Construction process for implanting composite section hollow pile by pouring filling mortar into expanded guide hole

A composite cross-section and construction technology technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that it is difficult to achieve the expected effect, and there are no relevant documents, reports and regulations, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

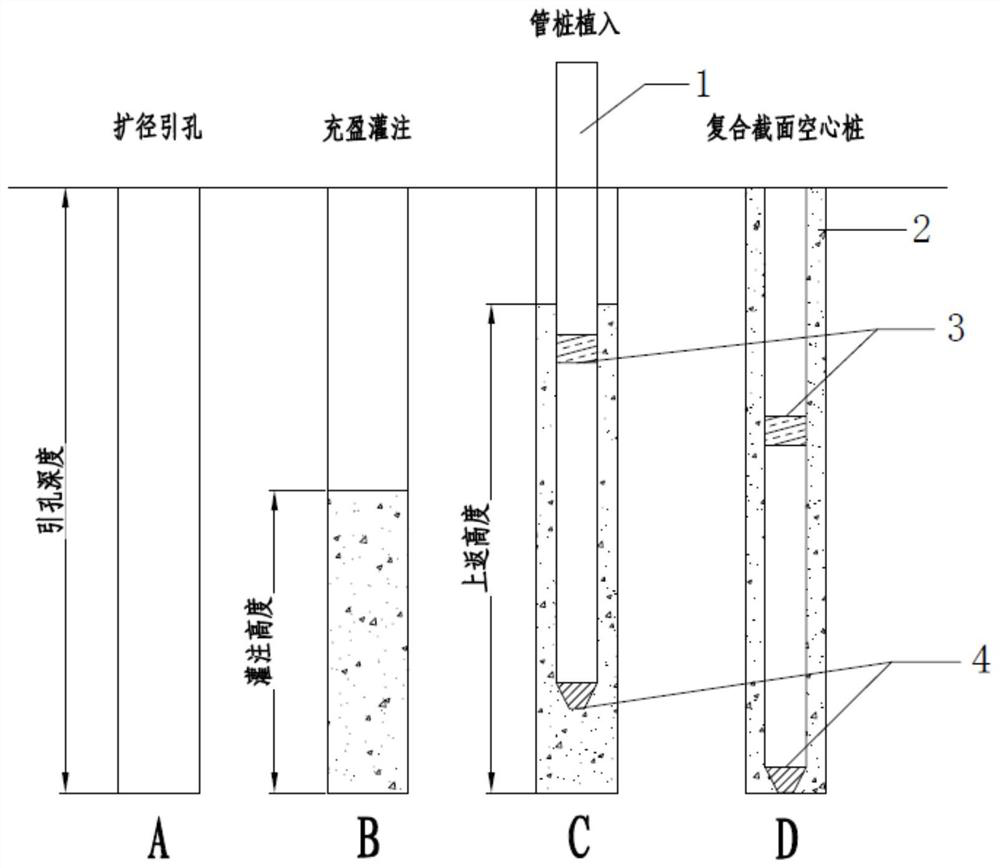

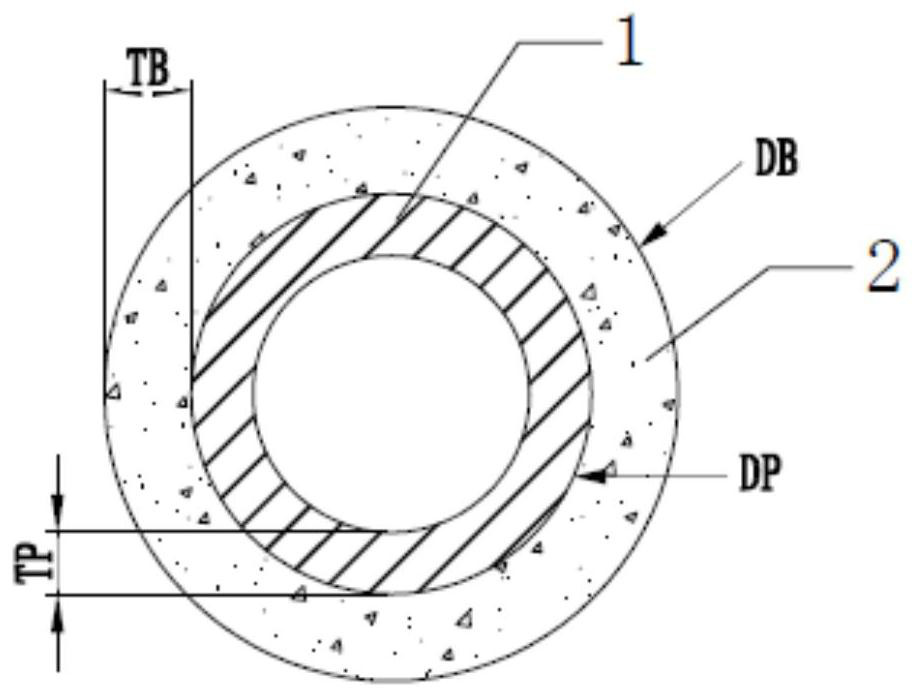

[0029] Implementation example I—subgrade pile-slab structure

[0030] An expressway is located in the hilly valley area of central Anhui. The natural sediments along the line are thin, and the underlying (full) strongly weathered rocks and moderately weathered rocks are mainly argillaceous sandstone and tuff. Due to the scarcity of filling soil for the subgrade, the difficulty of land acquisition for the subgrade, and the tight construction period of the project, the pile-slab structure of the subgrade was adopted after demonstration, and the cumulative mileage reached 60km.

[0031] Due to the relatively short length of piles in the surface sediment and (full) strong weathered layer, the pile system based on the pile-sheet structure is stable, and the prefabricated piles need to enter the moderately weathered rock, or even pass through the moderately weathered layer, making it difficult to install the prefabricated piles directly. The pile foundation of the subgrade pile-sl...

Embodiment II

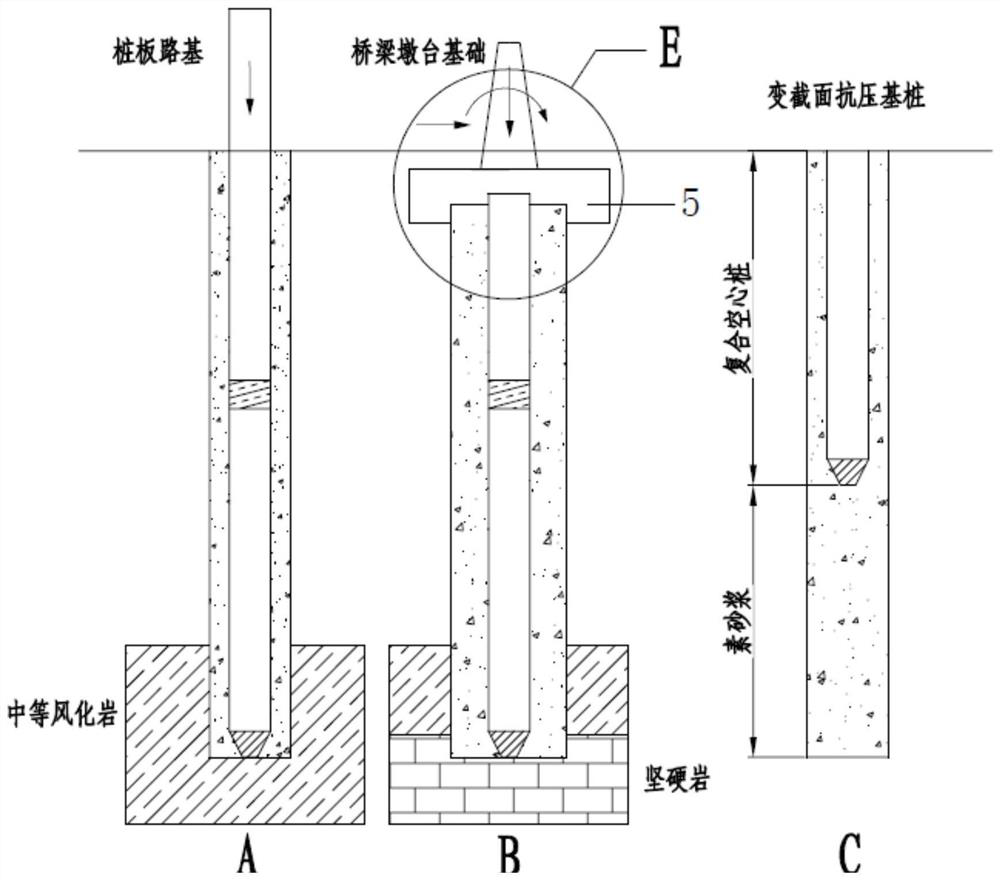

[0035] Implementation Example II——Bridge Pier Foundation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com