Solvent-assisted horizontal well interwell communication method

A horizontal and solvent-based technology, applied in the field of solvent-assisted horizontal well connection, can solve the problems of high energy consumption and high cost, and achieve the effects of low energy consumption, low cost and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

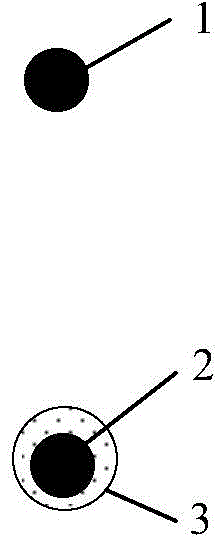

[0052] The present invention proposes a solvent-assisted horizontal well communication method for establishing the communication between dual horizontal wells (including steam injection well 1 and production well 2). of organic solvent, the steam injection well 1 and the production well 2 are communicated by means of solvent huff and puff (similar to steam huff and puff).

[0053] The solvent-assisted horizontal well communication method of the present invention includes the following steps S1 to S5:

[0054] Step S1: inject the first organic solvent 4 into the steam injection well 1 and the production well 2 respectively, such as figure 1 , figure 2 As shown, for example, the injection is stopped until the wellbore of the steam injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com