Patents

Literature

177 results about "Gravity drainage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

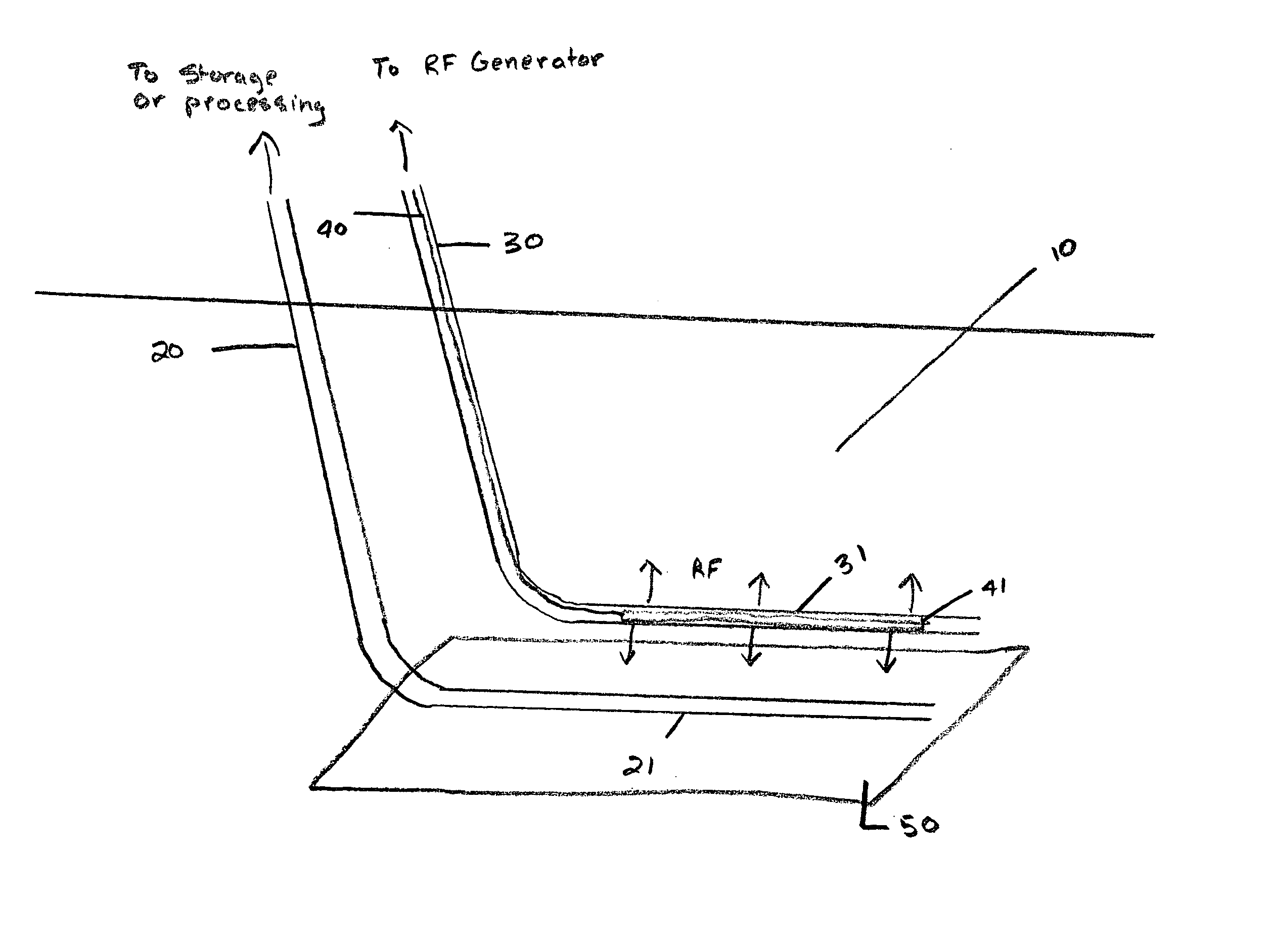

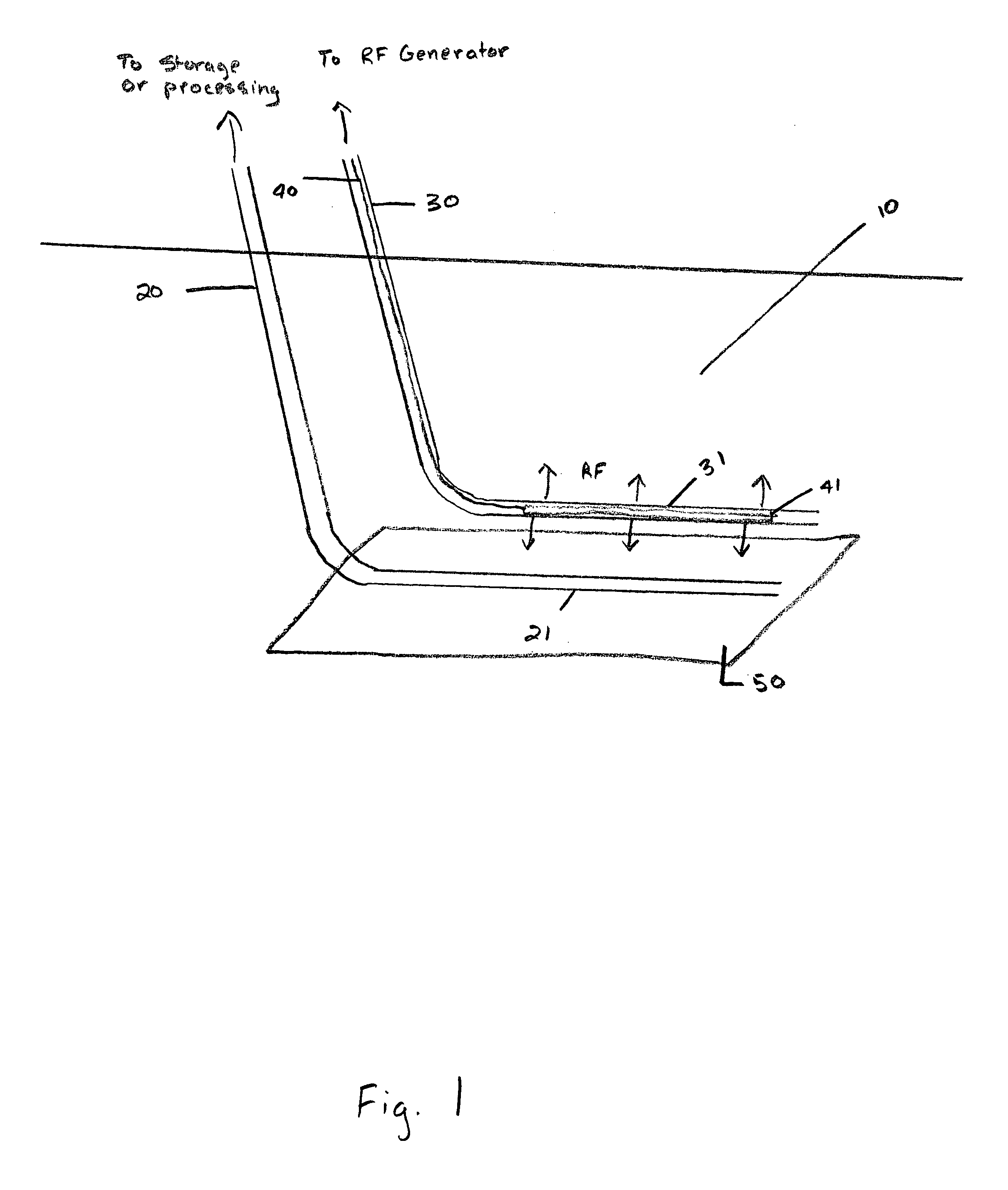

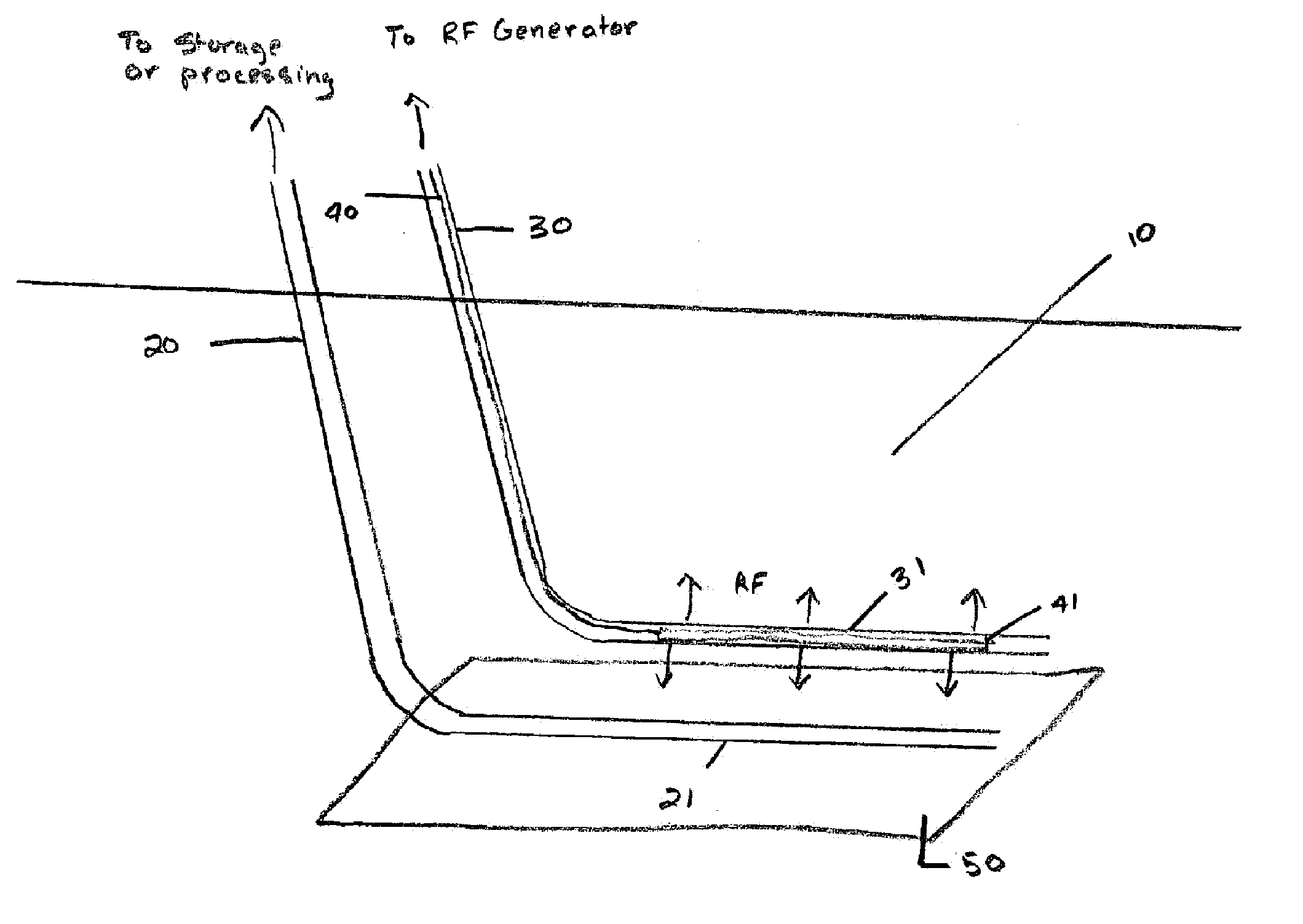

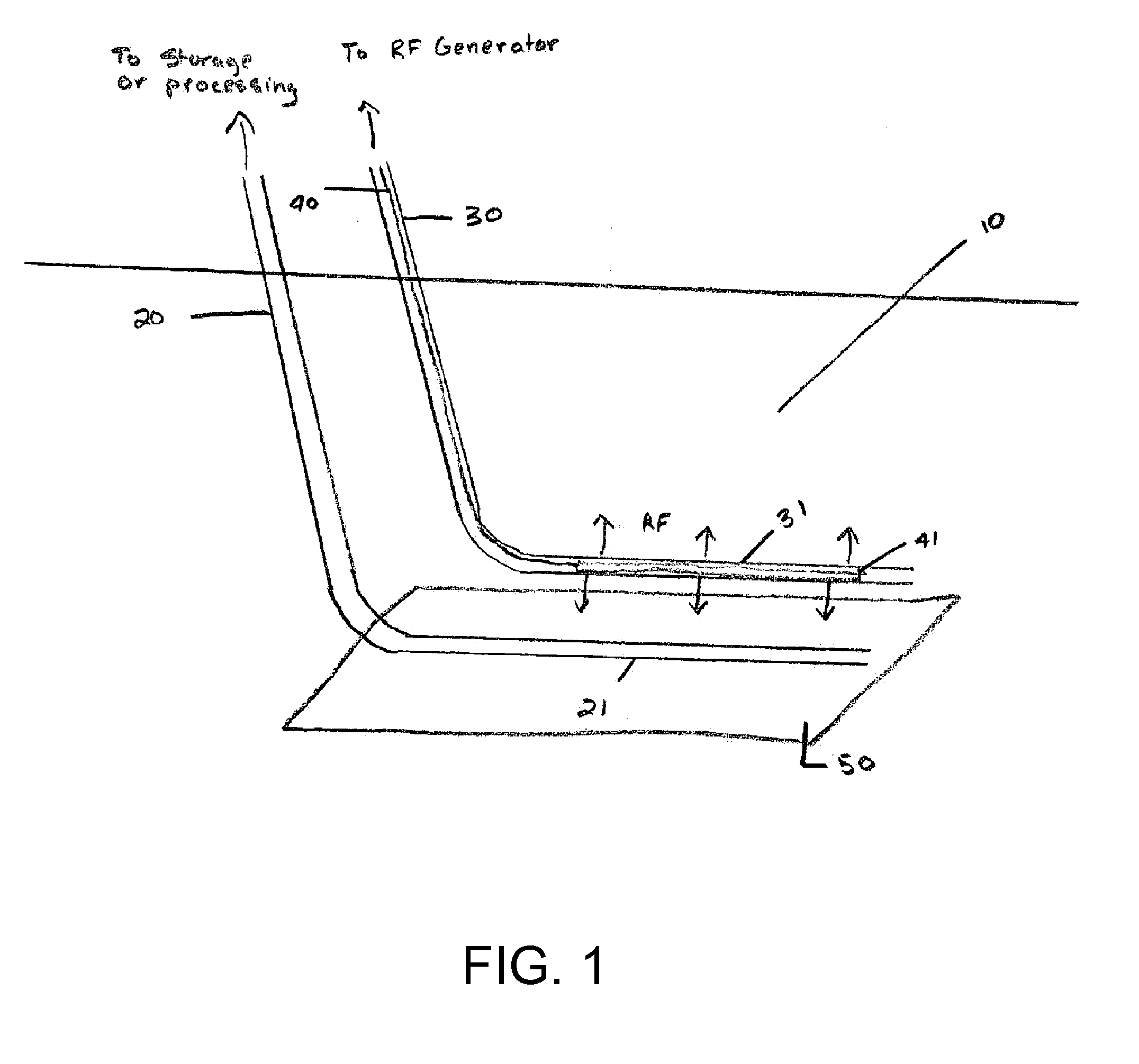

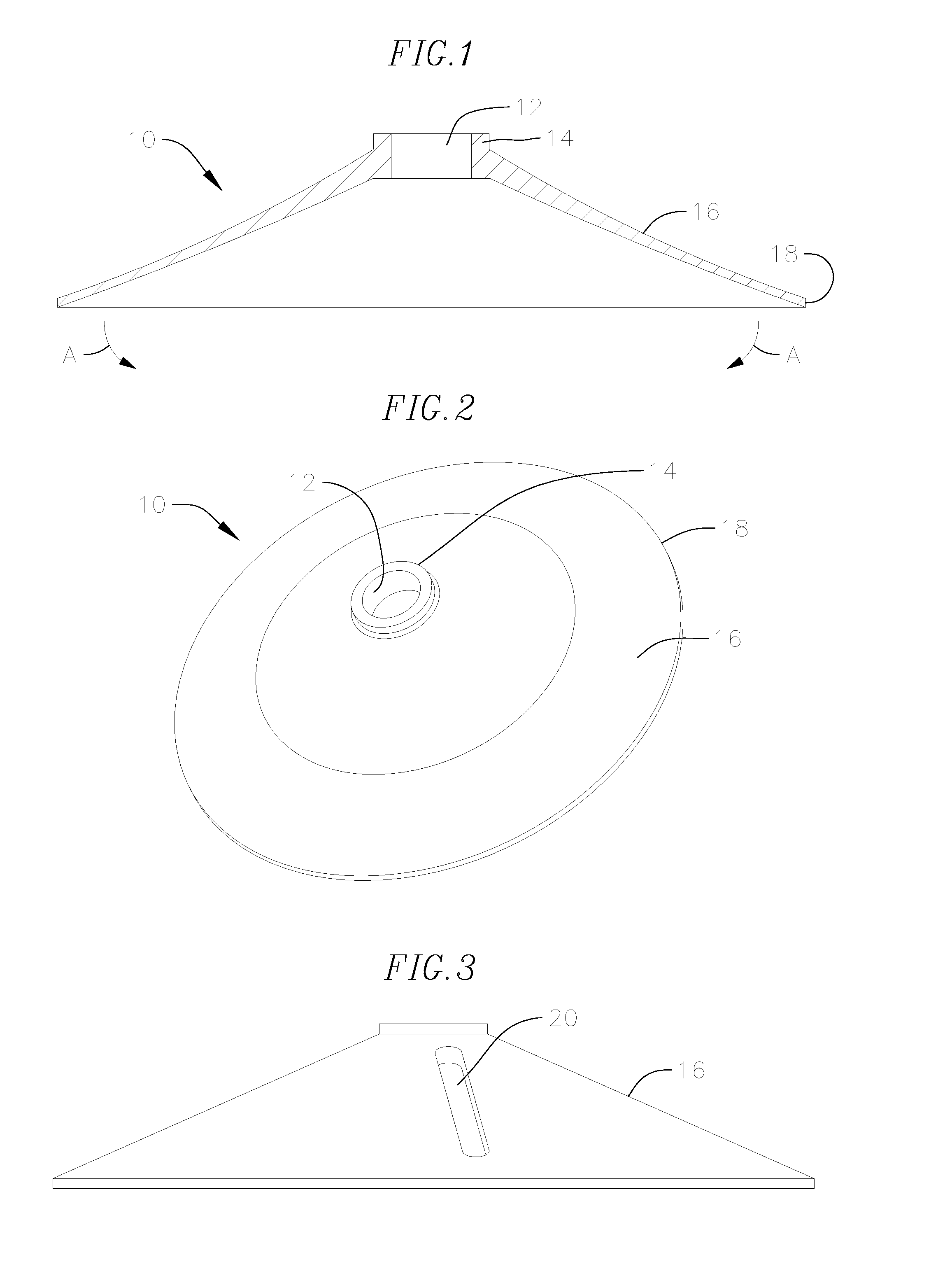

Method and apparatus for in-situ radiofrequency assisted gravity drainage of oil (RAGD)

InactiveUS7441597B2Promote recoveryEnhanced overall recoveryInsulationFluid removalHeavy crude oilFuel oil

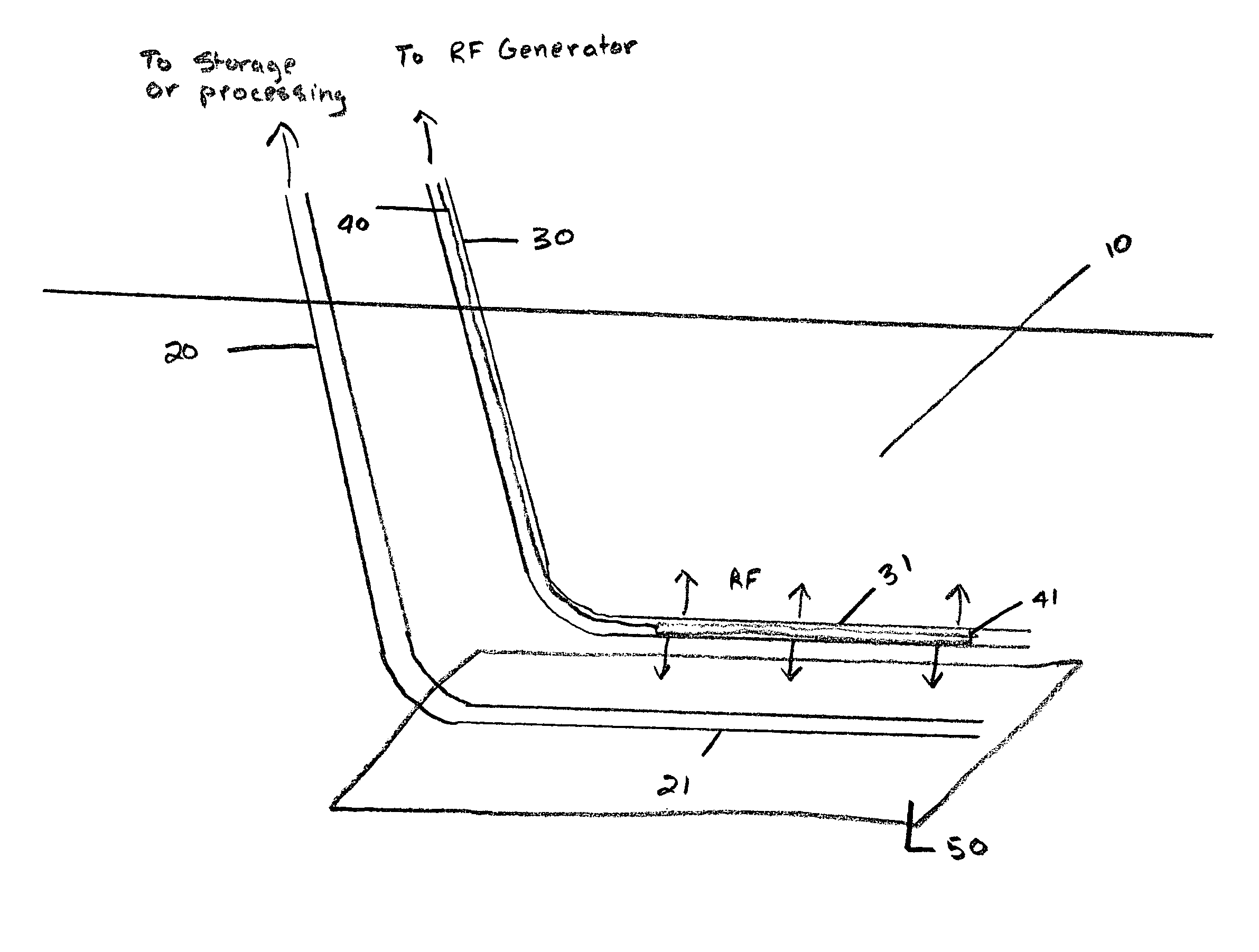

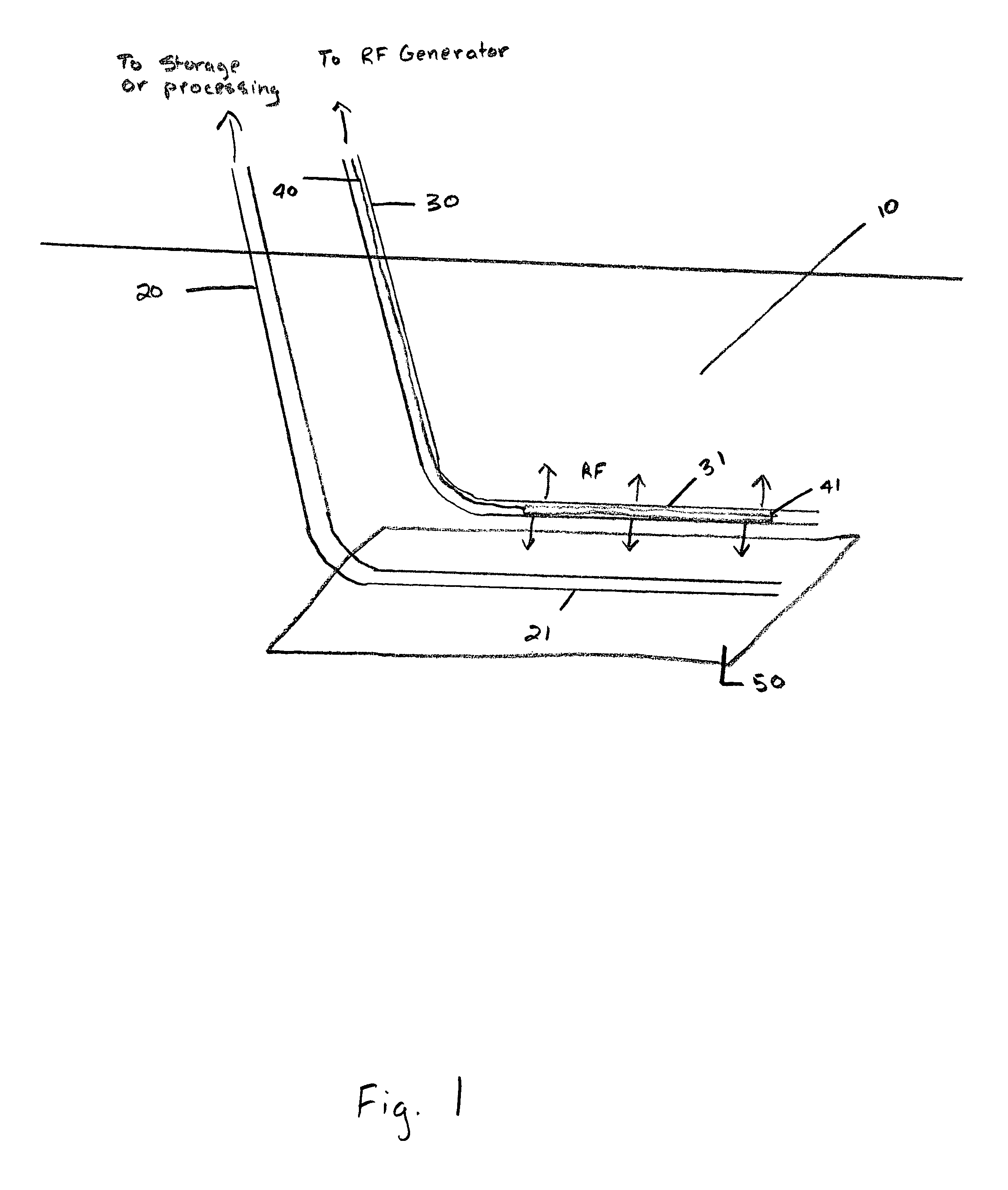

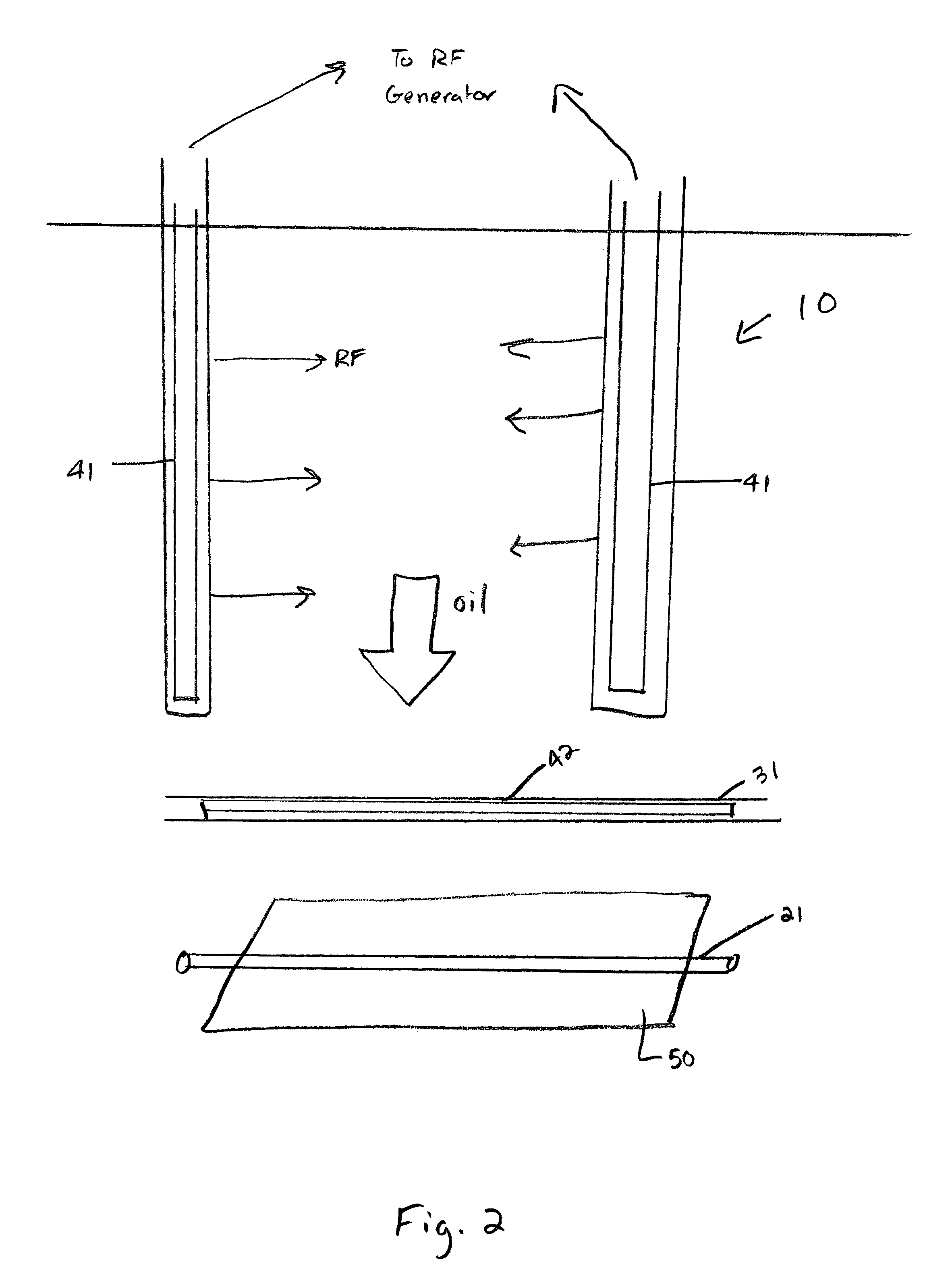

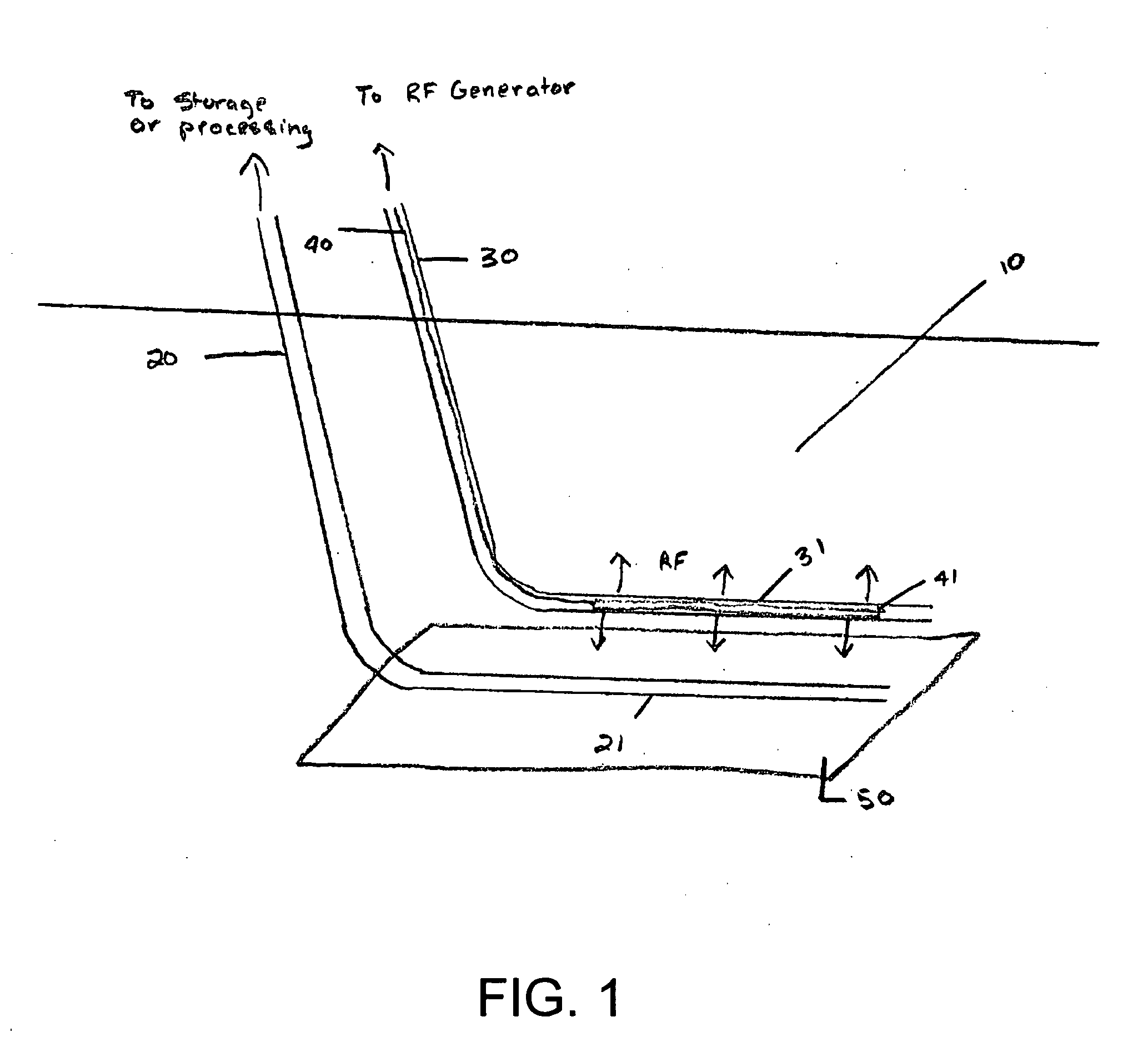

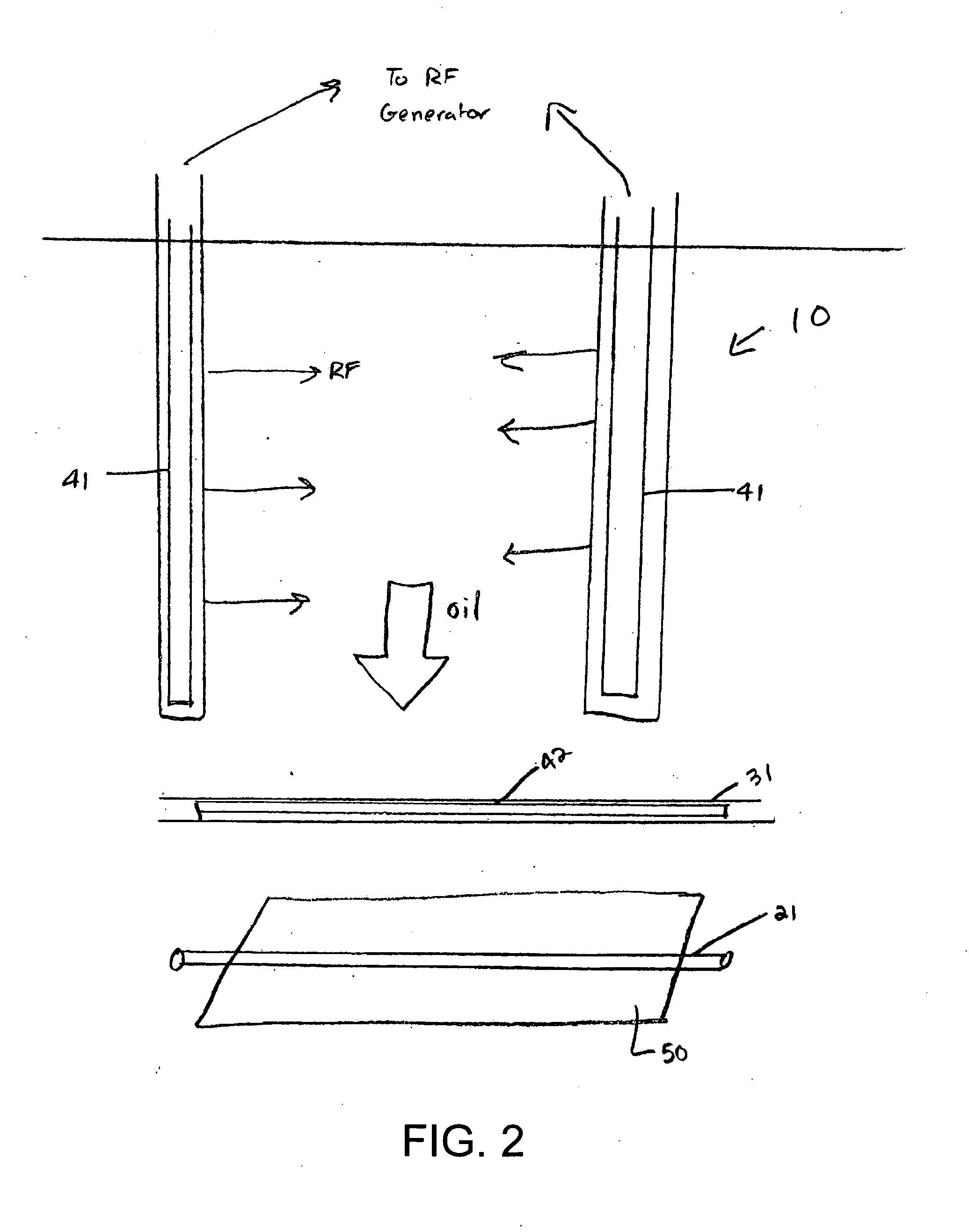

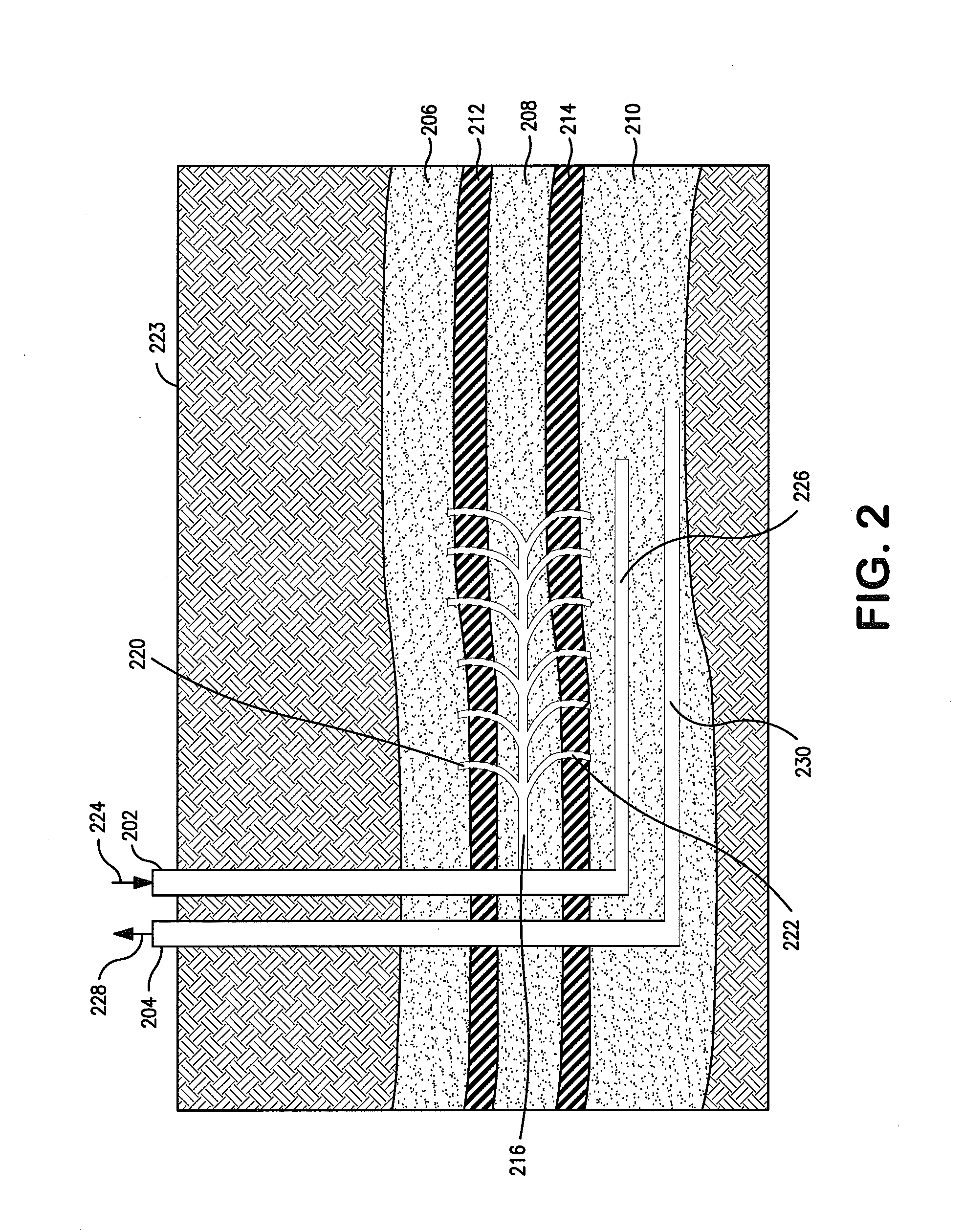

The present invention relates generally to the use of radiofrequency energy to heat heavy crude oil or both heavy crude oil and subsurface water in situ, thereby enhancing the recovery and handling of such oil. The present invention further relates to methods for applying radiofrequency energy to heavy oils in the reservoir to promote in situ upgrading to facilitate recovery. This invention also relates to systems to apply radiofrequency energy to heavy oils in situ.

Owner:KSN ENERGIES

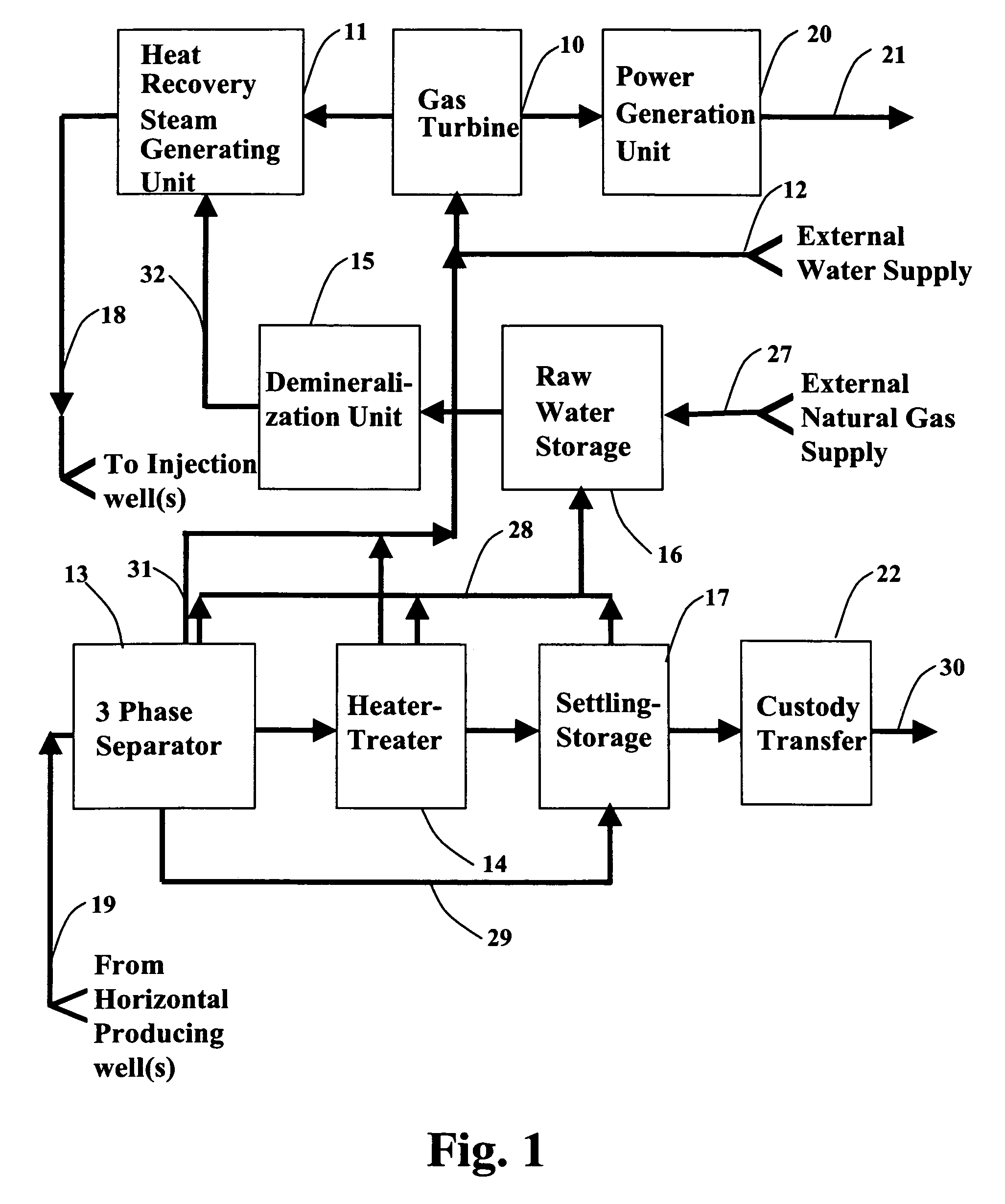

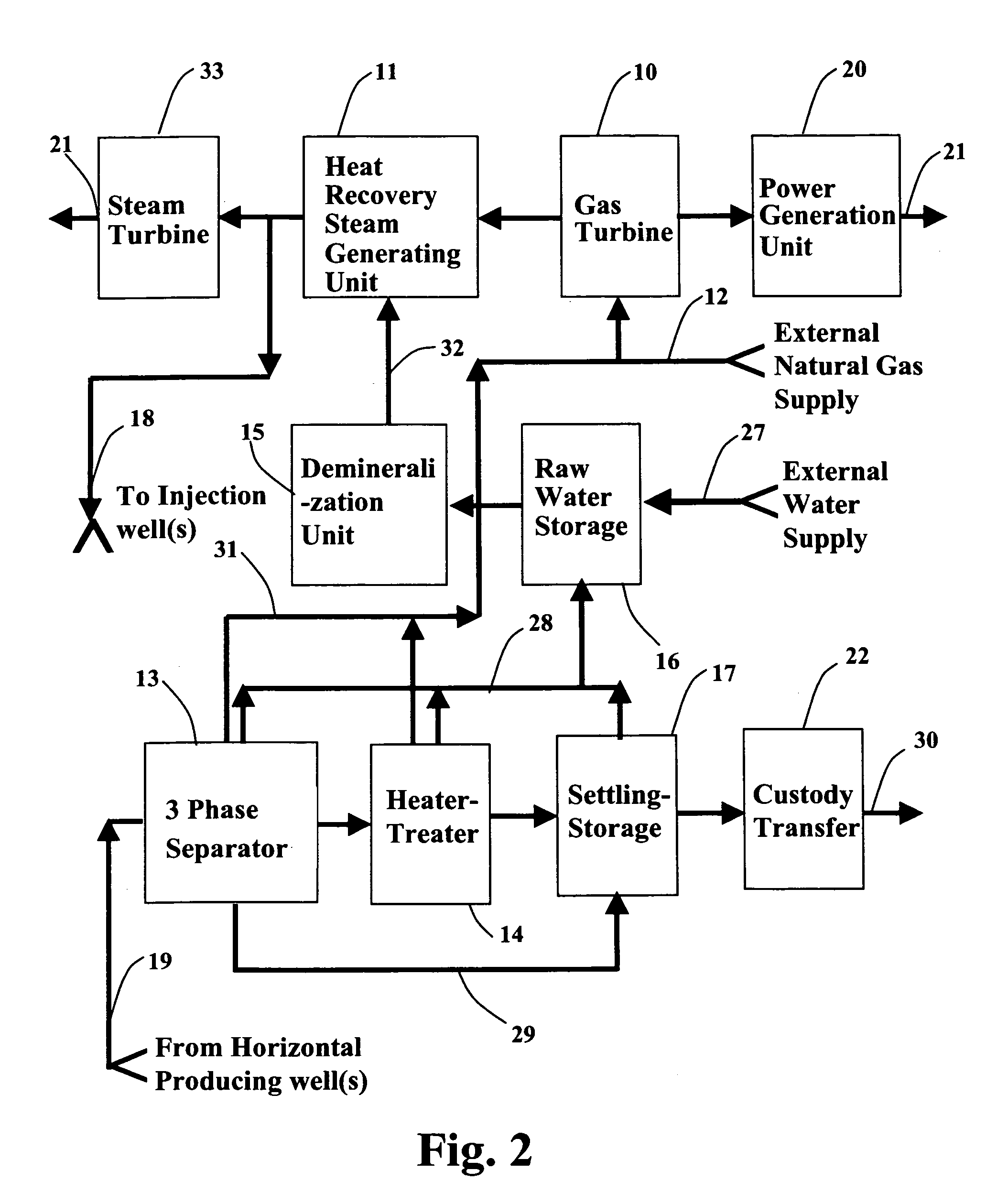

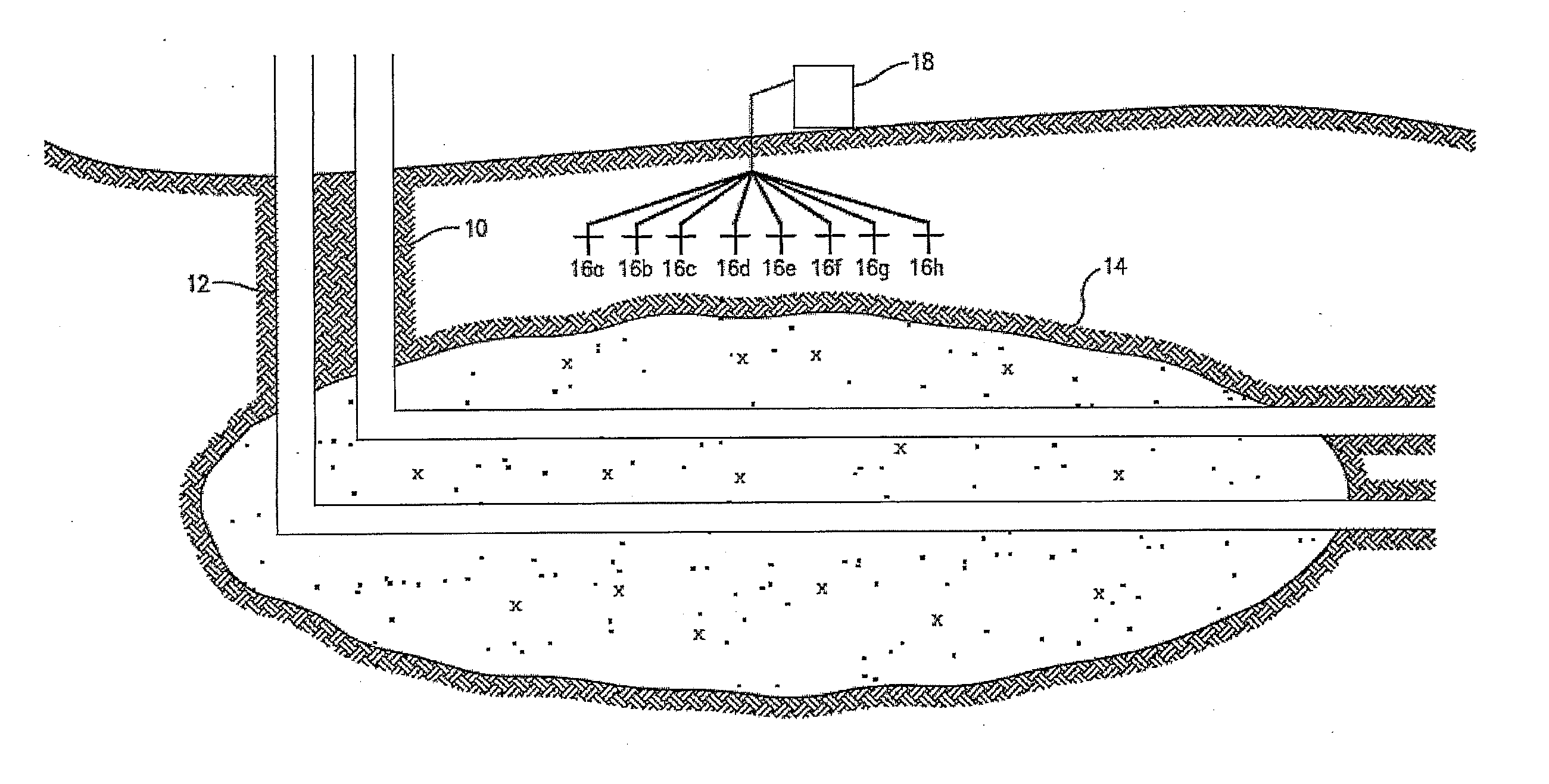

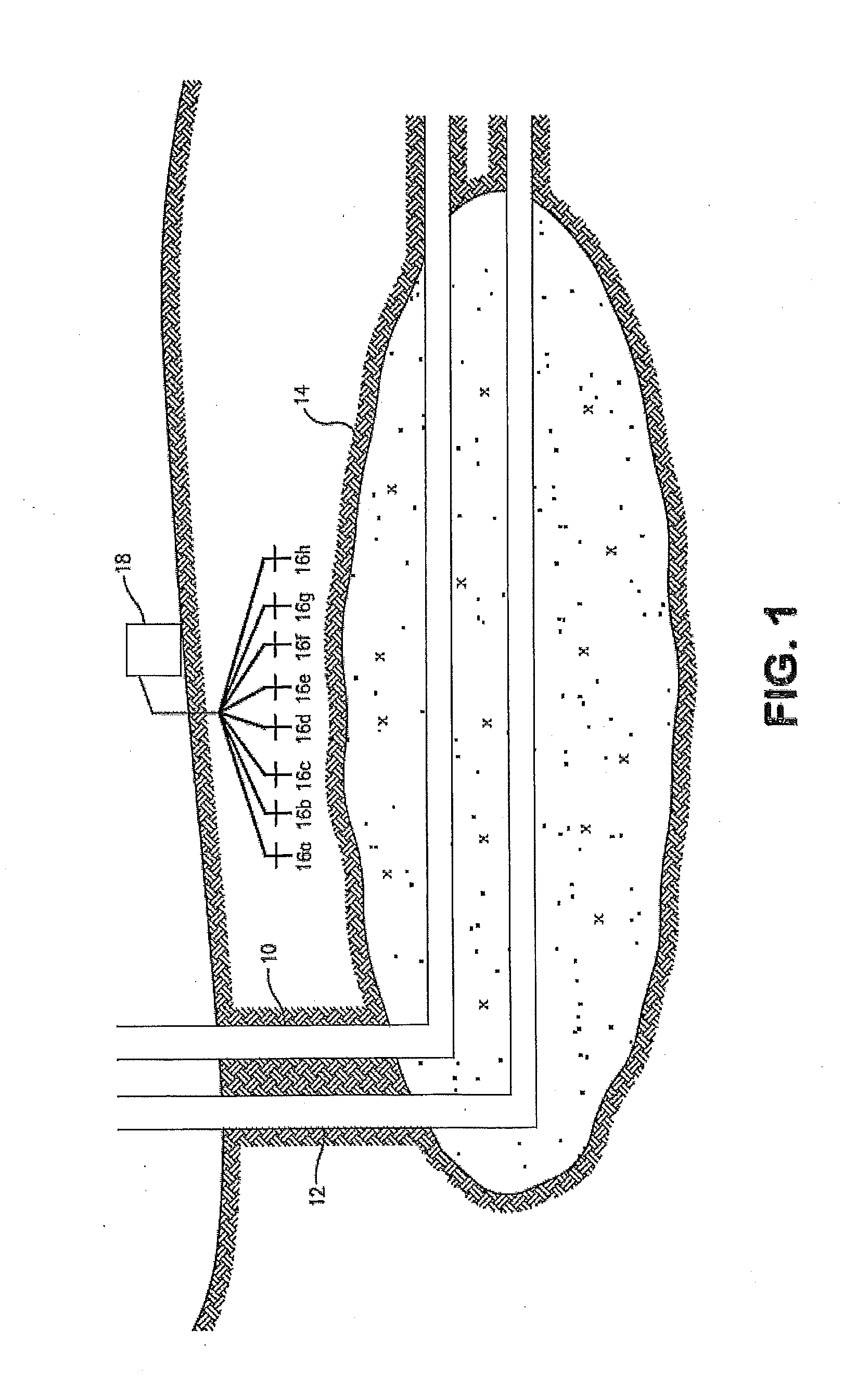

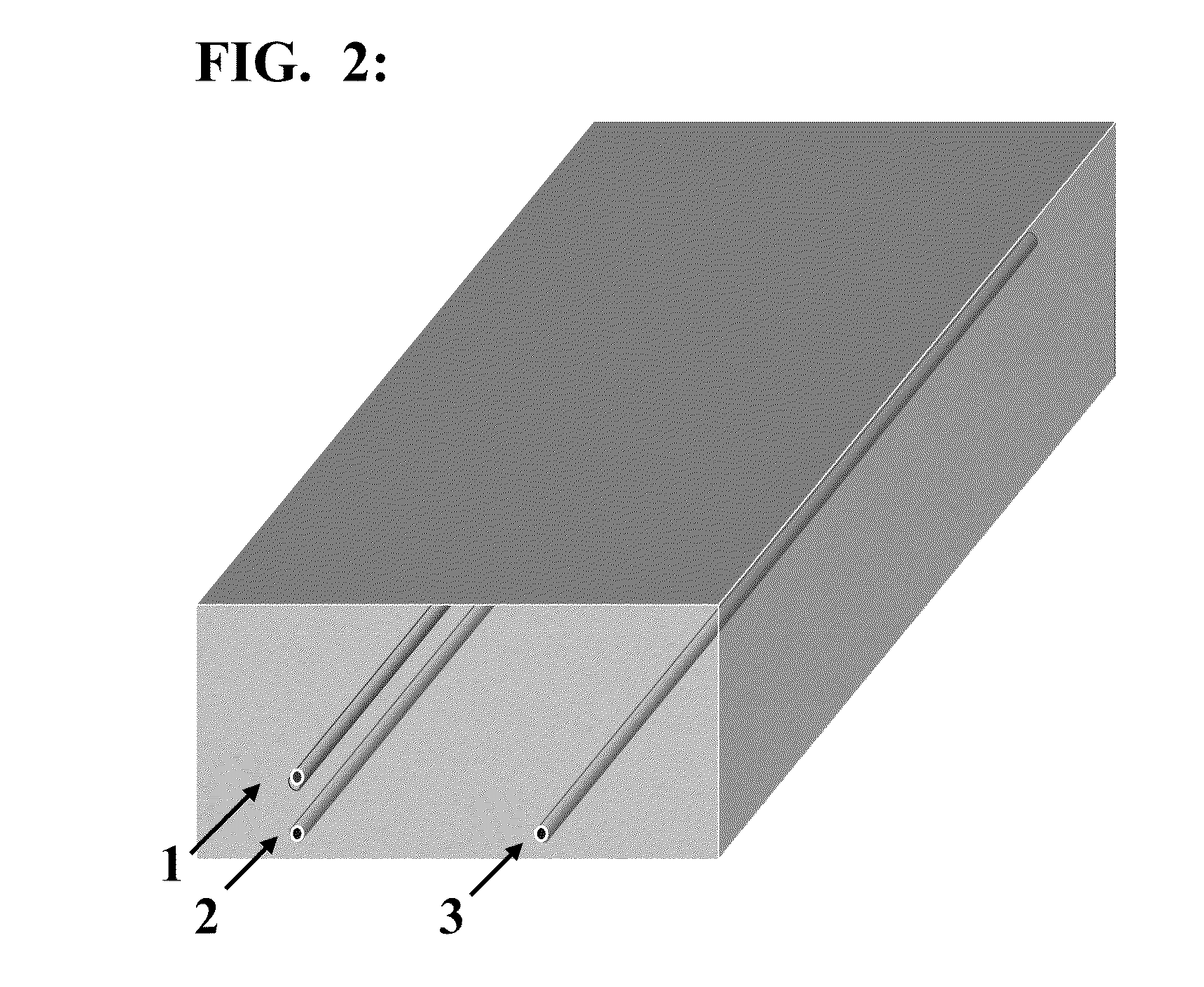

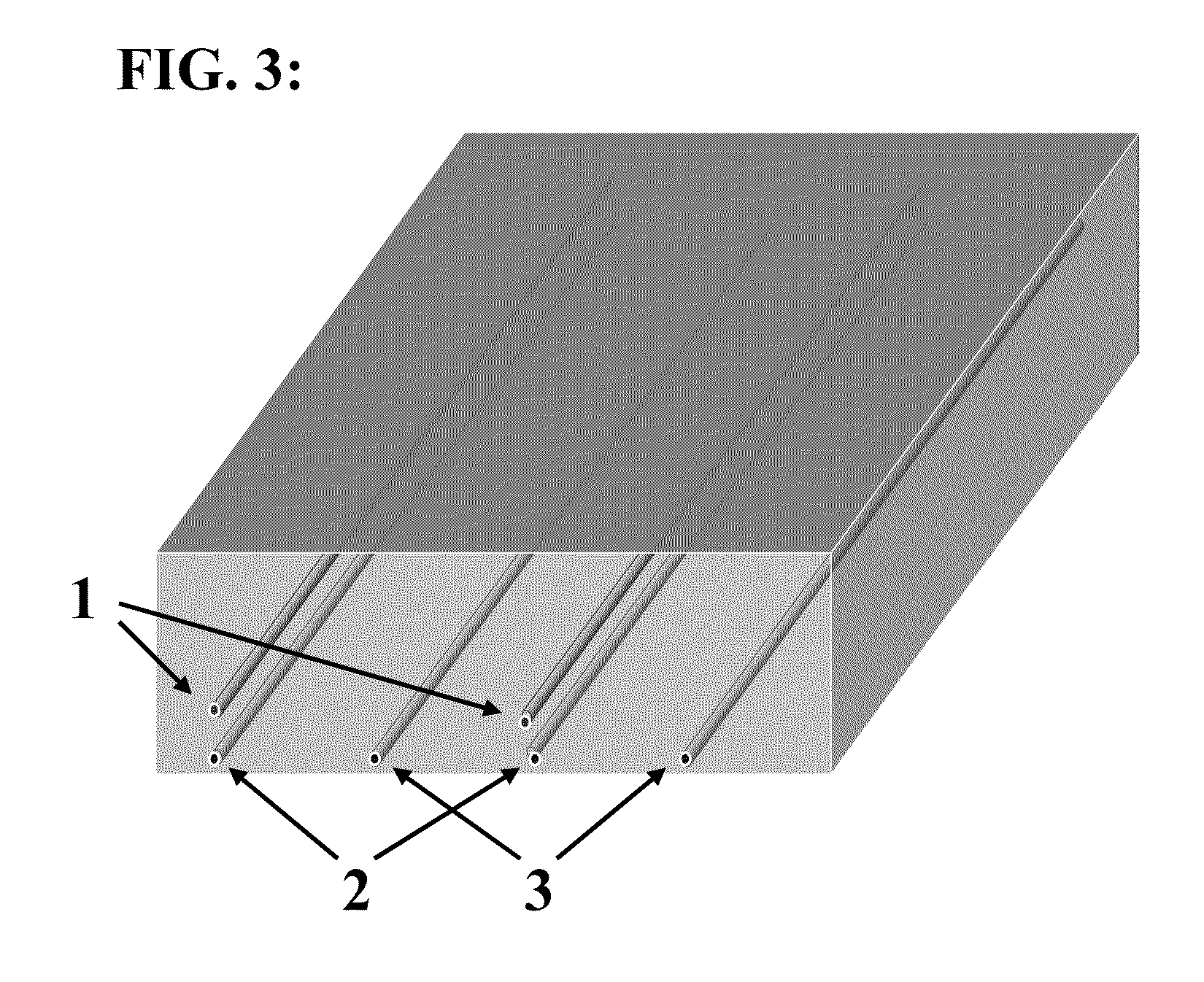

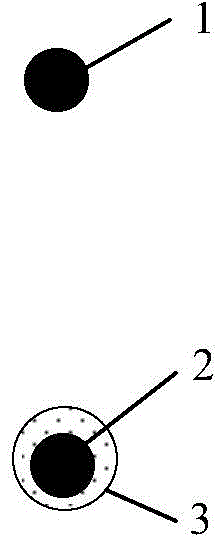

SAGD-plus

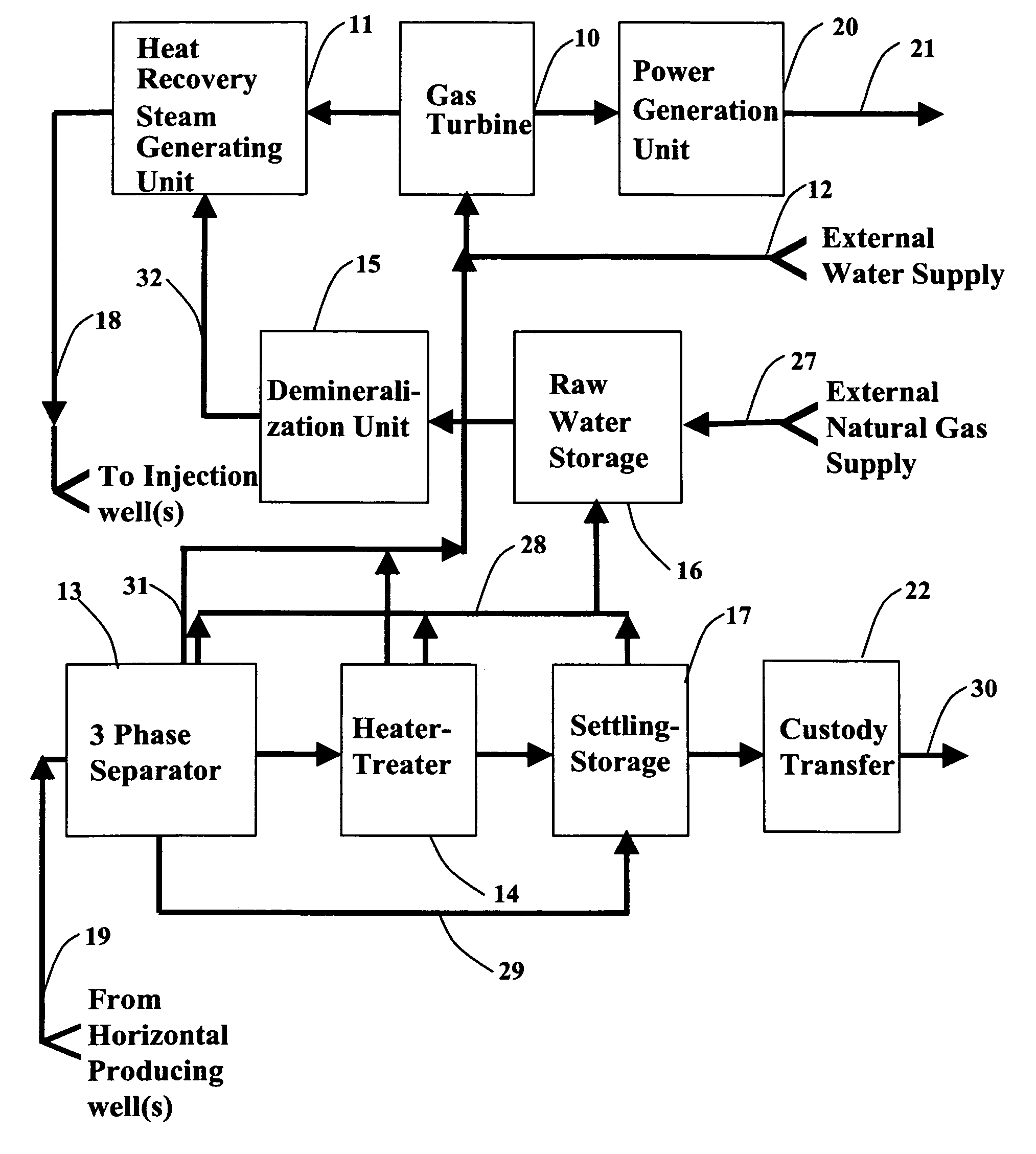

A combination of SAGD with cogeneration technology for exploiting shallow heavy oil and bitumen reservoirs under primary, secondary and tertiary thermal recovery. Superheated steam is generated by the heat recovery from the exhaust of an above-ground hydrocarbon powered turbine driven electric generator cogeneration plant and is injected through well bores into the hydrocarbon bearing reservoir that is traversed by at least one horizontal producing well bore and one injection well bore to heat the reservoir formation and to induce gravity drainage of the hydrocarbons and allowing their recovery from the horizontal producing well bore. Electrical power that is generated is sold to the electric grid and can be used to offset the fuel costs for the above ground hydrocarbon turbine-driven elector generators.

Owner:BABCOCK JOHN A

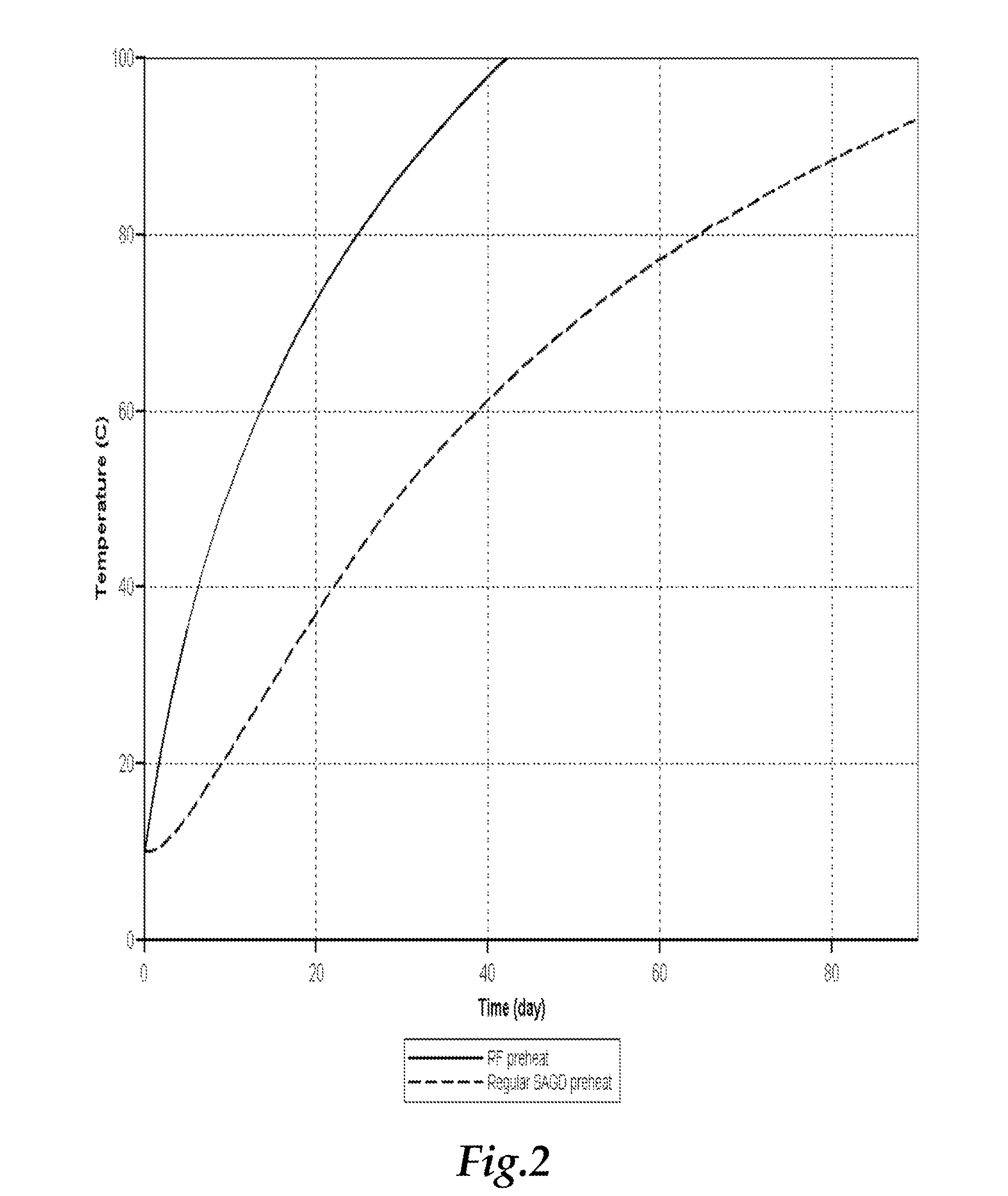

Accelerating the start-up phase for a steam assisted gravity drainage operation using radio frequency or microwave radiation

A method for preheating a formation prior to beginning steam assisted gravity drainage production. The method proceeds by forming a steam assisted gravity drainage production well pair within a formation. A preheating stage is then begun by injecting an activator into the formation. The preheating stage is then accomplished by exciting the activator with radio frequencies. This is followed by beginning the steam assisted gravity drainage operation.

Owner:CONOCOPHILLIPS CO

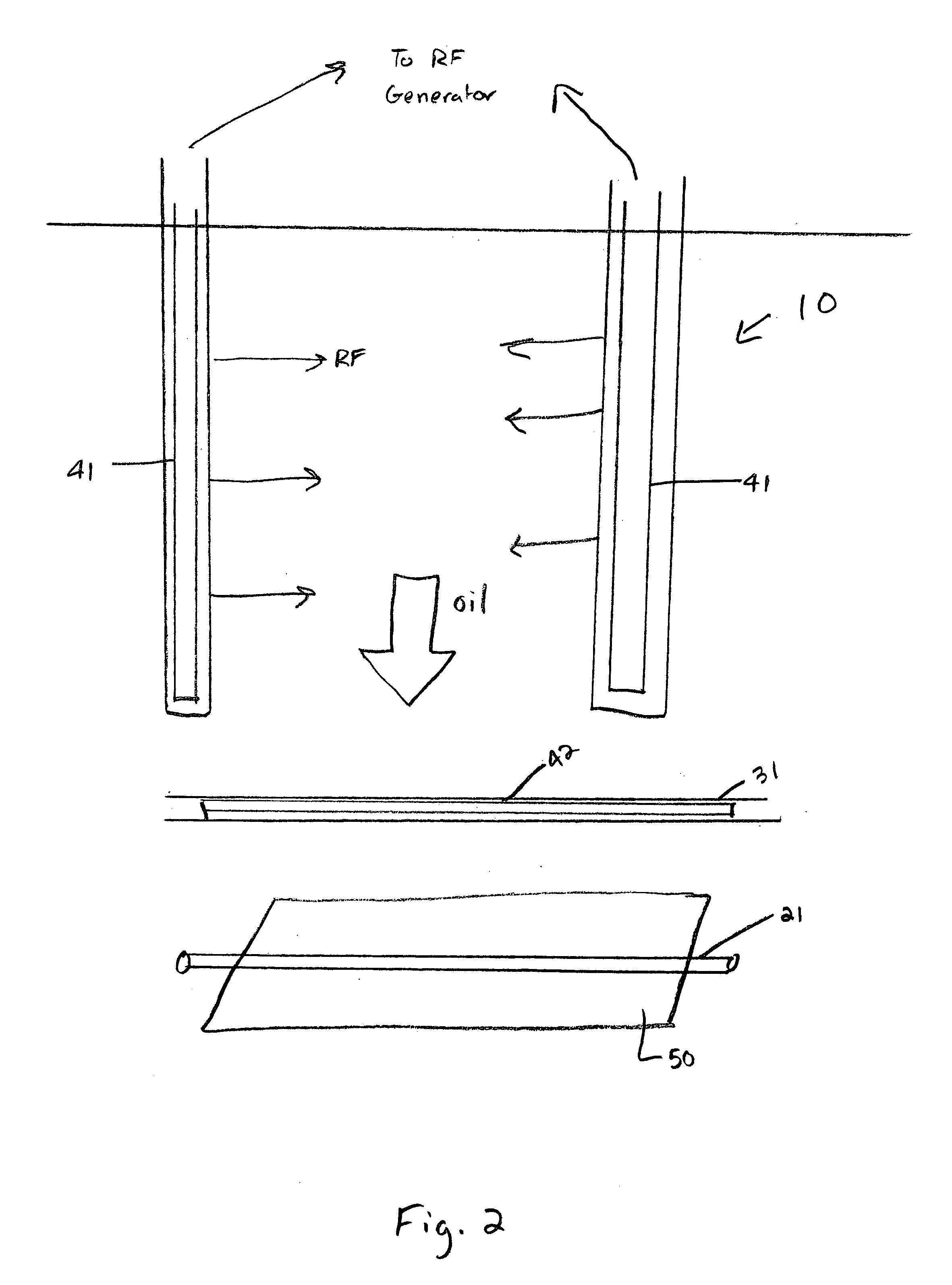

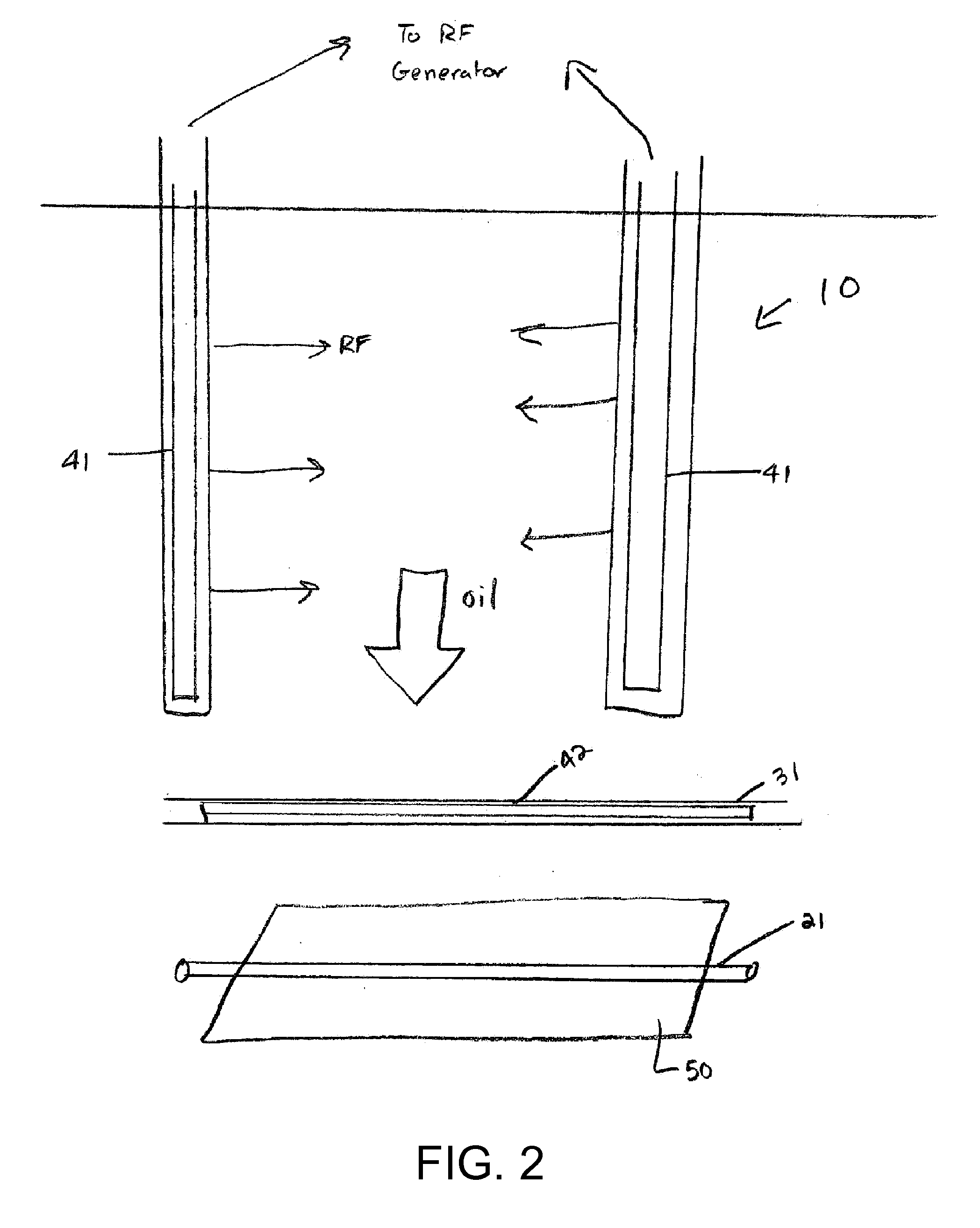

Method and apparatus for in-situ radiofrequency assisted gravity drainage of oil (RAGD)

InactiveUS20090050318A1Promote recoveryEnhanced overall recoveryInsulationFluid removalElectricityNuclear engineering

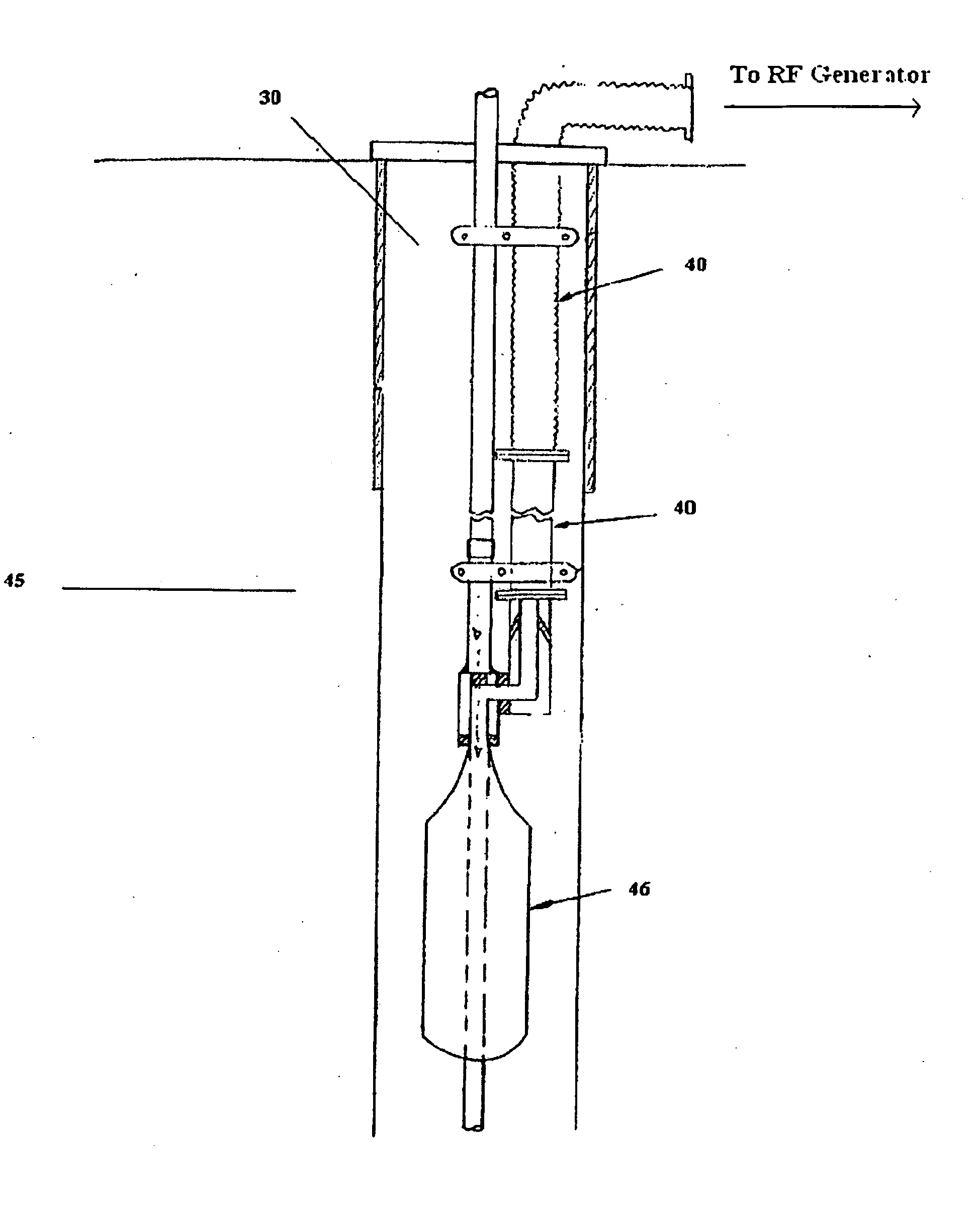

The present invention relates generally to a radiofrequency reactor for use in thermally recovering oil and related materials. The radiofrequency reactor includes a radiofrequency antenna configured to be positioned within a well, where the well is provided within an area in which crude oil exists in the ground. The radiofrequency antenna includes a cylindrically-shaped radiating element for radiating radiofrequency energy into the area in which crude oil exists. The cylindrically-shaped radiating element is configured to allow passage of fluids there through. The radiofrequency reactor also includes a radiofrequency generator electrically coupled to the radiofrequency antenna. The radiofrequency reactor is operable to control the radiofrequency energy generated.

Owner:KASEVICH RAYMOND S

Process for producing a low density acoustical panel with improved sound absorption

A process useful for producing low density high mineral wool based acoustical panels with improved acoustical absorption properties using a water felting process is disclosed. The process includes forming a dilute slurry mixture including water, mineral wool, a thermoplastic binder and / or starch; and distributing the dilute slurry on a porous carrier to have the slurry dewatered to a base mat by gravity drainage to remove water by gravity. A vacuum is adjusted to gradually apply vacuum to the gravity dewatered base mat to further dewater the base mat without subjecting the mat to static pressure that would compress the base mat. The base mat is dried to form an acoustical ceiling product that has a low density and excellent acoustical absorption properties.

Owner:USG INTERIORS INC

Method and apparatus for in-situ radiofrequency assisted gravity drainage of oil (RAGD)

InactiveUS20060283598A1Promote recoveryEnhanced overall recoveryInsulationFluid removalHeavy crude oilFuel oil

The present invention relates generally to the use of radiofrequency energy to heat heavy crude oil or both heavy crude oil and subsurface water in situ, thereby enhancing the recovery and handling of such oil. The present invention further relates to methods for applying radiofrequency energy to heavy oils in the reservoir to promote in situ upgrading to facilitate recovery. This invention also relates to systems to apply radiofrequency energy to heavy oils in situ.

Owner:KSN ENERGIES

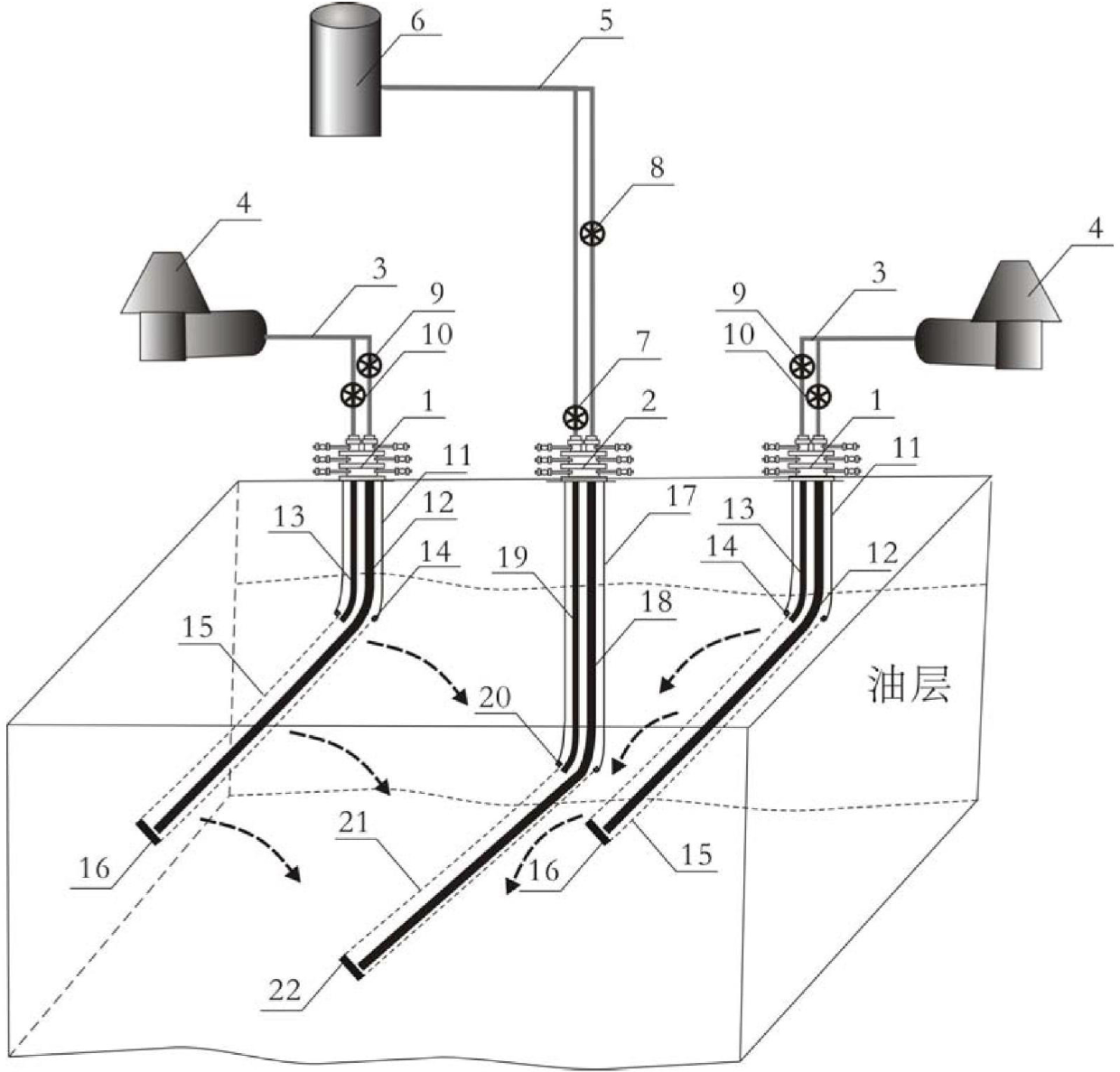

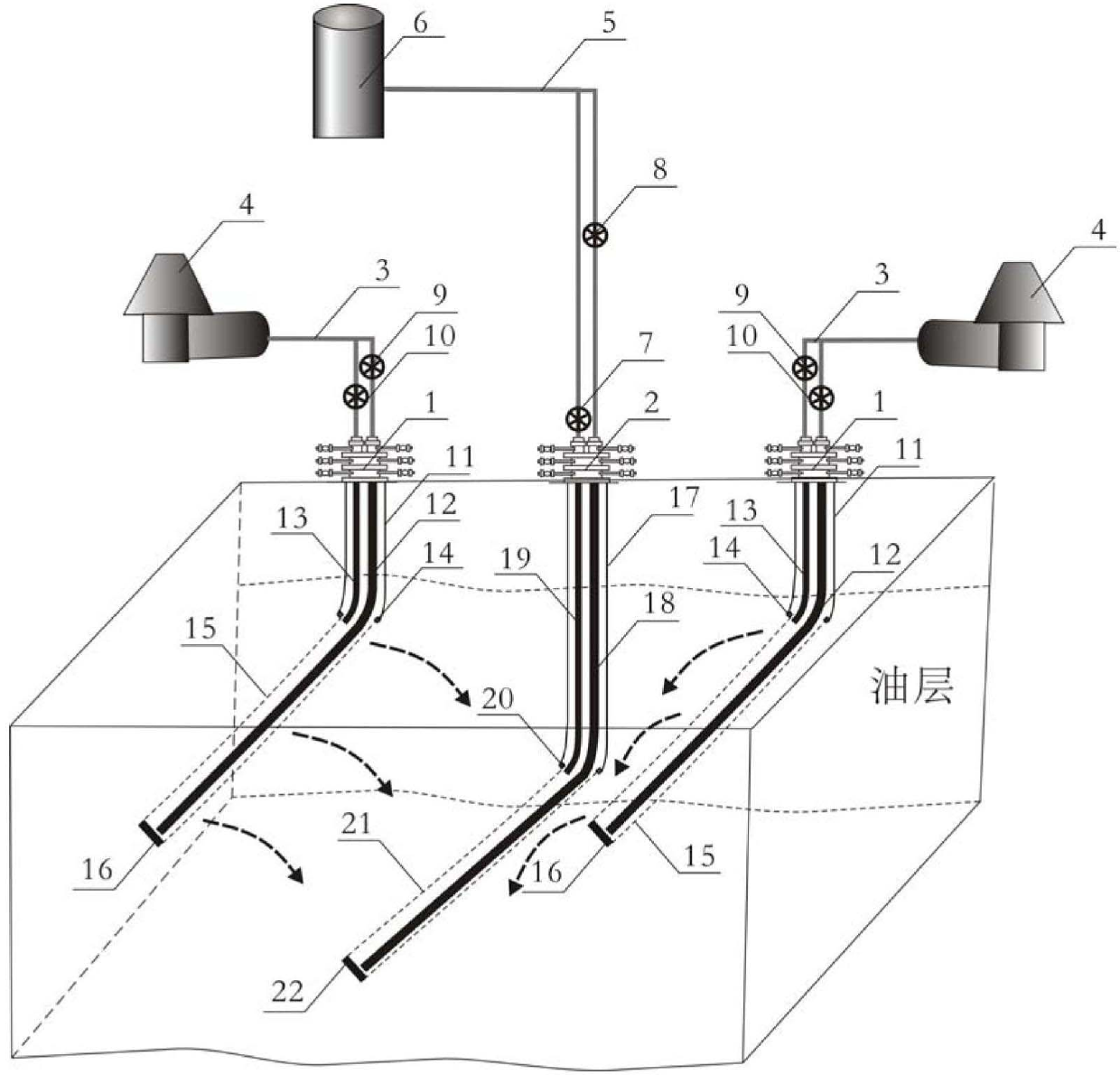

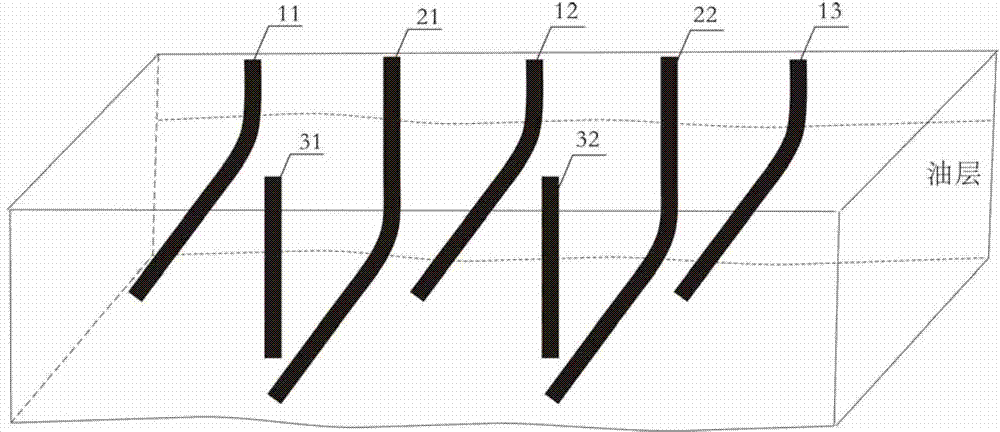

A method of gravity drainage assisted steam flooding to enhance the recovery of deep ultra-heavy oil reservoirs

The invention relates to a method for improving the oil deposit recovery ratio of deep massive extremely-viscous oil in an extraction mode of gravity drainage assisted steam flooding. In the method, superposition horizontal wells are arranged among wells by combining results of researches on the fine contrast of small geological strata of massive oil deposit, the distribution rule of interlayer, the distribution rule of remaining oil and the like and a fine research on numerical simulation; an upper superposition horizontal well is used for injecting steam, a peripheral vertical shaft is used for production, and a lower superposition horizontal well is used for discharging liquid (crude oil between condensate water and the horizontal wells); and thus, a production-injection ratio of high-speed steam injection of deep oil deposit is improved, the dryness of steam on the well bottom is improved, the pressure of an oil layer is reduced, a steam cavity is easy to expand, the swept volume is improved, a development effect is improved, and the aim of improving the recovery ratio finally is fulfilled.

Owner:PETROCHINA CO LTD

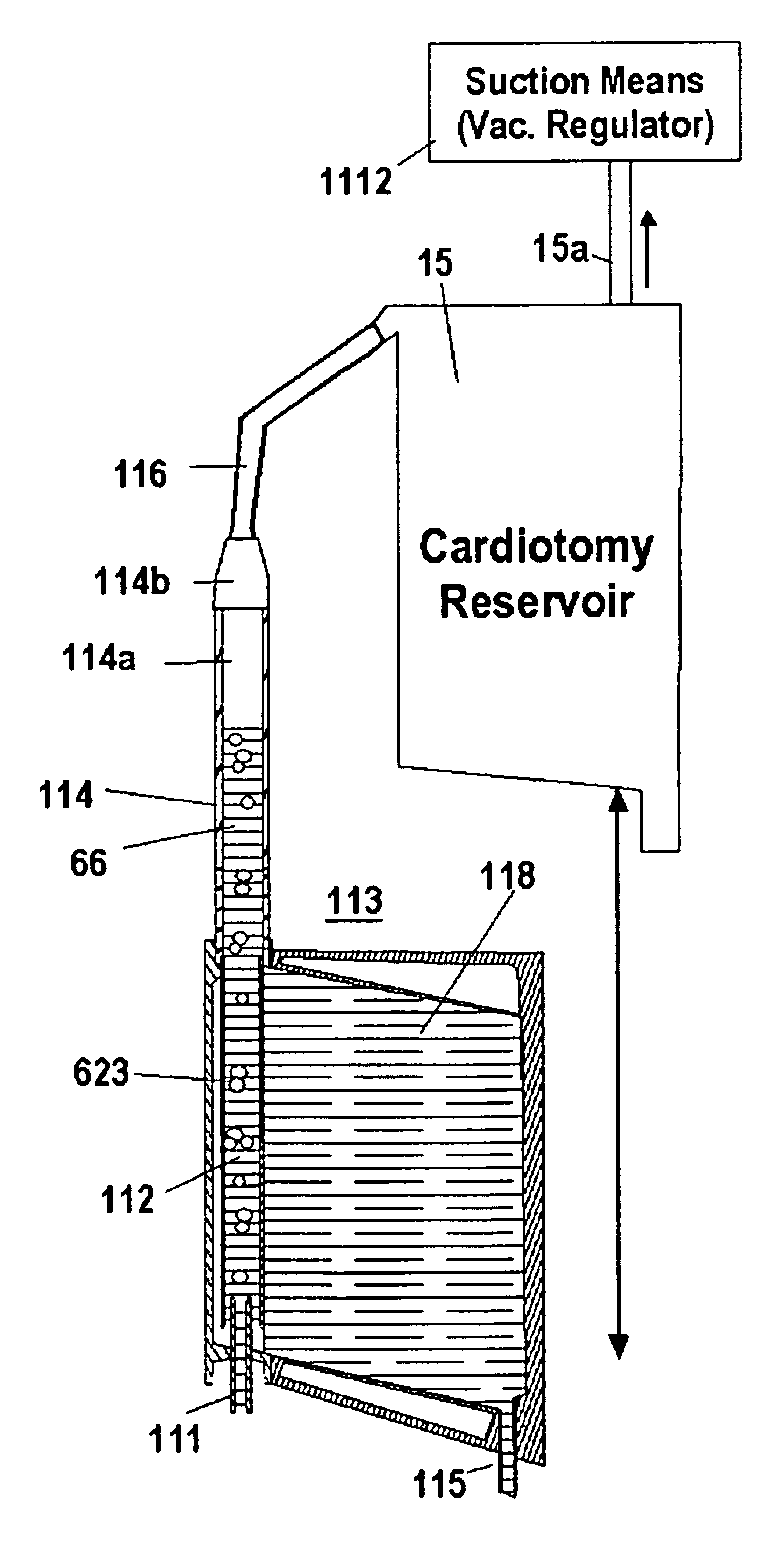

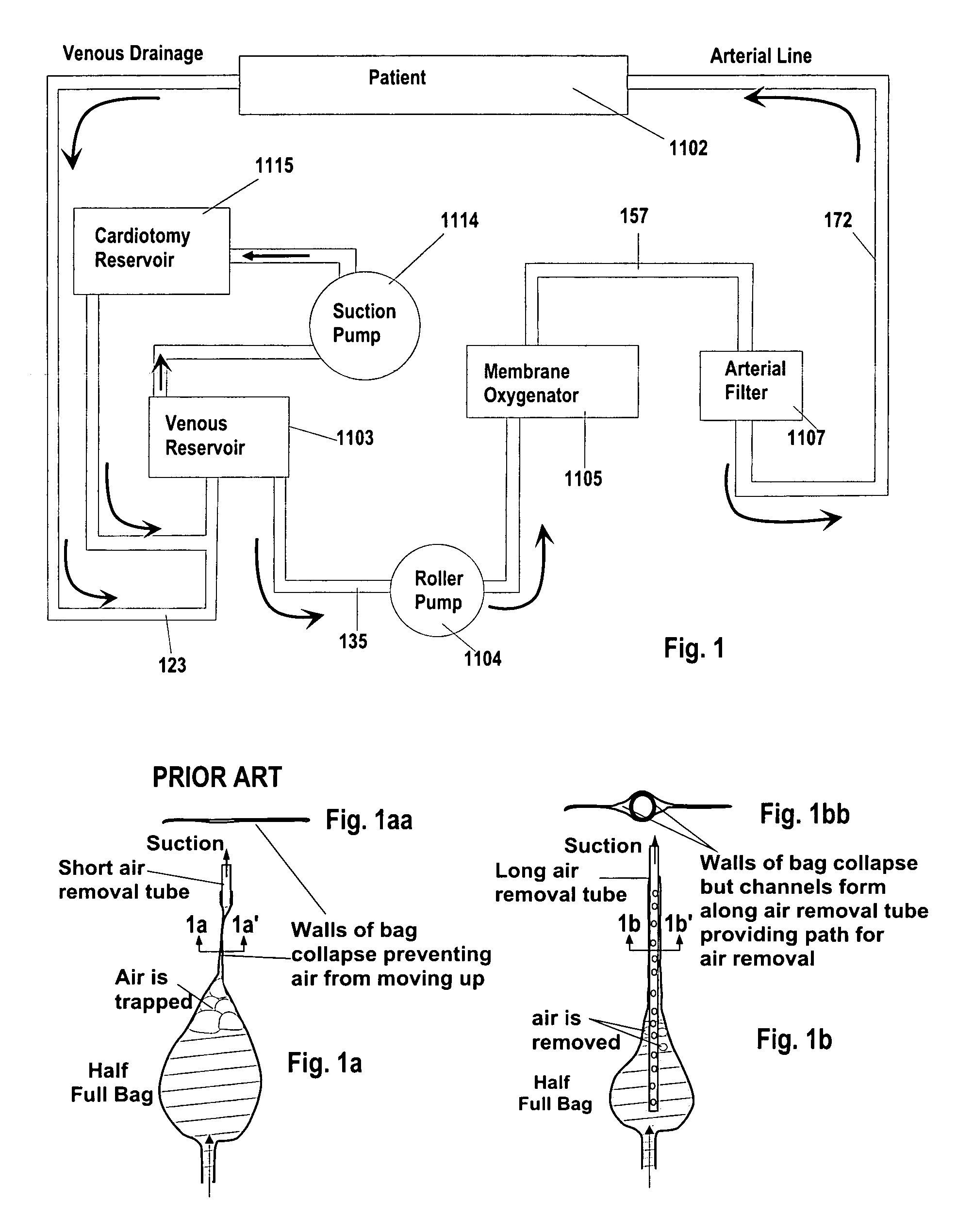

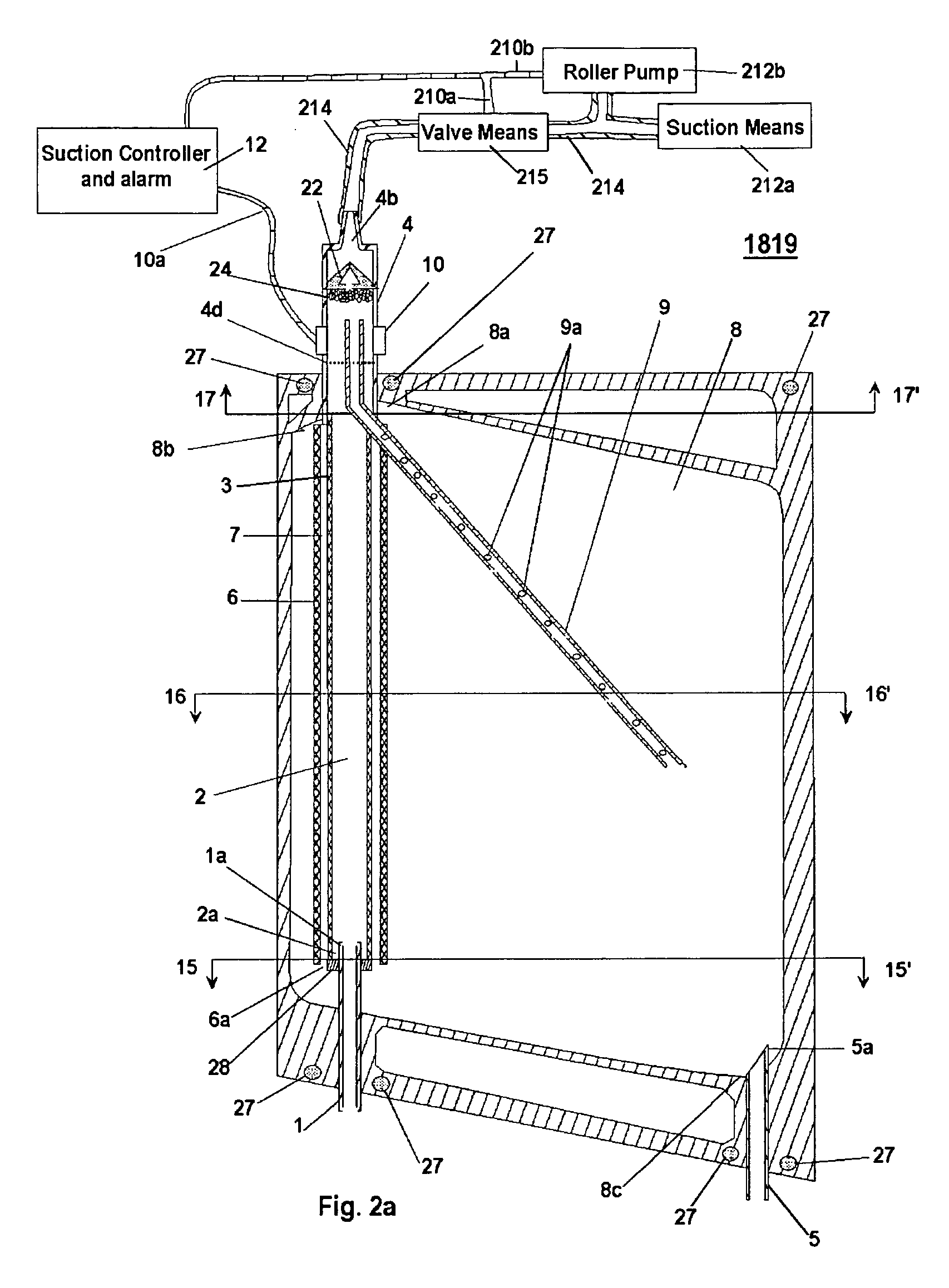

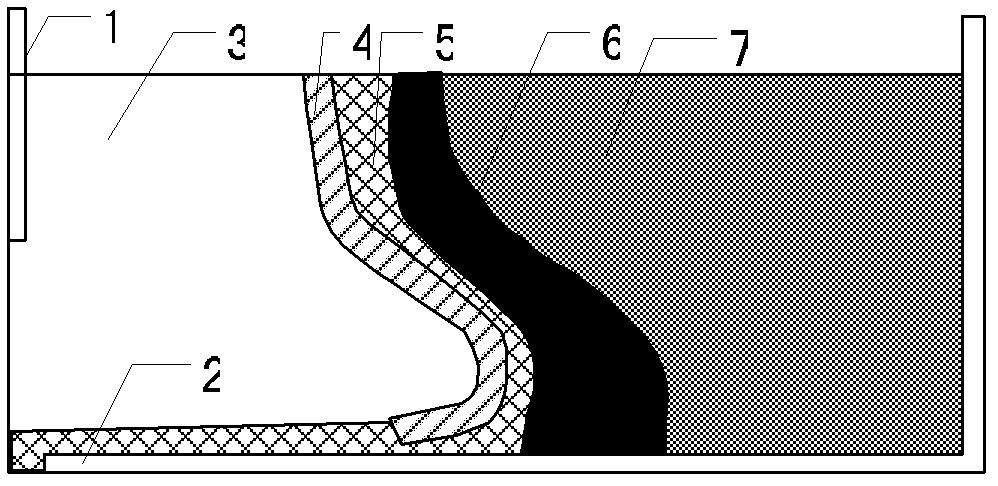

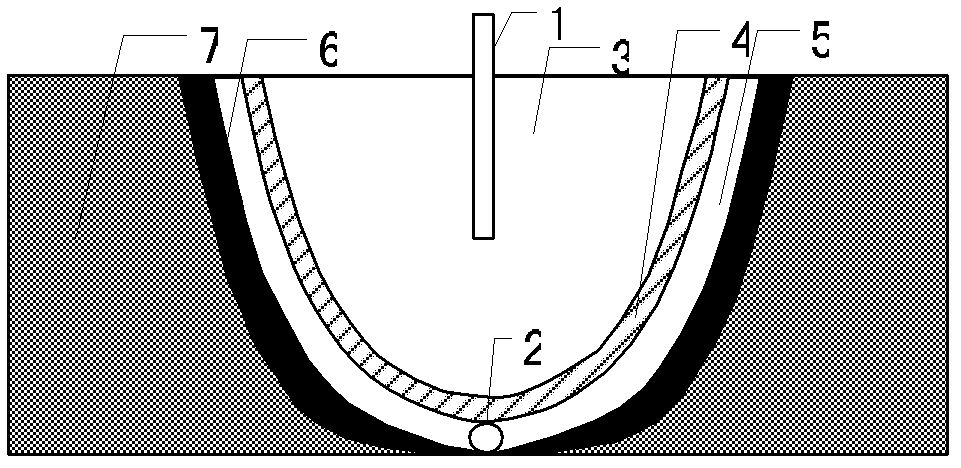

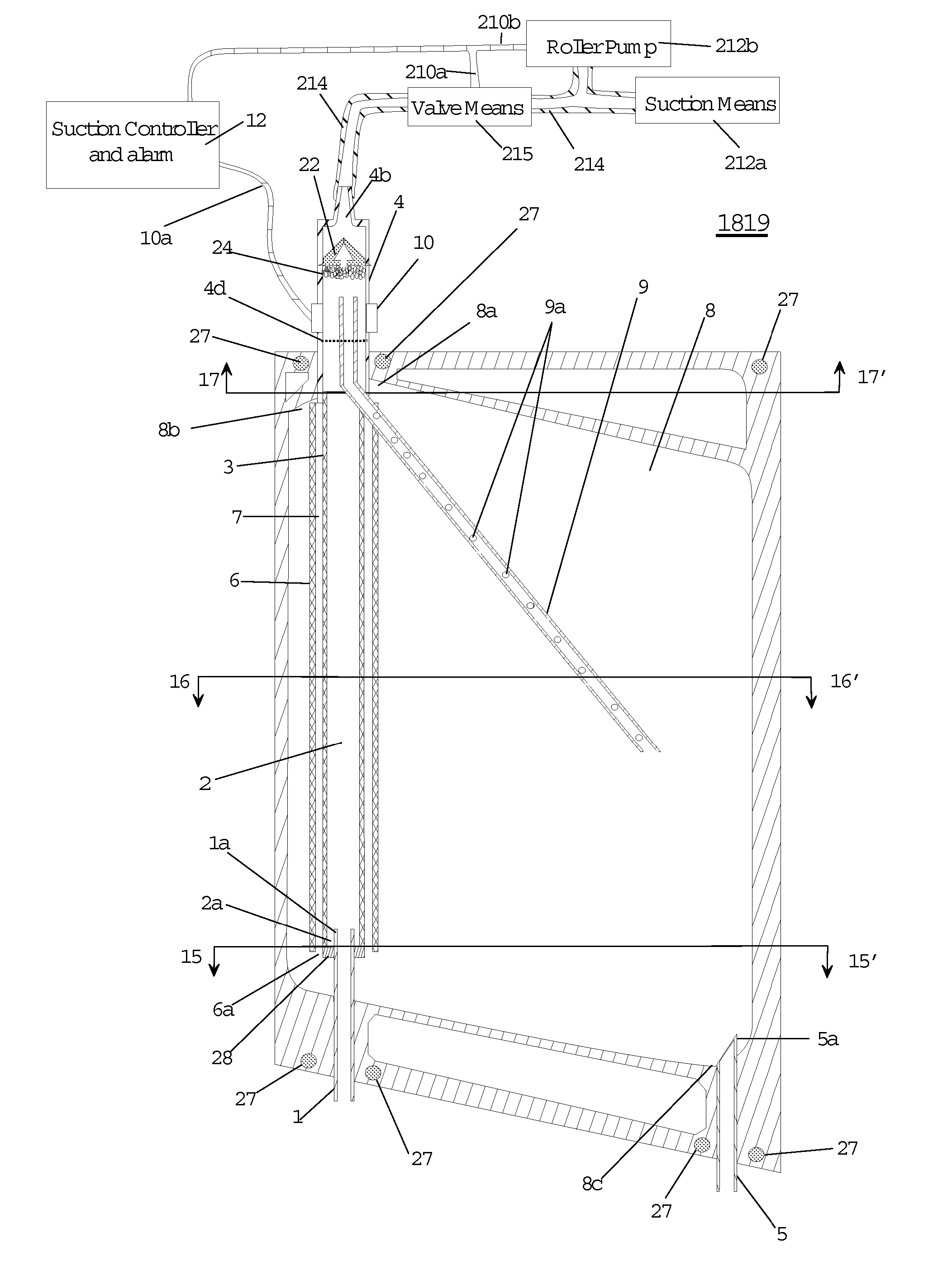

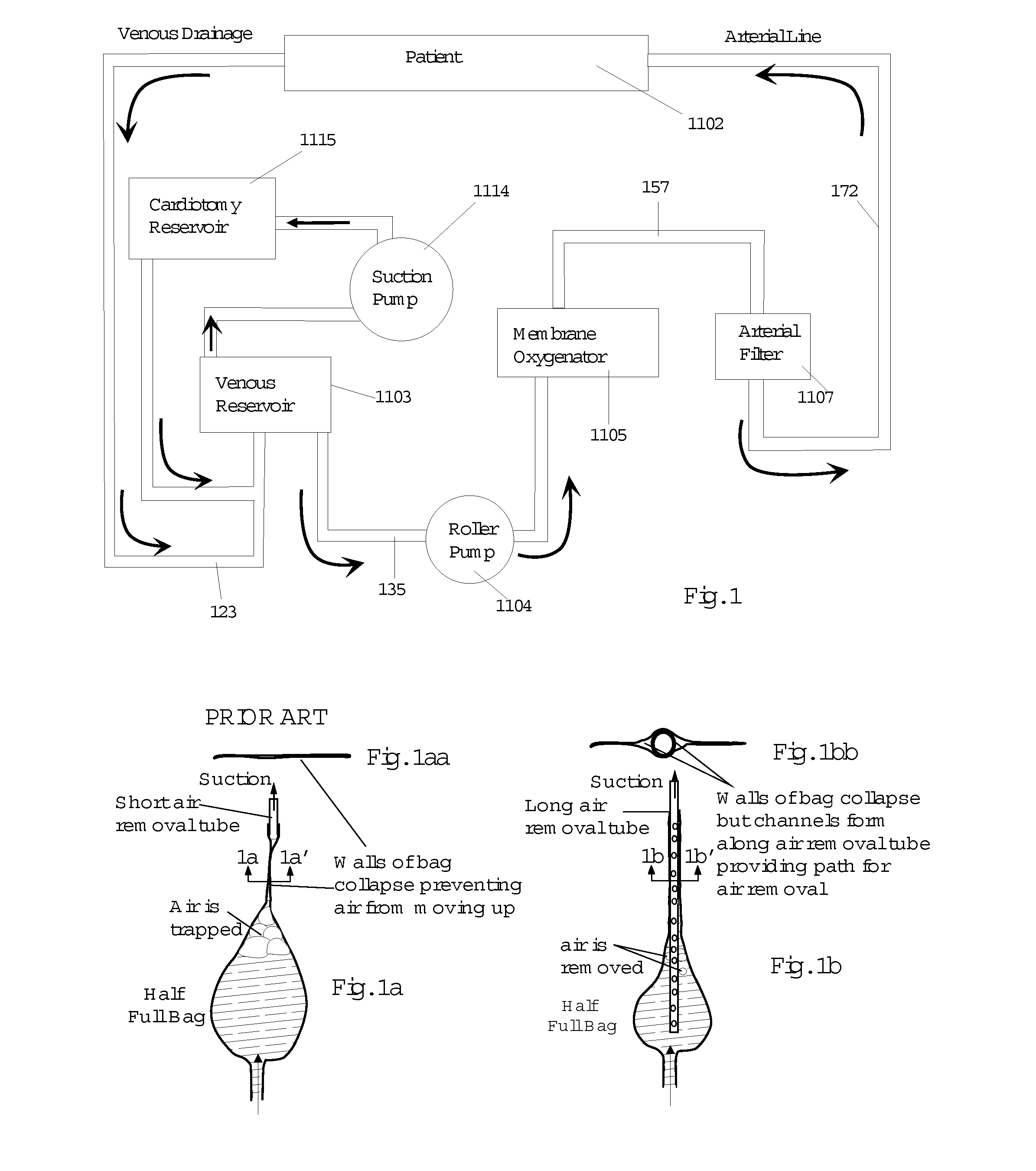

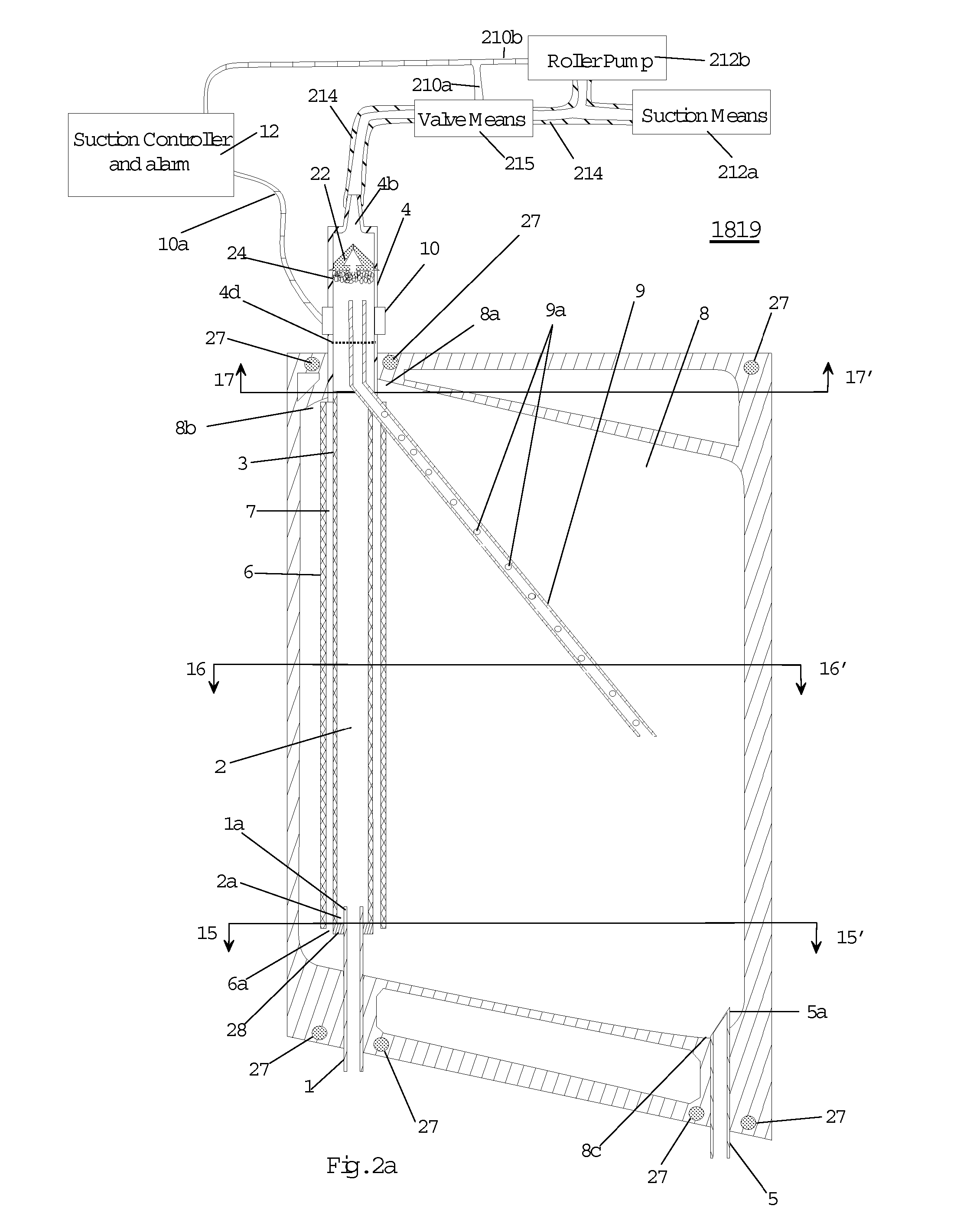

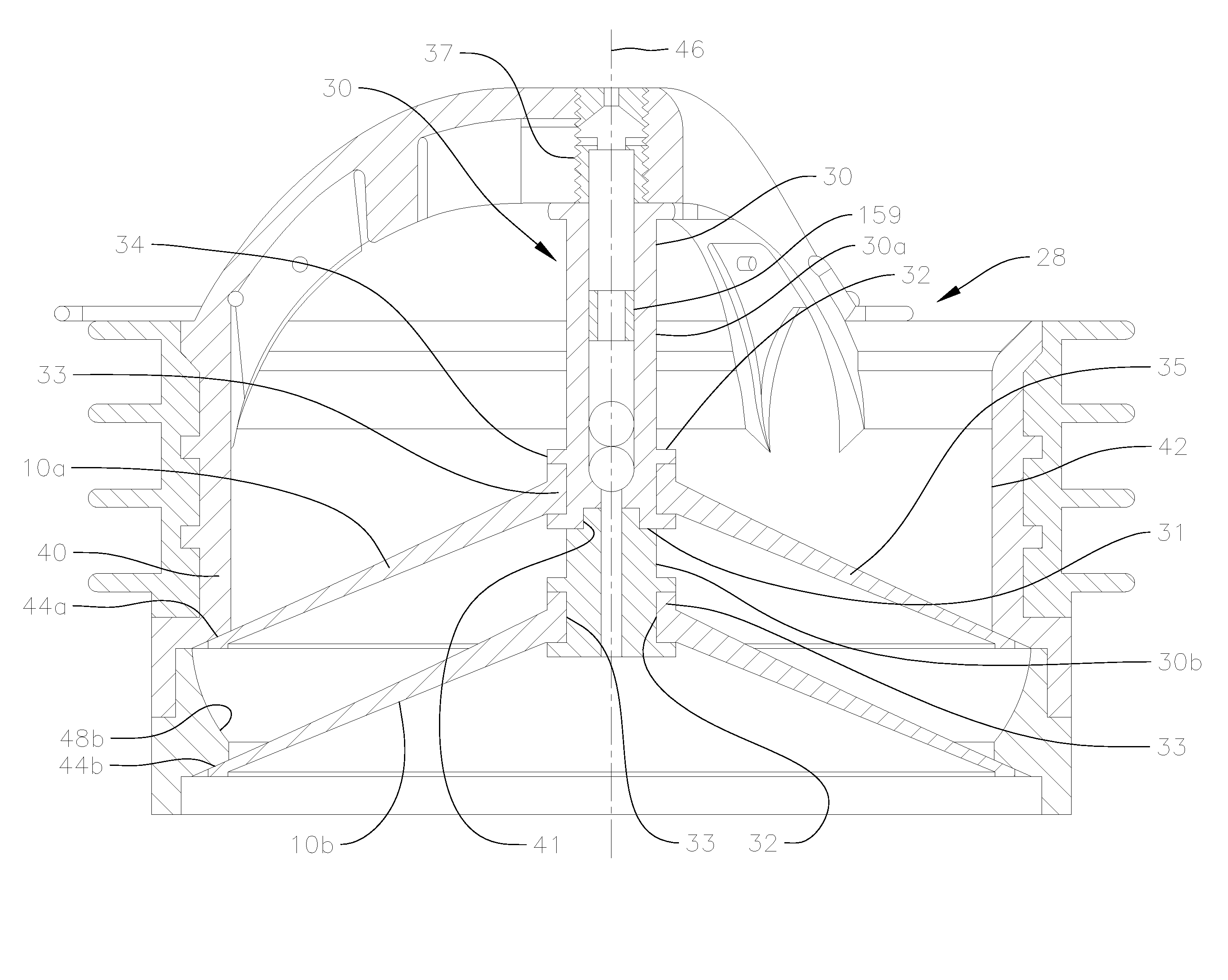

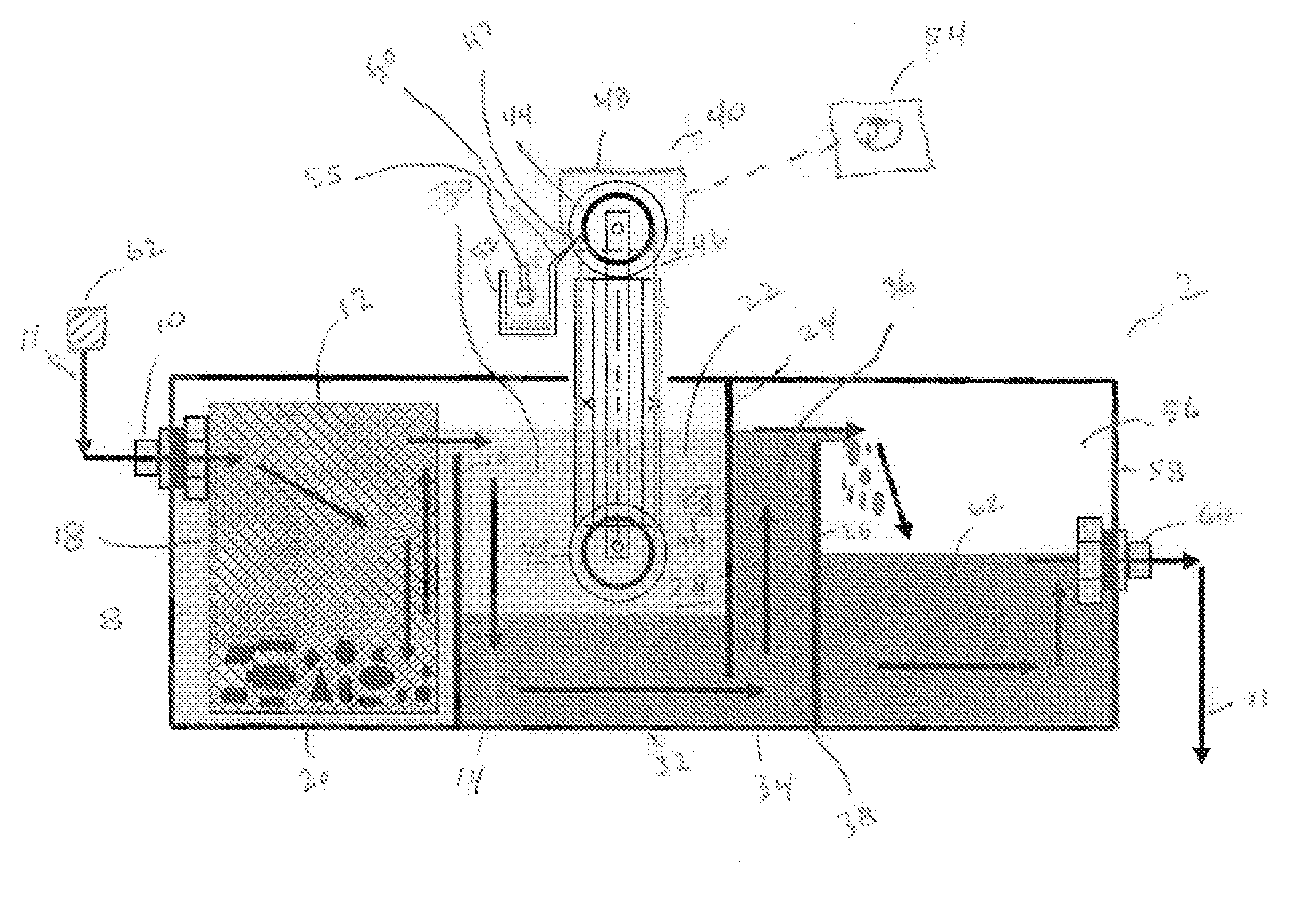

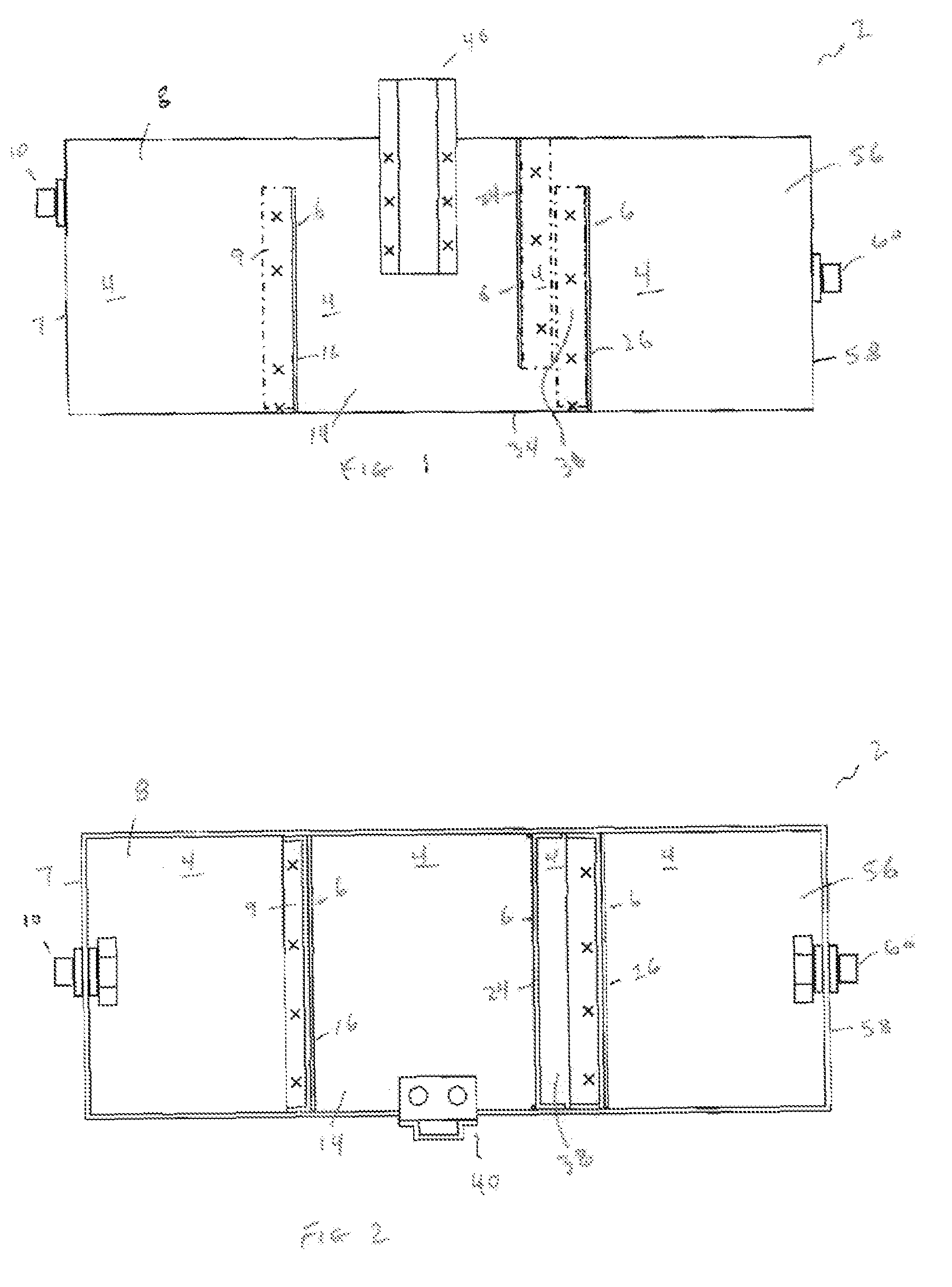

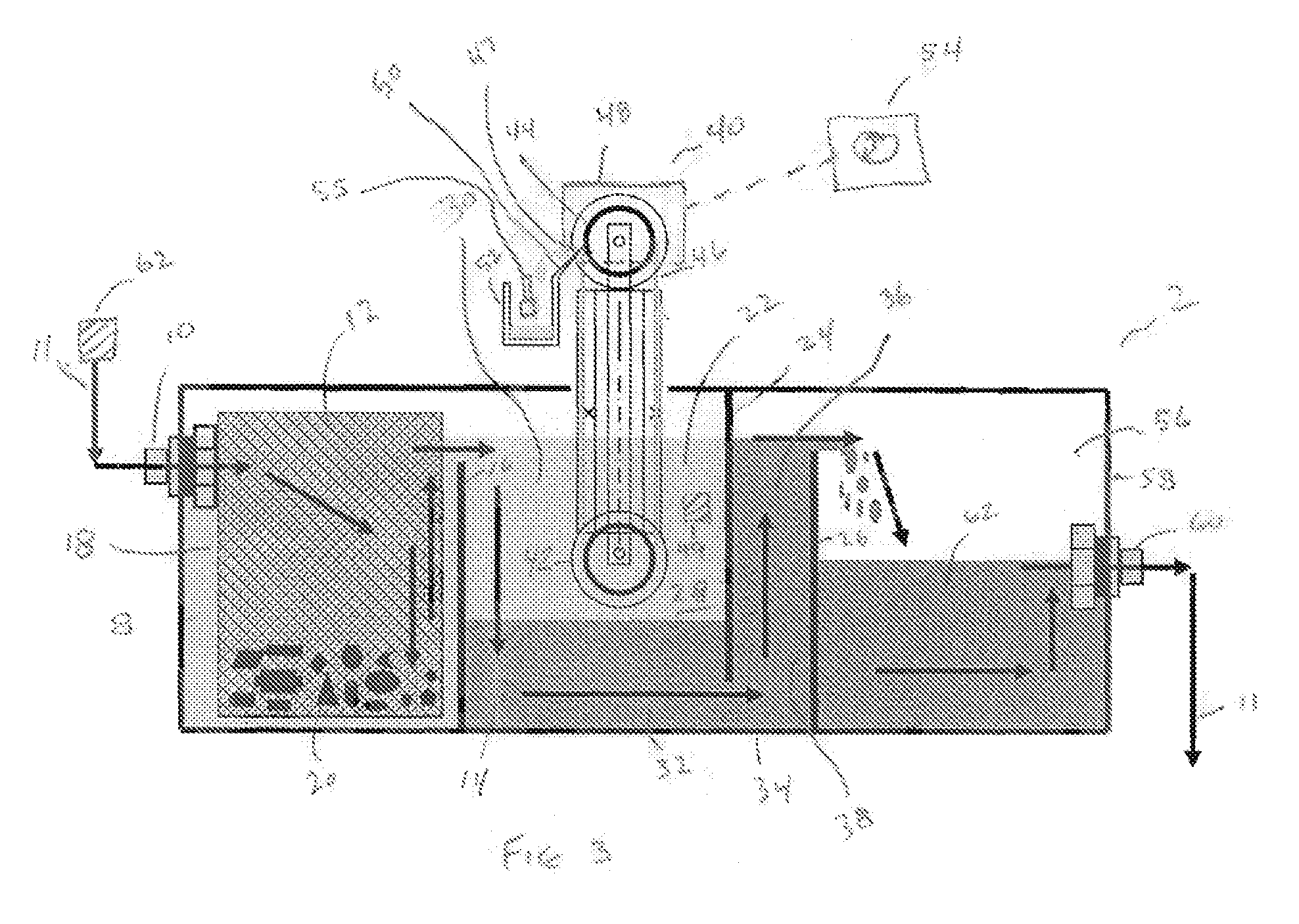

Automated means to remove air from venous blood during CPB

InactiveUS7131966B1Enhanced advantageImprove uniquenessOther blood circulation devicesDiagnosticsVacuum assistedVenous blood

Venous reservoirs are interposed between the patient and the arterial pump and serve to remove air bubbles and provide compliance that accommodates variations in the volume of blood circulating in the extracorporeal circuit during cardiopulmonary bypass (CPB). The invention is a reservoir that incorporates automated means to remove air bubbles from the venous line prior to the blood entering the arterial blood pump. In another form, the reservoir includes means that handles foam prior to the blood entering the blood pump. In yet another form, the invention is means that improve air removal in a soft shell venous reservoir. These features are applicable to CPB circuits using gravity drainage or vacuum assisted venous drainage.

Owner:TAMARI YEHUDA

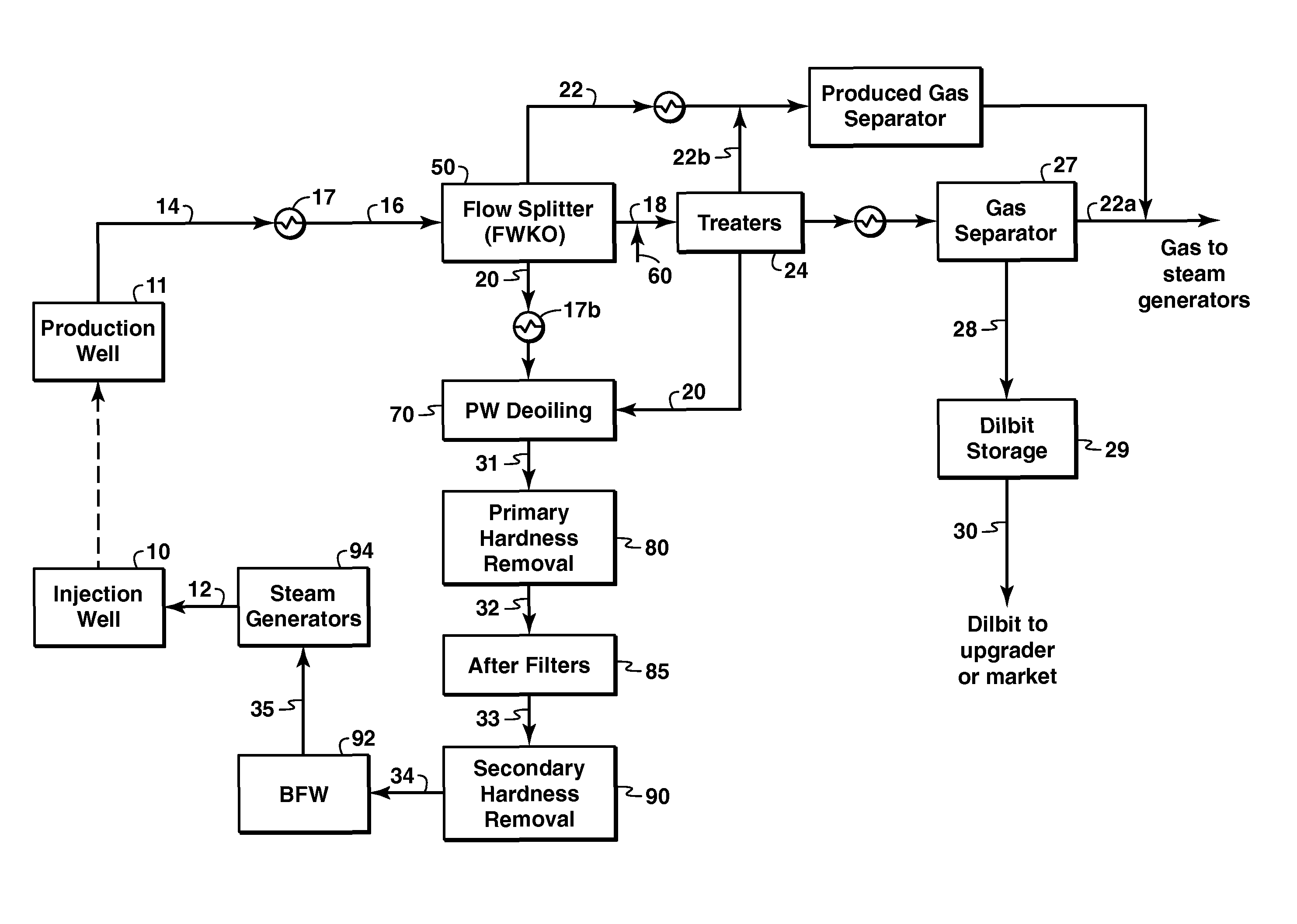

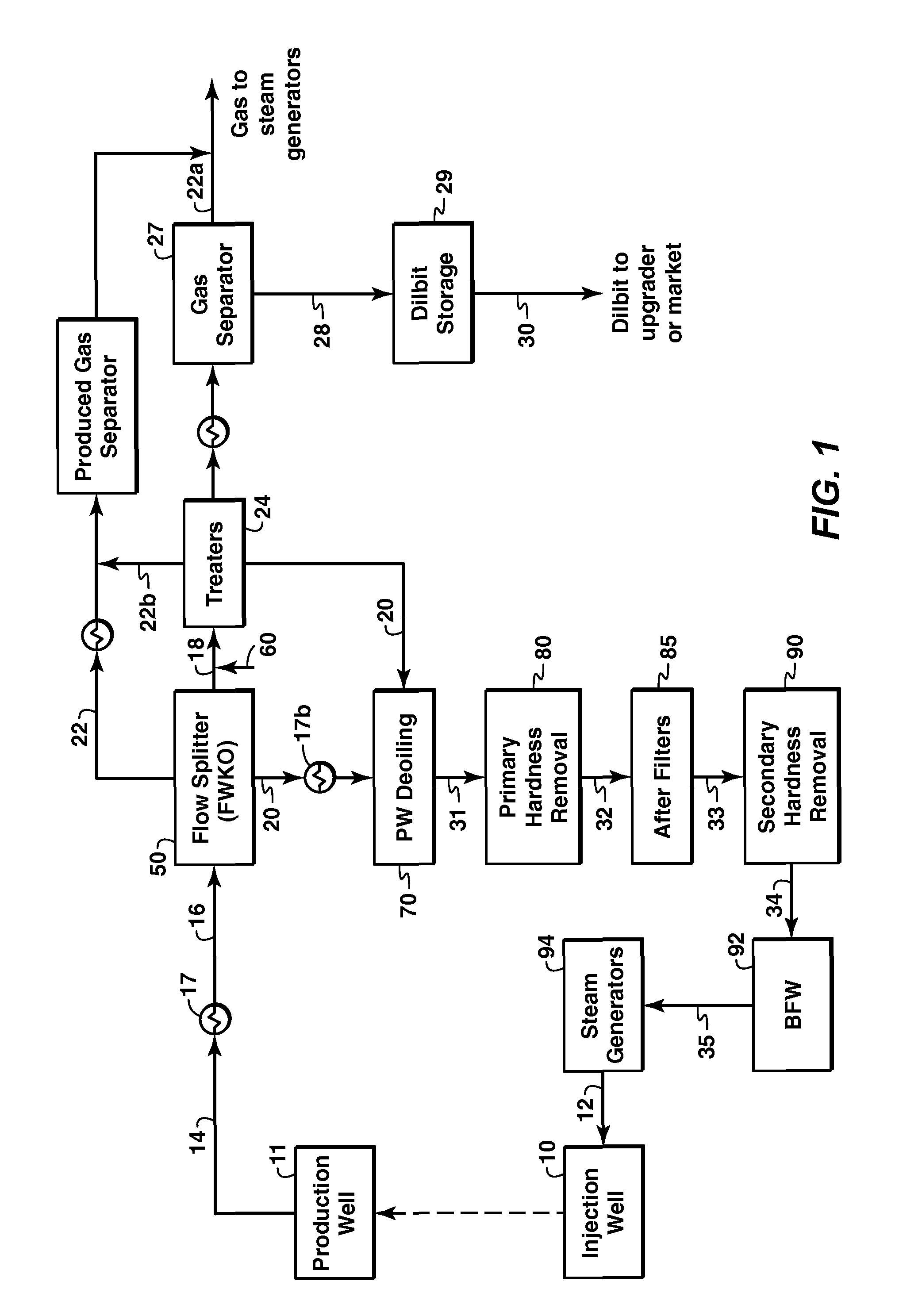

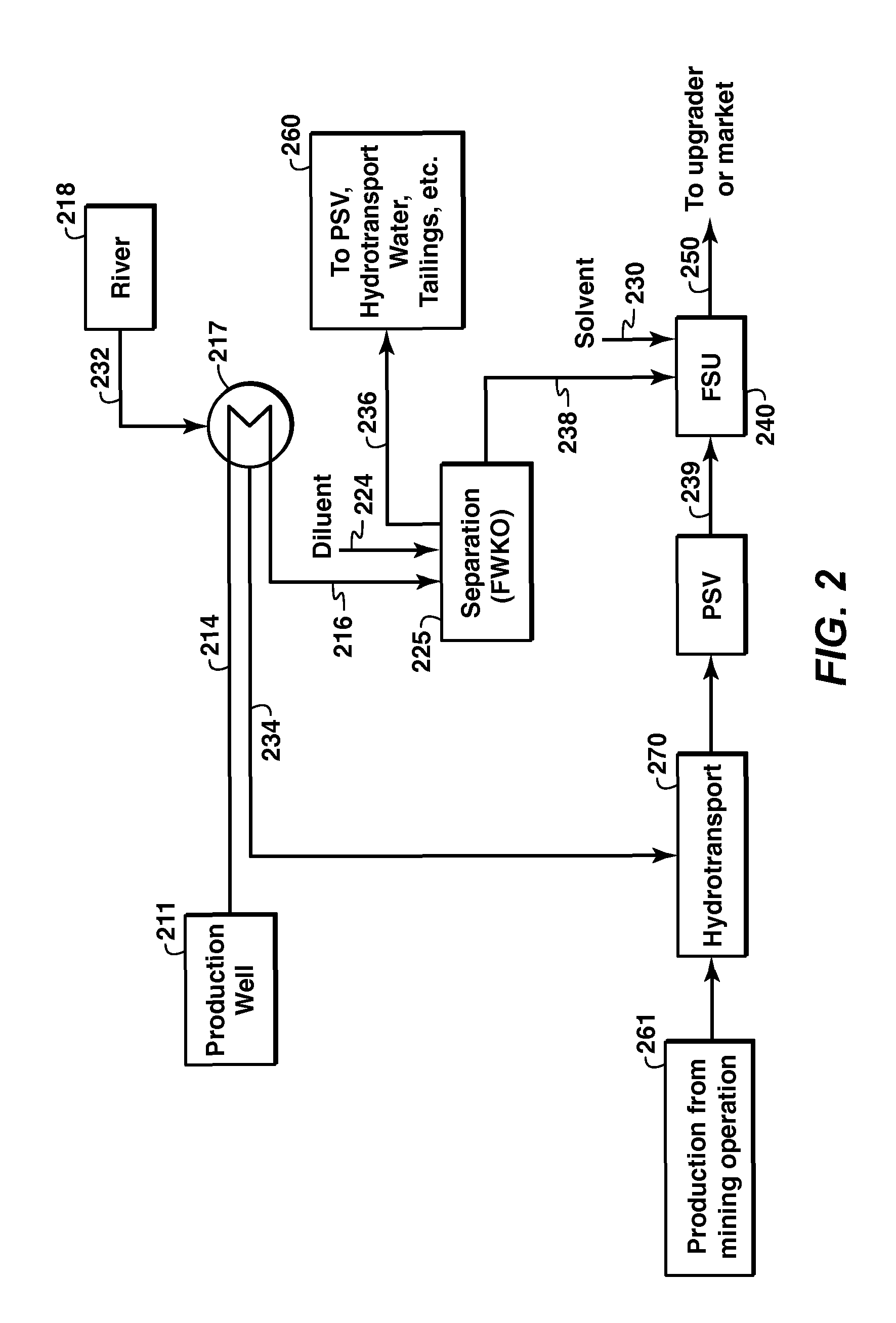

Integration of an in-situ recovery operation with a mining operation

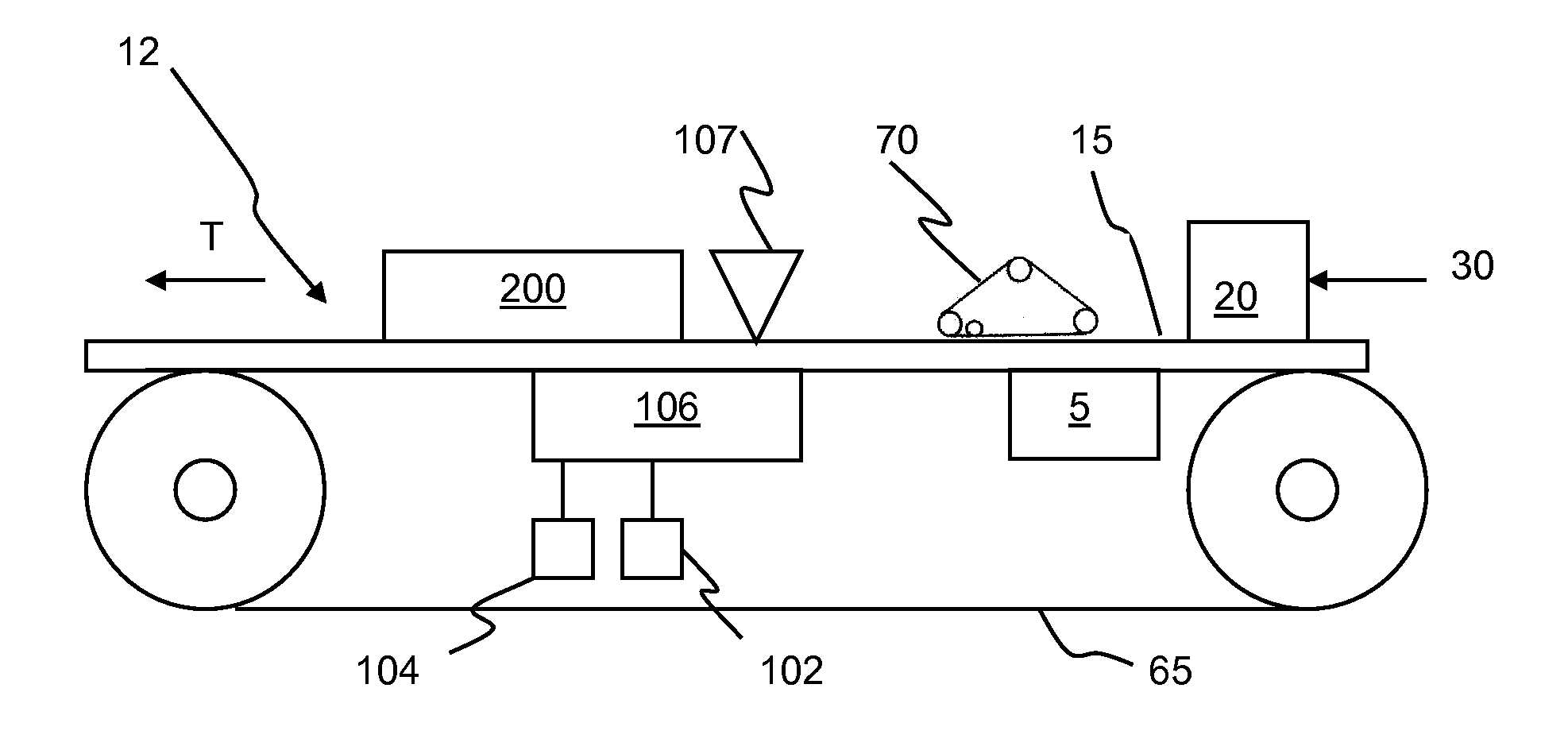

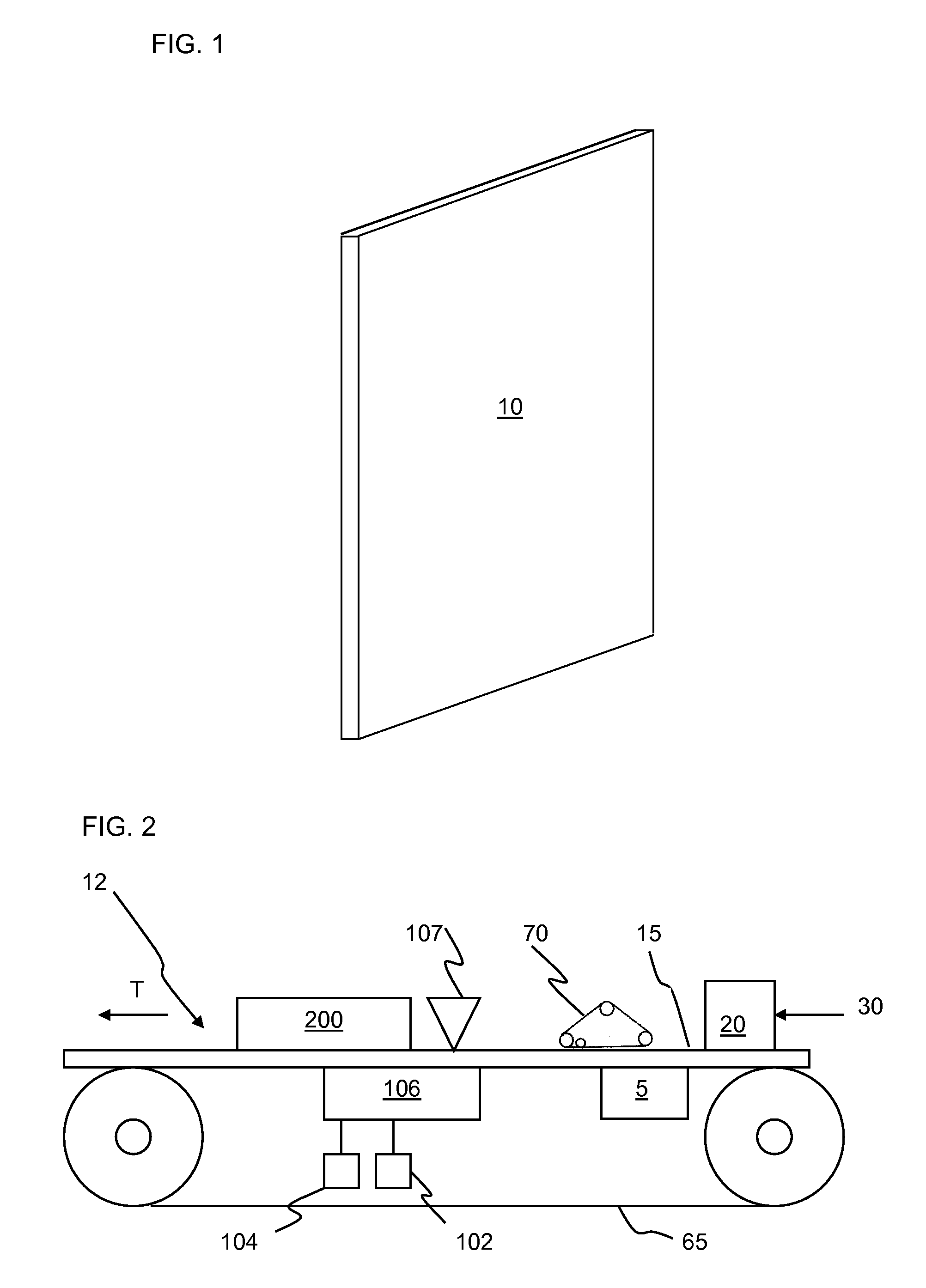

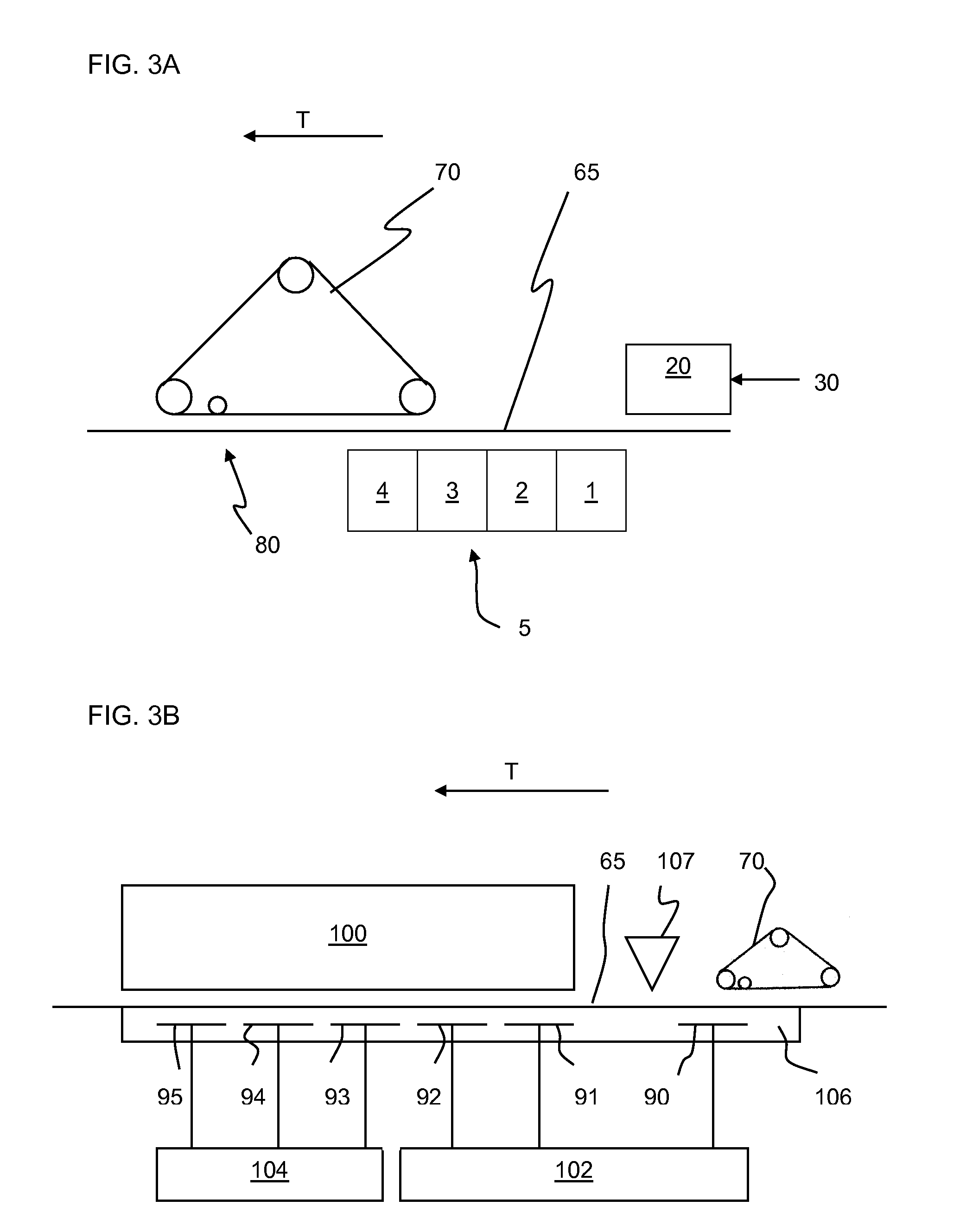

InactiveUS20100276983A1Disloding machinesUnderground chambersSteam-assisted gravity drainageIntegrated systems

This description is directed to a method and system for integrating an in-situ bitumen recovery operation with a bitumen mining operation for improved efficiencies and synergies therebetween. The method comprises obtaining a production fluid from the in-situ bitumen recovery operation, directing the production fluid to the bitumen mining operation, and incorporating the production fluid into the bitumen mining operation. The basic integrated system comprises a production well for recovering production fluid from the in-situ bitumen recovery operation, a bitumen mining and extraction facility, and a transporter for directing the production fluid from the production well to the bitumen mining and extraction facility for incorporation into the mining and extraction operation. The in-situ recovery operation may be a thermal operation, such as steam-assisted gravity drainage (SAGD), cyclic steam stimulation (CSS), or a derivative thereof.

Owner:EXXONMOBIL UPSTREAM RES CO

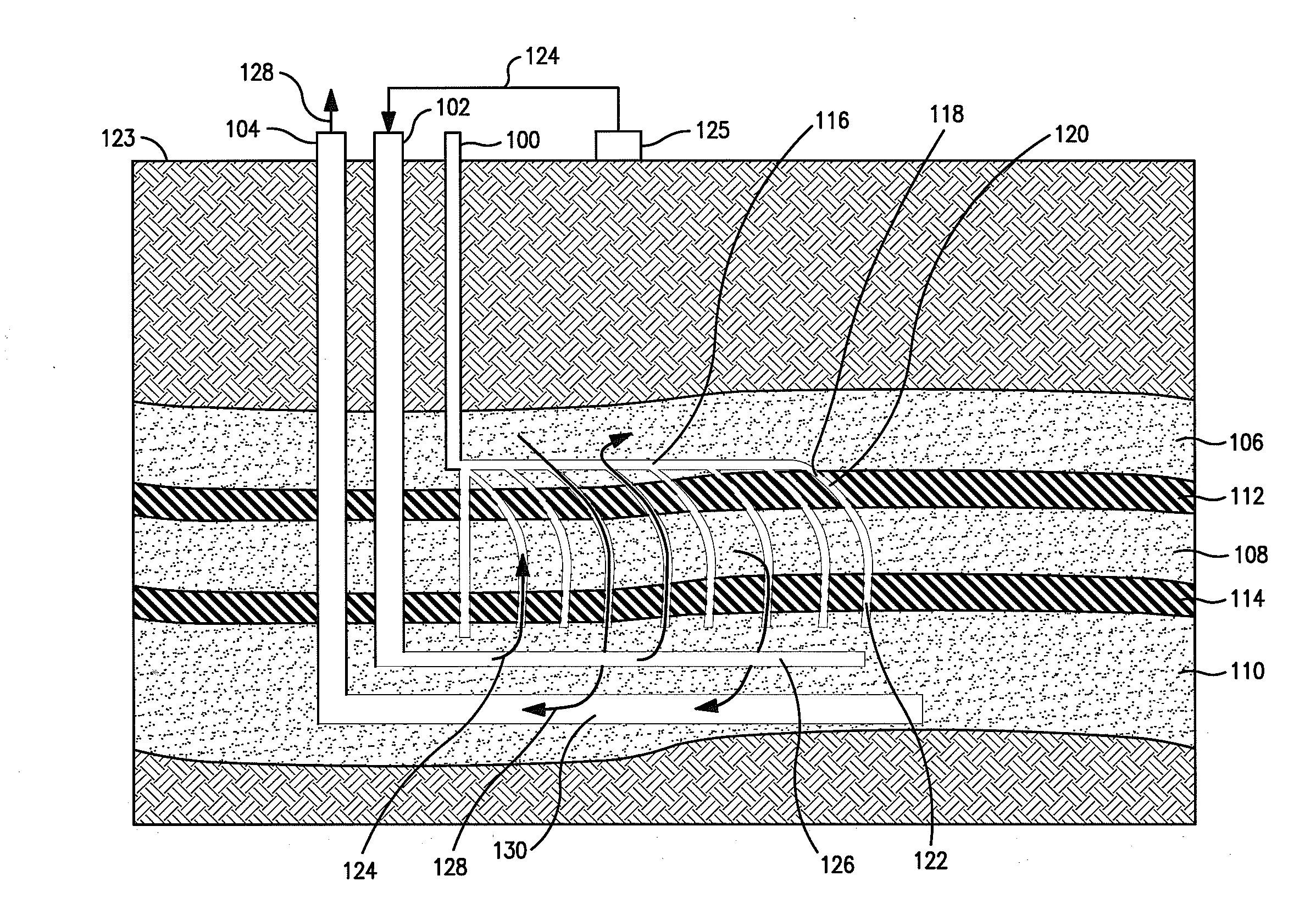

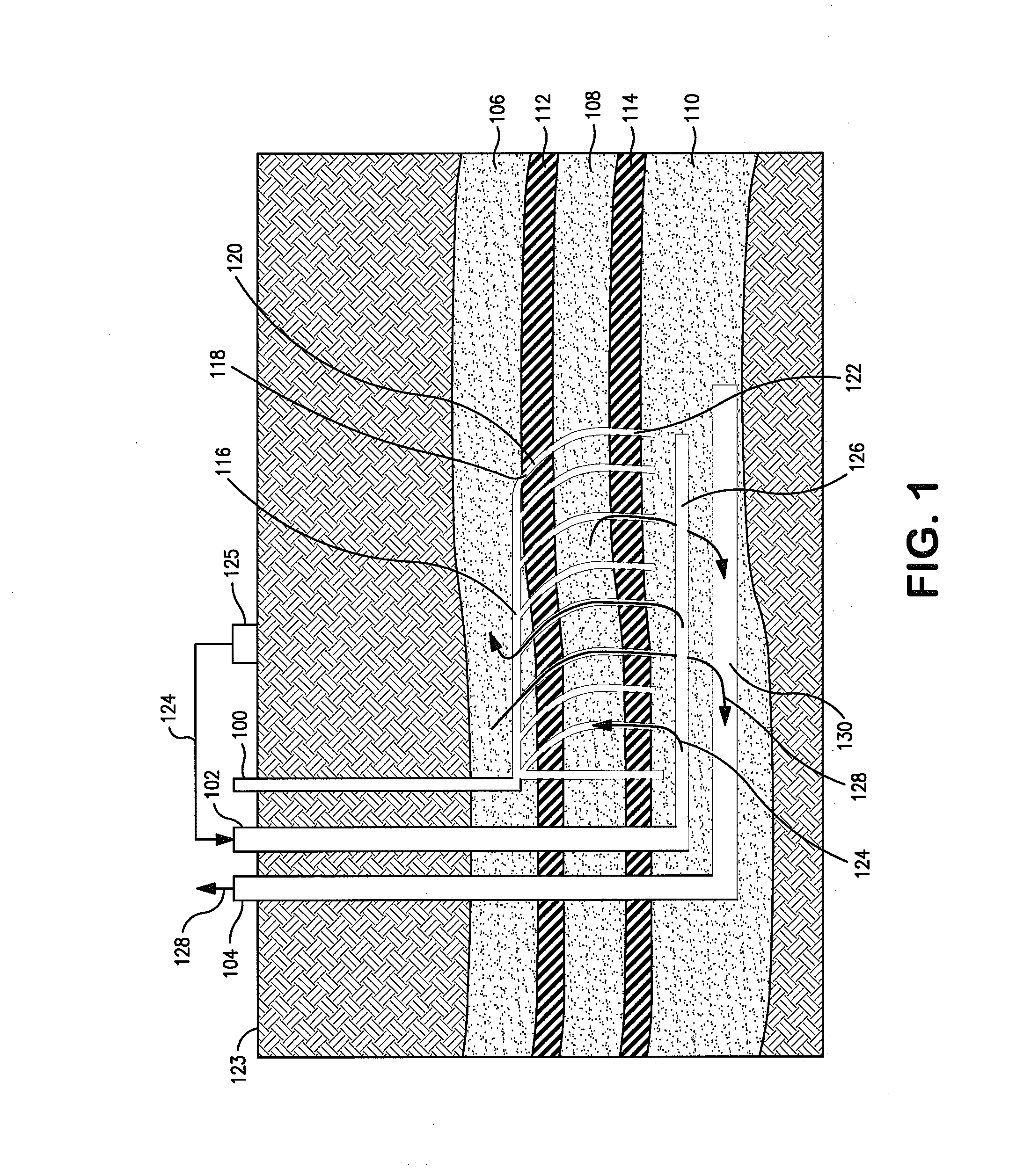

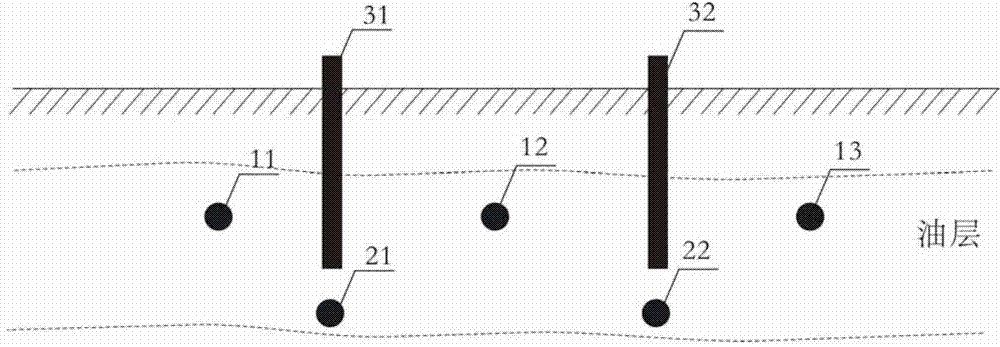

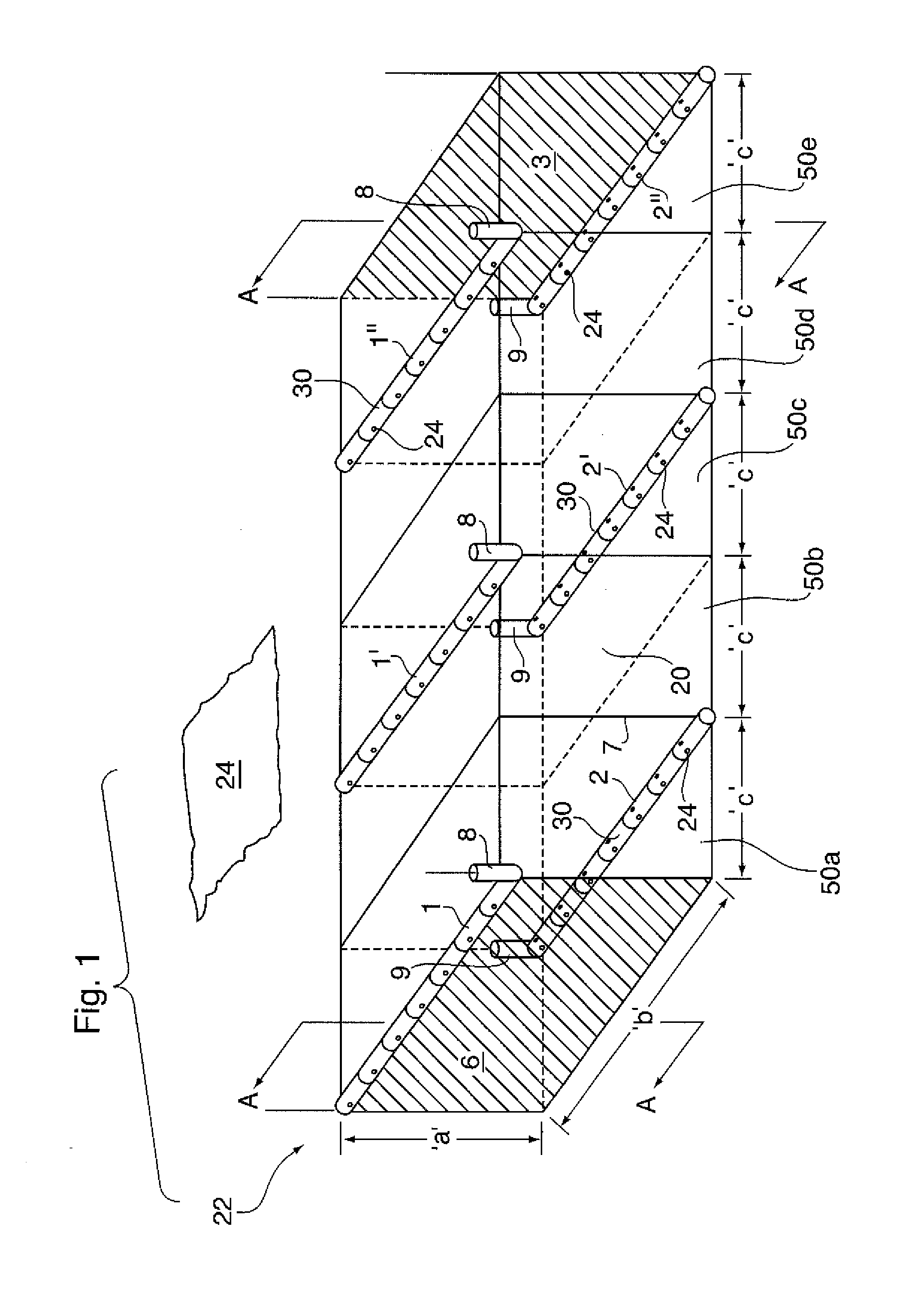

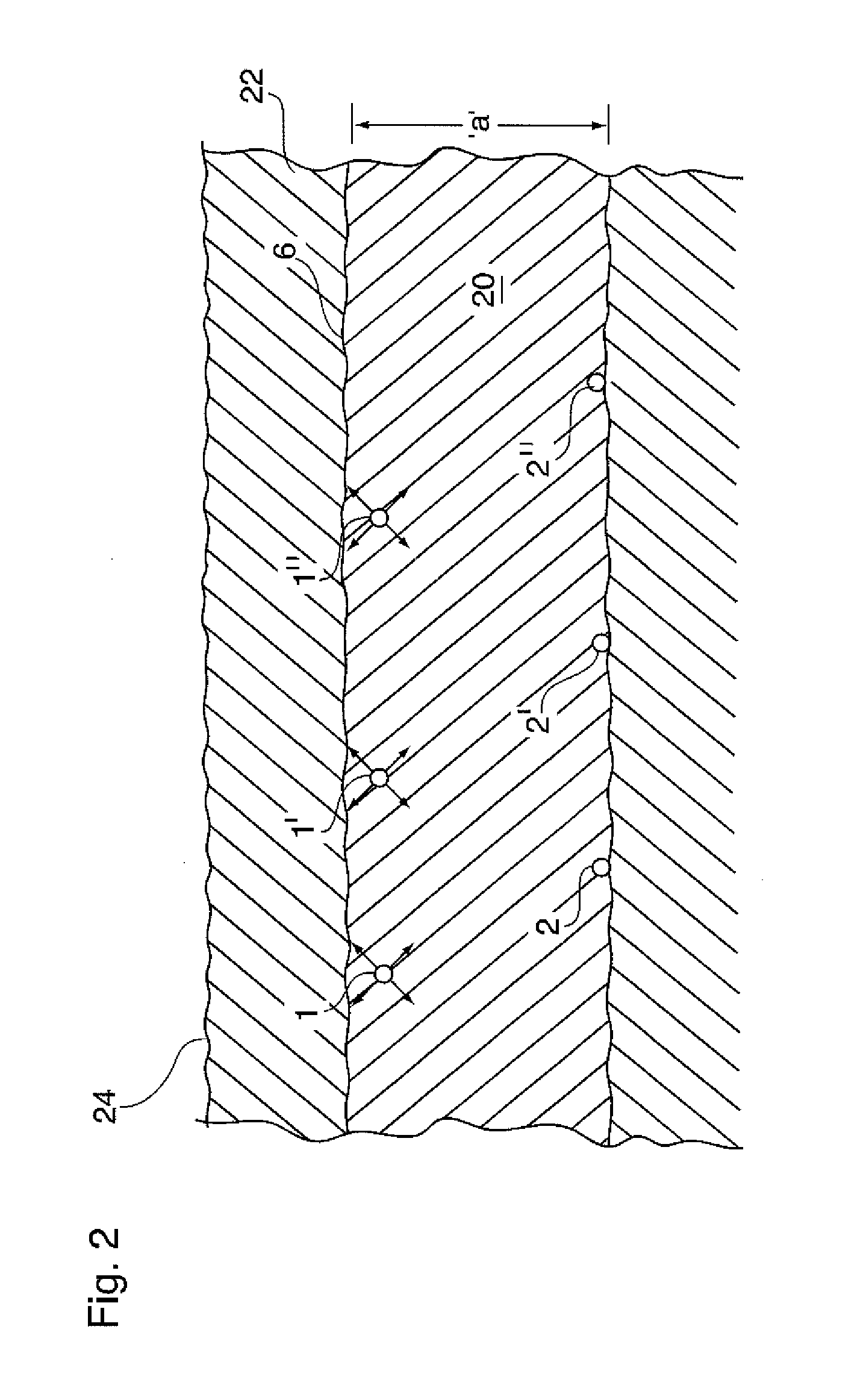

Draining a reservoir with an interbedded layer

Methods and systems relate to recovering hydrocarbons from within formations in which hydrocarbon bearing reservoirs are separated from one another by a fluid flow obstructing natural stratum. Relative to the reservoirs, the stratum inhibits or blocks vertical fluid flow within the formation. Drilled bores arranged to intersect the stratum provide an array of fluid flow paths through the stratum. Fluid communication established by the drilled bores enables production utilizing a producer borehole deviated from vertical and processes that rely on techniques such as gravity drainage through the fluid flow paths and / or injection through the fluid flow paths.

Owner:CONOCOPHILLIPS CO

Oil extraction method

ActiveCN102587880AIncrease Controlled ReservesExpand well spacingFluid removalLayer thicknessFront edge

The invention discloses an oil extraction method for extracting raw oil in a horizontal well. The oil extraction method comprises the steps of: A, fracturing the horizontal well; and B, performing horizontal well fireflood assisted gravity drainage on the fractured horizontal well. According to the oil extraction method, the fracturing technology is combined with the single horizontal well fireflood assisted gravity drainage extraction technology, the double advantages of horizontal crack leading fireflood front edge expansion and gravity assisted drainage are made full use of, and a thick oil deposit with an oil layer thickness of more than 4m can be economically and effectively developed.

Owner:PETROCHINA CO LTD

Venous reservoir

InactiveUS20070078369A1Enhanced advantageImprove uniquenessOther blood circulation devicesSurgeryExtracorporeal circulationVacuum assisted

Venous reservoirs are interposed between the patient and the arterial pump and serve to remove air bubbles and provide compliance that accommodates variations in the volume of blood circulating in the extracorporeal circuit during cardiopulmonary bypass (CPB). The invention is a reservoir that incorporates automated means to remove air bubbles from the venous line prior to the blood entering the arterial blood pump. In another form, the reservoir includes means that handles foam prior to the blood entering the blood pump. In yet another form, the invention is means that improve air removal in a soft shell venous reservoir. These features are applicable to CPB circuits using gravity drainage or vacuum assisted venous drainage.

Owner:TAMARI YEHUDA

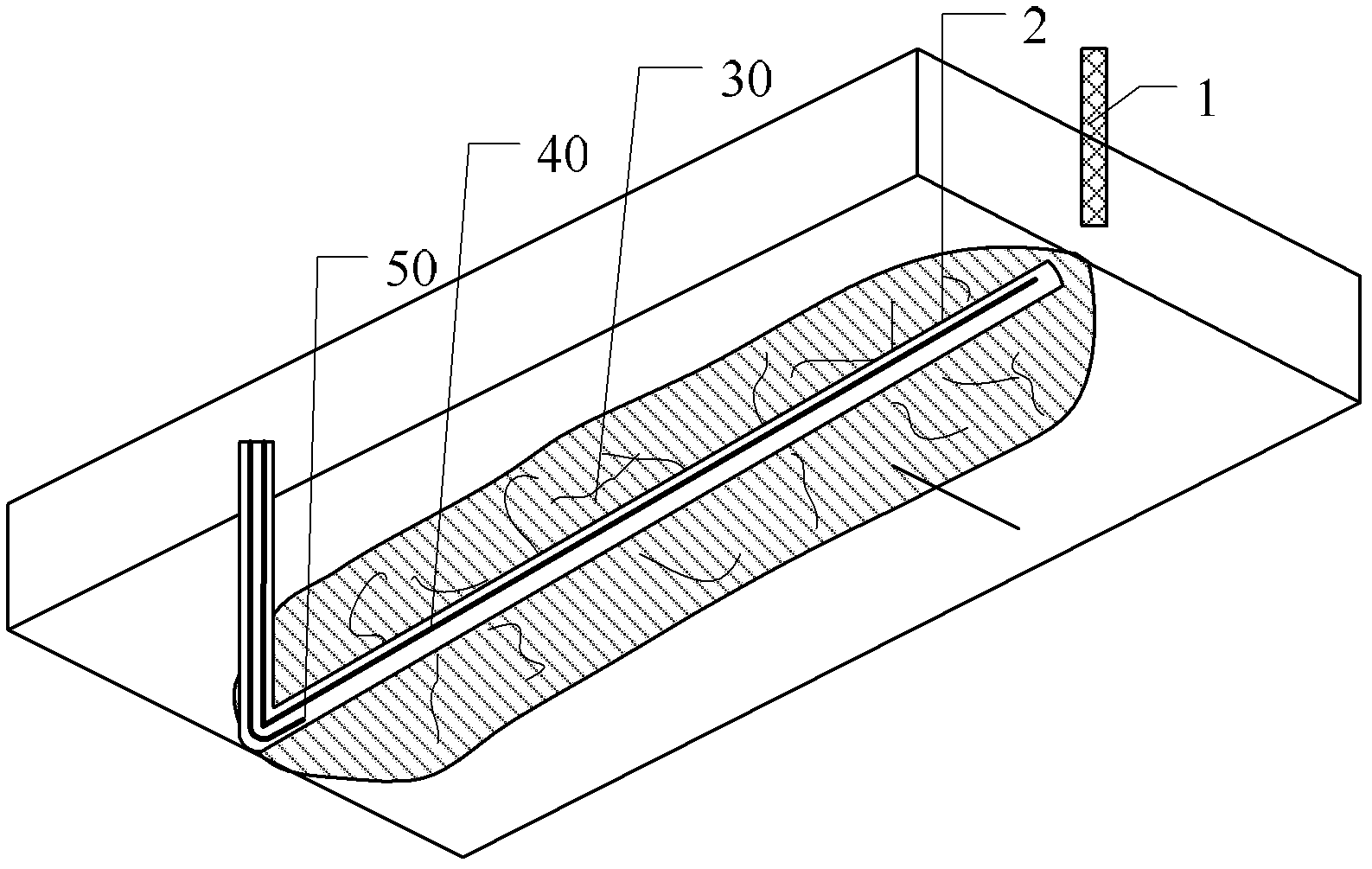

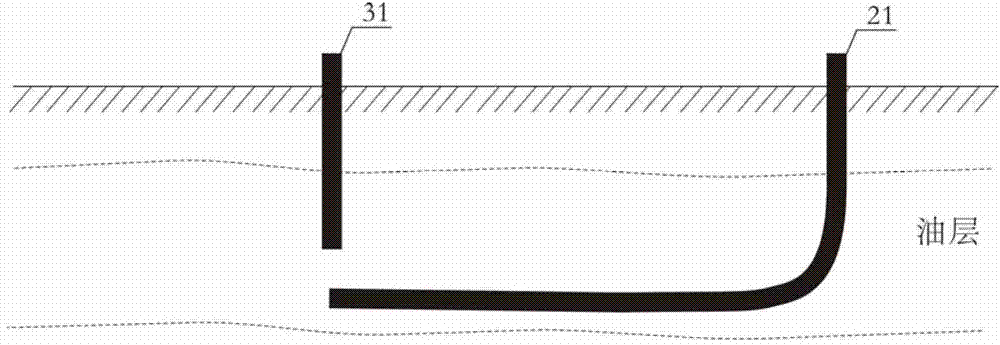

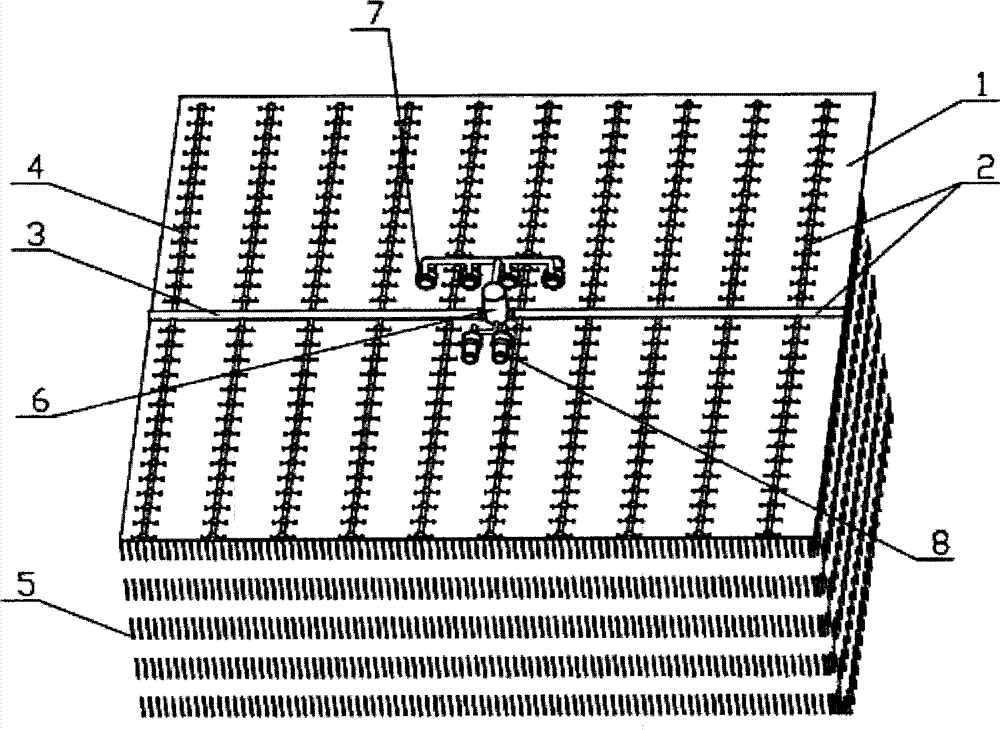

Hot water assisted gravity drainage method for mining high pour-point oil deposit

The invention relates to a hot water assisted gravity drainage method for mining a high pour-point oil deposit. The hot water assisted gravity drainage method for mining the high pour-point oil deposit comprises the following steps of: drilling a horizontal production well at the bottom of an oil reservoir of the high pour-point oil deposit; drilling two horizontal injection wells on the top of the oil reservoir of the high pour-point oil deposit; performing artificial fracturing and fissure forming on the horizontal injection wells and the horizontal production well; performing hot water huff and puff circulation preheating by using the horizontal injection wells and the horizontal production well simultaneously; and after circulation preheating is finished, starting to inject and produce continuously, namely continuously injecting hot water at the temperature of 100 DEG C by using the horizontal injection wells, and continuously producing by using the horizontal production well. The hot water assisted gravity drainage method for mining the high pour-point oil deposit can be applied to the high pour-point oil deposit of which the effective thickness is greater than 10 meters on large scale, and the well productivity and the recovery efficiency are improved.

Owner:PETROCHINA CO LTD

Oil deposit extraction method of solvent assisted fireflooding gravity drainage

ActiveCN103089230ALong-term auxiliary oil drainage effectImprove liquidityFluid removalSection planeCombustion

The invention relates to an oil deposit extraction method of solvent assisted fireflooding gravity drainage. The method comprises a first step that the extraction area of the oil deposit is provided with a horizontal producing well and an injection-production pattern of a vertical injecting well, the horizontal producing well and the vertical injecting well are arranged on the same vertical section of the same oil layer and form an injection-production well group, and a second step that a cosolvent horizontal well is arranged between the adjacent injection-production well group of the oil layer in the first step. The cosolvent has the function of dissolving and viscosity reduction of the crude oil, the viscosity of the oil layer on the flank of the horizontal producing well of the injection-production well group is reduced substantially, and the effective production time is long and the recovery efficiency is high. Moreover, due to the horizontal tractive effort of a cosolvent cavity of the horizontal flank, a large amount of air expands toward the flank following the combustion zone, and therefore the safety risk that the air penetrates into the production well bottom directly is lowered.

Owner:PETROCHINA CO LTD

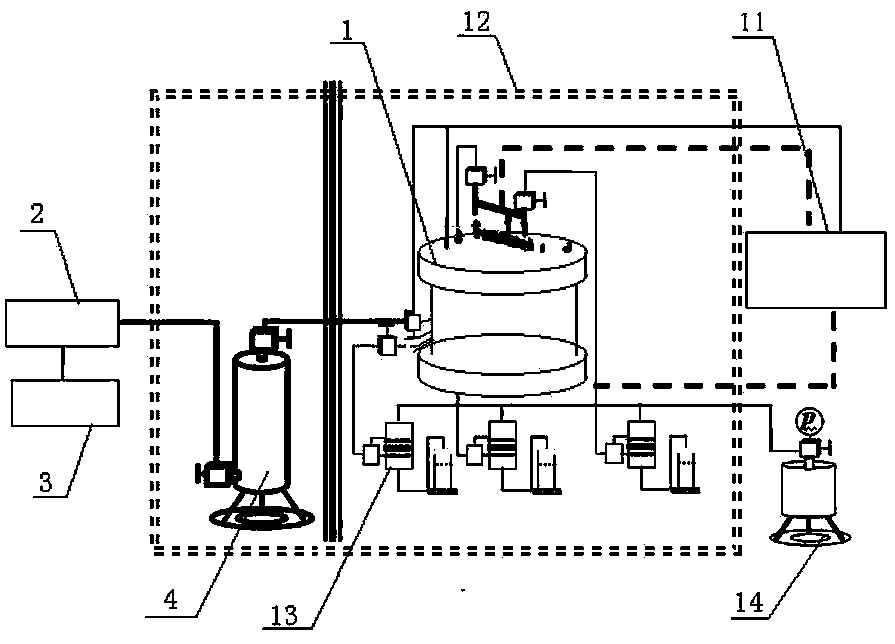

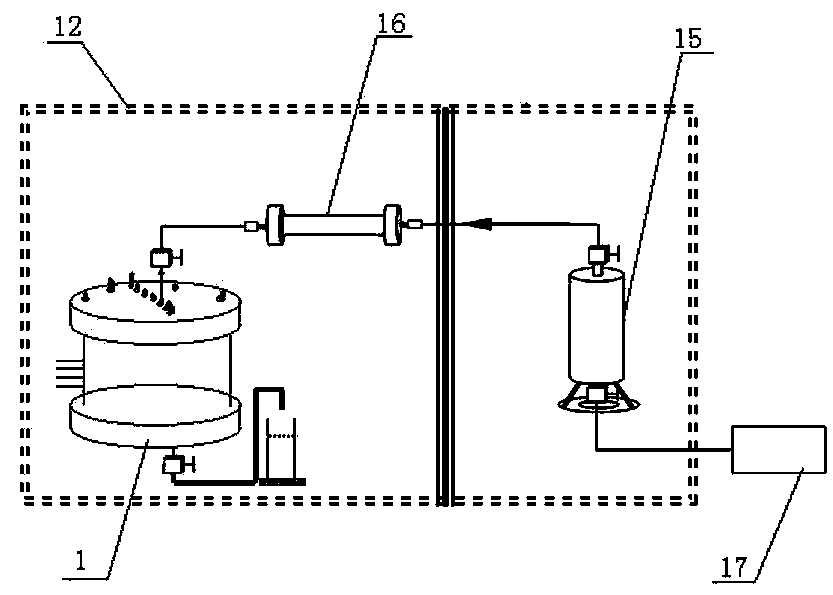

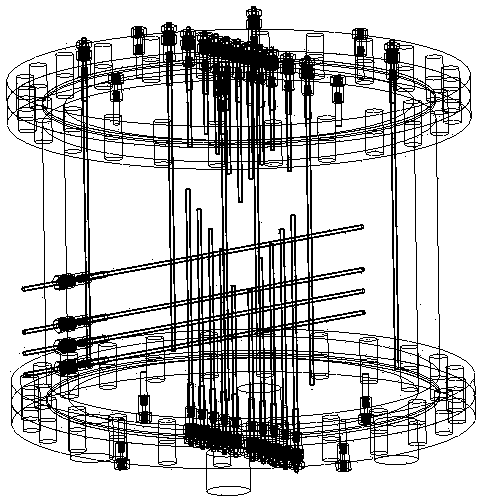

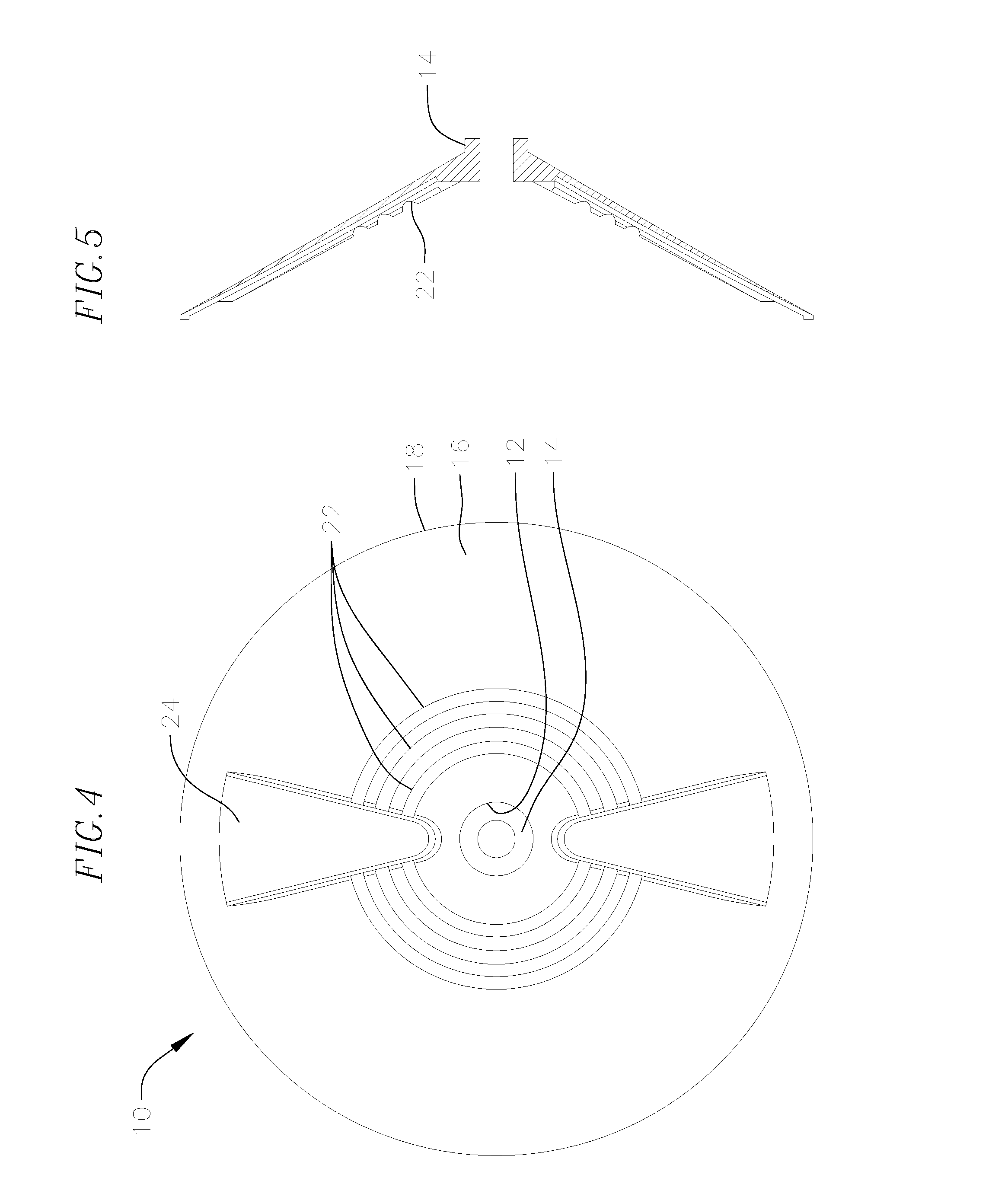

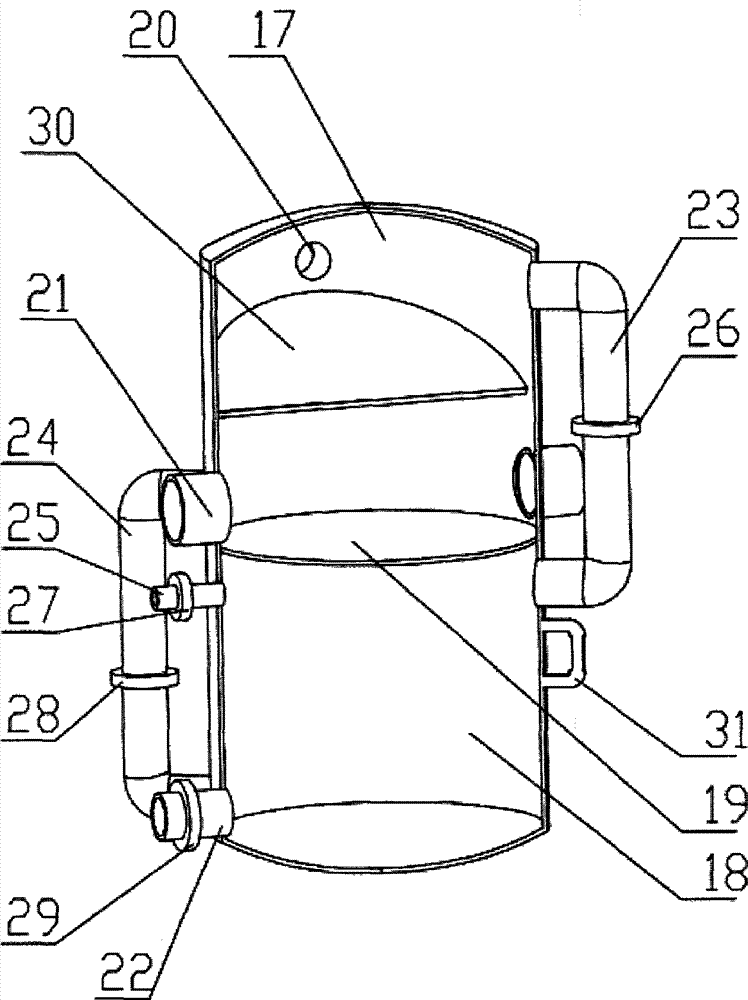

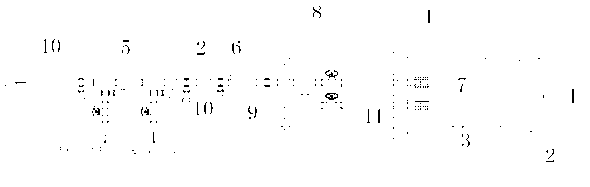

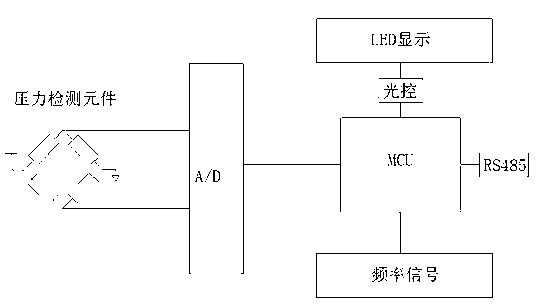

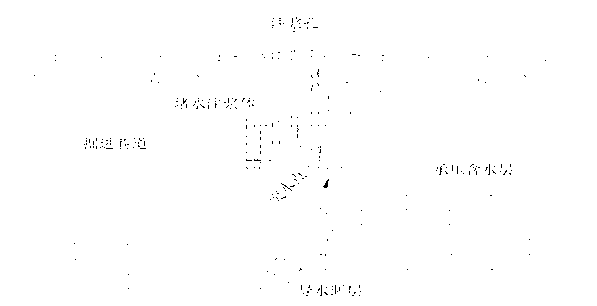

Stereoscopic development three-dimensional experimental device of heavy oil reservoir

InactiveCN103527176ALow cost of experimentsShorten experiment timeSurveyFluid removalRock coreMonitoring system

The invention relates to a stereoscopic development three-dimensional experimental device of a heavy oil reservoir. The stereoscopic development three-dimensional experimental device of the heavy oil reservoir comprises a three-dimensional rock core model, a constant temperature box, a steam generator, a temperature and pressure monitoring system, constant flux pumps and an intermediate container. Vertical well connectors are arranged on an upper cover plate of the three-dimensional rock core model, and horizontal well connectors are arranged on the side face of the three-dimensional rock core model. A mixture of high-alumina cement and quartz sand is filled into an inner cavity of the three-dimensional rock core model, and the three-dimensional rock core model is further respectively provided with temperature monitoring interfaces, pressure monitoring interfaces and saturated oil holes. The first constant flux pump is connected with the steam generator, the steam generator is connected to an inlet in the lower end of a first piston container, and an outlet in the upper end of the steam generator is connected with one horizontal well connector of the three-dimensional rock core model. An outlet in the upper portion of a second piston container is connected with the intermediate container, and the intermediate container is connected to the saturated oil holes in the upper cover plate of the three-dimensional rock core model. The stereoscopic development three-dimensional experimental device of the heavy oil reservoir integrates indoor experiments of three well pattern structures of SAGD, driving and draining combination and gravity drainage assisted steam driving, the experimental well pattern structures can be switched, and convenience is provided for indoor physical simulation of stereoscopic development of heavy oil.

Owner:NORTHEAST GASOLINEEUM UNIV

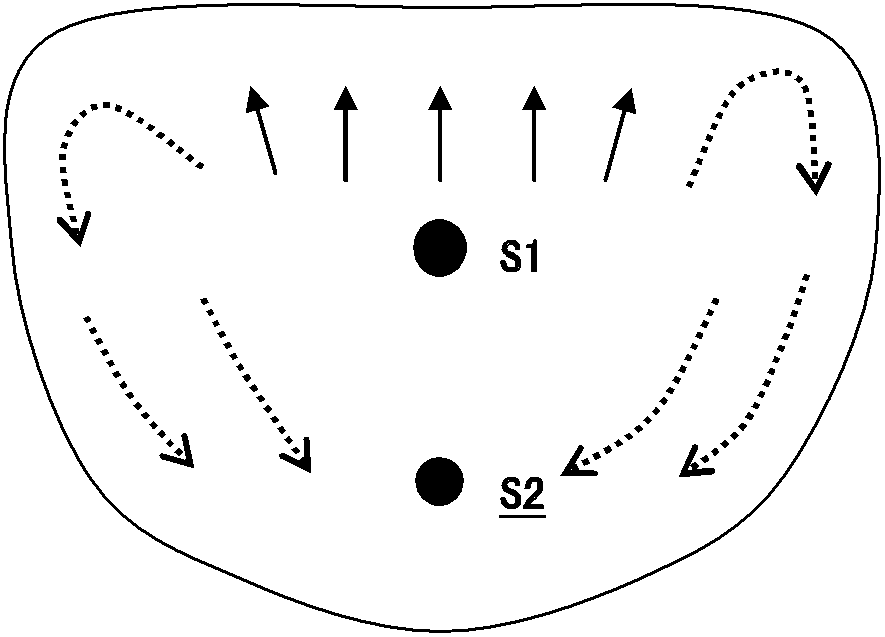

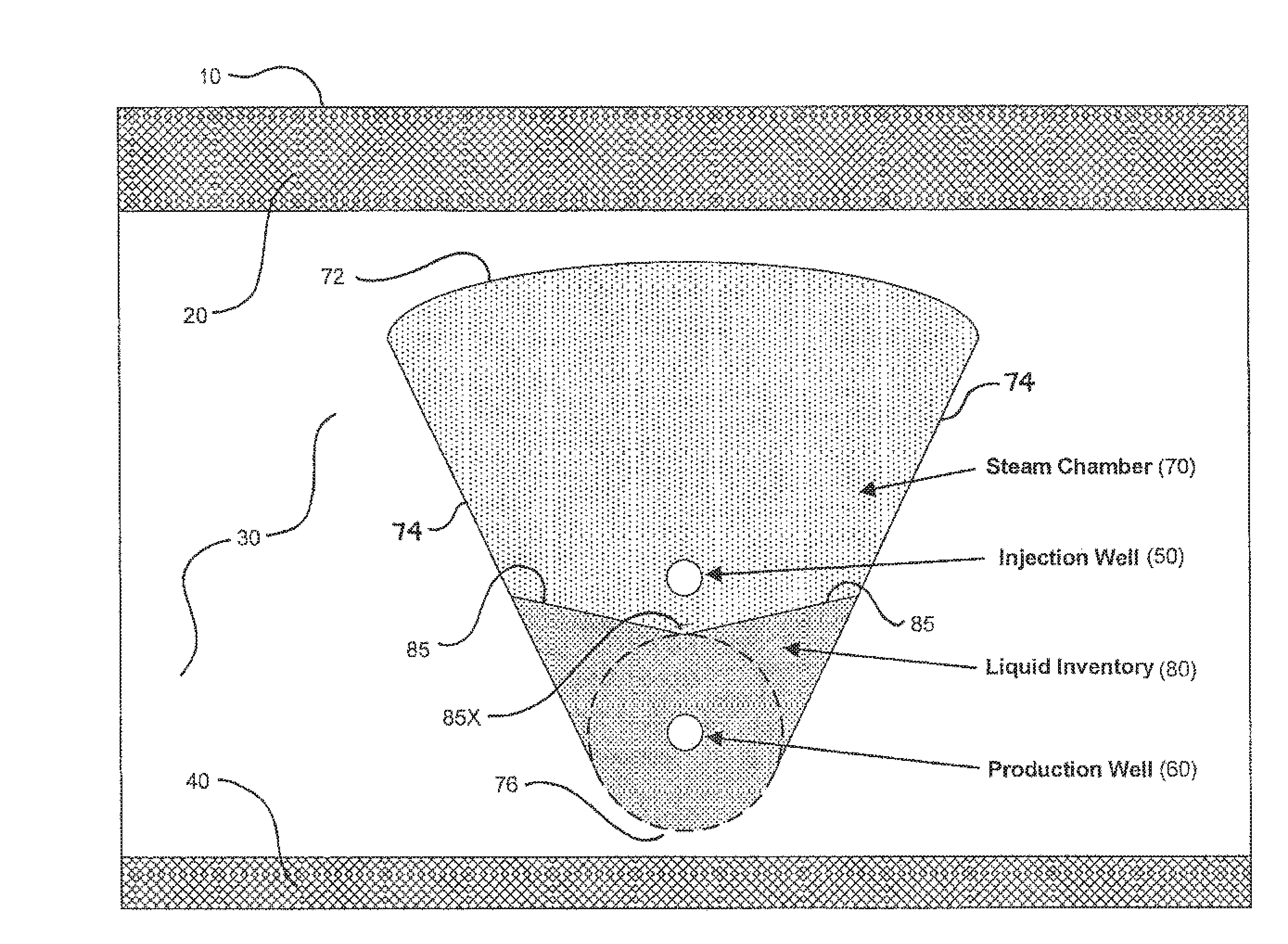

Method for controlling fluid interface level in gravity drainage oil recovery processes with crossflow

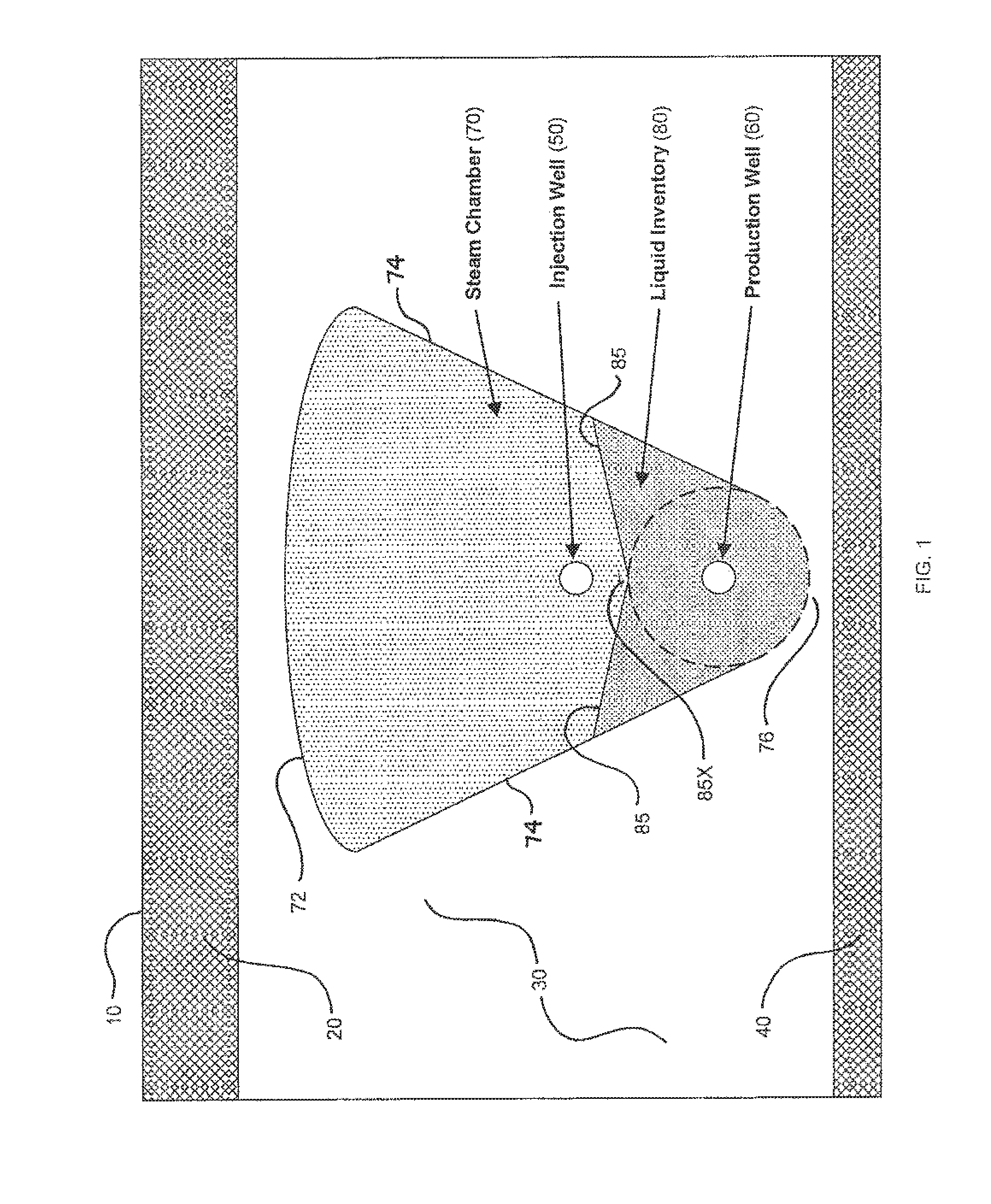

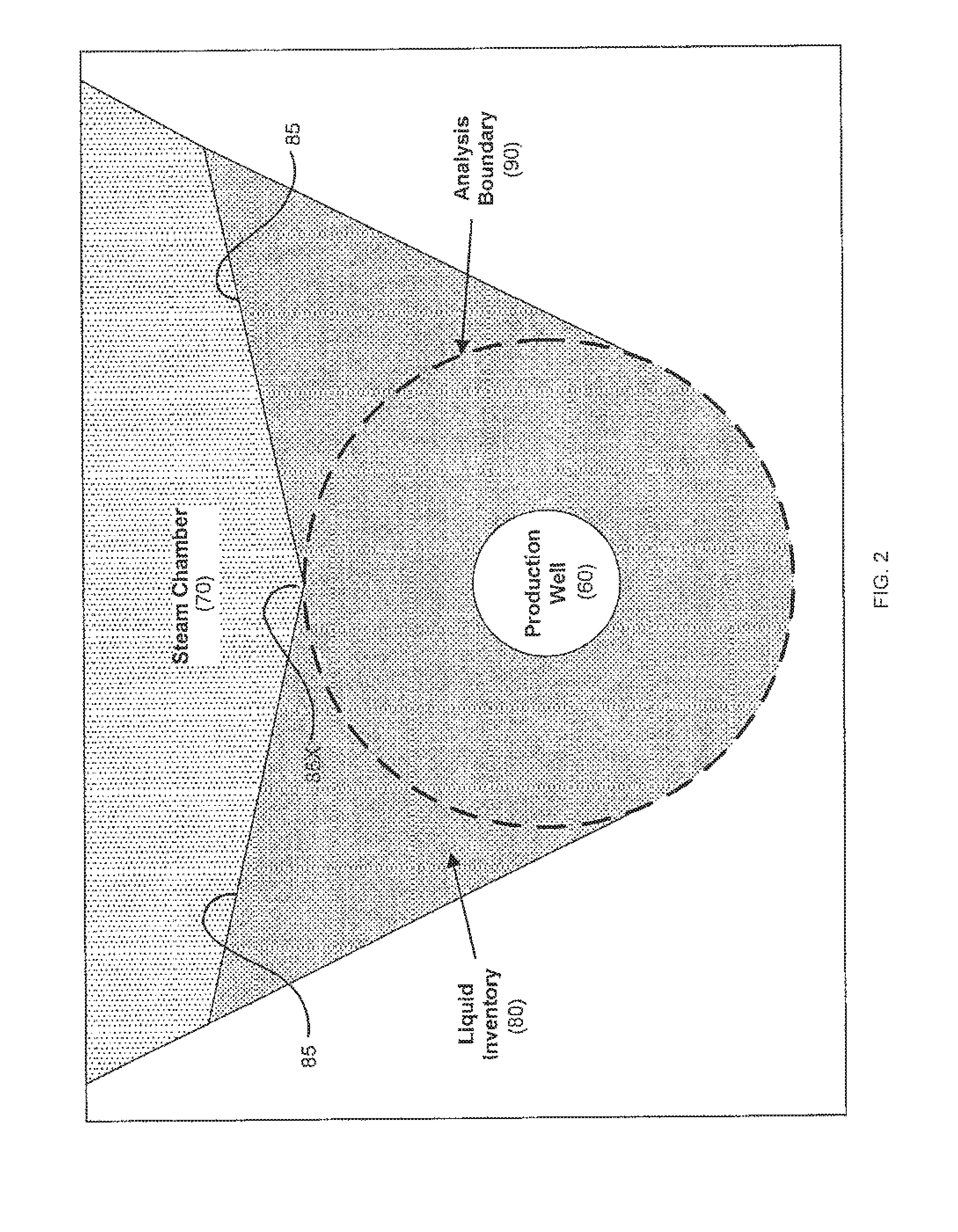

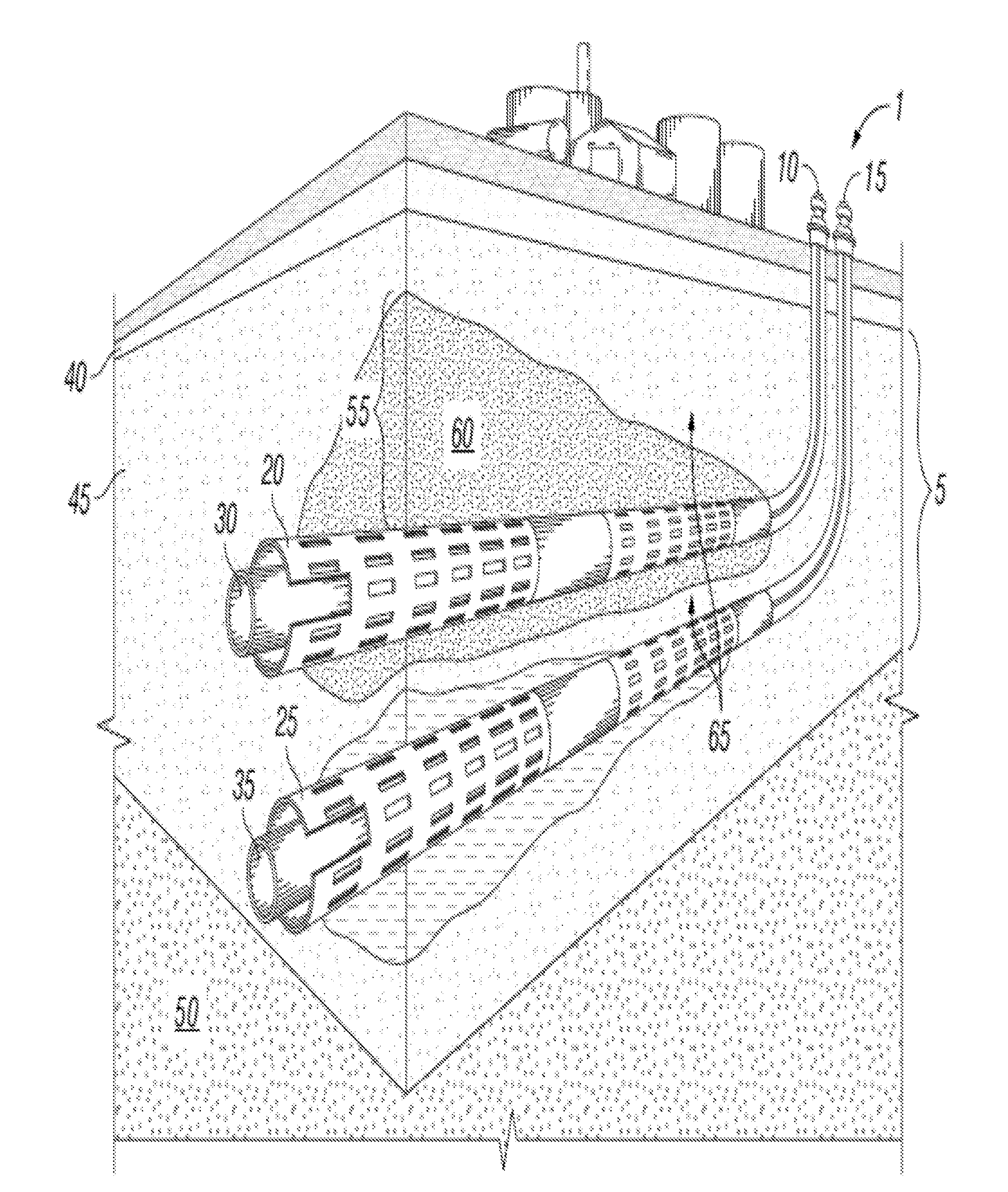

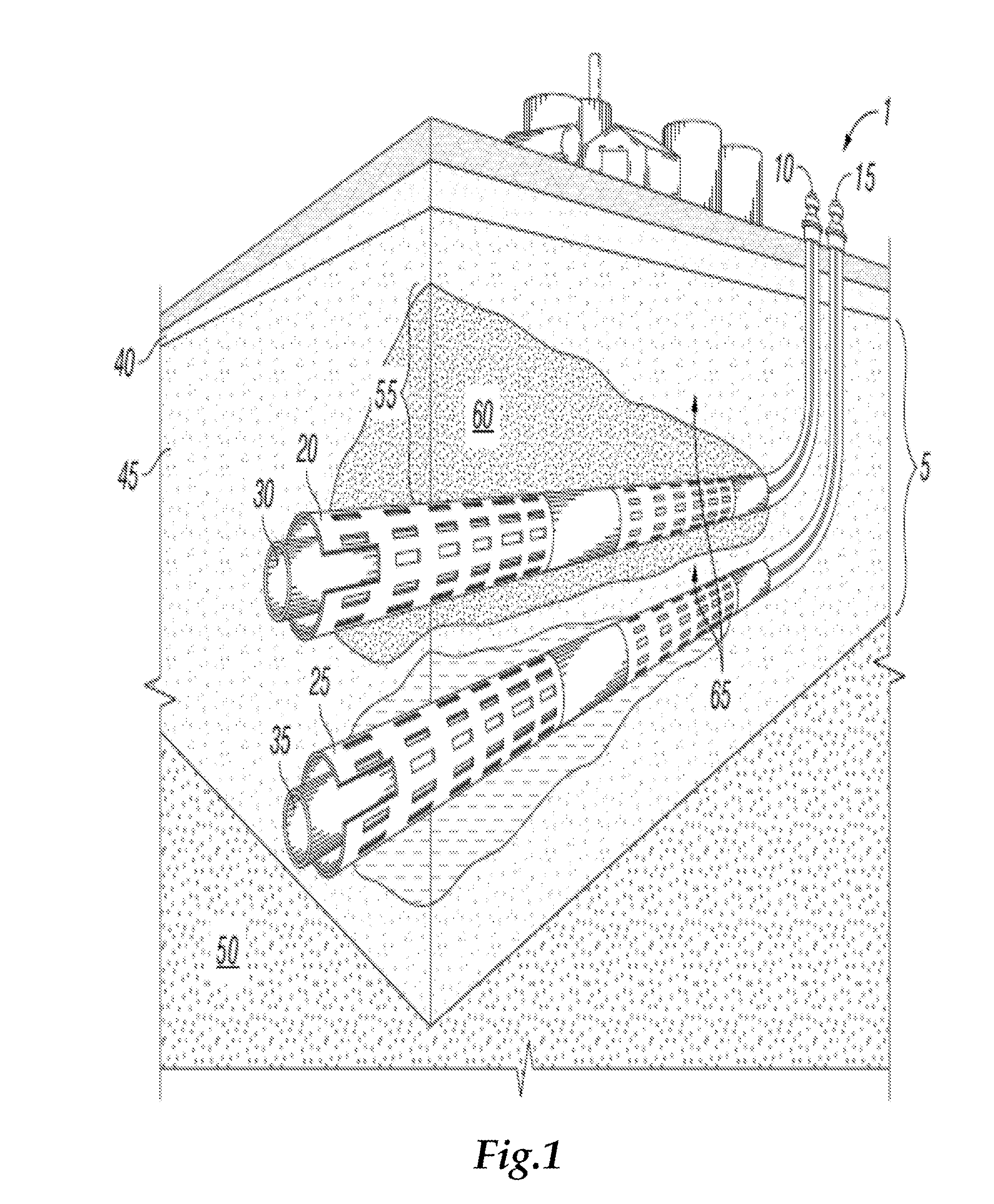

In a method for controlling the interface level between a liquid inventory and an overlying steam chamber in a subterranean petroleum-bearing formation, an inflow relationship is developed to predict the vertical position in a gravity field of the interface between two fluids with a density contrast (most commonly a water / oil emulsion and steam), relative to a horizontal producer well. The inflow relationship is applied to producer well completions by designing the completion to raise or lower sand face pressures over the horizontal length of the well. This pressure distribution will affect liquid levels according to the inflow relationship. Axial flow relationships for the liquid inventory may be developed to facilitate estimation of liquid levels at selected locations. Axial flow relationships for the steam chamber may also be developed to estimate the effect of the injector well completion on the steam chamber pressure and, in turn, the liquid level.

Owner:NOETIC TECH INC

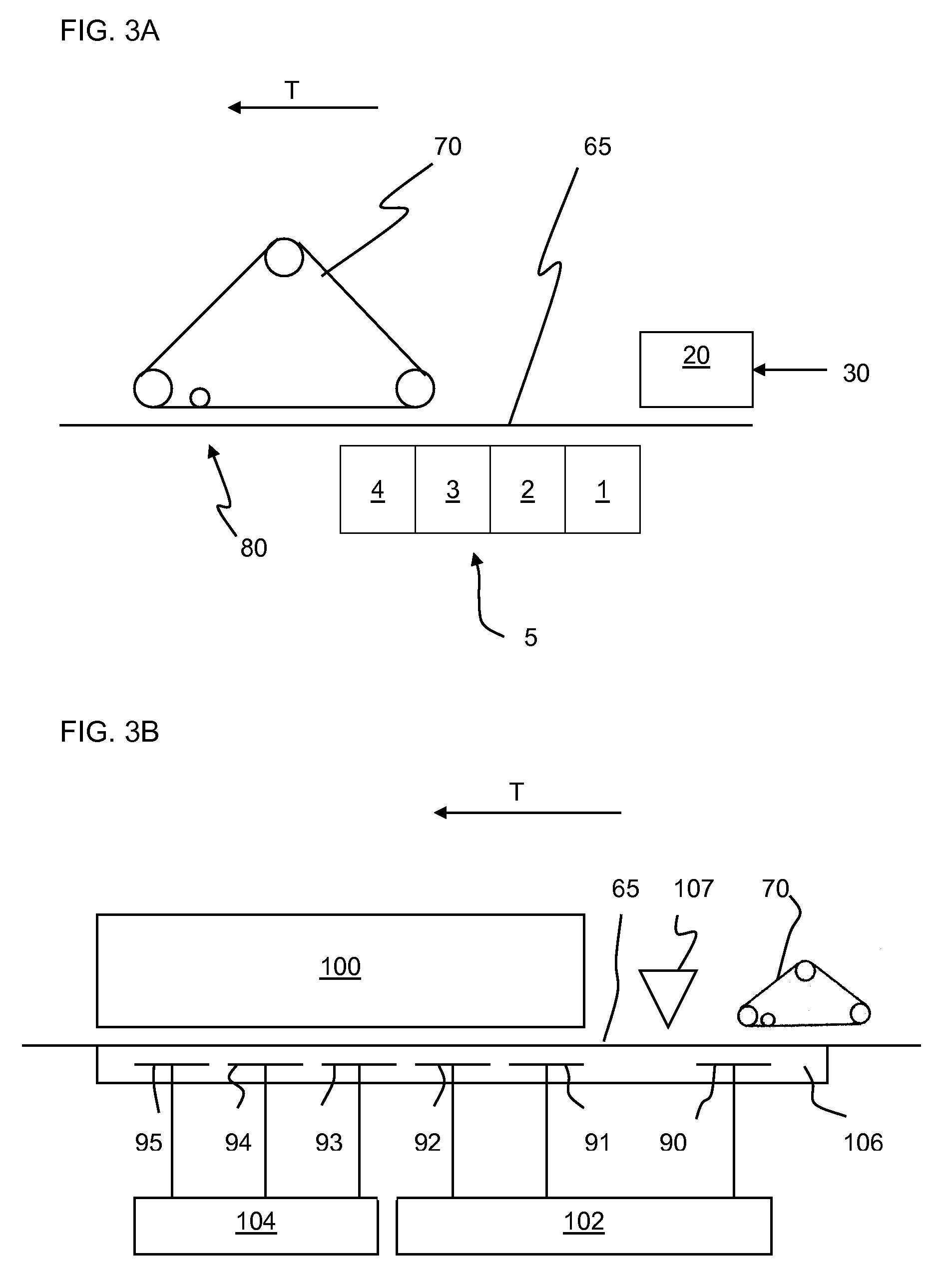

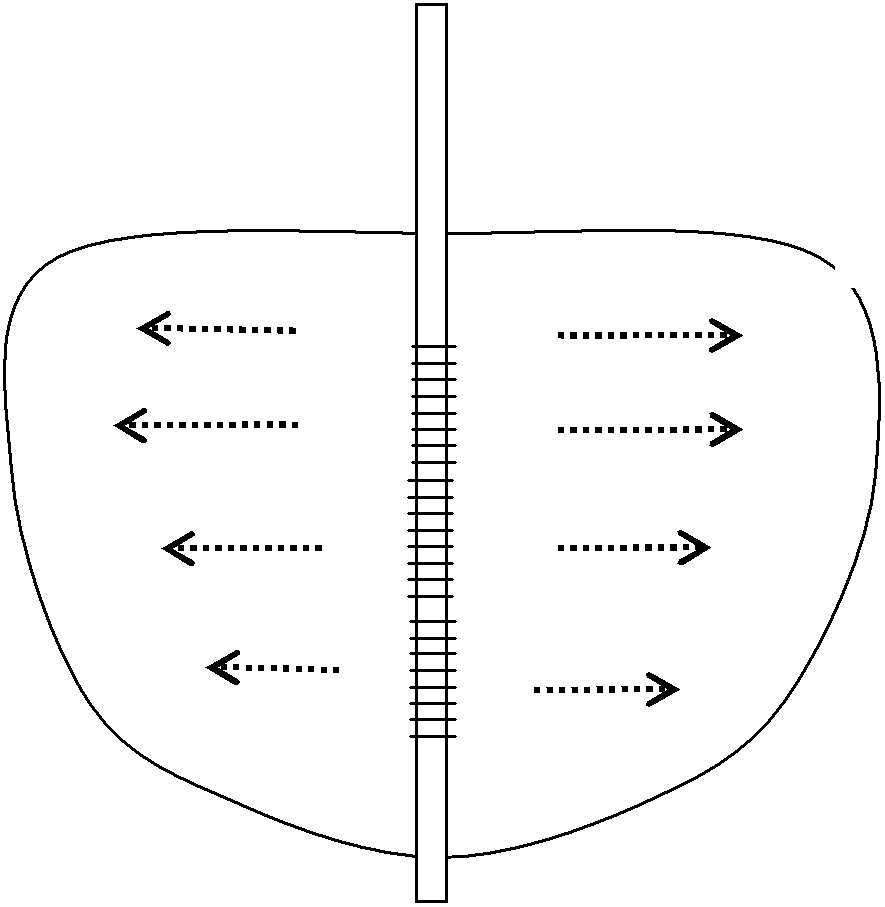

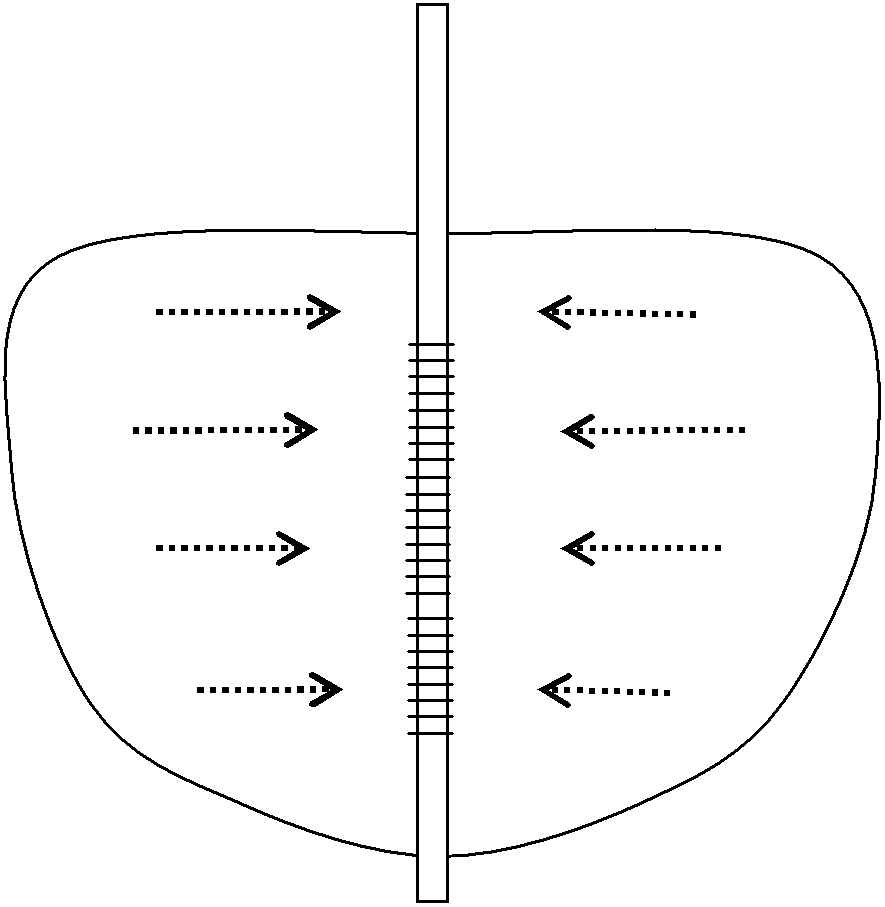

Gravity drainage startup using RF & solvent

The method begins by forming a gravity drainage production well pair within a formation comprising an injection well and a production well. The pre-soaking stage begins by soaking at least one of the wellbores of the well pair with a solvent, wherein the solvent does not include water. The pre-heating stage begins by heating the soaked wellbore of the well pair to produce a vapor. The squeezing stage begins by introducing the vapor into the soaked wellbore of the well pair, and can thus overlap with the pre-heating stage. The gravity drainage production begins after the squeezing stage, once the wells are in thermal communication and the heavy oil can drain to the lower well.

Owner:HARRIS CORP +1

Method and apparatus for in-situ radiofrequency assisted gravity drainage of oil (RAGD)

InactiveUS20100065265A1Promote recoveryEnhanced overall recoveryInsulationFluid removalElectricityNuclear engineering

The present invention relates generally to a radiofrequency reactor for use in thermally recovering oil and related materials. The radiofrequency reactor includes a radiofrequency antenna configured to be positioned within a well, where the well is provided within an area in which crude oil exists in the ground. The radiofrequency antenna includes a cylindrically-shaped radiating element for radiating radiofrequency energy into the area in which crude oil exists. The cylindrically-shaped radiating element is configured to allow passage of fluids there through. The radiofrequency reactor also includes a radiofrequency generator electrically coupled to the radiofrequency antenna. The radiofrequency reactor is operable to control the radiofrequency energy generated.

Owner:TURBOSHALE INC

Process for producing a low density acoustical panel with improved sound absorption

ActiveUS20090126886A1Low densityImprove sound absorptionFibreboardNon-fibrous pulp additionMetallurgySlurry

A process useful for producing low density high mineral wool based acoustical panels with improved acoustical absorption properties using a water felting process is disclosed. The process includes forming a dilute slurry mixture including water, mineral wool, a thermoplastic binder and / or starch; and distributing the dilute slurry on a porous carrier to have the slurry dewatered to a base mat by gravity drainage to remove water by gravity. A vacuum is adjusted to gradually apply vacuum to the gravity dewatered base mat to further dewater the base mat without subjecting the mat to static pressure that would compress the base mat. The base mat is dried to form an acoustical ceiling product that has a low density and excellent acoustical absorption properties.

Owner:USG INTERIORS LLC

Gravity drain valve

ActiveUS20150300511A1Saving in assemblyLow costUrinalsOperating means/releasing devices for valvesExhaust valveEngineering

Owner:NWS EUROPA

Vacuum preloading method and vacuum preloading device for water-air separation

ActiveCN103541345ARealize separate transmissionImprovement of Vacuum Preloading Construction MethodSoil preservationEngineeringAir separation

Disclosed are a vacuum preloading method and a vacuum preloading device for water-air separation. The vacuum preloading method includes that water-air separation pipelines, water-air separation tanks, a vacuumizing device and a water pumping device are mounted on the outer side of a vacuum sealing film, so that water pumped out from the soil mass of a soft ground treatment area and air are subjected to water-air separation in the water-air separation pipelines; the upper portions of the water-air separation pipelines are delivery channels for vacuum negative pressure and the air, and the water is allowed to flow into the water-air separation tanks along the lower portions of the water-air separation pipelines to be vacuumized and pumped through the vacuumizing device and the water pumping device respectively. A three-in-one type connecting device of plastic drainage plates and the water-air separation pipelines comprises a plastic drainage plate joint, a connecting pipe and a reducing-tee multipass joint, a bin-split type water-air separation tank is provided with an upper sealed cabin and a lower sealed cabin, and a gravity drainage type water-air separation tank comprises a tubular tank body and a drill bit, and a sinking pump is mounted at the lower end of the tank body. The vacuum preloading method and the vacuum preloading device have the advantages that vacuum preloading construction cost can be reduced, construction quality is improved, and construction period is shortened.

Owner:GUANGZHOU SHENGZHOU FOUND ENG

Gravity drainage system for underground roadway high-pressure water inrush

The invention discloses a gravity drainage system for underground roadway high-pressure water inrush. A retention wall is built in a roadway between a waterproof gate and an inrush point, and the roadway and the retention wall form a water storage space. The retention wall is provided with at least one drain pipe connected with the water storage space and space outside the retention wall. The drain pipes lead to a mining horizontal central water sump, an upper horizontal central water sump or the ground. The gravity drainage system for underground roadway high-pressure water inrush has the advantages that the cost is low, the structure is simple, no electricity is needed, drainage equipment is used less frequently or no drain pump is used, continuous drainage is facilitated and insusceptible to electricity, water resources are protected, sewage treatment cost is lowered, water release can be controlled through a valve, sampling is available anytime, the analysis on changing of the recharge water is assisted, and considerable water is provided for mine production.

Owner:CHINA UNIV OF MINING & TECH

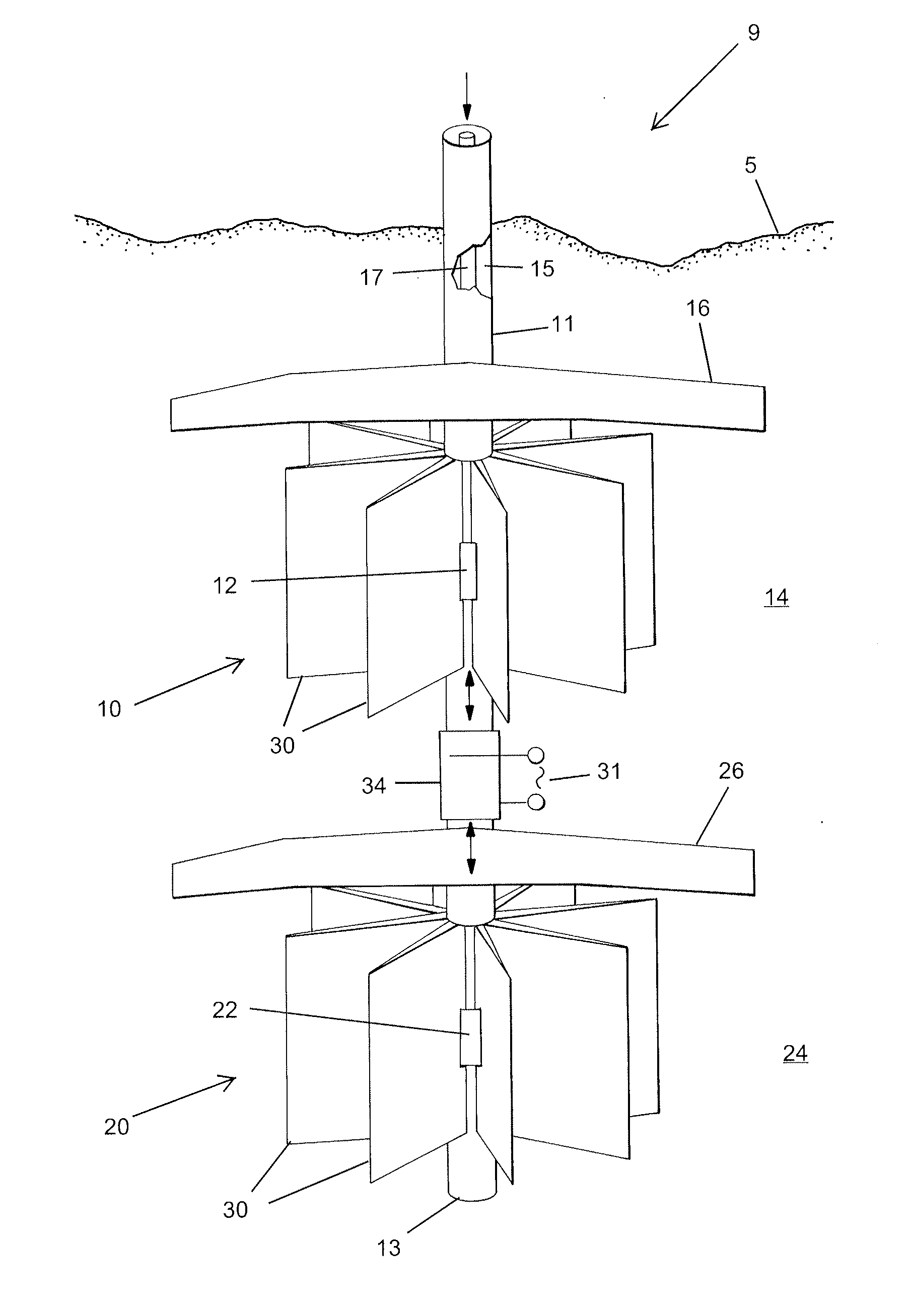

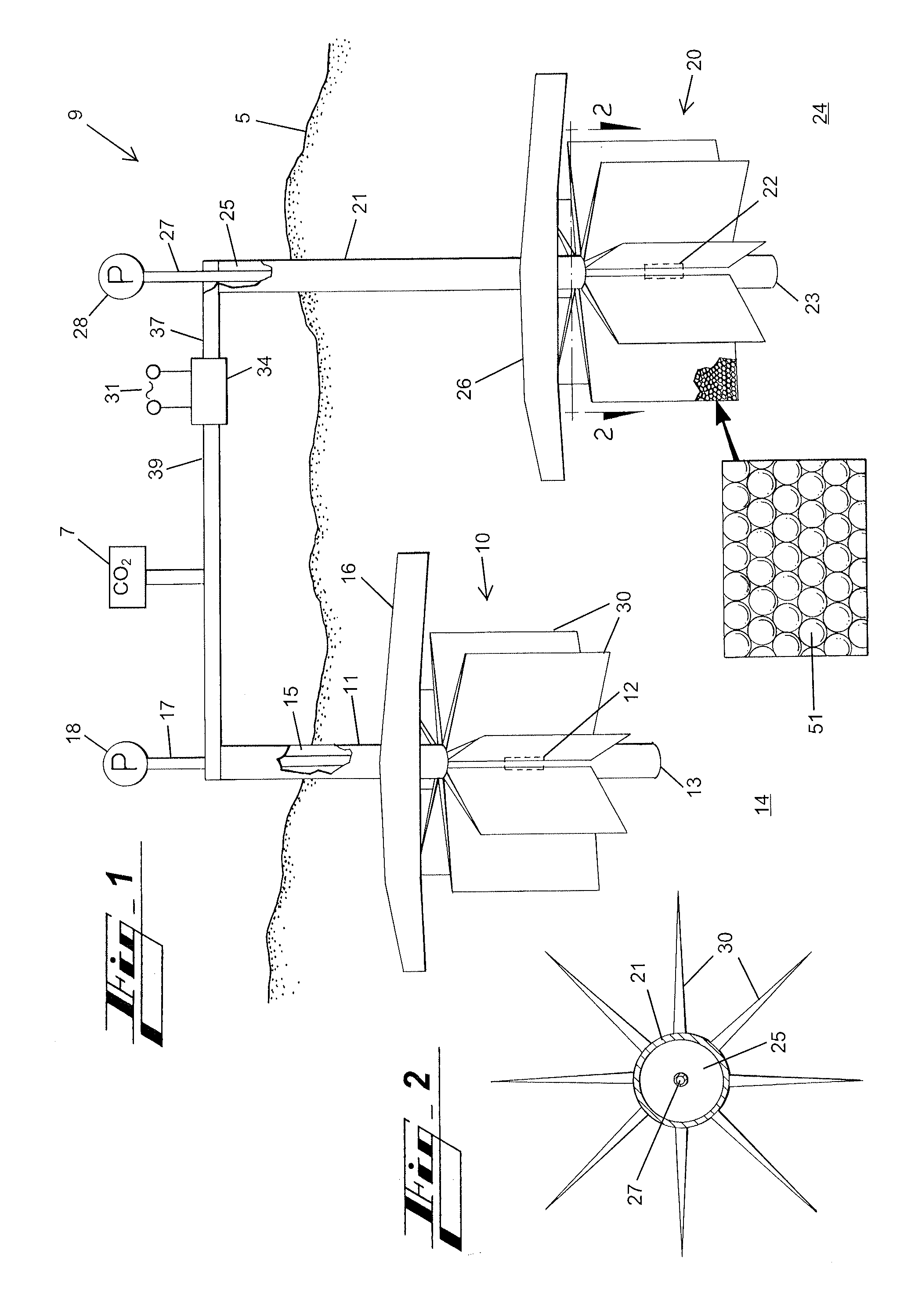

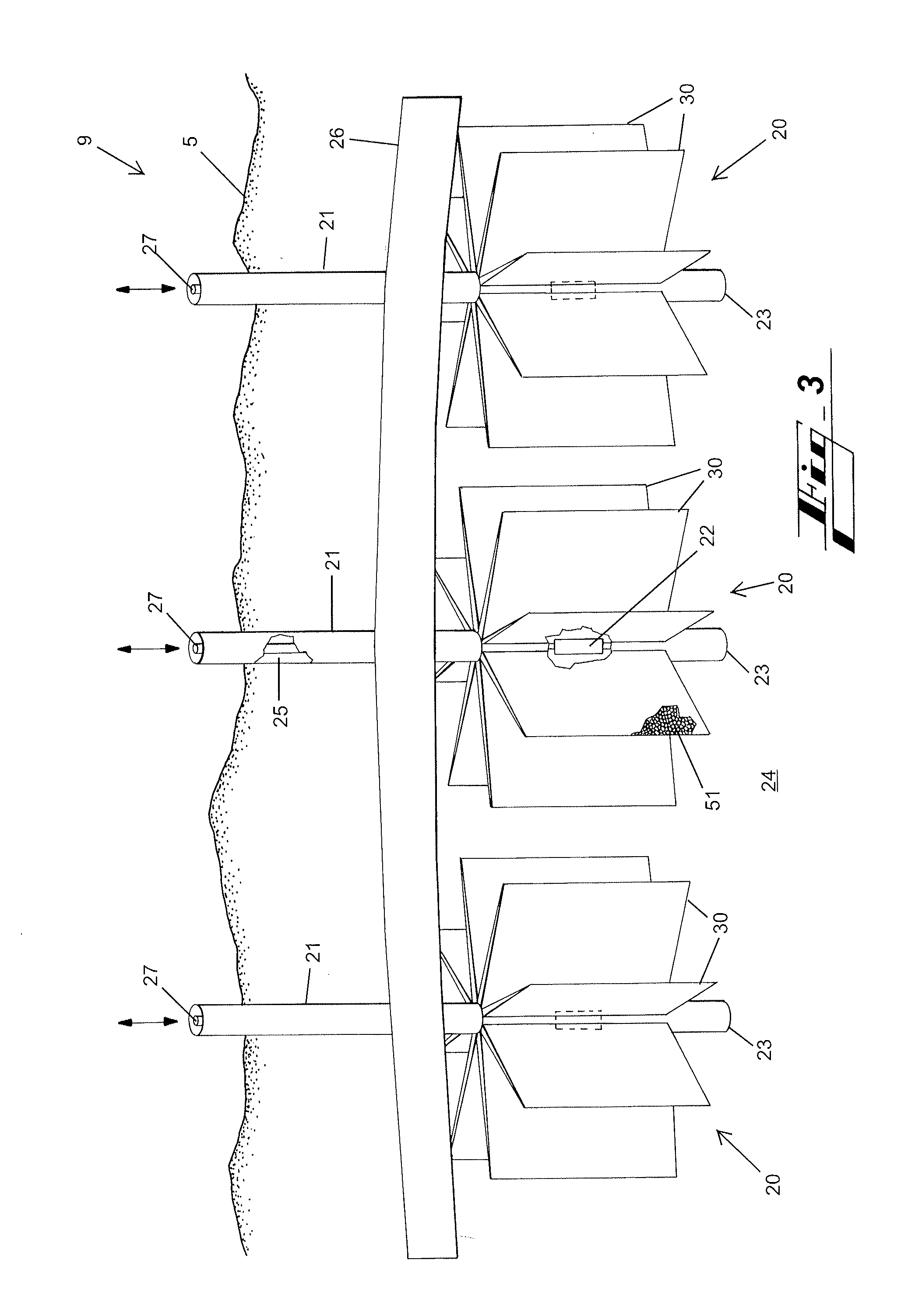

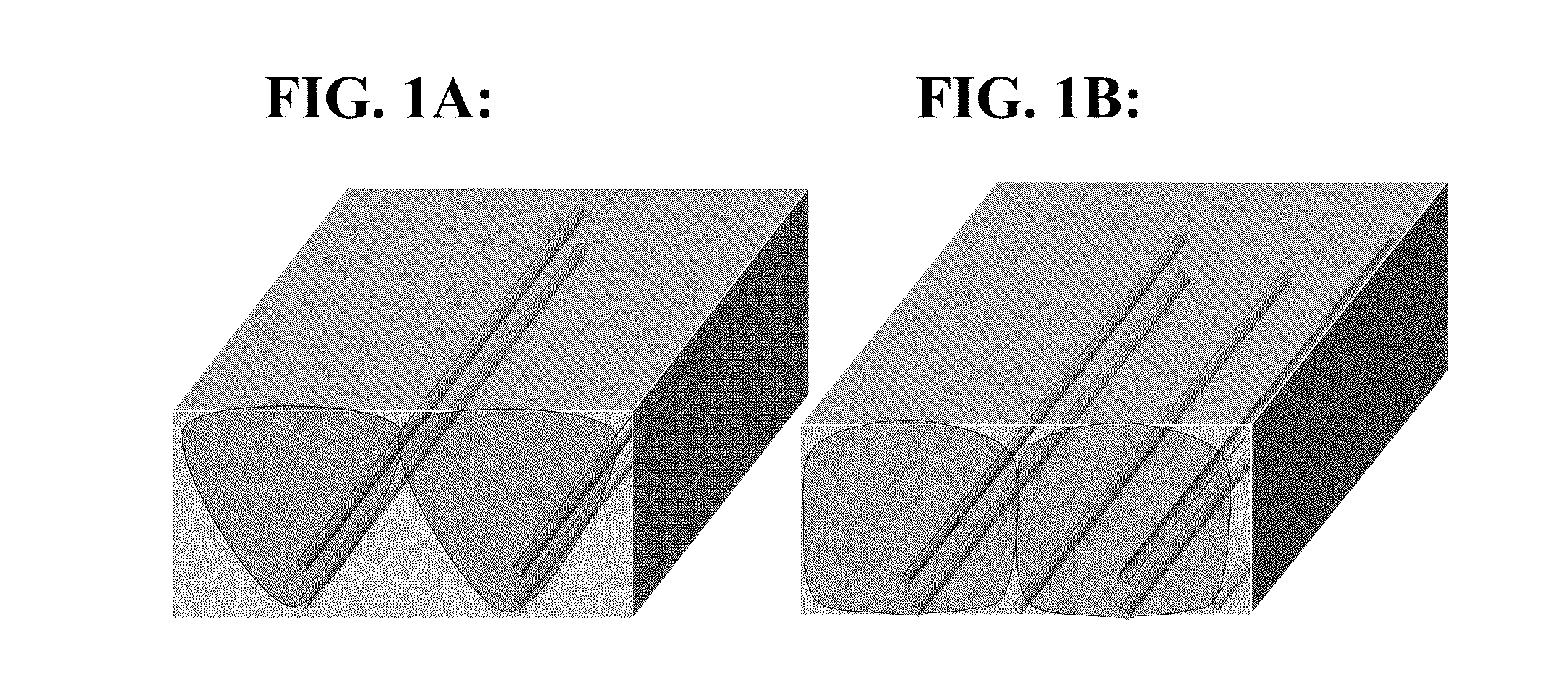

Carbon dioxide energy storage and enhanced oil recovery

InactiveUS20150204171A1Efficient and economical and less impactPromote recoveryOther gas emission reduction technologiesInsulationHigh energyElectric power

The present invention is a method and apparatus for the subsurface storage of carbon dioxide in reservoir formations, to provide energy storage for electrical load balancing, and to enable the enhanced recovery of hydrocarbon fluids from the subsurface formations by gravity drainage. Multiple propped vertical inclusions are propagated into hydrocarbon fluid bearing reservoir formations at various vertical depths from well casings. Carbon dioxide is injected and stored in the formations. At off-peak power demand periods, carbon dioxide is pumped by a pump / turbine from the low energy formation into a deeper high energy formation, and at peak power demand periods the carbon dioxide is released from the high energy formation and flows to the low energy formation, driving the pump / turbine to generate electricity. Hydrocarbon fluids are produced from the formations depending on the formation conditions. Additional carbon dioxide is injected into the system as hydrocarbon fluids are extracted.

Owner:GEOSIERRA

Hydrocarbon recovery method

InactiveUS20110017455A1Improve efficiencyReduce needInsulationFluid removalRecovery methodHorizontal wells

A process for increasing the efficiency of hydrocarbon recovery from an underground formation containing viscous hydrocarbons through the use of both gravity drainage and mobile water drive. The process comprises a pair of vertically-spaced horizontal wells and a laterally offset horizontal well. A heated fluid is injected into the formation via a first well pair, and an adjacent horizontal well creates a pressure sink to draw the heated fluid laterally to assist growth of the formation drainage area for hydrocarbon recovery improvement. Injected fluids recovered from both producers are collected for recycling.

Owner:CONOCOPHILLIPS CO

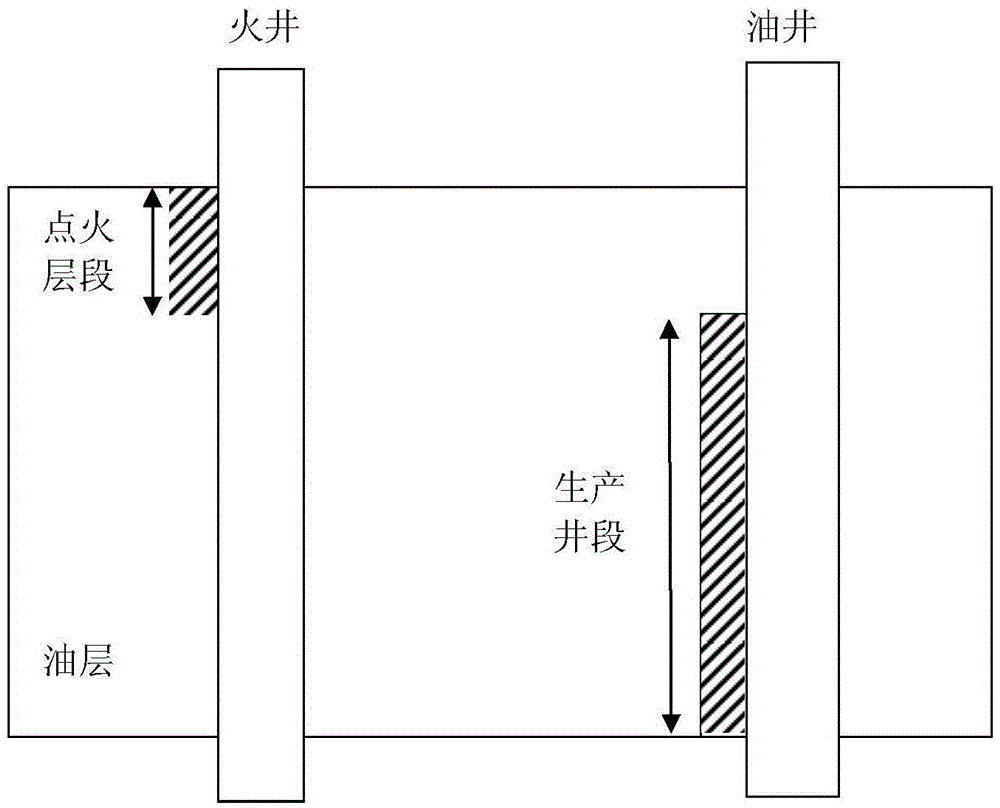

Method for exploiting thick-layer heavy oil reservoir by in situ combustion assisted gravity drainage

InactiveCN102392626AIncrease productionBurial depth limit is smallInsulationFluid removalCombustionCement slurry

The invention relates to the technical field of heavy oil thermal recovery, especially a method for exploiting thick-layer heavy oil reservoir by in situ combustion assisted gravity drainage. The method comprises the following steps: firstly, under condition that the existing well network is not exchanged, sealing the penetrated perforation in the middle-upper part of the production well by cement slurry or packer; setting aside a 10-meter perforation segment for releasing oil in the lower part of the oil layer; keeping 10 meters of the upper parts of the air injecting well and the combustion perforation, sealing the lower ground layer by cement or packer, so as to form the in situ combustion assisted gravity drainage well network; heating the air in the air injecting well to higher than the threshold temperature of the high-temperature oxidation reaction of the crude oil by formation preheating or electric heater; according to the designing requirement, continuously injecting the air into the formation, so that the crude oil can flow outside from the lower perforation oil discharging channel of the production well; the crude oil is lifted to ground by using a lifting device. The invention realizes small limit on reservoir depth, the gas channeling is reduced and the crude oil output is increased.

Owner:联合石油天然气(盘锦)有限公司

Solvent-assisted horizontal well interwell communication method

ActiveCN104832141AImprove solubilityImprove diffusion abilityFluid removalOrganic solventHorizontal wells

The invention provides a solvent-assisted horizontal well interwell communication method, which comprises steps: S1, a first organic solvent is injected to a steam injection well and a production well respectively, and shut-in immersion is carried out on the steam injection well ; S2, the first organic solvent in the production well is heated to enable the first organic solvent to be dissolved and diffused towards crude oil, a solvent cavity is formed, and the crude oil enters the solvent cavity and is diffused to the production well; S3, depressurizing stoping is carried out on the production well; S4, the first organic solvent is complementarily injected to the production well again; and S5, steps from S2 to S4 are repeated, and the solvent cavity is expanded continuously until the steam injection well and the production well are communicated. Advantages of gravity drainage of the horizontal wells are fully made use of, the horizontal section uniformly producing degree is improved, demands on the drilling technology are low, water consumption is little, energy consumption is little, and emission is little.

Owner:PETROCHINA CO LTD

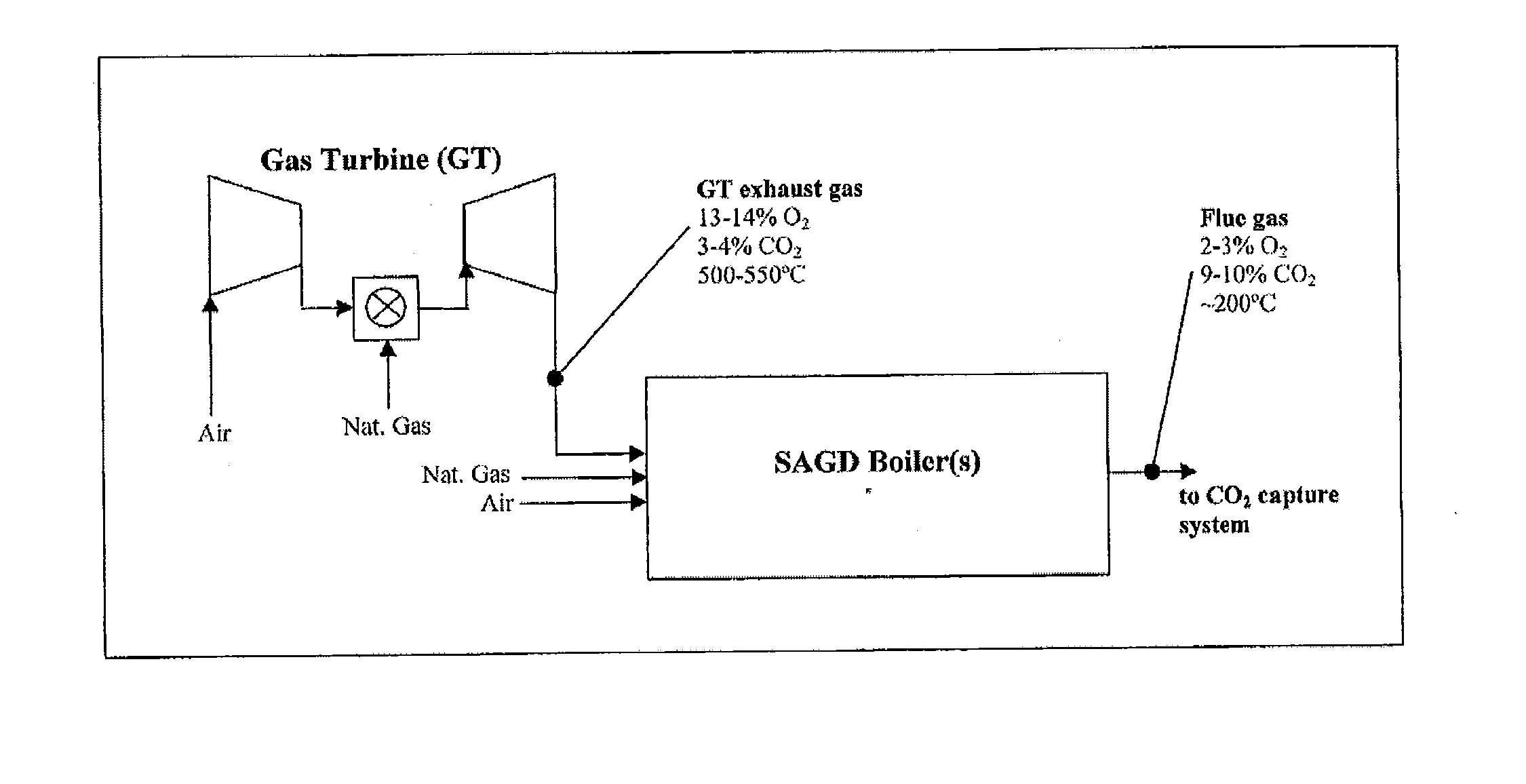

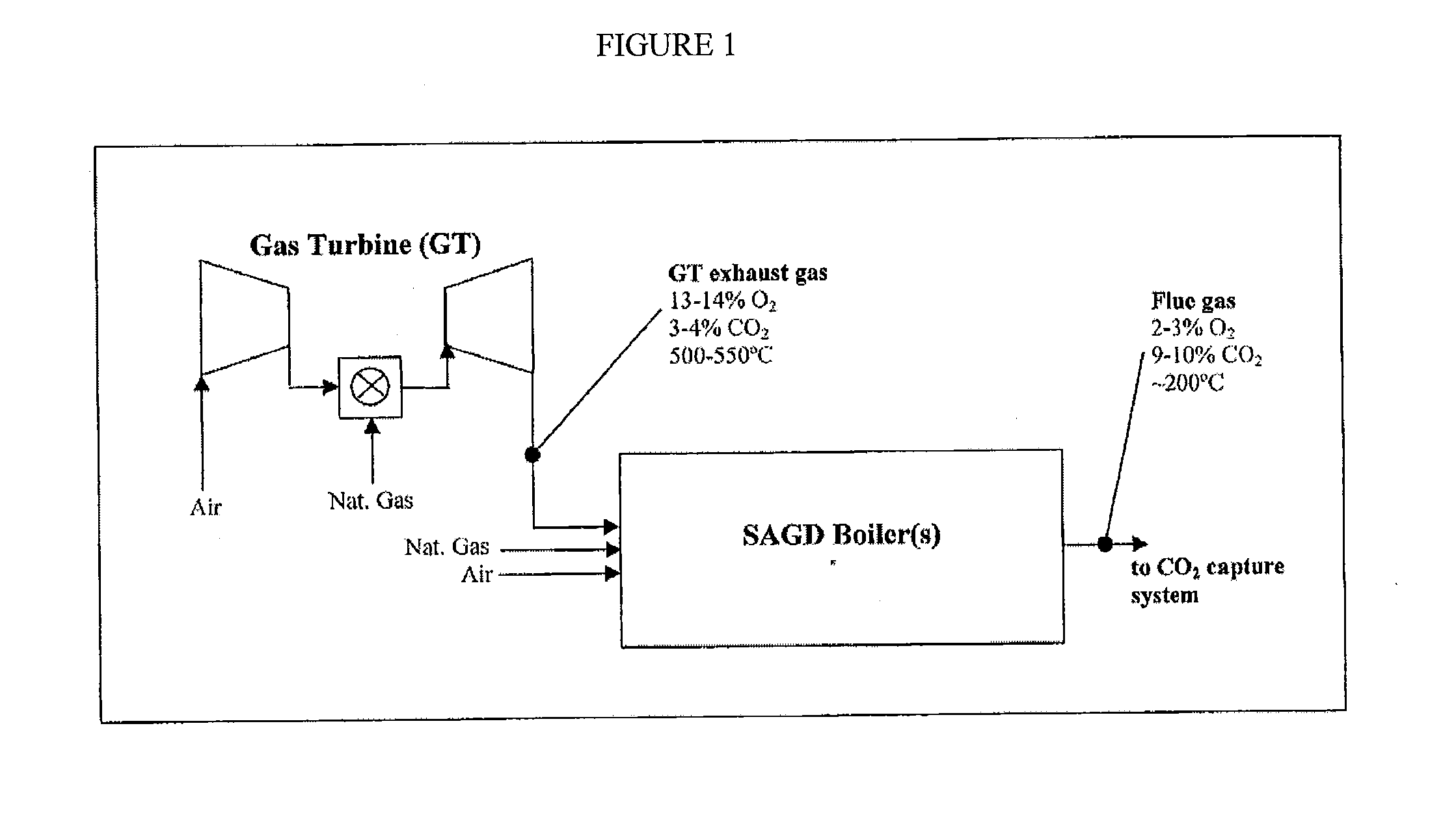

Integrated gas turbine, sagd boiler and carbon capture

InactiveUS20120222426A1Reduce the temperatureAvoid highBiofuelsGas turbine plantsFlue gasExhaust fumes

An integrated power generation system for reducing carbon dioxide emissions is provided. The integrated system comprises a gas turbine having an air inlet, a fuel inlet and an exhaust gas outlet; a steam-assisted gravity drainage (SAGD) boiler having an inlet connected to the exhaust gas outlet of the gas turbine, a fuel inlet, an optional air inlet, and a flue gas outlet; and a carbon dioxide capture system connected to the flue gas outlet of the SAGD boiler. A method for capturing the carbon dioxide exhausted from a gas turbine and a SAGD boiler is also provided.

Owner:CONOCOPHILLIPS CO

Fats, oil and grease interceptor

InactiveUS7427356B2Reduce maintenanceLess stressSedimentation tanksSewerage structuresOil and greaseGreywater

The present invention comprises a gravity draining automatic FOG interceptor with solids removal capability used as a first stage in the treatment of gray water. A preferred embodiment comprises a multi compartment container, the compartments separated by baffles, having a serviceable solids strainer in a first compartment, a second compartment having a cogged belt for FOG removal and collection, a third compartment for collection of clarified effluent, and a fourth compartment for tertiary treatment of the gray water effluent, for example, the introduction of biotechnology. The unique baffle configuration prevents biotechnology backflow migration from the fourth compartment with resulting bacterial contamination of the FOG.

Owner:CHAPIN PETER

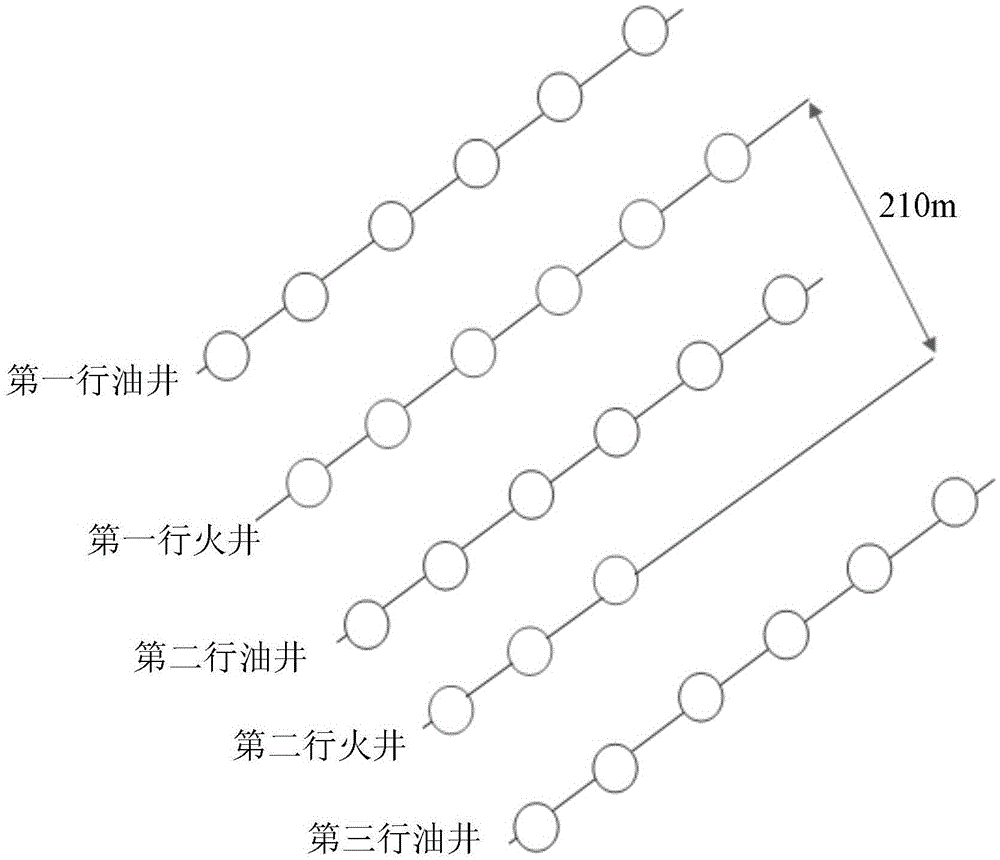

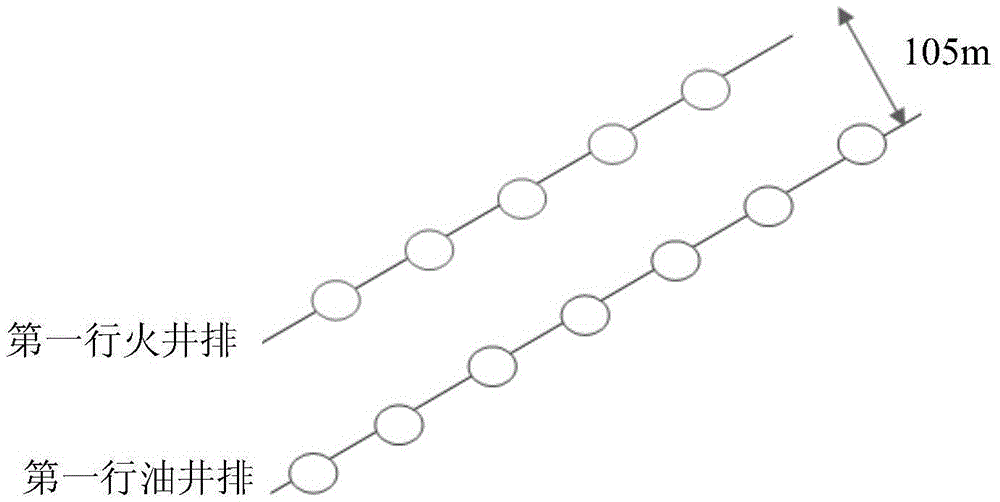

Well pattern and method for improving fire flooding effect of thick-layer heavy oil reservoir

ActiveCN105545274ATo achieve the purpose of gravity drainageEfficient use ofFluid removalGeological structureOil well

The invention provides a well pattern and a method for improving fire flooding effect of a thick-layer heavy oil reservoir. The well pattern is disposed on an oil reservoir whose geological structure is a uniclinal structure. The well pattern is characterized in that the well pattern comprises a fire well row and at least a row of oil well. The fire well row is on the high part of the uniclinal structure. The fire wells in the fire well row are disposed along the high part of the uniclinal structure in sequence. The oil well rows are in the uniclinal structure, and are below the fire well row, and are arranged along a downdip direction of the uniclinal structure in sequence. The two adjacent well rows are arranged in parallel. The invention also provides a method for improving fire flooding effect of a thick-layer heavy oil reservoir. The method comprises: injecting gas to the fire well on the high part of the oil reservoir structure, igniting an ignition layer section, start fire flooding oil extraction; and extracting oil from the oil well on the downdip direction. The technical scheme can fully use altitude differences of the geological structure of the thick-layer heavy oil reservoir to achieve an objective of gravity drainage.

Owner:PETROCHINA CO LTD

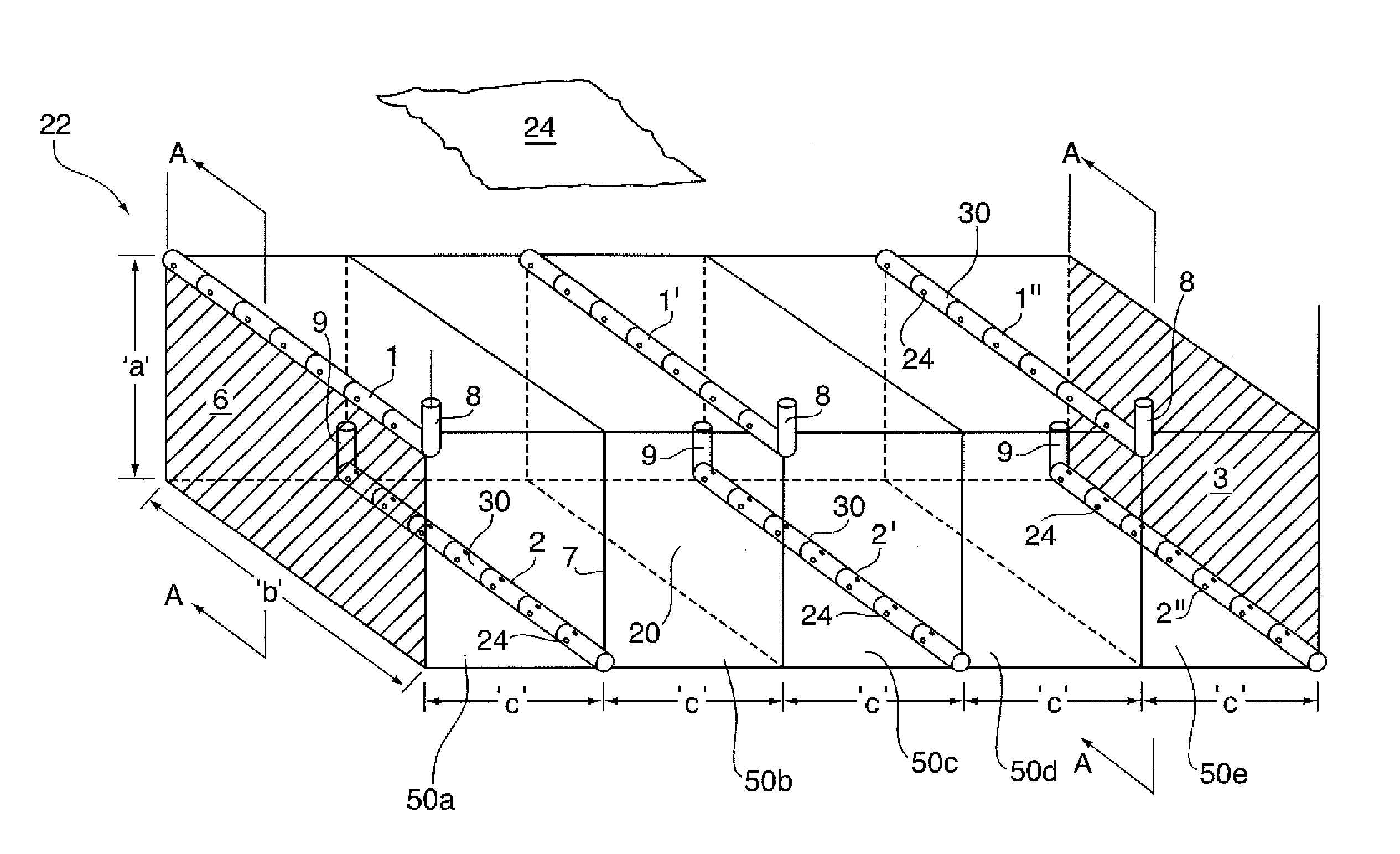

Staggered horizontal well oil recovery process

InactiveUS20130146284A1Lower ratioReduce compression costsFluid removalHorizontal wellsCombustion process

An in situ combustion process entailing the simultaneous production of oil and combustion gases that combines fluid drive, gravity phase segregation and gravity drainage to produce hydrocarbons from a subterranean oil-bearing formation, comprising initially injecting a gas through a pair of horizontal wells placed high in the formation and producing combustion gas and oil through parallel and laterally offset horizontal wells that are placed low in the formation intermediate the pair of horizontal wells placed high in the formation.

Owner:ARCHON TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com