Positive pressure concentrated phase constant pressure conveying system

A conveying system and dense phase technology, applied in the field of positive pressure dense phase constant pressure conveying system, can solve problems such as inability to adjust, and achieve the effects of simple system configuration, reliable system operation, and low maintenance workload and maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

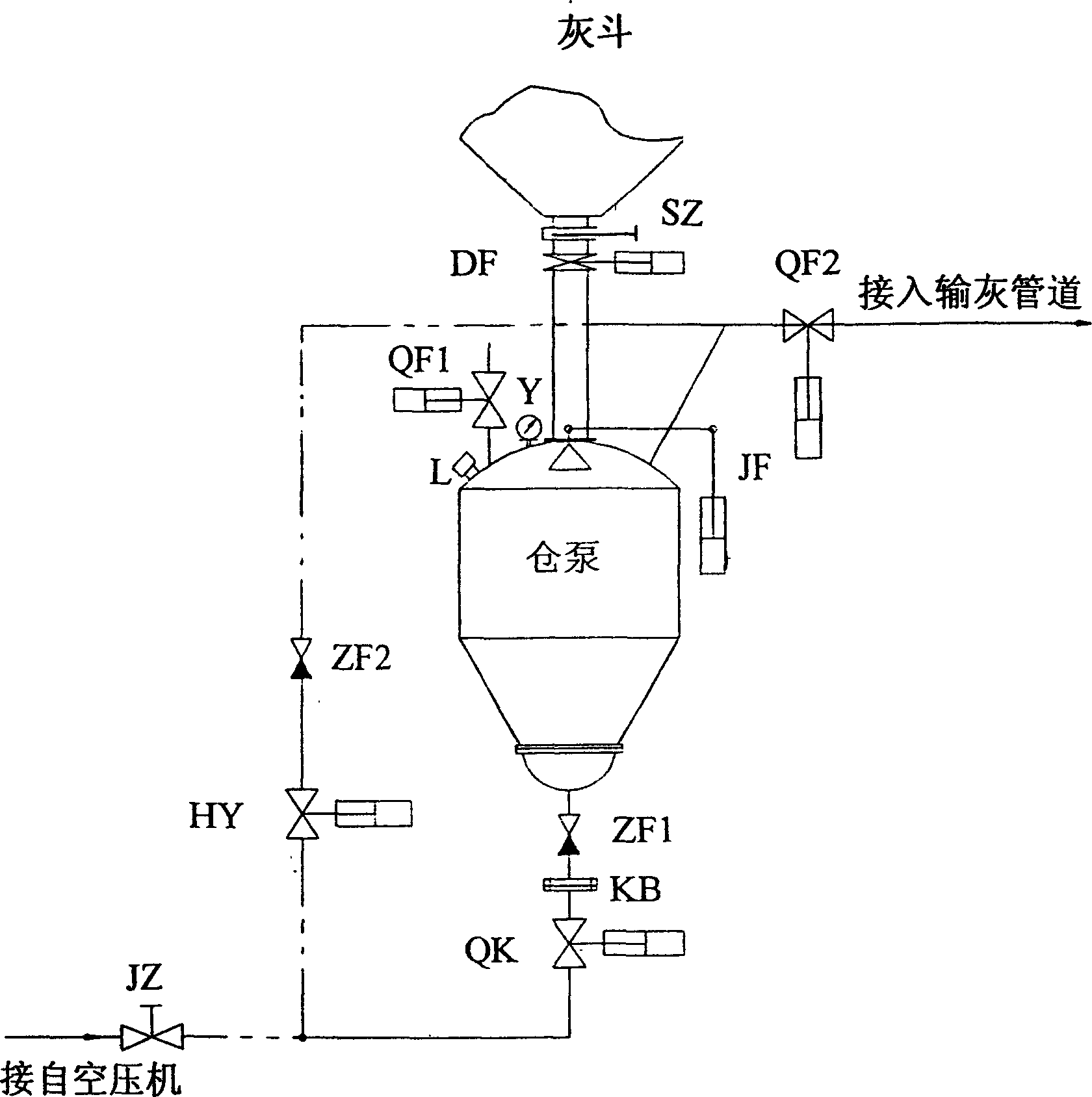

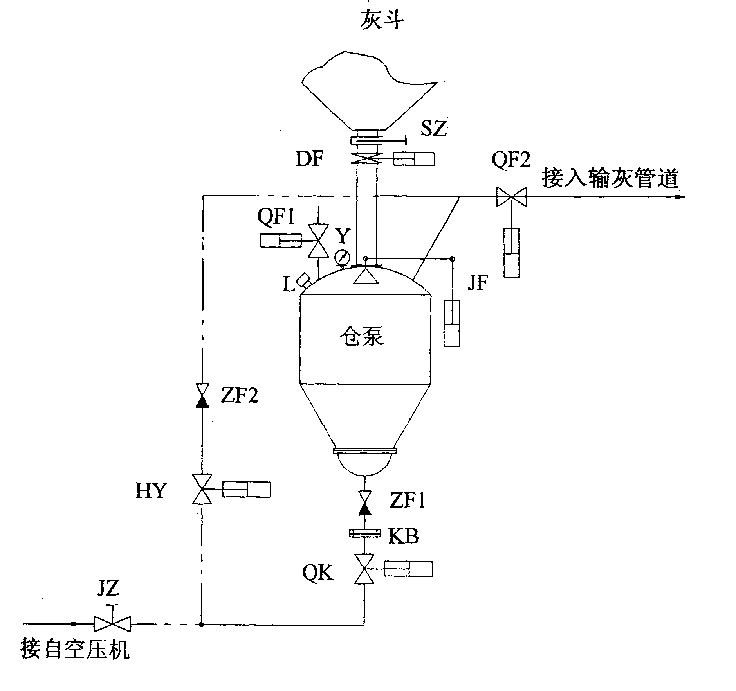

[0016] As shown in the accompanying drawings, the present invention includes a warehouse pump equipped with a material level gauge L, a pressure transmitter Y, a breathable pneumatic ball valve QF1, ash conveying pneumatic ball valve QF2, a feed valve JF, and a pneumatic butterfly valve DF on the upper part; it is connected to the lower part of the warehouse pump The air supply system; the conveying system connected with the ash conveying pneumatic ball valve QF2 of the warehouse pump.

[0017] 1) Air supply system: including air control valve QK, orifice KB, first check valve ZF1; one end of air control valve QK is connected to the air outlet end of manual shut-off valve JZ connected to the air compressor, and the air control valve QK One end is connected to one end of the orifice plate KB, one end of the first check valve ZF1 is connected to the other end of the orifice plate KB, and the other end of the first check valve ZF1 is connected to the lower part of the warehouse pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com