Method for preparing thermoplastic elastomer by supercritical fluid assisted dynamic vulcanization

A technology of thermoplastic elastomers and supercritical fluids, applied in the production of bulk chemicals, etc., can solve problems such as the method and application of SCF-assisted polymers that have not been mentioned, and achieve the effects of easy implementation and promotion, simple operation, and reasonable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

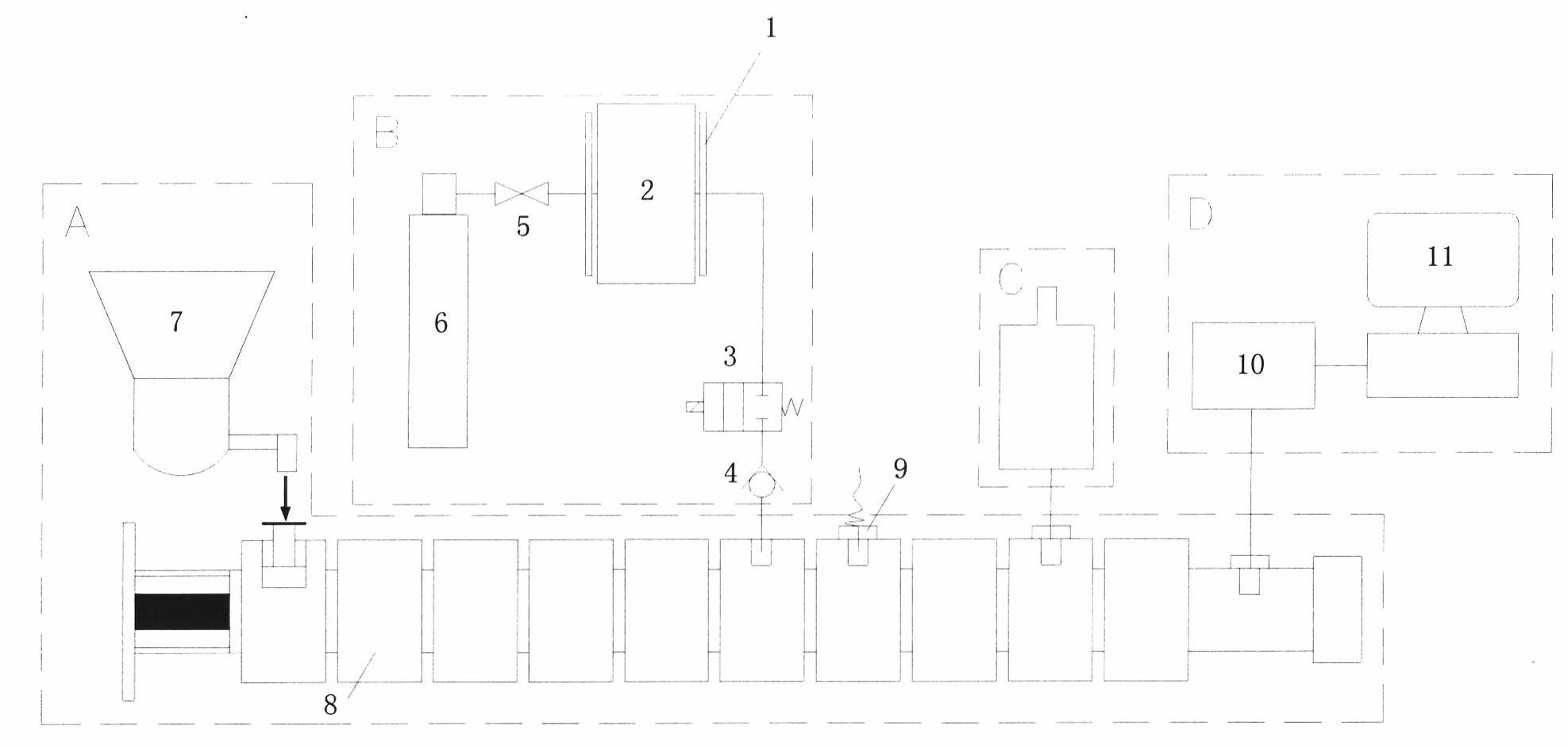

[0027] figure 1 Show the concrete structure that realizes the inventive method to carry out plastics / rubber dynamic vulcanization with twin-screw extruder, by figure 1 It can be seen that the SCF-assisted polymer reaction molding processing equipment includes twin-screw extruder A, supercritical CO 2 Delivery system B, vacuum pump C and online rheological system D; supercritical CO 2The delivery system B is connected with the self-locking gas injection check valve 4; the self-locking gas injection check valve 4, the pressure sensor 9, the vacuum pump C and the online rheological system D are sequentially connected with the twin-screw extruder A along the extrusion direction. connect. Described twin-screw extruder A comprises feeder 7, machine barrel 8, screw rod (not shown in the figure) and pressure sensor 9, the rear end of machine barrel 8 links to each other with feeder 7, and the periphery of machine barrel 8 There is a temperature control heating ring (not shown in th...

Embodiment 2

[0039] (1) Weigh 20 parts of polypropylene, 80 parts of EPDM rubber, 5 parts of sulfur, 1 part of accelerator CZ (N-cycloethyl-2-benzothiazole sulfenic acid amine), 2 parts of accelerator Agent DM (dibenzothiazole disulfide), 4 parts of stearic acid, 8 parts of zinc oxide, mixed together.

[0040] (2) Add the mixture in the step (1) to continuous supercritical carbon dioxide assisted polymer extrusion equipment, under the conditions that the supercritical carbon dioxide content is 2.5% of the total mass of the material, the reaction extrusion temperature is 160 ° C, and the extrusion time is 7 minutes Next, the polypropylene / EPDM thermoplastic elastomer can be obtained by extruding through the machine head.

Embodiment 3

[0042] (1) Weigh 60 parts of polypropylene, 40 parts of nitrile rubber (NBR), 4 parts of dicumyl peroxide, 4 parts of stearic acid, and 8 parts of zinc oxide and mix them together.

[0043] (2) Add the mixture in the step (1) to continuous supercritical carbon dioxide assisted polymer extrusion equipment, under the conditions that the supercritical carbon dioxide content is 1.5% of the total mass of the material, the reaction extrusion temperature is 180 ° C, and the extrusion time is 10 minutes Next, the polypropylene / nitrile rubber thermoplastic elastomer can be obtained by extruding through the machine head.

[0044] It can be seen from Table 3 that the supercritical CO 2 During the preparation of PP / NBR thermoplastic elastomers by assisted dynamic vulcanization, the motor current of the extruder was in supercritical CO 2 In the case of joining, there is a relatively large decrease.

[0045] Table 3 Motor current of PP / NBR(60 / 40) thermoplastic elastomer during preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com