Equipment for extruding/injecting polymer nano-composite through water-assisted mixing and realization method of equipment

A nano-composite material, mixing and extrusion technology, applied in the direction of coating, etc., can solve the problems of uniform dispersion of difficult nanoparticles, unfriendly environment, low efficiency, etc., and achieve the effects of stable production process, easy promotion and application, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

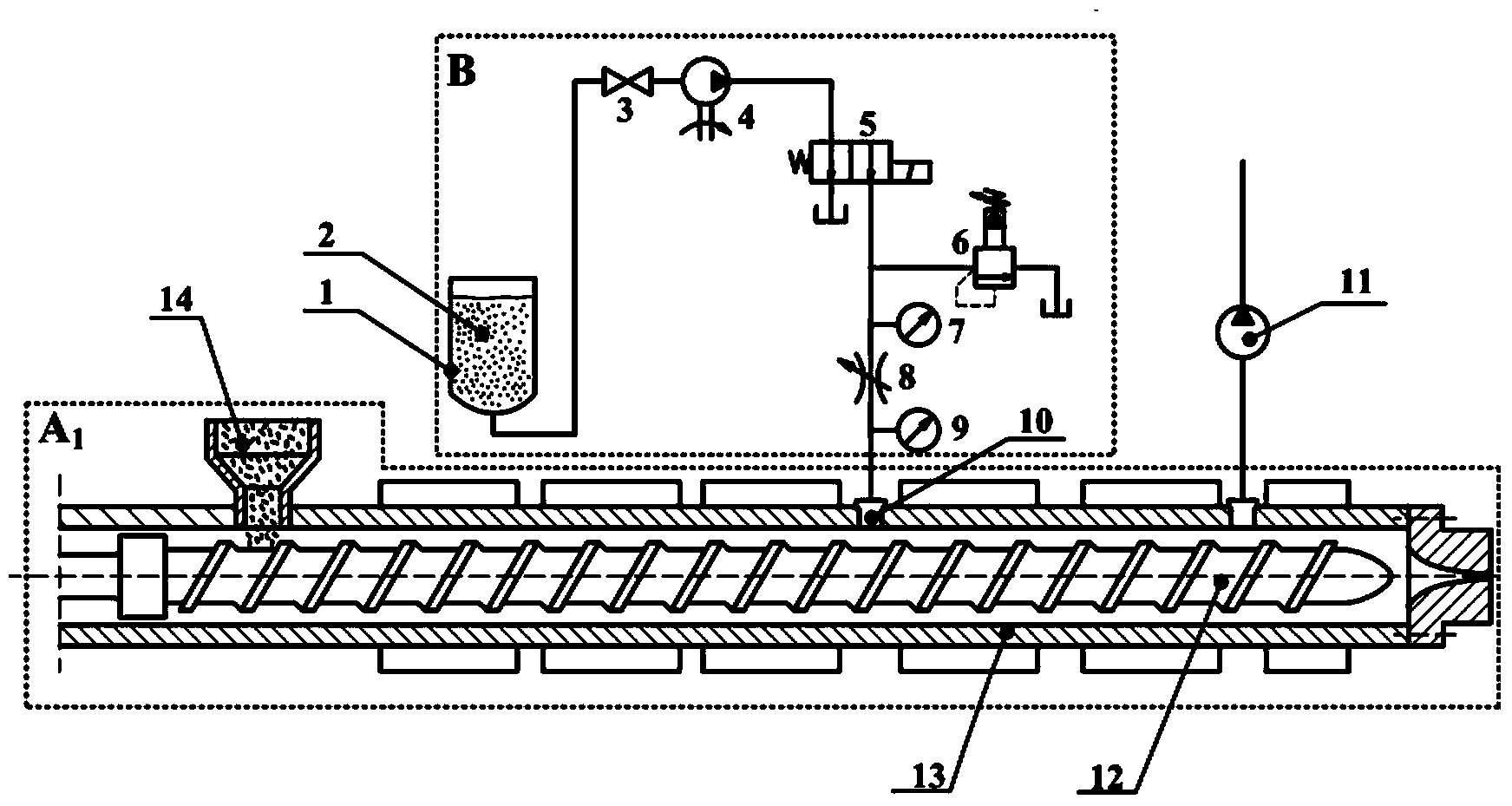

[0036] figure 1 The equipment for water-assisted mixing and extruding polymer nanocomposites of the present invention is shown, including extruder A 1 , water-based nano-particle suspension injection device B and the water vapor formed after the water vaporization in the water-based nano-particle suspension is discharged from the vacuum pump 11 of the extruder barrel 13; water-based nano-particle suspension injection device B and Vacuum pump 11 along extruder A 1 The extrusion direction is connected with the extruder barrel 13 in turn.

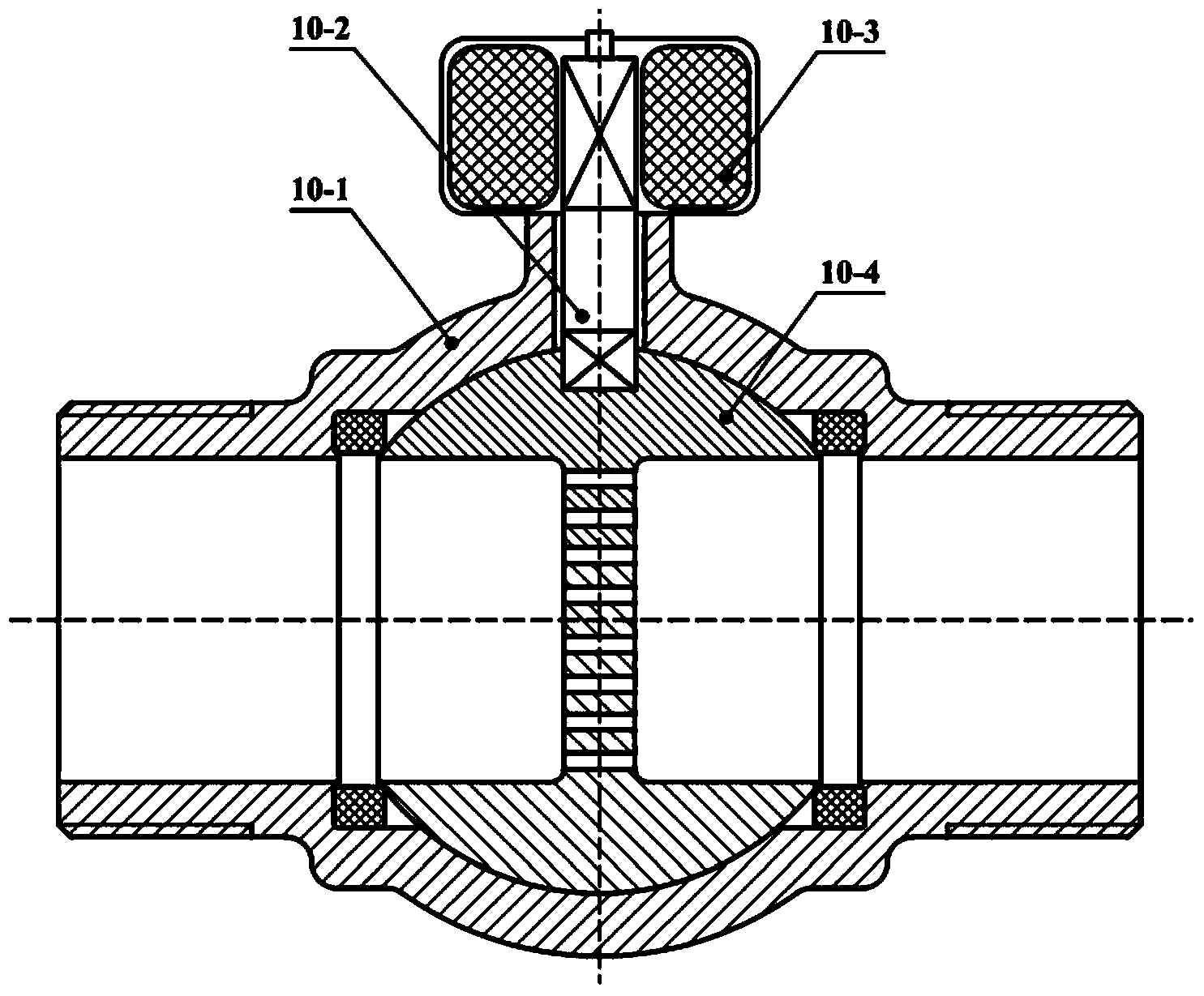

[0037] The water-based nanoparticle suspension injection device B includes a liquid storage cylinder 1, a valve switch 3, a high-pressure metering pump 4, a reversing valve 5, an overflow valve 6, a first pressure gauge 7, a throttle valve 8, and a second pressure gauge connected in sequence. Pressure gauge 9 and electric ball valve 10; Electric ball valve 10 is connected with extruder barrel 13 by thread. The pressure and flow rate of the ...

Embodiment 2

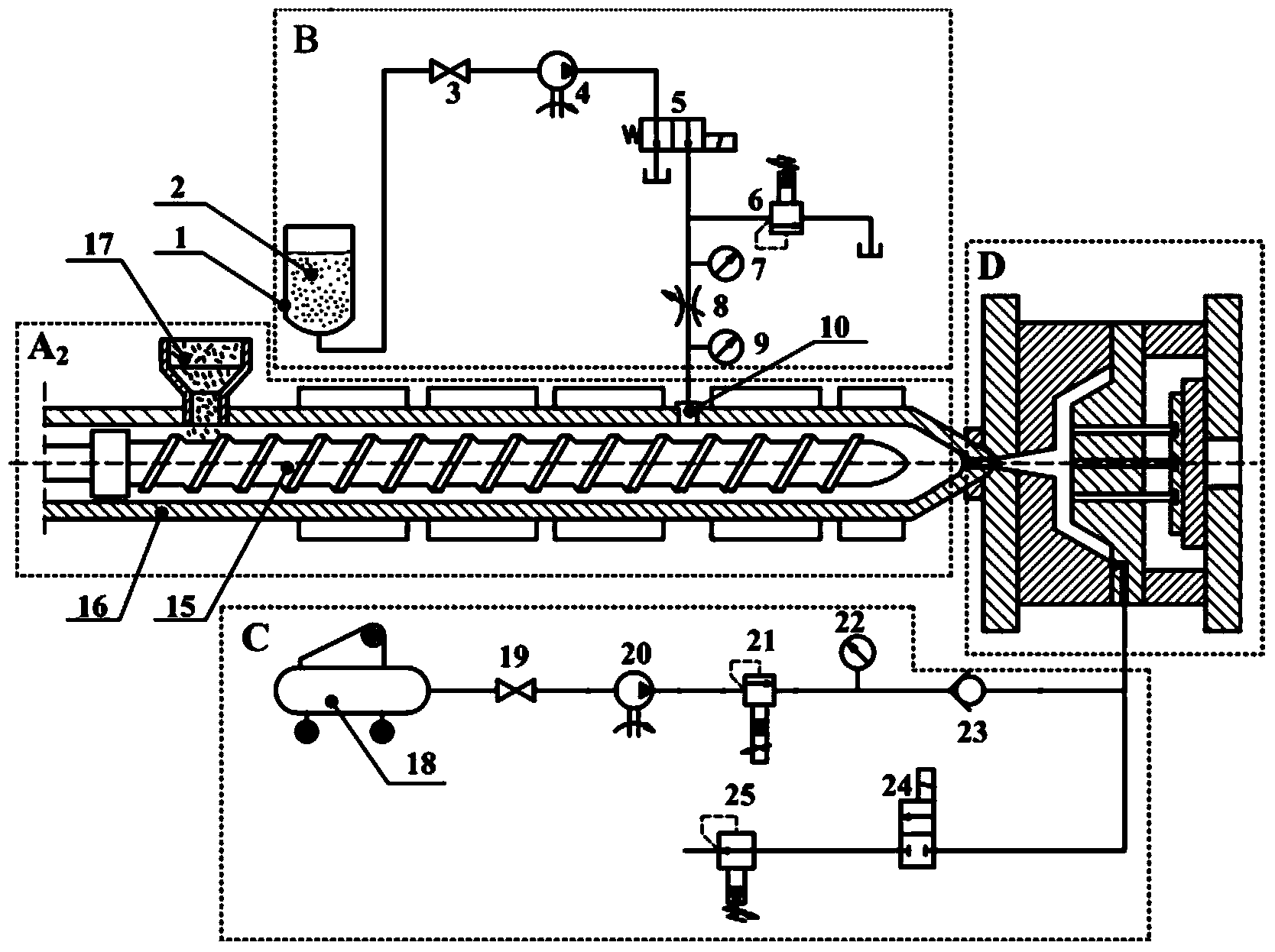

[0042] figure 2 An apparatus for water-assisted mixing injection-molded polymer nanocomposites according to the present invention is shown, including injection molding machine A 2 , injection mold D, water-based nano-particle suspension injection device B, and mold cavity gas back-pressure device C that provides and discharges back-pressure gas into the injection mold cavity; water-based nano-particle suspension injection device B and injection molding machine The cylinder 16 is connected; the mold cavity gas back pressure device C is connected with the injection mold D.

[0043] The water-based nanoparticle suspension injection device B includes a liquid storage tank 1 for storing the water-based nanoparticle suspension, a valve switch 3, a high-pressure metering pump 4, a reversing valve 5, an overflow valve 6, and a first pressure gauge 7 connected in sequence , throttle valve 8, second pressure gauge 9 and electric ball valve 10; The pressure and flow rate of the water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com