Stereoscopic development three-dimensional experimental device of heavy oil reservoir

A technology for heavy oil reservoirs and experimental devices, applied in the fields of fluid production, measurement, wellbore/well components, etc., can solve the problems of little mechanism research, difficult to design a simple and accurate reaction reservoir temperature measurement system, etc., to save experiments Consume, save experimental time, and facilitate the effect of filler filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

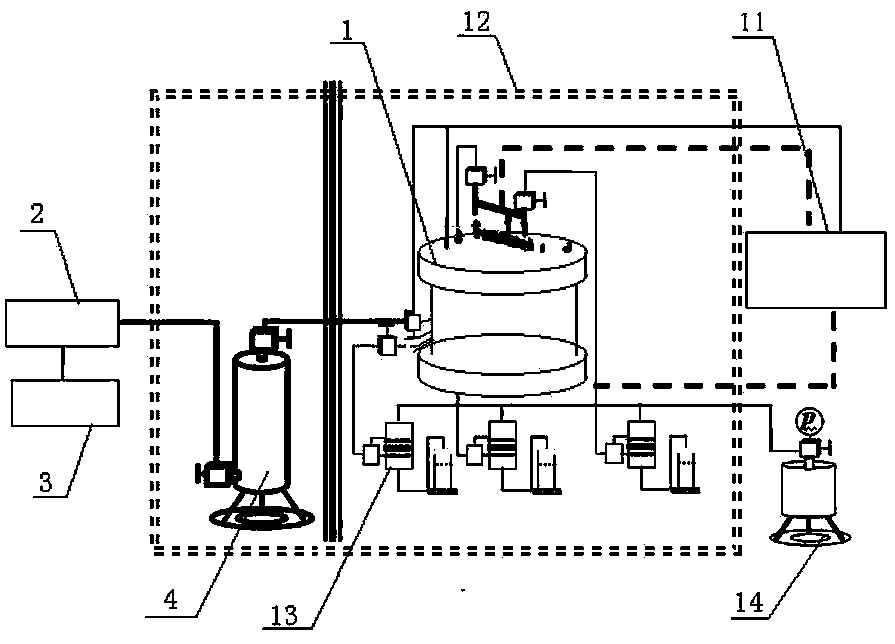

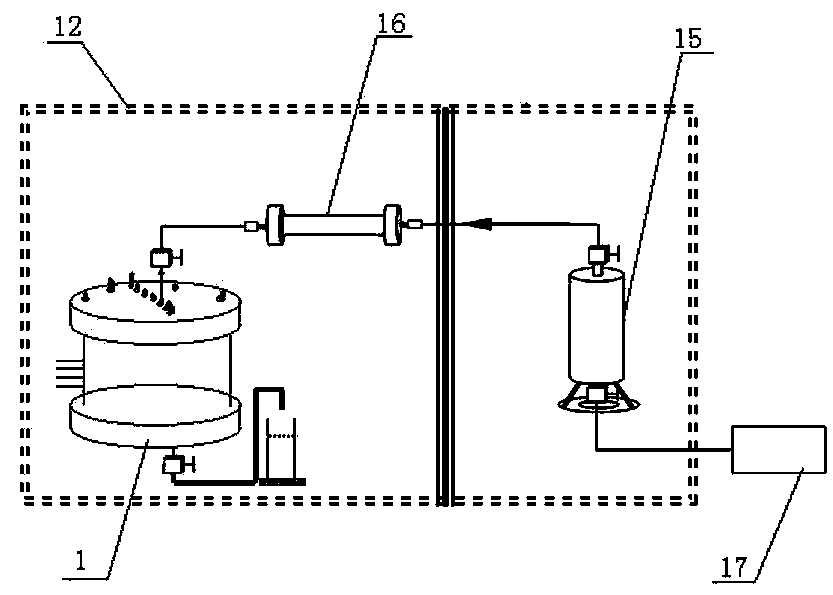

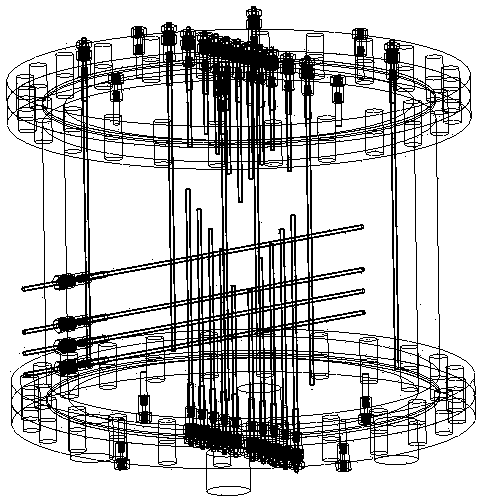

[0032] Such as figure 1 As shown, this three-dimensional experimental device for the three-dimensional development of heavy oil reservoirs includes a three-dimensional core model 1, a steam generator 2, a temperature and pressure monitoring system, a constant temperature box 12, an advection pump, and an intermediate container 16; the three-dimensional core model 1 is welded by stainless steel The formed cylinder has an upper cover plate 5 and a lower cover plate 6, and the bottom surface of the cylinder has four legs, and the four legs are used to support the cylinder; eight vertical well interfaces 7, 9 are arranged on the upper cover plate 5 1 temperature monitoring interface and 4 saturated oil holes 10; 10 temperature monitoring interfaces and 4 saturated oil holes are arranged on the lower cover plate 6; Figure 4 As shown, four horizontal well interfaces 8 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com