Drilling, cutting, discharging and diversion integrated coal seam physical and chemical combination permeability increase system and method

A physical chemistry and coal seam technology, which is applied in the direction of gas discharge, mining fluid, earthwork drilling, etc., can solve problems such as environmental degradation of the workplace, blockage of drilling jets, suspension of slotting operations, etc., to increase porosity and porosity Connectivity, reduce plugging, and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

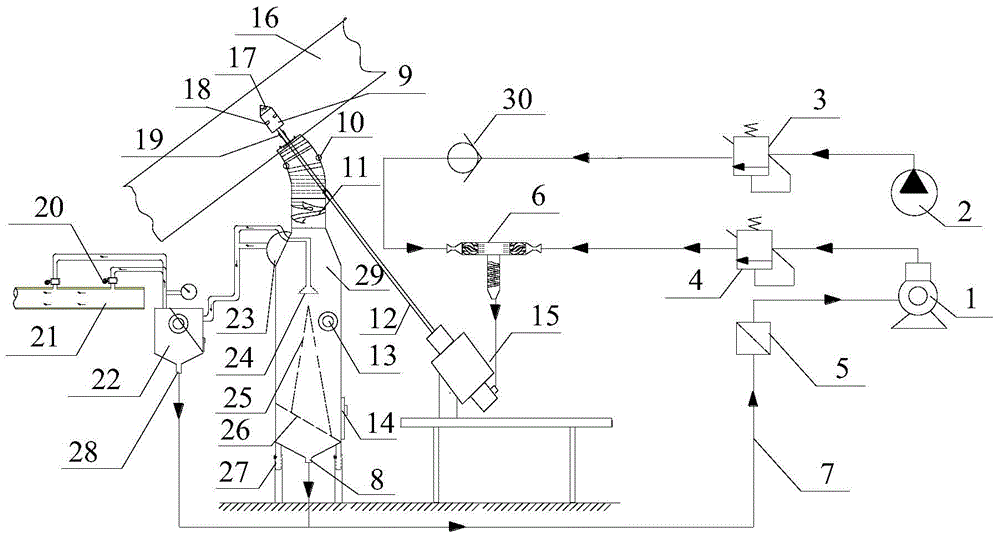

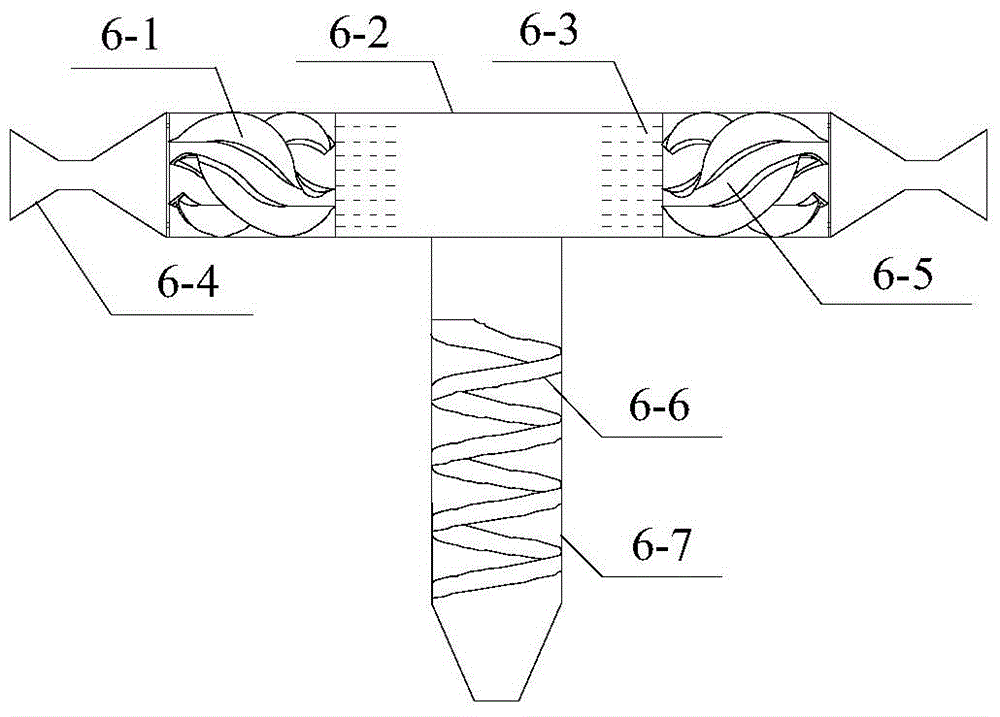

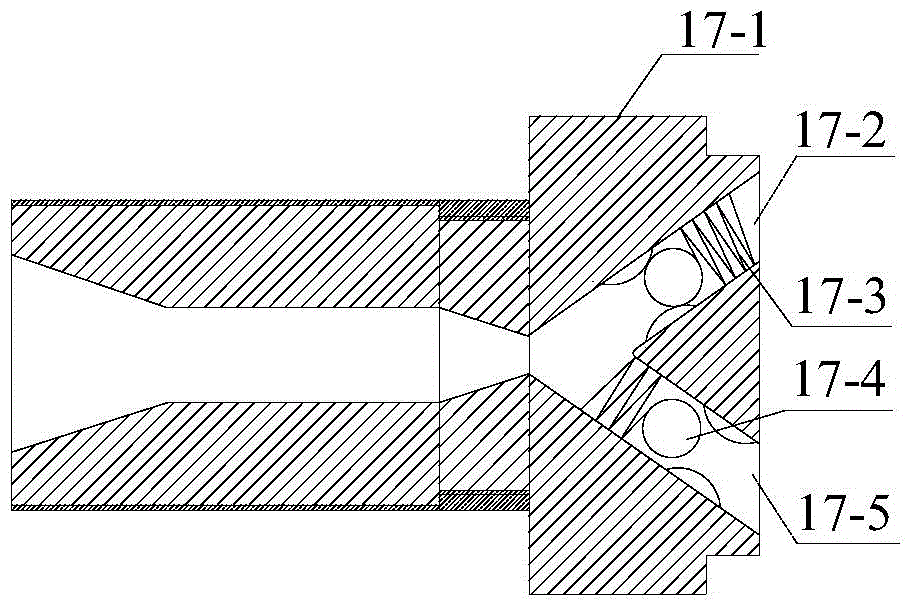

[0029] like figure 1As shown, the integrated coal seam physical and chemical anti-reflection system for drilling, cutting, rowing and dividing of the present invention consists of a high-pressure water pump 1, a dosing pump 2, a dosing pump pressure regulating valve 3, a high-pressure water pump regulating valve 4, a filter 5, and a dosing pump. Jet mixer 6, high-pressure rubber hose 7, main body drain port 8, pressure control drill bit 9, hanging lug 10, swirl generator 11, drill pipe 12, perspective window 13, slag discharge door 14, drilling rig 15, coal seam 16, front Nozzle 17, side nozzle 18, orifice sealer 19, ball valve 20, extraction pipeline 21, transfer purification box 22, hemispherical gas collection chamber 23, absorption cone 24, filter cone 25, filter plate 26, liftable support 27 , transfer purification box outlet 28, water gas separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com