Hot water assisted gravity drainage method for mining high pour-point oil deposit

A technology of high pour point oil and assisted gravity, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problems of inability to significantly improve the seepage capacity of the oil layer, low recovery degree, hidden danger of explosion, etc., and achieve improved Reserve swept volume and displacement efficiency, enhanced production and recovery, enhanced flow capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

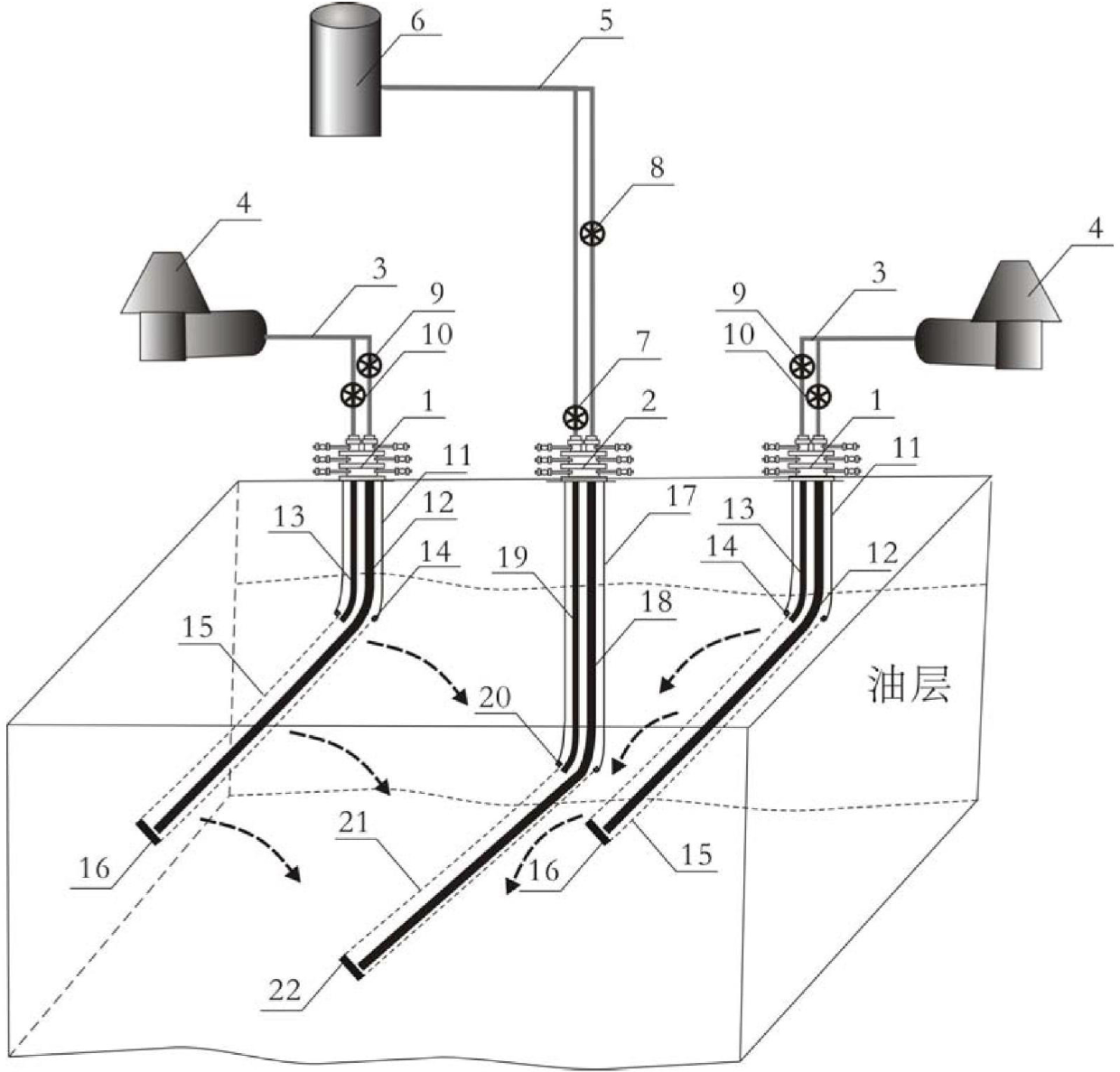

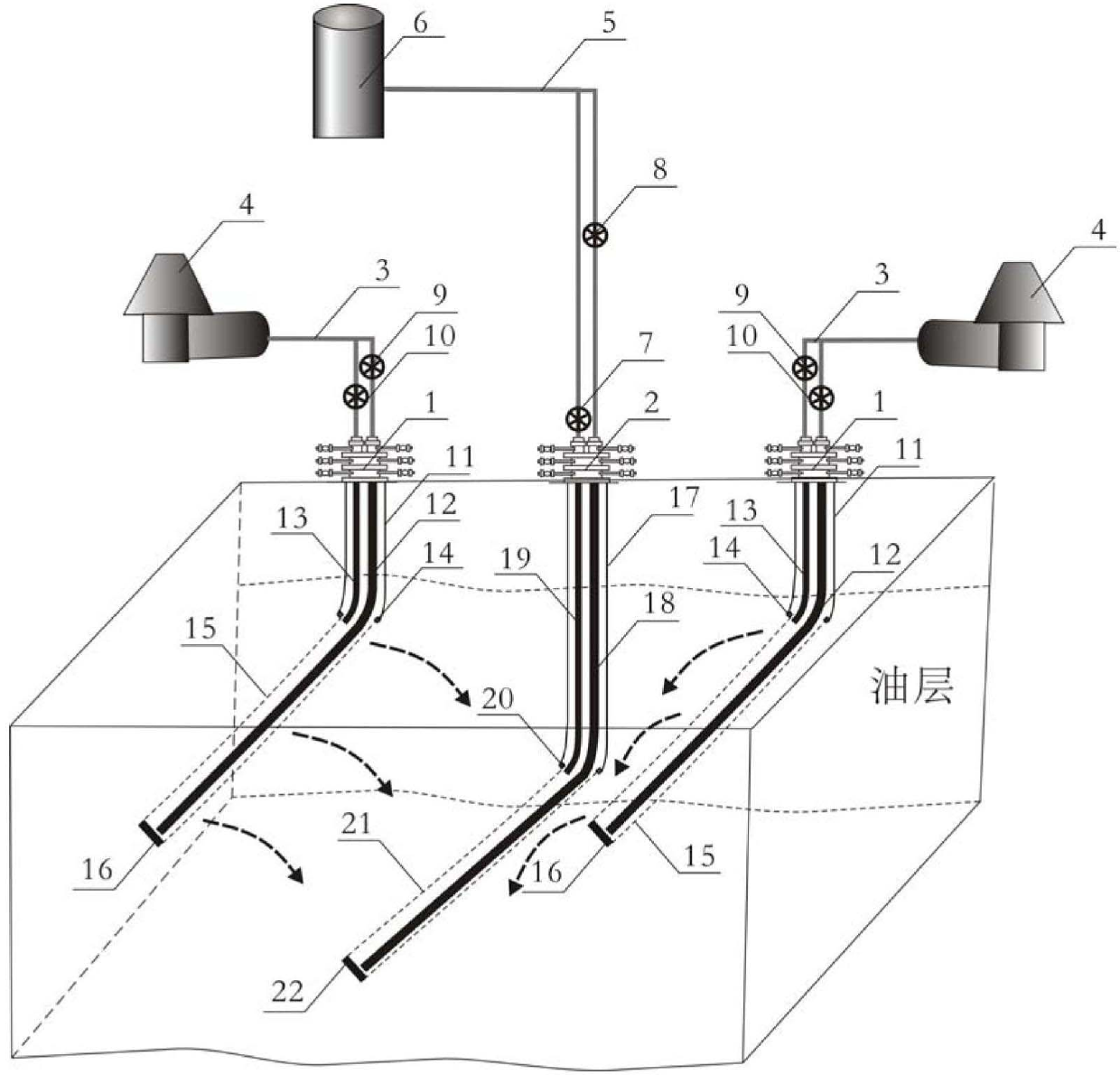

[0042] This embodiment provides a method for exploiting high pour point oil reservoirs by hot water assisted gravity drainage, the principle of which is as follows figure 1 shown. The method includes the following steps:

[0043] (1) Judging whether the reservoir is a high pour point oil reservoir suitable for hot water assisted gravity drainage

[0044] The reservoir is buried at a depth of 1600-1700 meters and has an oil layer with an average effective thickness of 27 meters, an average porosity of 26%, an average permeability of 679mD, an original reservoir temperature of 54.5°C, and a wax precipitation point of crude oil of 52°C, it is a thick block high pour point oil reservoir, which is suitable for the method of exploiting high pour point oil reservoir by hot water assisted gravity drainage provided by the present invention.

[0045] (2) Deploy injection-production well pattern

[0046] Select an area of 800m×200m inside the reservoir (an area selected in a horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com