Full automatic adjustment and test system for liquid crystal display

A liquid crystal display and test system technology, applied to static indicators, instruments, measuring electronics, etc., can solve problems such as personnel safety hazards, inability to perform other operations, and personnel operation leakage hazards, so as to reduce operation leakage hazards and prevent quality problems. problems, the effect of avoiding security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

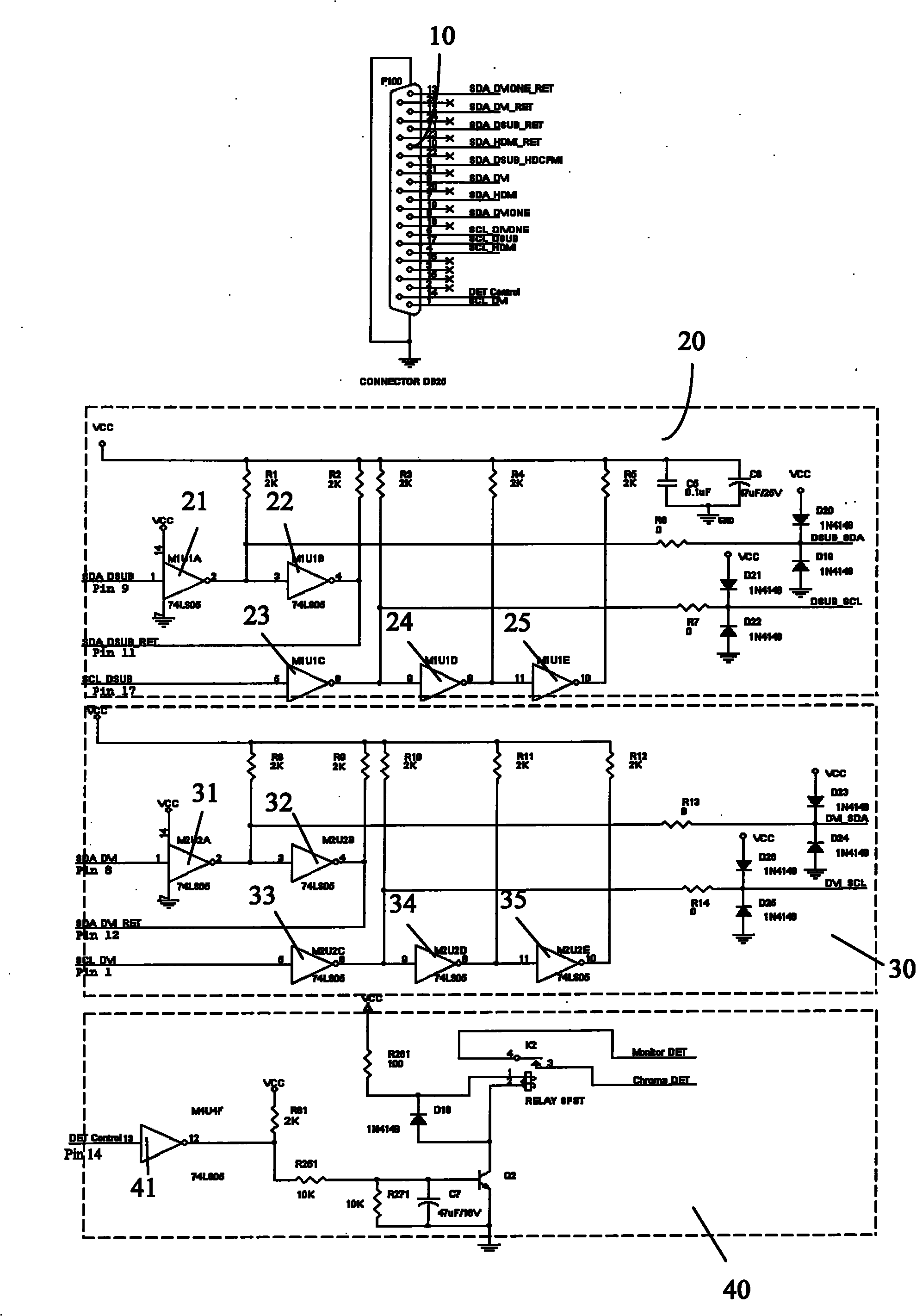

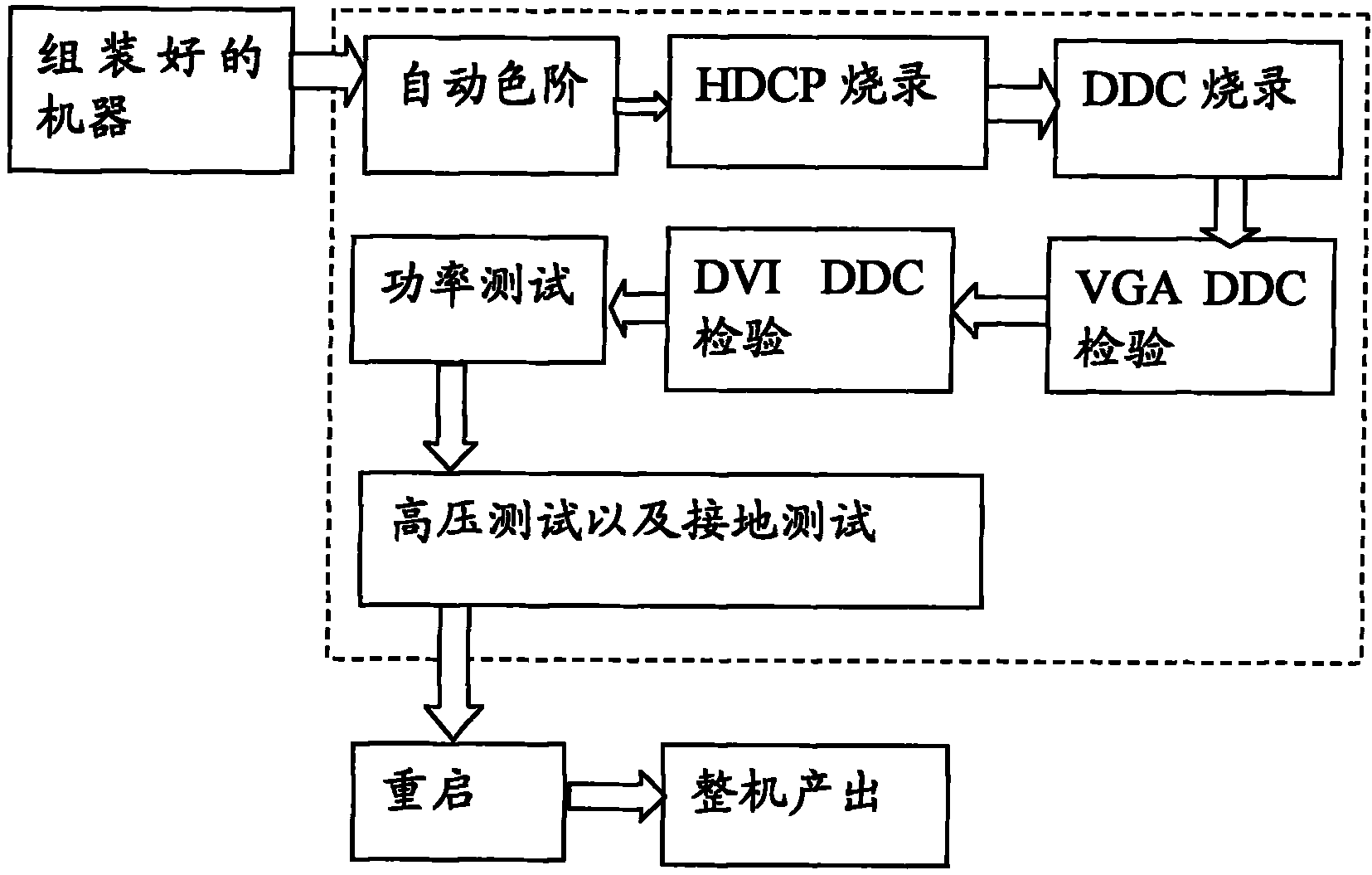

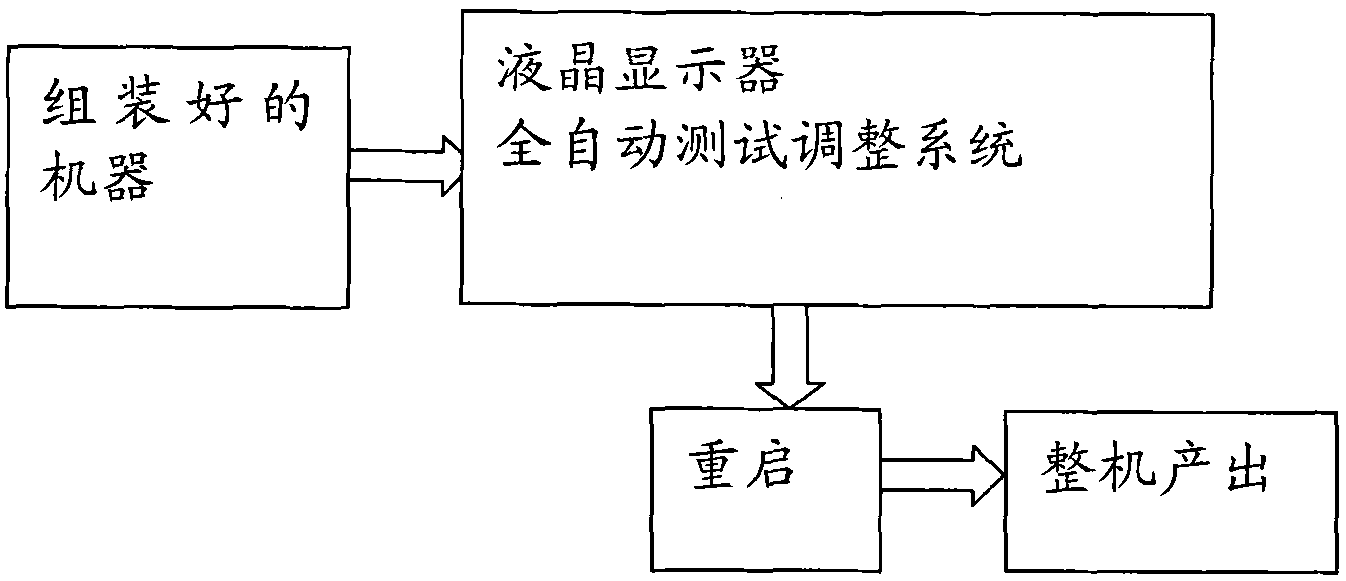

[0062] The main function of this system is to integrate all debugging, testing, programming and inspection into one program system, so that the operator can complete all functions through some simple actions. Its design idea is: Integrate the parts that require multiple repetitive actions in the production process, remove these repeated wiring actions and the waiting time of assembly line production, simplify the operation, test, burn and monitor the state control completely by the The system program is completed. Such as figure 2 Shown is the process diagram of the liquid crystal display production line after using the automatic adjustment test system of the present invention. After the assembled machine (liquid crystal display or liquid crystal TV) enters the production line, it can be restarted after passing through the automatic adjustment test system. machine output. From figure 2 It can be seen that after using this system, multiple stations are merged into one stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com