Patents

Literature

82 results about "Water assisted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

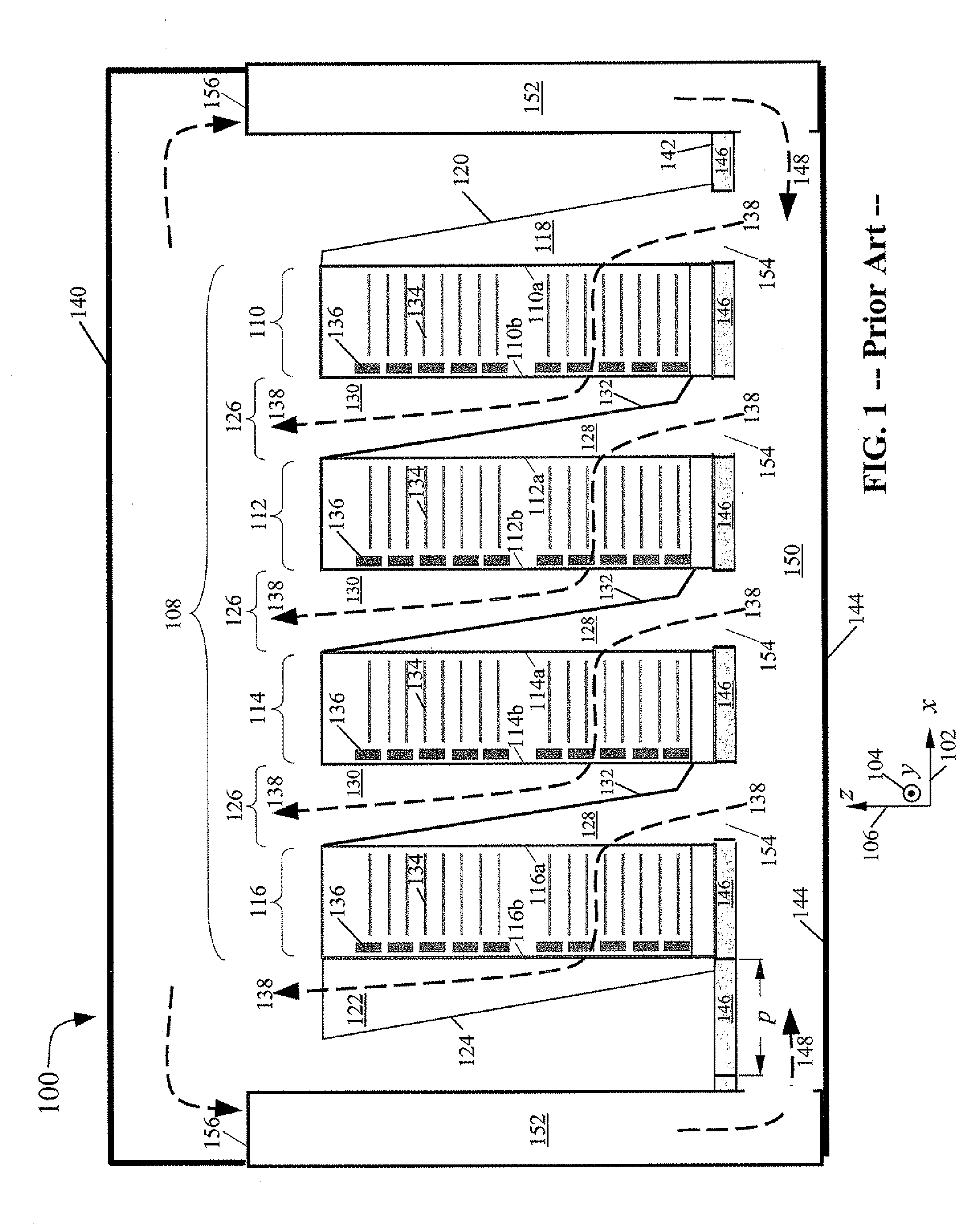

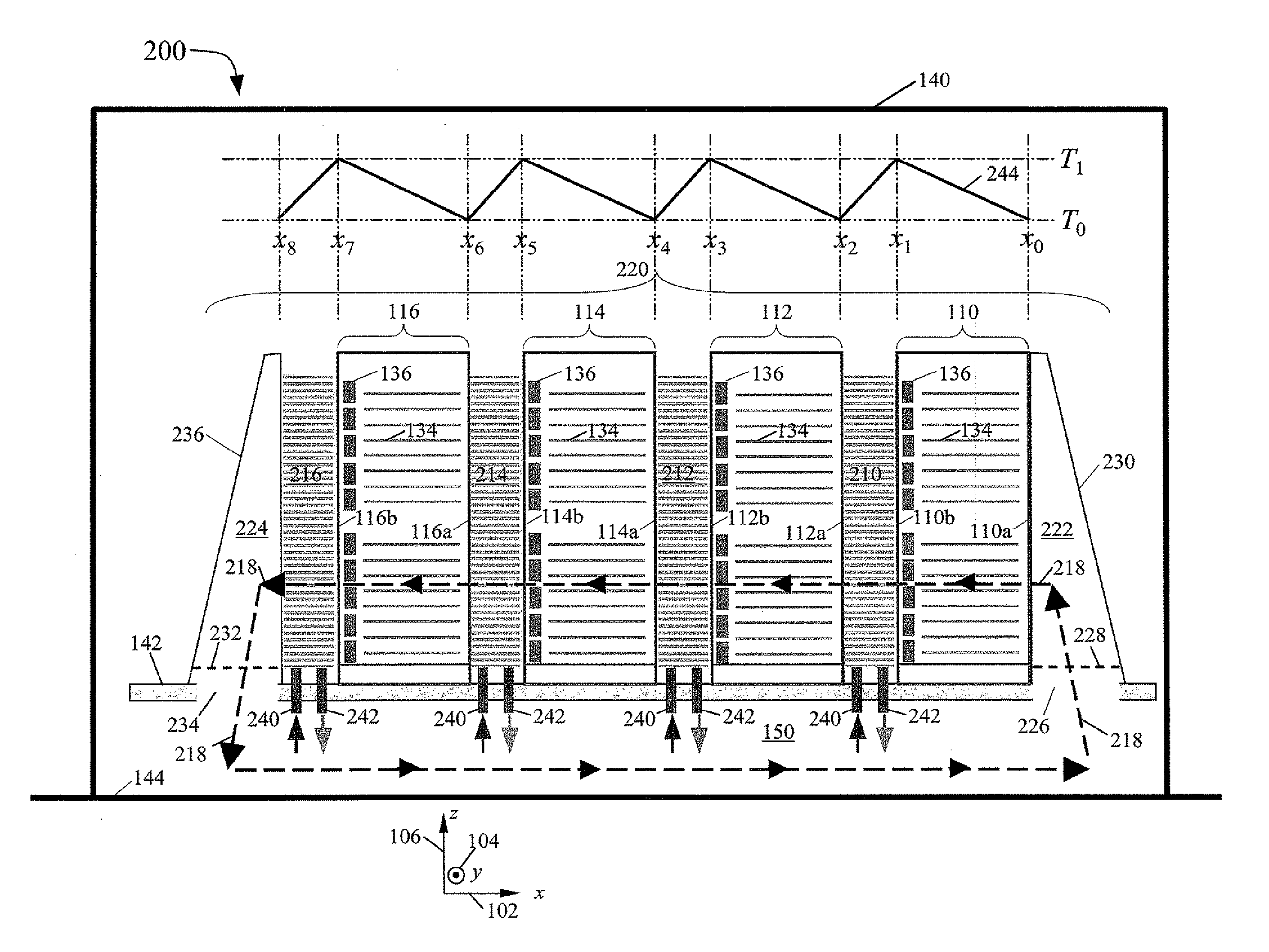

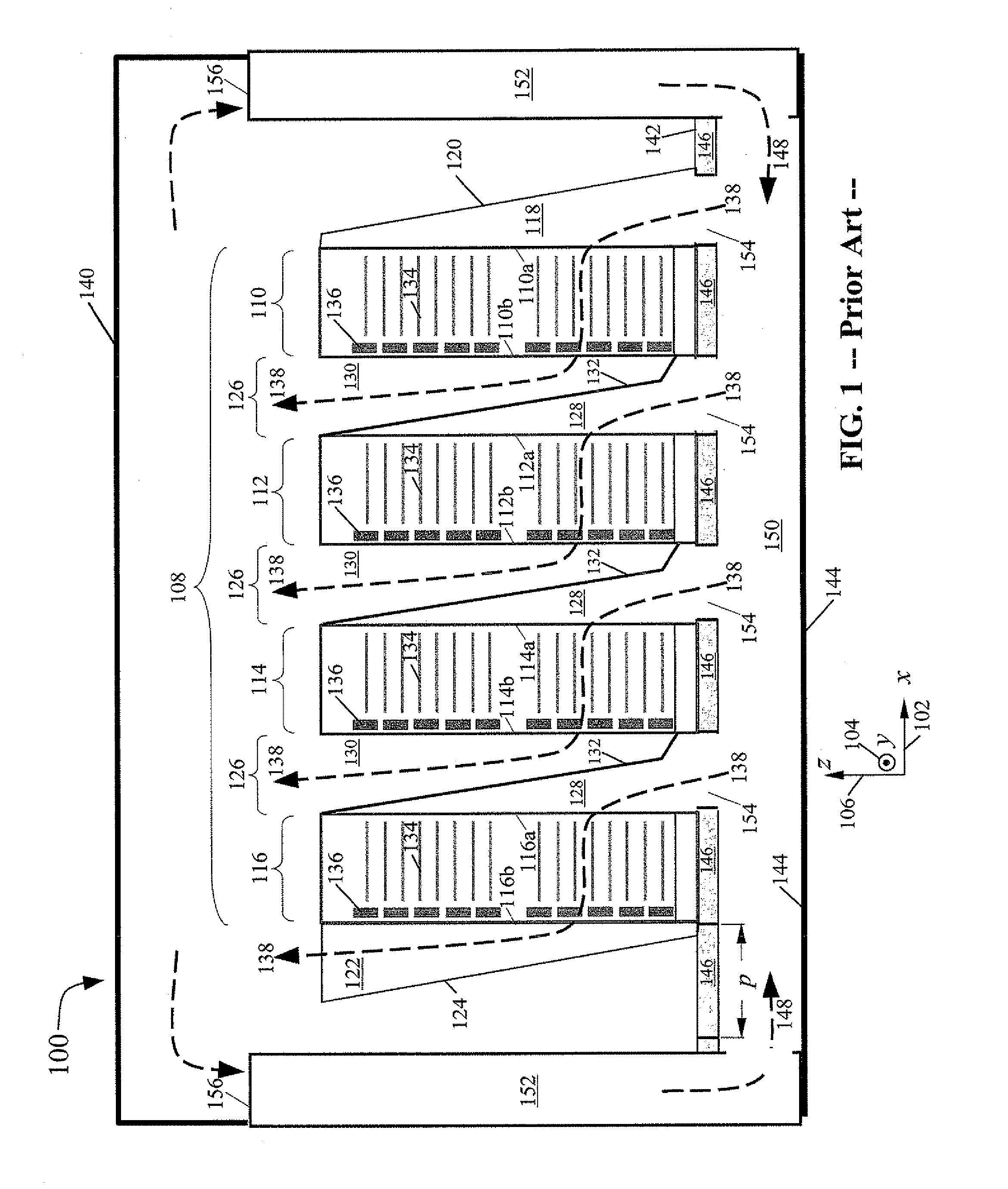

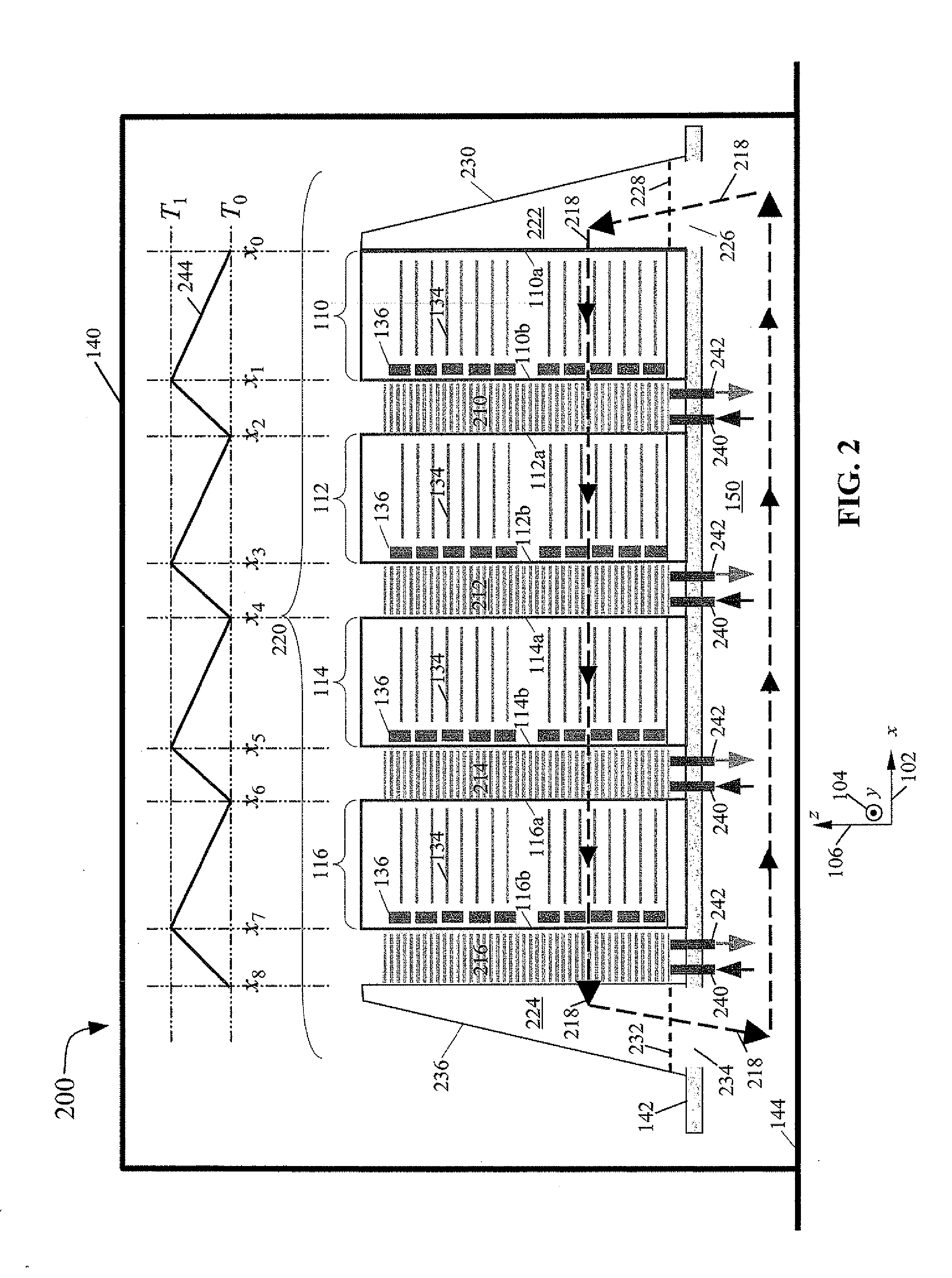

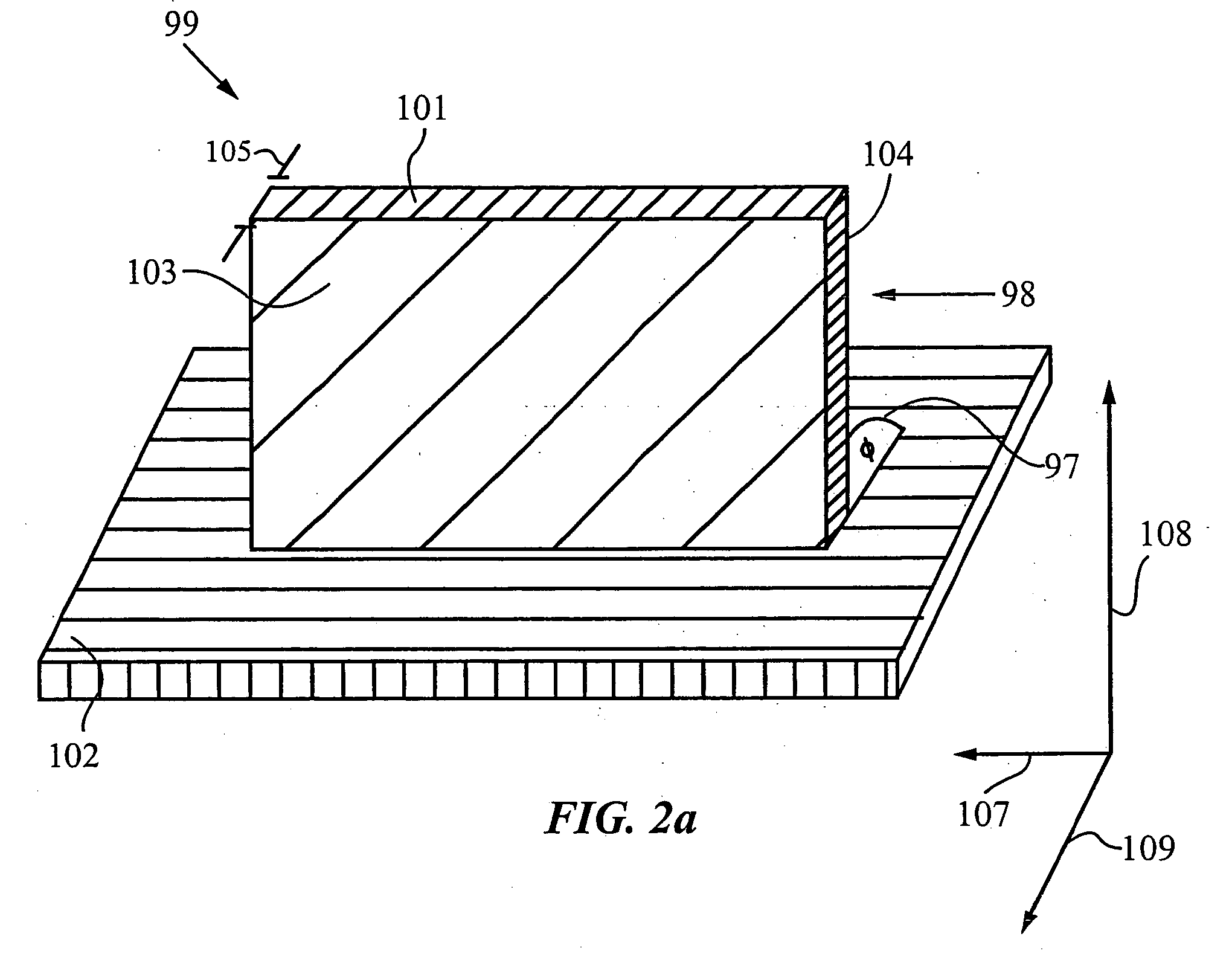

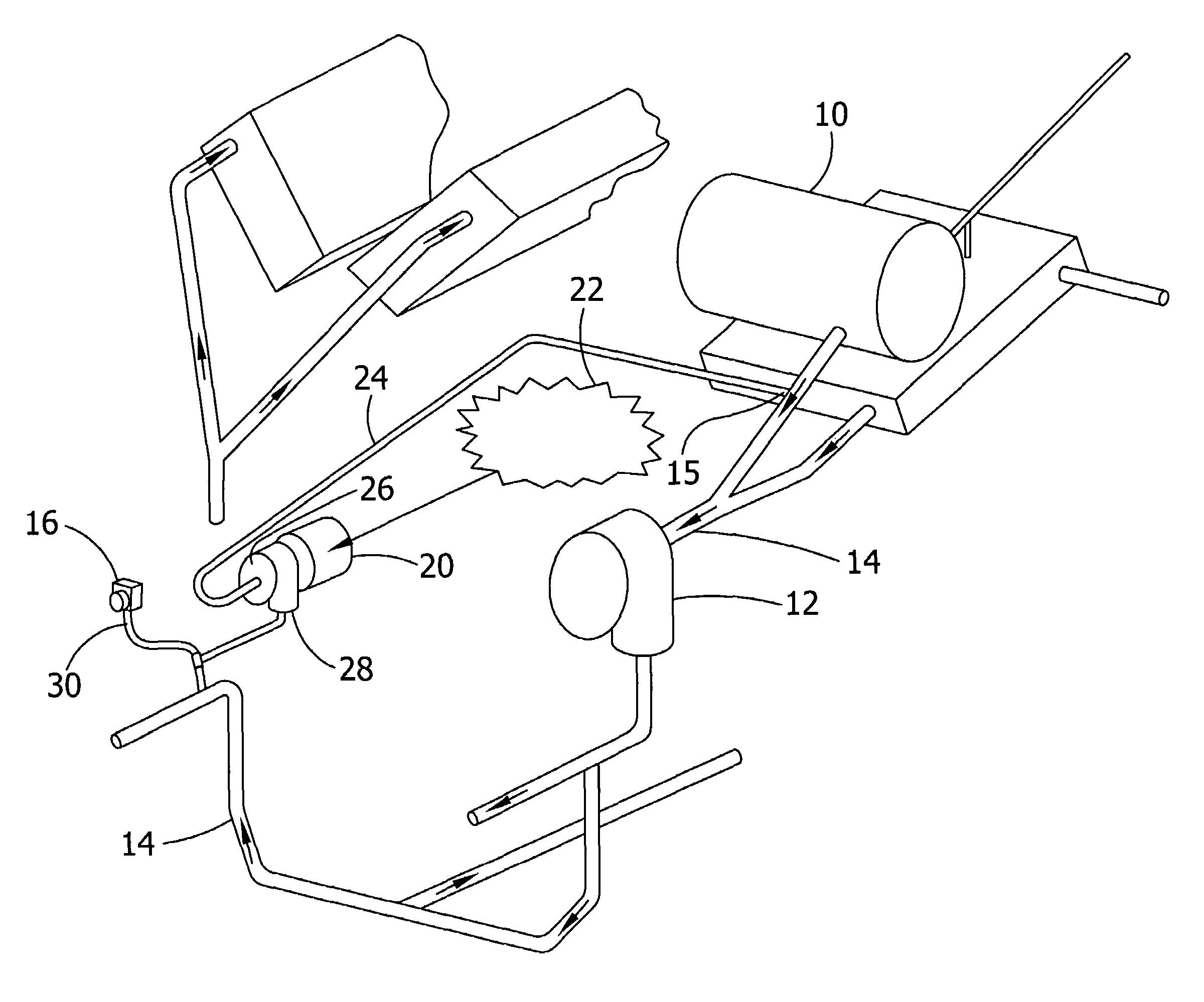

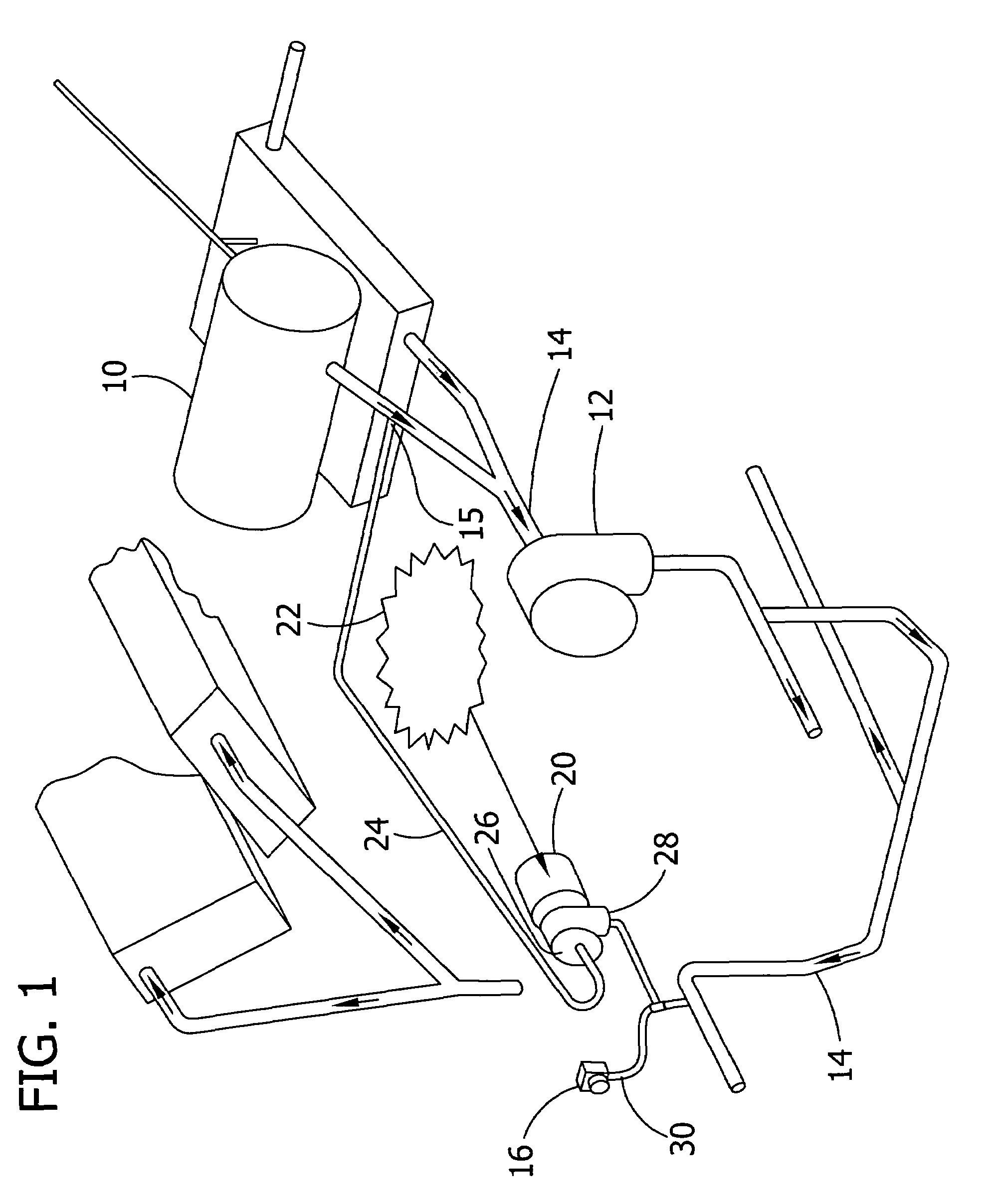

Water-assisted air cooling for a row of cabinets

InactiveUS20090122483A1Transfer of heatCooling/ventilation/heating modificationsWater assistedEngineering

A cooling apparatus and method including a plurality of heat-producing devices positioned in a plurality of cabinets arranged in a row that allows flow of a first fluid through the heat-producing devices and cabinets where the flow is directed from an upstream end of the row to a downstream end of the row. The cabinets have a space therebetween wherein a heat exchanger is positioned between and adjacent to the cabinets, thereby the cabinets and heat exchangers alternate in the row. Each heat exchanger allows flow of a second fluid therethrough for cooling the first fluid. A fluid-moving device is positioned adjacent the heat-producing devices for encouraging flow of the first fluid through the cabinets' heat-producing devices and through the heat exchangers, thereby encouraging heat transfer in each of the heat exchangers from the first fluid to the second fluid.

Owner:IBM CORP

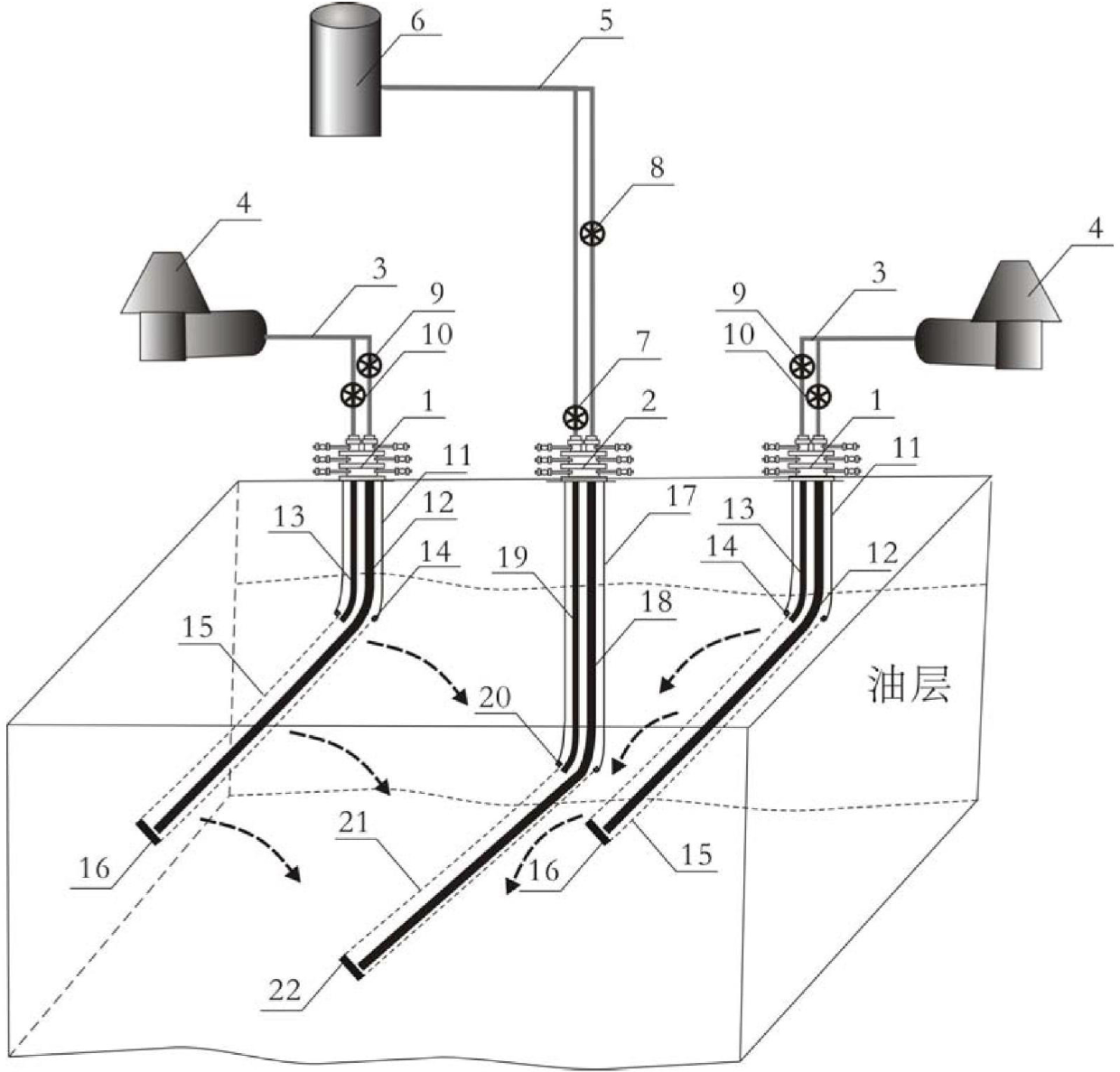

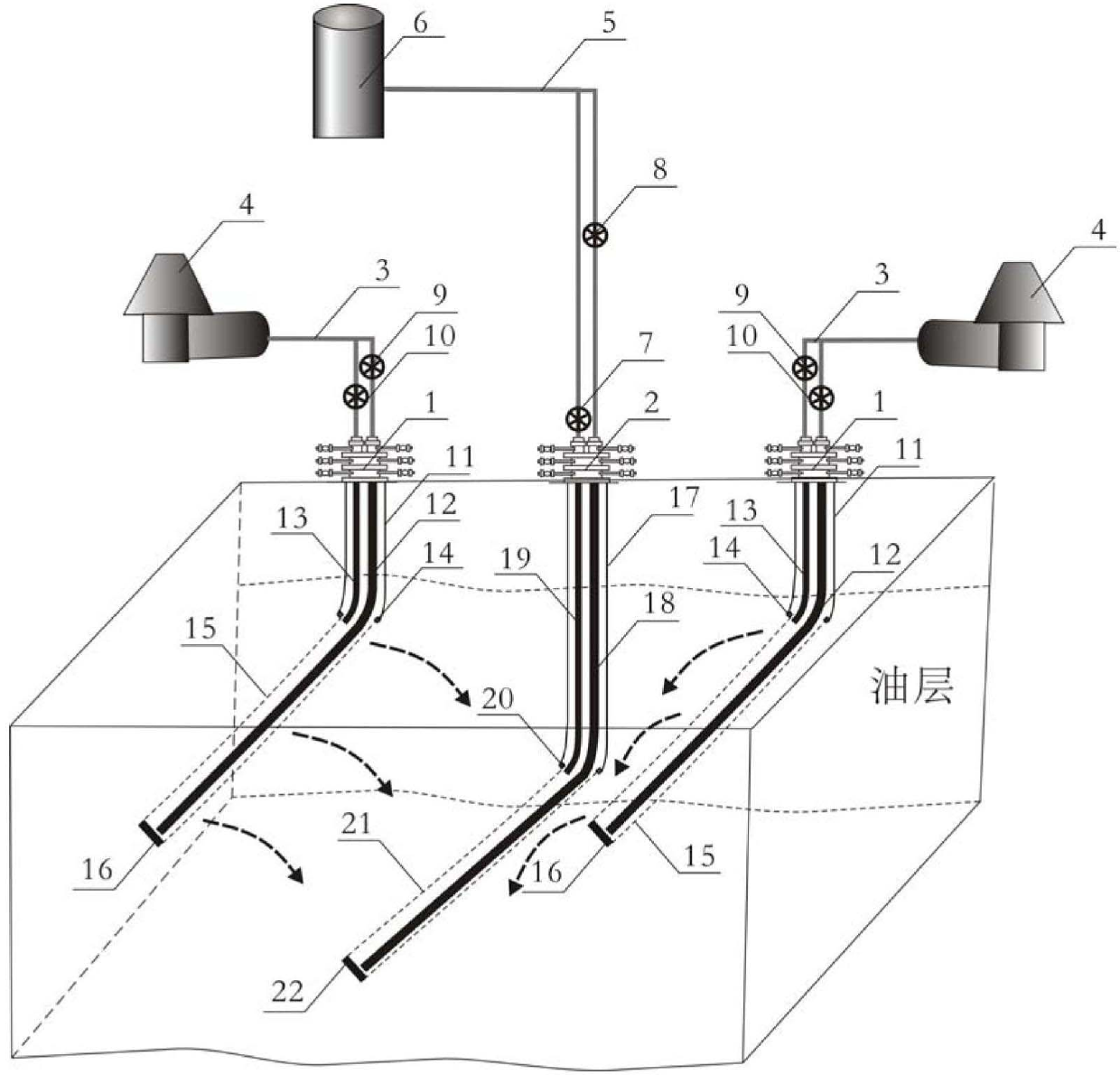

Hot water assisted gravity drainage method for mining high pour-point oil deposit

The invention relates to a hot water assisted gravity drainage method for mining a high pour-point oil deposit. The hot water assisted gravity drainage method for mining the high pour-point oil deposit comprises the following steps of: drilling a horizontal production well at the bottom of an oil reservoir of the high pour-point oil deposit; drilling two horizontal injection wells on the top of the oil reservoir of the high pour-point oil deposit; performing artificial fracturing and fissure forming on the horizontal injection wells and the horizontal production well; performing hot water huff and puff circulation preheating by using the horizontal injection wells and the horizontal production well simultaneously; and after circulation preheating is finished, starting to inject and produce continuously, namely continuously injecting hot water at the temperature of 100 DEG C by using the horizontal injection wells, and continuously producing by using the horizontal production well. The hot water assisted gravity drainage method for mining the high pour-point oil deposit can be applied to the high pour-point oil deposit of which the effective thickness is greater than 10 meters on large scale, and the well productivity and the recovery efficiency are improved.

Owner:PETROCHINA CO LTD

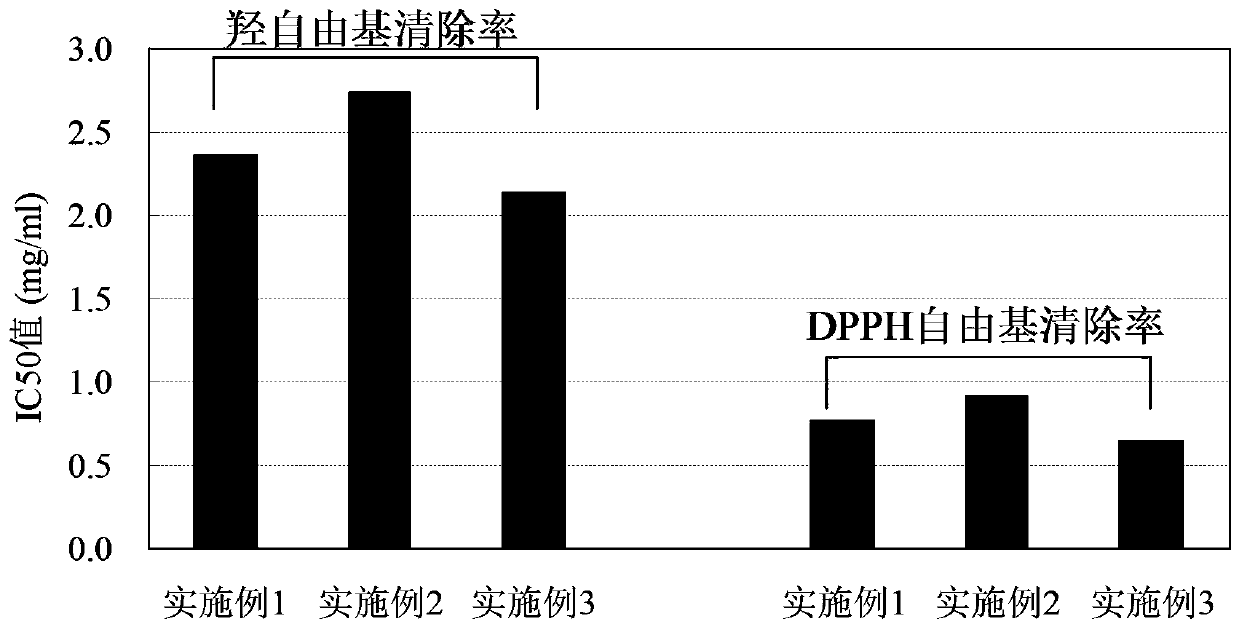

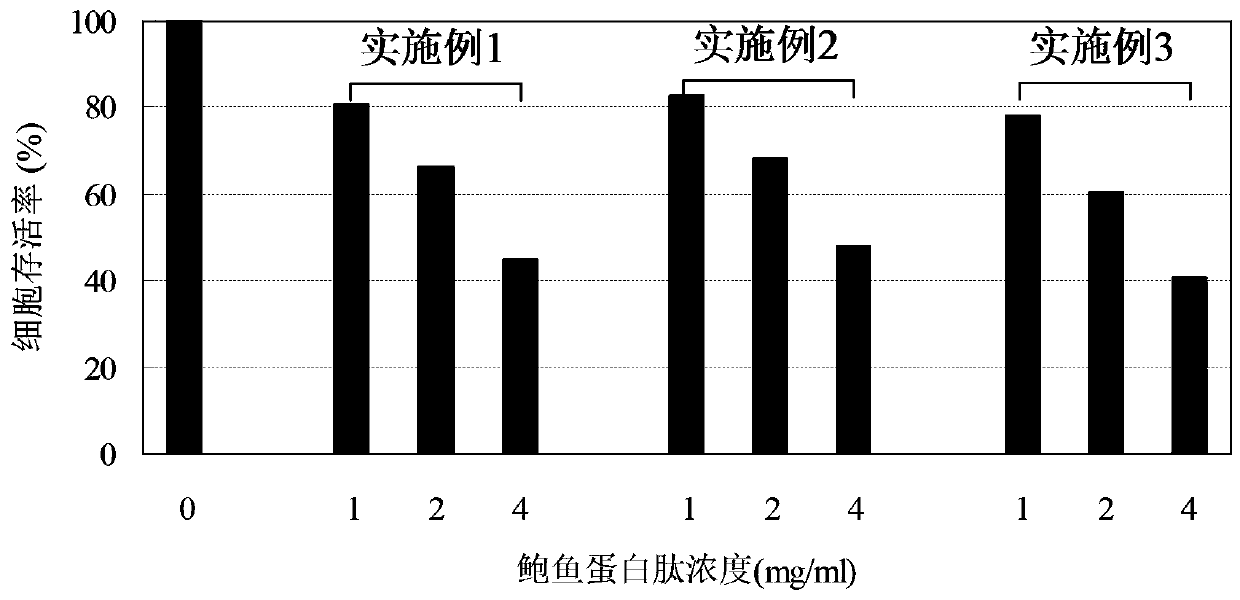

Method of extracting abalone protein peptides by subcritical water assisted enzymolysis and product

ActiveCN107556364AReduce pollutionEfficient use ofPeptide preparation methodsFermentationPectinaseWater assisted

The invention discloses a method of extracting abalone protein peptides by subcritical water assisted enzymolysis and a product. The technical process comprises the following steps: by taking abaloneviscera as a raw material, firstly treating the abalone viscera with subcritical water to extract proteins; then performing enzymolysis on the extracted proteins by means of pectinase and protease; preparing abalone protein peptide powder by means of column chromatography isolation, nanofiltration membrane concentration, vacuum concentration and spray drying; and developing a functional health-care product by using the abalone protein peptide powder. The technology provided by the invention improves the conventional technology of preparing protein peptides by enzymolysis, and extracts abaloneprotein peptides by subcritical water assisted enzymolysis, so that the dosage of enzymes can be reduced, the production time can be shortened to a great extent, and the production cost is lowered. Moreover, the prepared abalone protein peptides have good antioxidant and anti-tumor functions, thereby providing conditions for application and popularization of abalone protein peptides.

Owner:XIAMEN DAOZHIYUAN BIOTECH

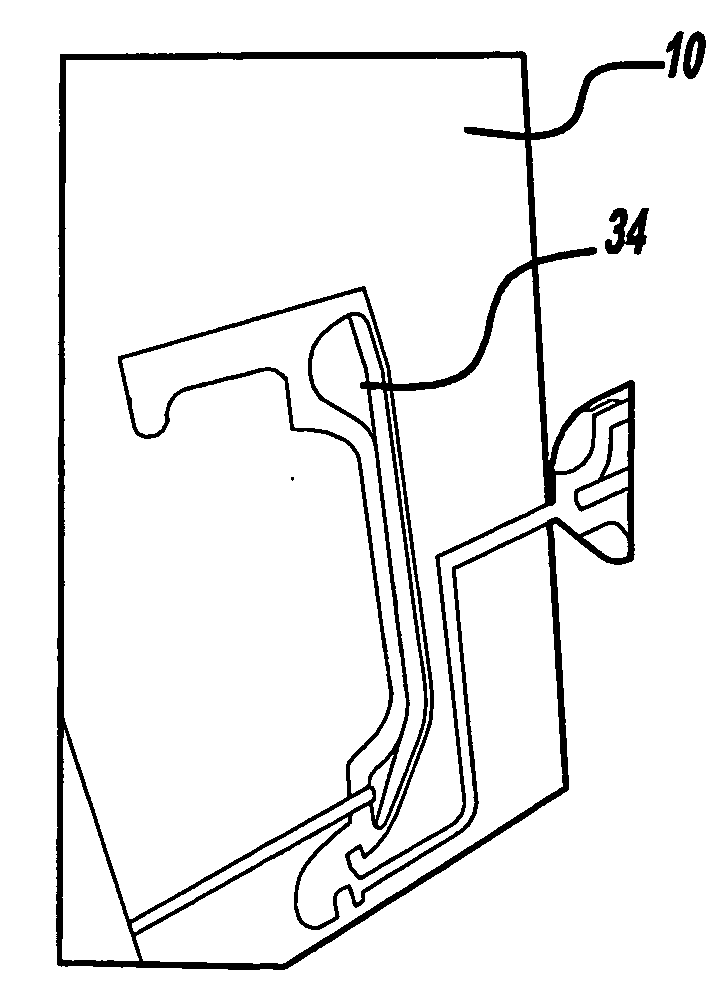

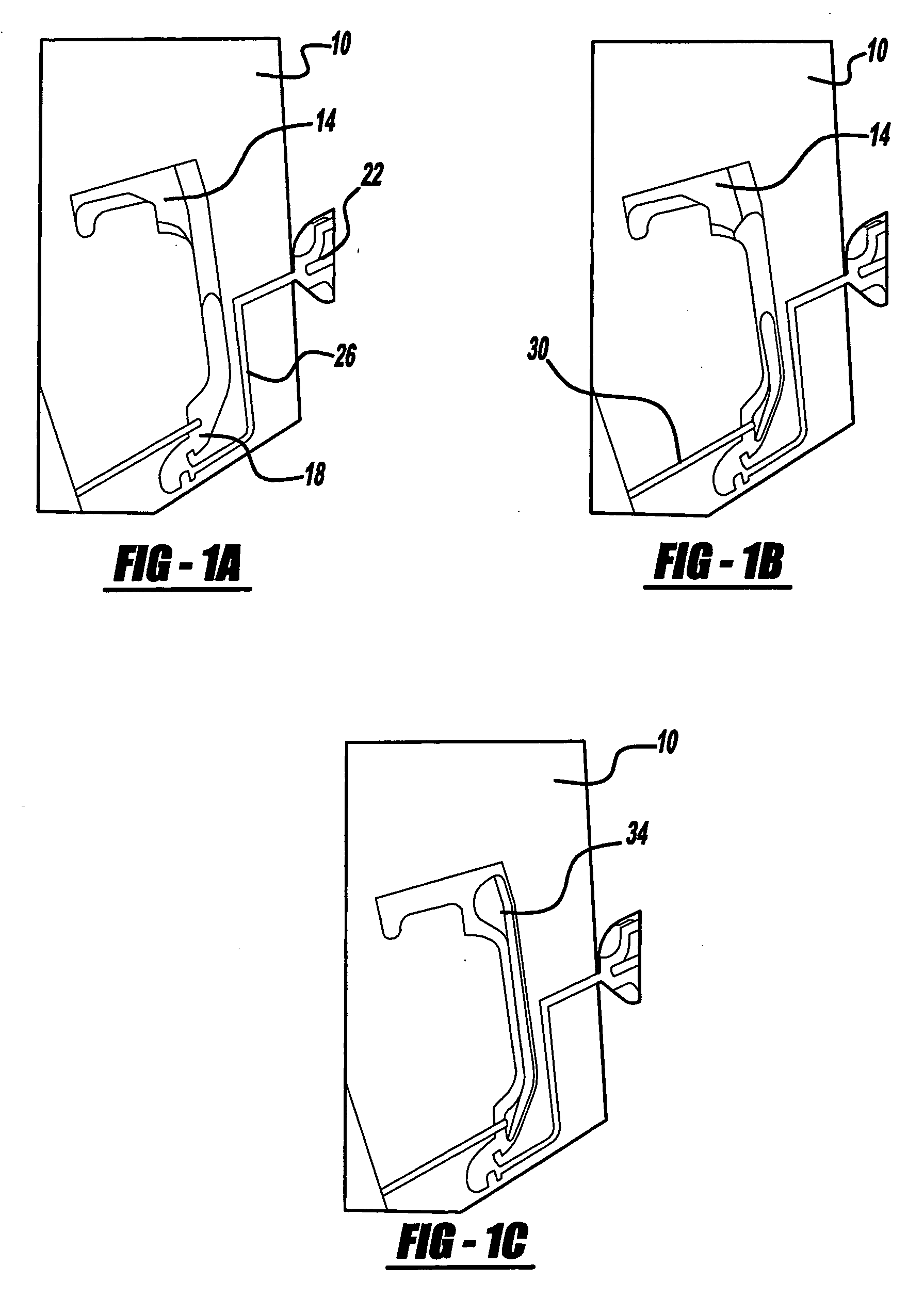

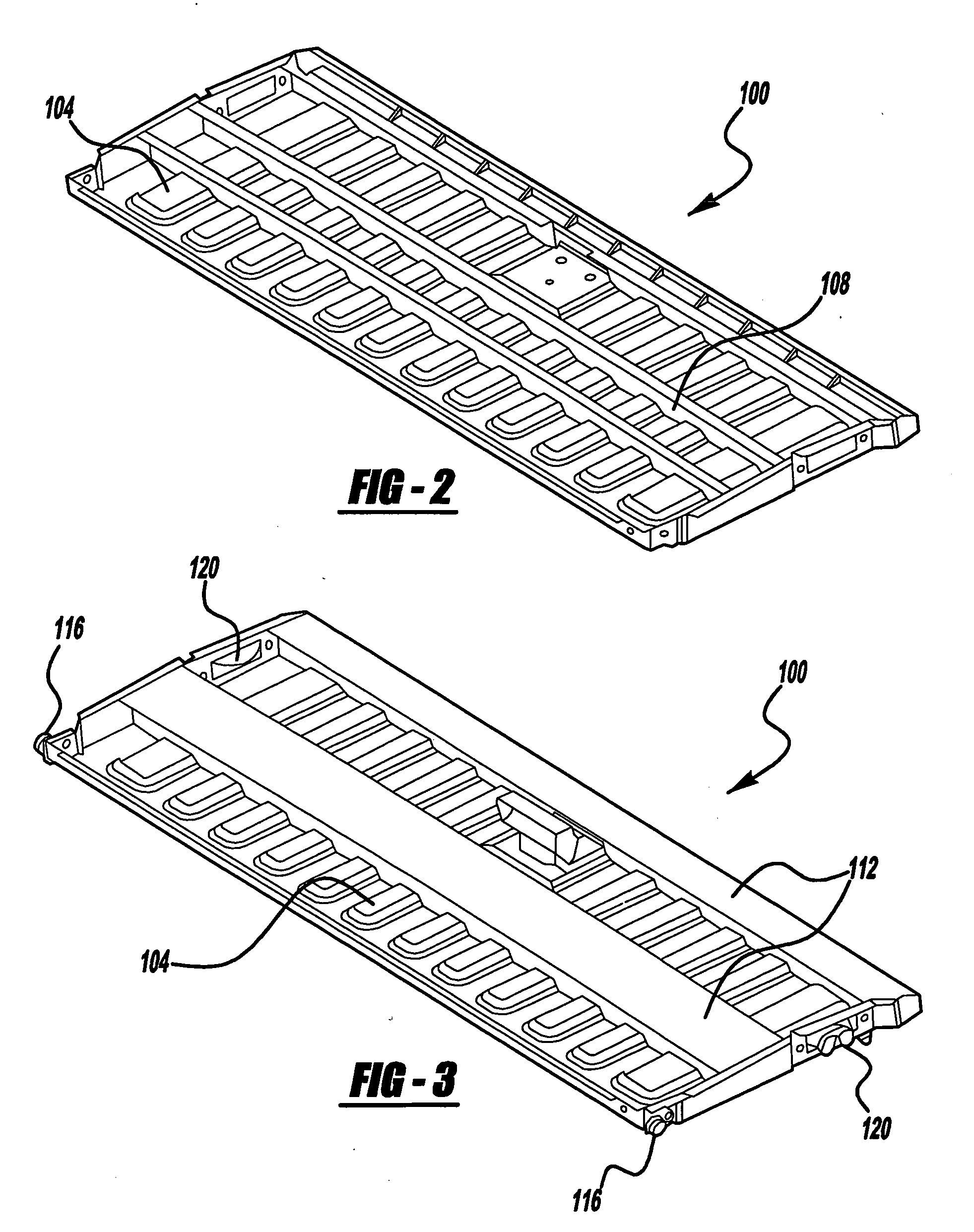

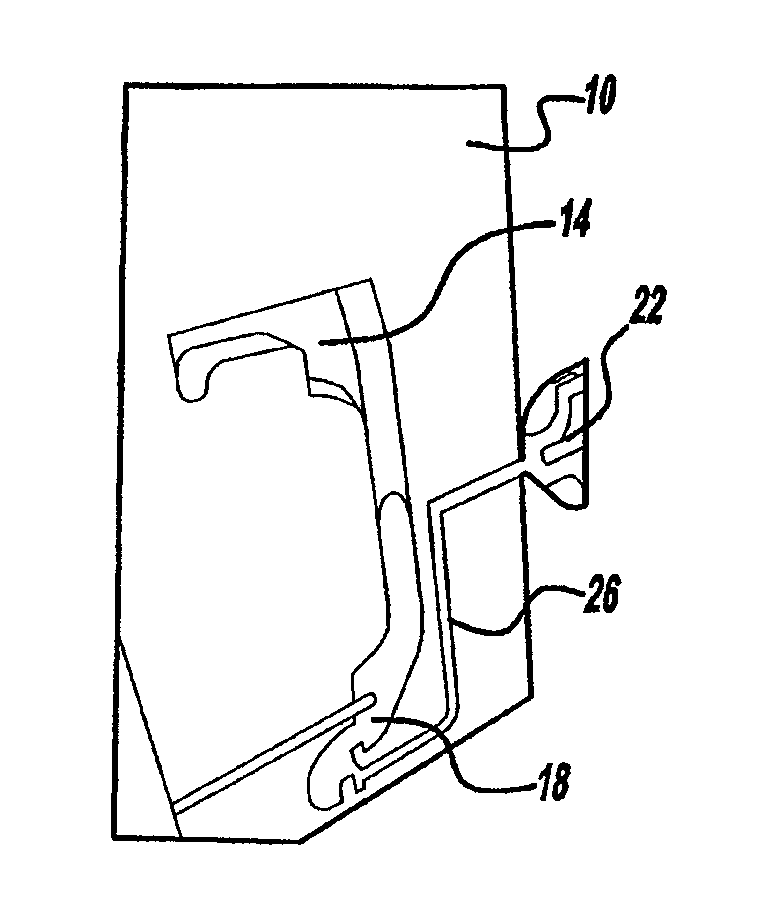

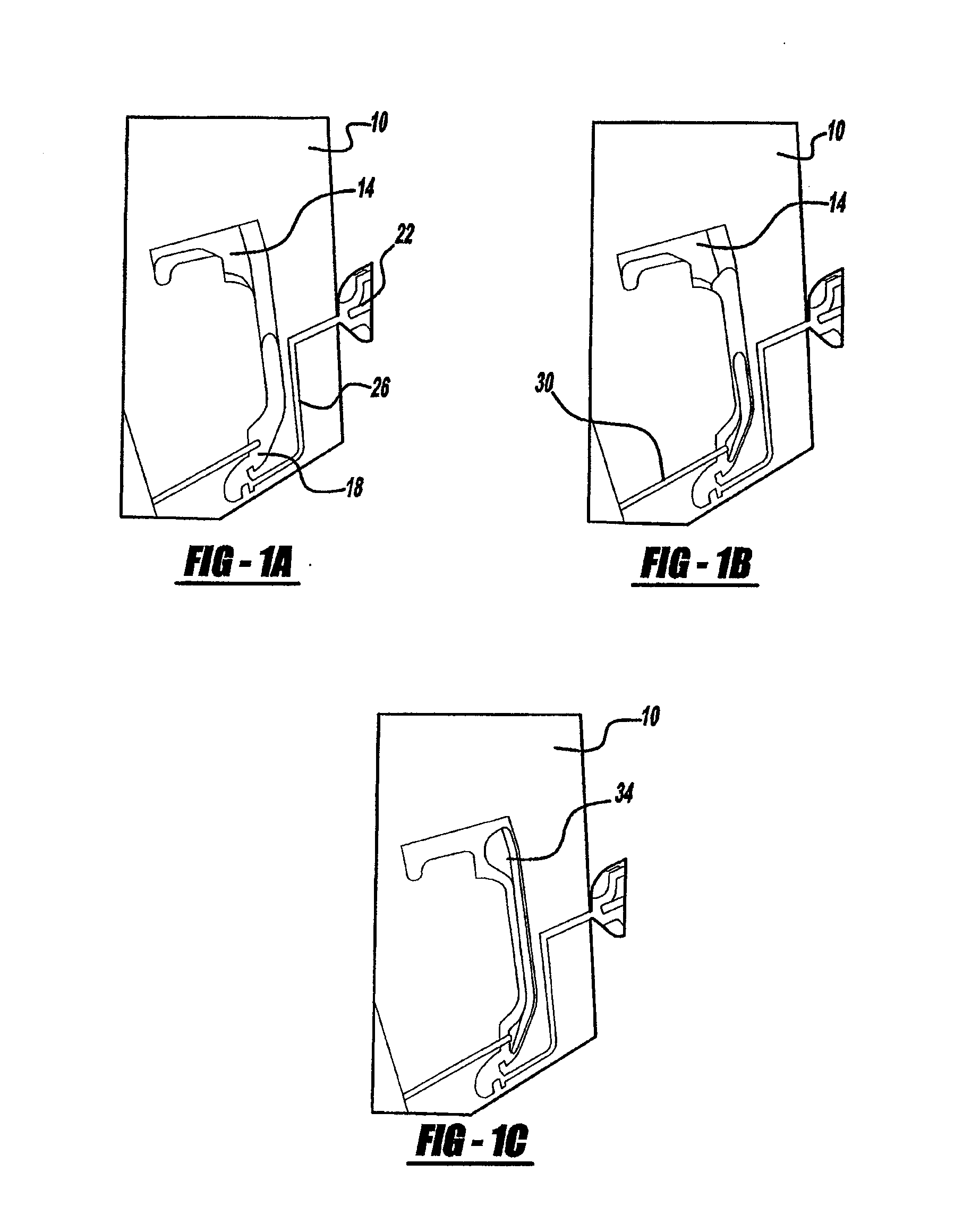

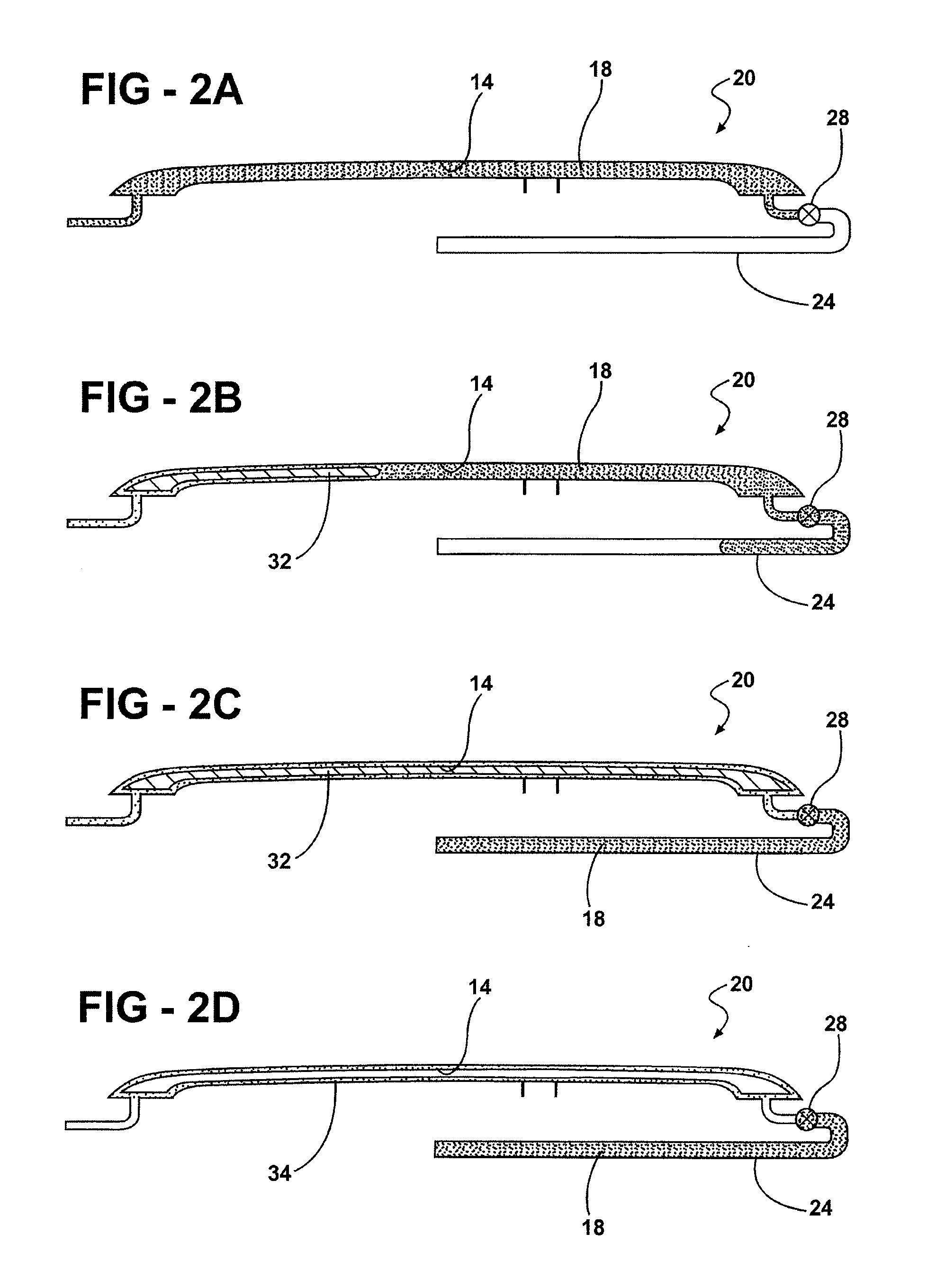

Water-assist injection molded structural members

A method of forming members of fiber reinforced thermoplastic members via molding, the members including at least one hollow chamber, formed by water injection into the melt in the mold, to stiffen the finished member. The thermoplastic is preferably selected from a group comprising polypropylene, Nylon, PET, ABS, TPO and thermoplastic polyurethane, while the reinforcing fibers are preferably selected from a group comprising glass, aramid, carbon and natural fibers. Preferably, the extruded melt is produced such that the average length of the reinforcing fibers is longer than the length conventionally obtained.

Owner:MAGNA INTERNATIONAL INC

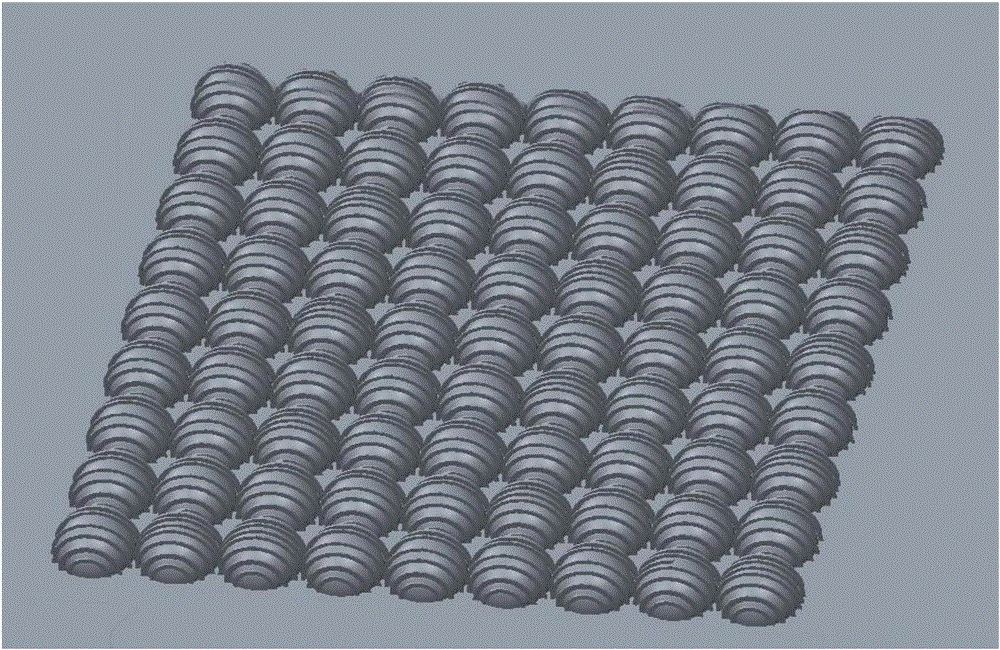

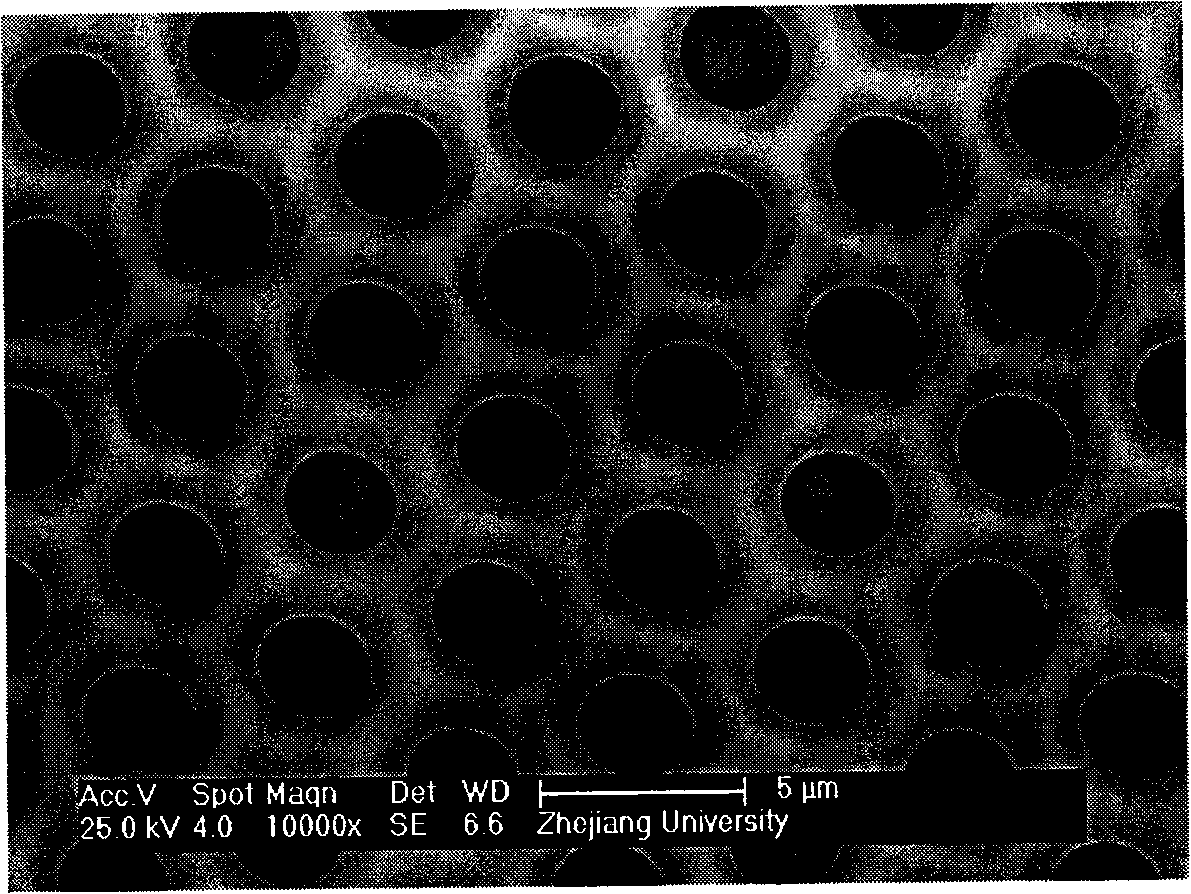

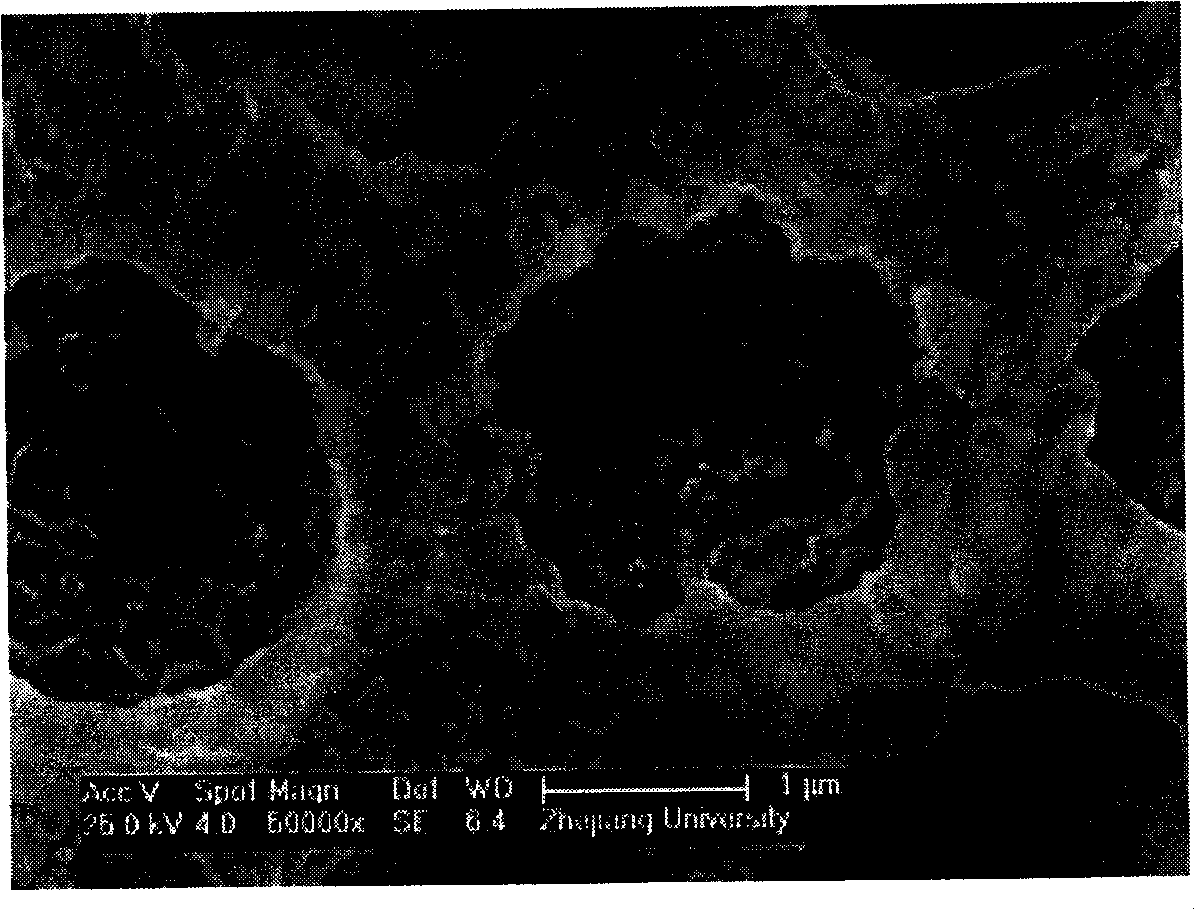

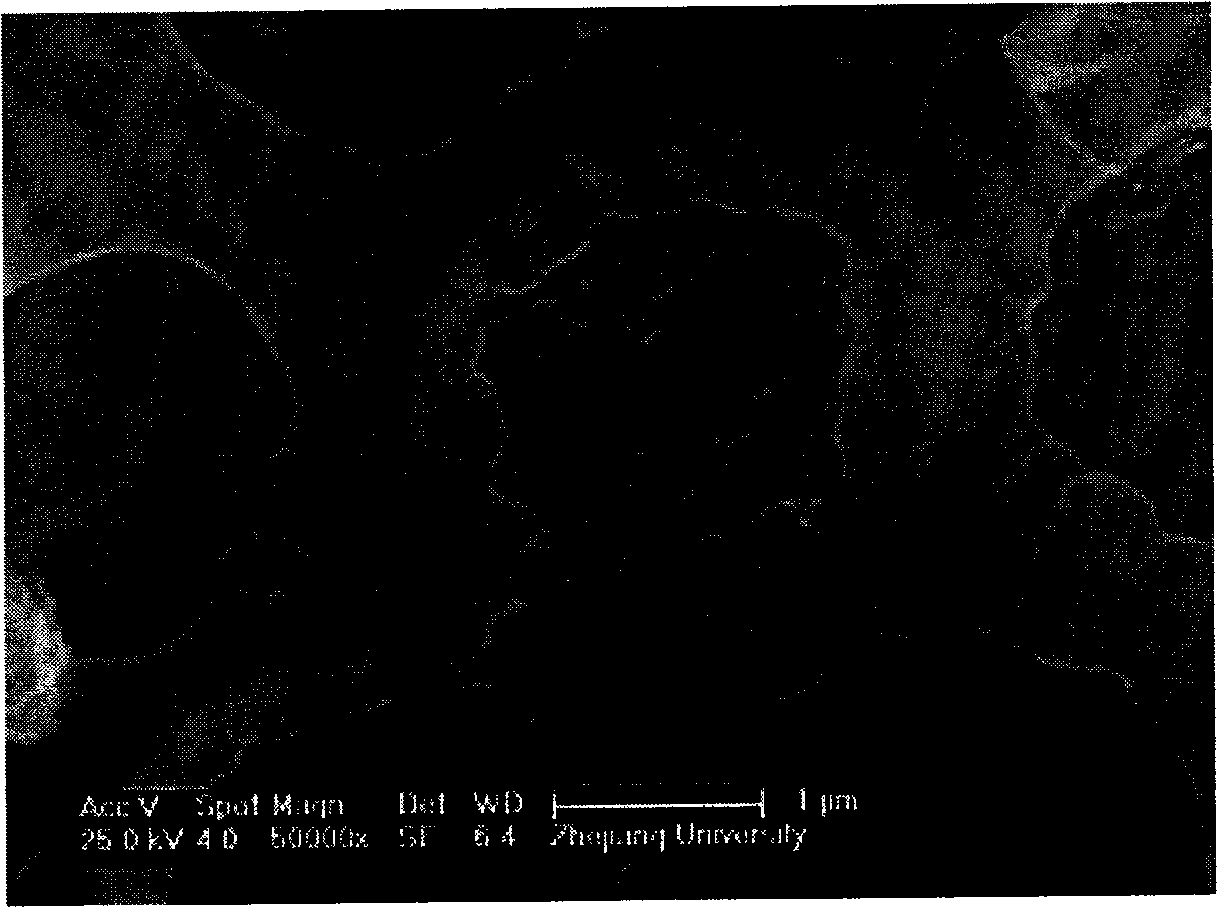

Semiconductor double-stage surface structure laser machining method based on electronic dynamic regulating and control

ActiveCN106216833AShort processing cycleLow costDecorative surface effectsChemical vapor deposition coatingMicro nanoElectronic temperature

The invention relates to a semiconductor double-stage surface structure laser machining method based on electronic dynamic regulating and control, and belongs to the technical field of femtosecond laser application. Under the water-assisted condition, a time domain shaping pulse sequence is designed, the local-area instantaneous electronic density and electronic temperature are adjusted, the phase change process of a material is changed, and therefore a micro-nano composite double-stage structure is obtained. Compared with a traditional multistage structure machining method, the method for machining the semiconductor multi-stage structure through the time domain shaping pulse sequence has the beneficial effects of being short in period, low in cost and good in repeatability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

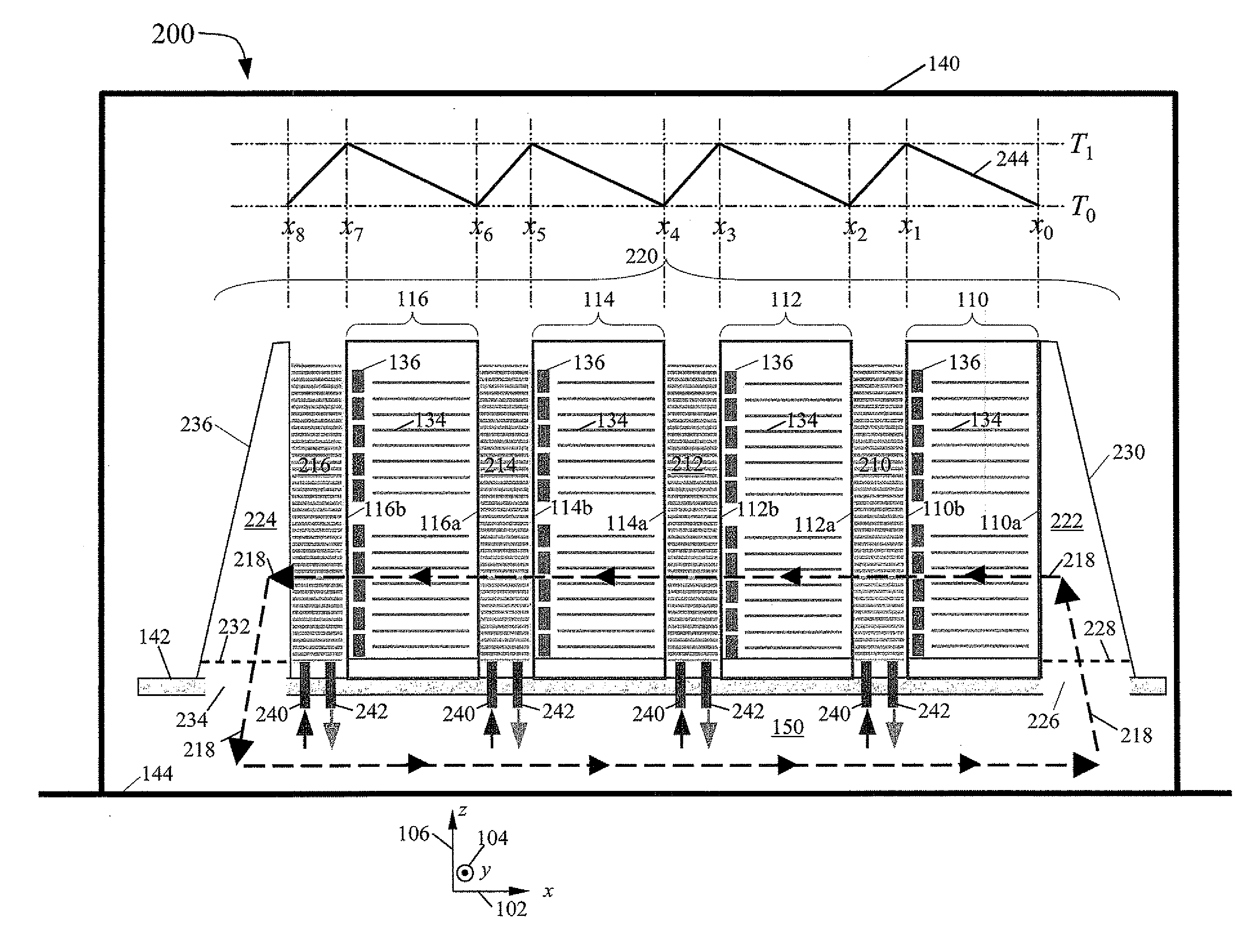

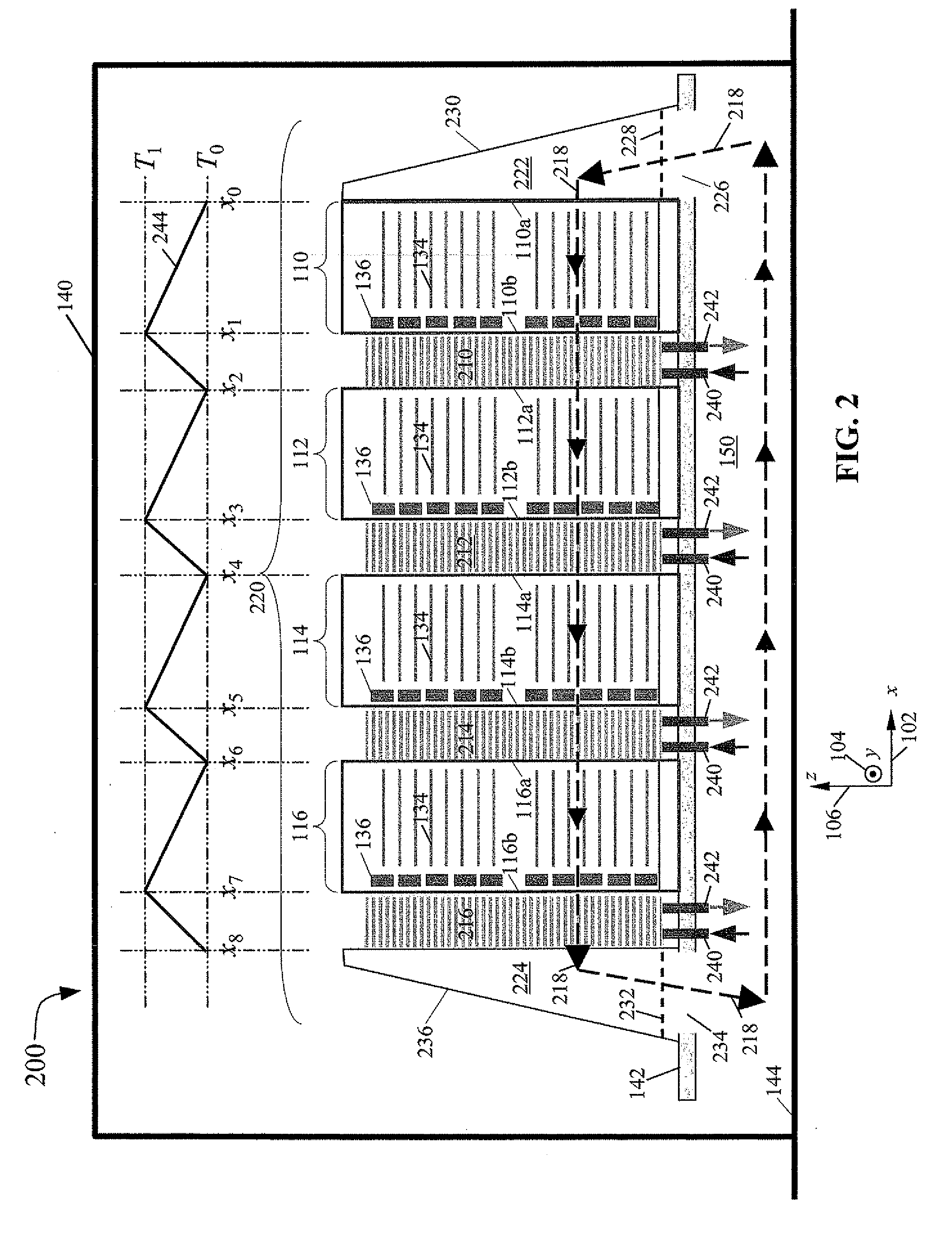

Water-assisted air cooling for a row of cabinets

InactiveUS20140223946A1Transfer of heatHeat exchange apparatusCooling fluid circulationWater assistedEngineering

A cooling apparatus and method including a plurality of heat-producing devices positioned in a plurality of cabinets arranged in a row that allows flow of a first fluid through the heat-producing devices and cabinets where the flow is directed from an upstream end of the row to a downstream end of the row. The cabinets have a space therebetween wherein a heat exchanger is positioned between and adjacent to the cabinets, thereby the cabinets and heat exchangers alternate in the row. Each heat exchanger allows flow of a second fluid therethrough for cooling the first fluid. A fluid-moving device is positioned adjacent the heat-producing devices for encouraging flow of the first fluid through the cabinets' heat-producing devices and through the heat exchangers, thereby encouraging heat transfer in each of the heat exchangers from the first fluid to the second fluid.

Owner:IBM CORP

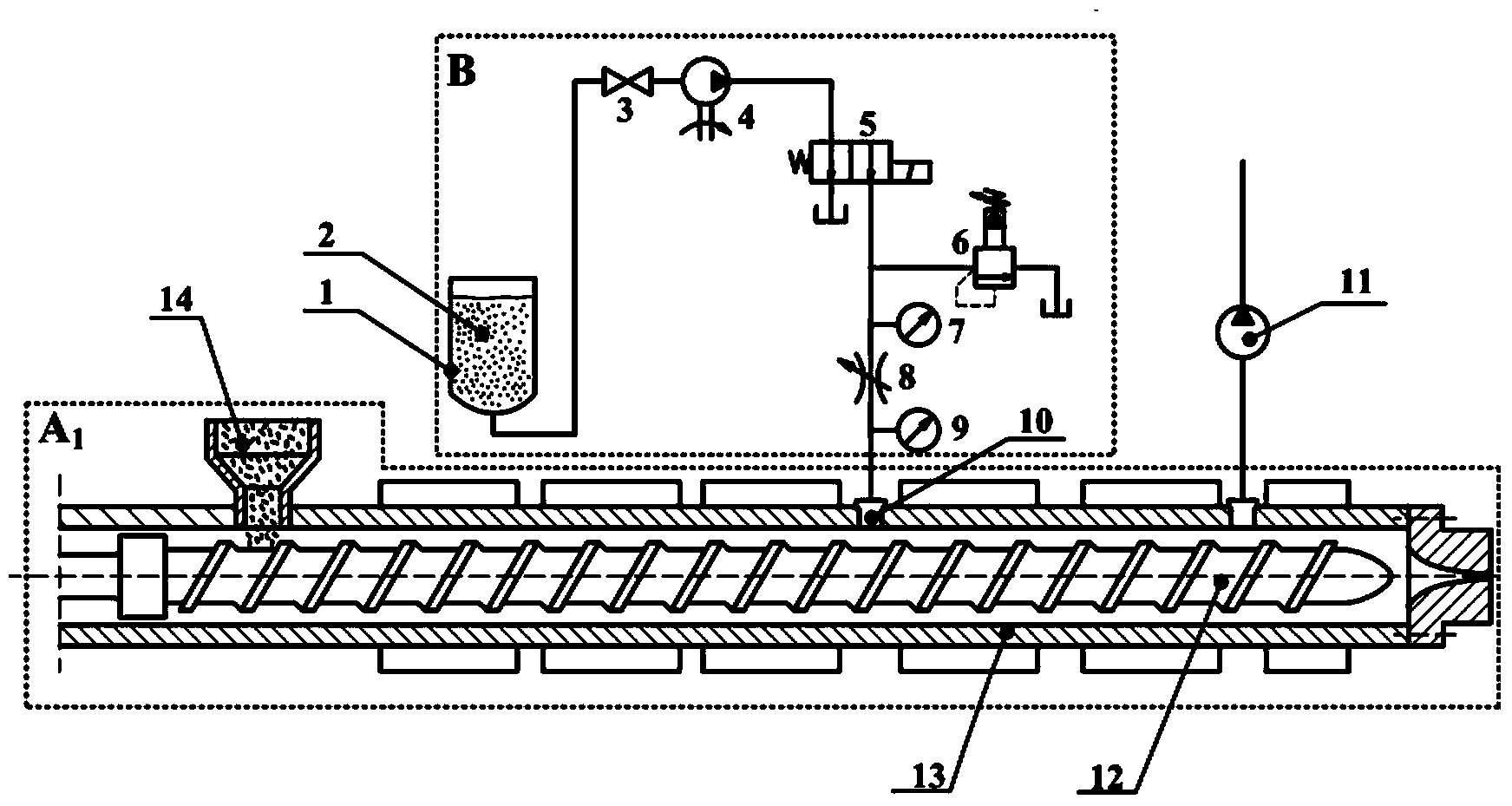

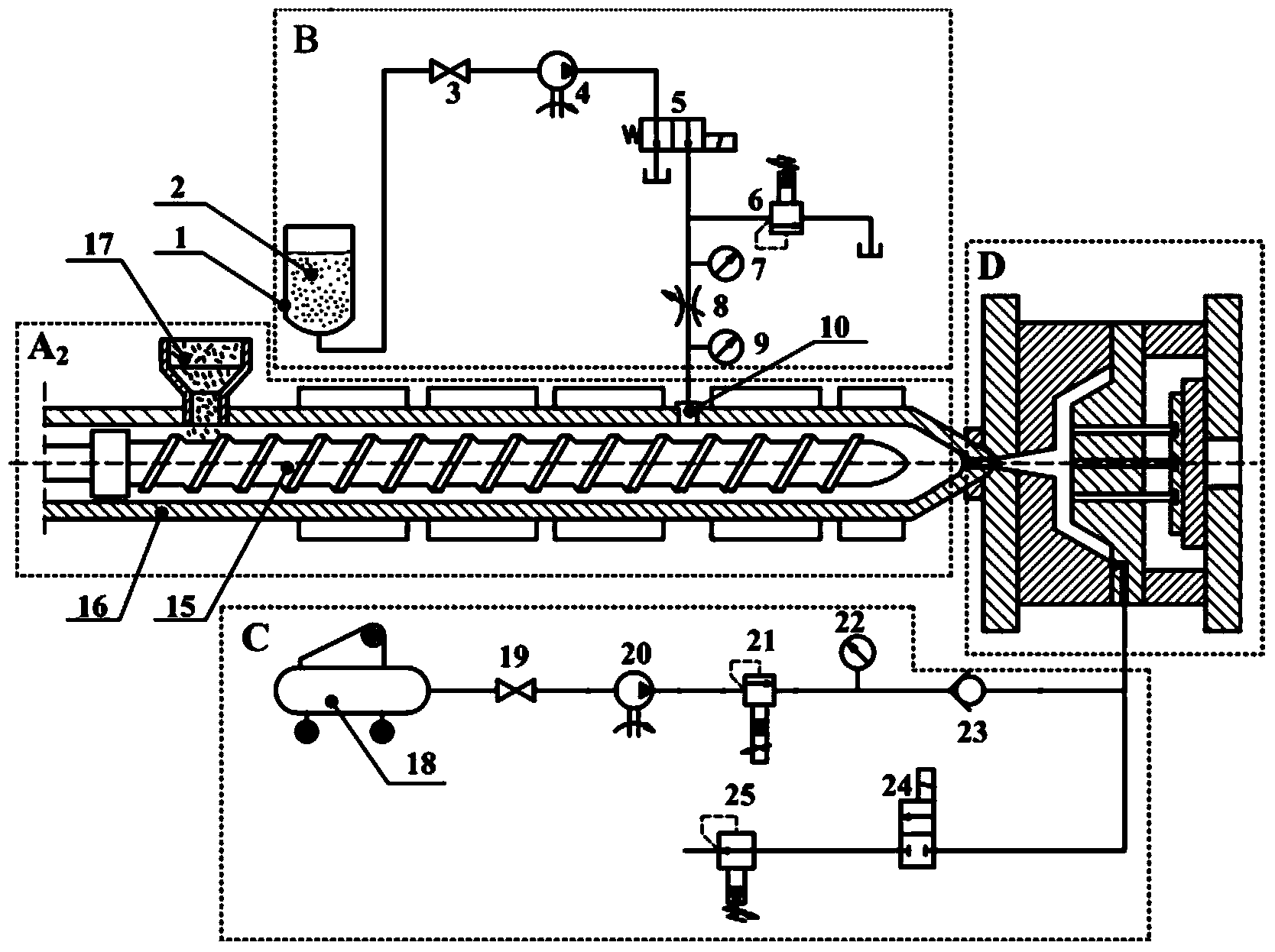

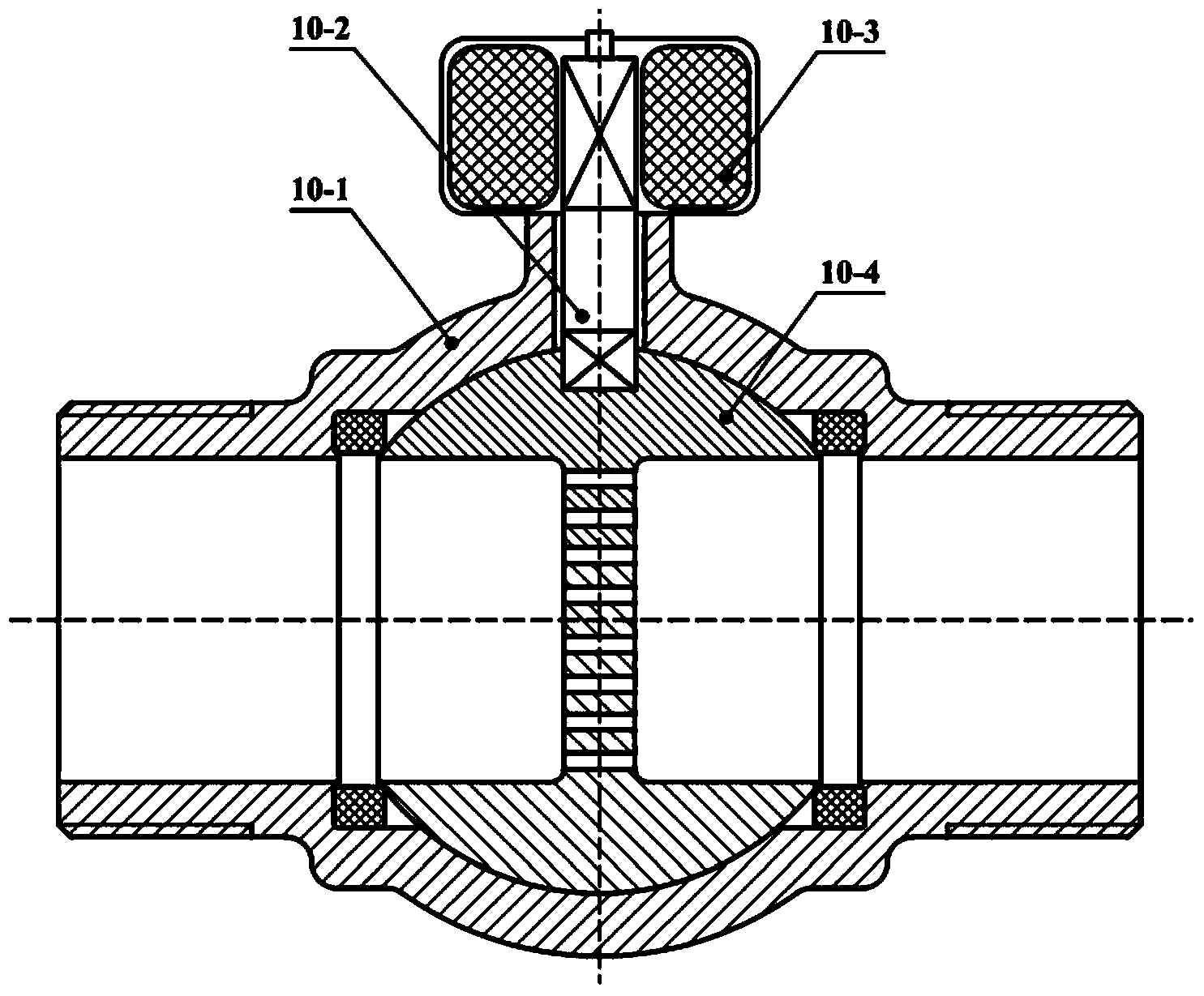

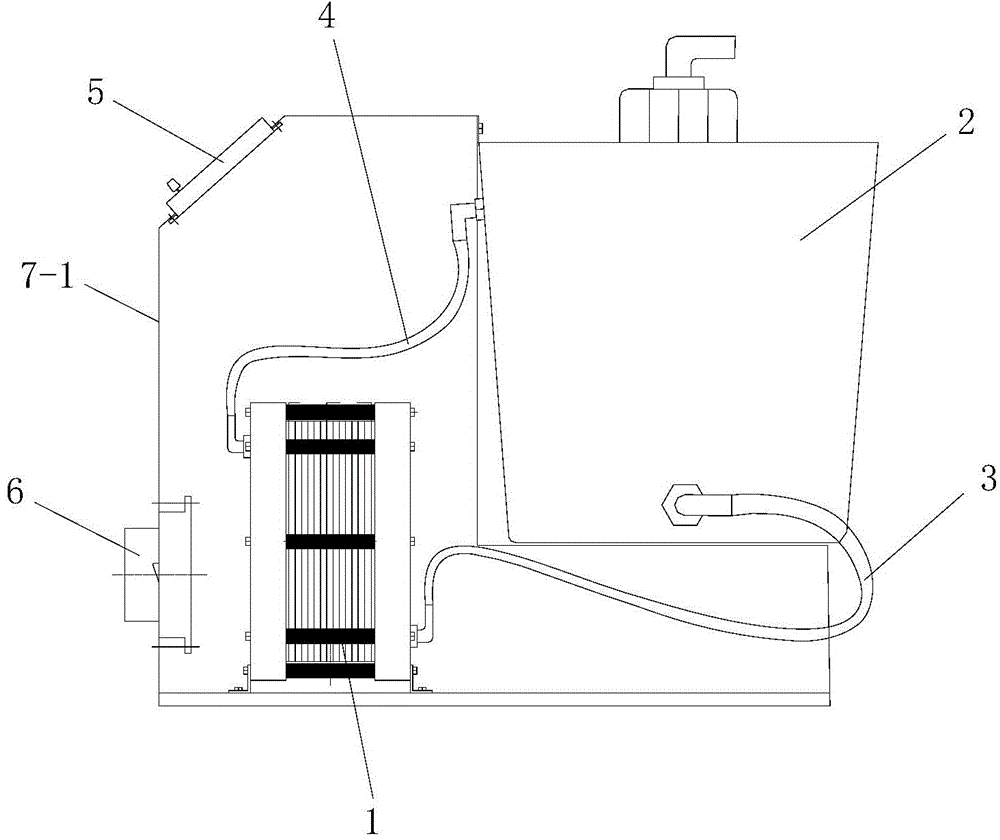

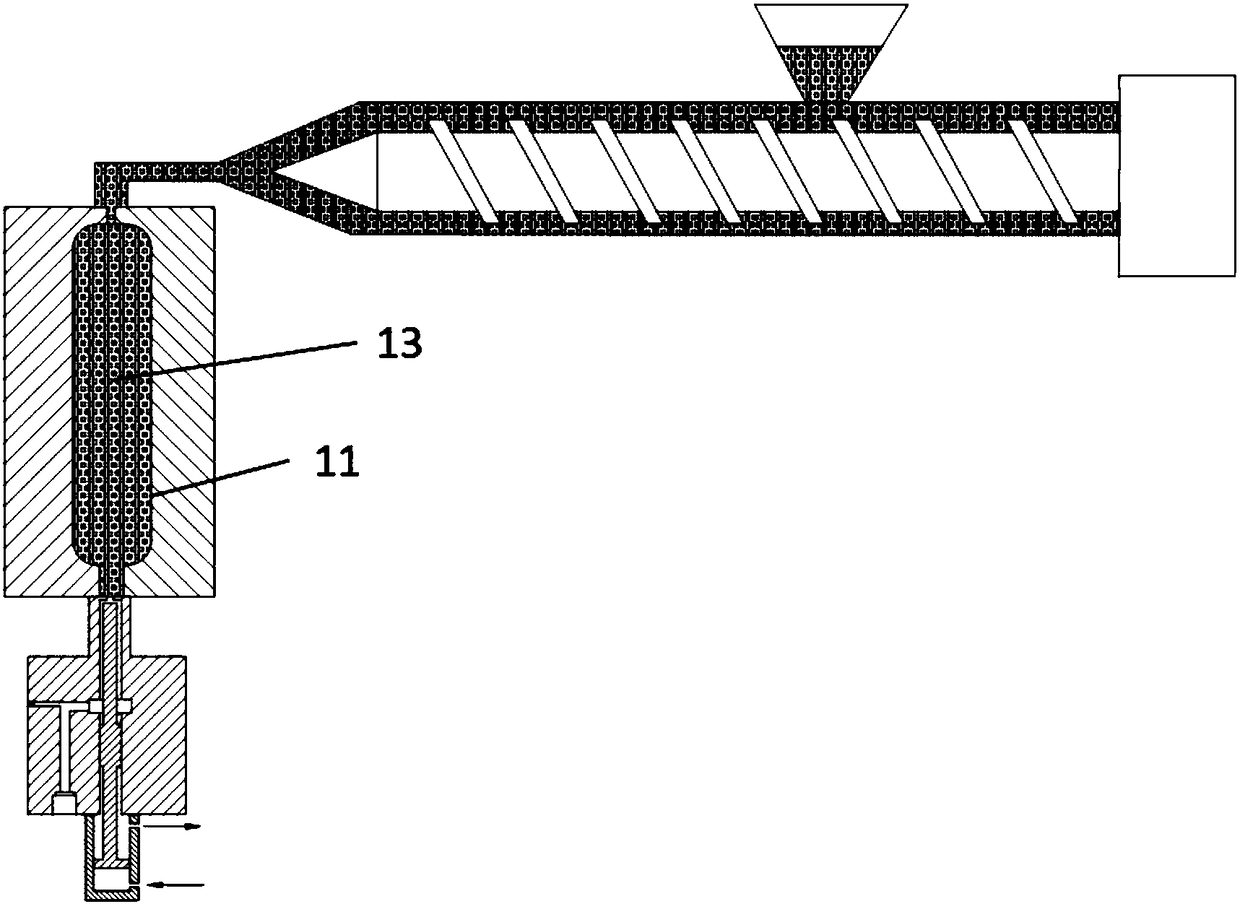

Equipment for extruding/injecting polymer nano-composite through water-assisted mixing and realization method of equipment

The invention provides equipment for extruding / molding a polymer nano-composite through water-assisted mixing. The equipment for extruding / molding the polymer nano-composite through the water-assisted mixing comprises an extruder, a water-based nano particle suspension injection device and an exhausting device which is capable of discharging vapor formed after vaporization of a water-based nano particle suspension from a machine cylinder of the extruder; the equipment for extruding / molding the polymer nano-composite through the water-assisted mixing comprises an injection molding machine, an injection molding mould, a water-based nano particle suspension injection device and a mould cavity gas back-pressure device which is capable of supplying back-pressure gas into a cavity of the injection molding mould and discharging the back-pressure gas. The invention further provides a method for extruding and molding the polymer nano-composite through the water-assisted mixing. The equipment and the method provided by the invention can be used for uniformly dispersing nano particles into a polymer matrix, have the advantages of low cost, compact structure, simplicity and convenience in operation, and are applicable to industrial application.

Owner:SOUTH CHINA UNIV OF TECH

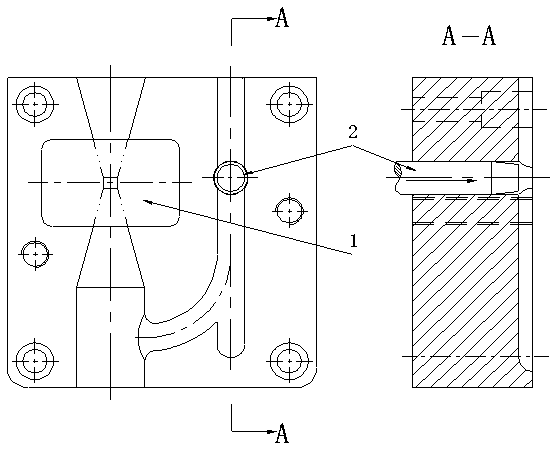

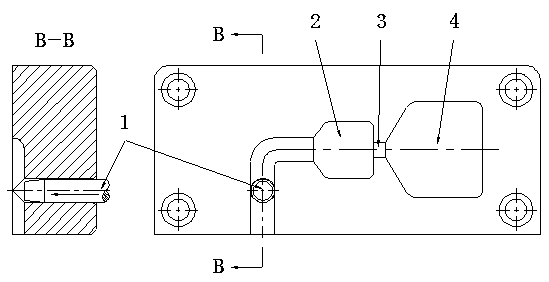

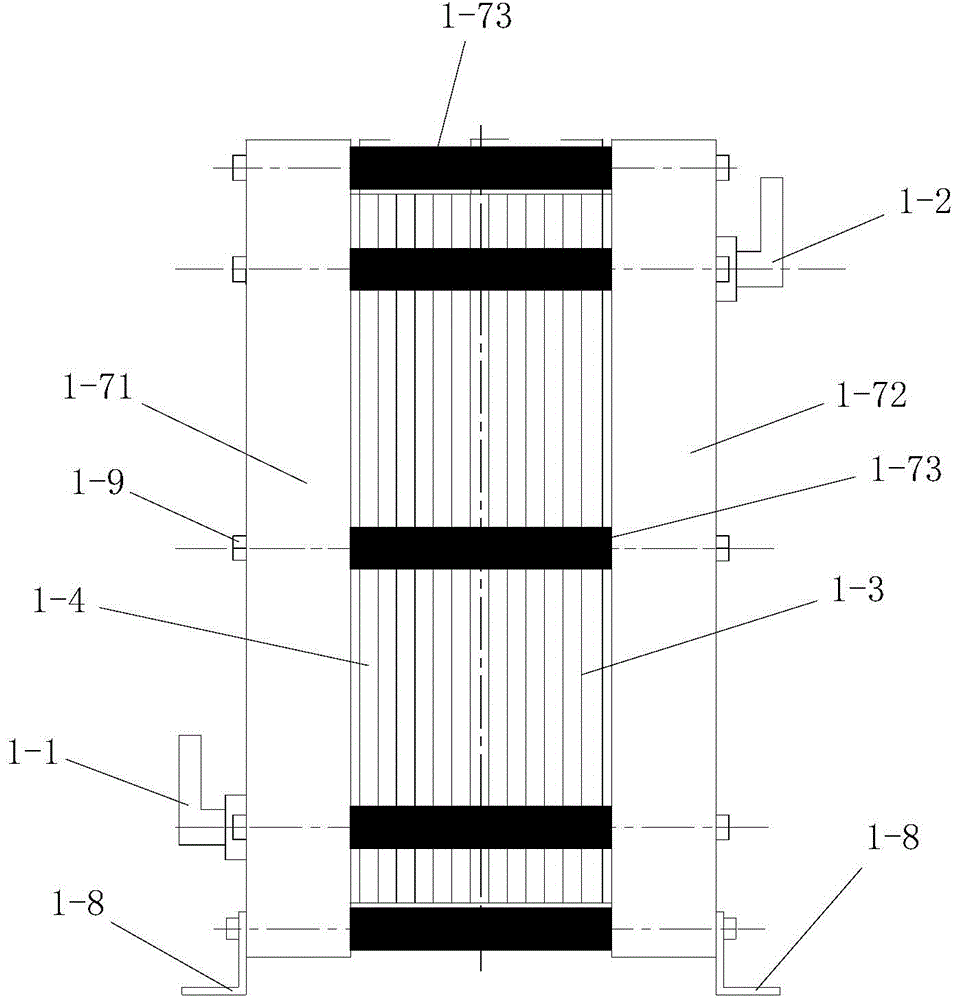

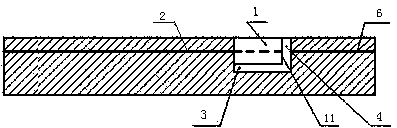

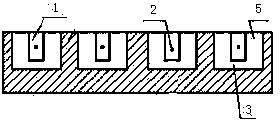

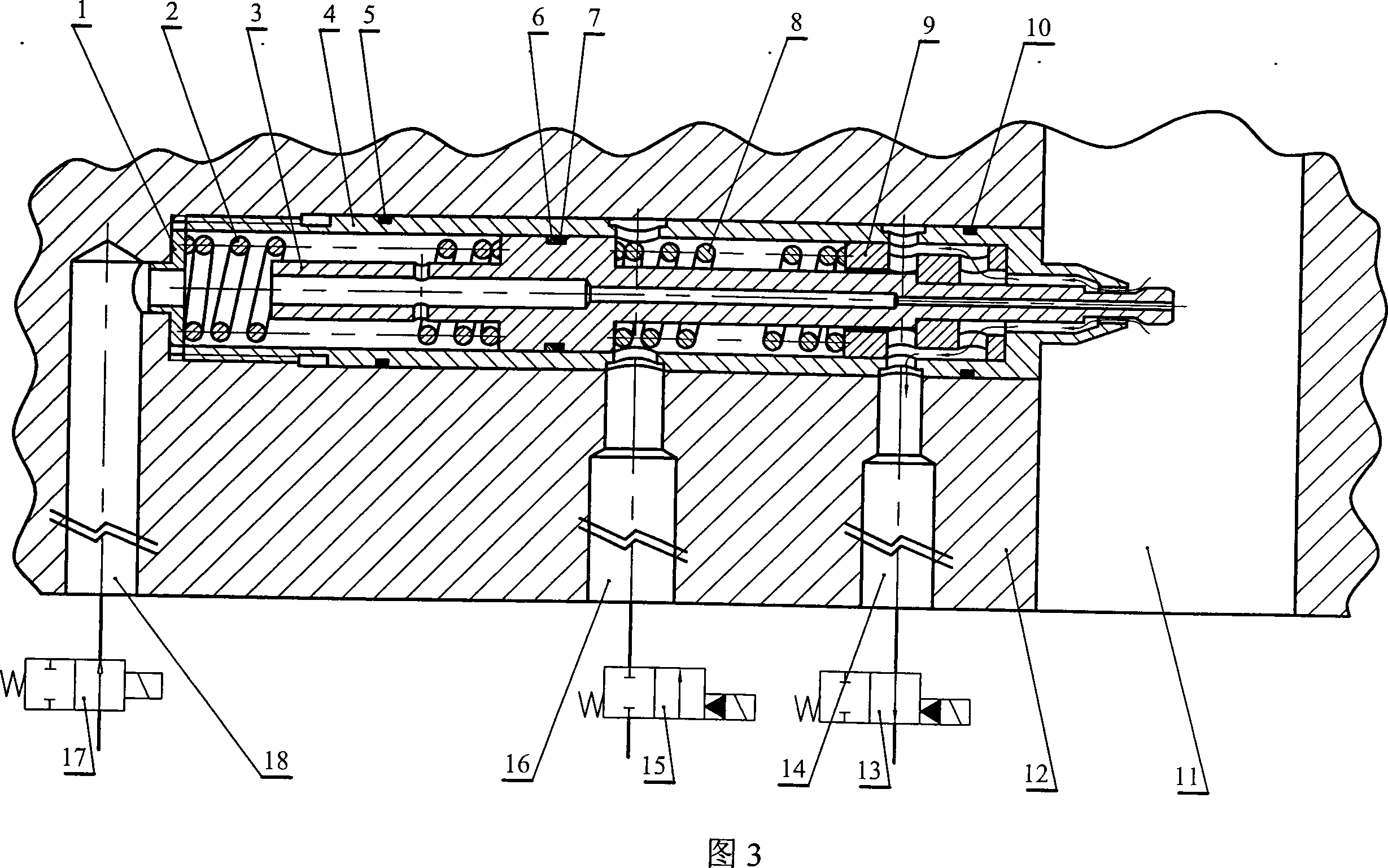

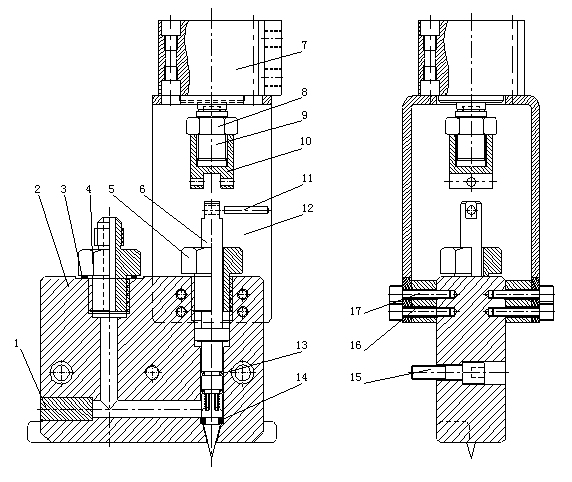

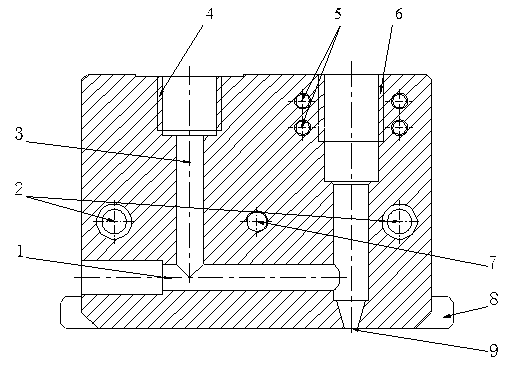

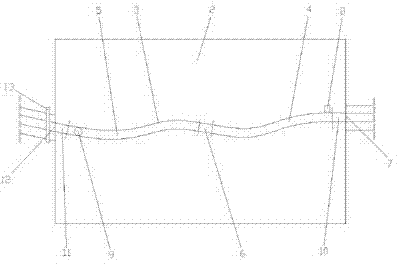

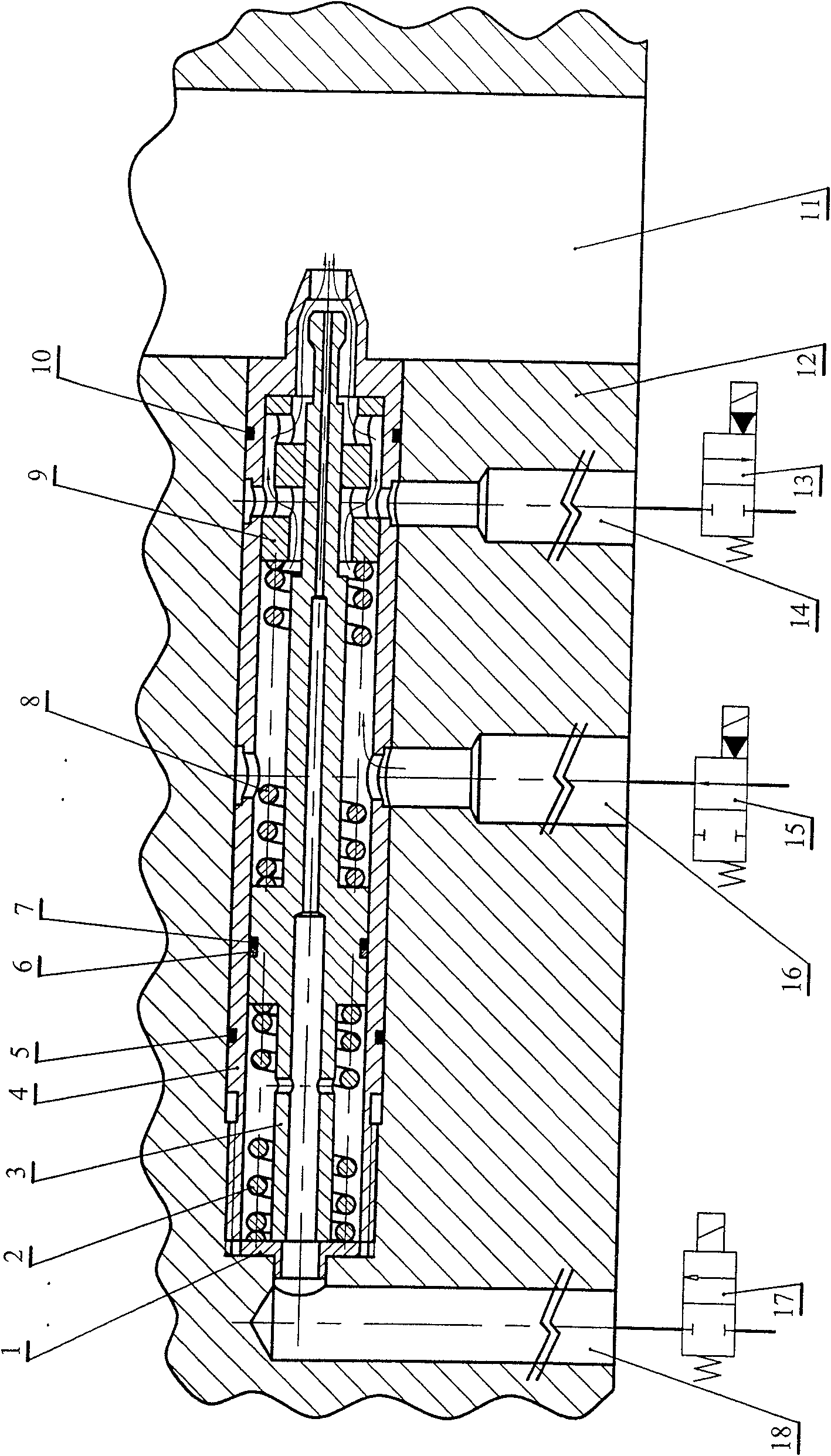

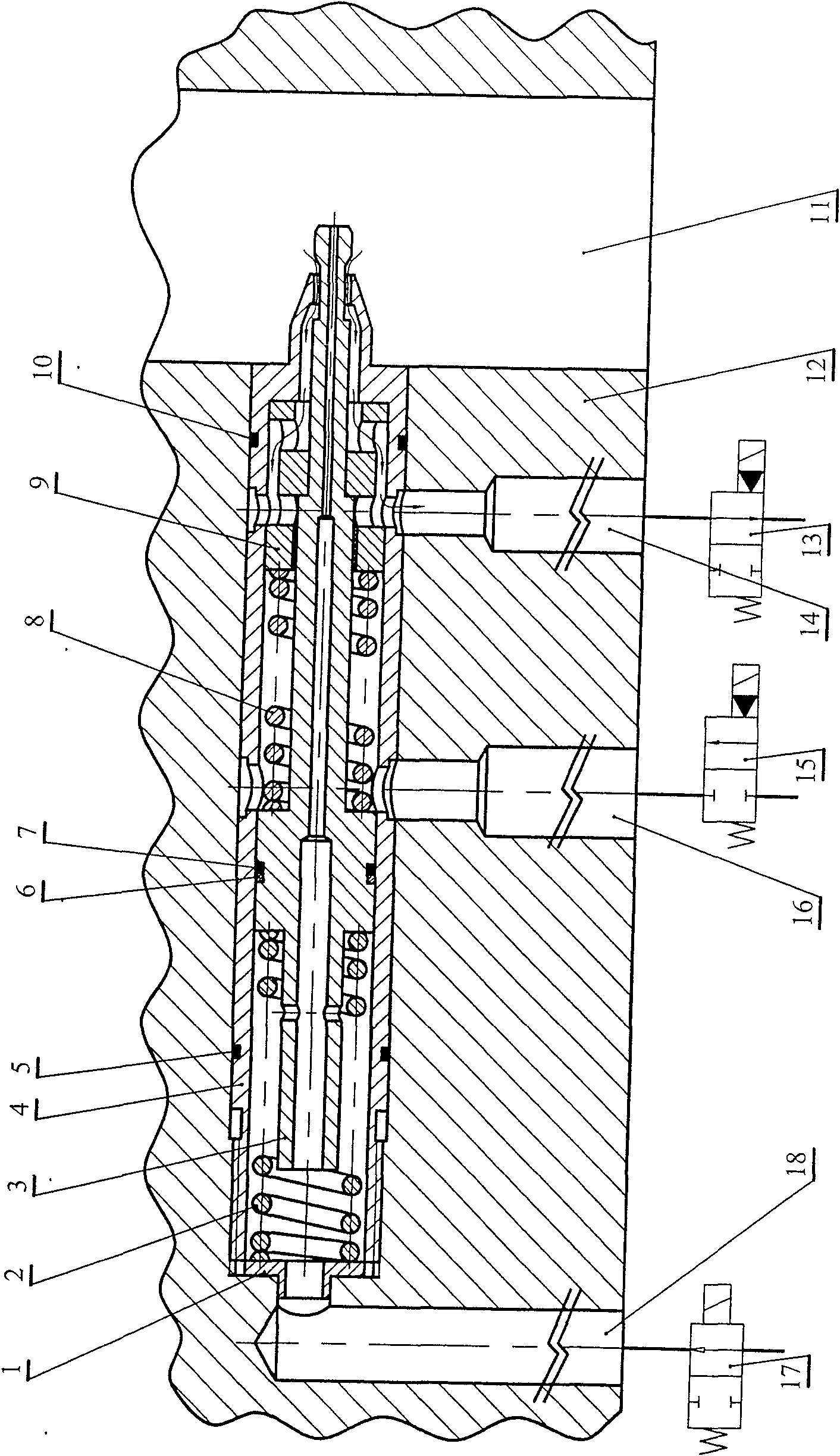

Water-assisted (co-injection) injection mold for complex-formed tube and stick plastic parts

The invention discloses a water-assisted (co-injection) injection mold for complex-formed tube and stick plastic parts. The water-assisted (co-injection) injection mold comprises movable / fixed mold bodies, movable / fixed mold gate inserts, a gate bush, movable / fixed mold cavity inserts, movable / fixed mold material-overflowing cavity inserts, a runner sealing needle, an overflow runner sealing needle and a water needle. After mold assembly, one or two kinds of moderate plastic melts are sequentially injected into a mold cavity, and the runner sealing needle is closed to prevent backflow. After delaying, the water needle is opened, and high-pressure water is injected into the inner parts of the melts to push the melts of a core part to flow forwards to complete filling. After pressure maintaining, the water needle is closed. After cooling, a mold is disassembled, and a high-quality hollow single-layer / multiple-layer tube and stick workpiece is obtained. In the injection process, the transformation between full-material injection and material-shortage injection can be realized through the opening and closing of the overflow runner sealing needle. The water-assisted (co-injection) injection mold has the characteristics of easiness in replacement and adjustment of insert structures, varied application processes, stable forming process, high forming quality and the like and is suitable for experimental research and production of water-assisted injection and water-assisted co-injection processes and even an air-assisted injection process.

Owner:EAST CHINA JIAOTONG UNIVERSITY

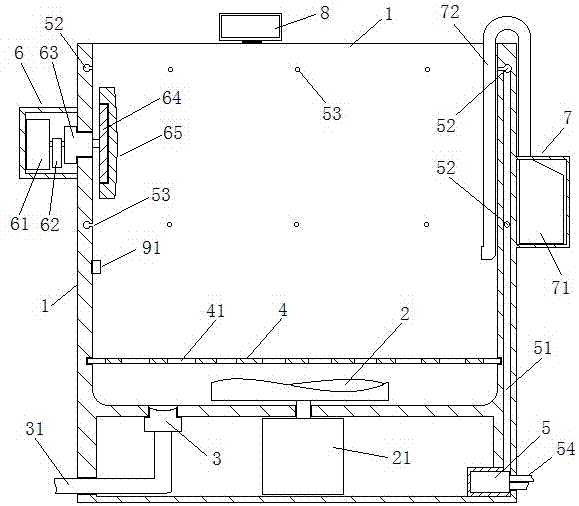

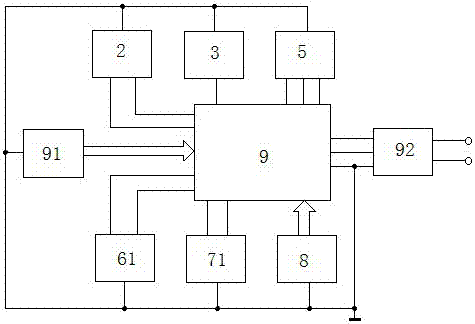

Multifunctional bathtub

InactiveCN106923716AComfortable and labor-saving bathingWith physical therapy effectBathsDouchesAutomatic controlWater leakage

The invention discloses a multifunctional bathtub, which comprises a round-barrel type bathtub, a wave wheel rotary disc, an electronic water drainage valve, an electronic water supply valve, a water leakage stepping plate, spraying openings, a scrubbing device, a warm-air machine, a control panel, an integrated sensor module and a control circuit, wherein the periphery of the inner wall of the bathtub is communicated with the spraying opening of the electronic water supply valve; the scrubbing device is arranged on the bathtub wall; the warm-air machine is used for drying the body. By utilizing the scrubbing device with a vibration massage function, bathing is carried out with the aid of running water which simulates wave and is generated by the wave wheel rotary disc, so that the bathing is labor-saving and comfortable, and has a physical therapy effect; after the bathing is completed, people can instantly take a shower of the whole body in the bathtub through a plurality of surrounding spraying openings and the whole body can be dried by utilizing the warm-air machine, and the wiping is eliminated; by the function of the control panel, full automatic control of water infusion, water drainage, assisted bathing, massaging and drying also can be realized, and one bathtub has a full-process comprehensive function of bathing, such as scrubbing, massaging, running water assisted washing, shower and drying, so that the bathing is quick and convenient.

Owner:吴为生

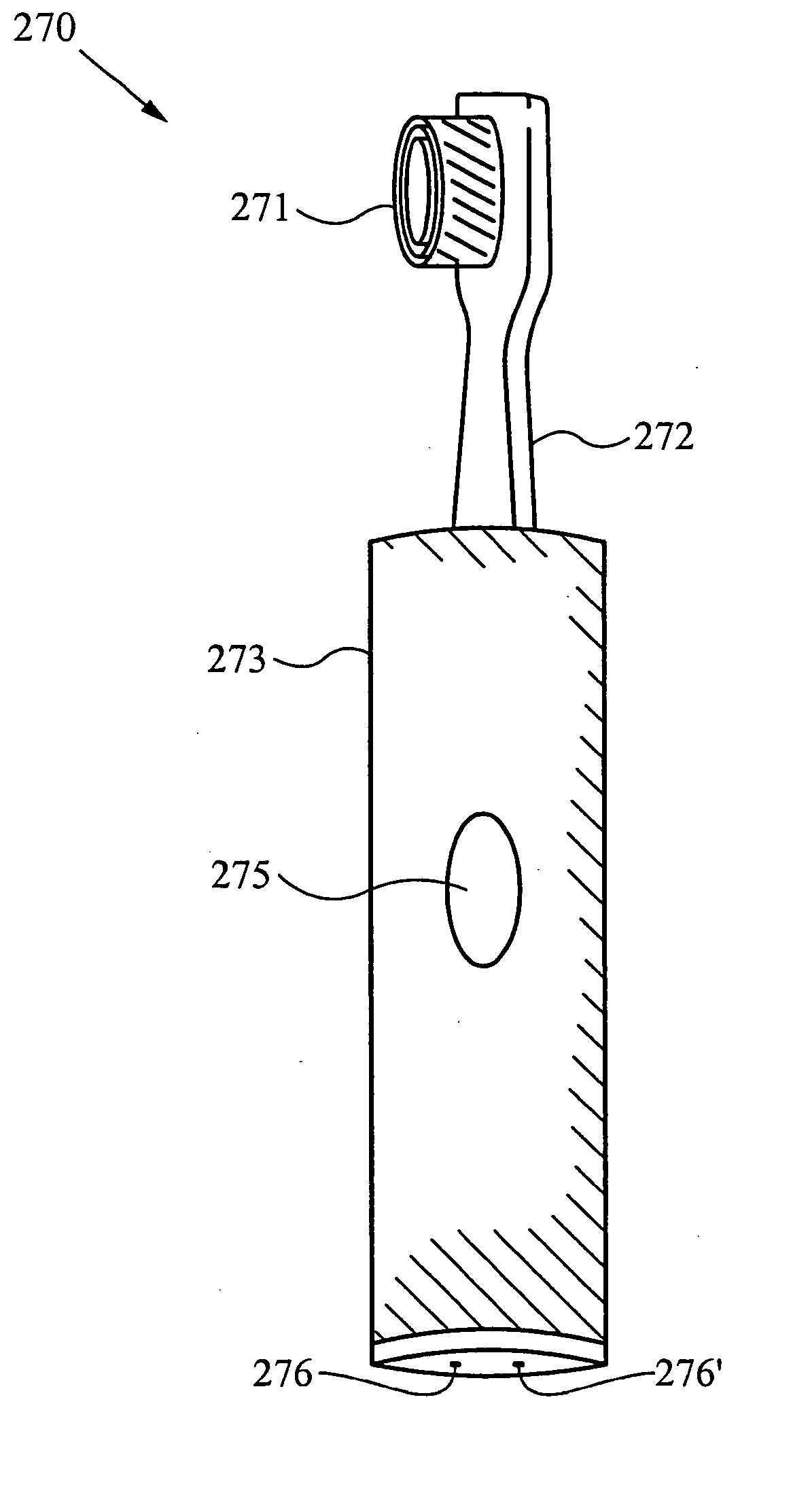

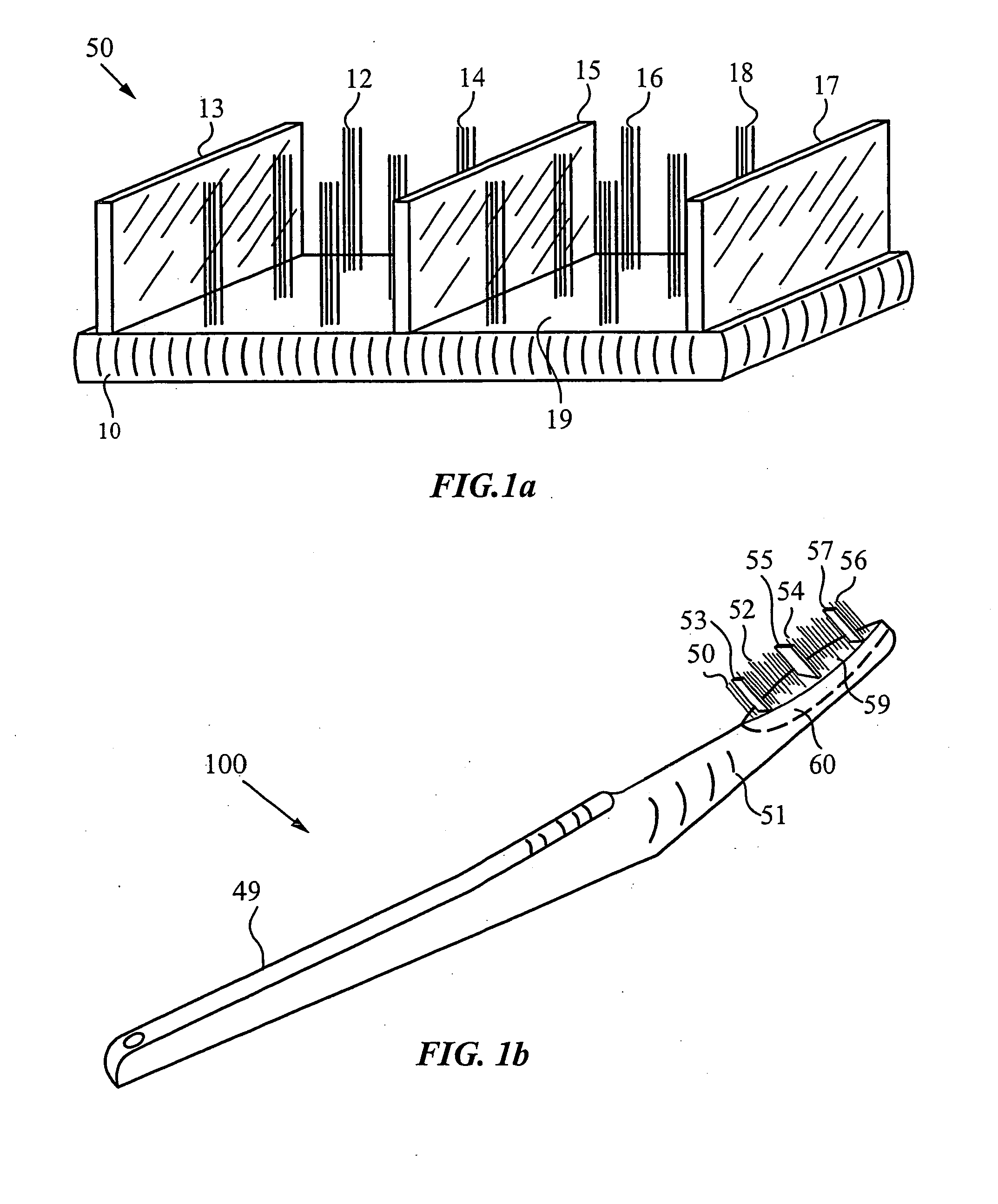

Dentition cleaning device and system

InactiveUS20050066456A1Improve efficiencyLow viscosityCarpet cleanersBrush bodiesBristleWater assisted

A dentition cleaning device and system is disclosed for cleaning teeth, gums and dentures. The dentition cleaning device utilizes squeegees that protrude from a cleaning head to provide efficient contact of dentition surfaces during cleaning. The dentition cleaning device is particularly useful for cleaning teeth because the squeegee contact surfaces and remove residues, such as plaque, without causing significant abrasion to surrounding gum tissue which can lead to gum recession. The dentition cleaning device can be configured with bristle sections or with squeegees that are configured to retain water in squeegee channels. The dentition cleaning device is adaptable to water assisted tooth cleaning system and motorized electric teeth cleaning systems. The dentition cleaning device is also particularly useful to be used in conjunction with a low viscosity tooth cleaner that is capable of being delivered through a conventional pump dispenser.

Owner:GAVNEY JR JAMES A

Water Assist Injection Moulded Structural Members

A method of forming members of fiber reinforced thermoplastic members via molding, the members including at least one hollow chamber, formed by water injection into the melt in the mold, to stiffen the finished member. The thermoplastic is preferably selected from a group comprising polypropylene, Nylon, PET, ABS, TPO, and thermoplastic polyurethane, while the reinforcing fibers are preferably selected from a group comprising glass, aramid, carbon, and natural fibers. Preferably, the extruded melt is produced such that the average length of the reinforcing fibers is less than four millimeters.

Owner:GRGAC STEVEN +3

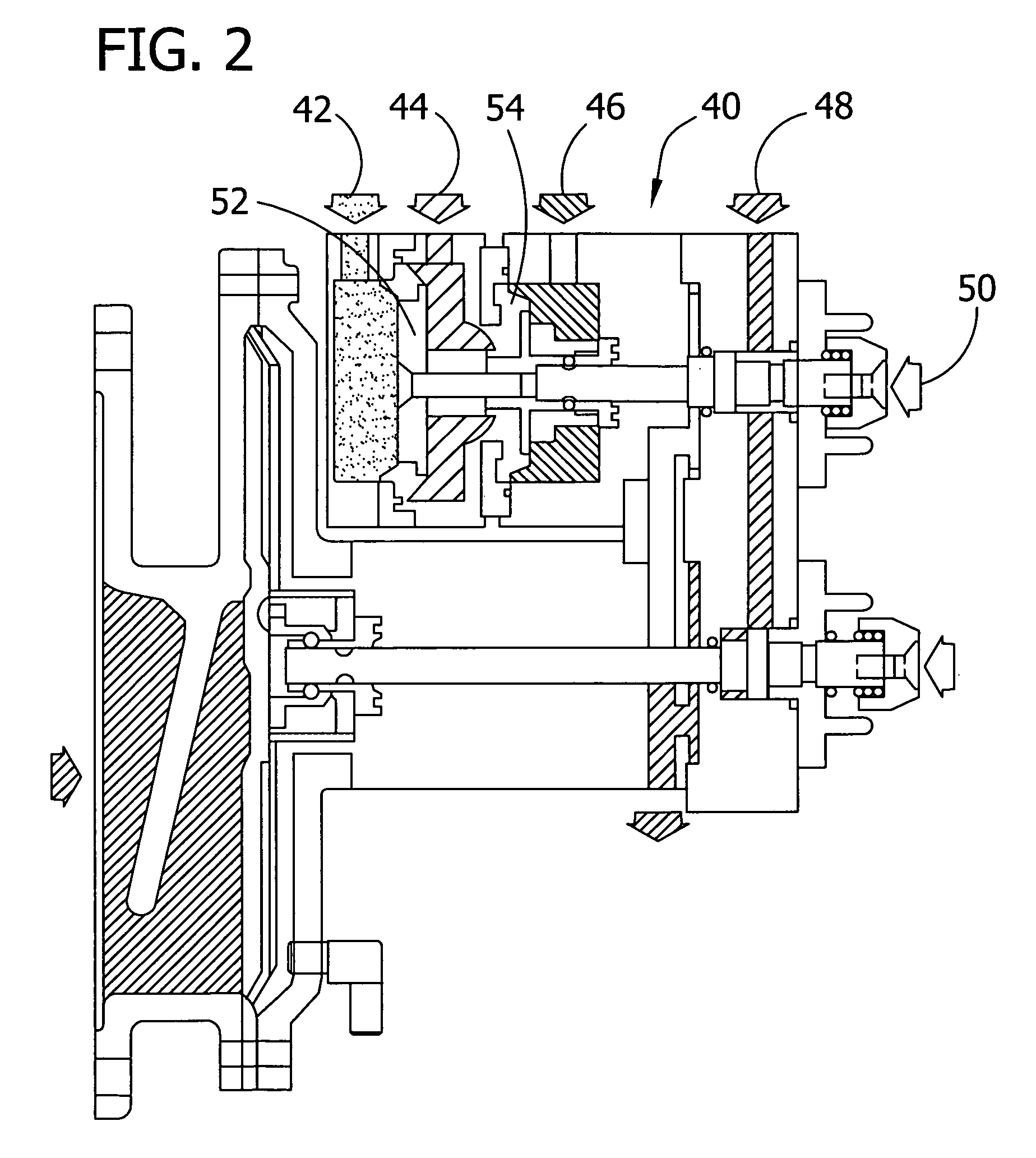

Automobile water-assisted engine

ActiveCN103982337ASimple structureReasonable designNon-fuel substance addition to fuelInternal combustion piston enginesHydrogenElectrolysis

The invention discloses an automobile water-assisted engine. The automobile water-assisted engine comprises a water electrolysis reactor for water electrolysis and a kettle for collecting and conveying oxygen and hydrogen generated by the water electrolysis reactor to a vehicle engine, wherein the water electrolysis reactor is provided with a reactor water inlet and a reactor gas outlet, the kettle is provided with a kettle gas inlet, a kettle gas outlet, a kettle water inlet and a kettle water outlet, the kettle water outlet and the reactor water inlet are connected through a water conveying pipe, and the reactor gas outlet and the kettle gas inlet are connected through a water communication pipe. The automobile water-assisted engine is simple in structure, reasonable in design, convenient to install and arranged, easy to operate and good in usage effects, can effectively improve the power of the vehicle engine and can achieve the fuel saving effects.

Owner:姜明吾 +1

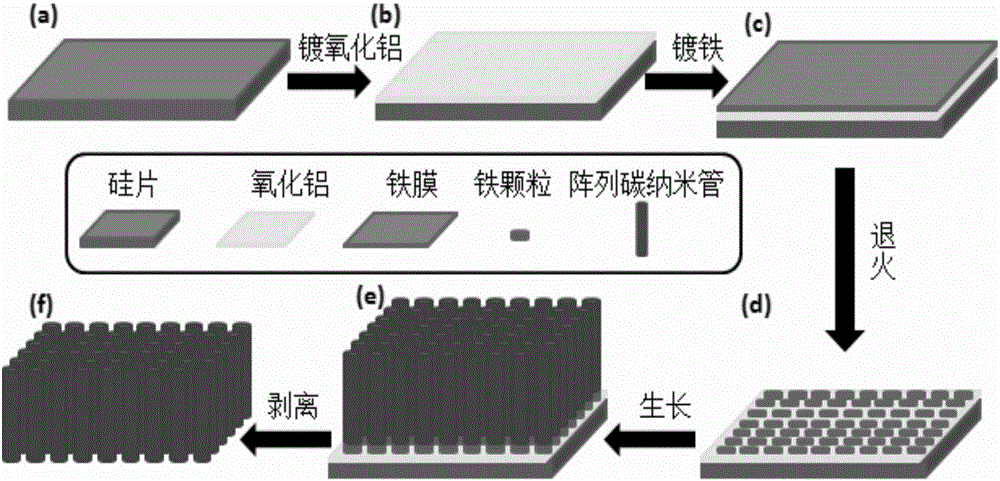

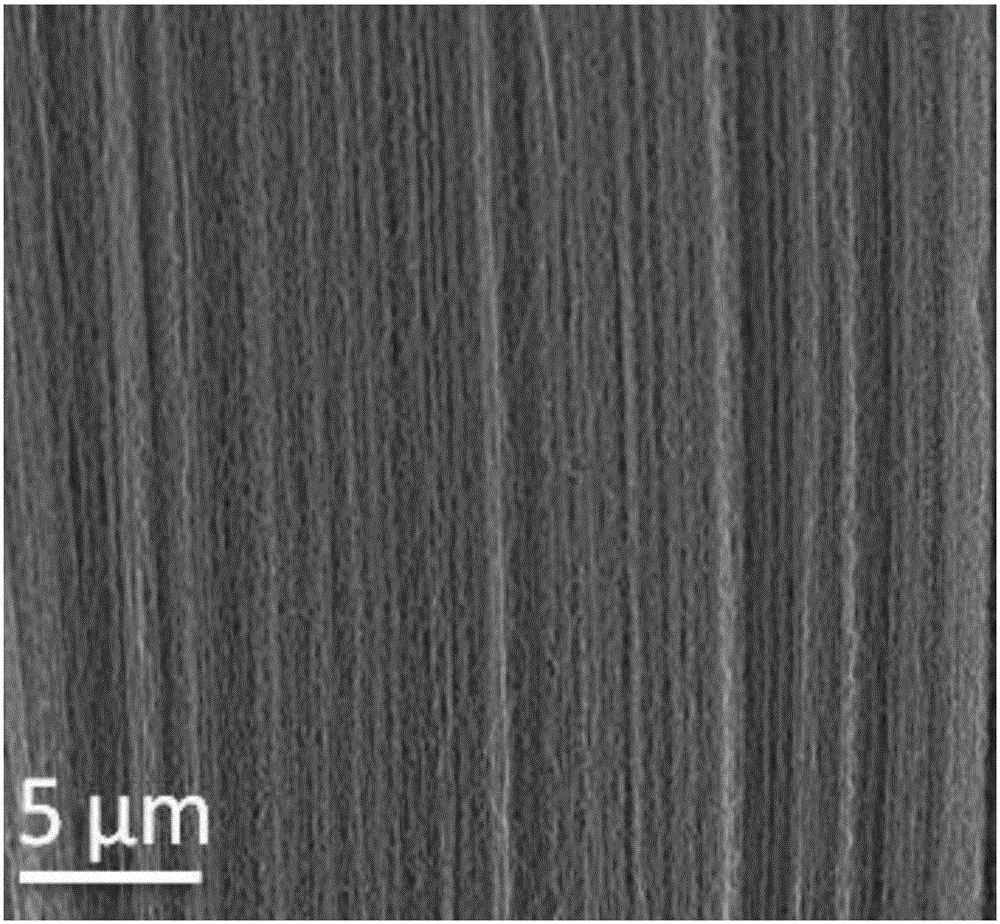

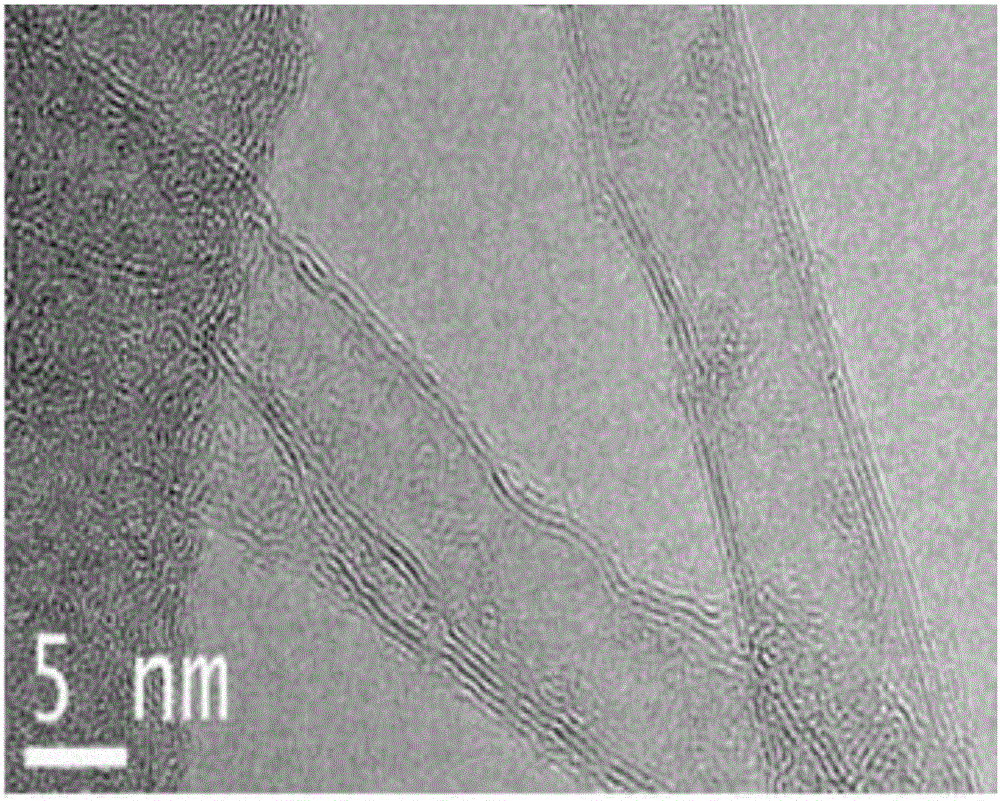

Ultra-high-purity carbon nanotube conductive paste and preparation method thereof

ActiveCN106531287ASimple preparation processImprove adhesionCell electrodesNon-conductive material with dispersed conductive materialWater assistedCarbon nanotube

The invention belongs to the field of preparation and modification of nano materials, and particularly discloses ultra-high-purity carbon nanotube conductive paste. A preparation method of the ultra-high-purity carbon nanotube conductive paste comprises the following steps of firstly depositing an aluminum oxide film on the surface of a silicon wafer and sputtering an iron film on the aluminum oxide film; annealing the silicon wafer to which the iron film is attached and obtaining array carbon nanotubes by using a water-assisted super growth method; and finally stripping the carbon nanotubes and dispersing the carbon nanotubes into a solvent N-methylpyrrolidone by using ultrasonic and ball-mixing dispersion method to obtain the ultra-high-purity carbon nanotube conductive paste. The invention further discloses an application of the ultra-high-purity carbon nanotube conductive paste in a lithium battery. The ultra-high-purity carbon nanotube conductive paste is prepared by optimizing a preparation technology of the carbon nanotube, the acidizing graphitization process before the carbon nanotubes are used is reduced, and the paste has more excellent rate capability and cycling stability when used for a positive electrode of a lithium iron phosphate battery.

Owner:HUAZHONG UNIV OF SCI & TECH +1

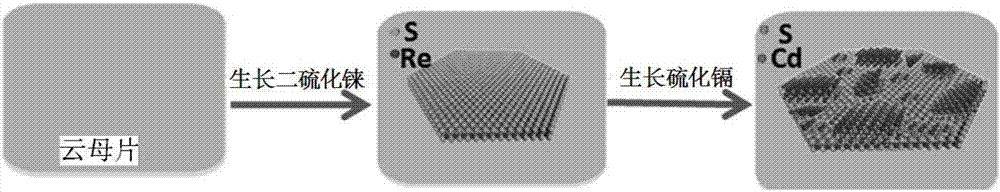

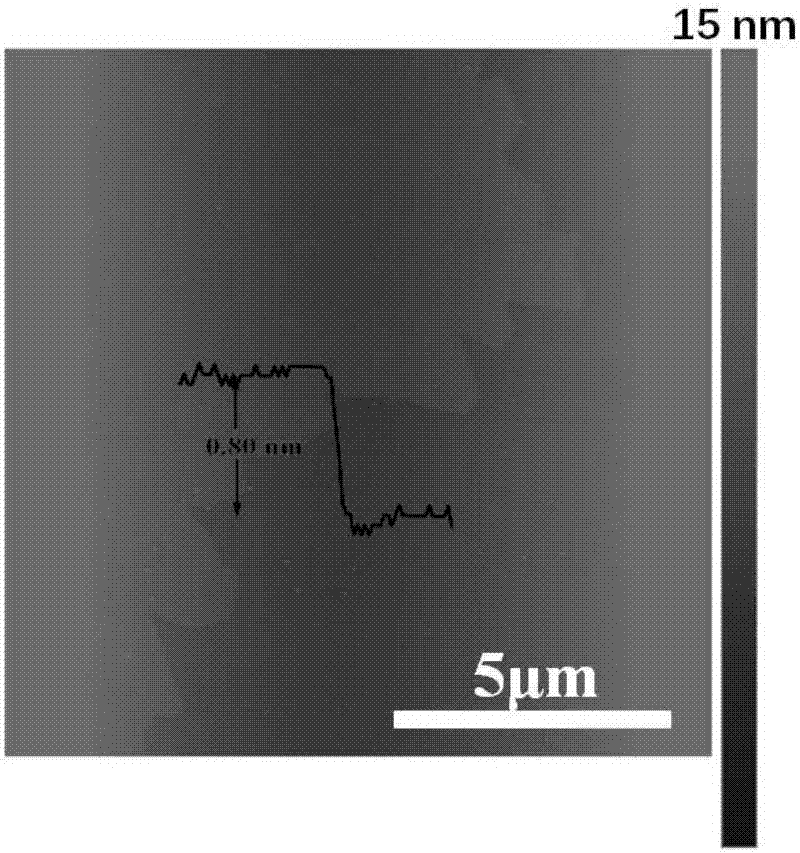

Preparation of rhenium sulfide and cadmium sulfide/rhenium sulfide composite material

ActiveCN108002445AImprove photoresponsivityImprove external quantum efficiencyRhenium compoundsSulfurWater assisted

The invention discloses preparation of rhenium sulfide and a cadmium sulfide / rhenium sulfide composite material. A two-dimensional monolayer rhenium disulfide is grown on a mica sheet substrate through an ordinary pressure chemical vapor deposition method with sulfur powder as a sulfur source and rhenium trioxide as a rhenium source under protection of an inert gas and a water-assisting precondition; by means of a secondary growth method, cadmium sulfide particles are again deposited on the mica sheet substrate with the two-dimensional monolayer rhenium disulfide, and a CdS / ReS2 composite material with the cadmium sulfide particles growing on the surface of the rhenium sulfide is obtained. The preparation of the rhenium sulfide and the cadmium sulfide / rhenium sulfide composite material have the advantages that the process is simple, low-cost, rapid, highly efficient and controllable, and the high-quality single-layer rhenium sulfide is prepared. The CdS / ReS2 composite material obtained by depositing the cadmium sulfide on the two-dimensional material rhenium sulfide has more excellent photoelectric properties and has a high response rate while being applied to a photoelectric device.

Owner:WENZHOU UNIVERSITY

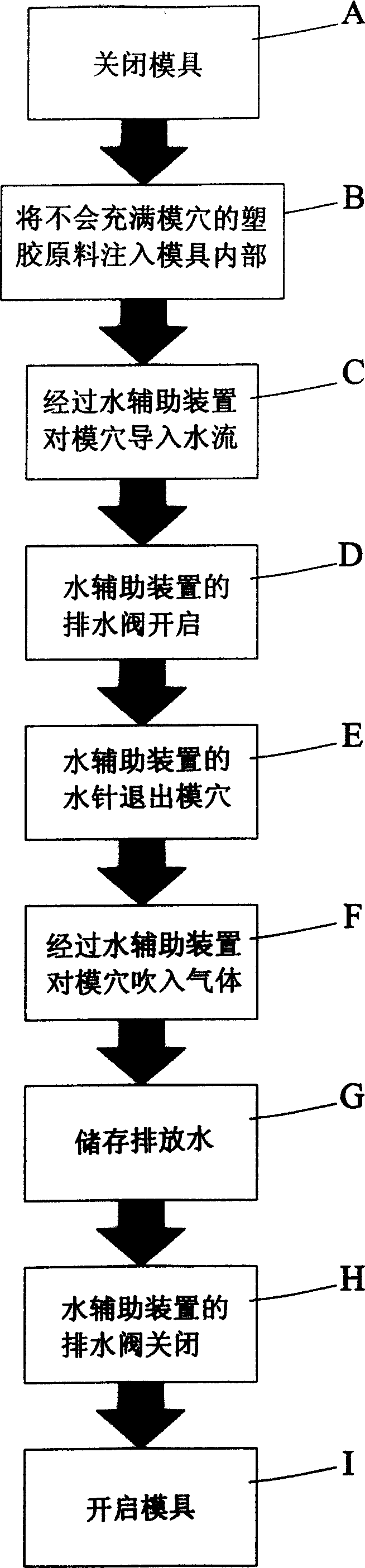

Water assistant jetting and forming method

InactiveCN1565825AReduce the disadvantages of high manufacturing costsReduce the absence of uneven thicknessWater assistedWater flow

The invention relates to a water-assisted injection molding method which includes the following steps: A. closing the mold, B. injecting plastic raw material into the mold, C. guiding water into the mold cavity by water-assisted device, D. opening the drainage valve of water-assisted device, E. the water needle of water-assisted device exiting from mold cavity, F. blowing gas into the mold cavity by water-assisted device, G. storing drainage water, H. closing the drainage valve of water-assisted device, I. opening the mold. By the sequent steps of inside jetting water, blowing, pushing liquid and draining, the plastic product with hollow part can be obtained.

Owner:CHUAN LIH FA MACHINERY WORKS CO LTD

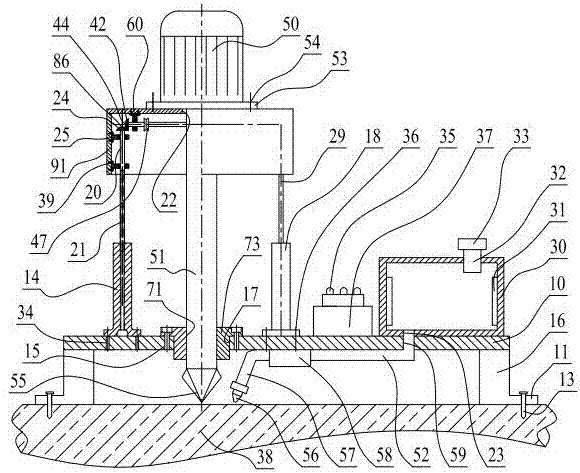

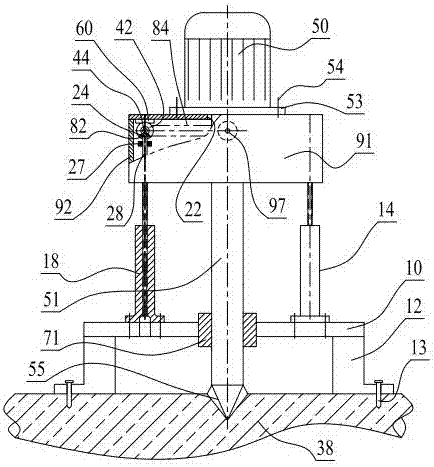

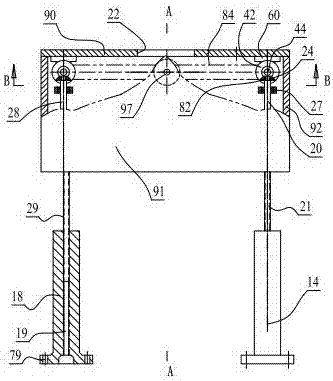

Hot water assisted alloy drill pipe ice breaking equipment

PendingCN107190716AIcebreaker is fastImprove ice breaking abilityWater cleaningMotor driveWater assisted

The invention relates to the technical field of ice-breaking and fishing machinery. The hot-water-assisted alloy drill pipe ice-breaking equipment includes an ice layer fixing device, a preheating device, an ice-breaking device and a four-screw lifting assembly. As an improvement, the ice-breaking device includes: a drilling motor , ice-breaking drill pipe, ice-breaking drill bit, two front pillars and two rear pillars and the four-screw lifting assembly; the two front pillars and two rear pillars jointly support the four-screw lifting assembly; the center of the lifter base plate The position is provided with a substrate through hole, and there are motor fixing screw holes around the substrate through hole; the motor flange is provided on the drilling motor, and the motor flange is fixed on the upper plane of the lifter substrate, and the output shaft of the drilling motor and the icebreaker drill The upper ends of the tubes are connected and fixed by unions, and the ice-breaking drill tube passes through the through-hole of the base plate and the centering inner hole of the bearing bush; the drilling motor drives the ice-breaking drill tube and the ice-breaking drill bit, combined with the adjustment of the nozzle head setting in the preheating device, the speed is accelerated. The ice-breaking speed can effectively improve the ice-breaking ability.

Owner:泉州台商投资区天工机电设计有限公司

Method for preparing glycosylated ordered pore membrane by controllable glycerol polymerization

InactiveCN101555324AControllable Glycosyl DistributionControllable densityBiological testingProtein detectionWater assisted

The invention discloses a method for preparing glycosylated ordered pore membrane by controllable glycerol polymerization; a styrene block copolymer containing hydroxide radicals is used as a base material and a water-assisted method is adopted to prepare the ordered pore membrane; the glycerol polymerization of the surface atom transfer radical is initiated by the surface-initiated atom transfer radical polymerization under the existence of a catalyst to obtain the glycosylated ordered pore membrane. The method for preparing glycosylated ordered pore membrane by controllable glycerol polymerization is characterized by simple method, mild technical condition, low production cost as well as controllable glycosyl distribution and density of the prepared glycosylated ordered pore membrane, and can be applied to the fields of protein detection and cell culture and the like.

Owner:ZHEJIANG UNIV

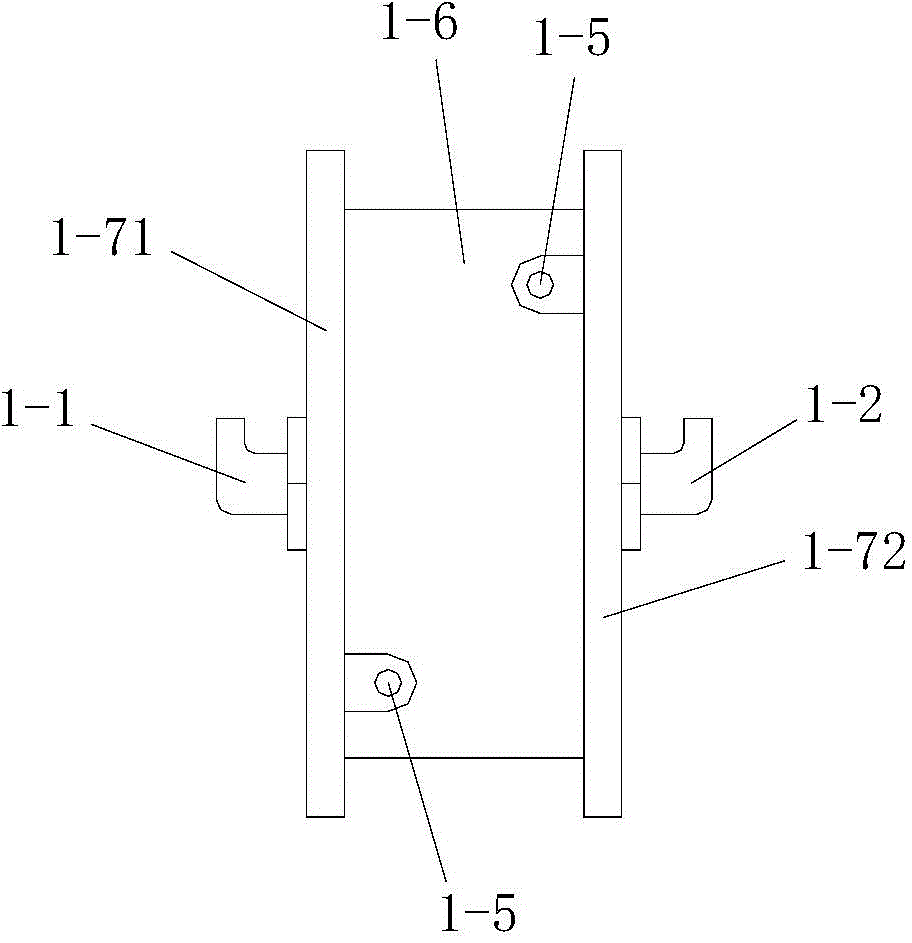

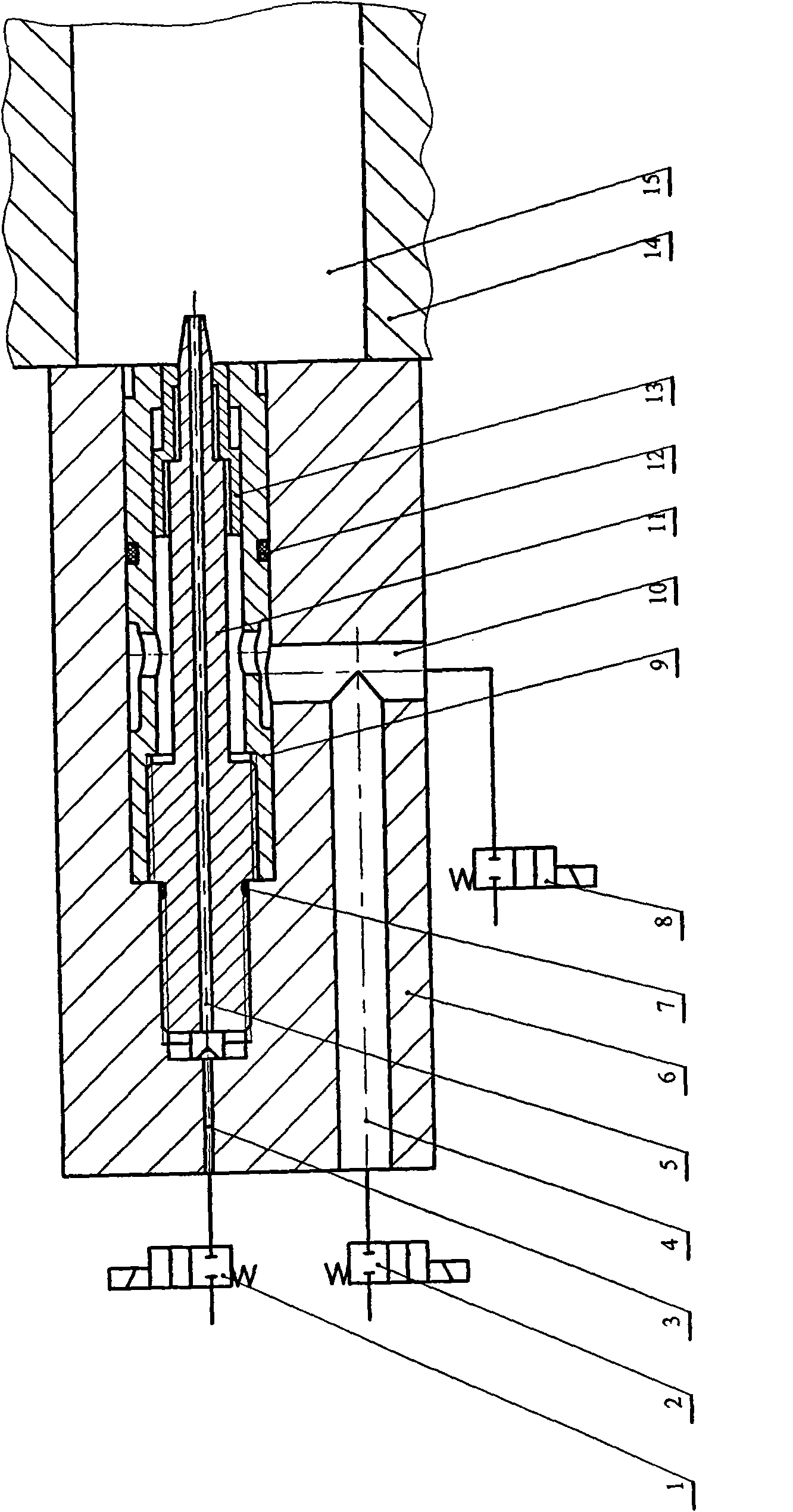

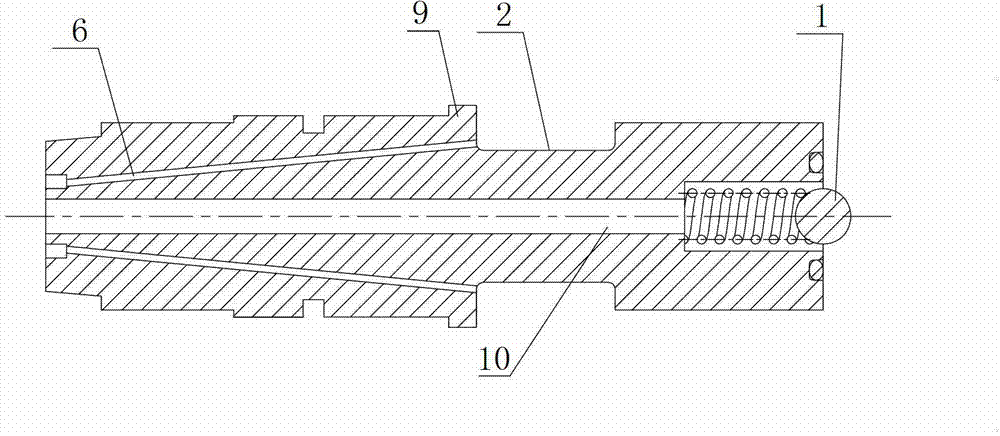

Movable core type squirt cut device applied to water-assisted injection molding

The invention discloses a movable core type squirt cut device applied to water-assisted injection molding, comprising a squirt cut cover, a squirt cut body, a movable core, a gaseous core and a seal element, wherein the squirt cut cover is provided with an inlet opening, an air inlet and a movable core mating hole; the squirt cut body is fixed in the squirt cut cover, the movable core and the gapof a squirt cut body ring form an injection water flow path; the movable core moves to open and close the gap to control on and off of the flow path; the position of the movable core is determined bythe differential pressure of water inlet pressure and pressure in an outlet mould; a through hole is arranged in the squirt cut body, the gaseous core is arranged in the hole; and the gaseous core andthe through hole form a gap passage in a fit clearance manner. The invention can realize a water-assisted injection molding water inlet, air inlet and drainage function. The flow path is automatically switched on and off according to differential pressure of pressure water inlet and pressure in mould cavity to prevent high-temperature fusant in the mould cavity from entering the squirt cut. The squirt cut adjusts the maximum through-flow gap between the movable core and the squirt cut body by adjusting the relative position of the squirt cut body and the squirt cut cover according to different specifications of the mould, thus the squirt cut has adjustable through-flow capability and favourable popularity.

Owner:ZHEJIANG UNIV

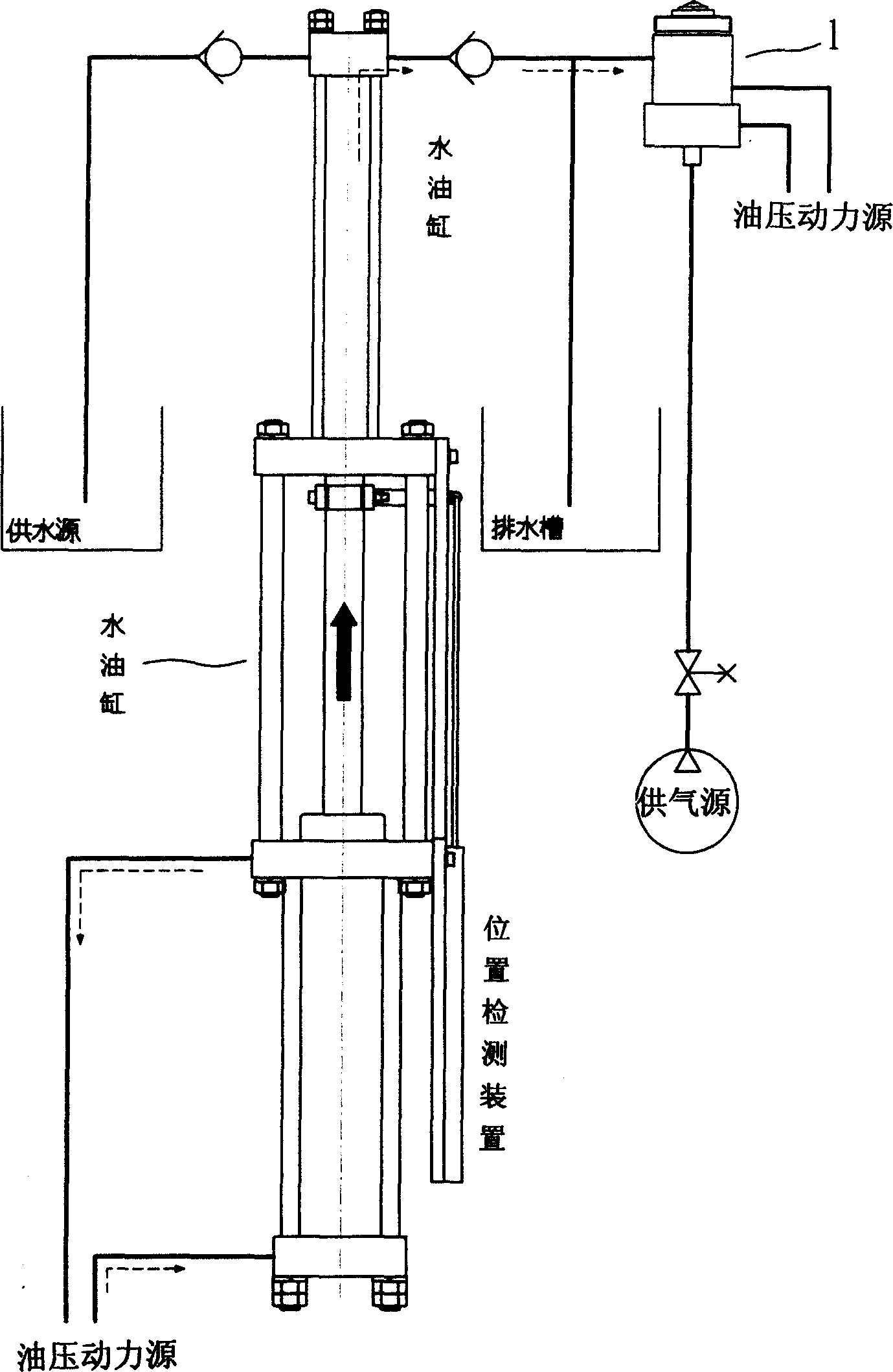

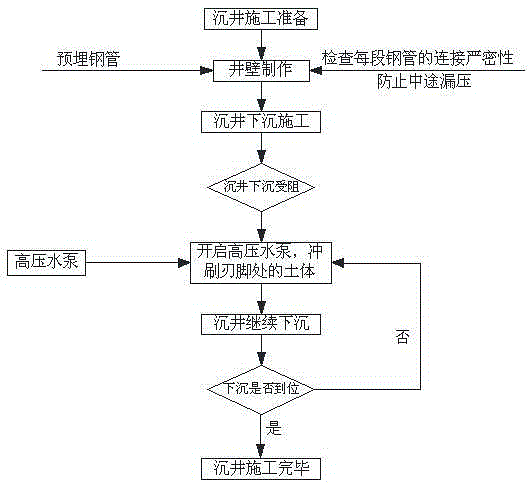

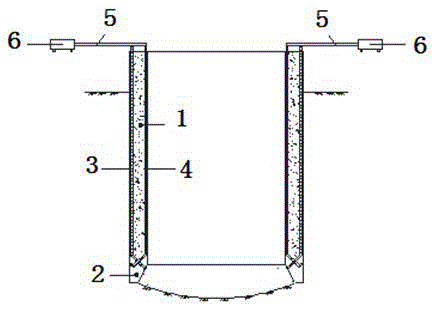

Construction method for assisting in sinking of open caisson through high-pressure water

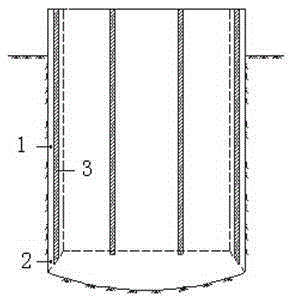

The invention relates to a construction method for assisting in sinking of an open caisson through high-pressure water. The construction method includes the steps that firstly, when the caisson wall of the open caisson is manufactured, steel pipes are pre-arranged on the two sides of the caisson wall and evenly arranged along the caisson wall in the form of extending to blade feet from top to bottom; secondly, if sinking is resisted, high-pressure water is pressed into the upper end openings of all the steel pipes through a high-pressure water pump to destroy the soil mass on the inner sides and the outer sides of the blade feet of the open caisson, and the sinking resistance is reduced; and thirdly, whether the open caisson sinks in place or not is checked, if not, the second step is executed till the open caisson sinks in place. According to the construction method assisting in sinking of the open caisson through high-pressure water, the high-pressure water sinking assists in sinking of the two sides of the blade feet, and the construction efficiency of traditional water-assisting sinking is improved.

Owner:SHANGHAI FOUND ENG GRP

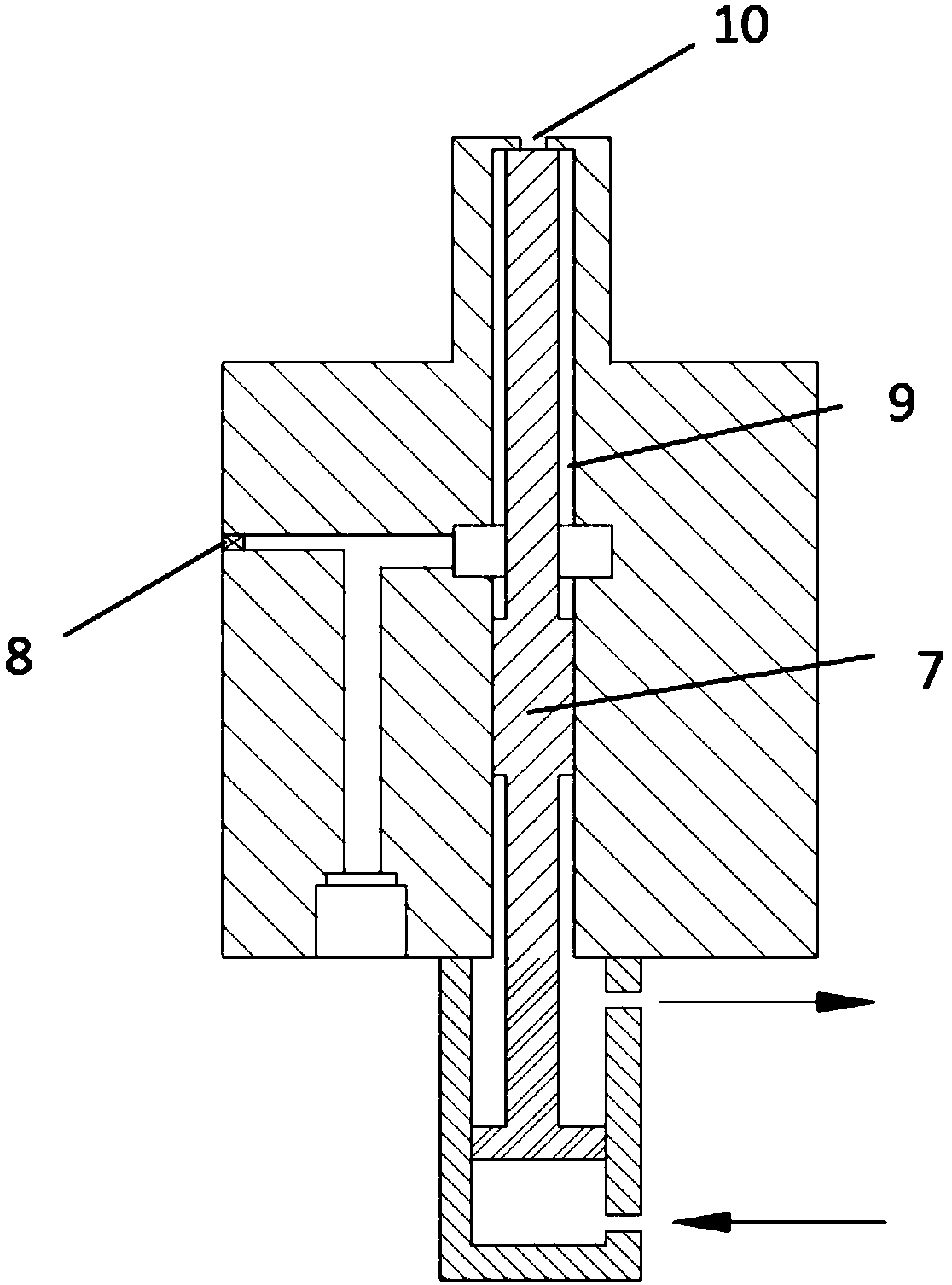

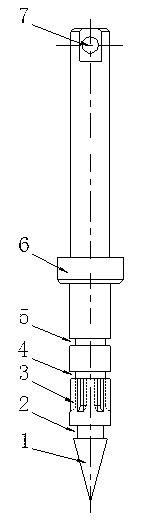

Water needle device for water-assisted injection molding production

The invention discloses a water needle device for water-assisted injection molding production. The water needle device comprises a water needle body, wherein an elastic head device is arranged at the front end of the water needle body, and a water channel is arranged in the water needle body; a water groove is arranged at a water inlet of the water channel; an air channel is arranged in the middle of the water needle body; and a valve is arranged at an air inlet of the air channel. The water needle device provided by the invention has the beneficial effects that the water channel and the air channel are arranged in the water needle body, so that a water-assisted injection molding technology has the advantage of water-assistant injection molding, besides the advantage of an air-assisted formation technology, thus, a finger-type effect caused via a plastic component which is large in volume and thinner in wall and is manufactured via the water-assisted injection molding technology can be effectively avoided.

Owner:NINGBO SUNNY MOLD

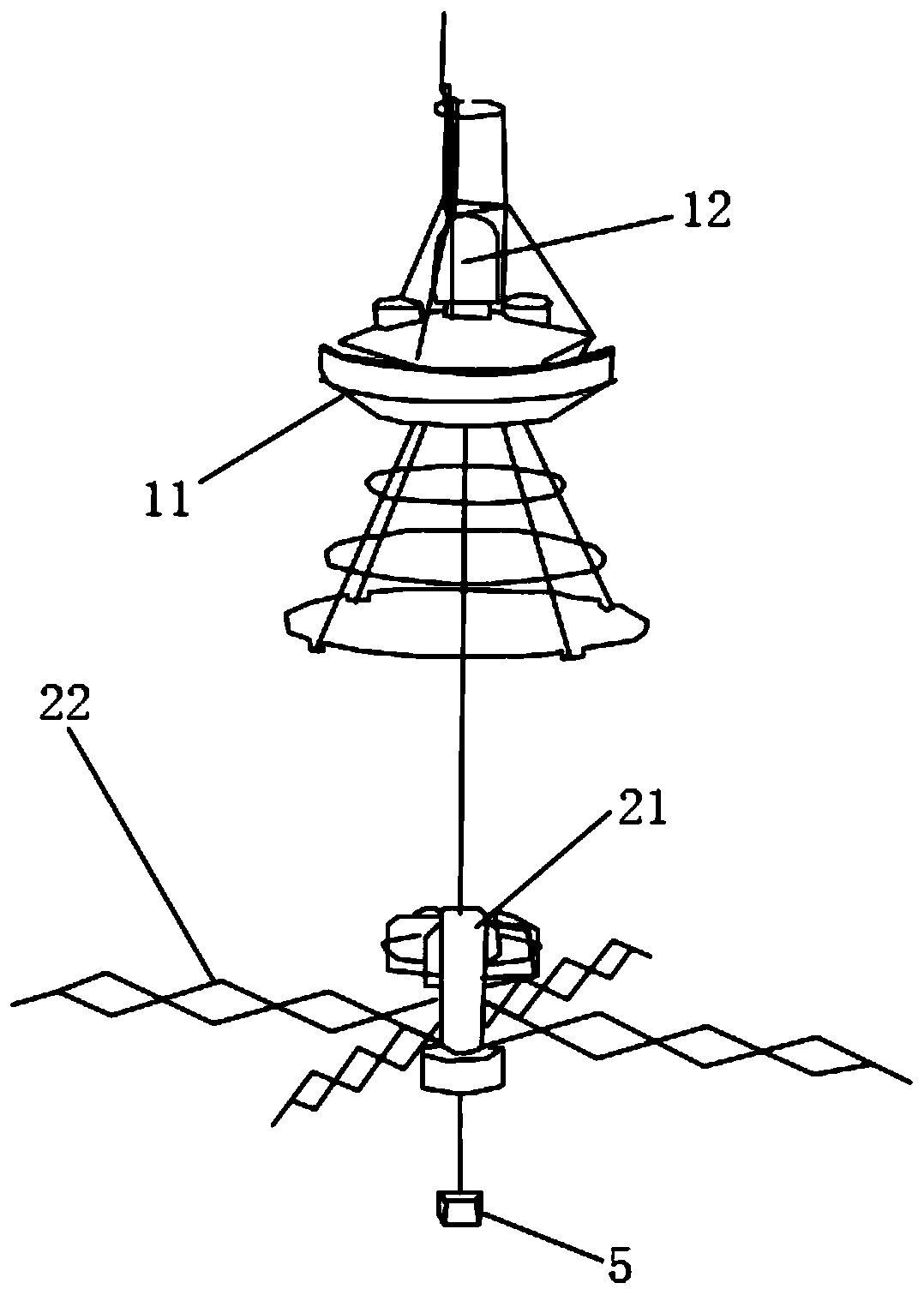

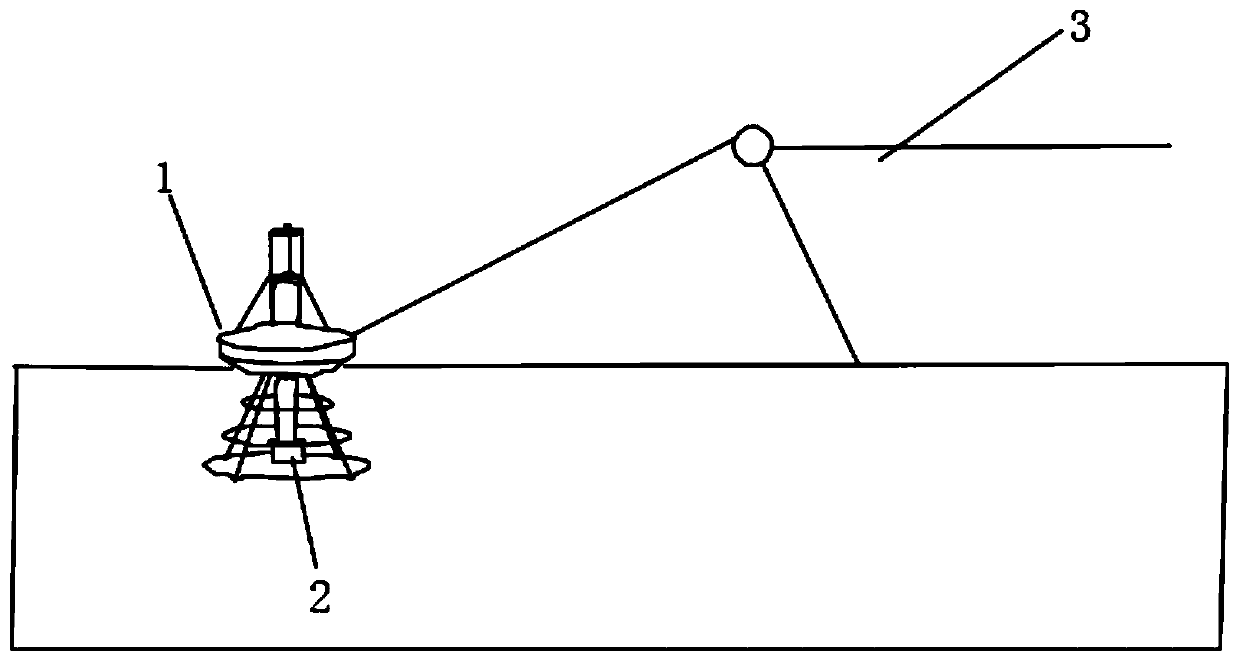

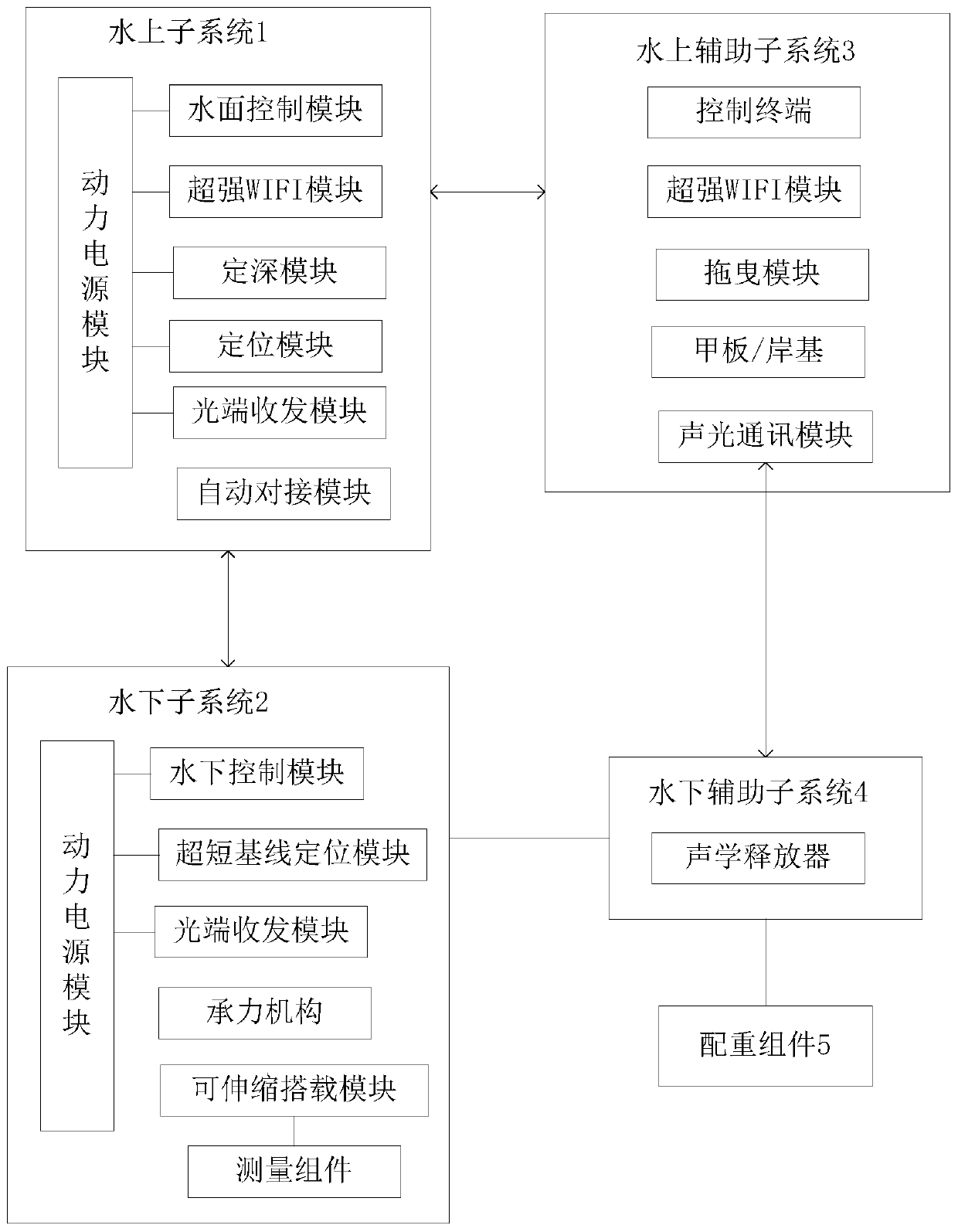

Underwater comprehensive measurement system

PendingCN109969343ASolve the lossThe problem caused by the failure of the solver to recycleWaterborne vesselsOpen water surveyWi-FiWater assisted

An underwater comprehensive measurement system comprises an over-water subsystem, an underwater subsystem and an over-water assisting subsystem, wherein the over-water subsystem communicates with theover-water assisting subsystem through ultra-intense Wi-Fi; the over-water subsystem communicates with the underwater subsystem through photoelectric transmission; the underwater subsystem can be stored inside the over-water subsystem so that the over-water assisting subsystem can integrally deploy and recover the over-water subsystem and the underwater subsystem; after the overall structure of the over-water subsystem and the underwater subsystem is deployed to a preset position, the underwater subsystem is detached from the over-water subsystem to submerge into the water for measurement; andthe over-water subsystem adjusts the submerging depth of the underwater subsystem in real time so that the underwater subsystem can submerge into a preset submerging depth. Since the over-water subsystem can adjust the submerging depth and position of the underwater subsystem in real time, and transmit data measured by the underwater subsystem to a measurement and control terminal in real time, the problems of return delay of the data measured by the underwater subsystem and loss or recovery failure of the underwater subsystem are solved.

Owner:CHINA SHIP SCI RES CENT SHANGHAI DIV +1

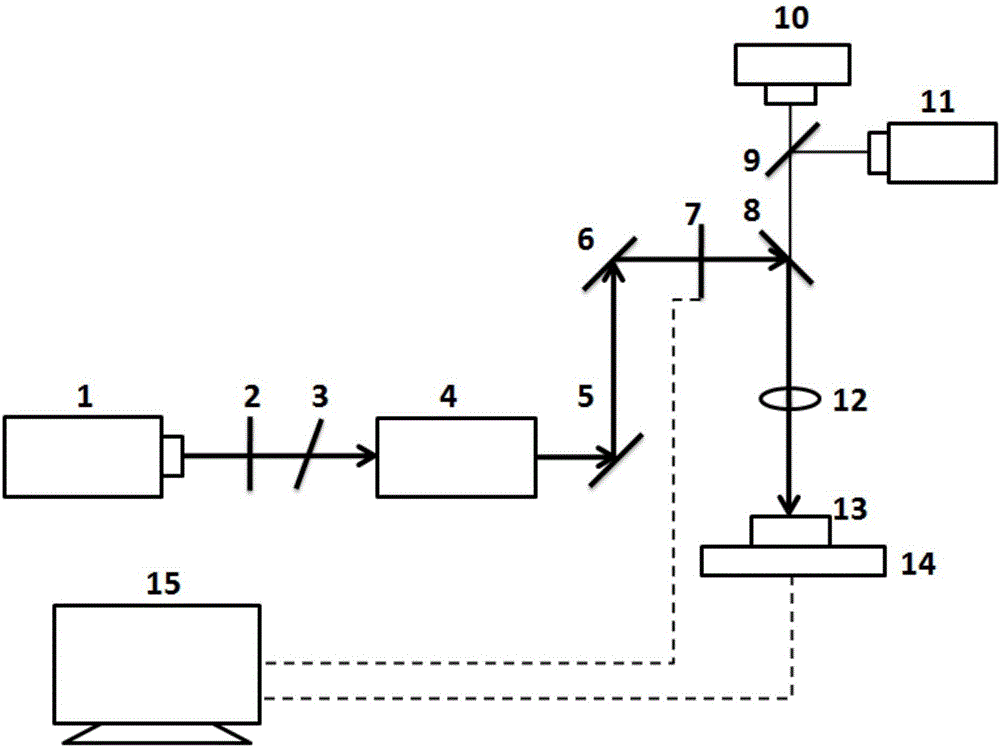

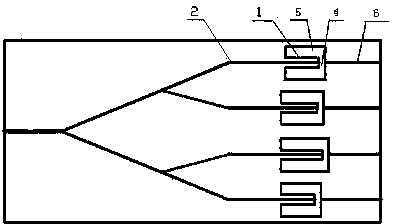

Planar optical waveguide vibrating sensor chip cantilever beam manufacturing method

InactiveCN103954347ADoes not affect etching processIncrease the arrangement densitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansWater assistedWaveguide

Provided is a planar optical waveguide vibrating sensor chip cantilever beam manufacturing method. A water assisting femtosecond laser machining method is used for machining a cantilever beam on a planar optical waveguide splitter chip, a pair of equal-length longitudinal grooves is formed in the two sides of each input splitter optical waveguide strip in parallel in a digging mode respectively, then a bottom gap is formed below a core layer zone where the input splitter optical waveguide is placed in a cutting mode, so that longitudinal grooves in the two sides are communicated in the bottom, then a horizontal groove communicated with the longitudinal grooves in the two sides is formed in the front ends of the longitudinal grooves in the two sides in a digging mode, and the cantilever beam which can vibrate freely is formed in the middle zone defined by the longitudinal grooves, the horizontal groove and the bottom gap. The cantilever beam with large size can be machined, the size of the cantilever beam is at the micron magnitude order or the millimeter magnitude order, and a manufactured planar optical waveguide vibrating sensor chip can respond to high-frequency wave band mechanical vibration and low-frequency wave band mechanical vibration.

Owner:HARBIN INST OF TECH AT WEIHAI

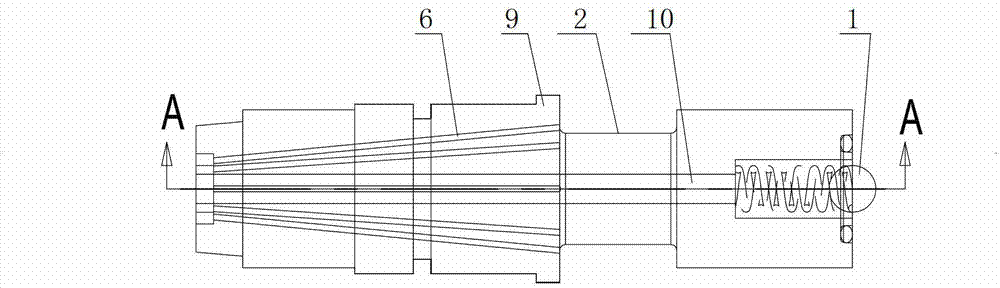

Water needle applied for water shaping production

The invention discloses a water needle applicable to water-assisted molding production, which comprises a needle sleeve, a core rod internally arranged in the needle sleeve, springs, a spacing ring and sealing elements. A water inlet and a water outlet are opened on the needle sleeve, a through hole which supports the middle of the spacing ring is an air inlet, and a slender through hole opened inside the core rod forms a gas passage. The water needle is connected into one end of a die cavity, the core rod and the end portion of the needle sleeve are engaged to seal a passage of water to the die cavity, the core rod opens a water entry or a drainage passage under the driving of the springs and the water intake pressure or gas intake pressure, and the engagement of the end portion and the reasonable size arrangement of the small air hole of the core rod prevent plastic melt inside the die cavity from entering the water needle. The invention realizes the zero leakage of the water and gas through the direct sealing of the needle sleeve and die and the direct sealing of the core rod and the needle sleeve. The invention is capable of fulfilling all the water supply and drainage of water intake, gas intake and water draining which are required in the water-assisted molding technique, and has the advantages of compact and simple structure and easy standardization. The invention used in the water-assisted molding production is a crucial arrangement of water-assisted molding technique.

Owner:ZHEJIANG UNIV

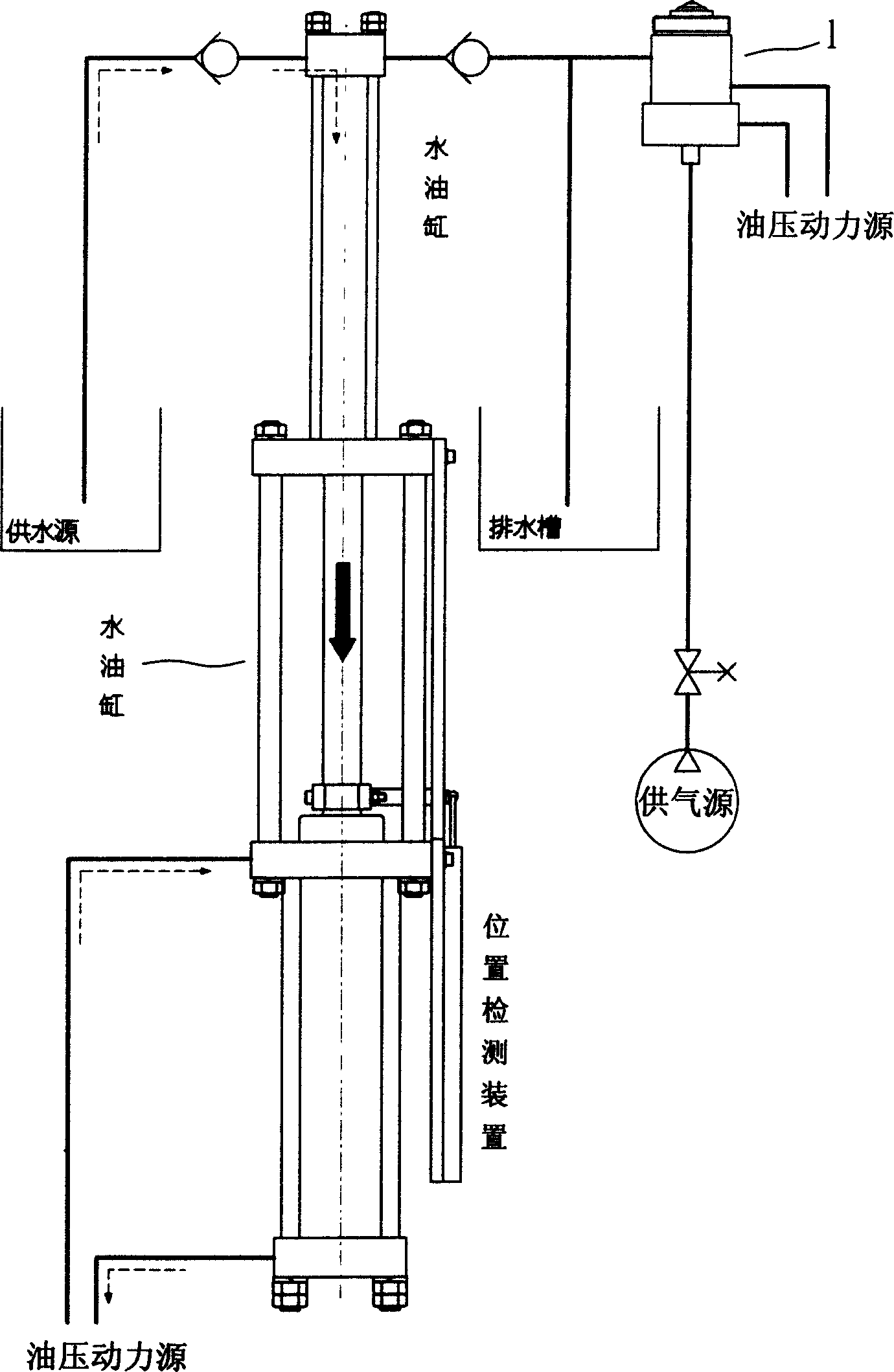

Water-assisted injection-molding injecting device having pressure detection function

The invention discloses a water-assisted injection-molding injecting device having a pressure detection function. The water-assisted injection-molding injecting device comprises a screw injector, a mold and a water needle device; a screw of the screw injector is divided into a feeding section, a compression section and a metering section; the water needle device comprises a water needle core rod and a water needle pedestal; the water needle pedestal is provided with a water charging passage and a water pressure detecting device; a water feeding clearance is formed between the water needle corerod and the water needle pedestal; the water feeding clearance is connected with the water charging passage and a mold cavity; the mold is provided with a pouring gate; a pressure sensor is arrangedat the pouring gate; and the water pressure detecting device and the pressure sensor are connected with the screw injector. The water-assisted injection-molding injecting device disclosed by the invention adopts an injecting device body which has a pressure detection function, is simple in structure and can prevent a high-molecular molten body from blocking a water needle; a screw controller can be used for precisely controlling the returning pressure of the screw, so the character consistency of polymer molten bodies is guaranteed.

Owner:宁波科隆阁机械有限公司

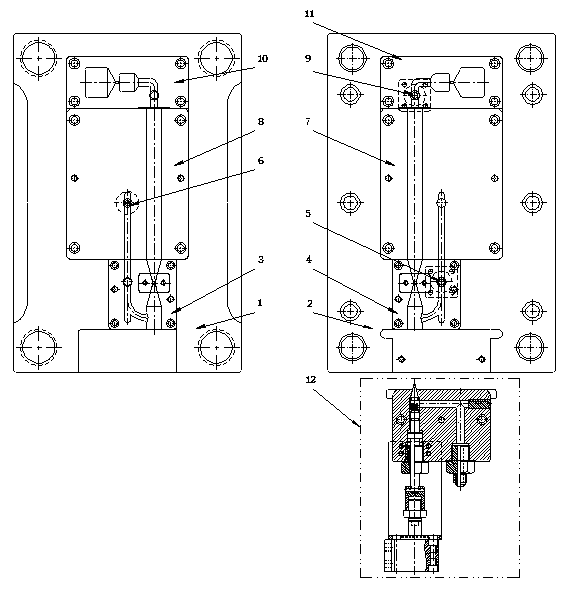

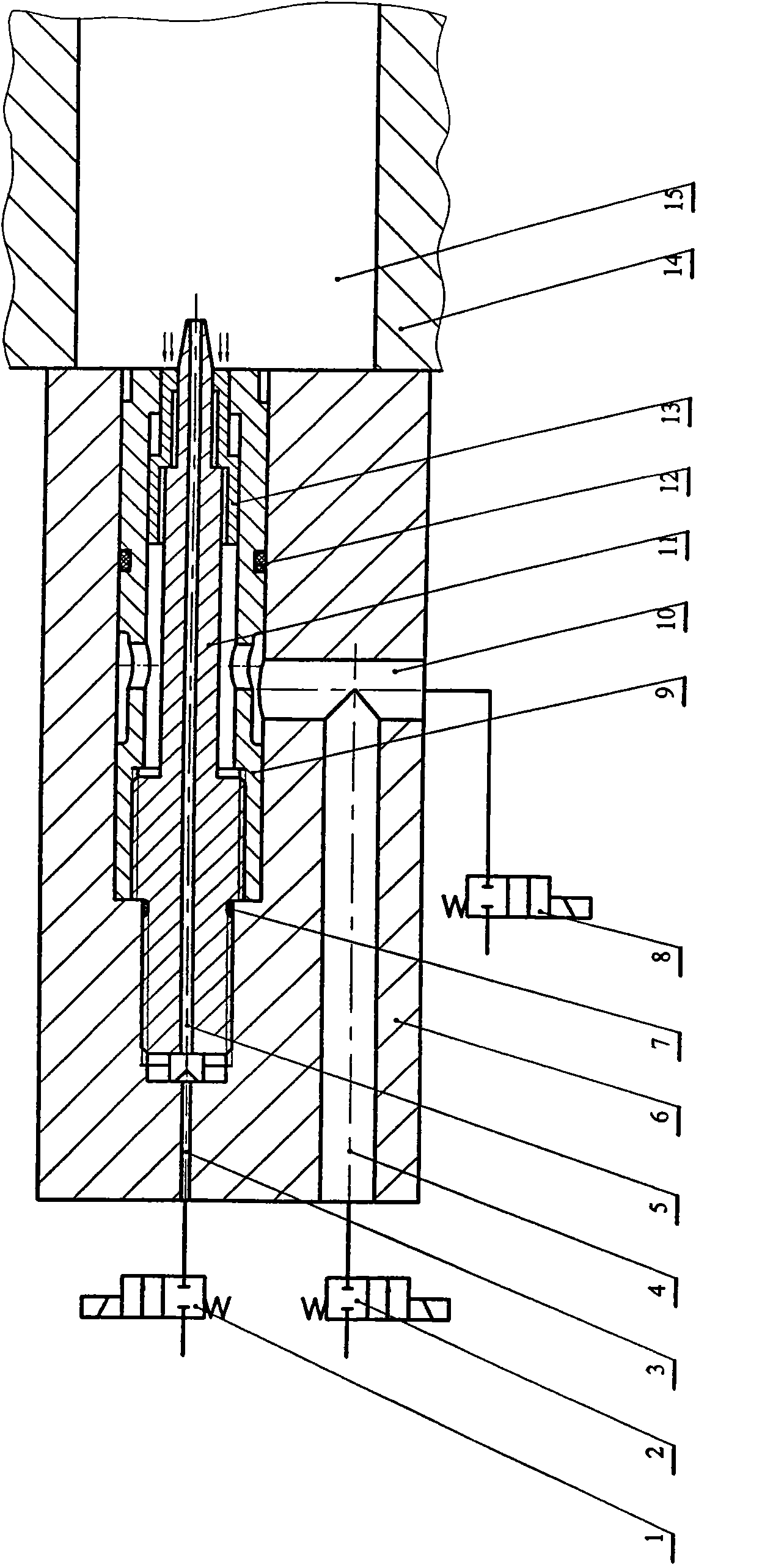

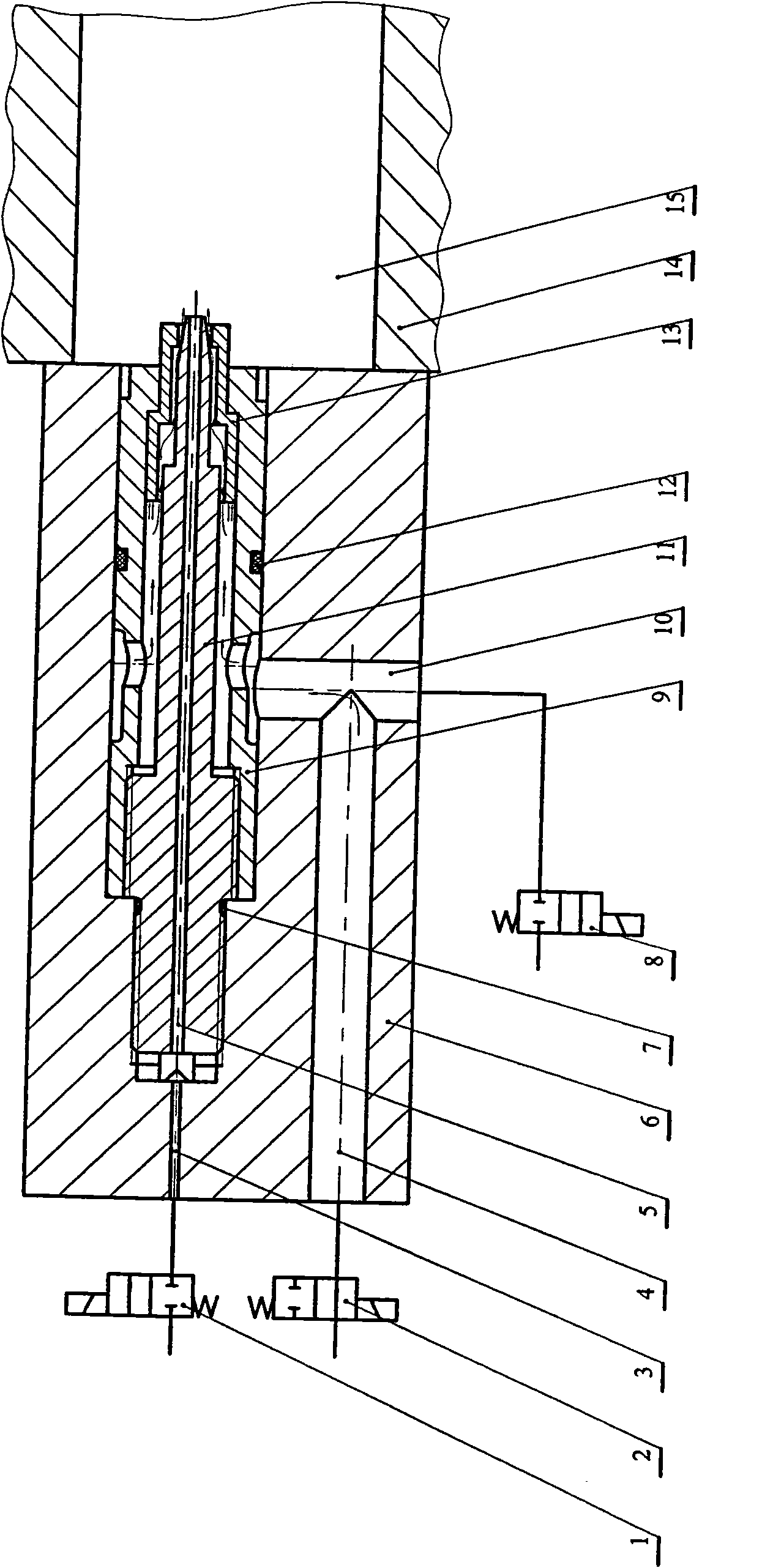

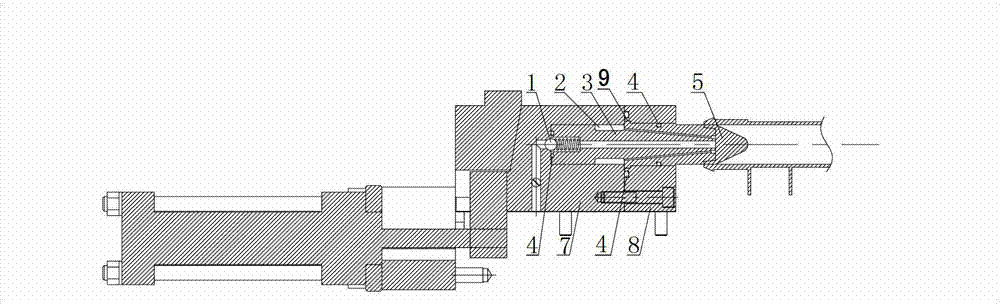

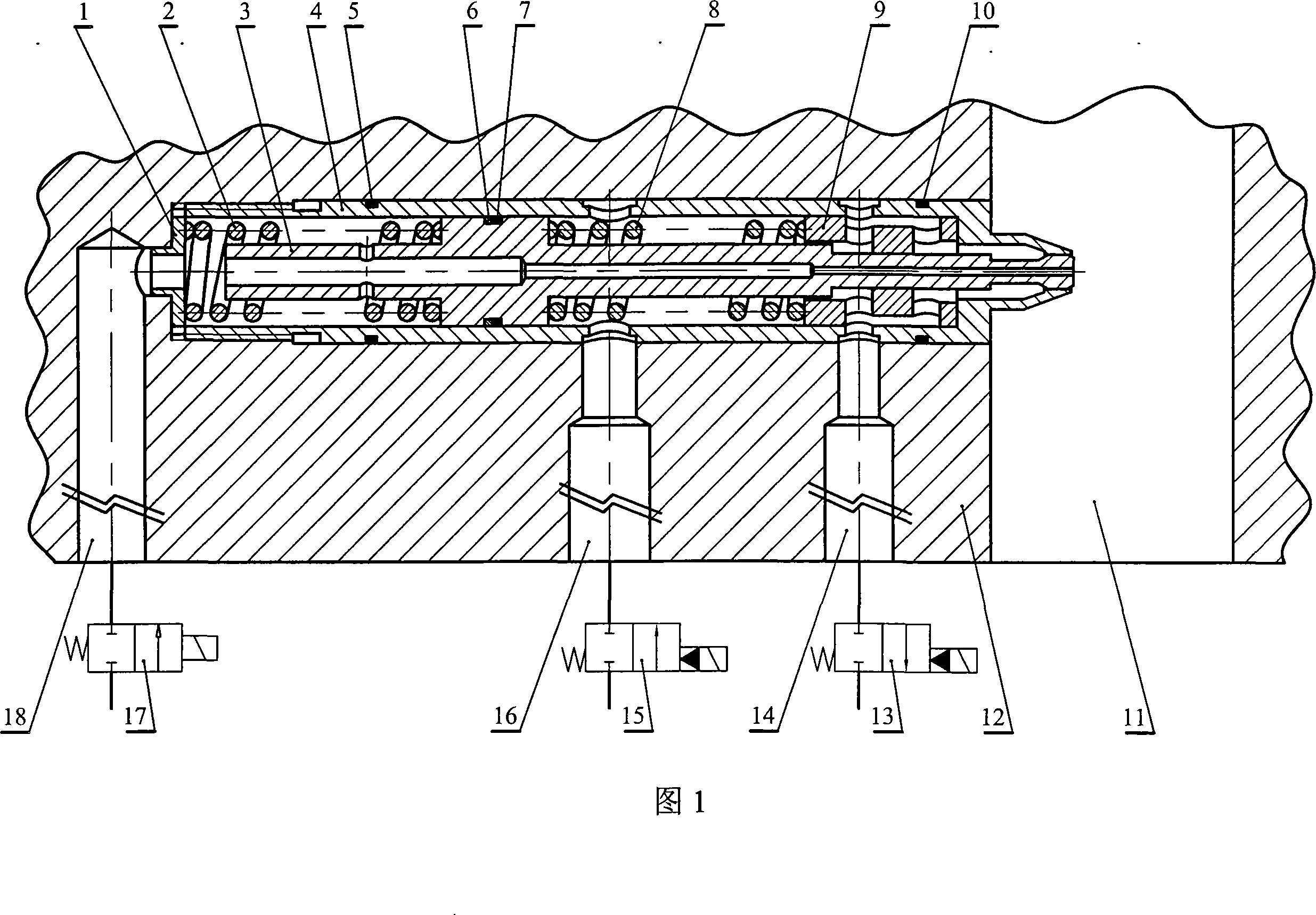

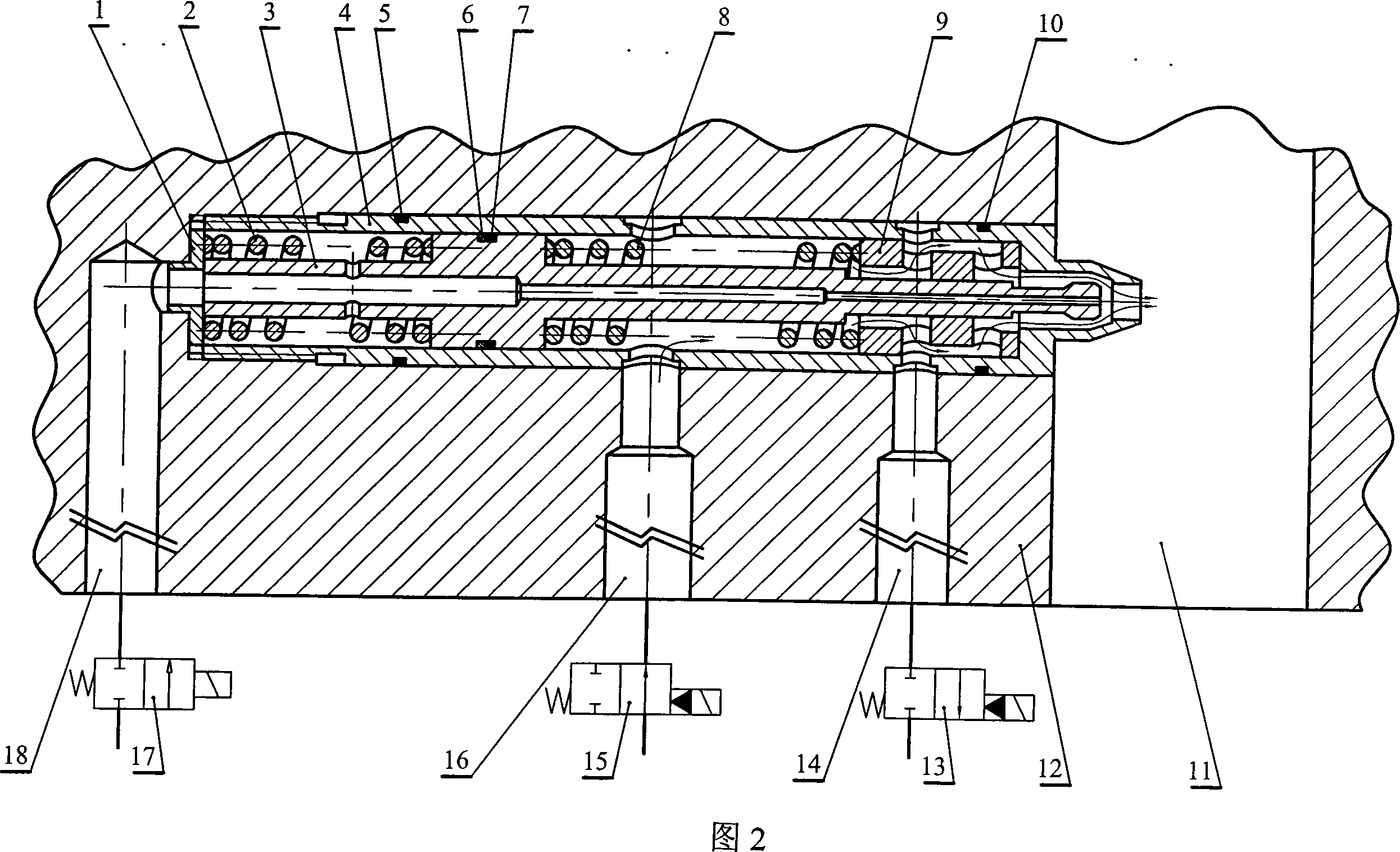

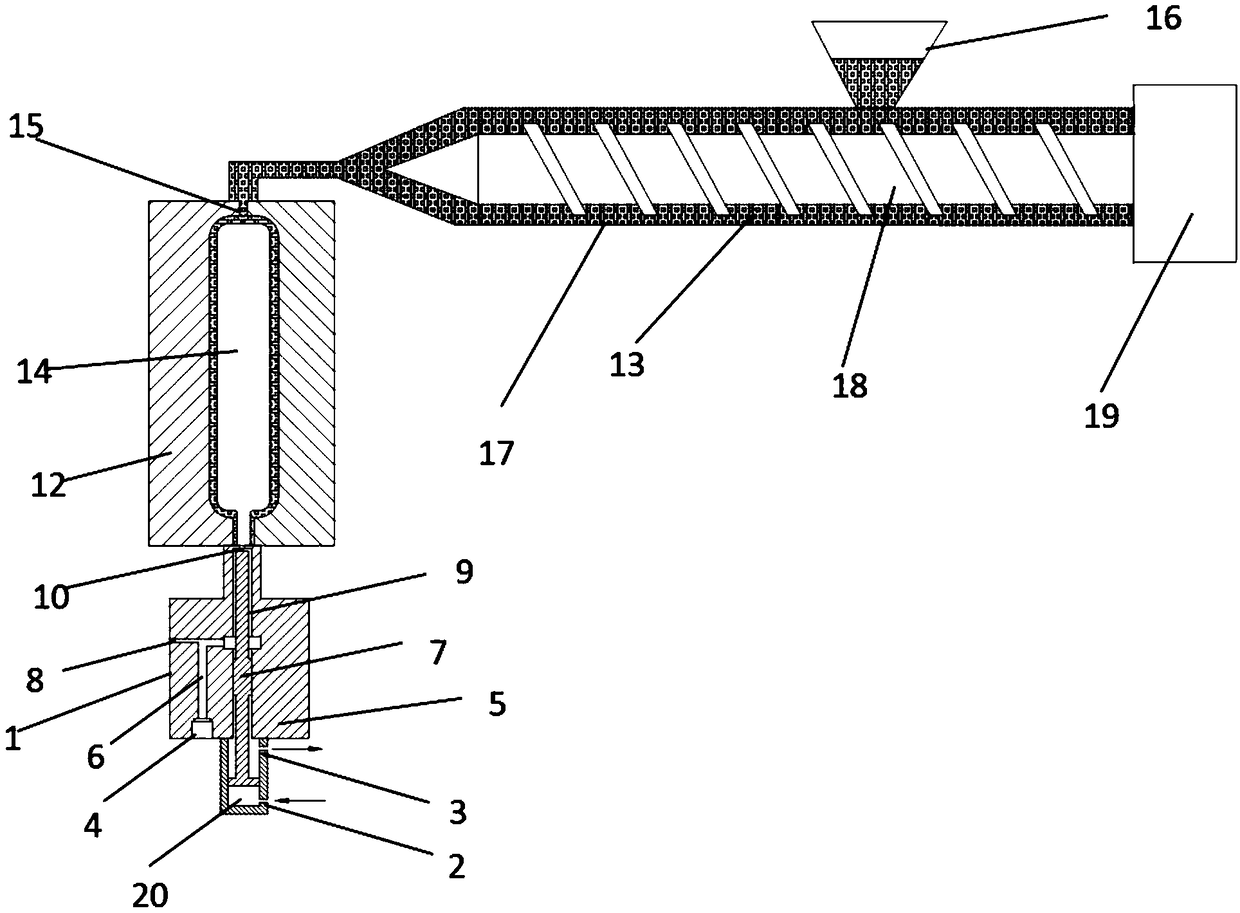

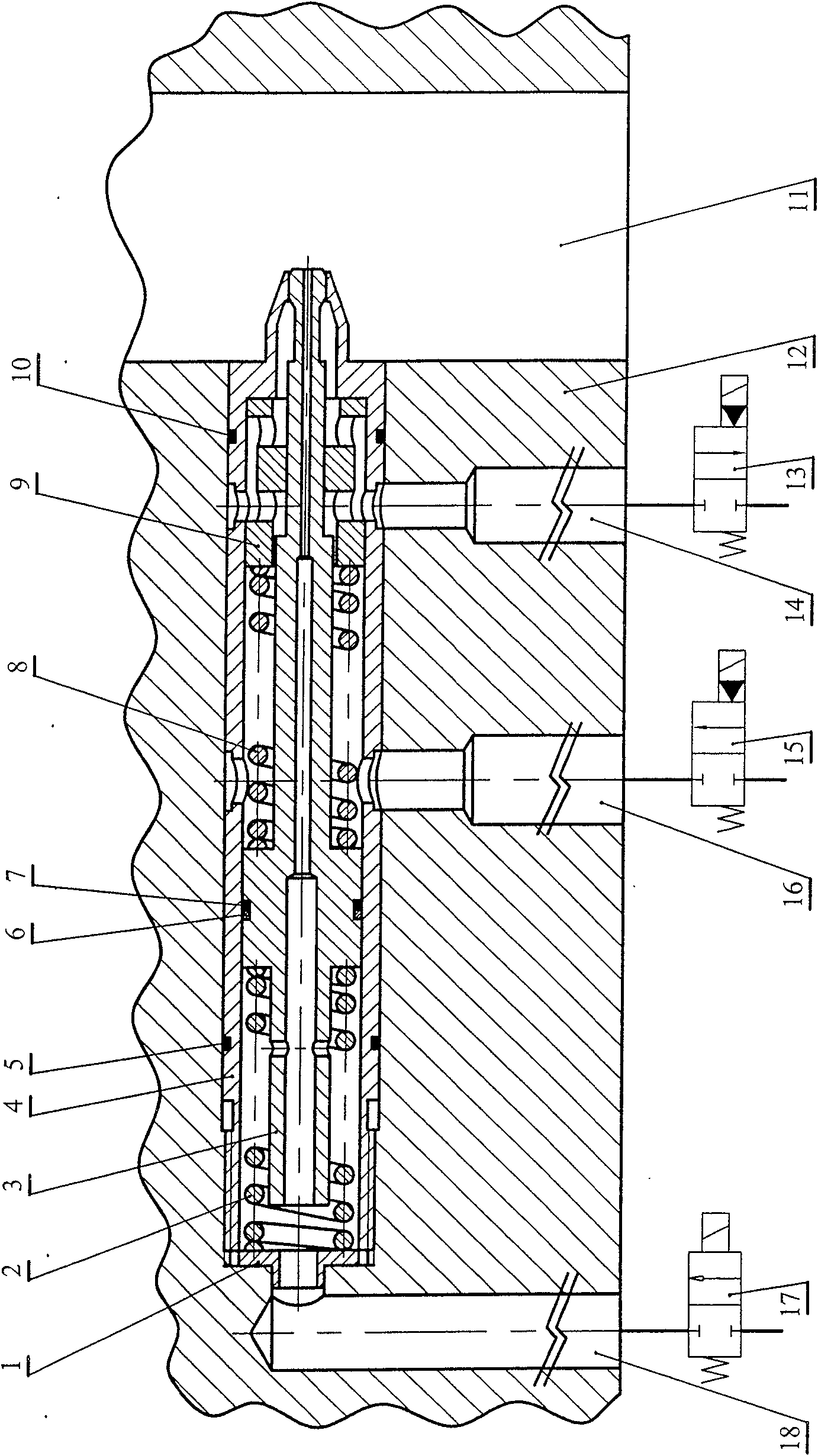

Simple and reliable water injection device for water-assisted injection molding

InactiveCN103307288AGuaranteed sealing performanceSolve rust problemsOperating means/releasing devices for valvesLift valveWater assistedCoupling

The invention discloses a water injection device for water-assisted injection molding, and the water injection device is simple in structure and reliable in action. The water injection device comprises a plug 1, a valve body 2, a seal pad 3, a diameter-variable high-pressure water pipe joint 4, a position-adjustable flange 5, a valve core 6, an SDA thin air cylinder 7, an adjusting nut 8, an air cylinder joint 9, a shaft coupler 10, a shaft coupling pin 11, an air cylinder mounting bracket 12, an O-shaped seal ring 13, a rectangular seal ring 14, a valve body mounting bolt 15, bracket mounting pads 16 and bracket mounting bolts 17. The end surface of the valve core is designed to be conical, so that the phenomena of difficulty for water injection and high-pressure water advancing direction deviation caused by solidification of molten plastics near a water injection hole can be removed and reliable water injection and accurate water injection direction are guaranteed; the conical surfaces of the valve core and the valve body are clung to each other, and various auxiliary seal rings are arranged on the valve core, so that a needle valve is guaranteed to excellently seal up sizing materials and water; an air cylinder is adopted to drive a valve needle to be started / stopped, and the action is reliable; the water injection device is suitable for water-assisted injection molding and similar processes.

Owner:EAST CHINA JIAOTONG UNIVERSITY

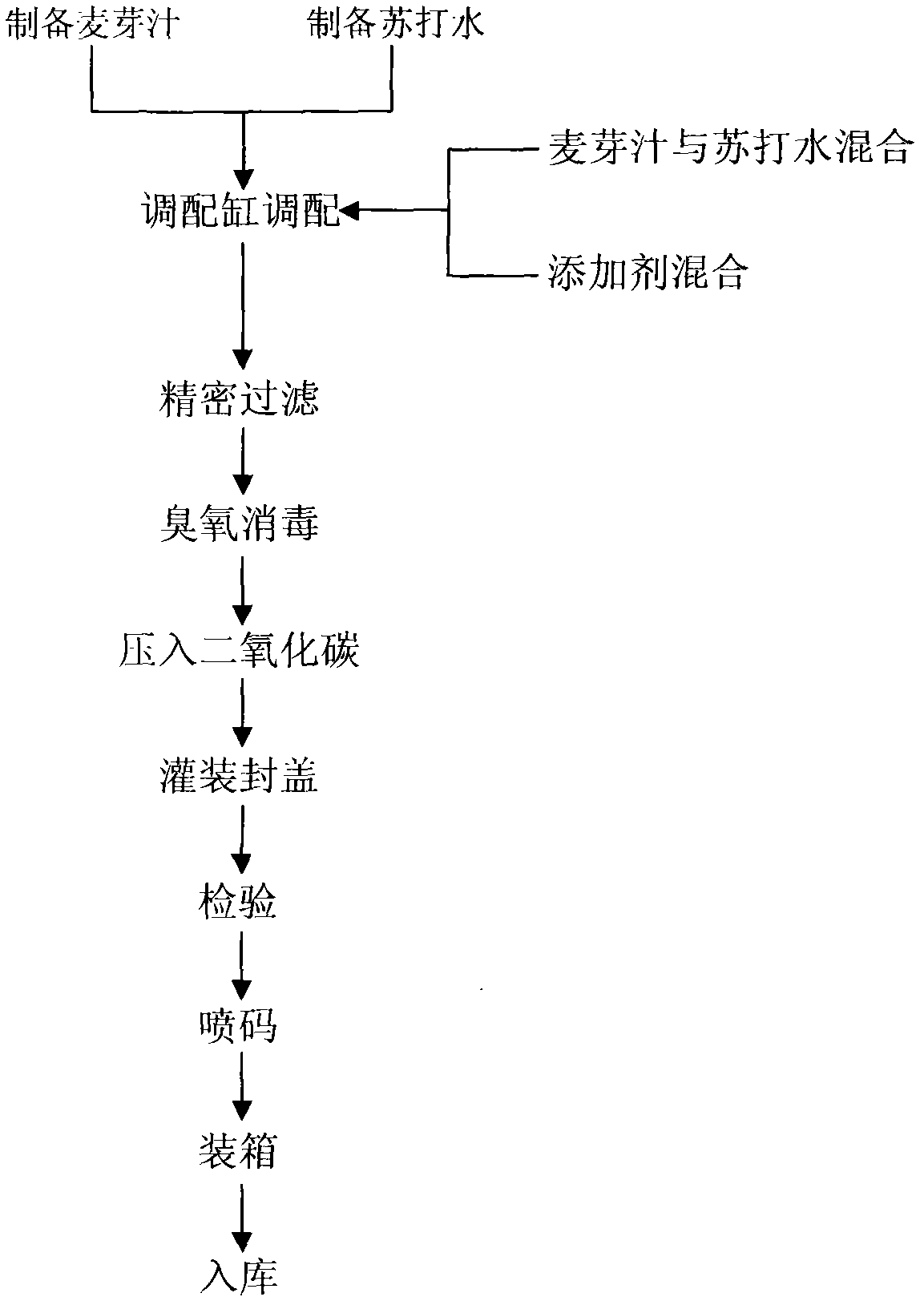

Malt and soda sweet beverage

ActiveCN102232595APreserve health benefitsSolve the disadvantages that it is not easy to produce liquid beveragesFood ingredientsFood preparationWater assistedMalt Flavor

The invention belongs to the technical field of beverage processing, and relates to a malt and soda sweet beverage. The beverage is produced through the steps that: prepared malt wort and soda water are mixed according to certain proportions; additives are added and blended into the mixture according to a certain formula; the mixture is then processed through ozone disinfecting, rough filtrating, and fine filtrating; carbon dioxide is then pressed into the filtrated material, such that the malt and soda carbonated beverage is obtained. According to the invention, malt and soda water with certain health care efficacies are adopted as raw materials. The raw materials are elaborately blended and produced into a novel carbonated beverage through an improved modern technology. The invention provides consumers with a novel carbonated beverage with a refreshing malt flavor and certain health care functions. According to the invention, defects of malt wort and soda water are overcome. A defect in soda water mouthfeel is solved by a refreshing malt wort mouthfeel. Relevant additives are added, such that various flavors are well-blended, and the beverage is refreshing and tasty. Alkalescence of soda water assists in balancing human acidic physiques, and malt assists in promoting digestion. A specification on the figure is that: in Figure 1, processing procedures of the malt and soda sweet beverage is described in detail.

Owner:王春鸣

Locomotive engine restart shutdown override system and method

A system for overriding an EMD locomotive engine protective device which includes a low water pressure sensing device in communication with the engine cooling system for shutting down the engine when low water pressure in the engine is sensed, the override system comprising a water assist pump connected to a source of water and communicating with the protective device for supplying pressurized water to the low water pressure sensing device to maintain relatively high water pressure to prevent the device from shutting down the engine; and a controller for activating the water assist pump during start up of the engine.

Owner:GE GLOBAL SOURCING LLC

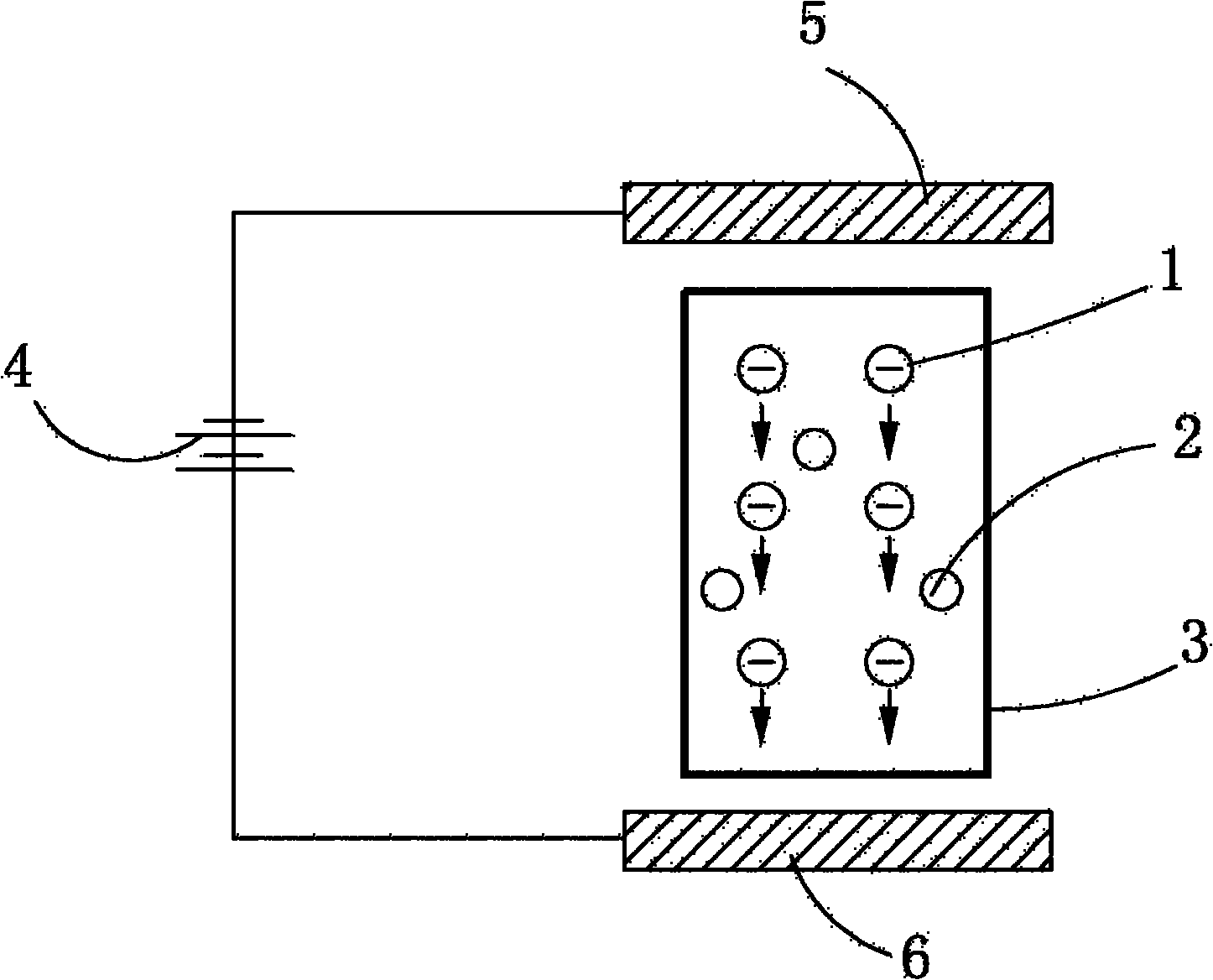

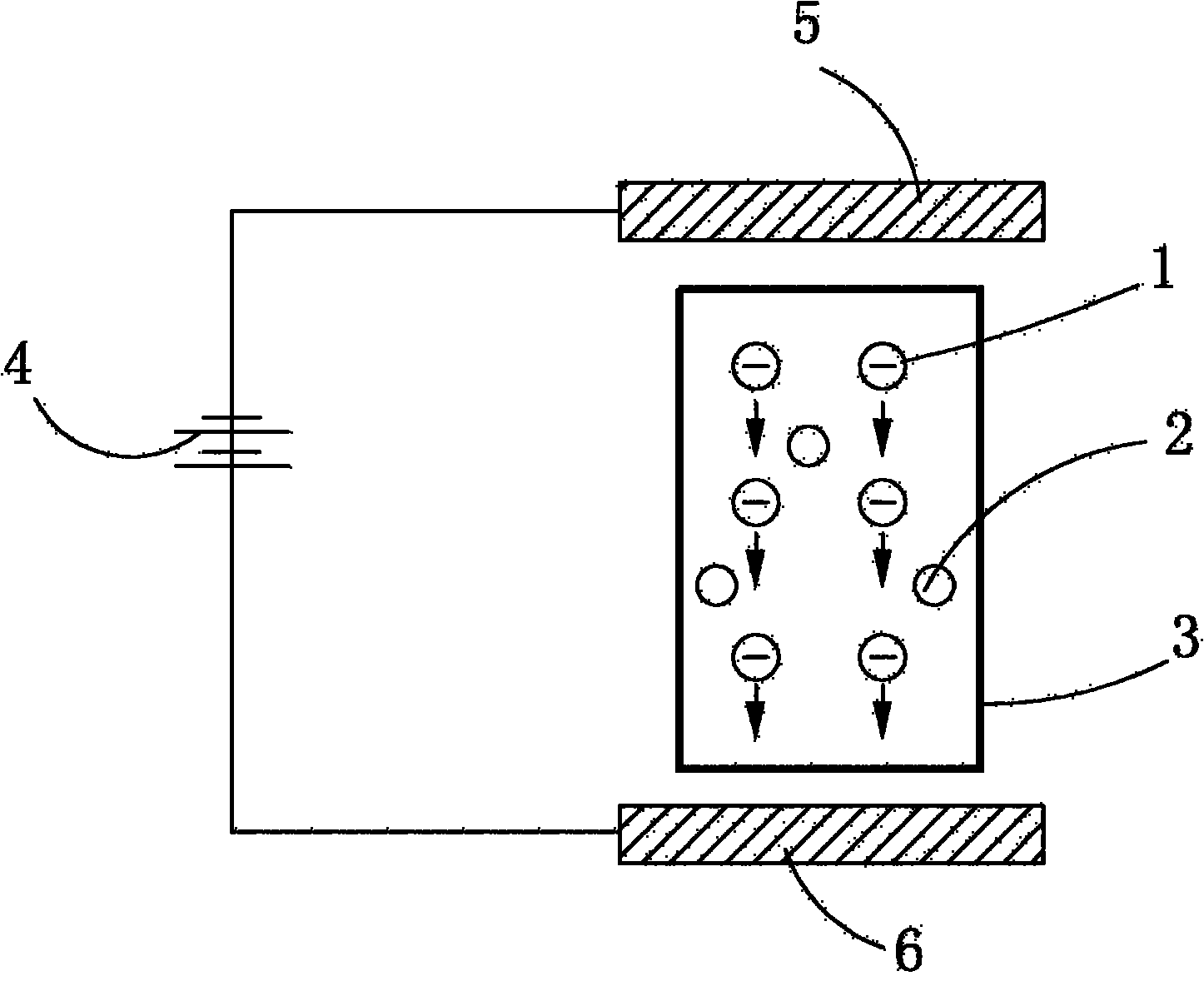

Method for precipitating and clarifying coal slime water assisted by extra electric field

The invention discloses a method for precipitating and clarifying coal slime water assisted by an extra electric field. The method is characterized in that the extra electric field is added to the coal slime water by utilizing negative charges carried in coal slime particles in the coal slime water so that the coal slime particles carrying the negative charges in the coal slime water move towards an anode plate under the action of the extra electric field, thereby achieving the rapid precipitation of the coal slime particles in the coal slime water. By using the method, coal washing with clear water in a coal preparation plant can be achieved, and the dosage of medicament is reduced, thereby facilitating subsequent filtration dehydration treatment, improving circulating water utilization in the coal preparation plant, precluding coal slime water efflux and ore locus environment pollution and reducing loss and waste of coal resources; and compared with the cost by using the prior art, the total cost in the invention can be reduced by 15-50%. The method is simple and easy to implement.

Owner:ANHUI UNIV OF SCI & TECH

Water-assisted injection forming die of automobile cooling water pipe and using method thereof

InactiveCN103112126ASolve the problem that the core of the car cooling water pipe cannot be pulledTubular articlesHot runnerWater assisted

The invention discloses a water-assisted injection forming die of an automobile cooling water pipe. The water-assisted injection forming mold comprises a moving die and a fixed die; a die cavity is arranged on a bonding surface of the moving die and the fixed die; a sprue gate is arranged at one end of the die cavity; the water-assisted injection forming die is characterized in that a water injection port is arranged at the other end of the die cavity; the die cavity is divided into a water inlet pipe cavity and a water outlet pipe cavity; a partition section is arranged between the water inlet pipe cavity and the water outlet pipe cavity; a port of the die cavity connected with an injection molding machine is provided with a feeding assisted section, and a port of the die cavity connected with a water-assisted water spraying head is provided with a water spraying assisted section; a pressure sensor is arranged at the sprue gate of the die; and a hot runner valve needle is arranged at the water injection port. The using method of the water-assisted injection forming die comprises the following steps of injection molding, water injection and water returning. Through the application of the water-assisted injection forming die of the automobile cooling water pipe and the using method disclosed by the invention, the water-assisted forming method is creatively applied in the injection molding of the automobile cooling water pipe, and the automobile cooling water pipe is cast by adopting the traditional injection molding method.

Owner:ZHEJIANG CENTURY HUATONG AUTOMOTIVE PART

Water needle applied for water shaping production

The invention discloses a water needle used in water-assisted molding production. It includes a needle sleeve, a core rod placed in the needle sleeve, a spring, a limit ring and a seal. There are water inlets and drains on the needle sleeve; the through hole in the middle of the support limit ring is the air inlet, and the slender through hole is opened in the core rod to form a gas passage; at the end where the water needle is connected to the cavity, the core rod and the needle The end of the sleeve cooperates to seal the passage of water to the cavity, the core rod is driven by the spring and the water inlet pressure or the inlet pressure to open the water inlet or drainage passage, the end fit and the reasonable setting of the vent hole size of the core rod prevent The plastic melt in the cavity enters the water needle. The invention realizes zero leakage of gas and water through the direct sealing between the needle sheath and the mould, the core rod and the needle sheath. The water needle can complete all the water supply and drainage functions of water intake, air intake and drainage required by the water-assisted molding technology, and has the characteristics of simple and compact structure and easy standardization. The invention is used for water-assisted molding production and is a key device of water-assisted molding technology.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com