Method for preparing glycosylated ordered pore membrane by controllable glycerol polymerization

A technology of graft polymerization and porous membranes, which is applied in the field of preparation of ordered porous membranes, can solve the problem of not being able to control the density of glycosyl groups on the surface of ordered porous membranes according to needs, and achieve good application prospects, controllable glycosyl distribution and density , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The molecular weight of the block copolymer is 10,000, and the styrene / hydroxyethyl methacrylate block copolymer with a molar percentage of 0.5% of hydroxyethyl methacrylate is dissolved in carbon disulfide to form a concentration of 15% by weight. % polymer solution.

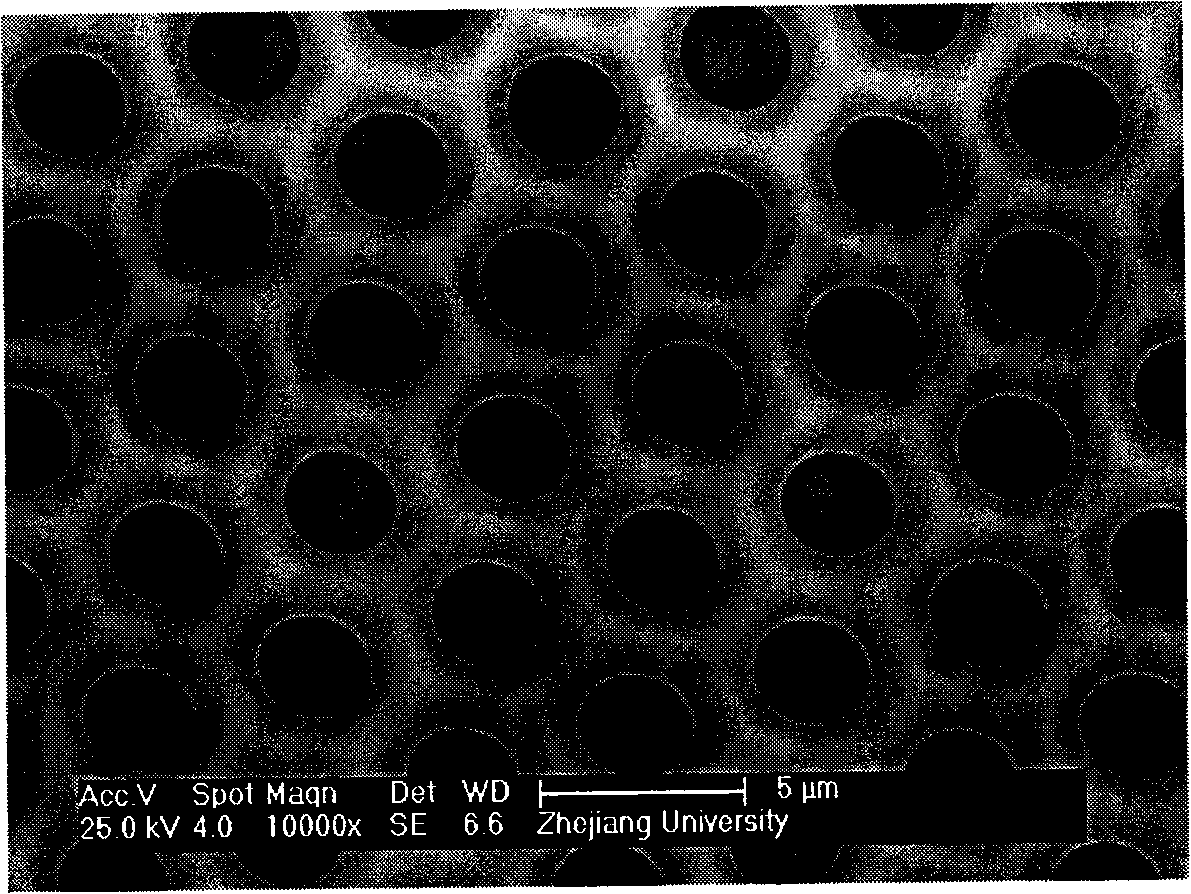

[0032] Take 0.1mL of the above polymer solution and apply it to the clean glass surface, and form a film at a relative humidity of 50% at 5°C to obtain an area of about 4cm 2 Ordered porous film; observed with a scanning electron microscope, the ordered porous film, the micropore diameter is 0.2 microns.

[0033] Put the above-mentioned ordered porous membrane, 5mL of n-heptane and 0.5mL of triethylamine in a flask, drop 0.3mL of bromoisobutyryl bromide at 0°C, react for 5 hours, take out the ordered porous membrane and wash it with methanol and water 3 times, and dried to constant weight to obtain an ordered porous membrane with immobilized bromine groups on the surface.

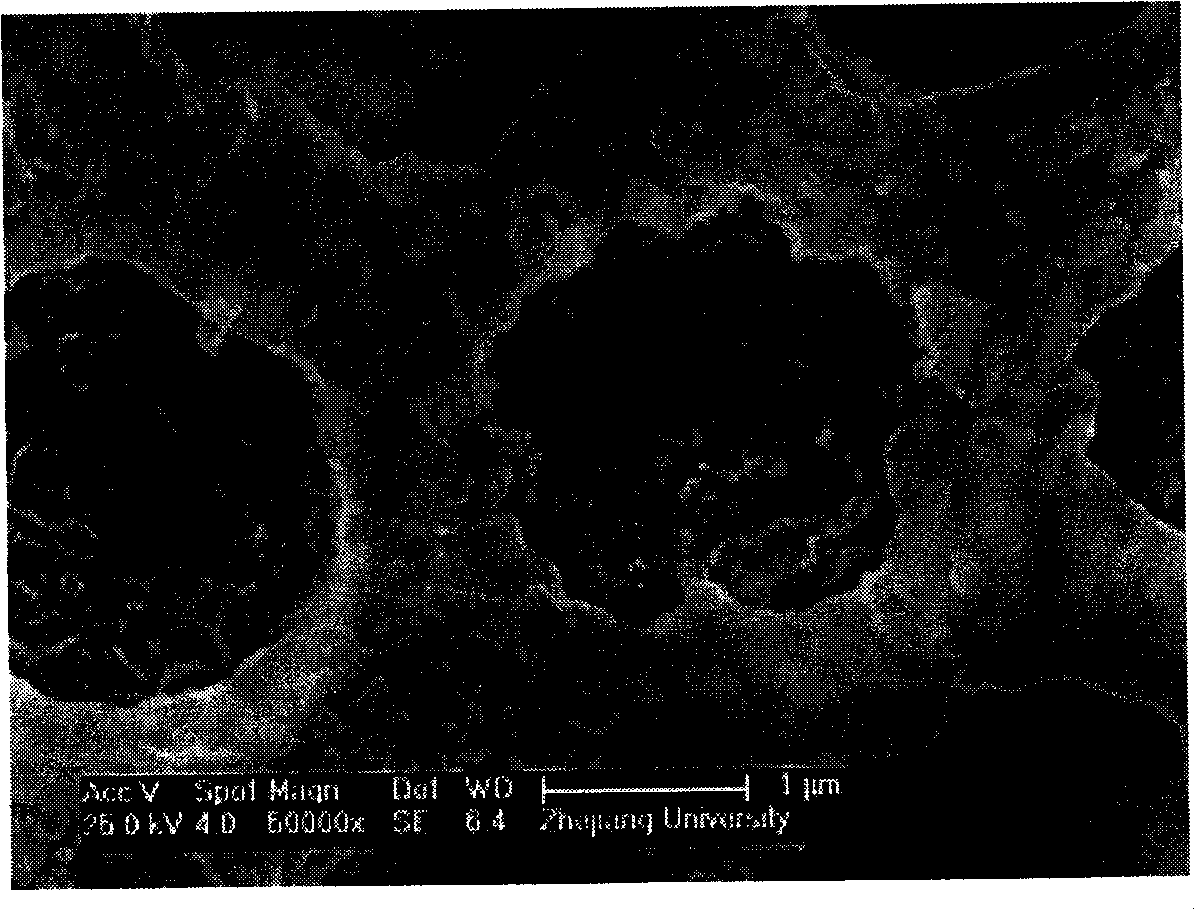

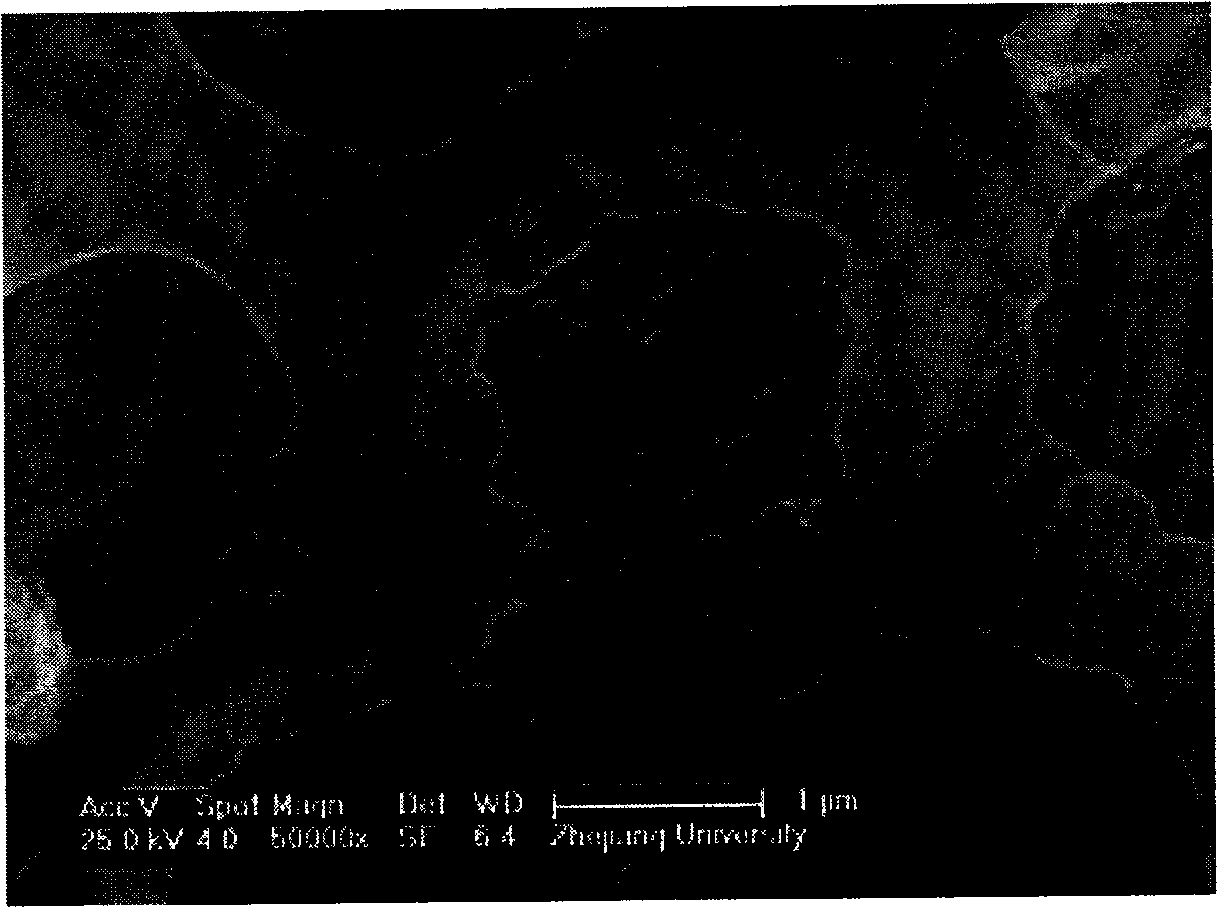

[0034] Then, the above-men...

Embodiment 2

[0036] The molecular weight of the block copolymer is 200,000, and the molar percentage of hydroxyethyl methacrylate is 10%. The styrene / hydroxyethyl methacrylate block copolymer is dissolved in carbon disulfide, and the concentration by weight is 5 % polymer solution.

[0037] Take 0.1mL of the above polymer solution and apply it to the clean glass surface, and form a film at a relative humidity of 90% and 50°C to obtain an area of about 4cm 2 Ordered porous film; observed with a scanning electron microscope, the ordered porous film, the micropore diameter is 2.5 microns.

[0038] Put the above-mentioned ordered porous membrane, 50mL of n-heptane and 5mL of triethylamine in a flask, drop 3mL of bromoisobutyryl bromide into the flask at 0°C, react for 12 hours, take out the ordered porous membrane and wash it three times with methanol and water , and dried to constant weight, an ordered porous membrane with bromine groups immobilized on the surface was obtained.

[0039]Th...

Embodiment 3

[0041] The molecular weight of the block copolymer is 50,000, and the styrene / hydroxyethyl methacrylate block copolymer with a molar percentage of hydroxyethyl methacrylate of 10% is dissolved in carbon disulfide to form a concentration of 5% by weight. % polymer solution.

[0042] Take 0.1mL of the above polymer solution and apply it to the clean glass surface, and form a film at a relative humidity of 90% and 50°C to obtain an area of about 4cm 2 Ordered porous film; observed with a scanning electron microscope, the ordered porous film, the micropore diameter is 2.5 microns.

[0043] Put the above-mentioned ordered porous membrane, 20 mL of n-heptane and 1.5 mL of triethylamine in a flask, drop 1 mL of bromoisobutyryl bromide into the flask at 0°C, react for 24 hours, take out the ordered porous membrane and wash it with methanol and water for 3 times, and dried to constant weight to obtain an ordered porous membrane with immobilized bromine groups on the surface.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com