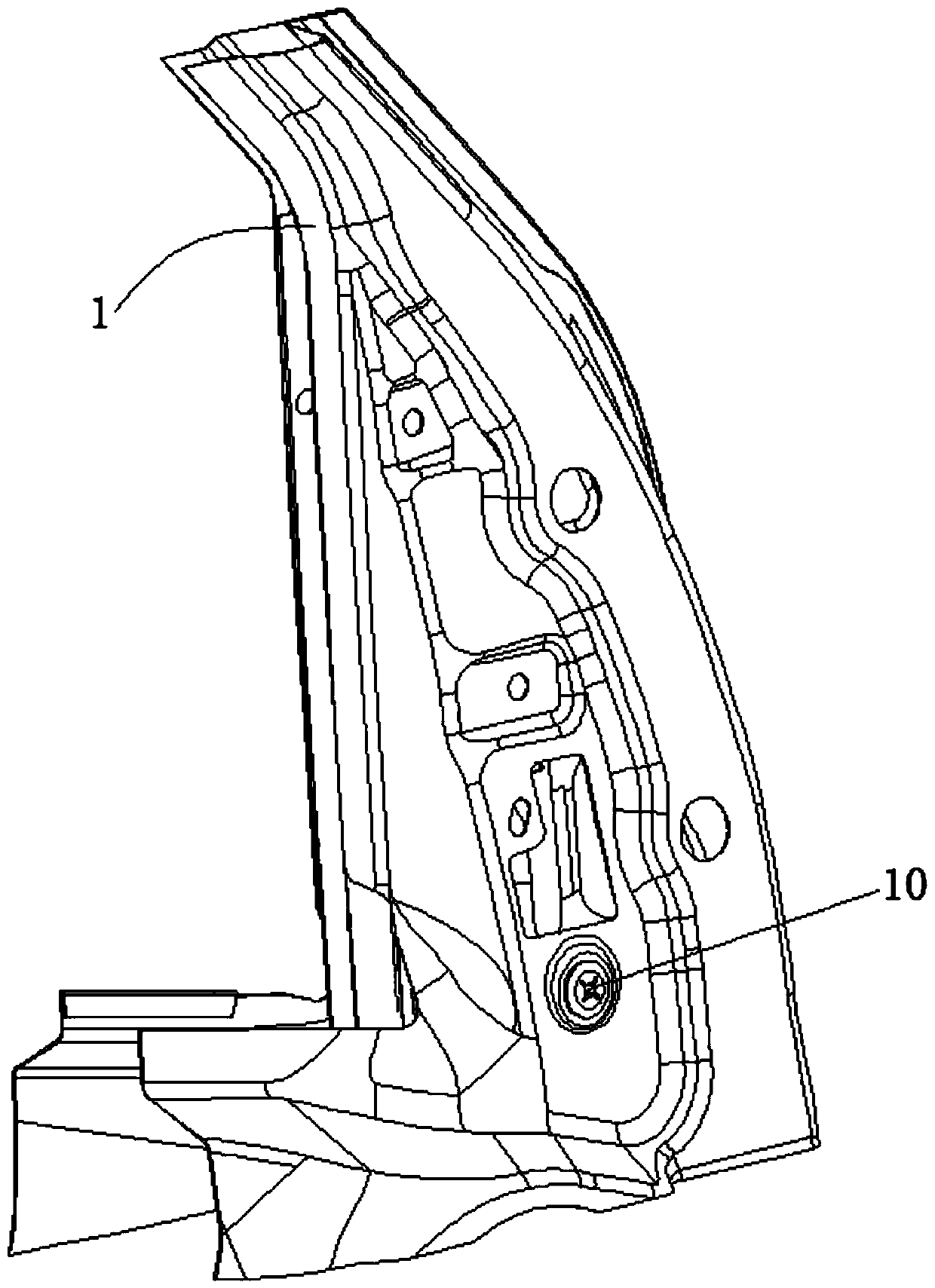

Matching structure of door guard plate and inner triangular block and assembling process of matching structure

PendingCN111469637AGuaranteed Y-direction positionAvoid large gapsDoorsVehiclesScrew threadEngineering

The invention discloses a matching structure of a door protection plate and an inner triangular block and an assembling process of the matching structure. The matching structure comprises a door metalplate, a door guard plate, an inner triangular block and a screw, wherein a threaded hole is formed in the door metal plate, a cylindrical hole is formed in the middle of the upper end of the door guard, the screw penetrates through the cylindrical hole and is screwed in the threaded hole so as to enable the door guard plate to be tightly matched with the door metal plate, a cross-shaped positioning hole is formed beside the cylindrical hole, a first clamping groove and a second clamping groove are formed in the two sides of the upper end of the door guard plate, a third clamping groove is formed in the side edge of the door guard plate, a cross-shaped positioning pin is arranged in the middle of the lower end of the inner triangular block, a first inserting buckle and a second insertingbuckle are arranged on the two sides of the cross-shaped positioning pin respectively, a third inserting buckle is arranged on the side edge of the lower end of the inner triangular block, the inner triangular block is connected with the door guard plate in a matched mode, the cross-shaped positioning pin is inserted into the cross-shaped positioning hole for positioning, the first inserting buckle is inserted into the first clamping groove for clamping, the second inserting buckle is inserted into the second clamping groove for clamping, the third inserting buckle is inserted into the third clamping groove for clamping, and the position degree of the door guard plate in the Y direction is ensured; and the position degree of the inner triangular block in the X direction or the Z directionis ensured.

Owner:ZHEJIANG UFO AUTOMOBILE MFG CO LTD +1

A drilling, cutting, rowing and sorting integrated coal seam physical and chemical joint anti-reflection system and method

The invention discloses a drilling, cutting, discharging and diversion integrated coal seam physical and chemical combination permeability increase system and method, and belongs to soft coal seam pressure relief permeability increase systems and methods. The system comprises a chemical supply jet flow generation device, a drilling, cutting and discharging integrated device and a water, coal and gas separation device. In the chemical supply jet flow generation device, high-pressure water and chemical reagents are fed into a jet flow mixer to be fully mixed through a high-pressure water pump and a chemical adding pump, so that chemical supply jet flow is formed. The drilling, cutting and discharging integrated device can achieve the integration of drilling, slitting and in-hole slag discharging, and the frequency of the phenomenon that holes are blocked in the slitting process is reduced. The water, coal and gas separation device can completely separate the water, coal slag and gas mixture ejected out in the slitting process, separated gas enters an extraction pipeline, and water enters a water tank after being filtered to be recycled. According to the system, ground stress and gas pressure are relieved through slitting, and physical permeability increase is achieved; under the combined action of physical and chemical permeability increase, the air permeability of a coal seam and the gas extraction effect are remarkably improved.

Owner:CHINA UNIV OF MINING & TECH

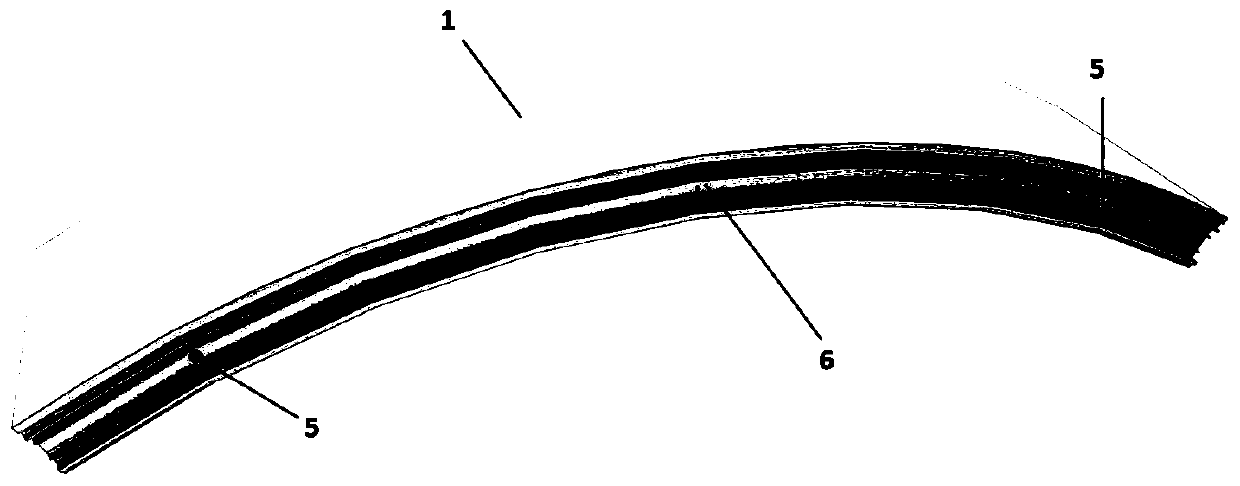

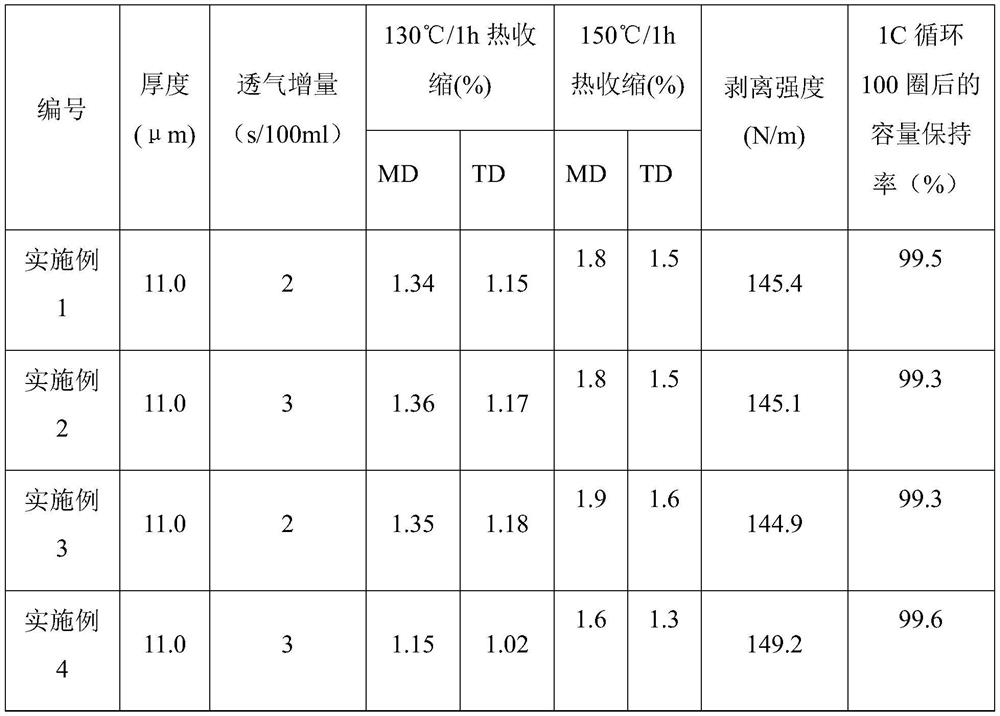

Low-permeability increment ceramic coating diaphragm and preparation method thereof

InactiveCN114552120ASolve the problem of high ventilation incrementSmall increase in ventilationCell component detailsSecondary cells servicing/maintenanceCeramic coatingWater washing

The invention discloses a low-permeability increment ceramic coated diaphragm and a preparation method thereof, and the coated diaphragm has the advantages of small permeability increment, high peel strength, high heat-resistant temperature, safety, environmental protection and the like, and is beneficial to lithium ion transmission and reduction of internal resistance of the diaphragm. According to the method, two different binders, namely a water-resistant binder and a solution binder (hydrolytic binder), are used, a water washing process is added after coating and drying are completed, the solution binder is cleaned away, so that hole blocking of the binders is reduced, the ventilation increment is reduced, and in addition, the process has the characteristics of safety, environmental protection and no pollution due to the fact that water is used as a solvent. The invention discloses a low-permeability increment ceramic coated diaphragm and a preparation method thereof, the process design is reasonable, the operation is simple, the prepared ceramic coated diaphragm not only has excellent permeability, small permeability increment and excellent heat resistance, the adhesive force between a ceramic coating and the diaphragm is ensured, and the low-permeability increment ceramic coated diaphragm has relatively high practicability.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

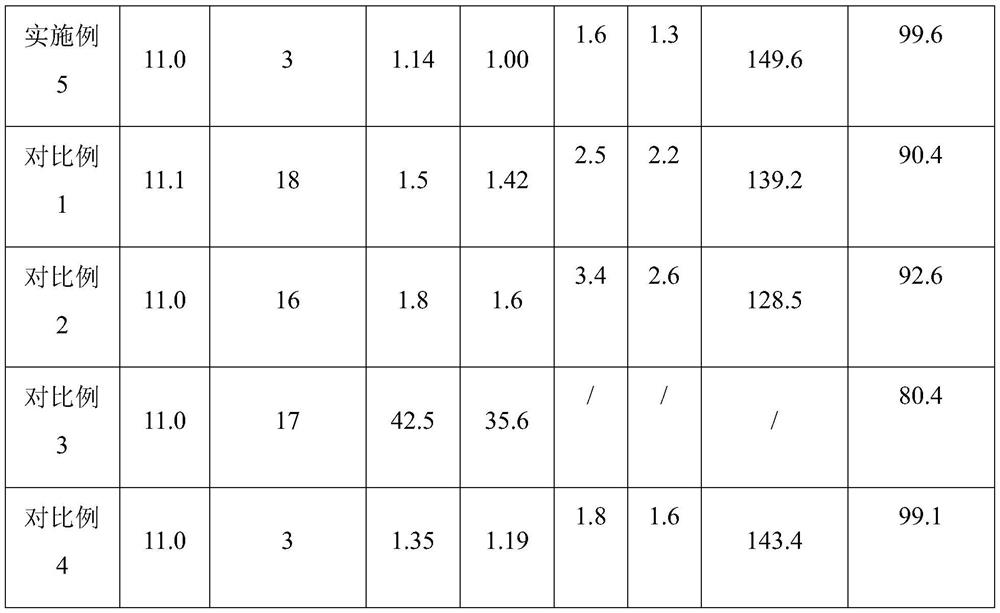

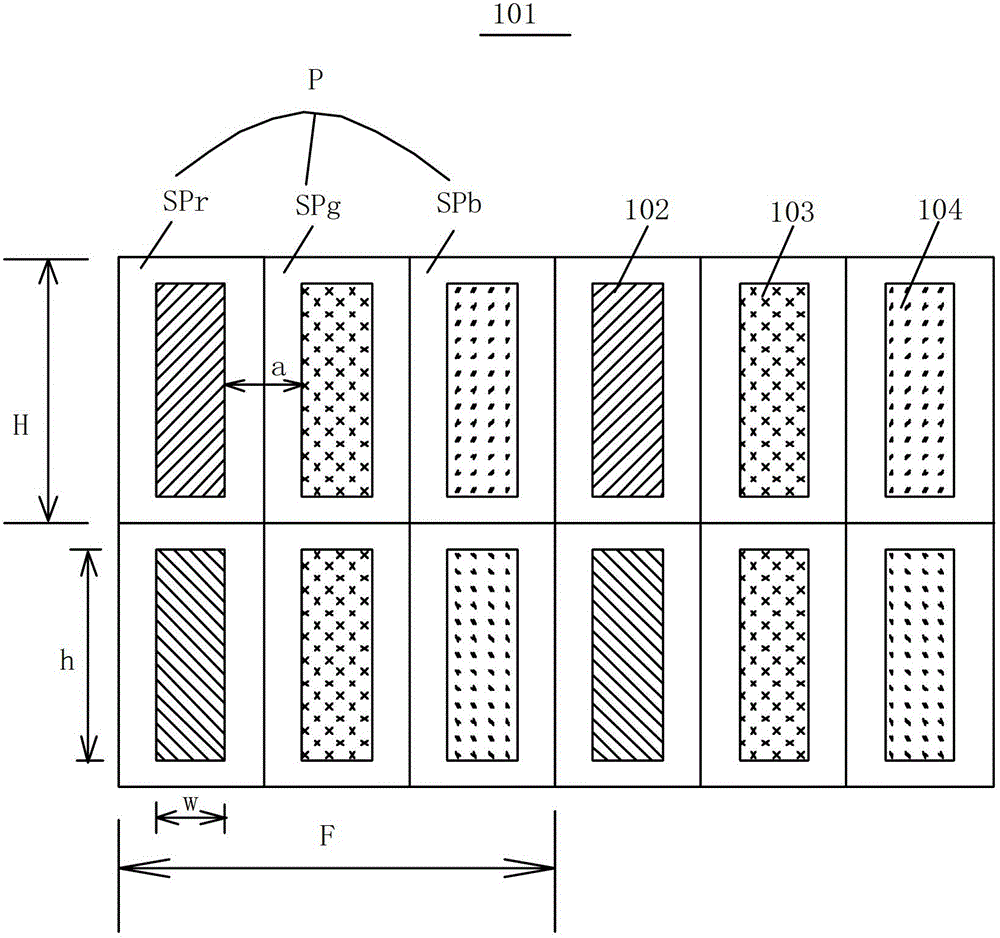

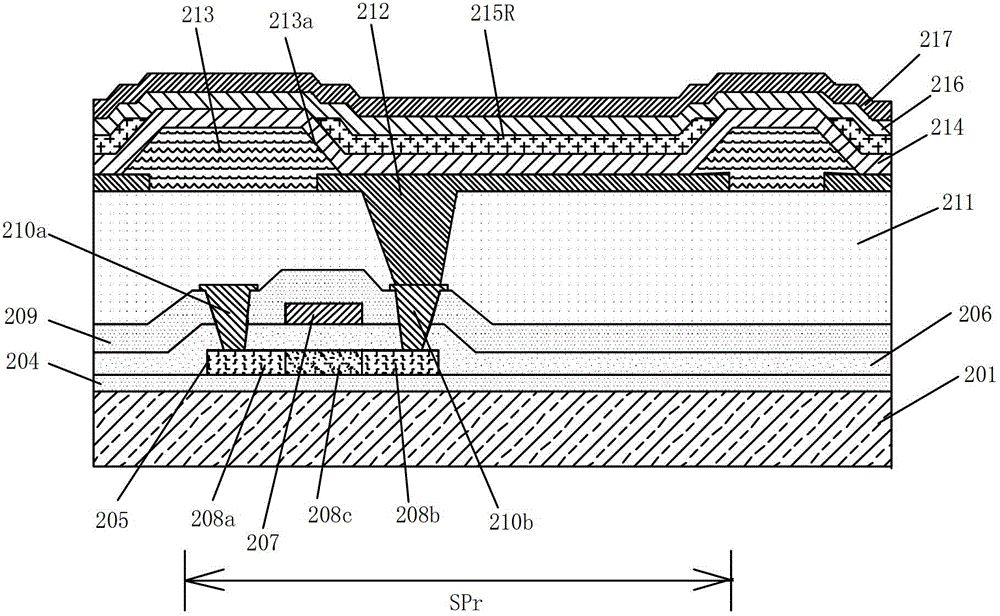

Organic light-emitting display device and mask plate thereof

ActiveCN103943650AExtended service lifeIncrease the hole sizeSolid-state devicesSemiconductor/solid-state device manufacturingDesign standardImage resolution

The invention provides an organic light-emitting display device. Specific layout is carried out on pixels, the hole size of the adopted vacuum evaporation mask plate is increased greatly, under the same mask plate design standards, a higher-resolution pixel design standards can be more applicable, and thus manufacturing of the display device of higher resolution can be realized. On the premise that the technology complexity and the processes are not increased, four-color display can be realized through using three-color stacking, and defects of blocked holes, deformation and the like of the mask plate can be reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

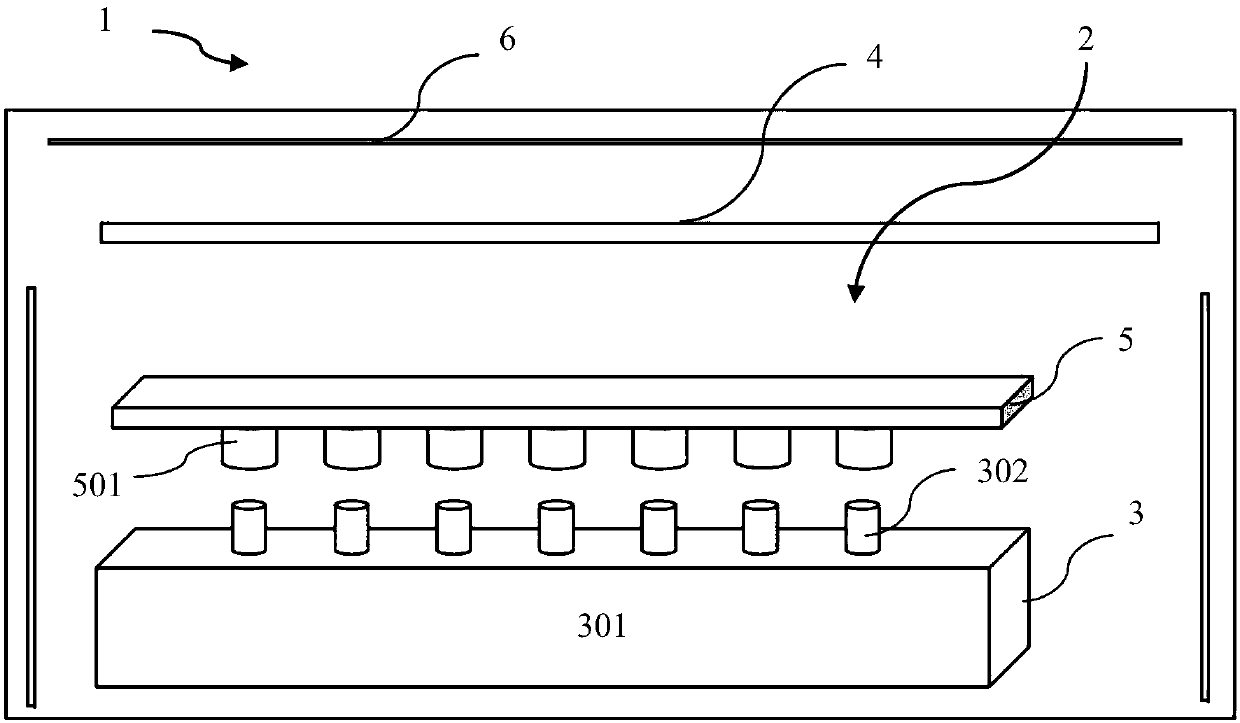

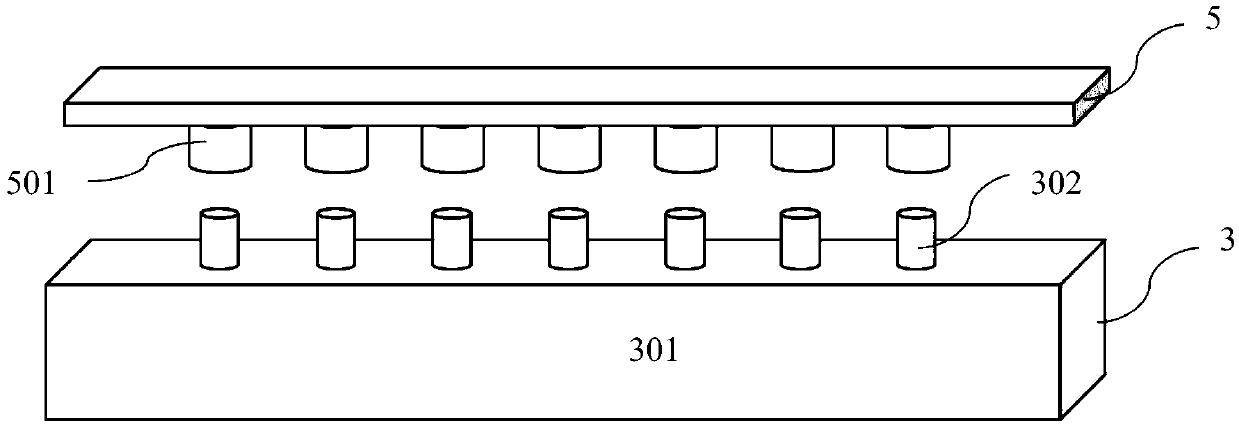

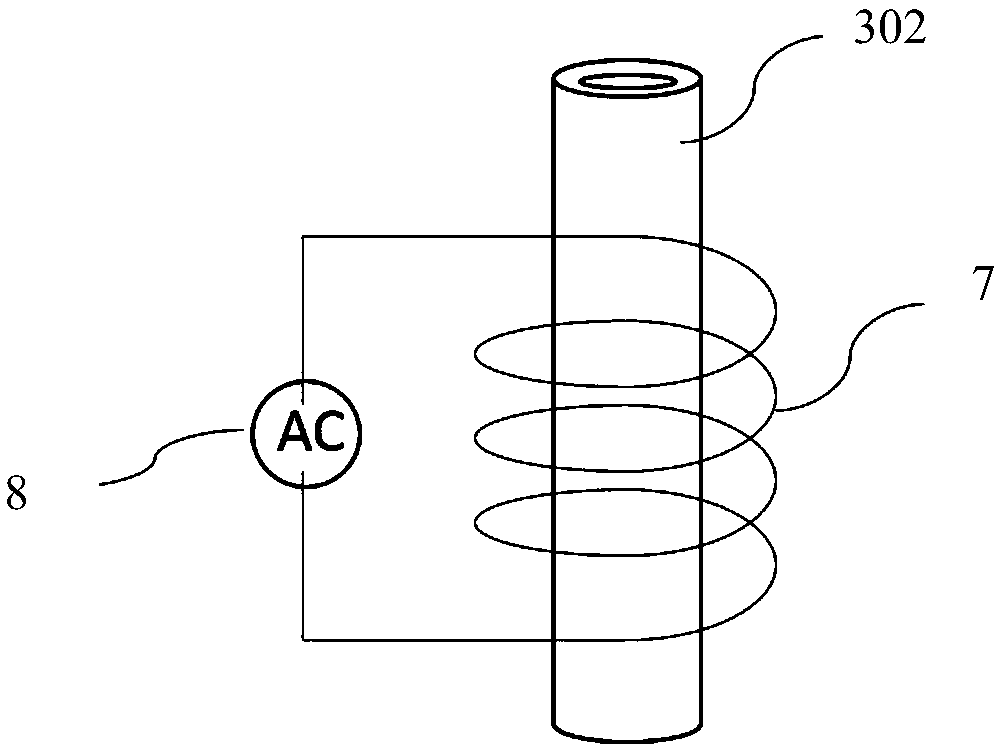

Evaporation device

PendingCN109930113AReduce pluggingEasy to evaporateVacuum evaporation coatingSputtering coatingSpray nozzleEvaporation

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Neutralization of deactivated polymerization catalyst using phosphoric or phosphonic acid salts

InactiveUS7999046B2Reduce corrosionReduce pluggingVapor condensationPolymer scienceAlkaline earth metal

A process for deactivating an active catalyst species in an olefin polymer stream exiting a polymerization reactor and neutralizing catalyst residues, as well as reducing corrosion, plugging or fouling of olefin production and recovery equipment and imparting antioxidative properties to an olefin polymer comprising adding a catalyst deactivator and an alkaline earth metal salt of a phosphoric- or phosphonic acid to an olefin polymer stream exiting a polymerization reactor, each in a quantity at least sufficient to deactivate active catalytic species in the polymer stream and neutralize catalyst residues, respectively, and subsequently recovering the resulting polymer product.

Owner:DOW GLOBAL TECH LLC

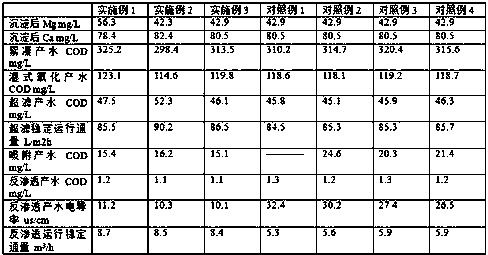

Integrated treatment method for viscous oil wastewater

InactiveCN110357298AGuaranteed uptimeImprove the water effectFatty/oily/floating substances removal devicesOther chemical processesFlocculationWater discharge

The invention relates to an integrated treatment method for viscous oil wastewater, and belongs to the technical field of water treatment. The method mainly utilizes demulsification, sedimentation hardness-removal, flocculation, oxidation, ultrafiltration, adsorption and reverse osmosis treatments to achieve the comprehensive and stable running effect. The method has the advantages of cooperationof all units, stability in running, and good water discharge effect.

Owner:江苏悠谷未来科技有限公司

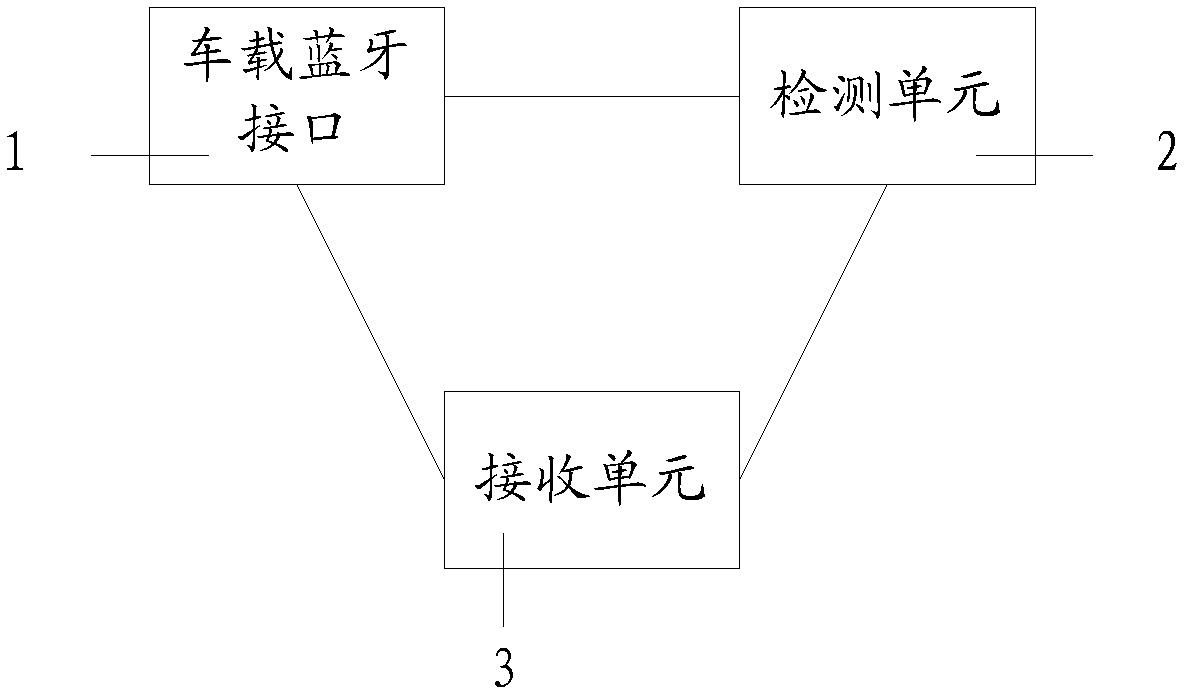

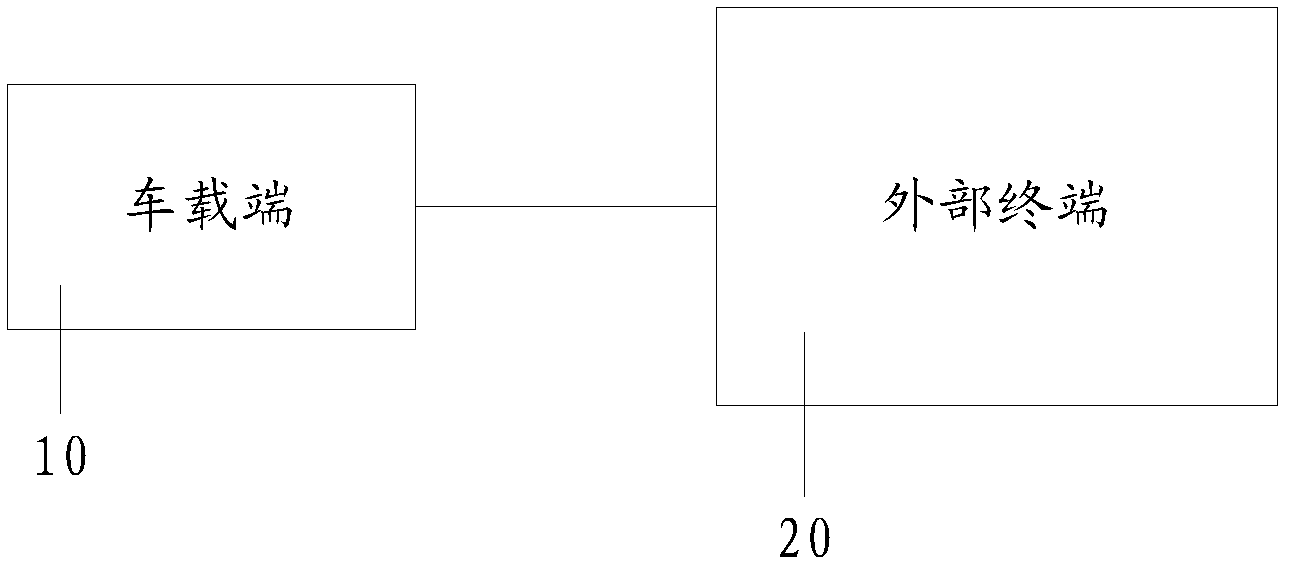

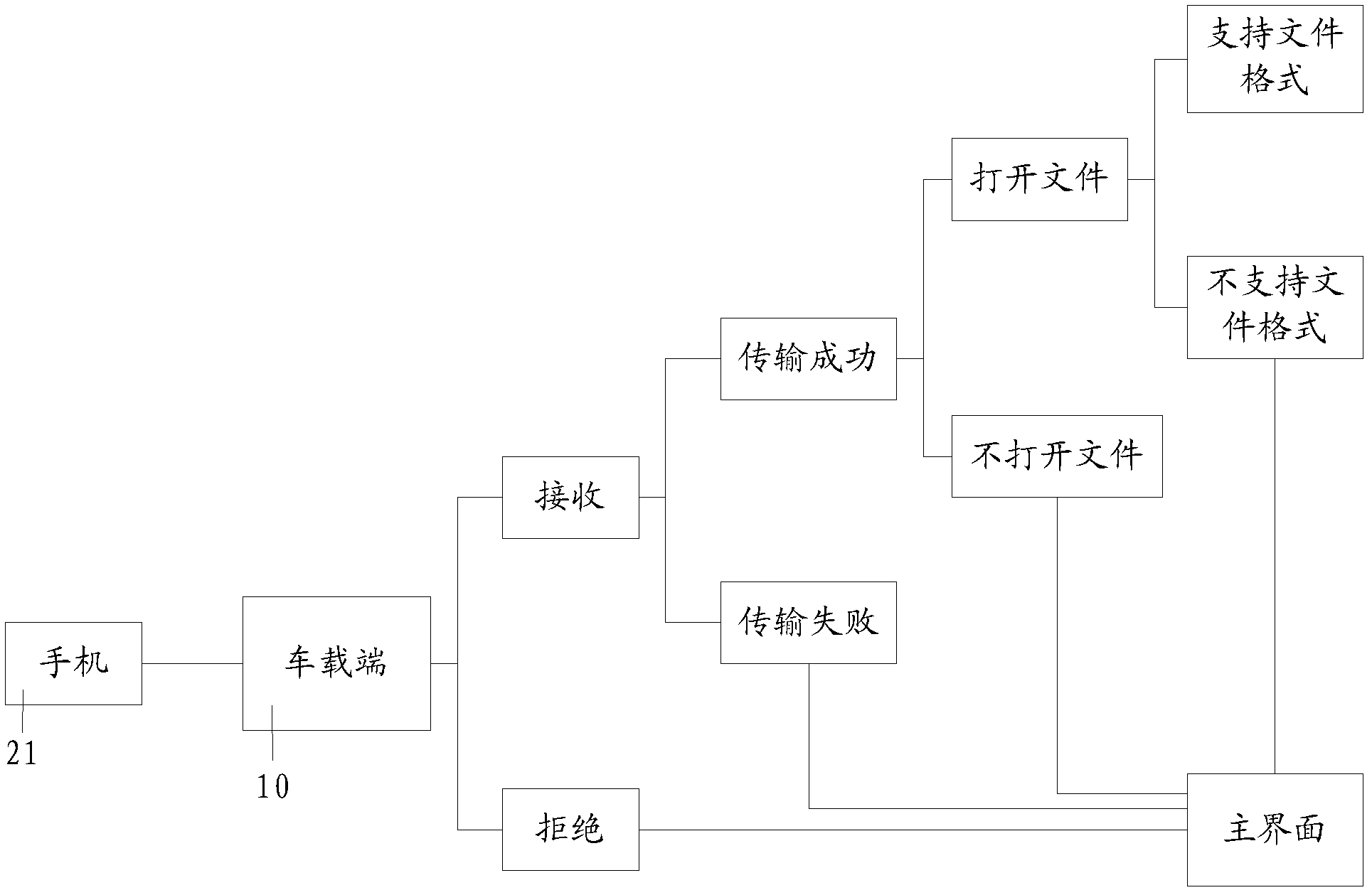

Vehicle terminal and document transmission system

ActiveCN103187992AReduce pluggingReduce wear rateNear-field transmissionExternal storageEmbedded system

The invention relates to a vehicle terminal and a document transmission system. The vehicle terminal comprises a vehicle bluetooth interface for bluetooth communication with an external terminal, a detection unit for detecting an external storage medium of the vehicle terminal after acquiring a document transmission request transmitted by the external terminal, and a receiving unit for receiving a document transmitted by the external terminal through the vehicle bluetooth interface after the detection unit detects that the external storage medium of the vehicle terminal is normal. With the adoption of the technical scheme a vehicle system can store more data, the data safety can be ensured, the inserting and drawing of the external storage medium are reduced, and user use is facilitated.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

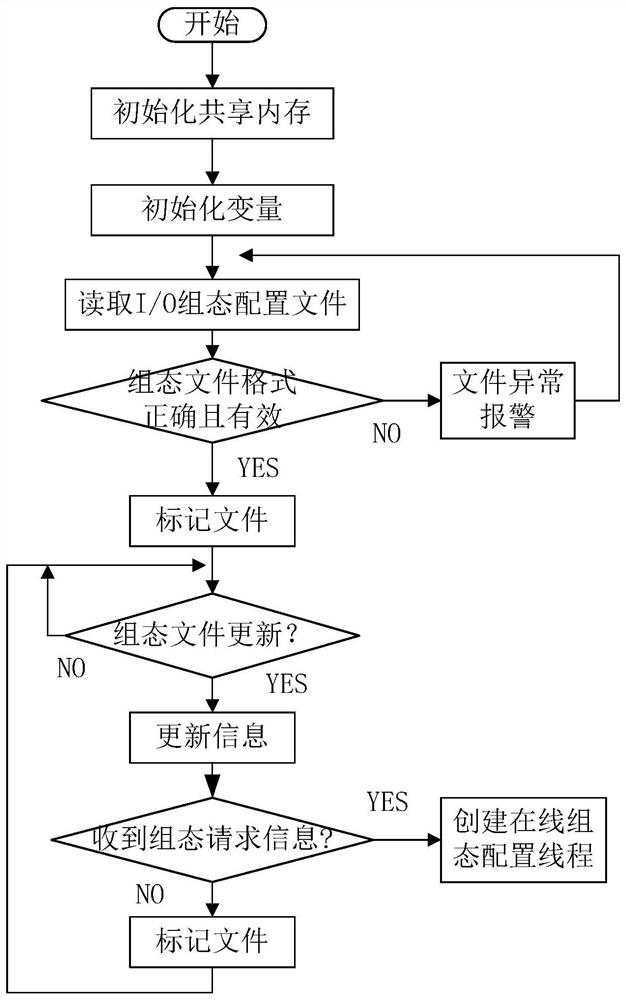

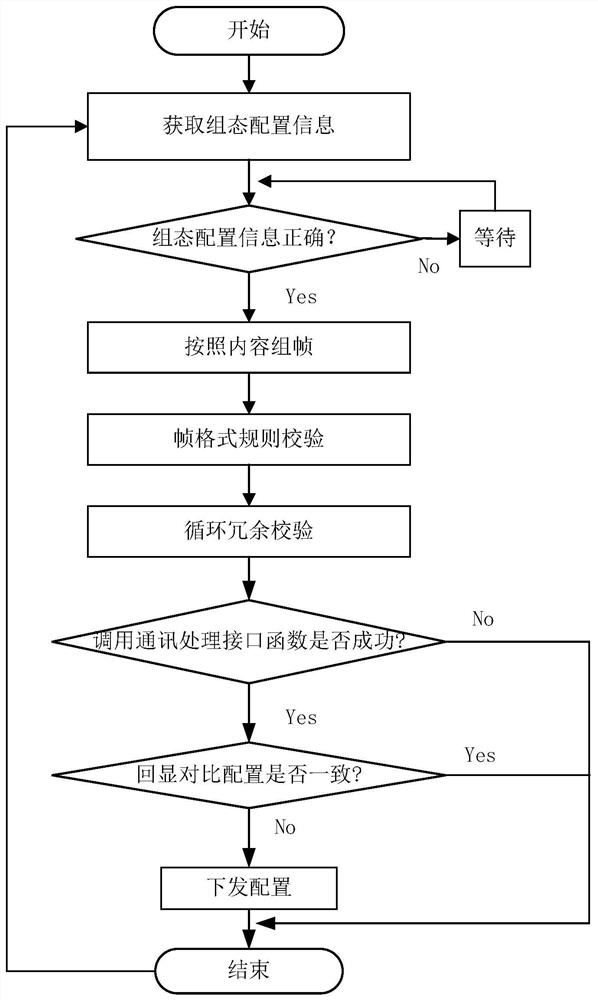

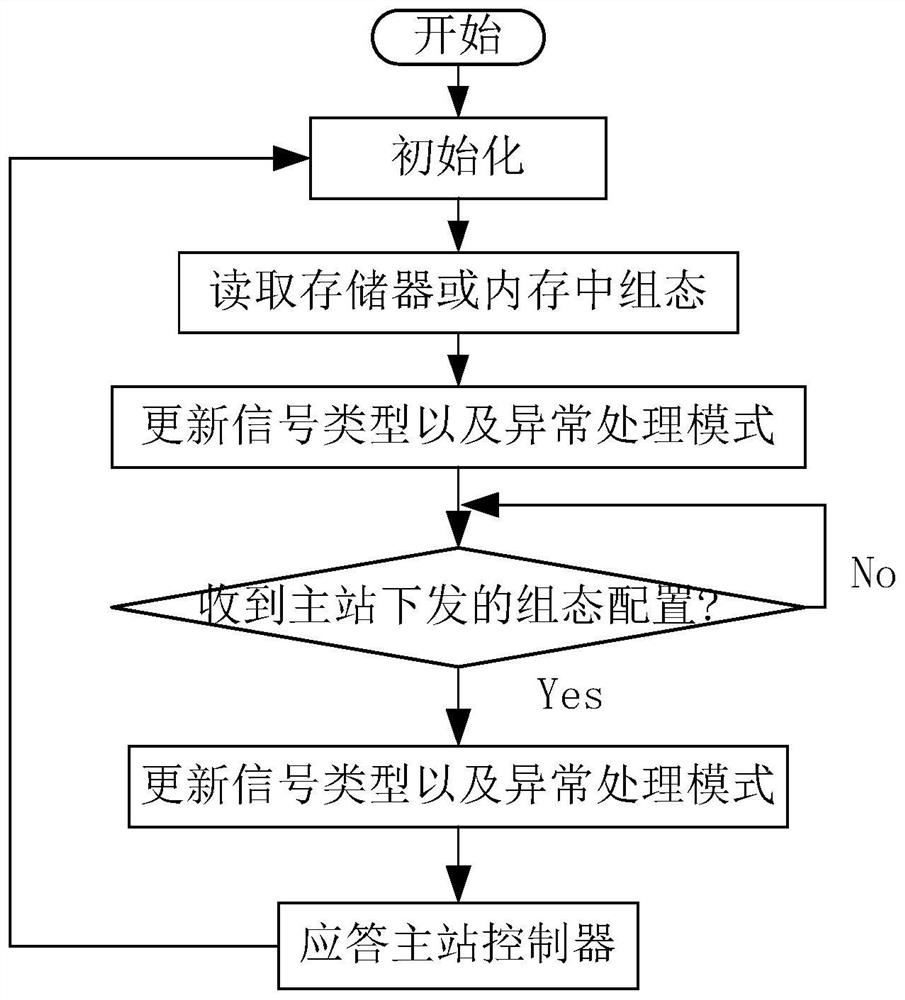

Online I/O undisturbed configuration method for distributed control system

ActiveCN113220229AReduce I/O configuration timeReduce configurationInput/output to record carriersTotal factory controlComputer hardwareDistributed control system

The invention discloses an online I / O undisturbed configuration method for a distributed control system, the distributed control system comprises a controller and at least one I / O module, when the controller is started, an I / O configuration file is called, marking is carried out according to the content of the I / O configuration file, whether an updated I / O configuration file is received or not is monitored in real time, after the updated I / O configuration file is received, framing is carried out, configuration information is added into communication information, the communication information is sent to the I / O module, and feedback information of the I / O module is received; and each I / O module checks the new configuration file in real time, and updates and replies to the controller after receiving the new configuration file. According to the invention, the I / O module configuration file is set in the controller, framing is carried out according to the I / O module configuration file, the configuration file is updated in real time, and the configuration file is issued to the corresponding I / O module, so that automatic online configuration of the I / O module is realized, the updated configuration file is generated when the I / O module changes, and the communication load is reduced.

Owner:浙江正泰中自控制工程有限公司

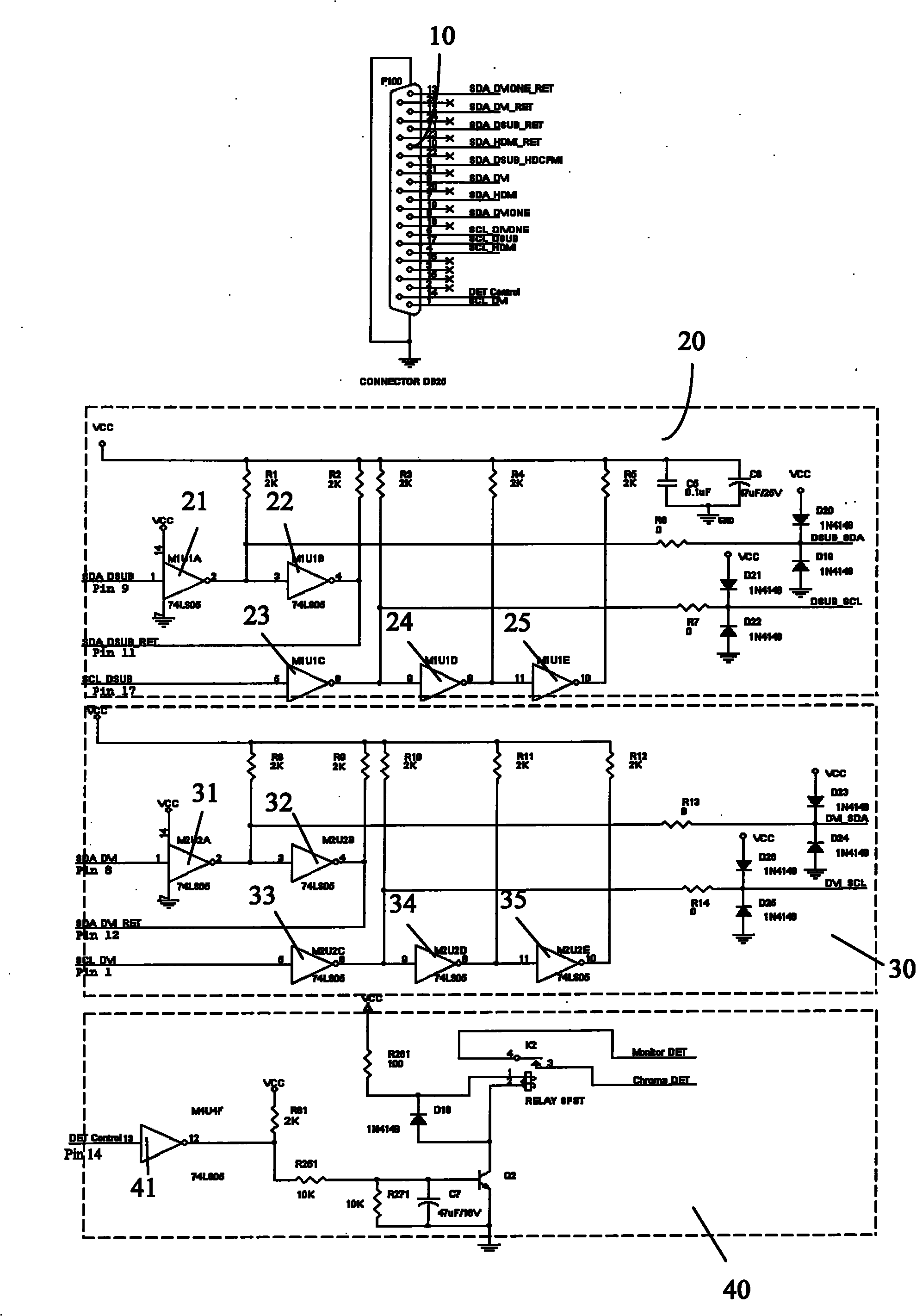

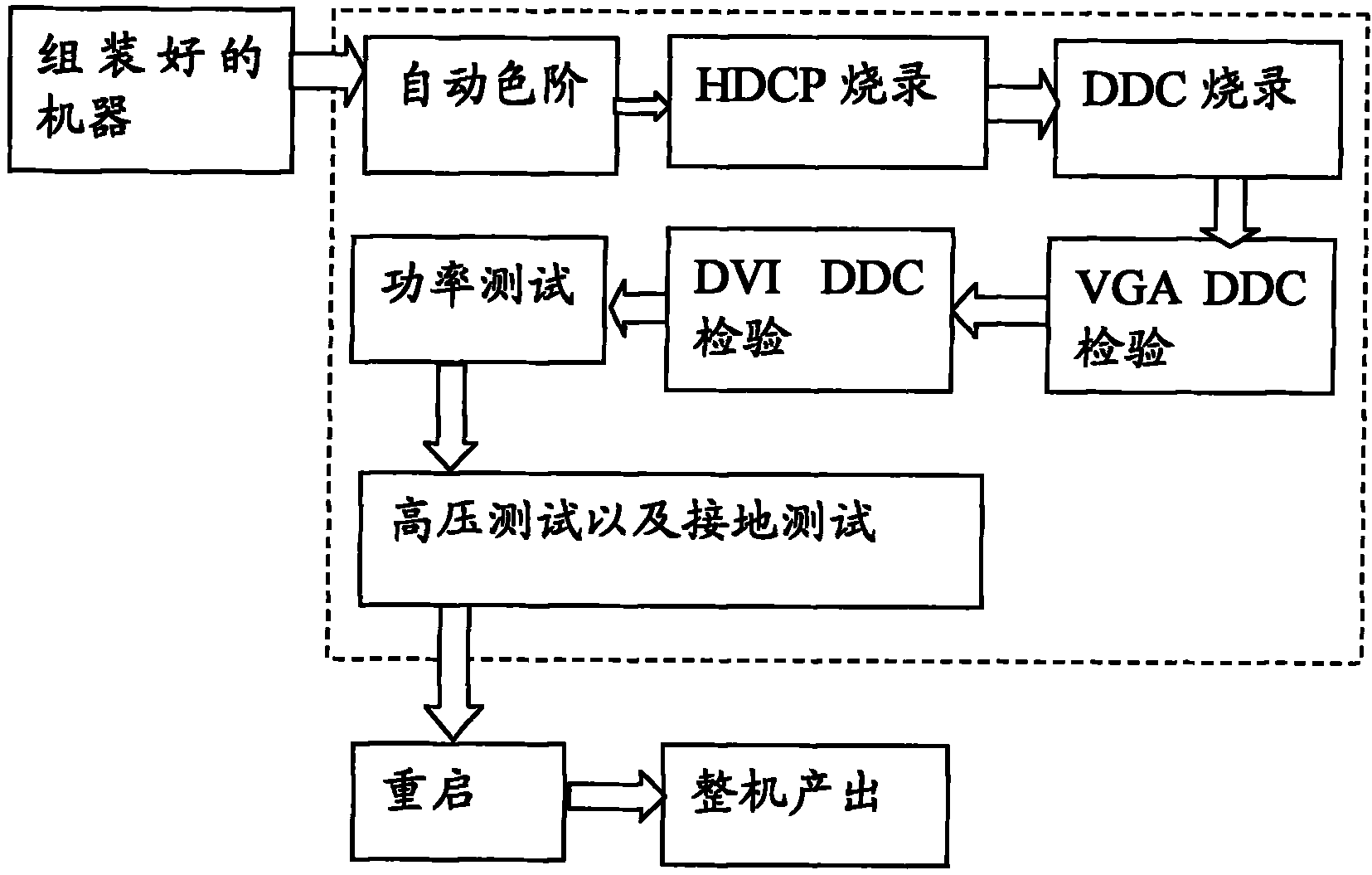

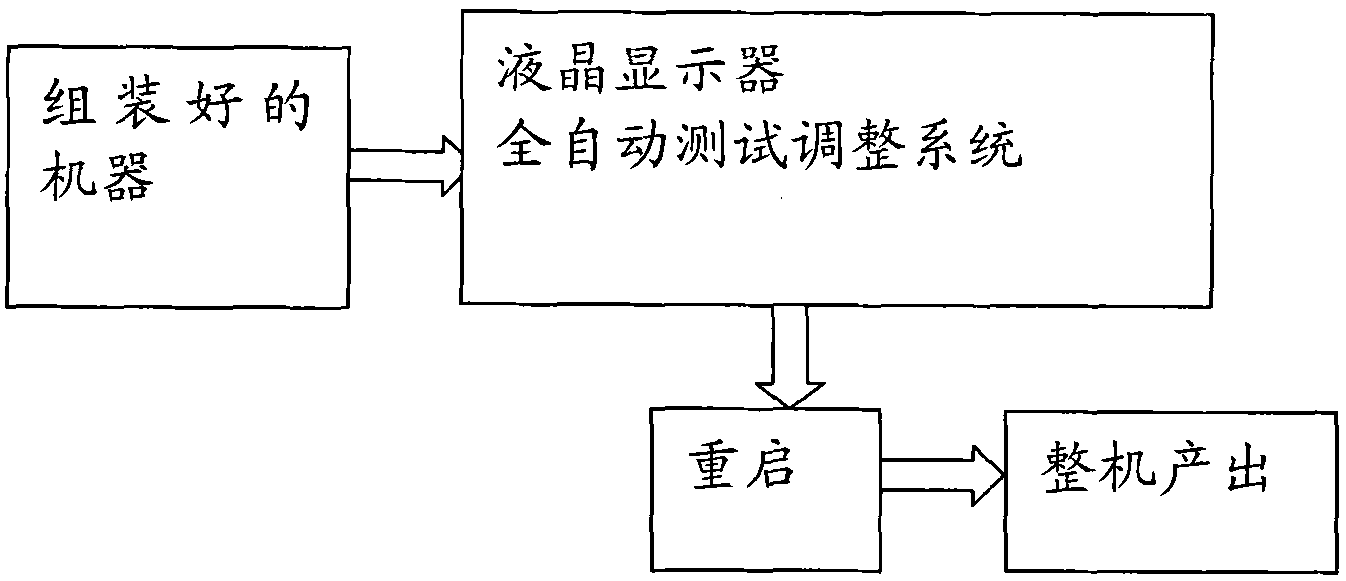

Full automatic adjustment and test system for liquid crystal display

InactiveCN101577078BReduce pluggingReduce homework actionsStatic indicating devicesElectrical testingLiquid-crystal displayTester device

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com