Planar optical waveguide vibrating sensor chip cantilever beam manufacturing method

A planar optical waveguide and vibration sensor technology, applied in instruments, using wave/particle radiation, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the incompatibility of connection and packaging processes, the inability to prepare optical waveguide cantilever beam structures, and the mechanical strength of silicon materials lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

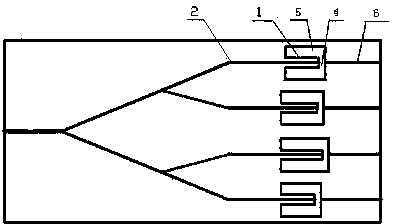

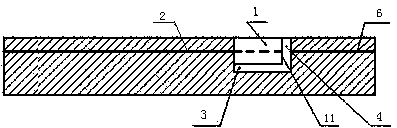

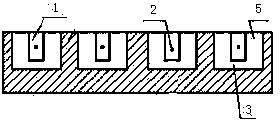

[0016] A method for manufacturing a planar optical waveguide vibration sensor chip cantilever beam, which uses a planar optical waveguide shunt chip on a glass substrate as a base material, and the planar optical waveguide shunt chip has an input shunt optical waveguide 2, an output shunt Optical waveguide 6; where the upper interface of the waveguide core layer of the input branch optical waveguide 2 is about 40 microns away from the upper surface of the planar optical waveguide branch chip. First, clean the upper and lower surfaces of the planar optical waveguide shunt chip. The upper and lower surfaces of the planar optical waveguide shunt chip are cleaned by placing the planar optical waveguide shunt chip on the glass substrate in acetone, deionized water, and alcohol in sequence. , cleaned with an ultrasonic wave with a power of 40 watts, put it into a vacuum drying oven, and heated it at a constant temperature of 80°C for half an hour. After cooling, clean the upper and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com