Ring sanding device and method for determining surface structure depth of road

A technology of surface structure and depth, which is applied in the field of annular sand laying devices for measuring the depth of pavement surface structure, can solve the problem of large sand hair error, etc., and achieve the effects of reducing measurement error, convenient observation and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

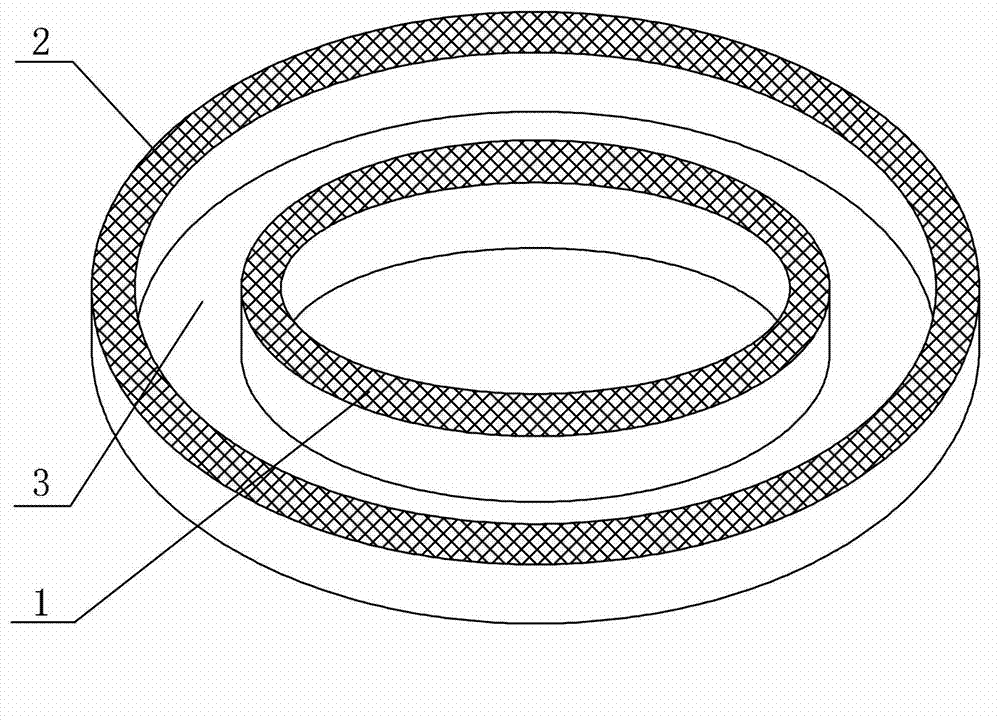

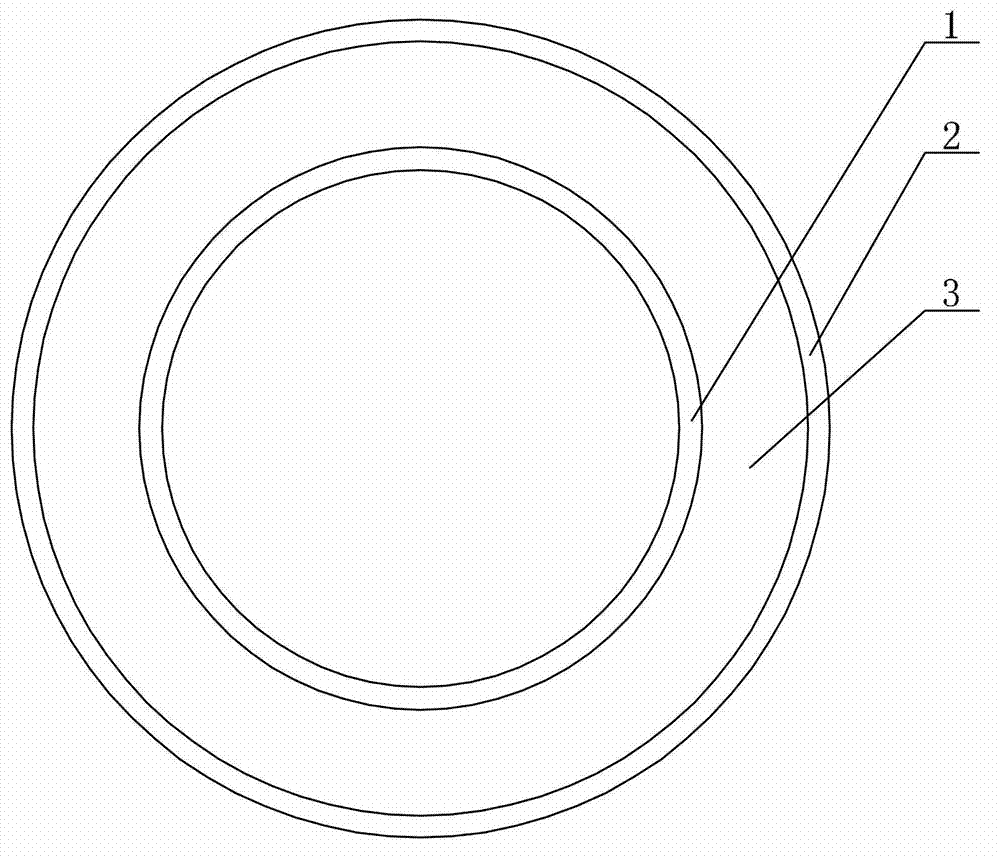

[0019] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a kind of annular sand paving device for measuring the depth of road surface structure described in this embodiment comprises inner ring body 1 and outer ring body 2, inner ring body 1 is arranged in outer ring body 2, and inner ring body 1 An annular sand groove 3 is provided between the outer wall of the ring body 1 and the inner wall of the outer ring body 2 .

[0020] In this embodiment, both the inner ring body 1 and the outer ring body 1 are made of stainless steel.

specific Embodiment approach 2

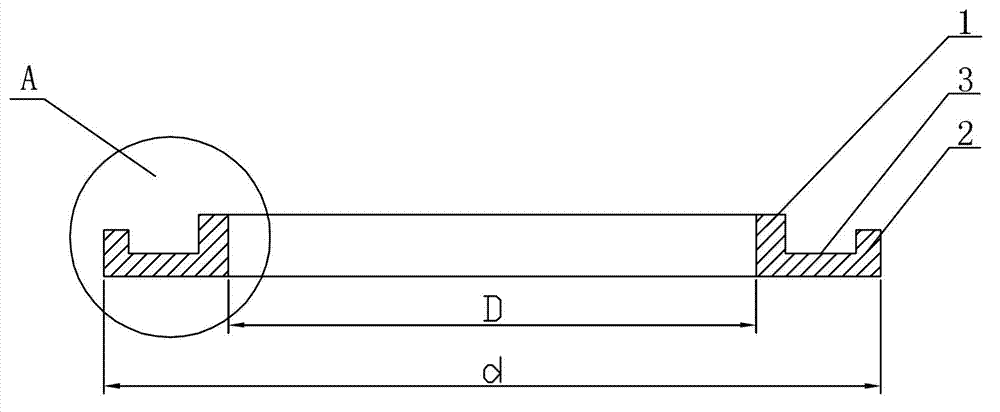

[0021] Specific implementation mode two: combination image 3 Describe this embodiment, the inner diameter D of the inner ring body 1 of a kind of ring sand laying device for measuring the depth of the road surface structure described in this embodiment is 290mm-310mm, the outer diameter d of the outer ring body 2 is 350mm-370mm . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination image 3 Describe this embodiment, the inner diameter D of the inner ring body 1 is 300 mm, and the outer diameter d of the outer ring body 2 is 360 mm.

[0023] The technical effect of this embodiment is: the inner diameter D and the outer diameter d are too small, the coverage area of the ring (measuring sand) is too small, and the measurement results cannot fully explain the actual structure depth of the road surface at the measuring point; the inner diameter D and the outer diameter d are too small. When it is large, the ring is inconvenient to carry, and consumes too much stainless steel to manufacture and also consumes too much sand during measurement. Therefore, considering the measurement results of the traditional manual sanding method and the general actual structural depth of the pavement, choosing D = 300mm and d = 360mm can fully explain the actual pavement structural depth of the measuring point, and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com