A kind of method that utilizes common fermenter to prepare coated microcapsule before microbial fermentation

A technology of microbial fermentation and microencapsulation, which is applied in the direction of fixing on or in the inorganic carrier, fixing on/in the organic carrier, etc., can solve the problem that the degree of mechanization and automation cannot meet the requirements and affect the shape of the product (sphericity yield) , increase the cost and complexity of the device, and achieve the effects of avoiding low microencapsulation efficiency and yield, controllable cell density, and good shape and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

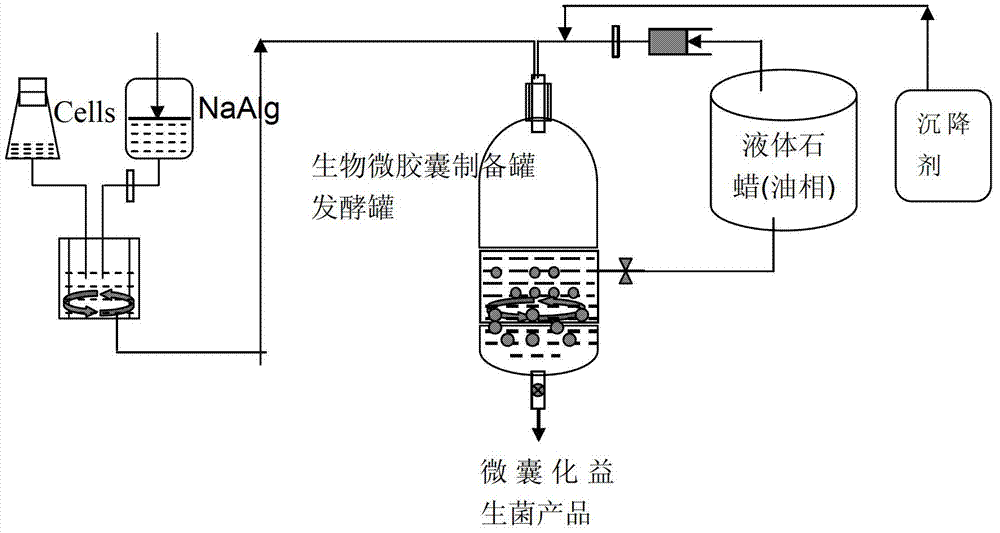

[0025] Embodiment 1: 50 liters of fermentation tanks produce yeast microcapsules

[0026] 1. Preparation of seed solution: inoculate the preserved yeast strains in YPD medium, culture in shake flasks at 30±1°C for 8-10 hours, until the yeast grows to the end of logarithmic growth, stop the cultivation for later use.

[0027] 2. Preparation of capsule material solution: Add 3L of water into the feeding tank, weigh 45g of food-grade sodium alginate, add it to the feeding tank, stir until completely dissolved, and prepare a sodium alginate solution with a concentration of 15g / L , sterilized at 115°C for 15-20 minutes.

[0028] 3. Preparation of the aqueous phase mixture: weigh 45g of CaCO2 in a ratio of 1:1 to the mass ratio of the sodium alginate used. 3 , put into the feeding tank, mix evenly, steam sterilize at 115°C for 20 minutes, cool to about 35°C, add microbial seed liquid at the end of logarithmic growth, and cultivate to a density of 10 6 About cfu / ml, mix well again ...

Embodiment 2

[0034]Embodiment 2: the yeast microcapsule produced by 1000 liters of fermentation tanks

[0035] 1. Preparation of seeds: inoculate the preserved yeast strains in YPD medium, and culture in shake flasks at 30±1°C for 8-10 hours until the yeast grows to the end of logarithmic growth, stop the cultivation for later use.

[0036] 2. Preparation of capsule material solution: Add 60L of water into the feeding tank, weigh 1.2kg of food-grade sodium alginate, add it to the feeding tank, stir until completely dissolved, and prepare sodium alginate with a concentration of 20g / L Solution, sterilized at 115°C for 15-20 minutes.

[0037] 3. Preparation of the aqueous phase mixture: Weigh 1.8kg of CaCO2 at a ratio of 1:1.5 to the mass ratio of the sodium alginate used 3 , put it into the feeding tank, mix well, steam sterilize at 115°C for 25 minutes, cool to about 38°C, add microbial seed liquid at the end of logarithmic growth, and reach 10 6 The density is about cfu / ml, and fully mix...

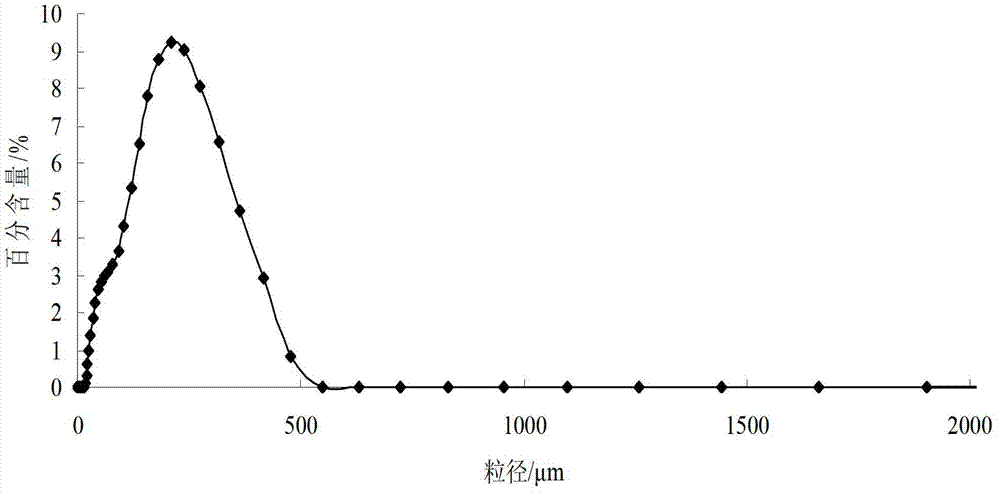

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com