Technical method and apparatus for surface compactness of timber

A technology of compacting device and surface of wood, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of difficulty in controlling the depth and degree of compaction of the surface compaction layer, low utilization rate of wood, etc. The effect of cultivation, small loss of wood volume, and alleviating the shortage of hard wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

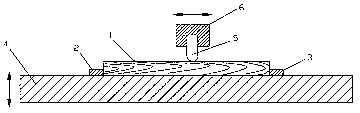

Embodiment 1

[0047] Plantation teak, 1000mm*120mm*25mm, air dry density 627kg / m 3 , compress its surface densely by 2.0mm. Select a cylindrical loading head with a radius of 8mm, adjust the height of the cylindrical loading head at the height of the lifting table plus the thickness of the door panel to be processed, so that it is at the same level to ensure the uniformity of the surface density; adjust the height control of the lifting table The compression amount is 1mm, the reciprocating stroke of the cylindrical loading head is set to 1000mm, and the pressurized feed rate is 3.0m / min; the plantation teak is placed in a wood softening tank and treated with water vapor at 130°C for 12 minutes to make the wood Softening: After softening, the test piece is fixed on the lifting worktable by the left and right clamping blocks, and the compression amount is increased to 2.0mm by 0.5mm gradient intermittently, and then the process is repeated 4 times, and the surface density of the made surface...

Embodiment 2

[0049] Oak olive wood, 600mm*110mm*25mm, air dry density 430kg / m 3 , compress its surface densely by 3.0mm. Select a cylindrical loading head with a radius of 5mm, adjust the levelness of the cylindrical loading head and the lifting table to ensure the uniformity of surface compactness; adjust the height of the lifting table to control the compression to 1mm, and set the level of the cylindrical loading head The reciprocating stroke is 300mm, and the pressurized feed speed is 8m / min; put the Oclamella wood in a wood softening tank, and soak it in hot water at 95°C for 20 minutes to soften the wood; after softening, the specimen passes through the left and right clamping blocks Fix it on the lifting table, use 0.5mm gradient to increase the compression amount to 3.0 mm and then repeat the process 5 times, the surface density of the made surface dense material can reach 783 Kg / m 3 , which is about 82% higher than that before undensification, the surface hardness is increased fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com