Gravity drainage system for underground roadway high-pressure water inrush

A self-flowing drainage and underground roadway technology, which is applied to drainage, safety devices, mining equipment, etc., can solve problems such as consuming manpower and material resources, wasting electric energy, and complex construction techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

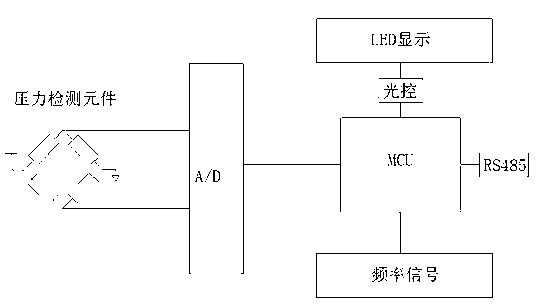

Method used

Image

Examples

Embodiment Construction

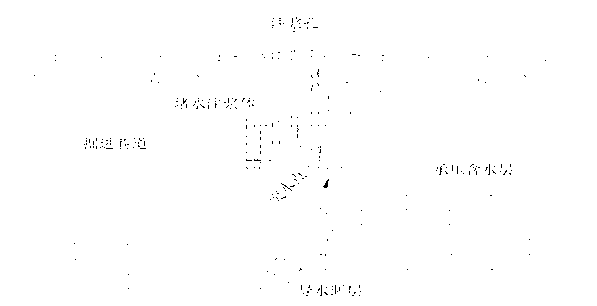

[0023] The present invention will be further described below in conjunction with accompanying drawing.

[0024] Such as figure 1 As shown, a water retaining wall 1 is built in the roadway 3 between the anti-water barrier gate 8 and the water gushing point 2. The roadway 3 is preferably reinforced by grouting and sprayed anchors. The water retaining wall 1 is made of steel bars, cement 1. Sand and stone masonry, with a thickness of not less than 3m, so that it can withstand not less than 3 times the hydrostatic pressure of the water storage space 4, and the two sides are embedded in the roadway 3 wall to a depth of at least 50cm, and the combination is tight. The masonry site should be selected in There is a certain safe distance from the water outlet point and the surrounding rock of the roadway 3 is stable. During construction, the original water pump drainage work needs to be continued to maintain the normal construction of the cutoff wall. After the completion, stop the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com