Water-assisted injection-molding injecting device having pressure detection function

A technology of injection molding and injection device, which is applied in the field of injection molding, can solve the problems of easy blockage of water injection device and difficulty in achieving the properties of polymer melt, and achieve the effect of avoiding water injection blockage and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

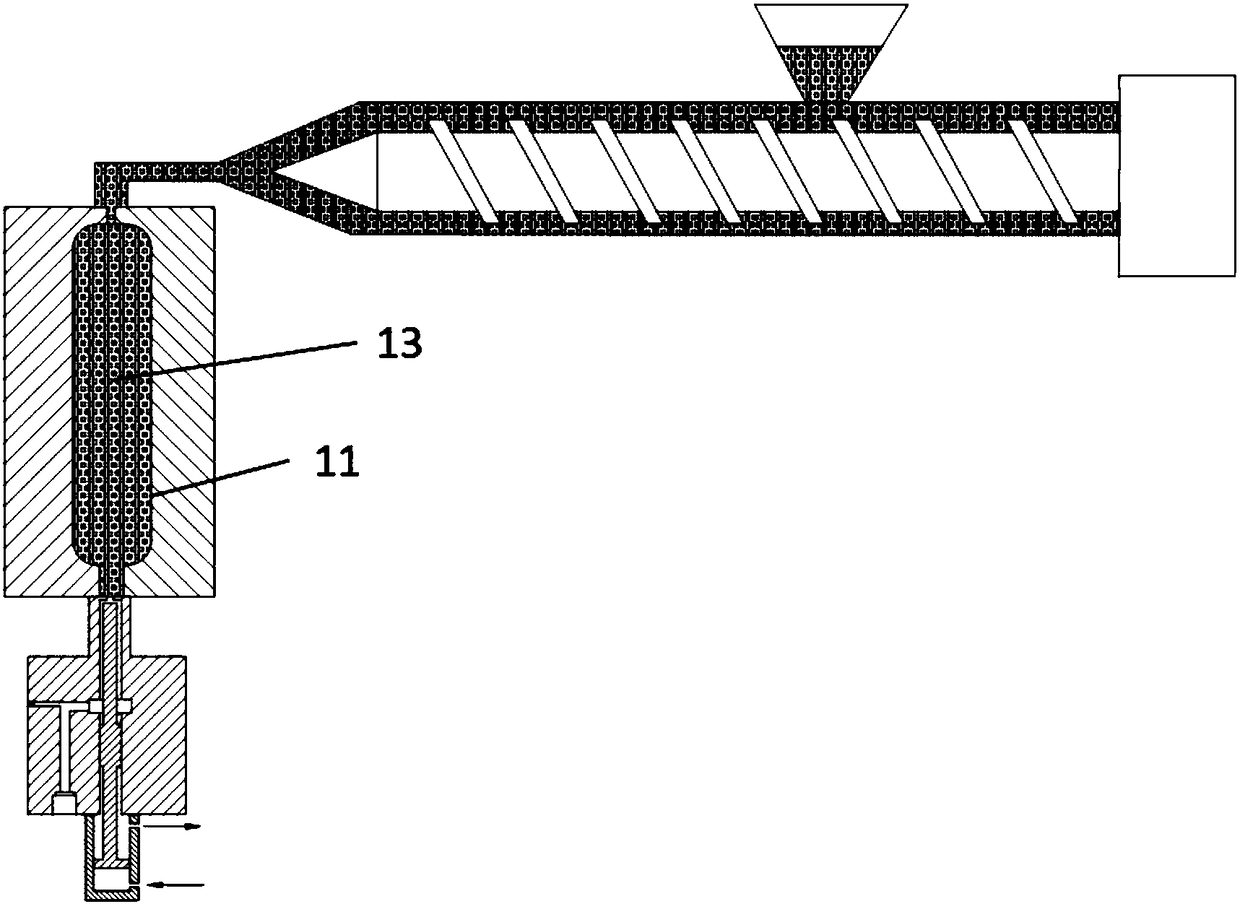

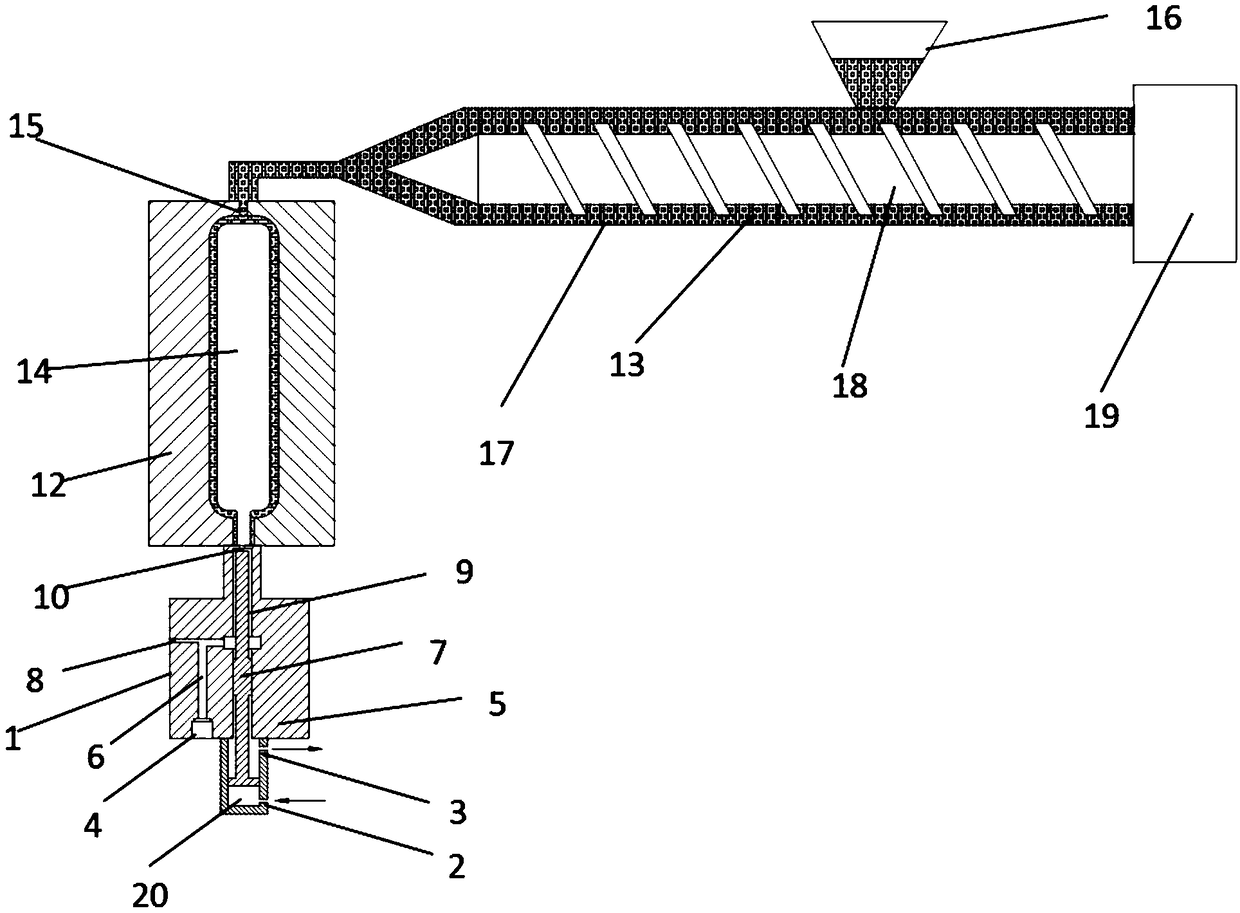

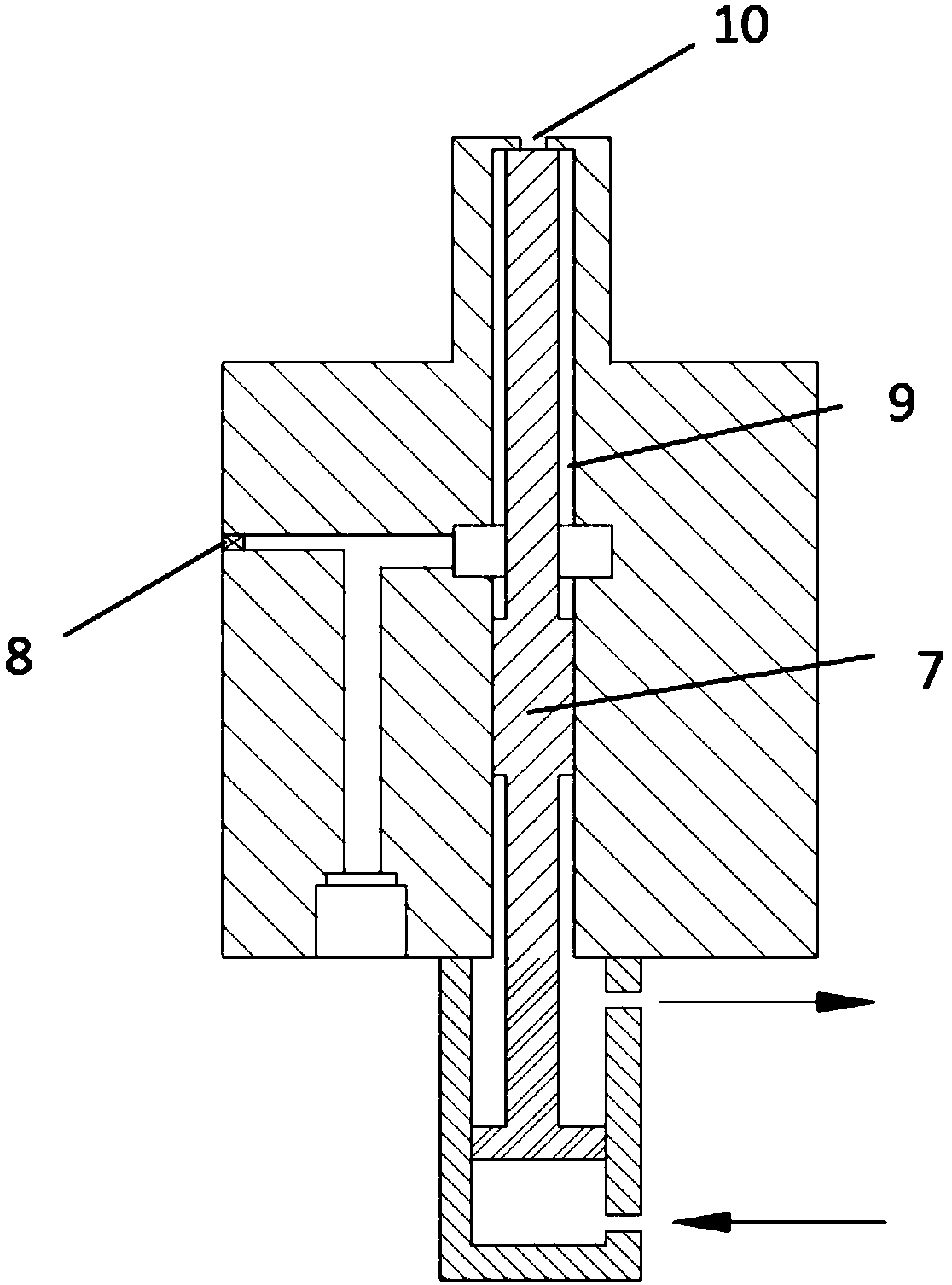

[0019] The water-assisted injection molding injection device with pressure detection includes a screw injection machine 17, a mold 12 and a water injection device 1. The screw injection machine 17 includes a screw 18, a feed hopper 16, a barrel and a screw controller 19. The screw 18 is divided into a feeding section, a compression section and a metering section, the feeding hopper 16 is located on the upper part of the screw injection machine 17, there is a melt 13 between the screw 18 and the cylinder, and the mold 12 is There is a gate 15, the lower end of the mold 12 is connected with the water needle device 1, the water needle device 1 includes a water needle core rod 7 and a water needle base 5, and the water needle base 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com