Matching structure of door guard plate and inner triangular block and assembling process of matching structure

A technology of matching structure and assembly process, applied to doors, transportation and packaging, motor vehicles, etc., can solve problems such as difficult control, gap between door guard plate and inner triangle block, loose inner triangle block, etc., and achieve saving Unit cost, reduce screw plugging, save mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

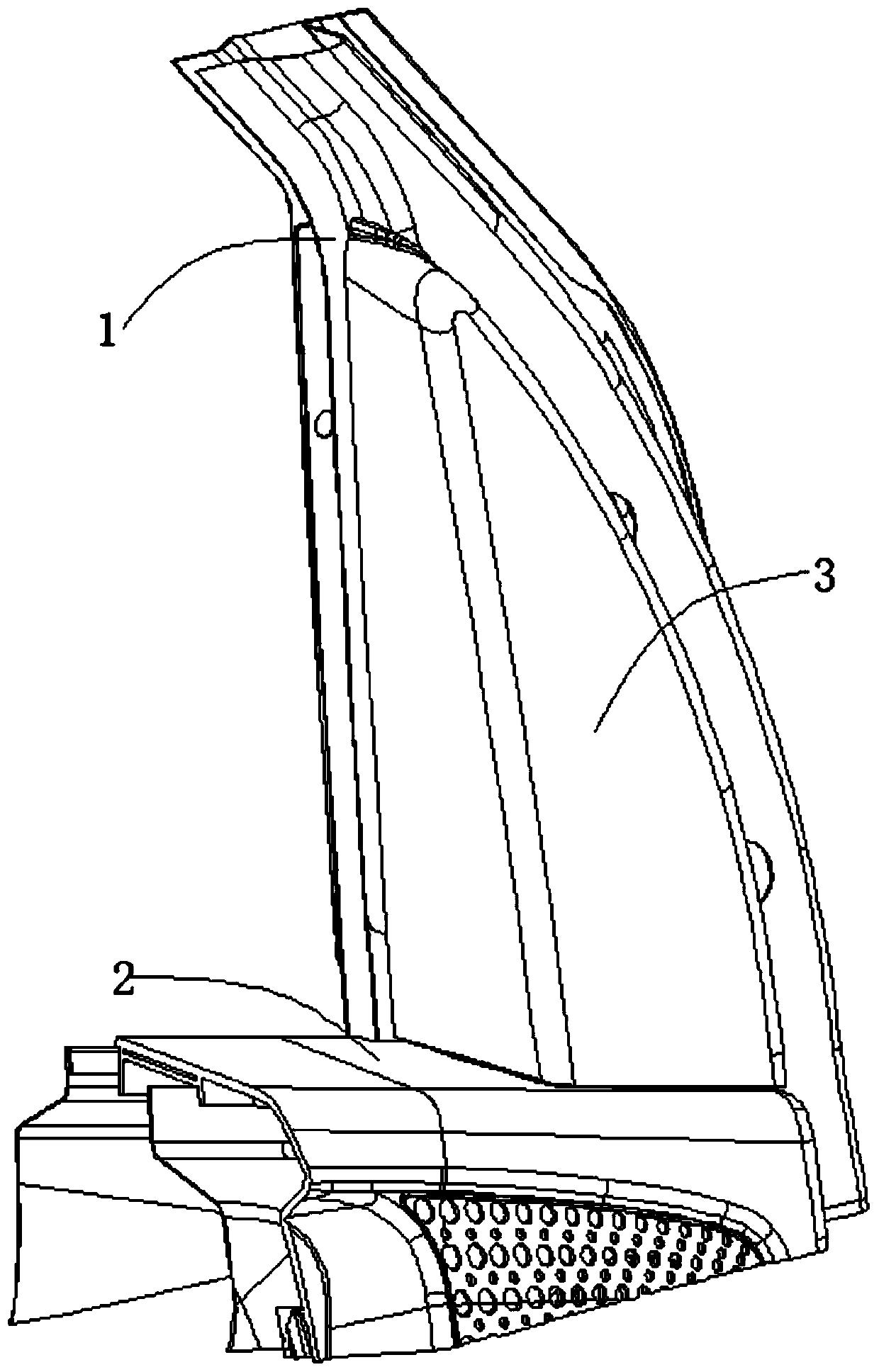

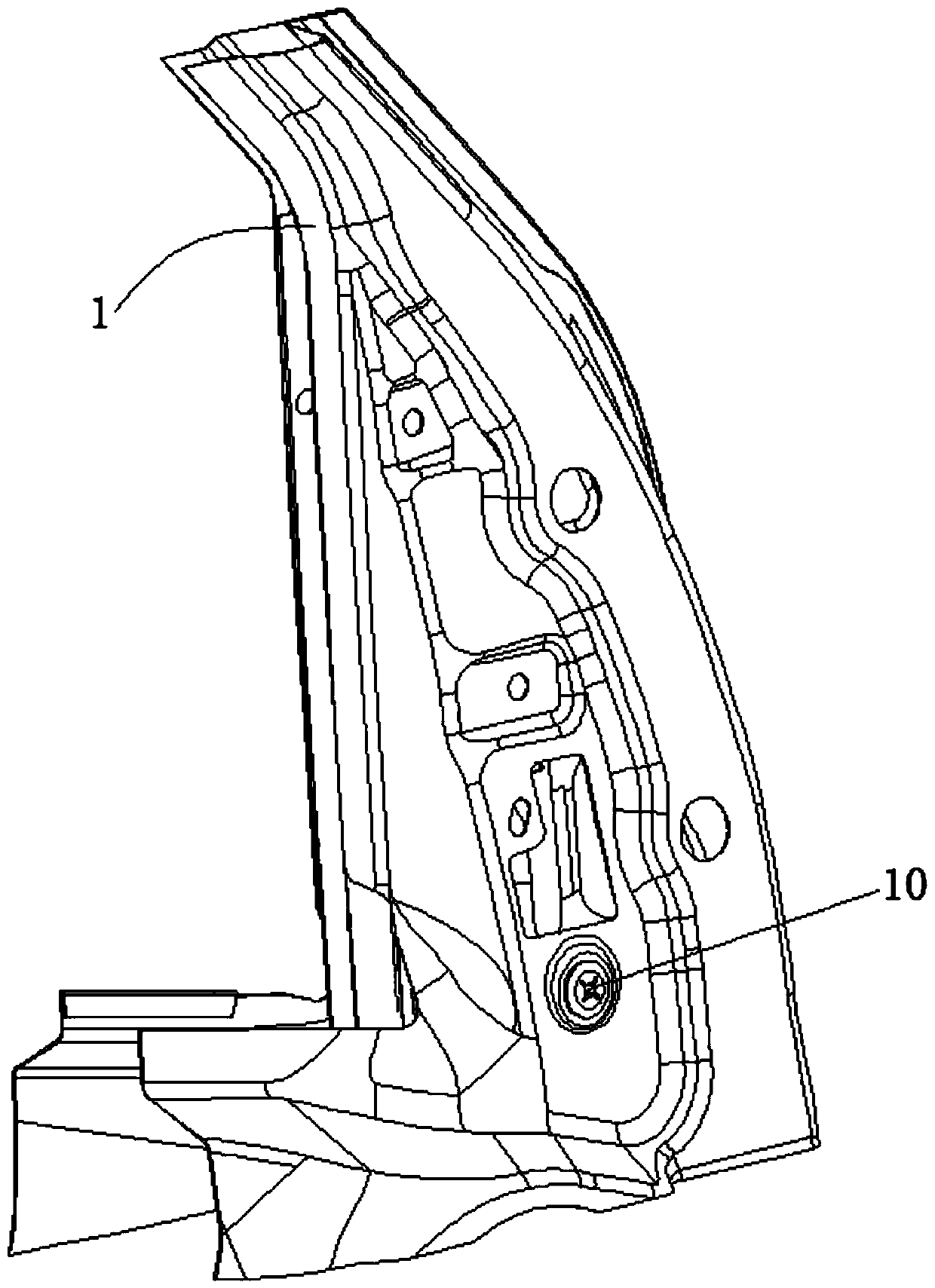

[0044] In the present invention, the screw 4 passes through the cylindrical hole 2-1 and is tightened in the threaded hole 10, so that the door guard plate 2 and the door sheet metal 1 are closely matched, and the screw 4 is strongly connected to prevent the door guard plate 2 from sinking due to its own weight. The gap with the inner triangle block 3 becomes larger, ensuring the position of the door guard plate 2 in the Y direction, so that after the door guard plate 2 and the door sheet metal 1 are closely fitted, the Y-direction gap between the door guard plate 2 and the side of the instrument panel is 2mm±0.01mm.

Embodiment 2

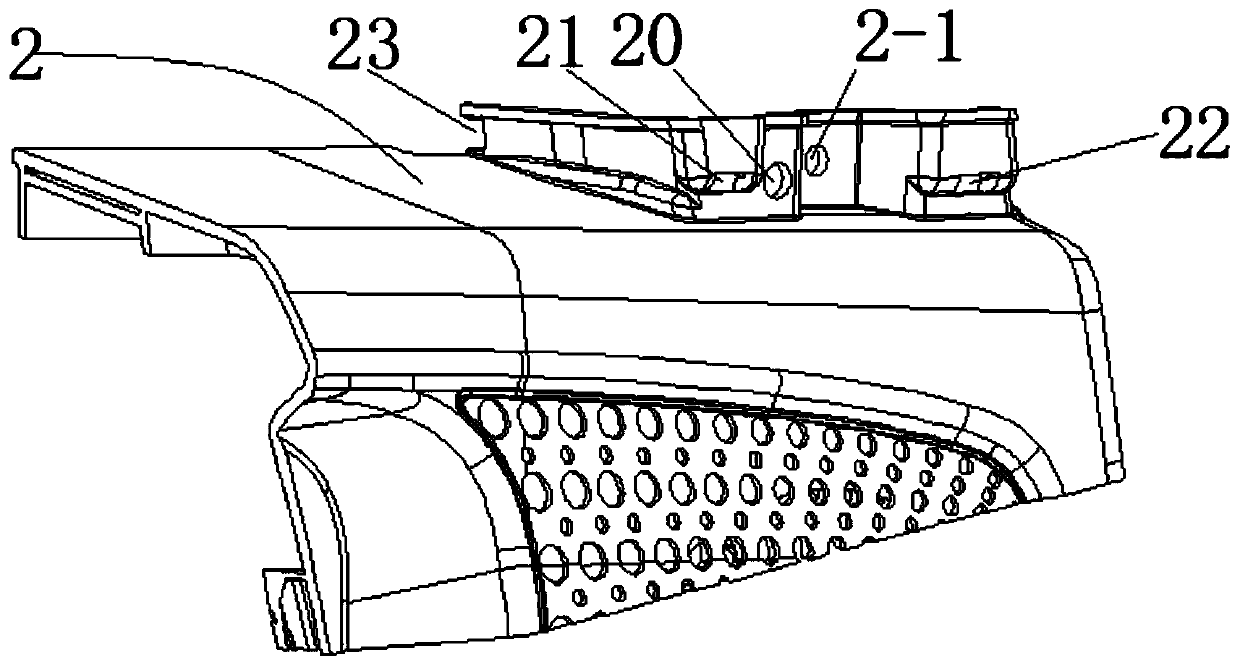

[0046] In the present invention, a cross positioning hole 20 is provided next to the cylindrical hole 2-1, a first card slot 21 and a second card slot 22 are respectively provided on both sides of the upper end of the door guard plate 2, and a second card slot 22 is provided on the side of the door guard plate 2. Three card slots 23, the middle part of the lower end of the inner triangle block 3 is provided with a cross positioning pin 30, the two sides of the cross positioning pin 30 are respectively provided with a first buckle 31 and a second buckle 32, and the inner triangle block 3 lower end sides are provided with The third buckle 33, the inner triangle block 3 is connected with the door guard plate 2, and the cross positioning pin 30 is inserted into the cross positioning hole 20 for positioning. The buckle 32 is inserted into the second card slot 22 for clamping, and the third buckle 33 is inserted into the third card slot 23 for clamping, which ensures that the inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com