Patents

Literature

31results about How to "Reasonable operation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

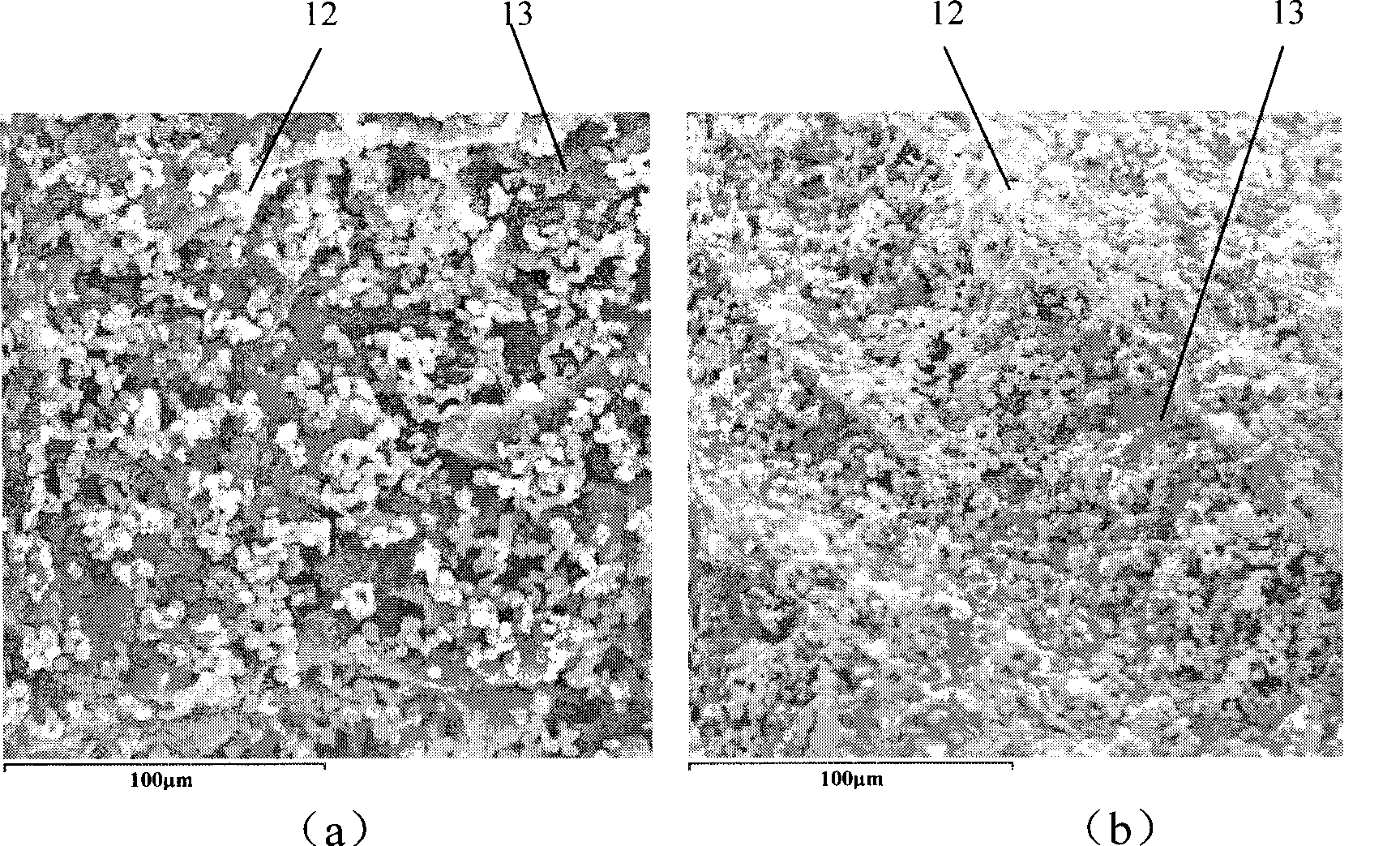

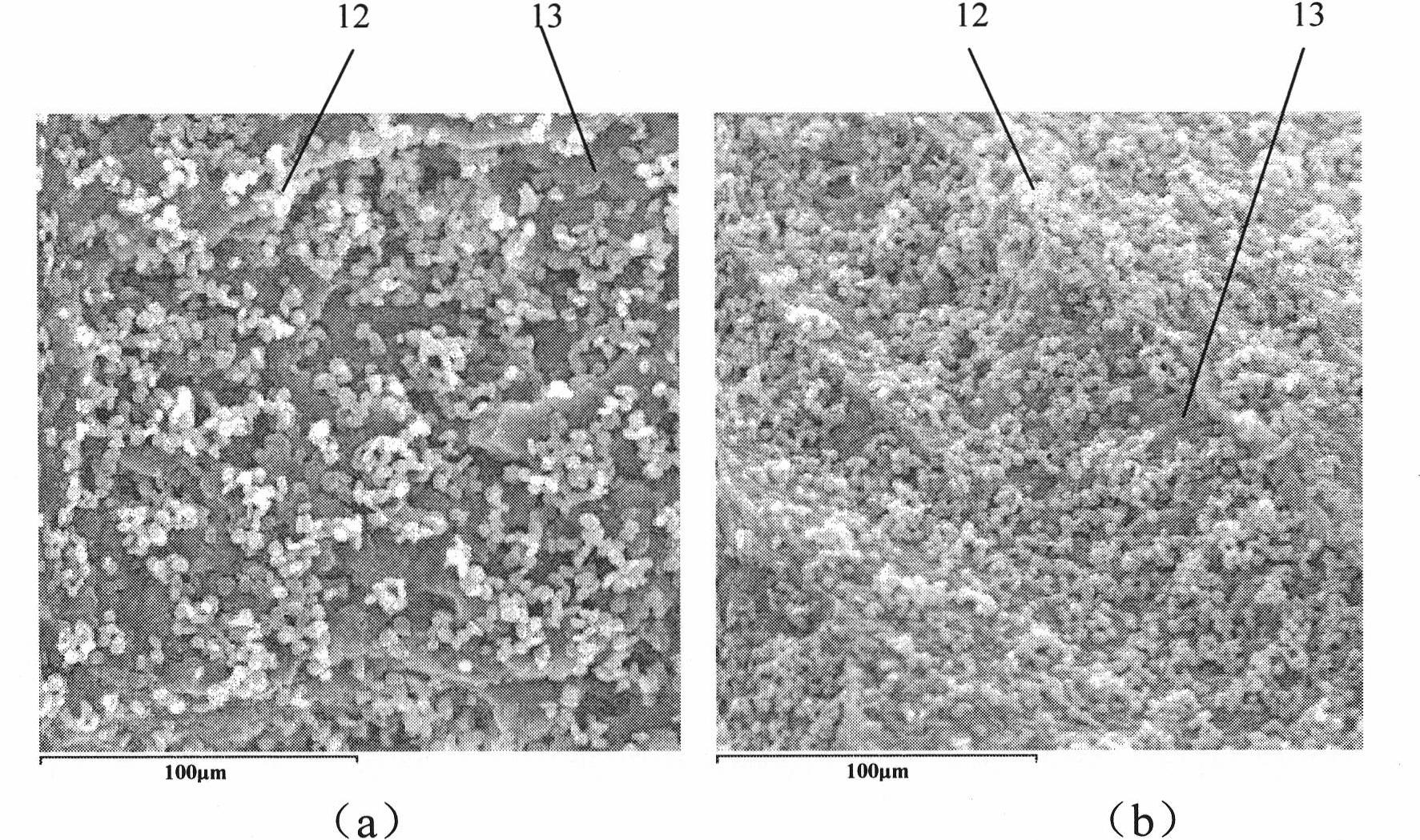

Method for preparing thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization

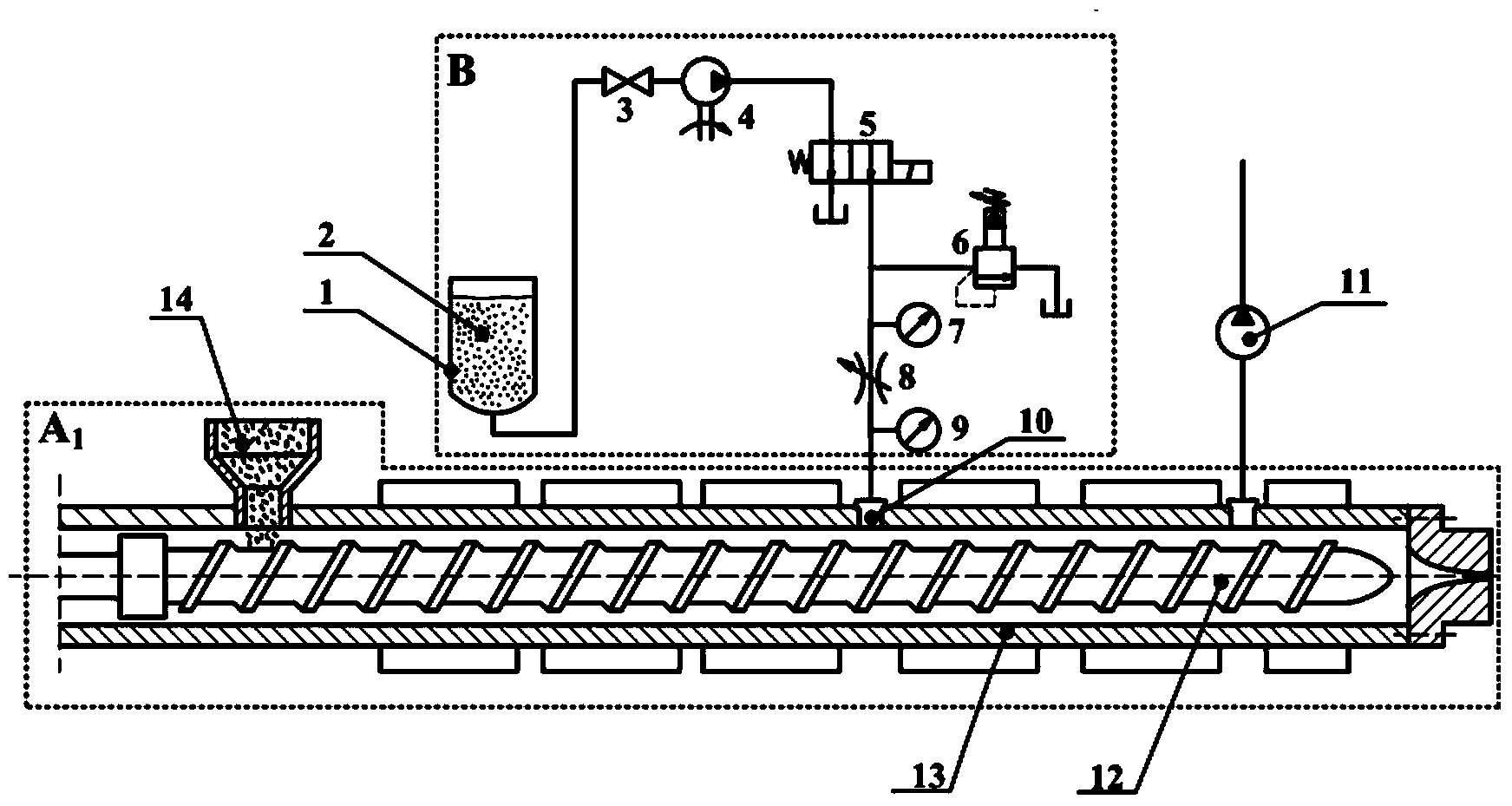

The invention discloses a method for preparing a plastic / rubber thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization. The method comprises the followings steps: (1) mixing plastic, rubber and a vulcanization system at a certain proportion, and putting the mixture into an extruder or an injection molding machine to mix, fuse and plasticize the polymer into a fusant; (2) controlling gas to be in a supercritical state by a supercritical fluid conveying system and injecting the gas into a cylinder of the extruder or the injection molding machine; (3) mixing the injected supercritical fluid with the polymer fusant and the vulcanization system; (4) causing a chemical reaction of the plastic, the rubber and the vulcanization system, which is promoted by the supercritical fluid; and (5) releasing the supercritical fluid from the polymer fusant at the pressure which is lower than a critical value, converting the supercritical fluid into gas to be discharged by a vacuum pump. The supercritical fluid assisted plastic / rubber dynamic vulcanization can promote dispersion and size decrease of the rubber phase in the plastic, and effectively reduce processing energy consumption for extrusion or injection shaping.

Owner:SOUTH CHINA UNIV OF TECH

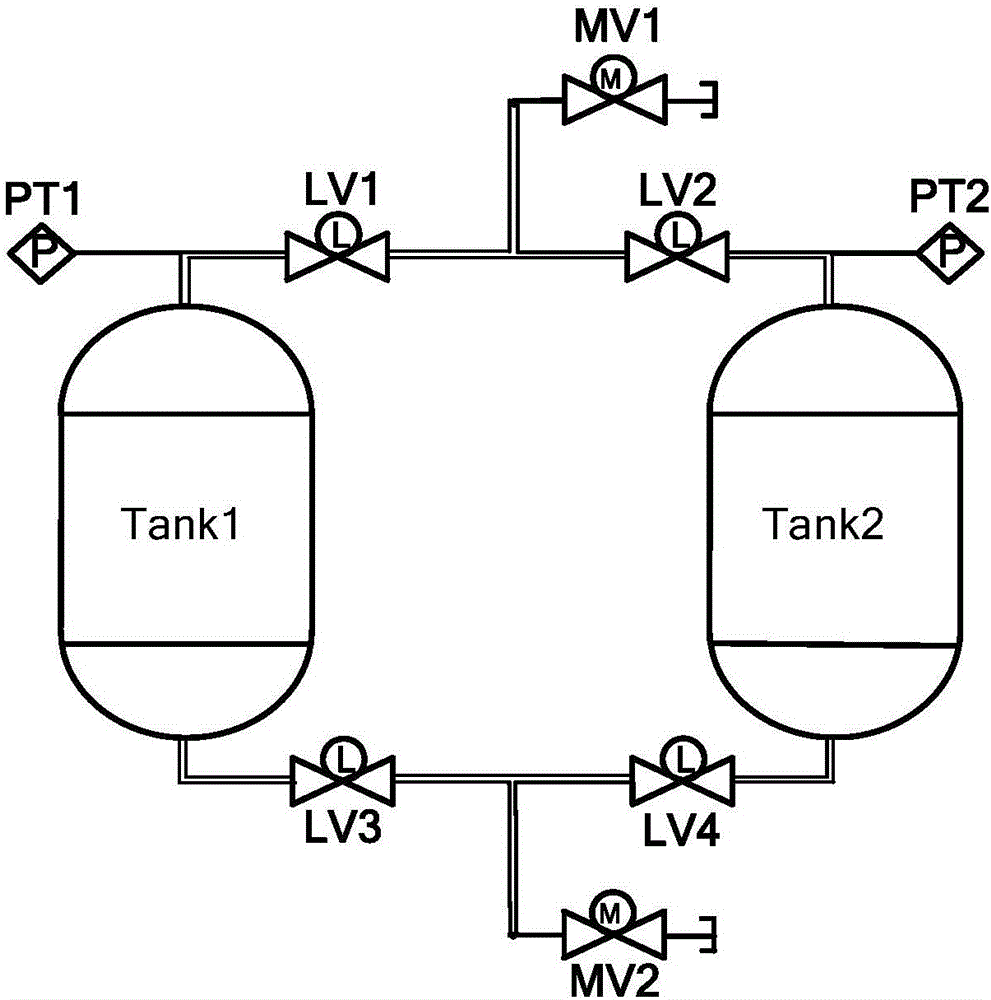

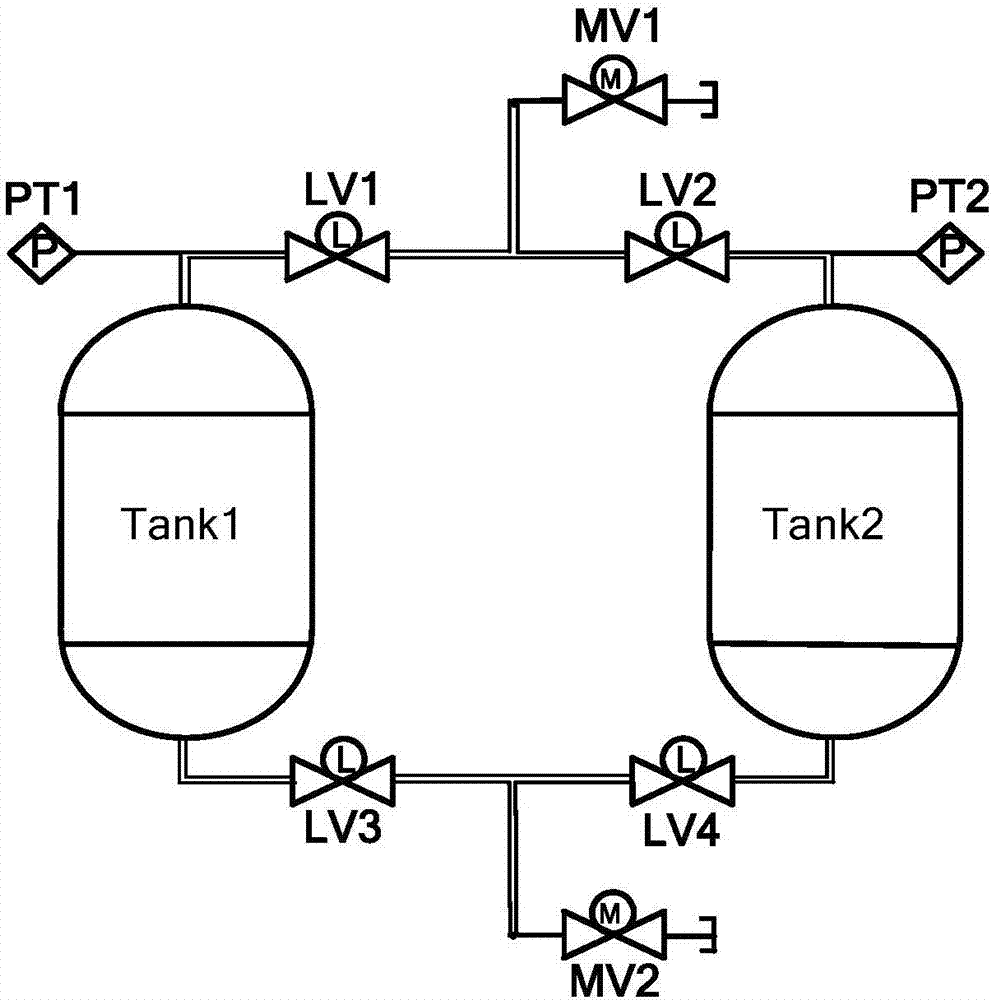

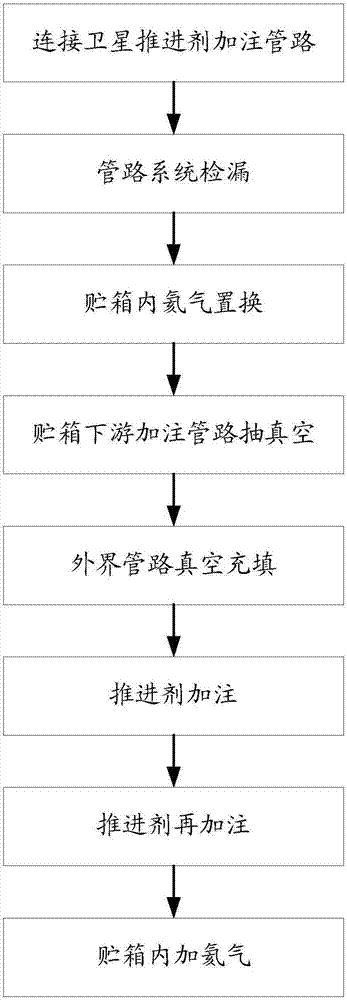

Parallel balanced filling method for high-capacity semi-management surface tension storage tank

ActiveCN106762224AReal-time display of total filling amountReal-time monitoring of parallel balanceLiquid handling installationsCosmonautic propulsion system apparatusEngineeringHelium

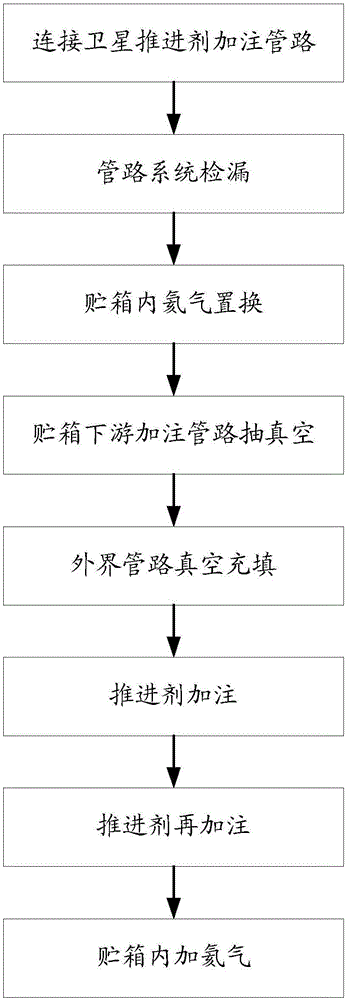

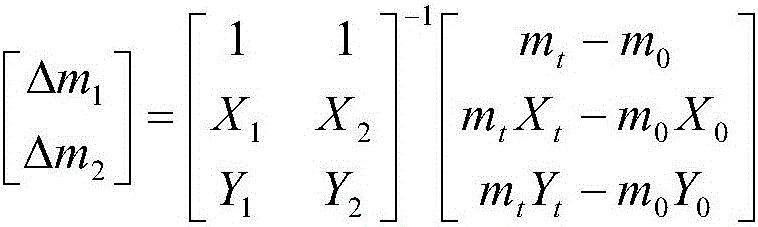

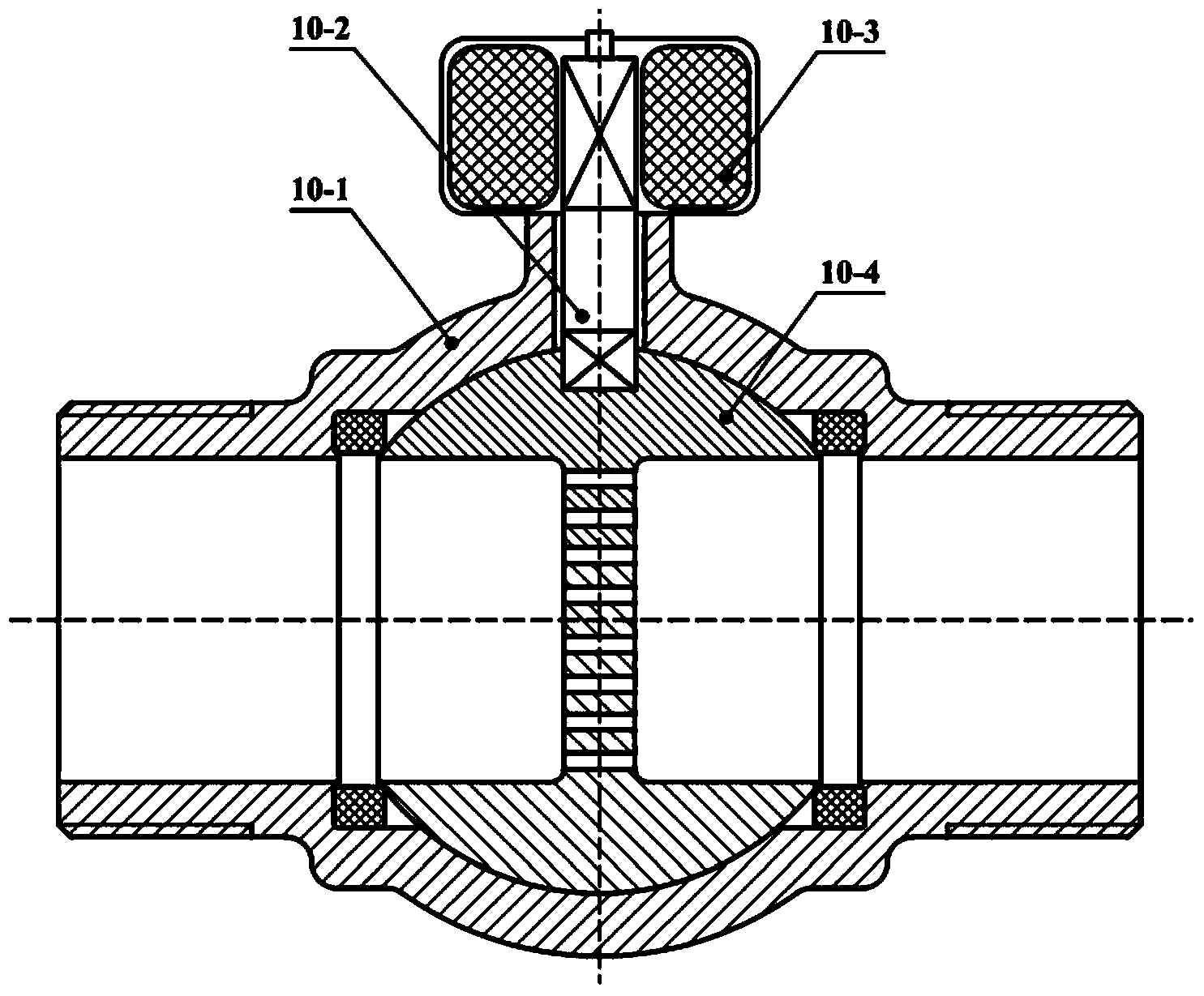

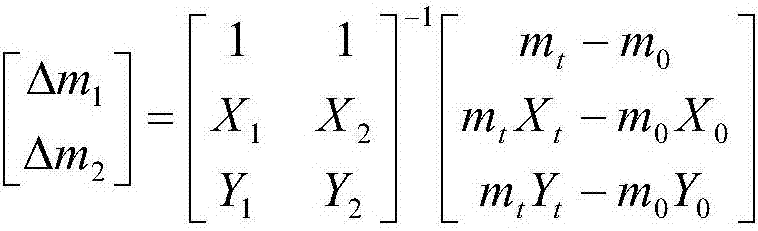

A parallel balanced filling method for a high-capacity semi-management surface tension storage tank comprises steps as follows: (1) a satellite propellant filling pipeline is connected, and the leakage rate of a filling pipeline system is ensured to meet the requirements; (2) two parallel storage tanks are simultaneously filled with helium or release helium for replacement until sampled gas is tested to be qualified; (3) the propellant filling pipeline and pipelines at the downstream of the parallel storage tanks are vacuumized; (4) valve ports of filling and drainage valves of the parallel storage tanks are filled with the propellant; (5) the parallel storage tanks are simultaneously and stably filled until 90% or above of the rated filling quantity is reached; (6) refilling is performed on the parallel storage tanks until the filling quantity of each storage tank meets the task requirement; (7) air cushions are added to the storage tanks until required air cushion pressure is reached. By means of the method, parallel balanced filling of the high-capacity semi-management surface tension storage tank can be realized, time for filling the parallel storage tanks with the propellant is shortened, and the reliability and the safety of the satellite filling process are guaranteed.

Owner:BEIJING INST OF CONTROL ENG

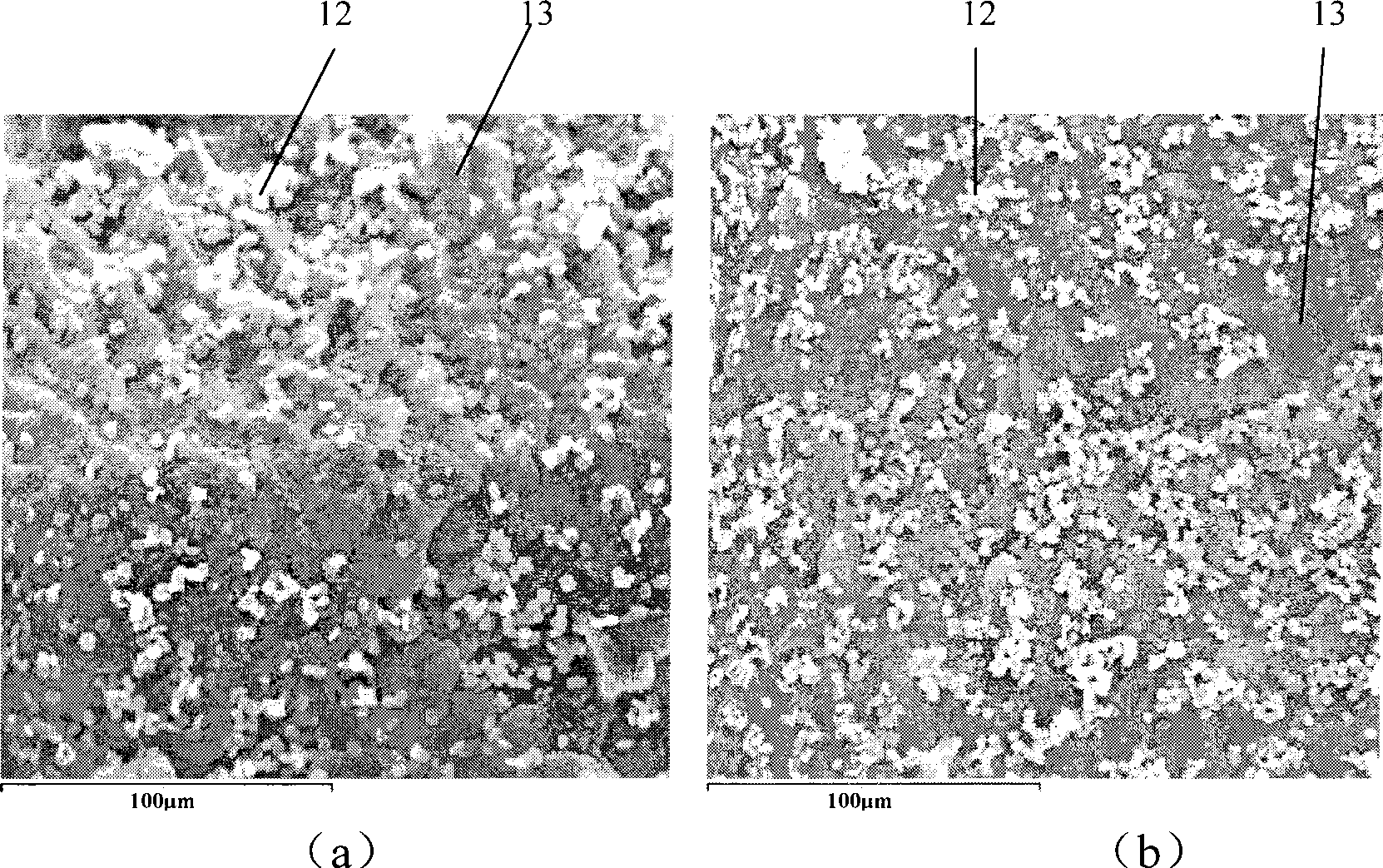

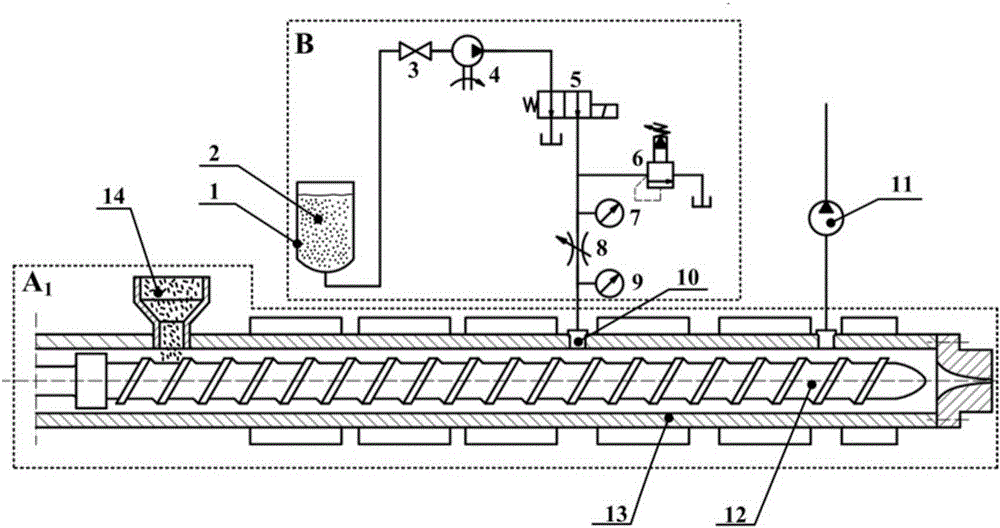

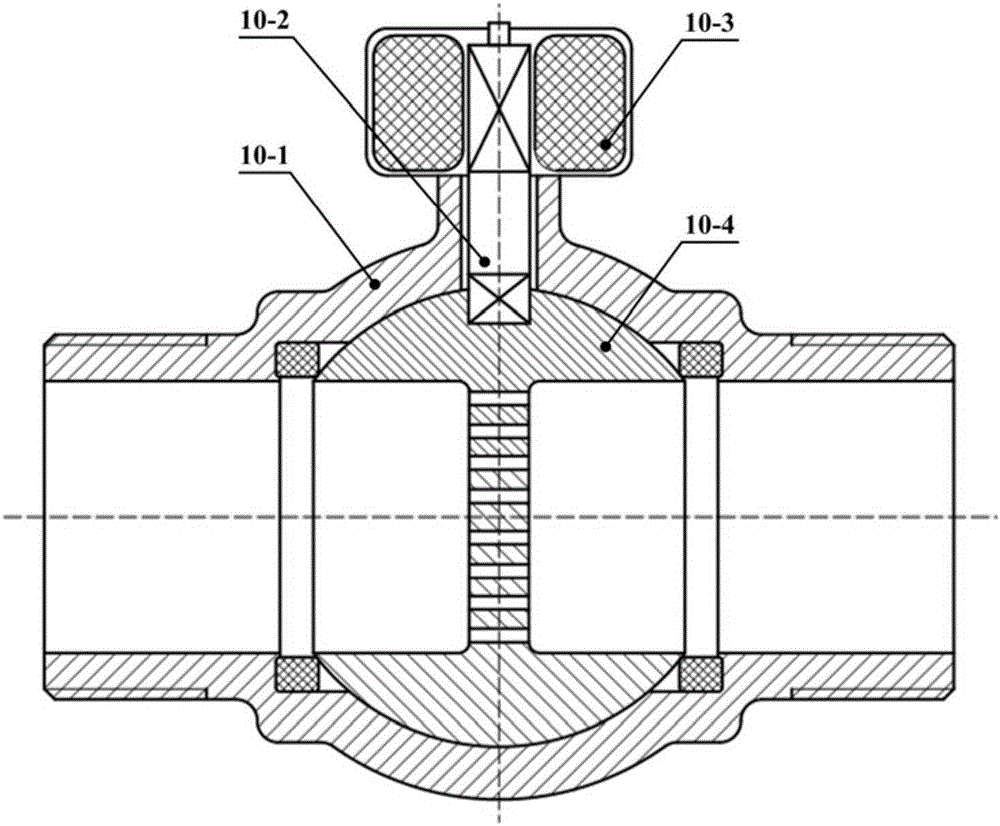

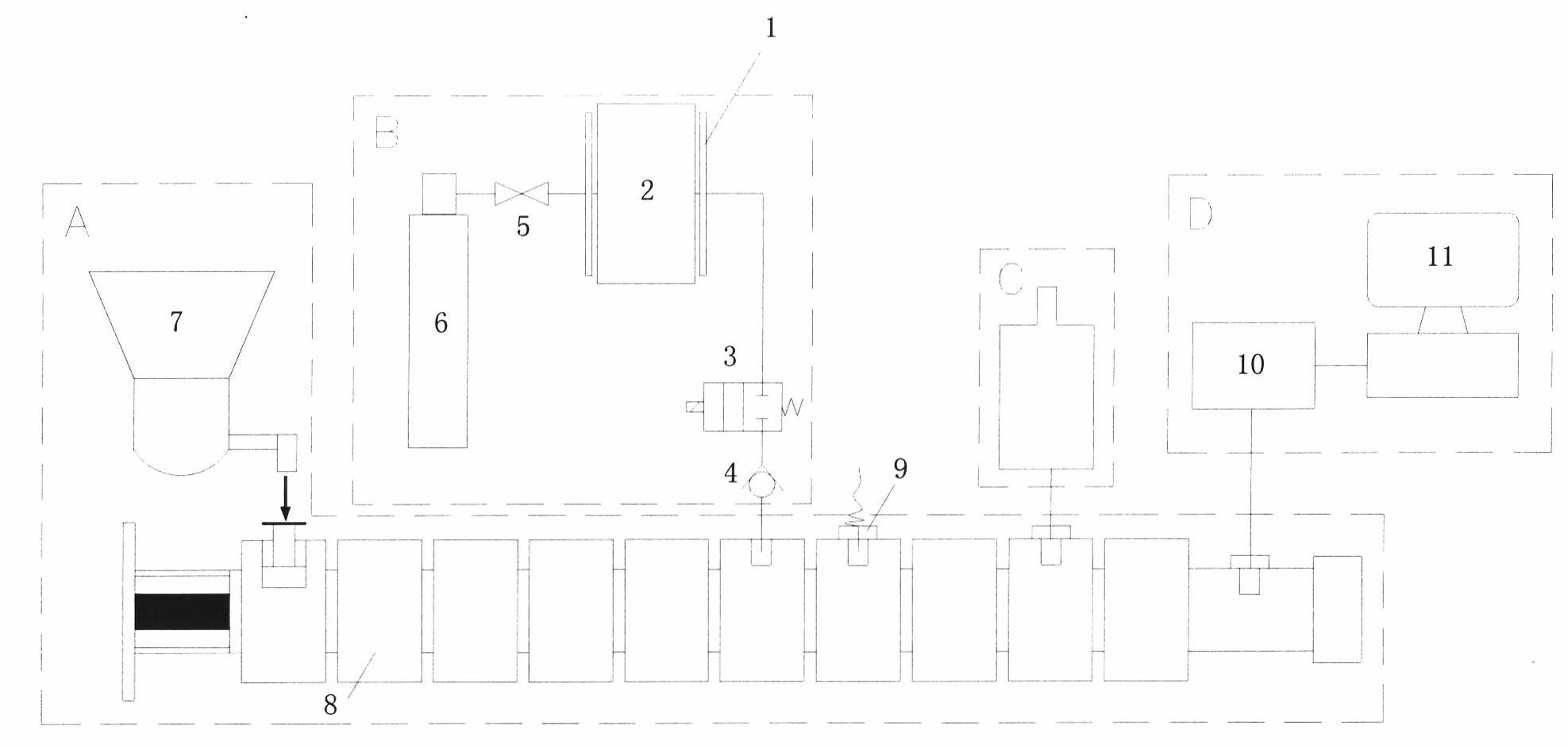

Equipment for extruding/injecting polymer nano-composite through water-assisted mixing and realization method of equipment

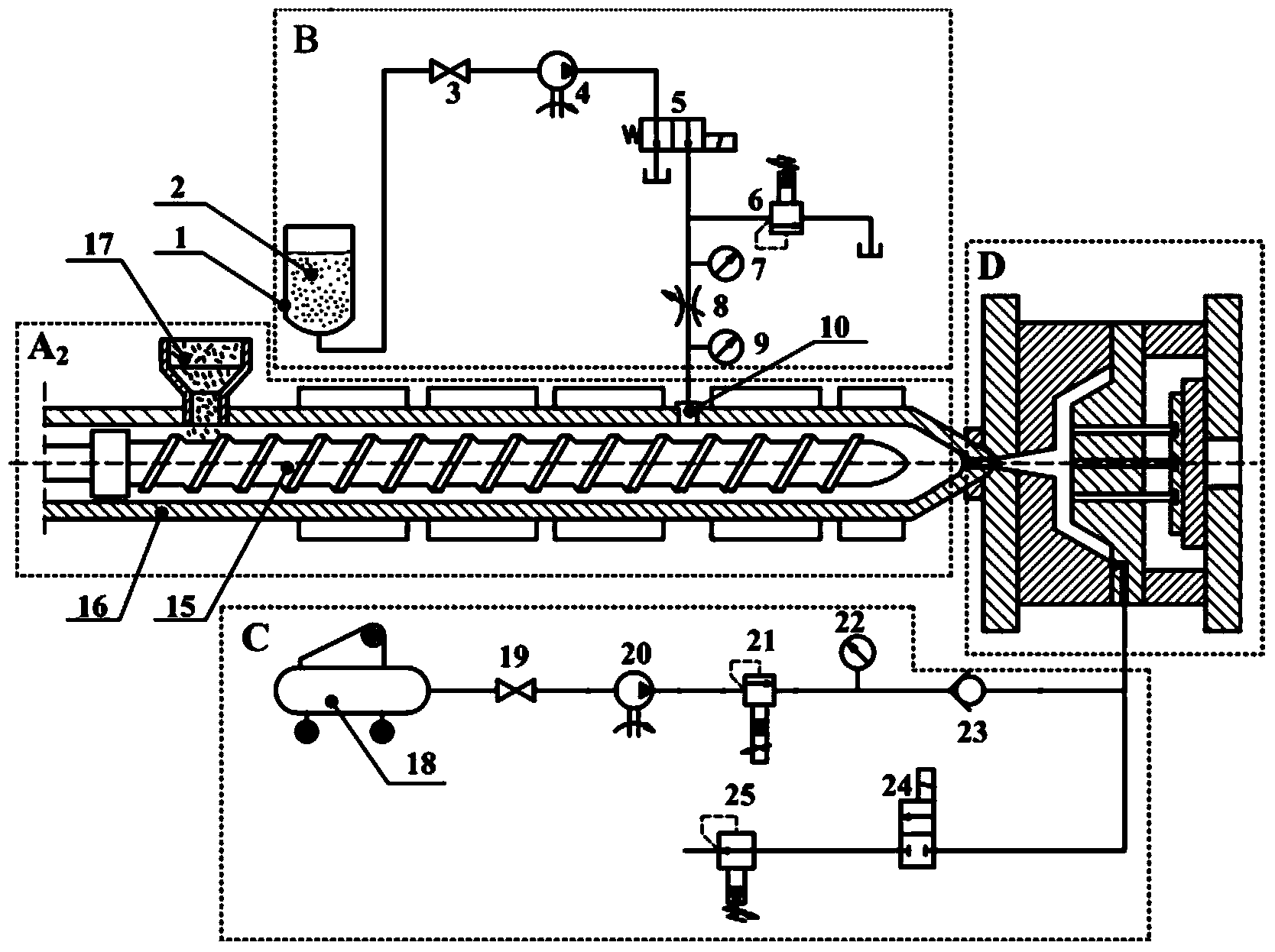

The invention provides equipment for extruding / molding a polymer nano-composite through water-assisted mixing. The equipment for extruding / molding the polymer nano-composite through the water-assisted mixing comprises an extruder, a water-based nano particle suspension injection device and an exhausting device which is capable of discharging vapor formed after vaporization of a water-based nano particle suspension from a machine cylinder of the extruder; the equipment for extruding / molding the polymer nano-composite through the water-assisted mixing comprises an injection molding machine, an injection molding mould, a water-based nano particle suspension injection device and a mould cavity gas back-pressure device which is capable of supplying back-pressure gas into a cavity of the injection molding mould and discharging the back-pressure gas. The invention further provides a method for extruding and molding the polymer nano-composite through the water-assisted mixing. The equipment and the method provided by the invention can be used for uniformly dispersing nano particles into a polymer matrix, have the advantages of low cost, compact structure, simplicity and convenience in operation, and are applicable to industrial application.

Owner:SOUTH CHINA UNIV OF TECH

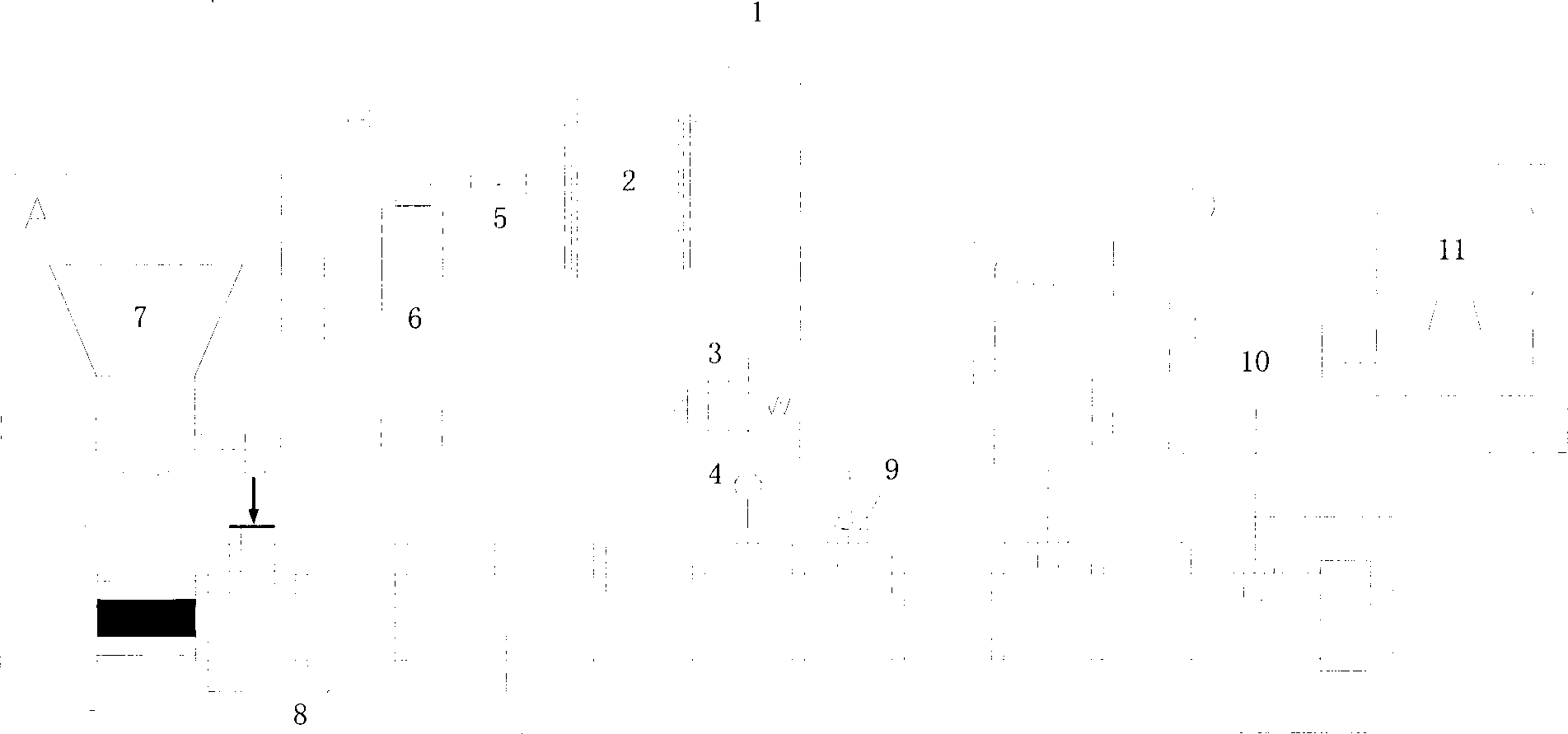

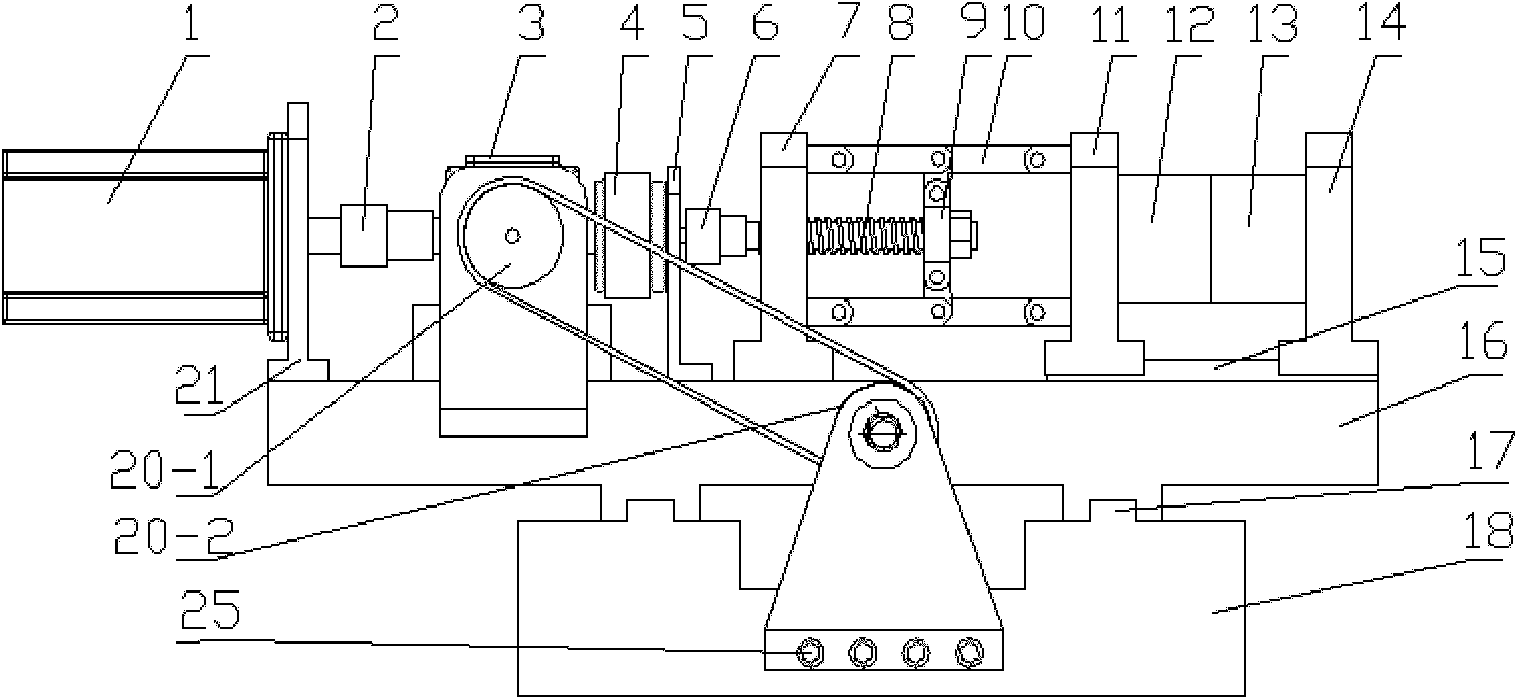

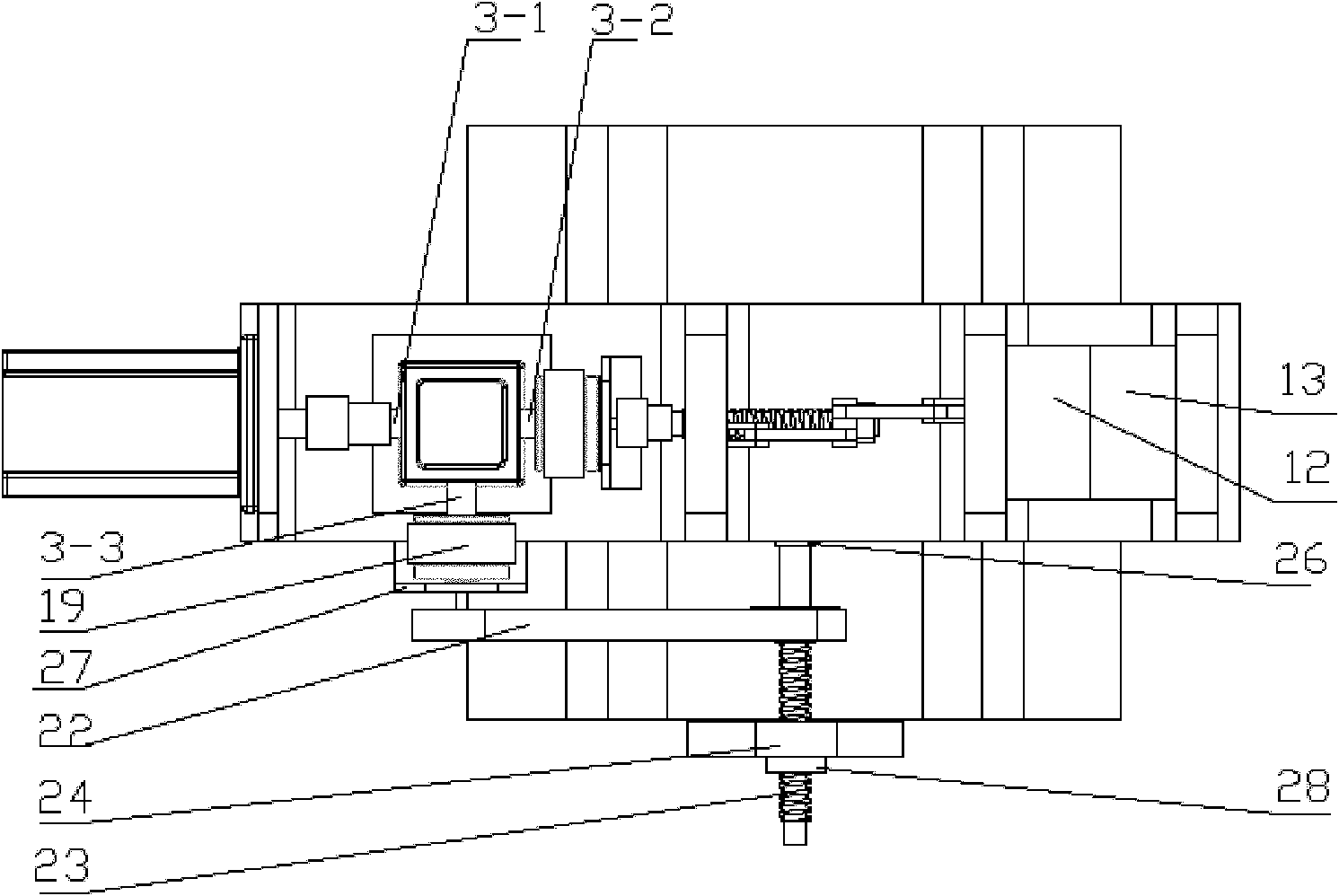

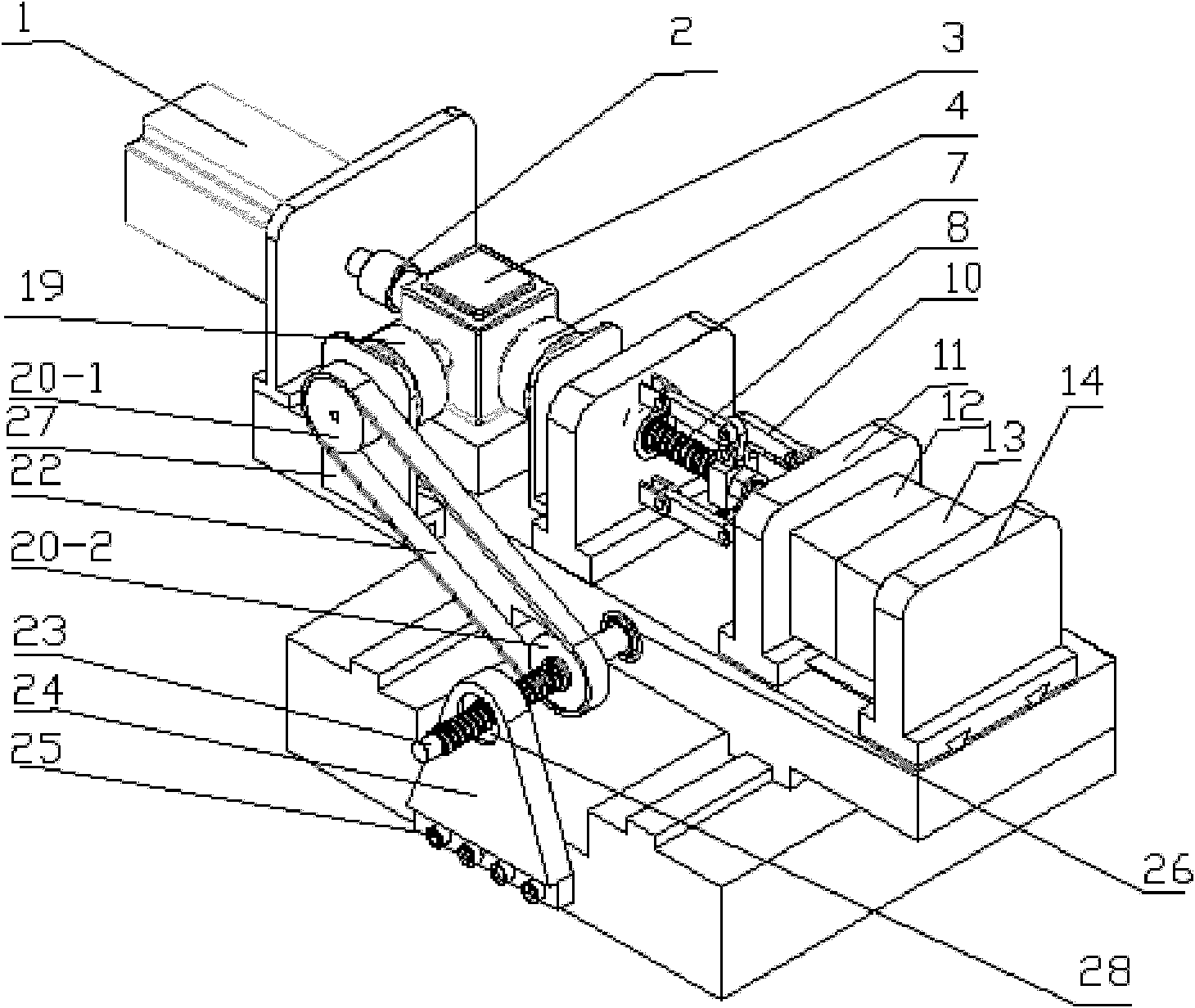

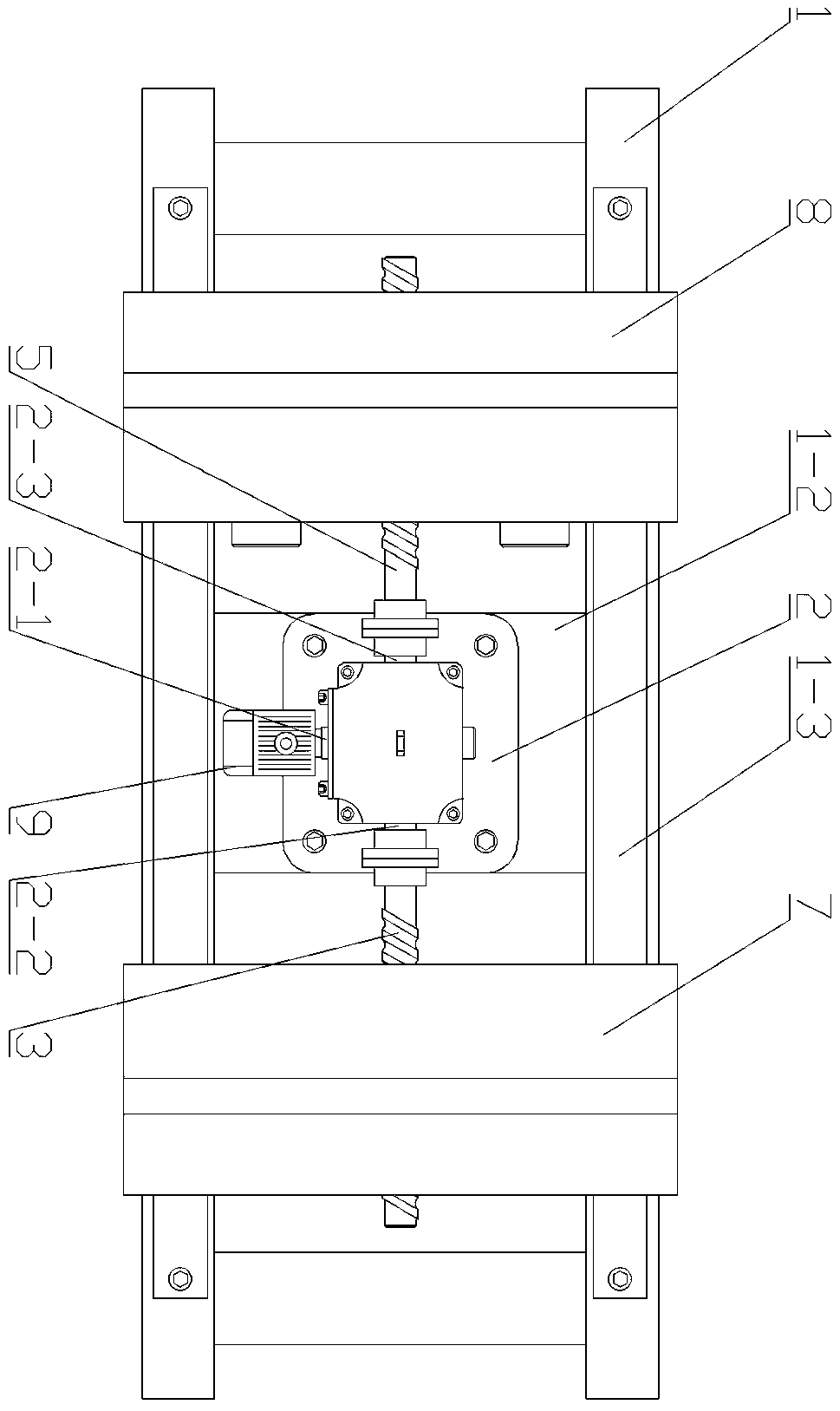

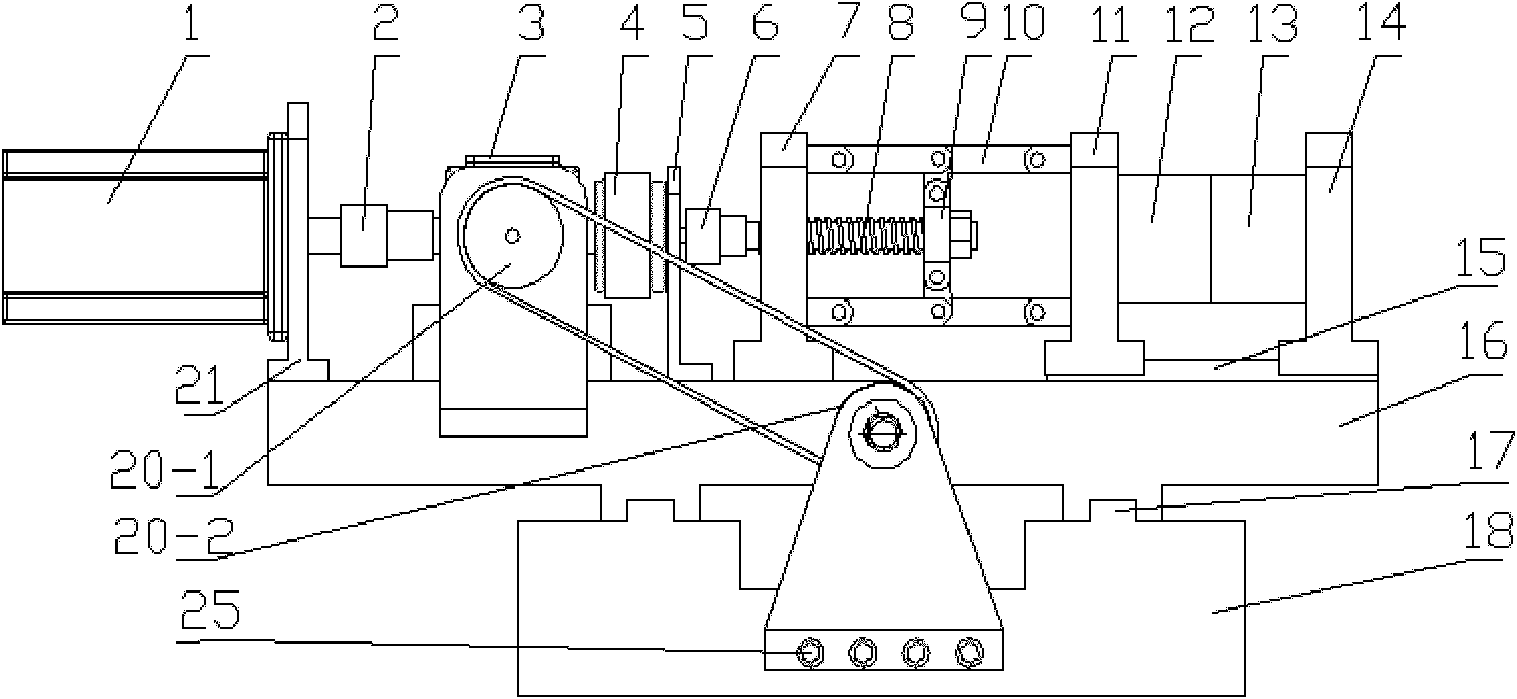

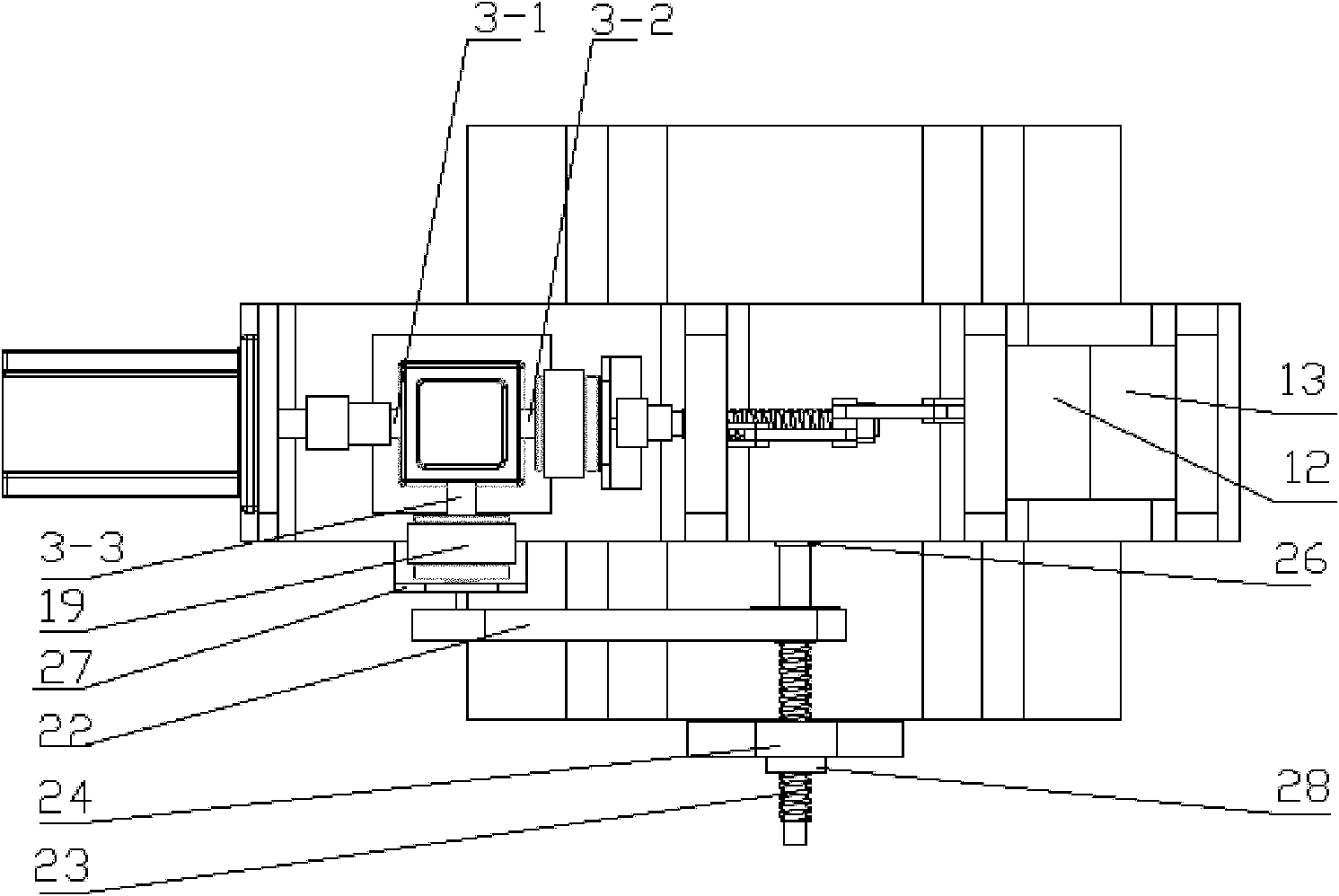

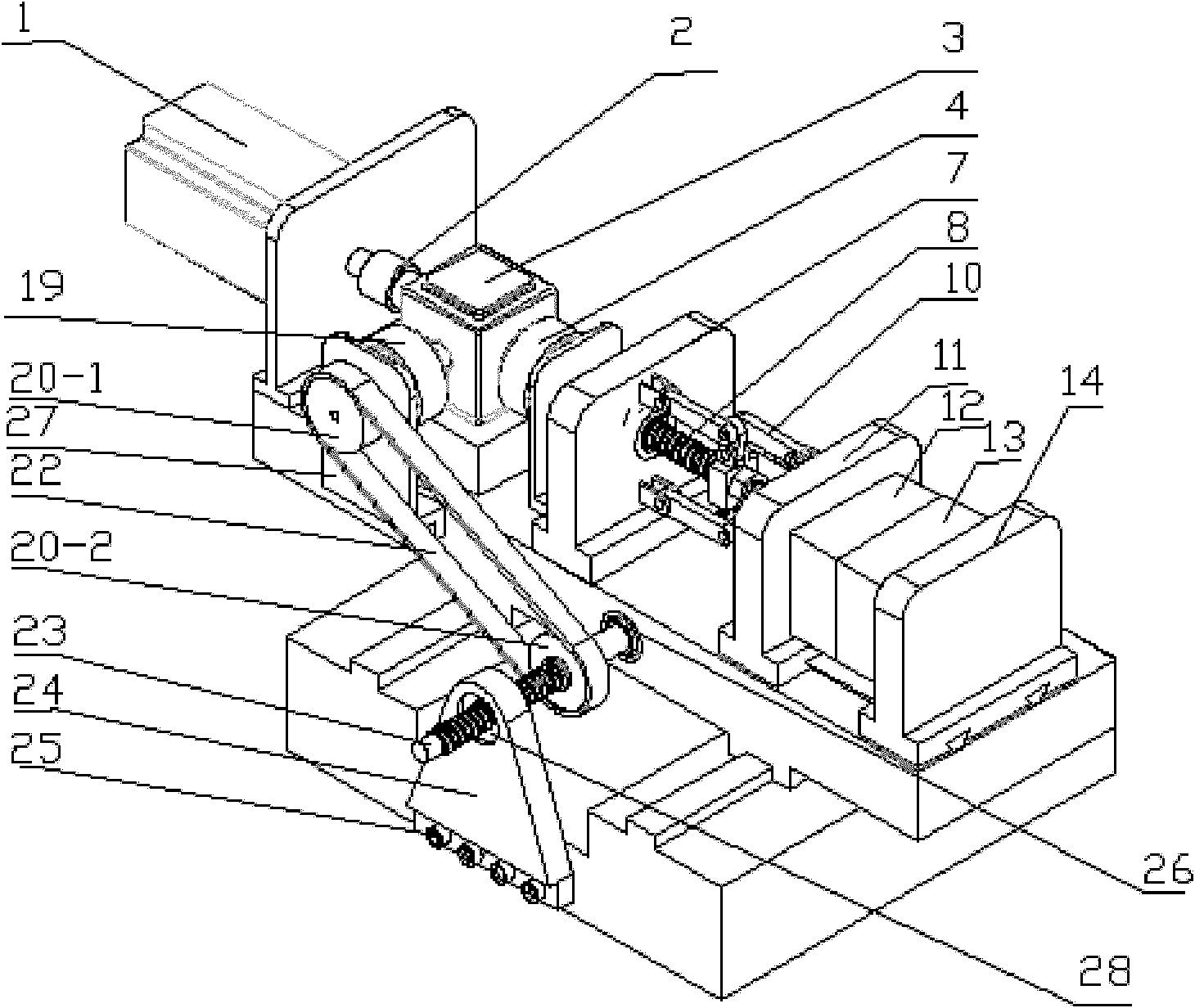

Single-motor-driven all-electric mold closing and moving system and implementation method and application thereof

The invention provides a single-motor-driven all-electric mold closing and moving system. The system comprises a motor, a main coupler, a steering device, a mold closing device, a mold moving device, a support plate and a base, wherein the motor is connected with the steering device through the main coupler; the steering device is provided with a plurality of output ends and is respectively connected with the mold closing device and the mold moving device; the motor, the main coupler, the steering device and the mold closing device are connected into a whole and fixed on the support plate; and the support plate and the mold moving device are connected with each other and are arranged on the base. Meanwhile, the invention provides a single-motor-driven all-electric mold closing and moving method realized by the system. The all-electric mold closing and moving system has a compact structure and is easy to popularize and apply, the manufacturing cost and energy consumption can be reduced, materials can be saved, reliability can be improved, and the service life of the motor and a ball screw can be obviously prolonged.

Owner:SOUTH CHINA UNIV OF TECH

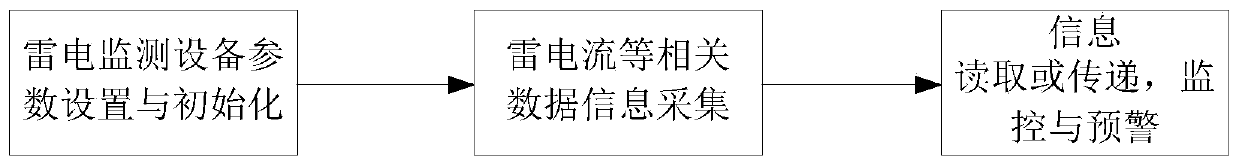

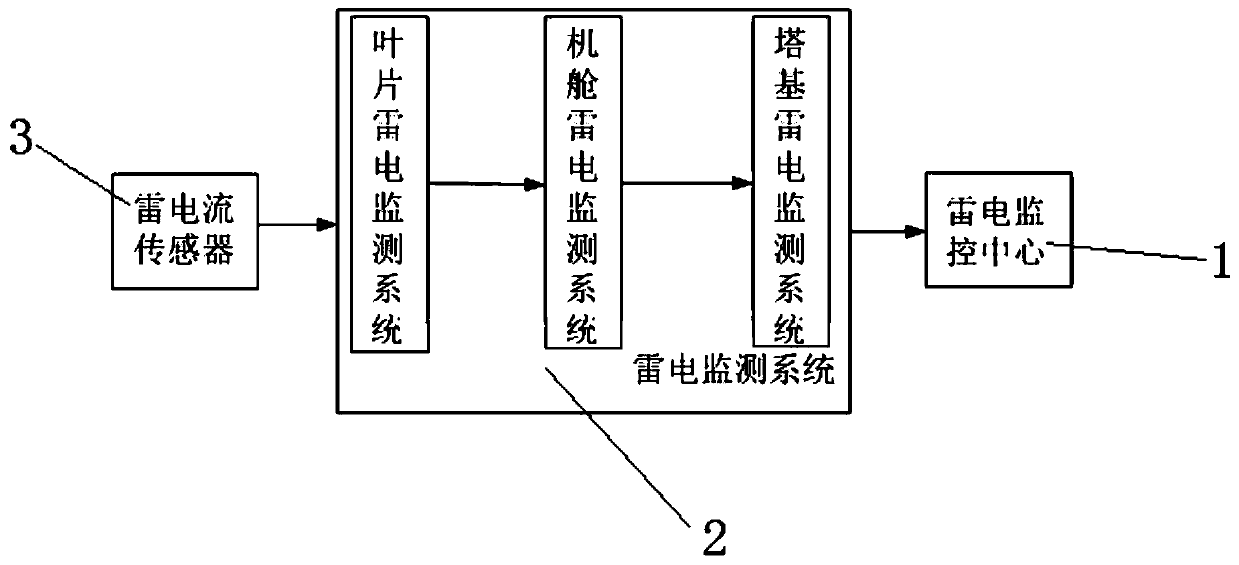

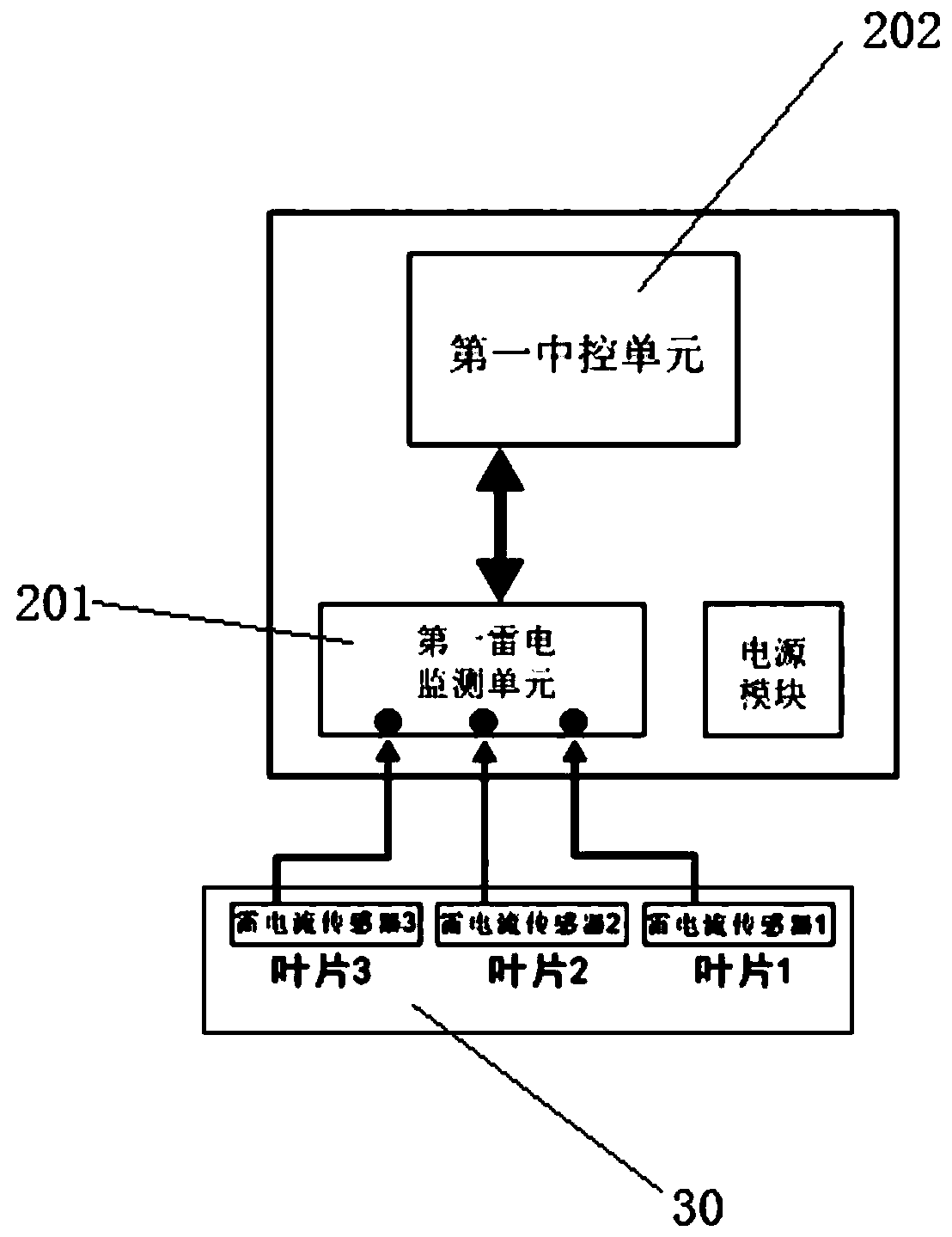

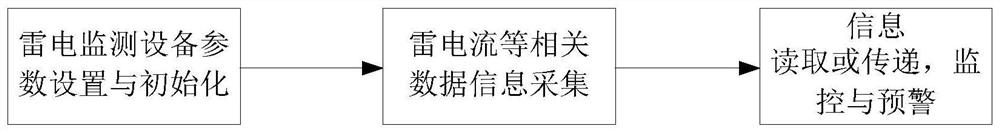

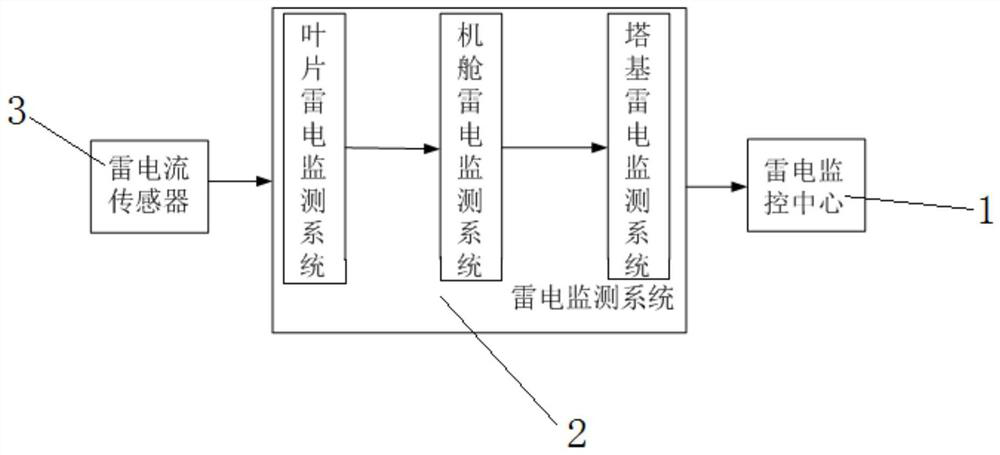

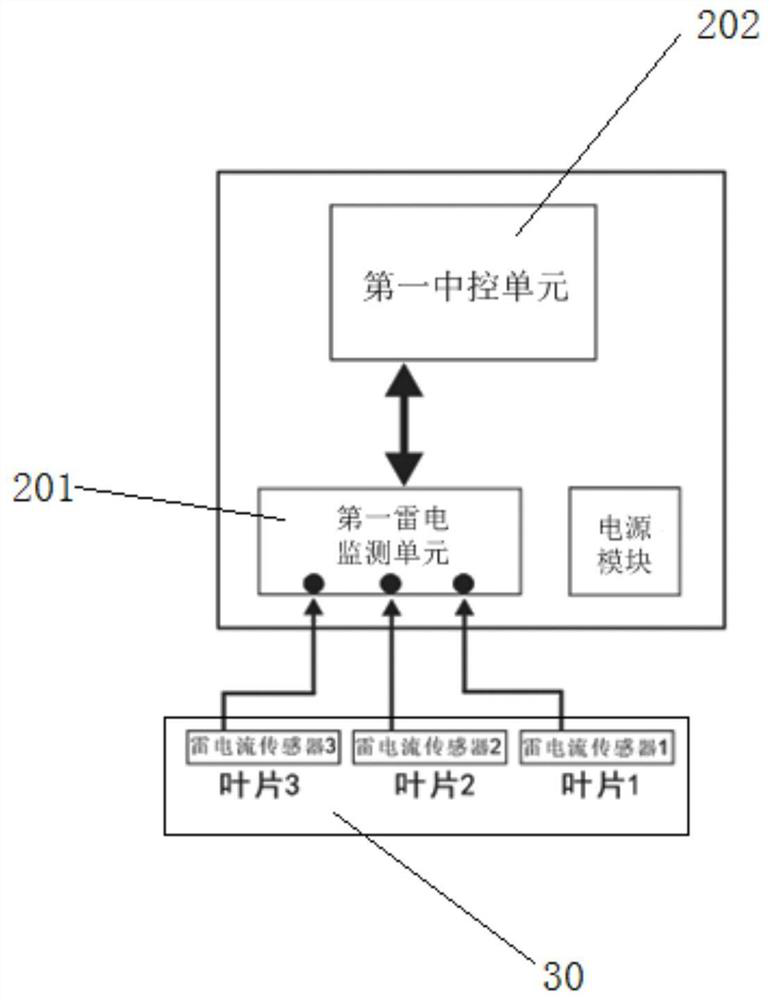

Wind power comprehensive lightning protection monitoring method

ActiveCN110045178AReal-time measurementReal-time processingElectrical testingMeasurement using digital techniquesWind drivenNacelle

The invention discloses a wind power comprehensive lightning protection monitoring method, and solves the problem that a lightning protection detection method in the current wind power field cannot accurately master the lightning stroke time, the number of times and the amplitude of a wind driven generator in real time, and cannot efficiently carry out fault early warning. The wind power comprehensive lightning protection monitoring method comprises the following steps of S1, performing initialization and parameter setting on a site, equipment, network information, touch screen calibration, alightning current acquisition module, an SPD unit module, a grounding resistance module and a connection resistance module of lightning monitoring equipment by using central controller configuration software; S2, according to various parameters set in step S1, consecutively collecting lightning current information when blades, a cabin and a tower foundation of the wind driven generator are subjected to lightning stroke, cabin and tower foundation SPD state information of the wind driven generator, and values of a cabin carbon brush connection resistor and a tower foundation grounding resistor;and S3, according to the step S2, carrying out reading or transmitting by accessing a fan control system, a remote monitoring platform or a local connection terminal, and monitoring and analyzing various measured values and carrying out early warning.

Owner:北京时域智控技术有限公司

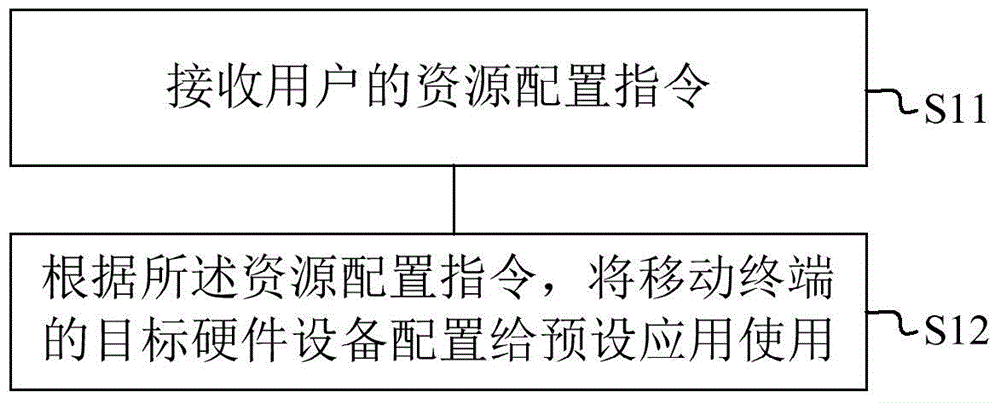

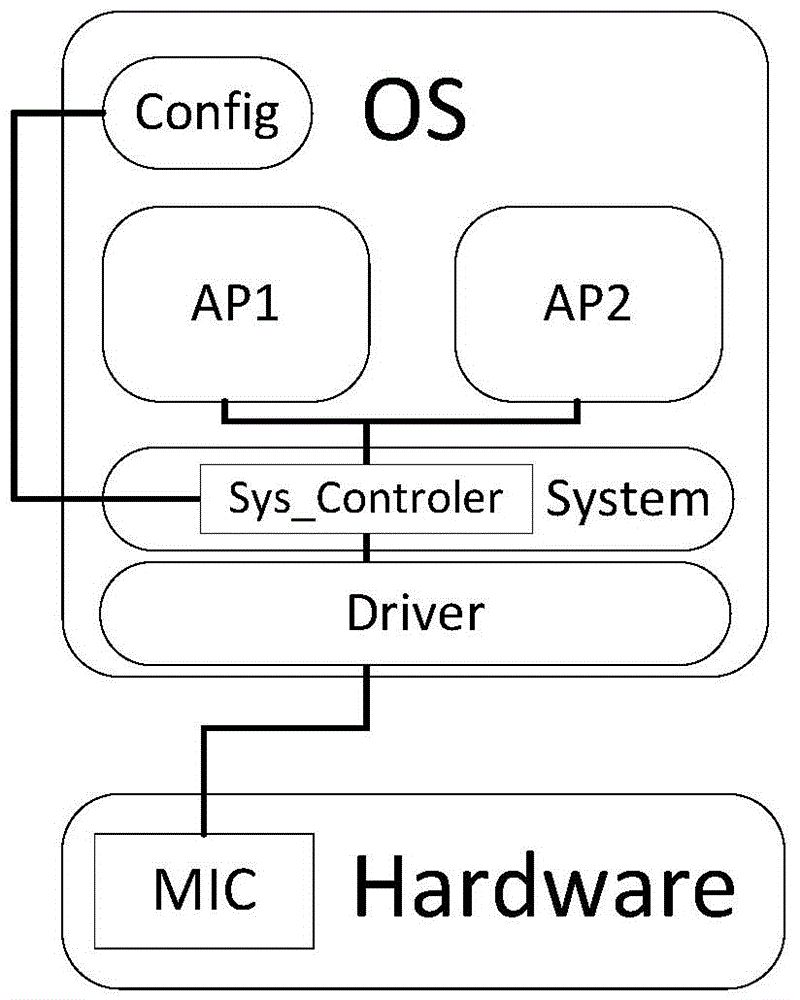

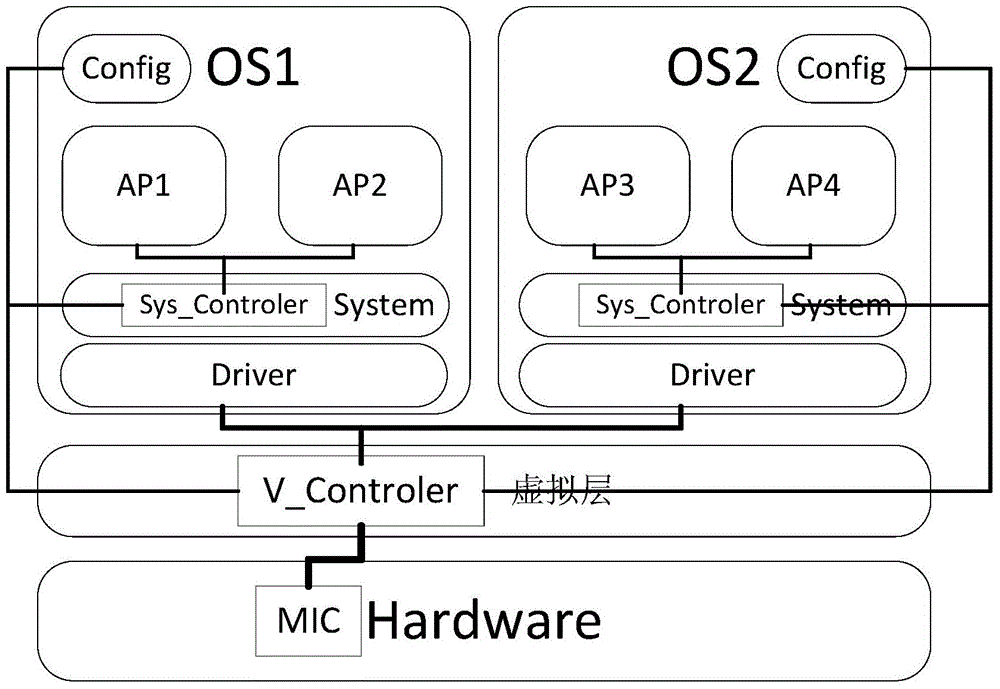

Method and apparatus for sharing hardware device by multiple applications

InactiveCN106293925AReasonable operation processImprove user experienceResource allocationMultiple applicationsComputer terminal

The invention discloses a method and an apparatus for sharing a hardware device by multiple applications, and relates to the technical field of mobile communications. A target hardware device can be configured for a preset application at any time according to a user demand, so that the user experience is effectively improved. The method comprises the steps of receiving a resource configuration instruction of a user; and configuring the target hardware device of a mobile terminal for the preset application according to the resource configuration instruction.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

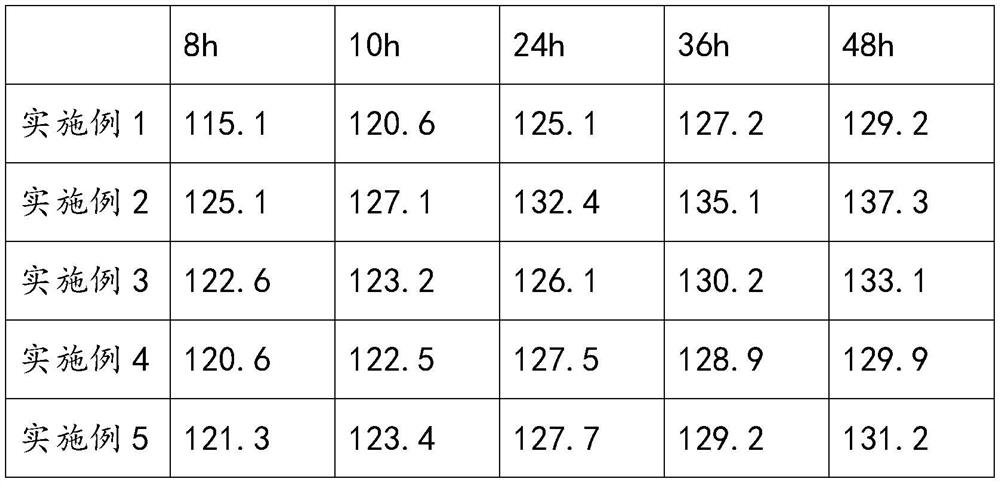

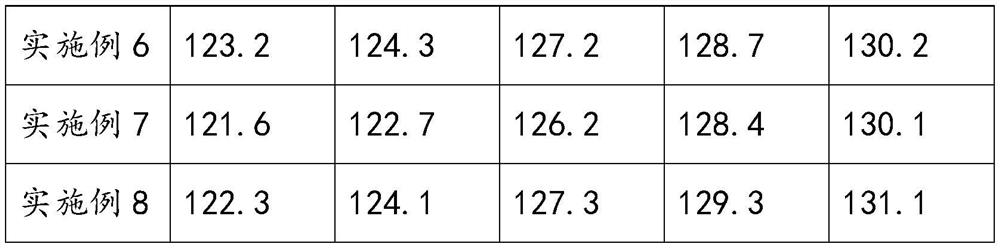

Oolong tea sugar-free buccal tablet and preparation method thereof

The invention discloses an oolong tea sugar-free buccal tablet which is prepared from the following raw materials by weight percentage: 8-12% of instant oolong tea powder, 60-70% of xylitol, 10-20% of beta-cyclodextrin, 2-5% of citric acid, 0.2-0.5% of sucralose, 0.2-0.6% of vitamin C, 0.4-0.6% of vanillin and 1-2% of magnesium stearate, wherein the sum of the weight percentages of all the raw materials is equal to 100%. Meanwhile, the invention discloses a preparation method of the oolong tea sugar-free buccal tablet. The preparation method comprises the steps of: pre-treating the raw materials, preparing raw material powder, and granulating and pressing. The prepared oolong tea sugar-free buccal tablet disclosed by the invention has the advantages of being uniform in color and luster, good in rigidity, rich in tea perfume after being placed into a mouth, fine and smooth in mouth feel, cool and palatable, and good in disintegrative performance.

Owner:HUAXIANG YUAN TEA IND

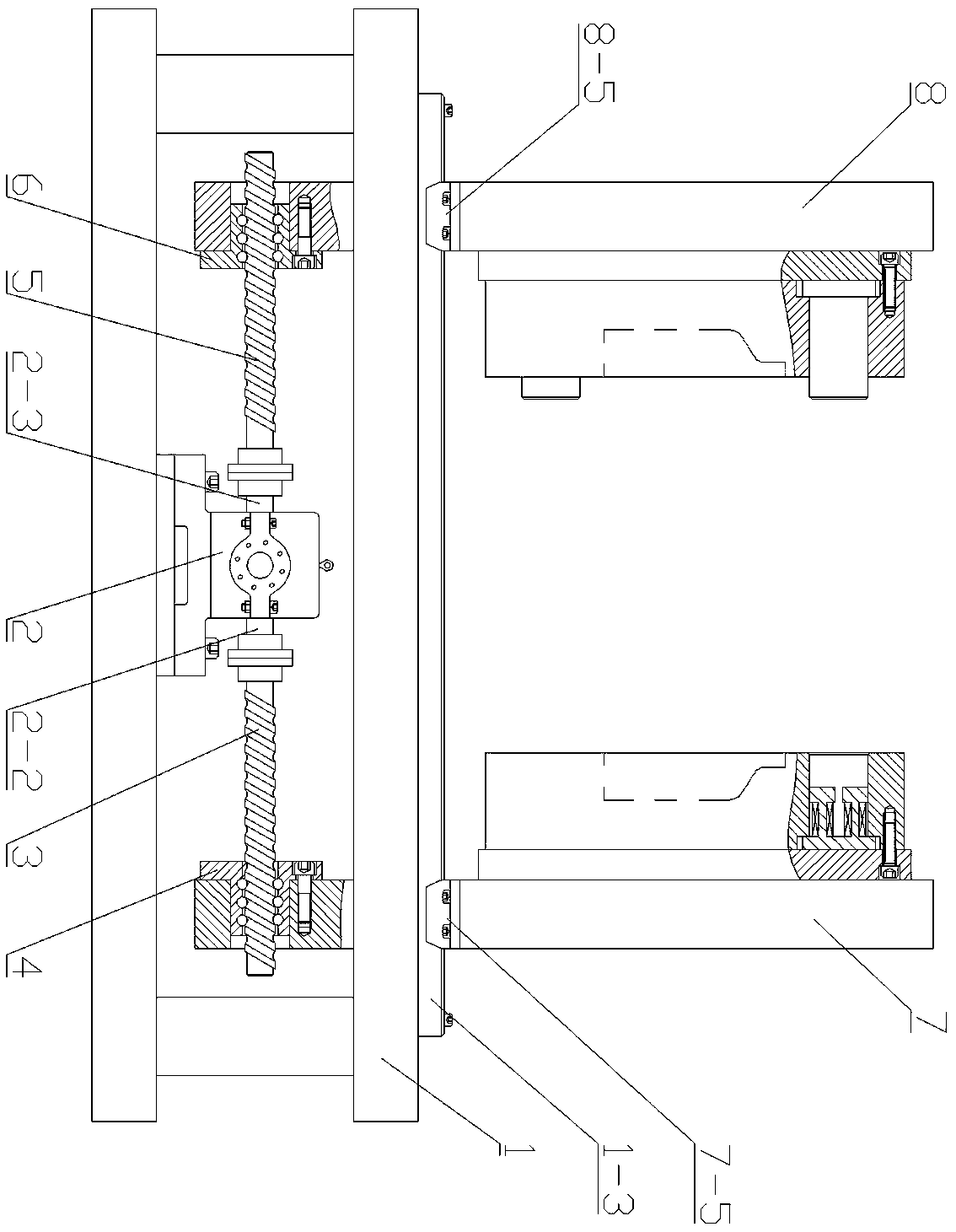

Extrusion blow molding machine electric mold opening and closing device and method based on mold electromagnetic attraction

The invention relates to an extrusion blow molding machine electric mold opening and closing device and method based on mold electromagnetic attraction. A mold cavity half mold assembly and a mold core half mold assembly in the device are integrally mounted on a machine frame linear guideway through a first slider and a second slider on the mold cavity half mold assembly and the mold core half mold assembly, a bevel gear box and a servo motor are fixedly mounted on a bevel gear box mounting plate of a machine frame, one end of a first ball screw is connected with a first output shaft on the bevel gear box, the other end of the first ball screw is connected with a first screw nut on the mold cavity half mold assembly, one end of a second ball screw is connected with a second output shaft onthe bevel gear box, the other end of the second ball screw is connected with a second screw nut on the mold core half mold assembly, and an output shaft of the servo motor is connected with an inputshaft of the bevel gear box. The servo motor controls the mold cavity half mold assembly and the mold core half mold assembly to realize mold closing and mold opening, and the electromagnetic attraction effect is used, so that generation of a gap between the mold cavity half mold assembly and the mold core half mold assembly under the effect of compressed air is avoided. The invention has the advantages of being compact in structure, low in cost and stable and reliable in clamping process, and facilitating industrial modular application.

Owner:NANHUA UNIV

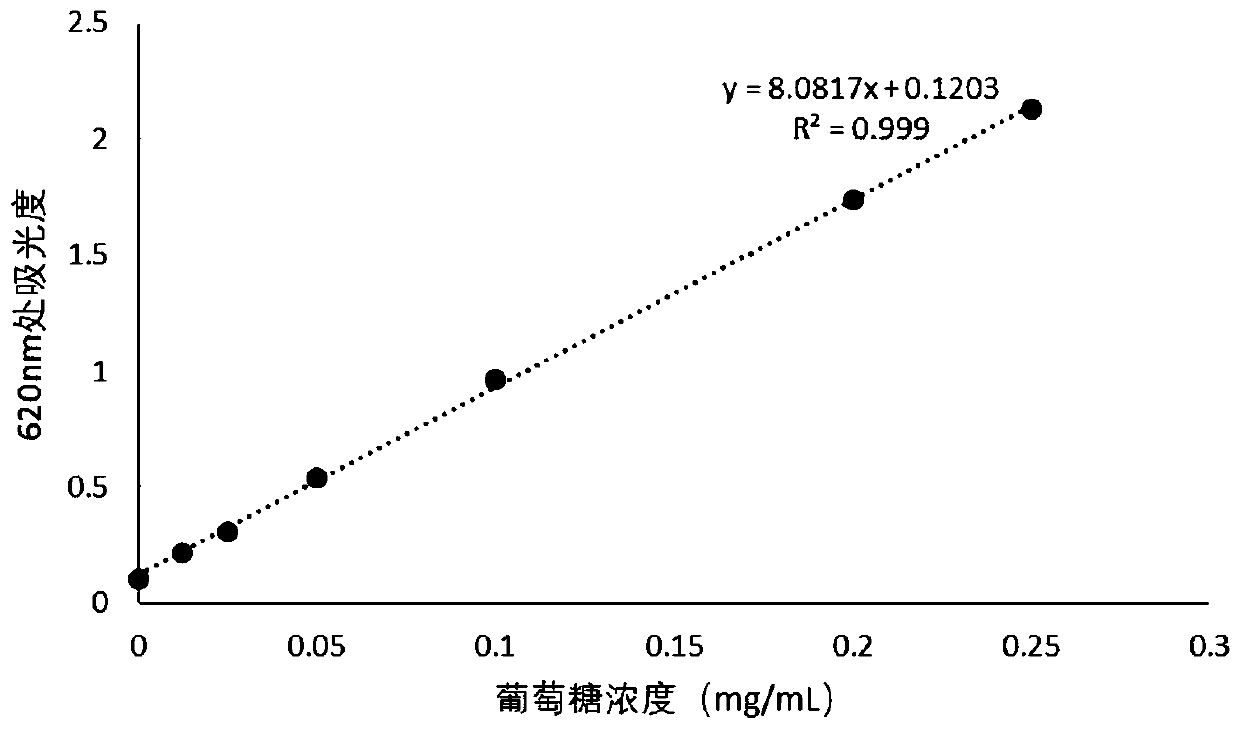

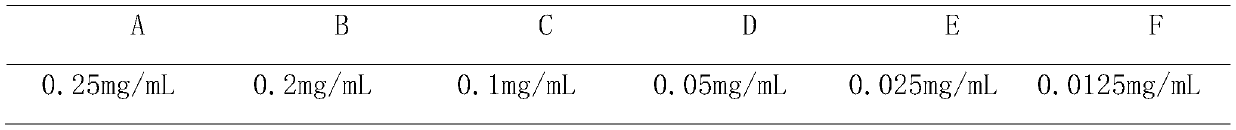

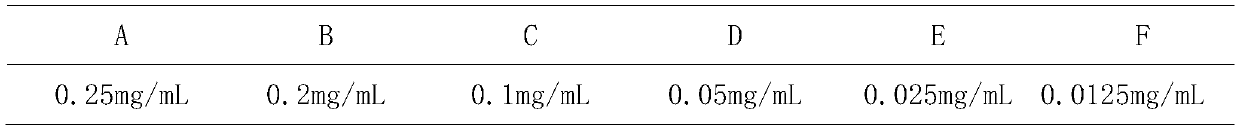

Method for determining glycogen content in oyster tissues

PendingCN111257254AStable and accurate measurementAvoid experimental errorMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsBiotechnologyReagent

The invention provides a method for determining glycogen content in oyster tissues, and belongs to the field of determination of glycogen content in animal tissues, and the method comprises the following steps: preparing a to-be-determined solution, making a standard curve, and determining glycogen content of a sample. In the sample weighing step, a dry weight sample of any mass in an interval range of 18.0-22.0 mg is weighed, for example, a high-precision analytical balance is used to make the sample accurate to 2 bits after a decimal point; meanwhile, a whole set of operation process for determining the glycogen content by an anthrone colorimetric method under a small reaction system (300mu L system) is constructed. The method has the advantages of simple sampling, less used chemical reagents, small reaction system, detection cost saving, and experiment risk reduction.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

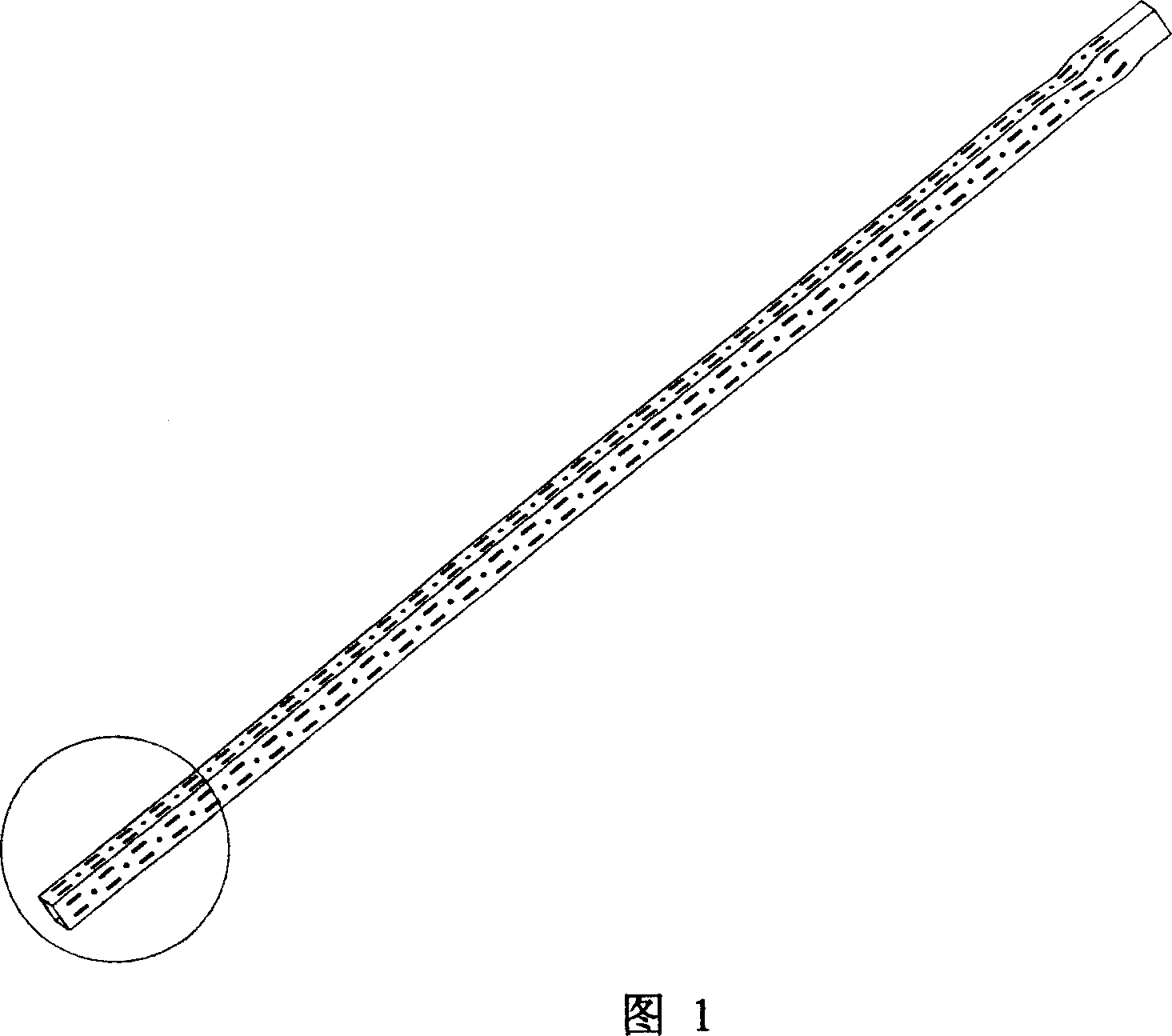

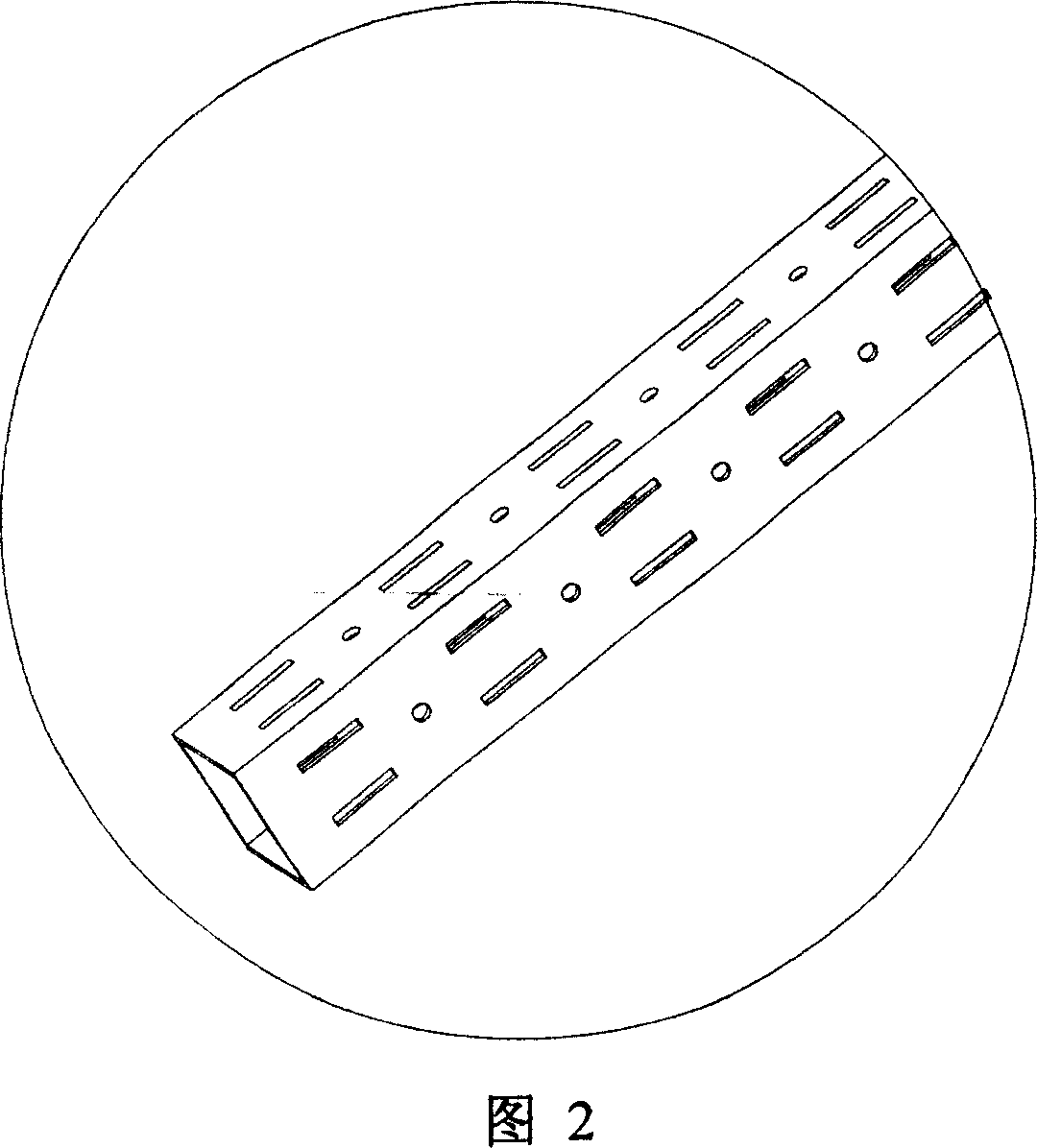

Porous stay tube, preparation method and application

InactiveCN1959177AImprove support strengthStrong rigidityElongated constructional elementsEngineeringButt joint

A method for preparing support tube with multihole includes punching continuous holes on strip material, folding strip material with punched holes, reshaping and butt-jointing folded material to form tubular product with butt-joint edge, welding butt-joint edge of tubular product for obtaining hollow support tube with multihole.

Owner:李明辉

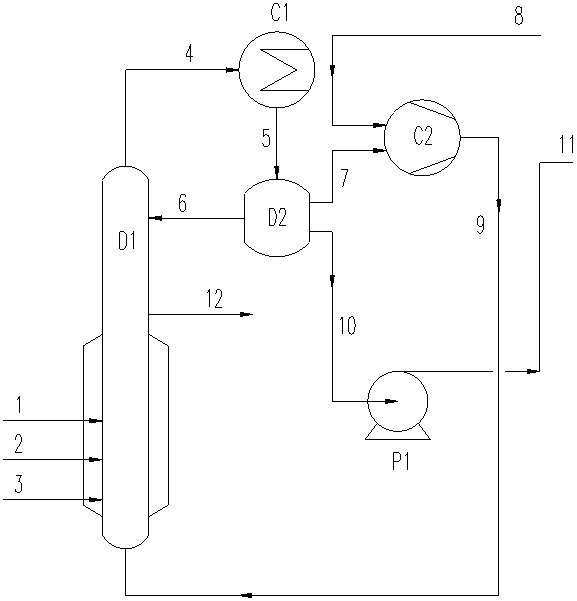

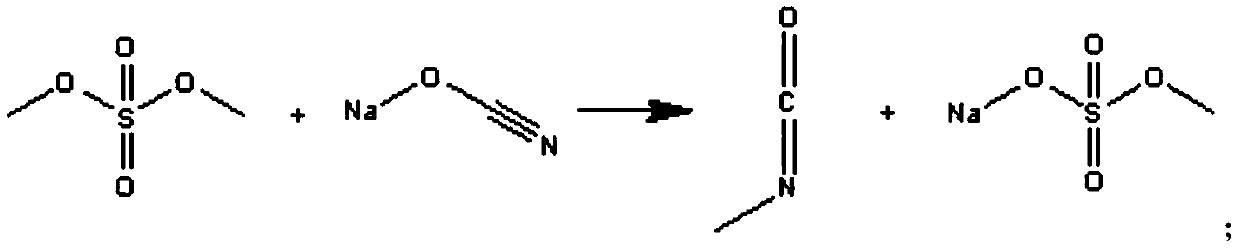

Device for producing methyl isocyanate from dimethyl sulfate and continuous process

ActiveCN111454179AIncrease reaction rateDischarge in timeOrganic compound preparationIsocyanic acid derivatives purification/separationNitrogen gasSodium cyanate

The invention belongs to the technical field of fine chemical synthesis, and particularly relates to a device for producing methyl isocyanate from dimethyl sulfate and a continuous process. The devicecomprises a methyl isocyanate reactor, wherein the methyl isocyanate reactor is connected with a raw material solvent oil feeding pipeline, a sodium cyanate feeding pipeline and a dimethyl sulfate feeding pipeline, the methyl isocyanate reactor is connected with a methyl isocyanate condenser through a post-reaction product discharging pipeline, and is connected with a gas-liquid separation tank through a post-condensation mixture conveying pipeline, the gas-liquid separation tank is connected with a methyl isocyanate reactor through a circulating solvent oil conveying pipeline, a nitrogen compressor is connected with a nitrogen conveying pipeline after gas-liquid separation, and the nitrogen compressor is connected with the methyl isocyanate reactor through a compressed nitrogen conveyingpipeline, and the gas-liquid separation tank is connected with a methyl isocyanate discharging pump through a methyl isocyanate conveying pipeline after gas-liquid separation. According to the method, continuous production of methyl isocyanate can be realized by using dimethyl sulfate, the reaction rate is high, and the yield is high.

Owner:河南金鹏化工有限公司

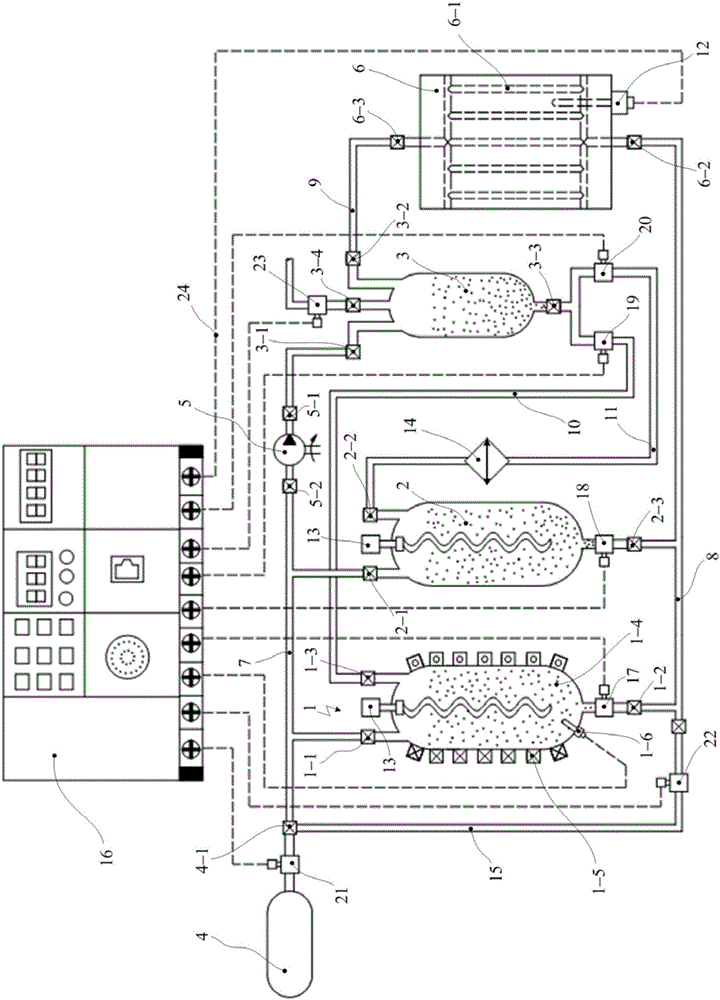

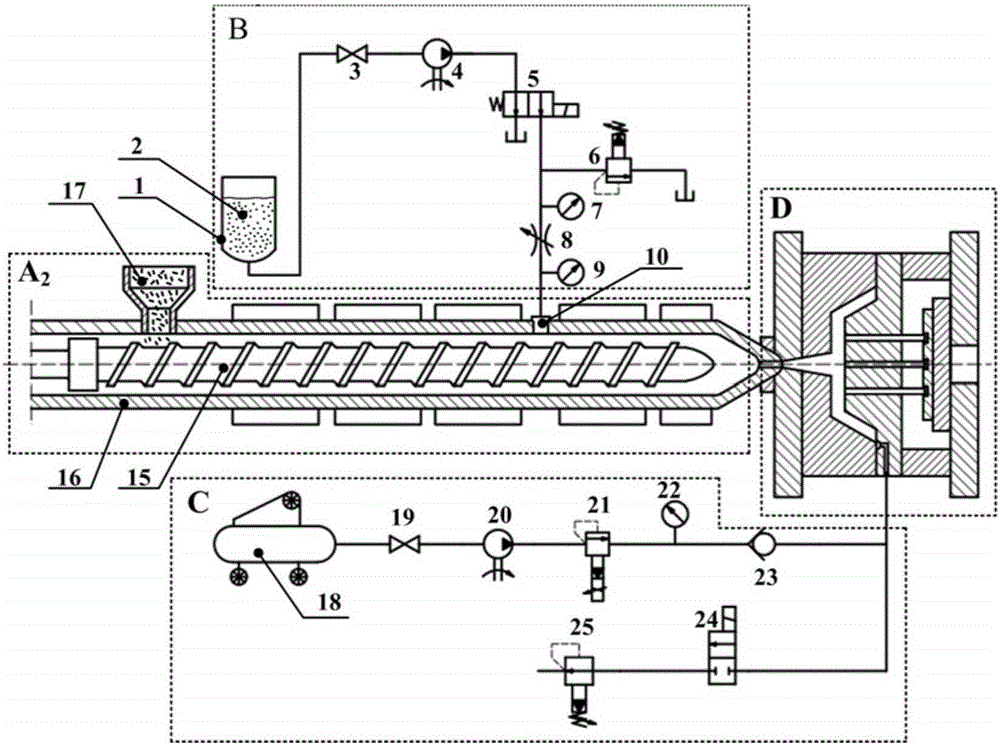

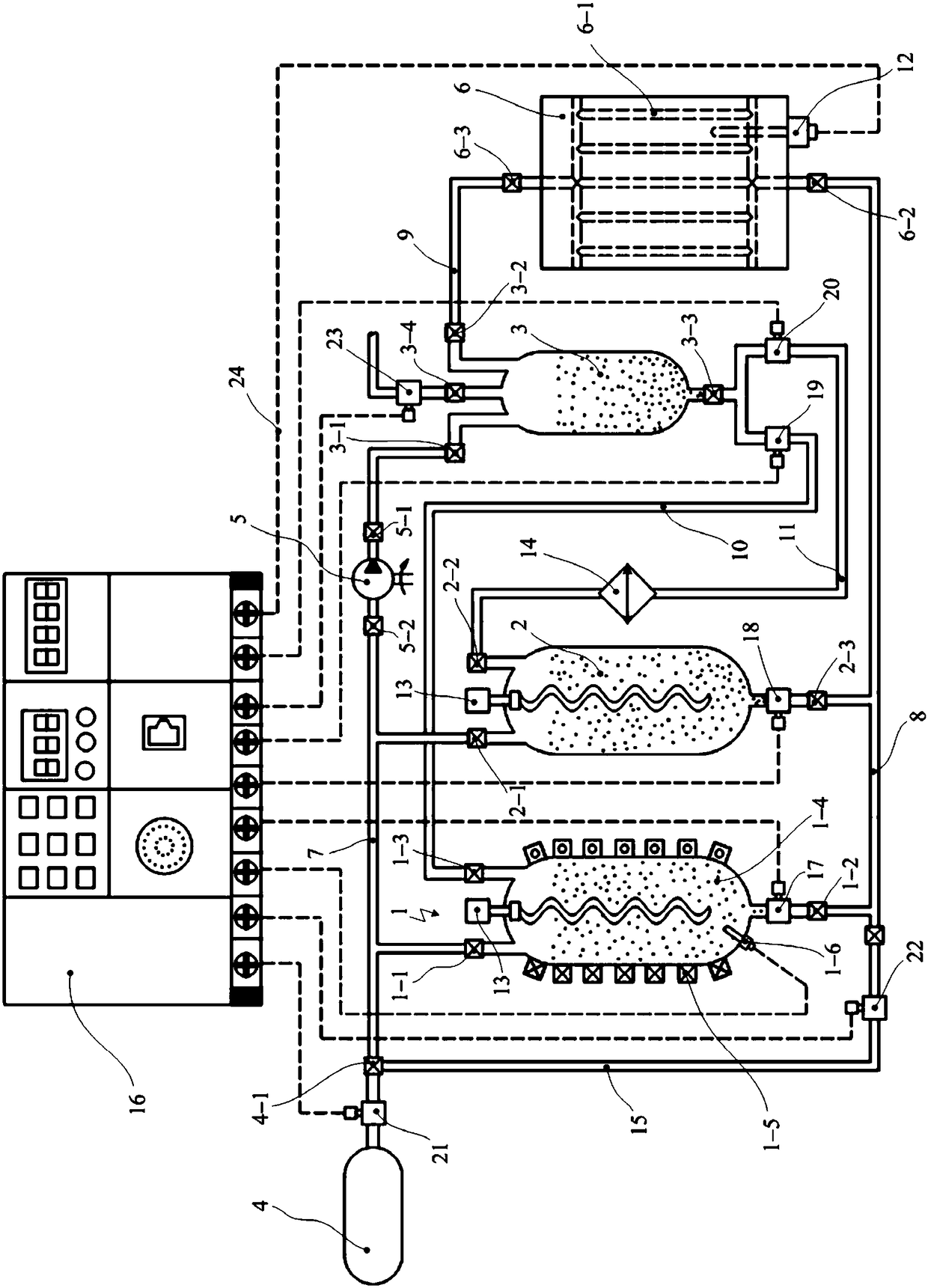

Nanofluid-assisted rapid heating cycle injection molding system and injection molding method

The invention provides a nanofluid-assisted rapid heating cycle injection molding system. The nanofluid-assisted rapid heating cycle injection molding system comprises a high-temperature nanofluid generation and storage device, a low-temperature nanofluid storage tank, a nanofluid recycle tank, a high-pressure gas supply device, a gas booster pump, an injection mold and a mold temperature control unit. The invention further provides a nanofluid-assisted rapid heating cycle injection molding method realized through the system. Compared with the existing rapid heating cycle injection molding technology based on high-temperature oil, superheated water or steam heating and cooling water cooling of molds, the system and the method have the advantages that the new heat transfer enhancement working medium, namely nanofluid is adopted as the heating medium and the cooling medium of the mold, and therefore the heating efficiency and the cooling efficiency of the mold can be remarkably improved. In addition, the system has the advantages that the structure is simple, the material is saved, the consumption is lowered, the work flow is reasonable and the structure of the existing molds do not need to be transformed when the prior art is replaced, thereby being suitable for being widely applied and popularized in industrial production. The invention belongs to the technical field of rapid heating cycle injection molding of high polymer material.

Owner:湖南省山力新材料有限责任公司

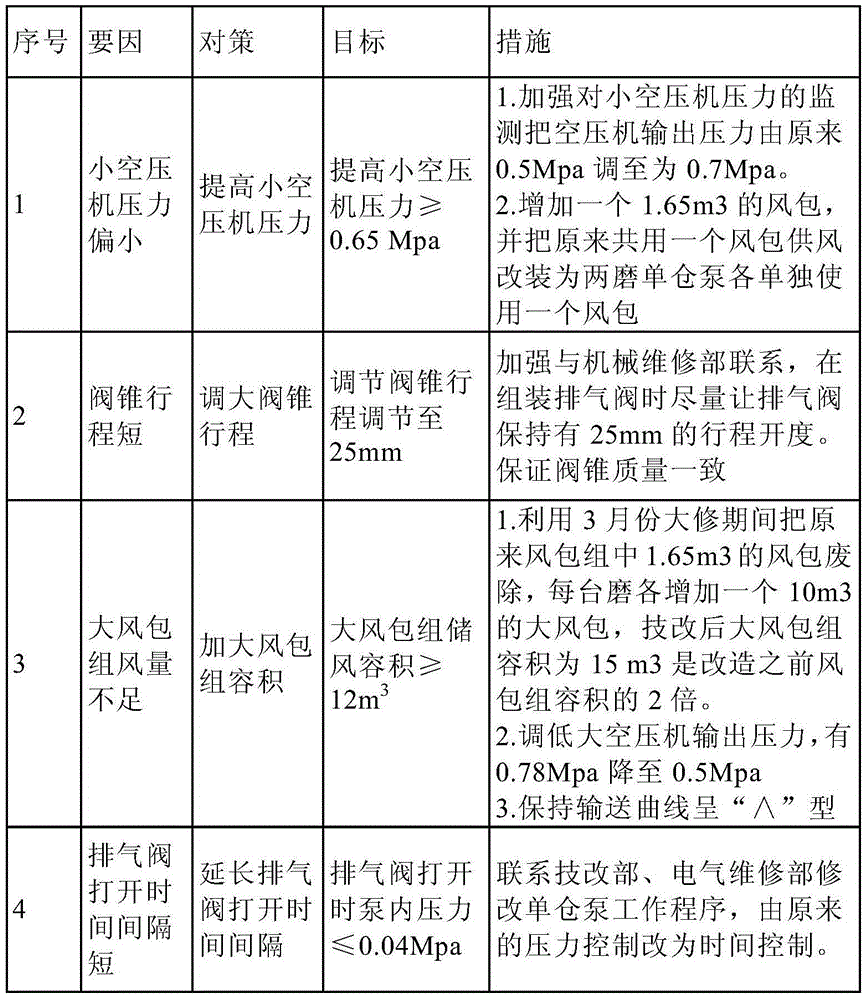

Method for prolonging service time of cement grinding mill

InactiveCN104549657AExtended use timeExtend the open intervalGrain treatmentsInternal pressureExhaust valve

The invention discloses a method for prolonging the service time of a cement grinding mill. The method comprises the following steps: increasing the pressure of a small air compressor, wherein the pressure of the small air compressor is greater than or equal to 0.65Mpa; increasing the stroke of a valve cone, wherein the stroke of the valve cone is adjusted to 25mm; increasing the volume of an air trap set, wherein the air storage volume of a large air trap set is greater than or equal to 12m<3>; and extending the open time interval of an exhaust valve, wherein the internal pressure of a pump when the exhaust valve is switched on is less than or equal to 0.04Mpa. The method for prolonging the service time of the cement grinding mill, disclosed by the invention, can be used for overcoming the defects of unreasonable structure, complex operation process and large manual labor intensity and the like in the prior art so as to achieve the advantages of reasonable structure, simple operation process and small manual labor intensity.

Owner:GUANGXI YUFENG CEMENT

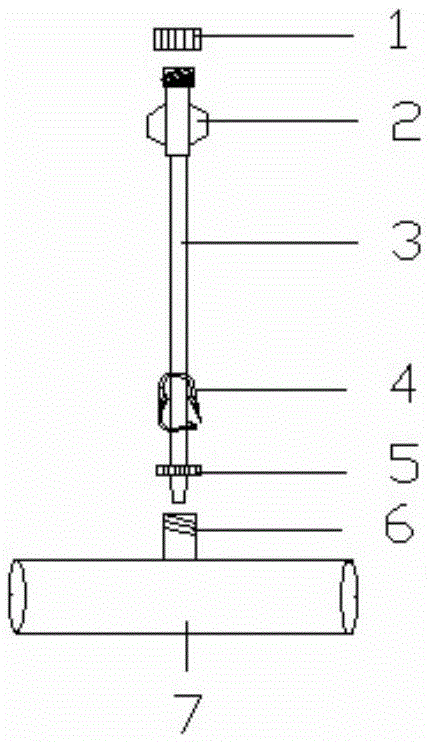

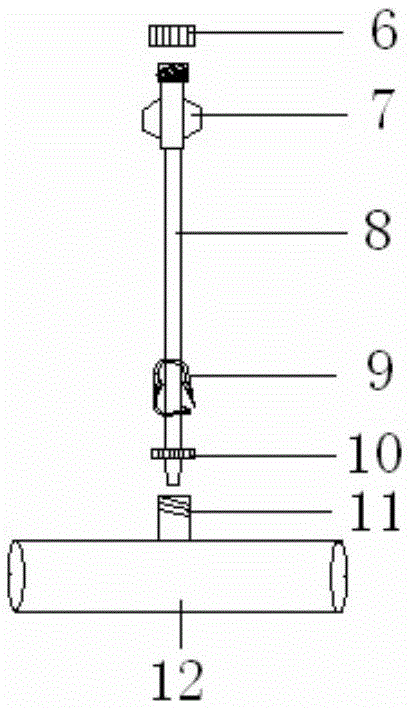

Hematodialysis pre-flushing waste liquid drainage tube

The invention provides a hematodialysis pre-flushing waste liquid drainage tube. The hematodialysis pre-flushing waste liquid drainage tube comprises a type A and a type B. The type A is composed of a cover, a port connected with a blood path tube in a pre-flushing mode, a connecting hose, a clamp and a connecting tube. The type B is composed of a connecting port cover, a connecting port with a thread, a waste liquid drainage connecting tube, a waste liquid drainage connecting tube clamp, a fastening ring, a tee joint vertical port and a tee joint. The idea of totally-closed pre-flushing of a disposable hematodialysis pipeline can be achieved, pre-flushing waste liquid can be directly drained into a waste liquid tube of a dialysis machine during pre-flushing of the disposable hematodialysis pipeline, working processes are simplified, the workload is relieved, and pre-flushing of the blood path tube is easier, more convenient and safer. The hematodialysis pre-flushing waste liquid drainage tube is reasonable in design, lower in use cost and more environmentally friendly, and environmental pollution is relieved.

Owner:ZHEJIANG UNIV

Preparation method of water-based cosmetic based on compositions such as angelica sinensis stem cell extract

InactiveCN112656757AReasonable operation processNo allergic reactionCosmetic preparationsToilet preparationsCell extractionAngelica Sinensis Root

The invention relates to the technical field of cosmetic preparation, and discloses a preparation method of a water-based cosmetic based on compositions such as an angelica sinensis stem cell extract, which comprises the following steps: S1: obtaining tissue component liquid of mesenchymal stem cells; s2, continuously adding a protein culture medium P1 and a double-antibody-containing PBS buffer solution into the cell culture factory, and continuously culturing; and s3, collecting a dissolving solution which does not precipitate after being filtered by the fiber filter paper or the filter membrane into a new container, so as to obtain a solution of a large amount of soluble micromolecular substances such as mucopolysaccharides and liposomes in cells. The invention provides a composition containing a mesenchymal stem cell secretion factor, an angelica sinensis stem cell extract, earthworm kinase and hyaluronic acid. More than 100 active substances are provided. A good absorption state is maintained through a framework body with good hyaluronic acid.

Owner:西安美丽起点生物科技有限公司

PC/PET alloy material production method

The invention relates to a method for preparing PC / PET alloy material, and belongs to plastic shaping processing technology. It comprises: mixing milled PC granulate powder, PET sheet and lubricating agent, precrystallizing, drying, mxing refining, plasticizing, neck ring mold shaping, cooling and calendering. The PC / PET alloy material is characterized by good thermal resistance, strength, tranparency, good size stability and small thickness deviation, and is ideal replacement for electrical switching membrane, car instrument board and car glass, and the production method is characterized by low cost and high efficiency.

Owner:扬州金丰新材料有限公司

Composition comprising mesenchymal stem cell secretion factor, contents and dandelion stem cell extract and preparation method thereof

InactiveCN112807270AWell absorbed stateNo allergic reactionCosmetic preparationsToilet preparationsBiotechnologyCell extraction

The invention discloses aims to implement a composition comprising a mesenchymal stem cell secretion factor, contents and a dandelion stem cell extract and a preparation method thereof by the following technical scheme that: the composition comprises the following component raw materials in parts by weight: 10 to 25 parts of mesenchymal stem cell secretion factor freeze-dried powder, 10 to 20 parts of dandelion stem cell extract, 10 to 30 parts of hyaluronic acid, 1 to 8 parts of earthworm kinase, 0.01 to 1 part of aromatic, 2 to 10 parts of emulsifier and 0.1 to 1 part of thickening agent. The composition has no allergic reaction for skin, cannot cause irritant or reactive dermatitis, is small in molecular weight, and is a high-quality cosmetic which can show various effects and can be effectively absorbed.

Owner:西安美丽起点生物科技有限公司

Water-assisted mixing extrusion/injection molding polymer nanocomposite equipment and realization method

The invention provides equipment for extruding / molding a polymer nano-composite through water-assisted mixing. The equipment for extruding / molding the polymer nano-composite through the water-assisted mixing comprises an extruder, a water-based nano particle suspension injection device and an exhausting device which is capable of discharging vapor formed after vaporization of a water-based nano particle suspension from a machine cylinder of the extruder; the equipment for extruding / molding the polymer nano-composite through the water-assisted mixing comprises an injection molding machine, an injection molding mould, a water-based nano particle suspension injection device and a mould cavity gas back-pressure device which is capable of supplying back-pressure gas into a cavity of the injection molding mould and discharging the back-pressure gas. The invention further provides a method for extruding and molding the polymer nano-composite through the water-assisted mixing. The equipment and the method provided by the invention can be used for uniformly dispersing nano particles into a polymer matrix, have the advantages of low cost, compact structure, simplicity and convenience in operation, and are applicable to industrial application.

Owner:SOUTH CHINA UNIV OF TECH

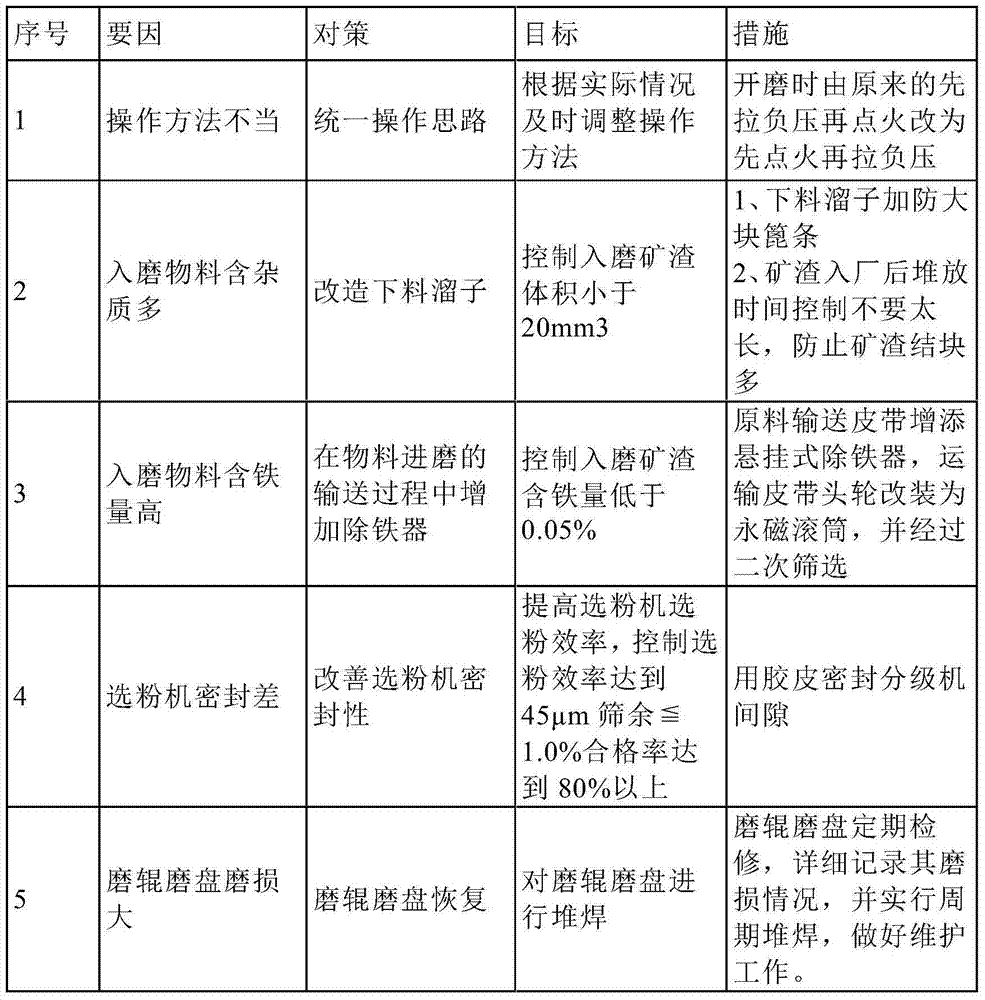

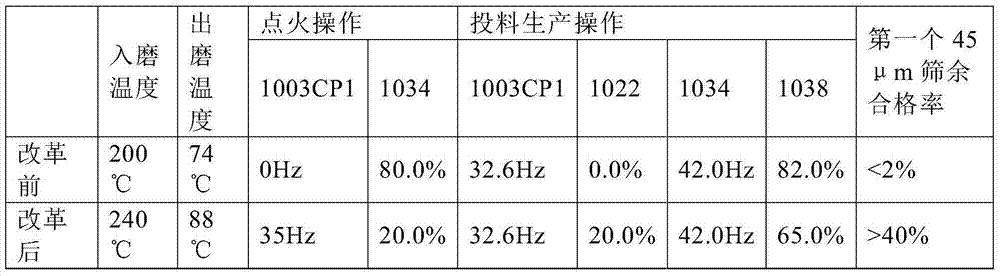

Method for improving qualification rate of mineral powder of slag vertical mill

InactiveCN104492549AImprove pass rateImprove powder selection efficiencyGrain treatmentsSlagImpurity

The invention discloses a method for improving the qualification rate of mineral powder of a slag vertical mill. The method comprises the following steps: adjusting an operation process from the operation of firstly drawing negative pressure and then igniting to the operation of firstly igniting and then drawing the negative pressure at the beginning of milling; adjusting the impurity content in materials entering the mill, transforming a discharging chute and controlling the volume of slag entering the mill to be less than 20mm<3>; adjusting the iron content in the materials entering the mill, increasing an iron remover in the conveying process for feeding the materials into the mill, and controlling the iron content in the slag entering the mill to be less than 0.05%; improving the sealing property of a powder concentrator, sealing a gap of a grader with rubber, improving the powder concentration efficiency of the powder concentrator, controlling the powder concentration efficiency to achieve the level that the content of 45mu m screen residues is not more than 1.0%, and controlling the qualification rate to be above 80%; and restoring a milling roller and a milling plate, performing overlay welding on the milling roller and the milling plate, performing regular maintenance on the milling roller and the milling plate, recording the abrasion situation in a detailed manner, performing periodic overlay welding and performing maintenance work. By adopting the method for improving the qualification rate of the mineral powder of the slag vertical mill, the advantages of reasonable equipment structure, simple operation process and low content of impurities can be realized.

Owner:GUANGXI YUFENG CEMENT

Nanofluid-assisted rapid thermal cycle injection molding system and injection molding method

The invention provides a nanofluid-assisted rapid heating cycle injection molding system. The nanofluid-assisted rapid heating cycle injection molding system comprises a high-temperature nanofluid generation and storage device, a low-temperature nanofluid storage tank, a nanofluid recycle tank, a high-pressure gas supply device, a gas booster pump, an injection mold and a mold temperature control unit. The invention further provides a nanofluid-assisted rapid heating cycle injection molding method realized through the system. Compared with the existing rapid heating cycle injection molding technology based on high-temperature oil, superheated water or steam heating and cooling water cooling of molds, the system and the method have the advantages that the new heat transfer enhancement working medium, namely nanofluid is adopted as the heating medium and the cooling medium of the mold, and therefore the heating efficiency and the cooling efficiency of the mold can be remarkably improved. In addition, the system has the advantages that the structure is simple, the material is saved, the consumption is lowered, the work flow is reasonable and the structure of the existing molds do not need to be transformed when the prior art is replaced, thereby being suitable for being widely applied and popularized in industrial production. The invention belongs to the technical field of rapid heating cycle injection molding of high polymer material.

Owner:湖南省山力新材料有限责任公司

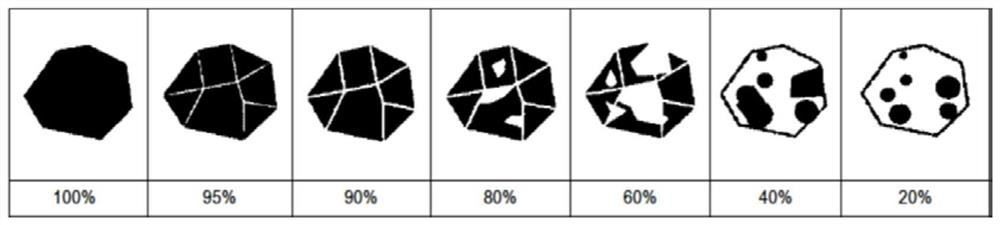

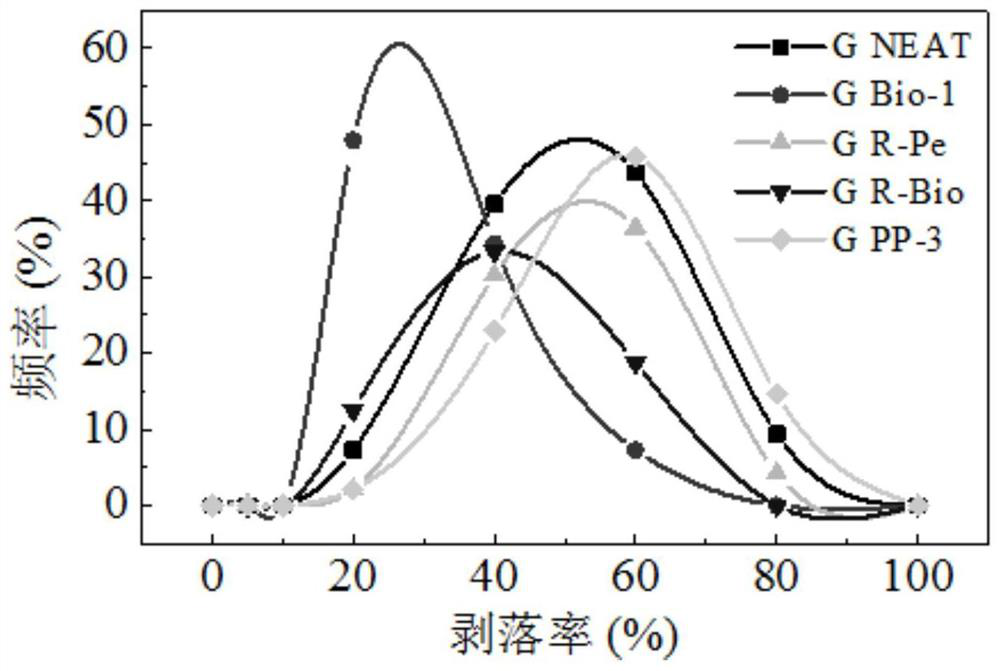

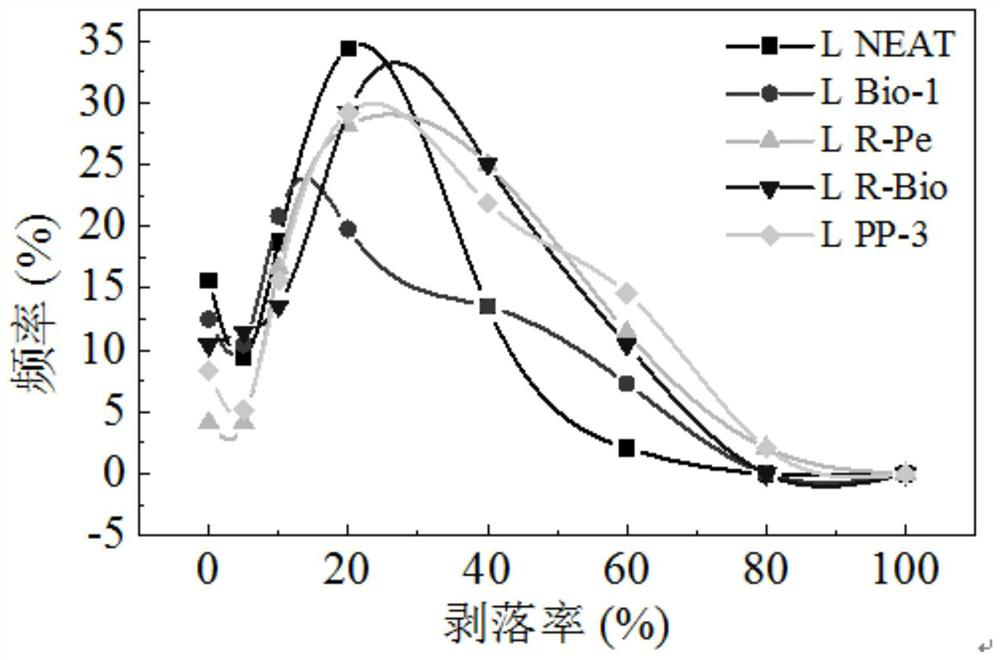

Evaluation method for adhesion of oil modified asphalt and aggregate

PendingCN113552163ARealize comparative evaluationRealize quantitative evaluationMaterial thermal analysisClimate change adaptationSoil scienceWater boil

The invention discloses a method for evaluating the adhesion of oil modified asphalt and aggregate, which comprises the following steps: selecting at least two aggregate samples, arranging a group of asphalt samples corresponding to each aggregate sample, and each group of asphalt samples comprising a matrix asphalt sample and a plurality of oil modified asphalt samples, performing water boiling operation on each aggregate sample and a group of asphalt samples corresponding to the aggregate sample, performing related calculation on an asphalt peeling index and an asphalt peeling rate, and evaluating the adhesion of the oil modified asphalt and the aggregate according to a calculation result. The evaluation method is reasonable and rigorous, and the evaluation mode is comprehensive and reliable. The quantitative evaluation of the adhesion performance between the oil modified asphalt and the aggregate is completed, and favorable conditions are provided for the quantitative evaluation of the water damage resistance of the asphalt mixture.

Owner:PETROCHINA CO LTD +1

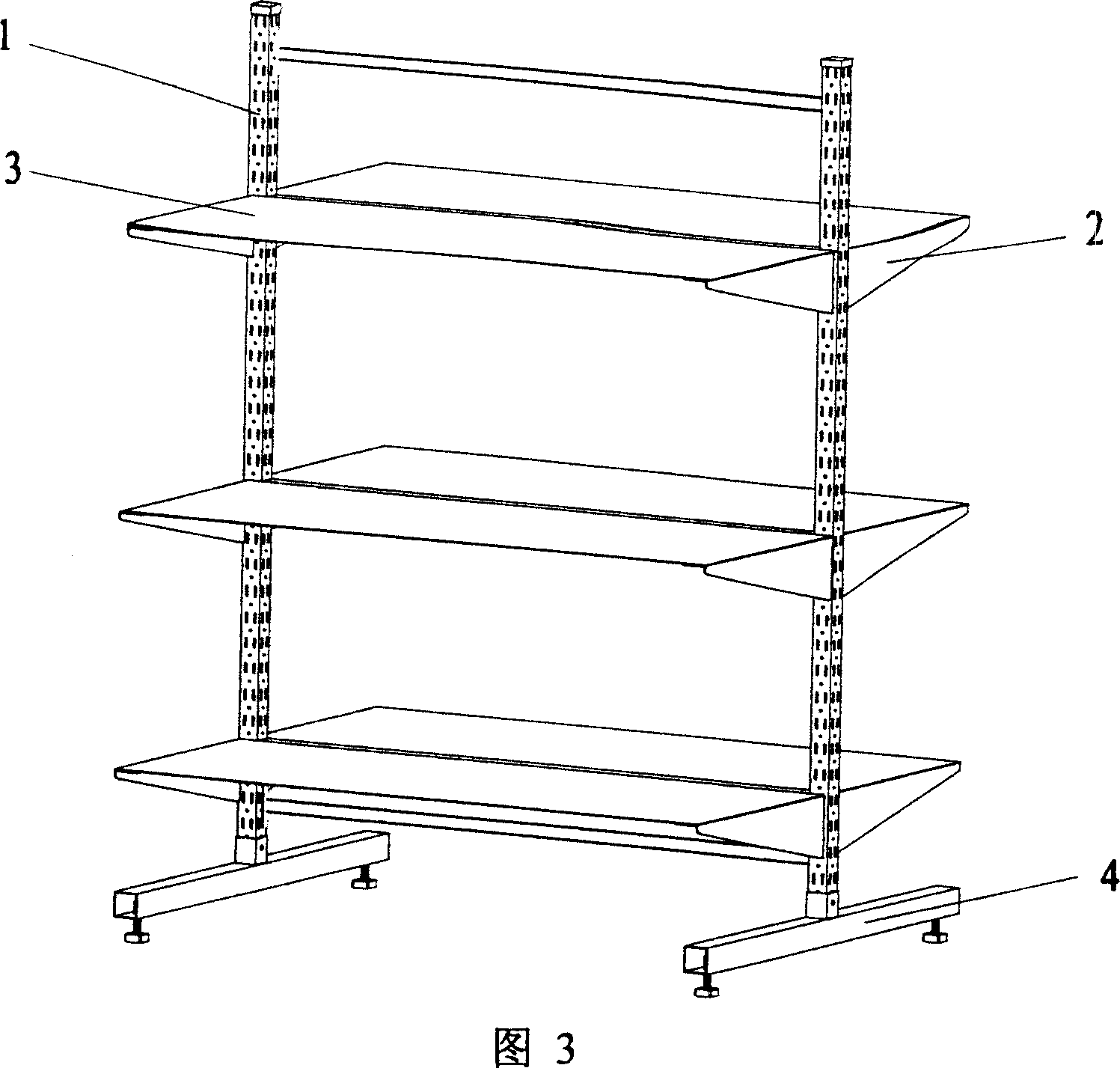

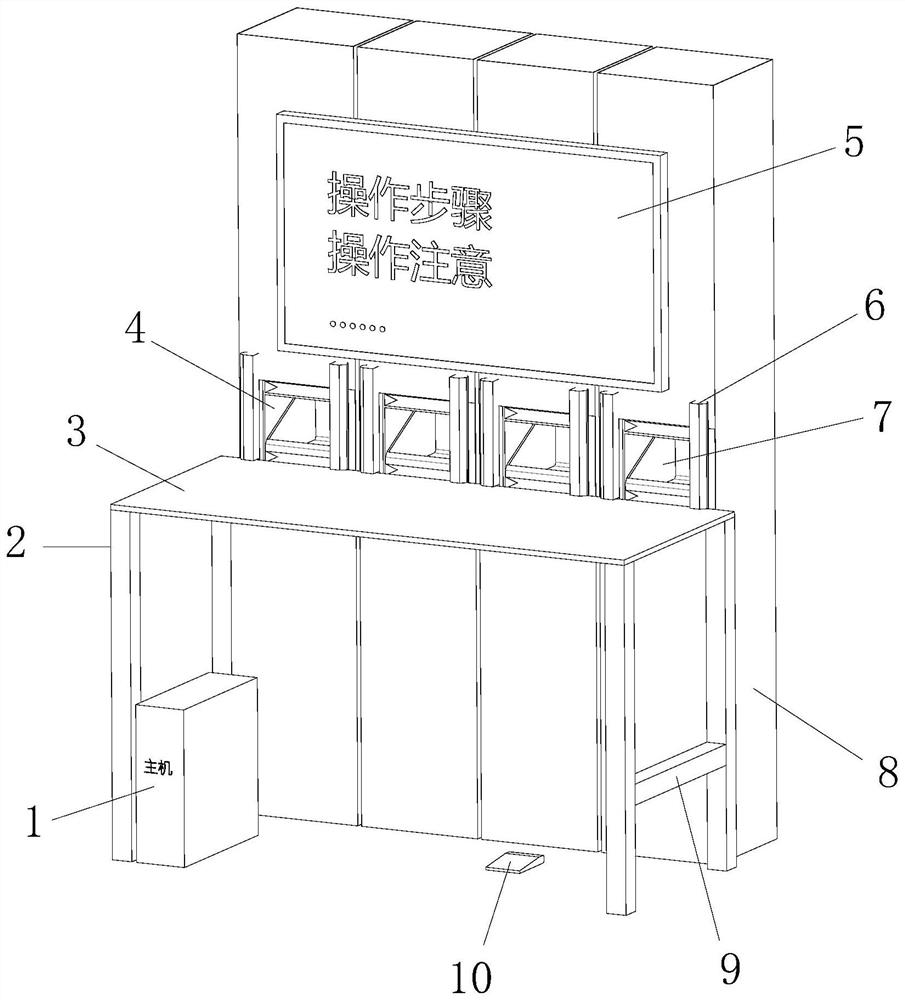

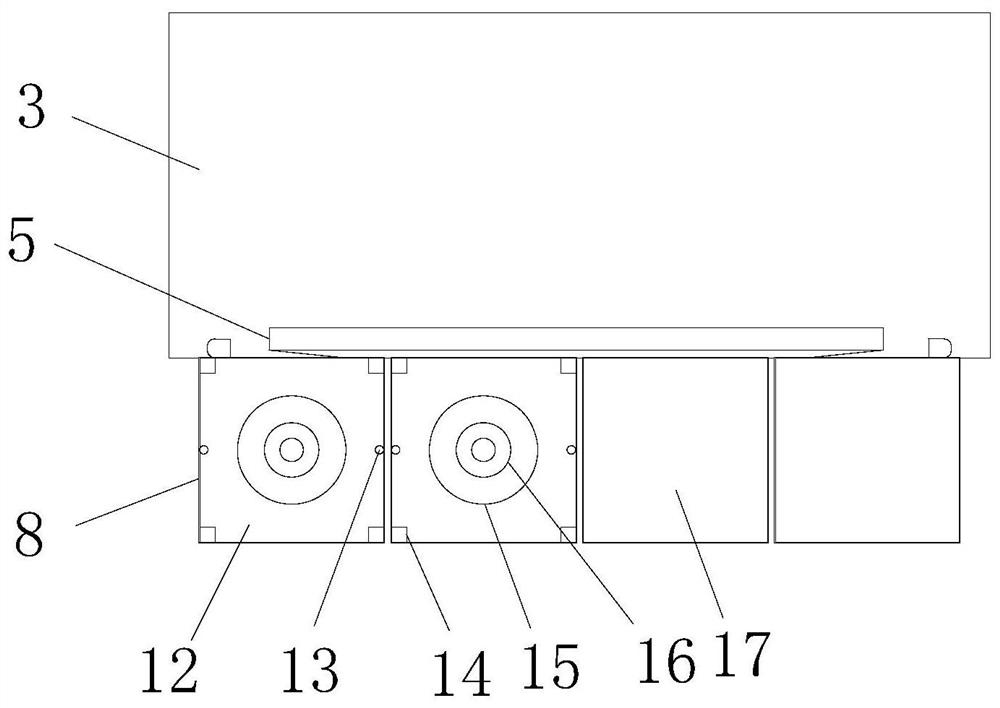

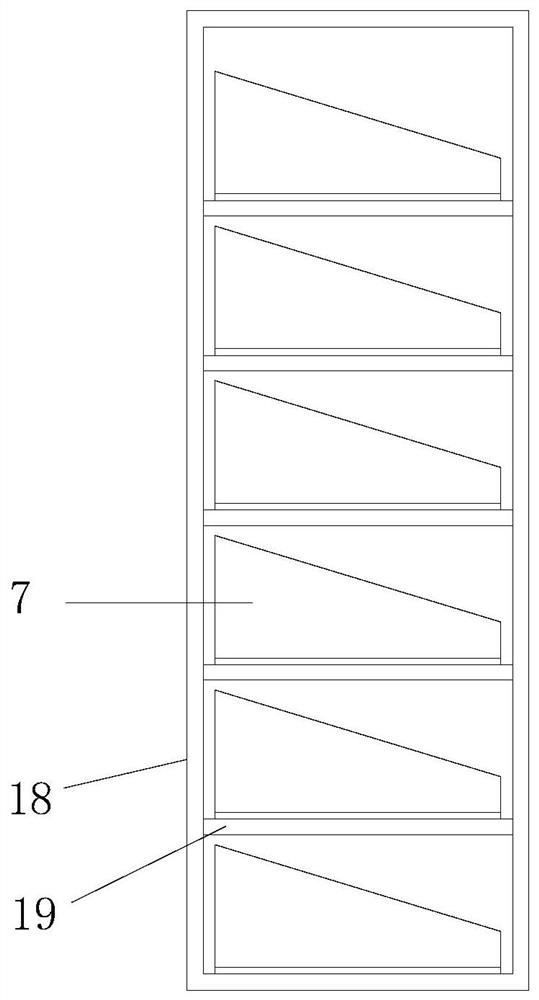

Intelligent feeding assembly platform

PendingCN111823198AMaster the assembly processFrequent list workWork benchesMetal-working hand toolsBill of materialsControl engineering

The invention discloses an intelligent feeding assembly platform comprising an operating platform. The bottom end face of the operating platform is connected with a plurality of support columns, and the front side of the operating platform is provided with a plurality of vertical material frames; lifting stock bins are arranged in the vertical material frames, and a plurality of material boxes arearranged in the lifting stock bins; material fetching ports are formed in the rear end faces of the vertical material frames, and a control host is installed below the operating platform; and the upper end of each vertical material frame is connected with a frame cover. The work that can be finished through a complex assembly line can be achieved through a single station or less stations. The efficiency is improved, and especially for small-batch work orders, switching between the work orders can be finished quickly; the intelligent feeding assembly platform has the advantages of the simple structure, reliable operation, low manufacturing cost, man-machine interaction and more reasonable operating process; fatigue caused by monotonous work is reduced, and physical and mental health of employees is benefited; the line changeover is simple, and frequent bill of material work is reduced; and complex construction is not involved, and the intelligent feeding assembly platform can be put into use after installation.

Owner:苏州巴拔依智能科技有限公司

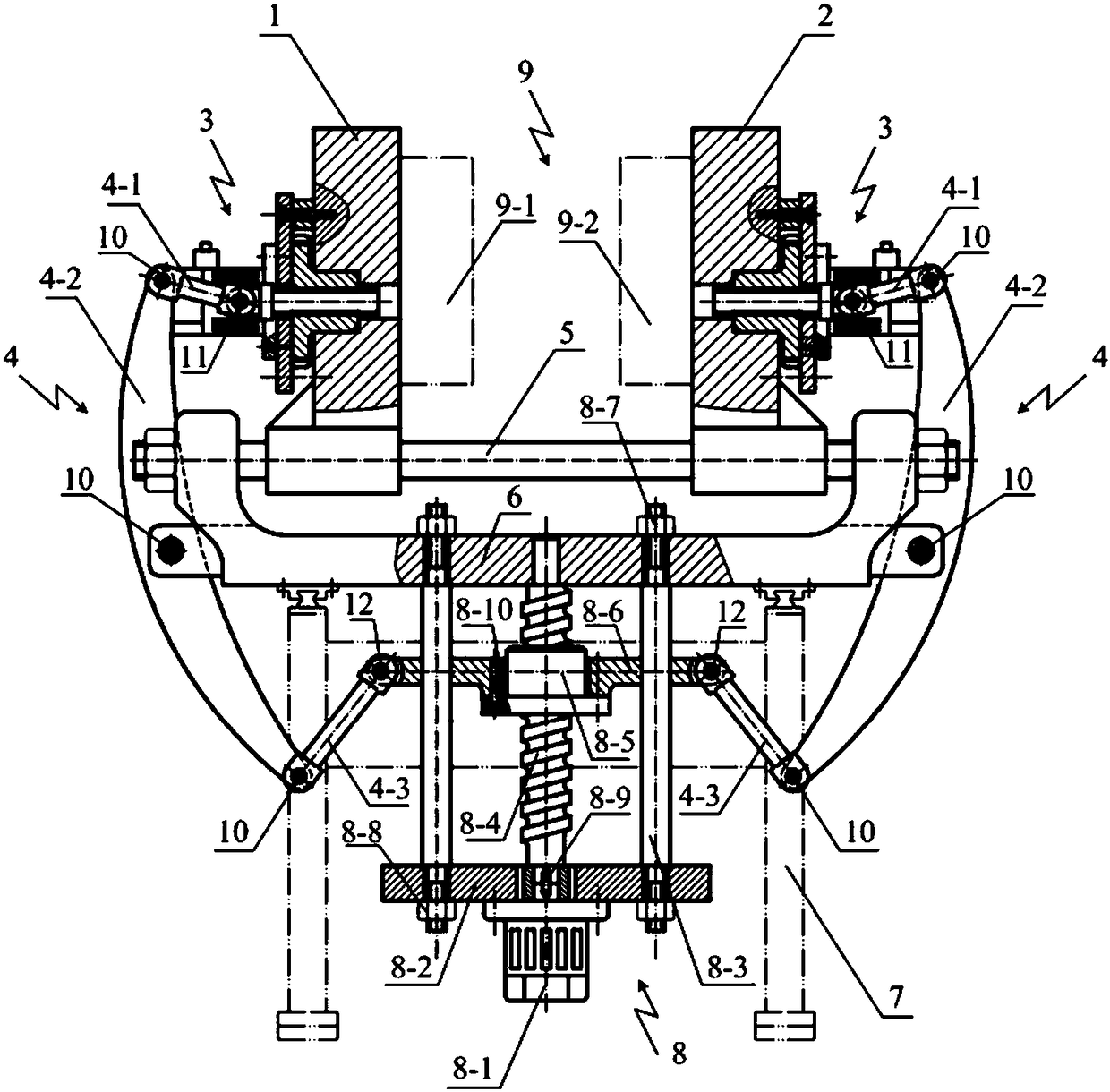

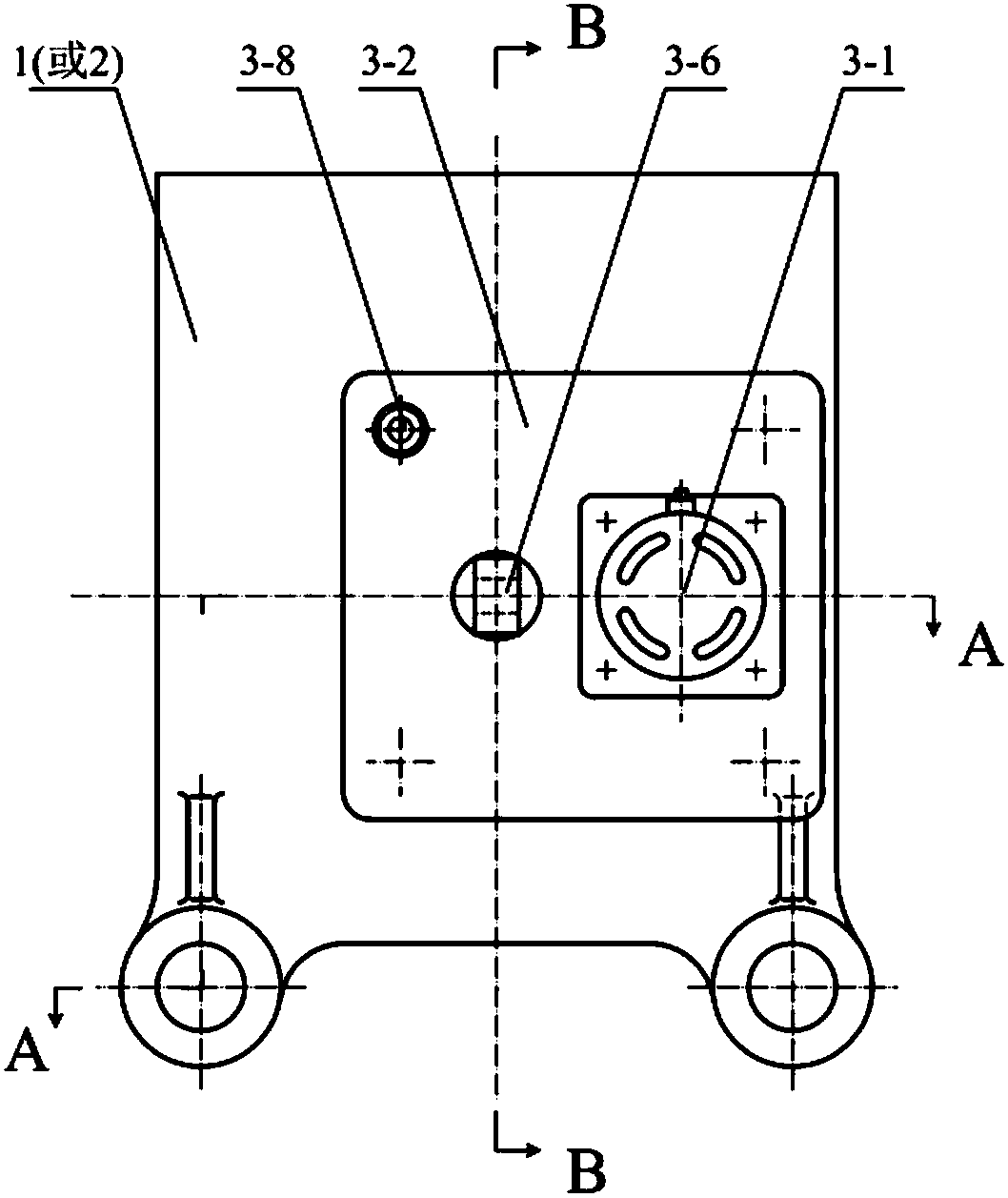

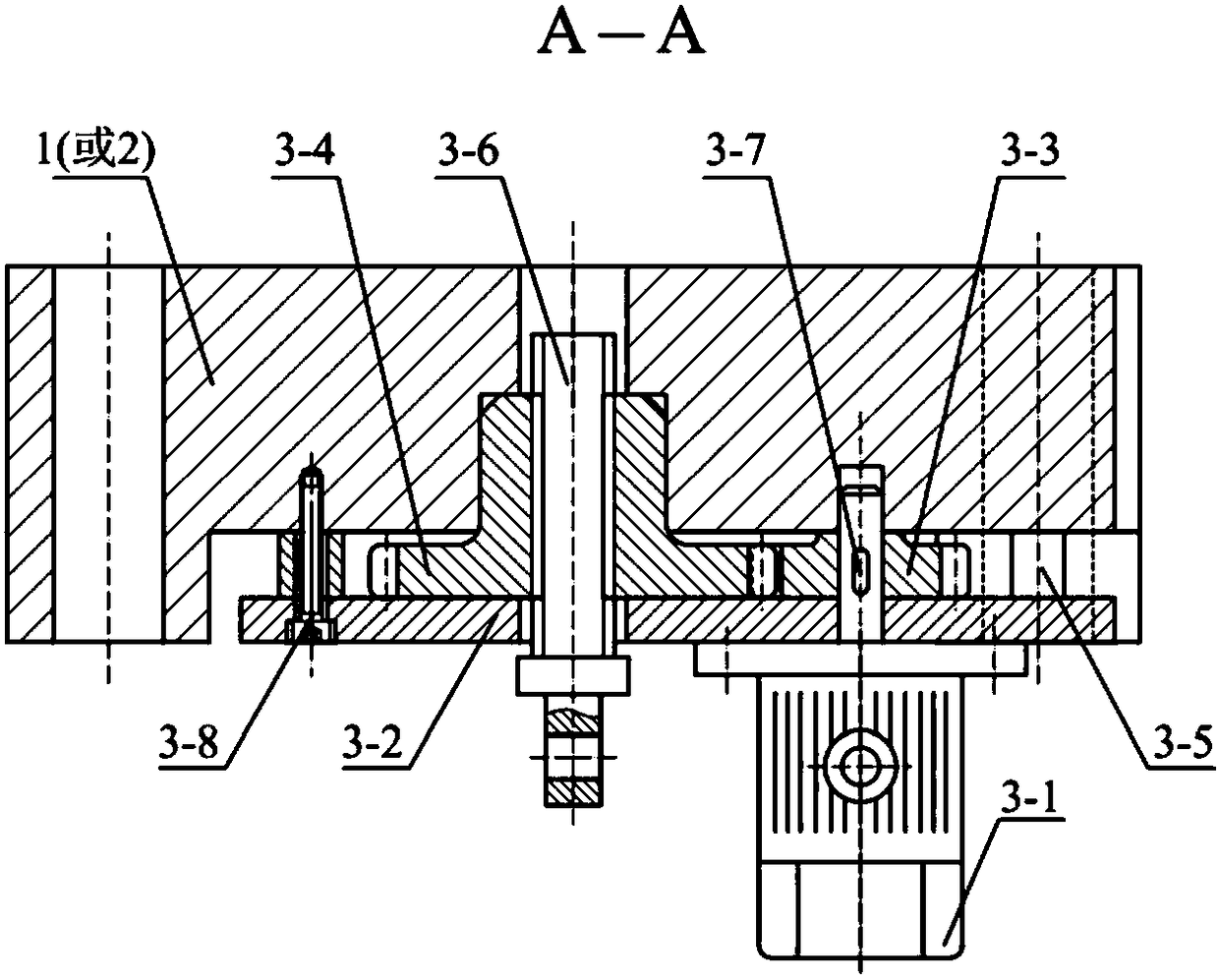

Tie-bar-less two-plate blow molding machine electric mold opening and closing device with quick mold adjustment function and method for realizing mold opening and closing

The invention relates to a pulling-rod-free two-plate type blow molding machine electric mould opening and closing device with a quick mould adjusting function. The device comprises a cavity half module installation plate, a mould core half module installation plate, mould adjusting assemblies, connection rod mechanisms, a guide element, a mould closing rack, a mould moving rack and a mould opening and closing electric driving unit. The cavity half module installation plate and the mould core half module installation plate directly face and are installed on the guide element fixed to the top end of the mould closing rack. The back of the cavity half module and the back of the mould core half module installation plate are each provided with a mould adjusting assembly. The mould opening and closing electric driving unit is installed at the lower end of the mould closing rack. The connection rod mechanisms are hinged to the mould adjusting assemblies, the mould closing rack and the mould opening and closing electric driving unit through hinge pins respectively. The cavity half module, the mould core half module installation plate, the mould adjusting assemblies, the connection rod mechanisms, the guide element, the mould closing rack and the mould opening and closing electric driving unit are integrally installed on the mould moving rack. The invention further relates to a blow molding machine electric mould opening and closing method. The device is compact in structure, the mould opening and closing stroke can be quickly adjusted, industrial application is convenient, and the device belongs to the technical field of high-molecular material blow molding machines.

Owner:NANHUA UNIV

Single-motor-driven all-electric mold closing and moving system and implementation method and application thereof

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization

The invention discloses a method for preparing a plastic / rubber thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization. The method comprises the followings steps: (1) mixing plastic, rubber and a vulcanization system at a certain proportion, and putting the mixture into an extruder or an injection molding machine to mix, fuse and plasticize the polymer into a fusant; (2) controlling gas to be in a supercritical state by a supercritical fluid conveying system and injecting the gas into a cylinder of the extruder or the injection molding machine; (3) mixing the injected supercritical fluid with the polymer fusant and the vulcanization system; (4) causing a chemical reaction of the plastic, the rubber and the vulcanization system, which is promoted by the supercriticalfluid; and (5) releasing the supercritical fluid from the polymer fusant at the pressure which is lower than a critical value, converting the supercritical fluid into gas to be discharged by a vacuumpump. The supercritical fluid assisted plastic / rubber dynamic vulcanization can promote dispersion and size decrease of the rubber phase in the plastic, and effectively reduce processing energy consumption for extrusion or injection shaping.

Owner:SOUTH CHINA UNIV OF TECH

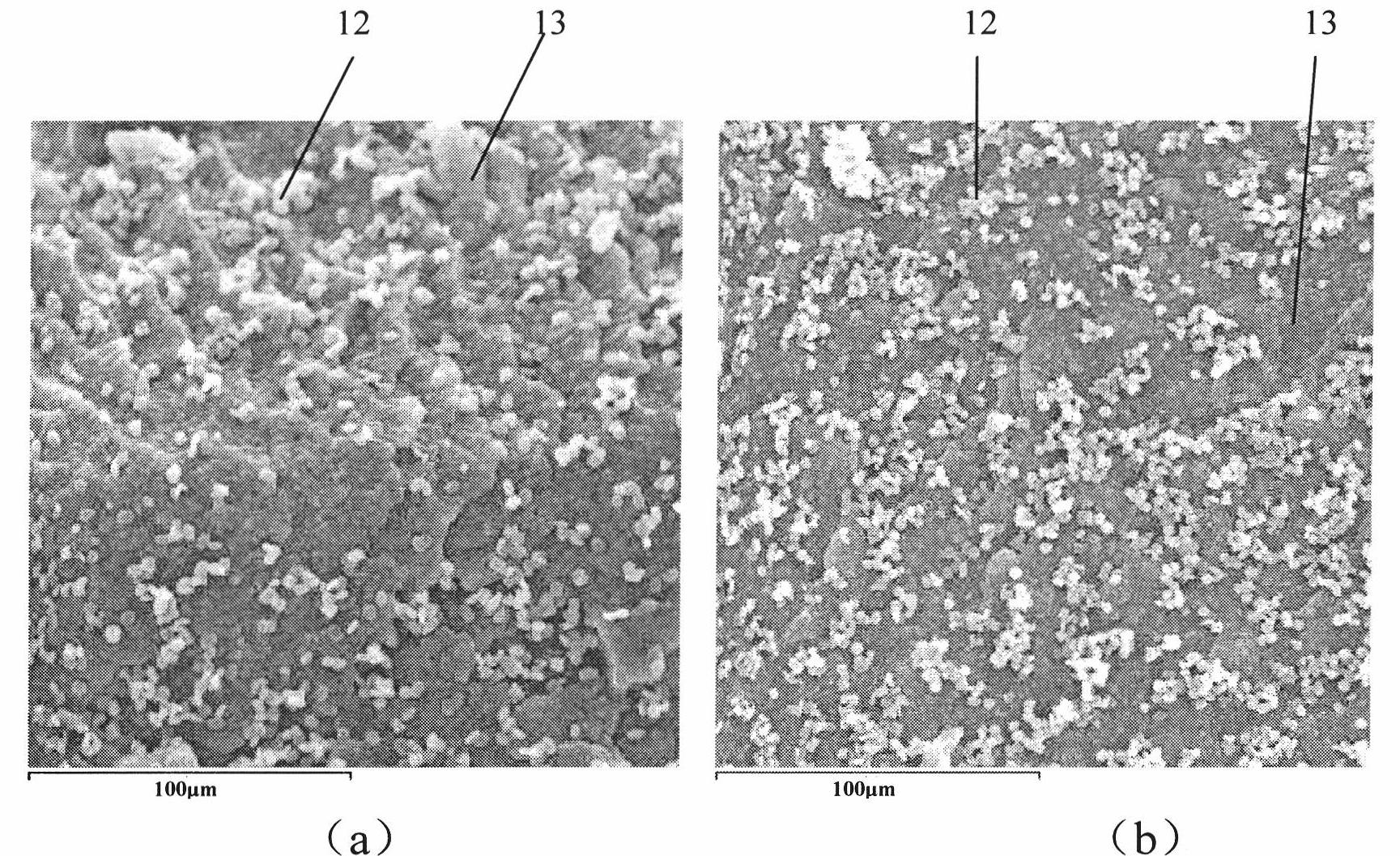

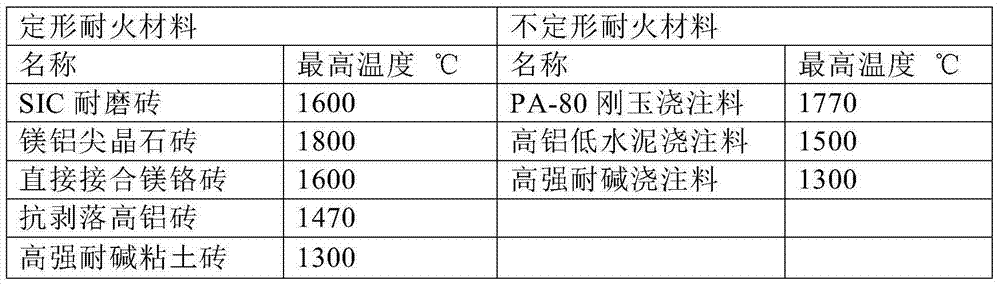

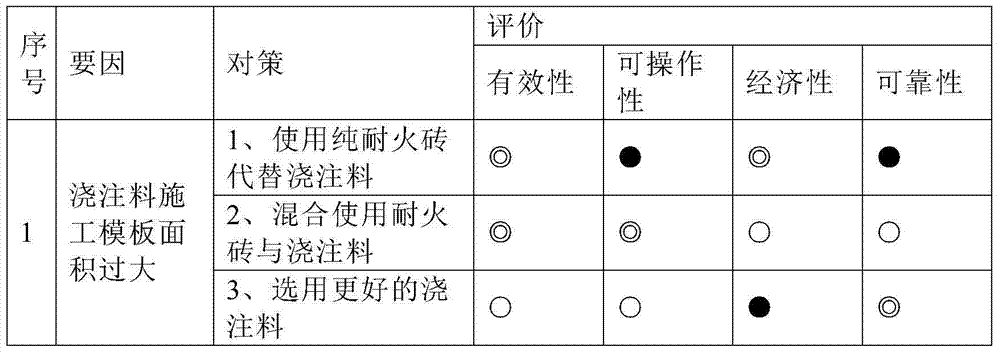

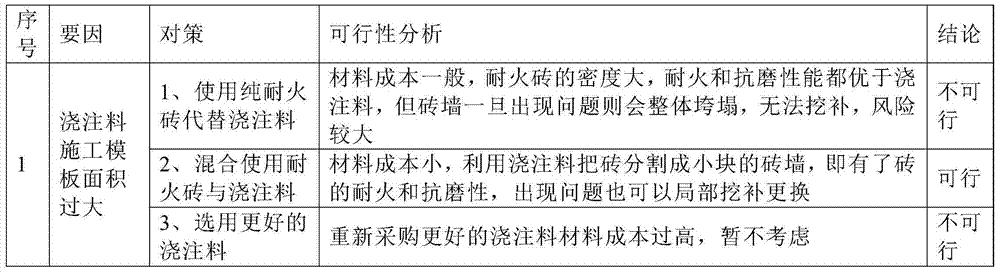

Method for prolonging service life of refractory material of grate cooler

InactiveCN104501604AExtended use timeExtended service lifeHandling discharged materialAir volumeBrick

The invention discloses a method for prolonging the service life of a refractory material of a grate cooler. The method comprises the steps of adjusting the air volume adopted by a grate cooler system in a center control chamber, keeping the grate cooler system to be in a negative pressure condition, mixing refractory bricks and castable in the grate cooler, prolonging the service life of the refractory material of the grate cooler to be 16 months, reducing the brick wall area in the grate cooler, and prolonging the service life of the refractory material of the grate cooler to be 16 months. The method can overcome the defects in the prior art that the construction template is large in area, unreasonable in structure, complex in operation technology, and the like, so as to achieve the advantages of small construction template area, reasonable structure and simple operation technology.

Owner:GUANGXI YUFENG CEMENT

Composition of mesenchymal stem cell secretion factor and content and gynostemma pentaphylla stem cell extract and preparation method thereof

InactiveCN112641716AWell absorbed stateNo allergic reactionCosmetic preparationsToilet preparationsLumbrokinaseGynostemma

The invention discloses a composition of a mesenchymal stem cell secretion factor and a content and a gynostemma pentaphylla stem cell extract and a preparation method thereof. Through the following technical scheme, the composition is prepared from the following raw materials in parts by weight: 10-25 parts of mesenchymal stem cell secretion factor freeze-dried powder, 10-20 parts of the gynostemma pentaphylla stem cell extract, 10-30 parts of hyaluronic acid, 1-8 parts of earthworm kinase, 0.01-1 part of aromatic, 2-10 parts of emulsifier and 0.1-1 part of thickener. The composition has no anaphylactic reaction to skin, no irritation and reactive dermatitis and small molecular weight, and is a high-quality cosmetic which can achieve multiple effects and be effectively absorbed.

Owner:西安美丽起点生物科技有限公司

Mesenchymal stem cell secretion factor and content and honeysuckle stem cell extract composition and preparation method thereof

InactiveCN112791007AReasonable operation processWell absorbed stateCosmetic preparationsToilet preparationsAllergic reactionHoneysuckle

According to the technical scheme, a mesenchymal stem cell secretion factor and content and honeysuckle stem cell extract composition and preparation method thereof are provided. The composition comprises the following raw materials in parts by weight: 10-25 parts of mesenchymal stem cell secretion factor freeze-dried powder, 10-20 parts of honeysuckle stem cell extract, 10-30 parts of hyaluronic acid, 1-8 parts of earthworm kinase, 0.01-1 part of aromatic, 2-10 parts of emulsifier and 0.1-1 part of thickening agent. The composition has no allergic reaction, no irritation or reactive dermatitis on skin, has small molecular weight, and is a high-quality cosmetic which can show many effects and can be effectively absorbed.

Owner:西安美丽起点生物科技有限公司

A Parallel Balanced Filling Method of Large-capacity Semi-Managed Surface Tension Storage Tanks

ActiveCN106762224BReal-time display of total filling amountReal-time monitoring of parallel balanceLiquid handling installationsCosmonautic propulsion system apparatusEngineeringHelium

A parallel balanced filling method for a high-capacity semi-management surface tension storage tank comprises steps as follows: (1) a satellite propellant filling pipeline is connected, and the leakage rate of a filling pipeline system is ensured to meet the requirements; (2) two parallel storage tanks are simultaneously filled with helium or release helium for replacement until sampled gas is tested to be qualified; (3) the propellant filling pipeline and pipelines at the downstream of the parallel storage tanks are vacuumized; (4) valve ports of filling and drainage valves of the parallel storage tanks are filled with the propellant; (5) the parallel storage tanks are simultaneously and stably filled until 90% or above of the rated filling quantity is reached; (6) refilling is performed on the parallel storage tanks until the filling quantity of each storage tank meets the task requirement; (7) air cushions are added to the storage tanks until required air cushion pressure is reached. By means of the method, parallel balanced filling of the high-capacity semi-management surface tension storage tank can be realized, time for filling the parallel storage tanks with the propellant is shortened, and the reliability and the safety of the satellite filling process are guaranteed.

Owner:BEIJING INST OF CONTROL ENG

Comprehensive Lightning Protection Monitoring Method for Wind Power

ActiveCN110045178BEasy to set upEasy to updateElectrical testingMeasurement using digital techniquesNacelleLightning strike

The invention discloses a wind power comprehensive lightning protection monitoring method, which solves the problem that the current lightning protection detection method in the wind power field cannot accurately grasp the time, frequency and amplitude of lightning strikes suffered by a wind power generator in real time, and cannot efficiently perform fault early warning. The method of the present invention includes the following steps: S1: use the central controller configuration software to initialize and monitor the site, equipment, network information, touch screen calibration, lightning current acquisition module, SPD unit module, grounding resistance module, and connection resistance module of the lightning monitoring device Parameter setting; S2: Set parameters according to step S1 to continuously collect the lightning current information when the wind turbine blades, nacelle, and tower foundation are struck by lightning, the SPD status information of the wind turbine nacelle and tower foundation, the connection resistance of the carbon brushes in the nacelle, and the tower foundation The value of the grounding resistance; S3: According to step S2, read or transmit by connecting to the fan control system, the remote monitoring platform or the local connection terminal, and monitor, analyze and warn each measured value.

Owner:北京时域智控技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com