Integrated treatment method for viscous oil wastewater

A technology of heavy oil wastewater and treatment method, applied in the field of water treatment, can solve the problems of large water quality fluctuation, large impurity content, unstable water quality of heavy oil wastewater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

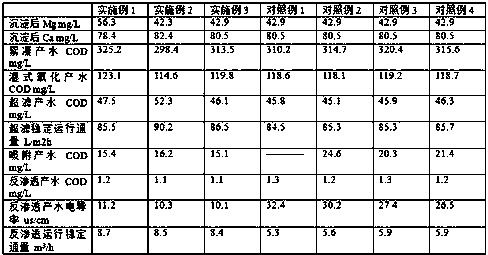

Examples

Embodiment 1

[0032] The first step is to send the heavy oil wastewater into the natural sedimentation tank to make the sediment in it settle;

[0033] In the 2nd step, add 200ppm polyether type demulsifier to the upper layer waste water that obtains in the 1st step and carry out demulsification treatment;

[0034] In the 3rd step, add Na to the waste water after demulsification obtained in the 2nd step 2 CO 3 And NaOH precipitates calcium and magnesium ions;

[0035] In the 4th step, 100 ppm polyaluminum chloride is added to the waste water obtained in the 3rd step for flocculation treatment, and after flocculation, sedimentation is carried out to remove the precipitate;

[0036] Step 5, perform wet oxidation treatment on the wastewater after flocculation and settlement, the temperature of wet oxidation is 160°C, the pressure is 2.5MPa, and the hydraulic retention time is 45min;

[0037] In the sixth step, the oxidized waste water is filtered with an ultrafiltration membrane, the molecu...

Embodiment 2

[0045] The first step is to send the heavy oil wastewater into the natural sedimentation tank to make the sediment in it settle;

[0046] In the 2nd step, add 500ppm polyether type demulsifier to the upper layer waste water that obtains in the 1st step and carry out demulsification treatment;

[0047] In the 3rd step, add Na to the waste water after demulsification obtained in the 2nd step 2 CO 3 And NaOH precipitates calcium and magnesium ions;

[0048] In the 4th step, 150 ppm polyaluminum chloride is added to the wastewater obtained in the 3rd step for flocculation treatment, and after flocculation, sedimentation is carried out to remove the precipitate;

[0049] The fifth step is to carry out wet oxidation treatment in the wastewater after flocculation and sedimentation. The temperature of wet oxidation is 180°C, the pressure is 3MPa, and the hydraulic retention time is 60min;

[0050] In the sixth step, the oxidized waste water is filtered with an ultrafiltration membr...

Embodiment 3

[0058] The first step is to send the heavy oil wastewater into the natural sedimentation tank to make the sediment in it settle;

[0059] In the 2nd step, add 400ppm polyether type demulsifier to the upper layer waste water obtained in the 1st step and carry out demulsification treatment;

[0060] In the 3rd step, add Na to the waste water after demulsification obtained in the 2nd step 2 CO 3 And NaOH precipitates calcium and magnesium ions;

[0061] In the 4th step, 120ppm polyaluminum chloride is added to the waste water obtained in the 3rd step for flocculation treatment, and after flocculation, sedimentation is carried out to remove the precipitate;

[0062] Step 5: Perform wet oxidation treatment on the wastewater after flocculation and sedimentation. The temperature of wet oxidation is 170°C, the pressure is 2.7MPa, and the hydraulic retention time is 50min;

[0063] In the sixth step, the oxidized waste water is filtered with an ultrafiltration membrane. The molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com