Three-dimensional experimental device for three-dimensional development of heavy oil reservoirs

A technology of heavy oil reservoirs and experimental devices, which is applied in the direction of production fluid, measurement, wellbore/well components, etc., can solve the problems of difficult design of simple and accurate reaction reservoir temperature measurement system, little mechanism research, etc., to save experiments Time saving, saving experiment cost, and convenient filler filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

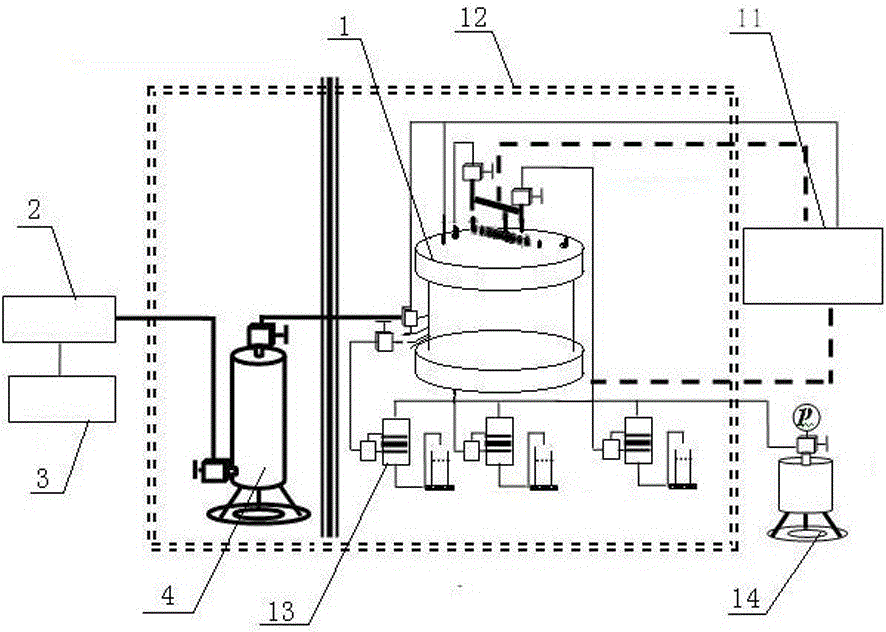

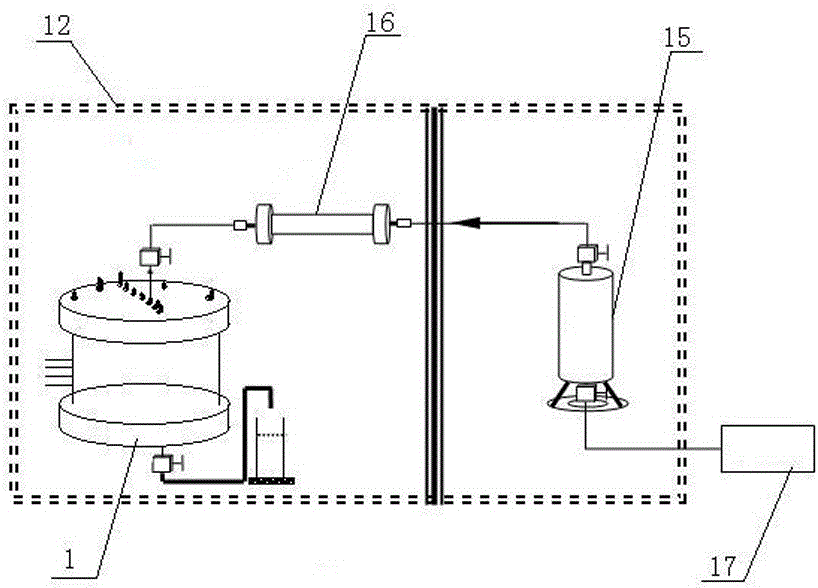

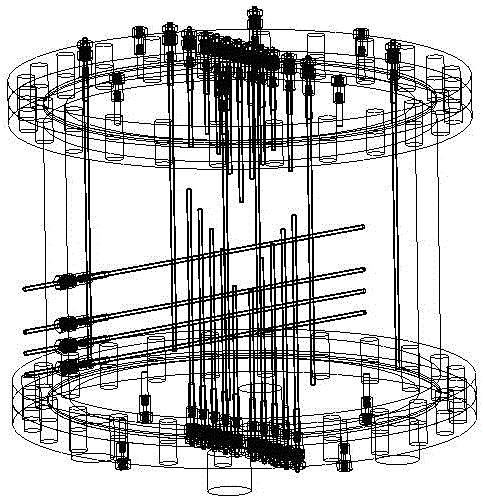

[0032] Such as figure 1 As shown, this three-dimensional experimental device for the three-dimensional development of heavy oil reservoirs includes a three-dimensional core model 1, a steam generator 2, a temperature and pressure monitoring system, a constant temperature box 12, an advection pump, and an intermediate container 16; the three-dimensional core model 1 is welded by stainless steel The formed cylinder has an upper cover plate 5 and a lower cover plate 6, and the bottom surface of the cylinder has four legs, and the four legs are used to support the cylinder; eight vertical well interfaces 7, 9 are arranged on the upper cover plate 5 1 temperature monitoring interface and 4 saturated oil holes 10; 10 temperature monitoring interfaces and 4 saturated oil holes are arranged on the lower cover plate 6; Figure 4 As shown, four horizontal well interfaces 8 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com