Patents

Literature

113 results about "Fracture risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

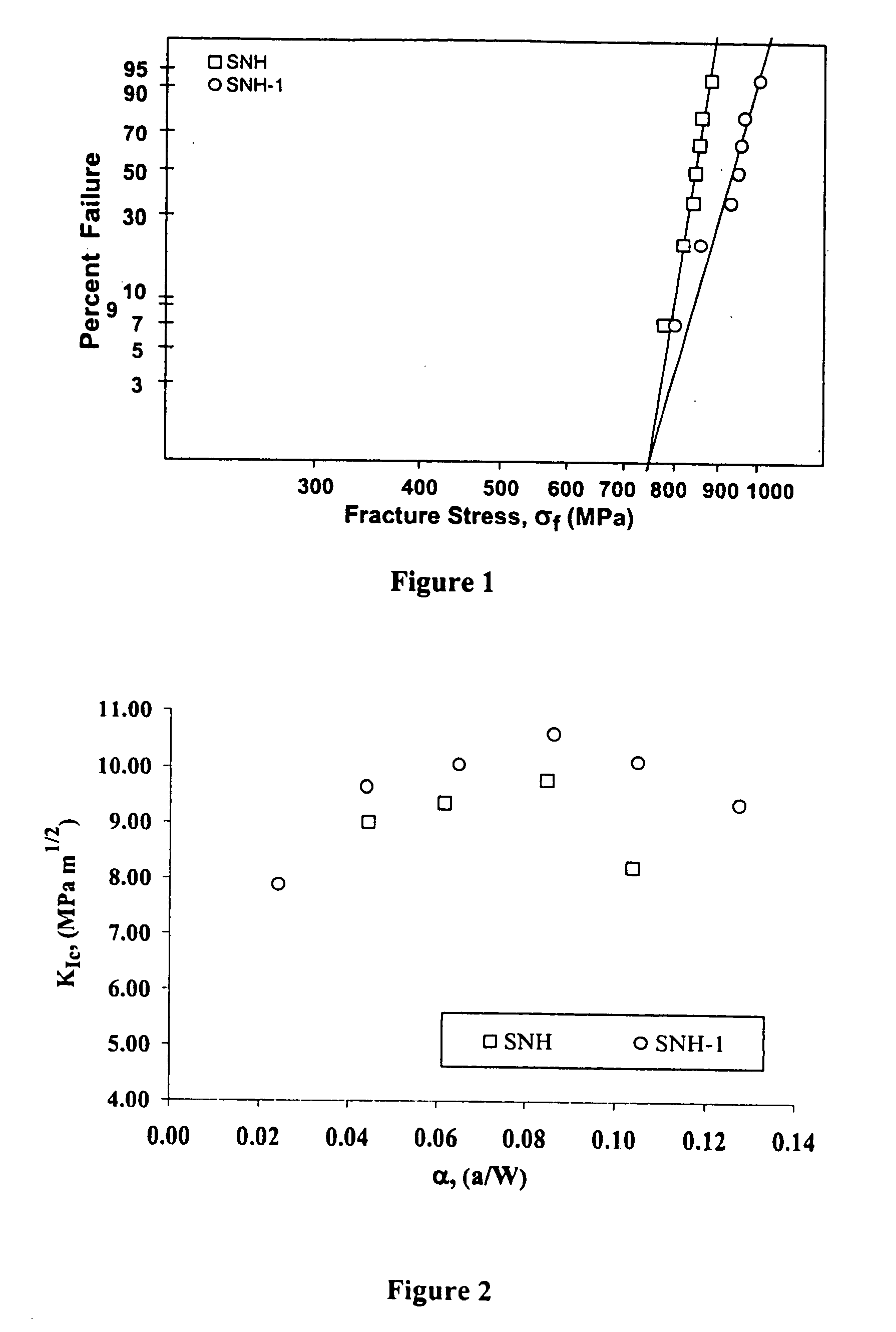

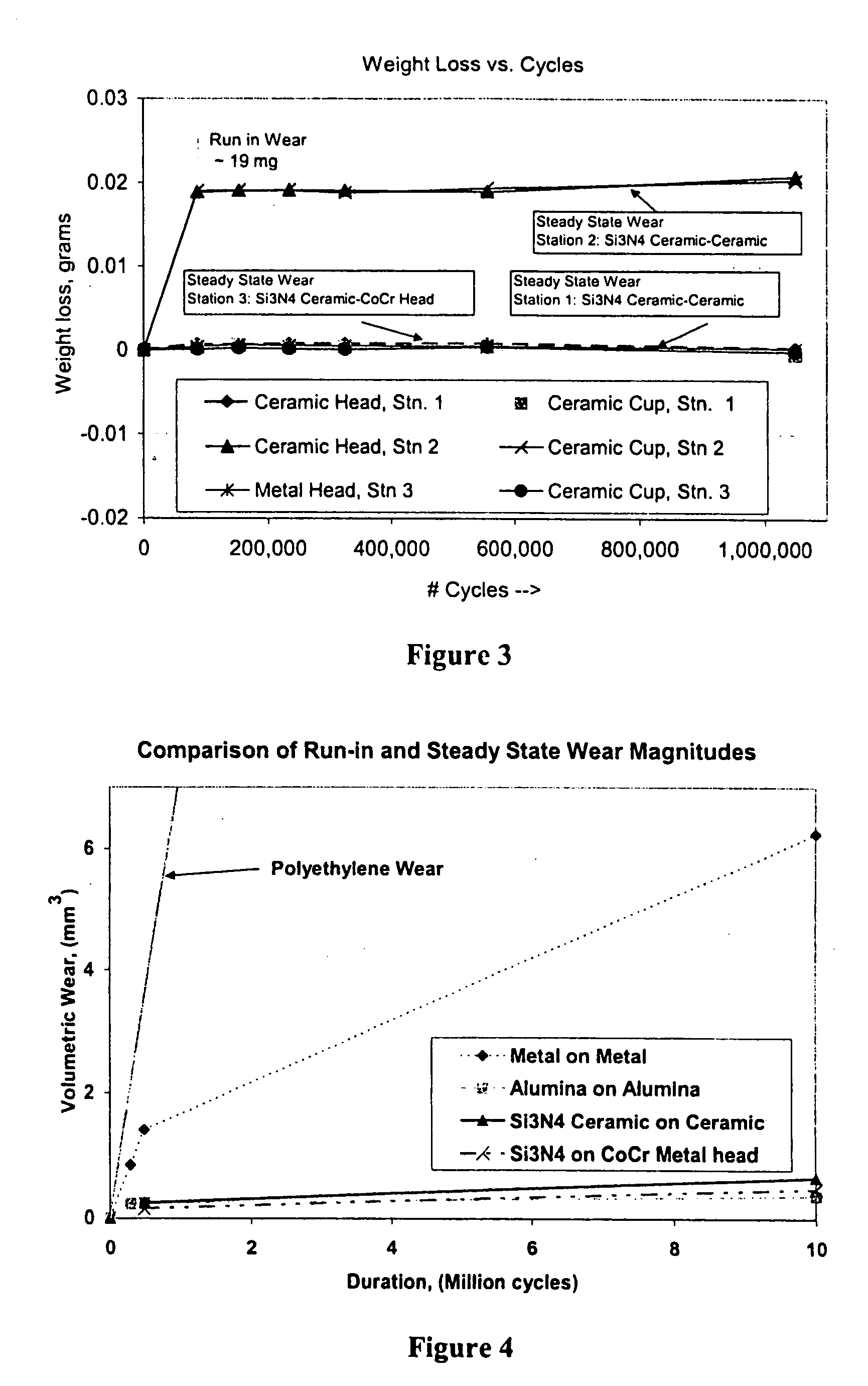

Metal-ceramic composite articulation

InactiveUS6881229B2Minimal productionImprove flexural strengthBone implantJoint implantsHigh fractureIn vivo

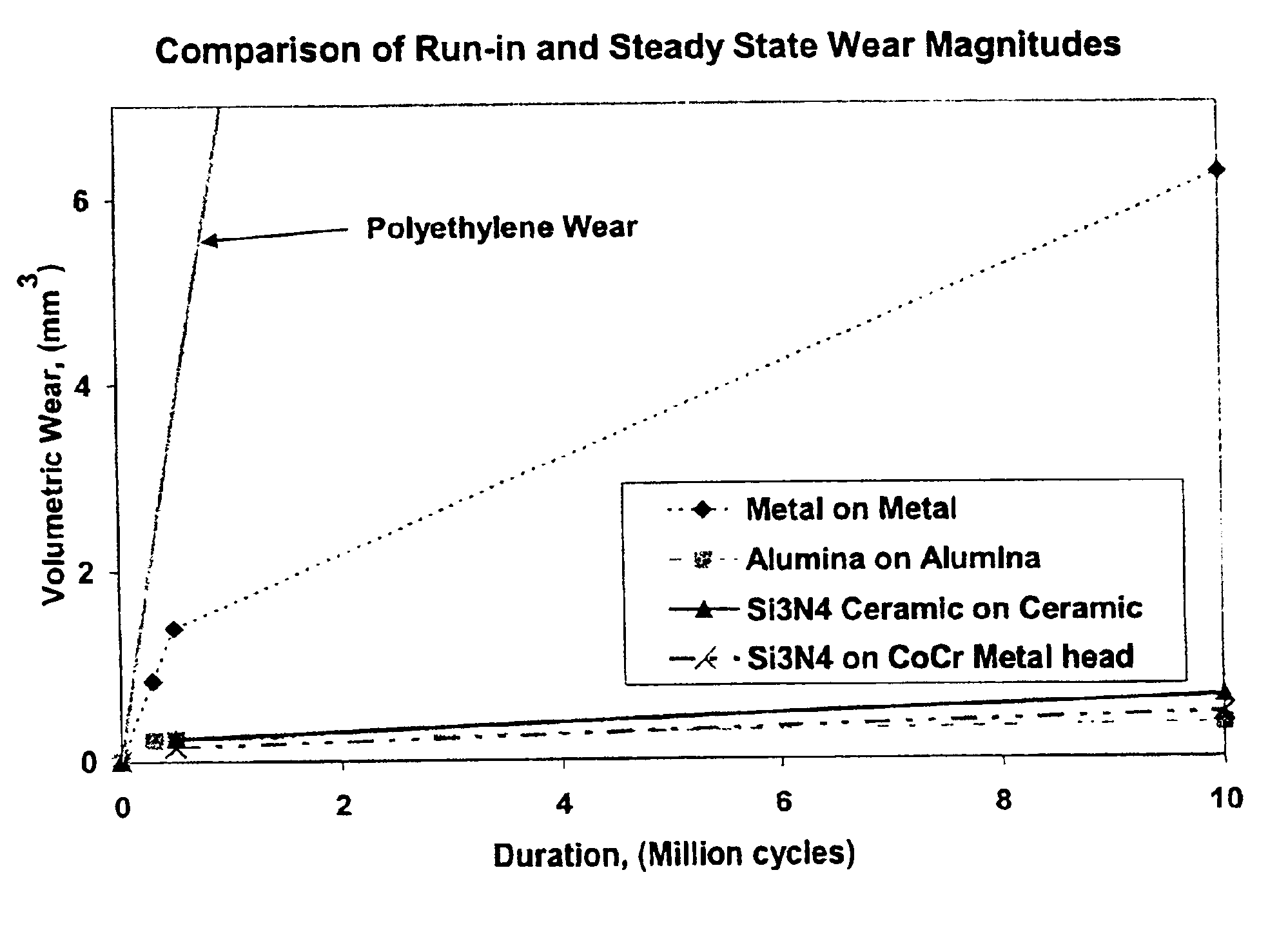

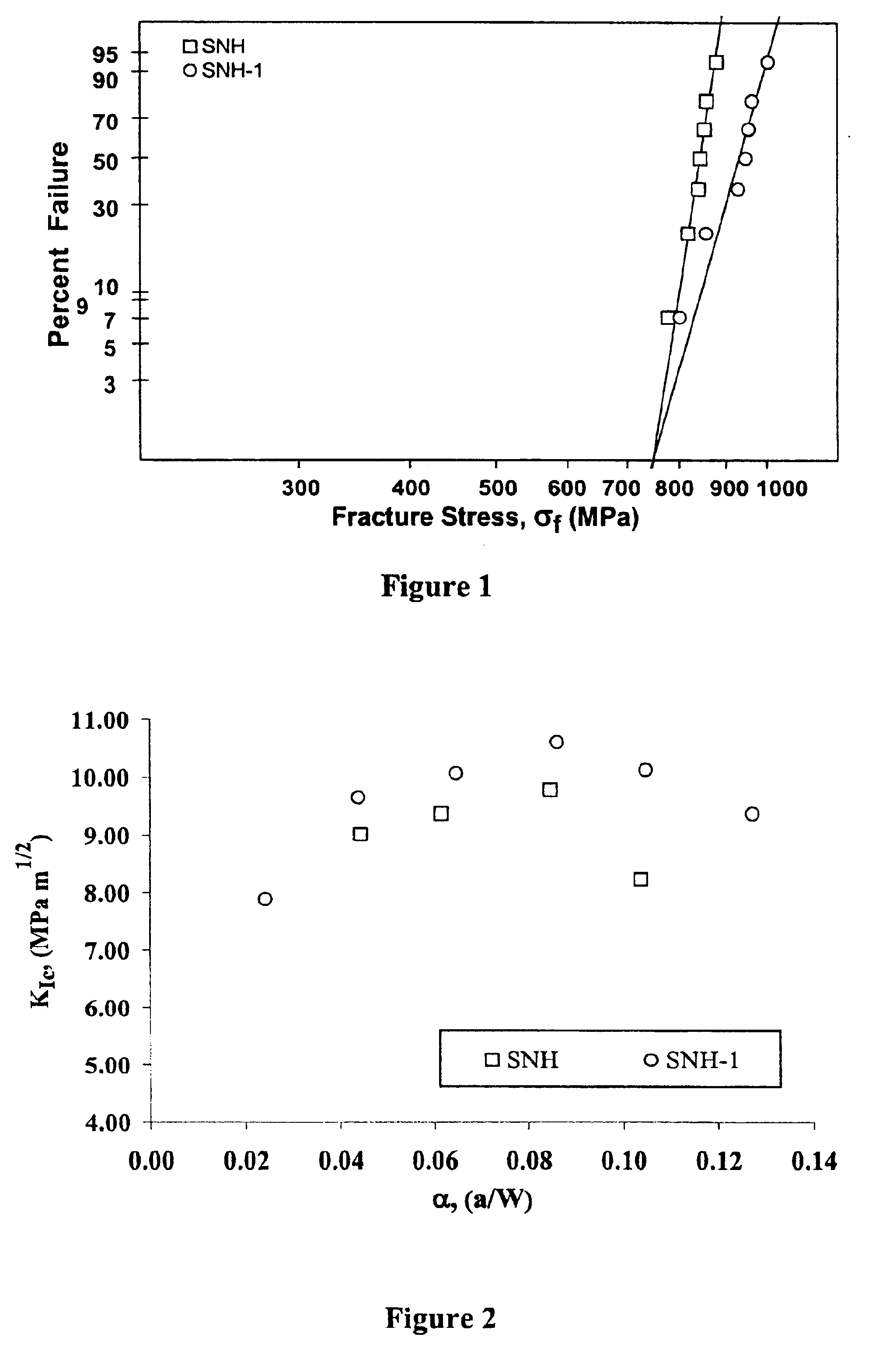

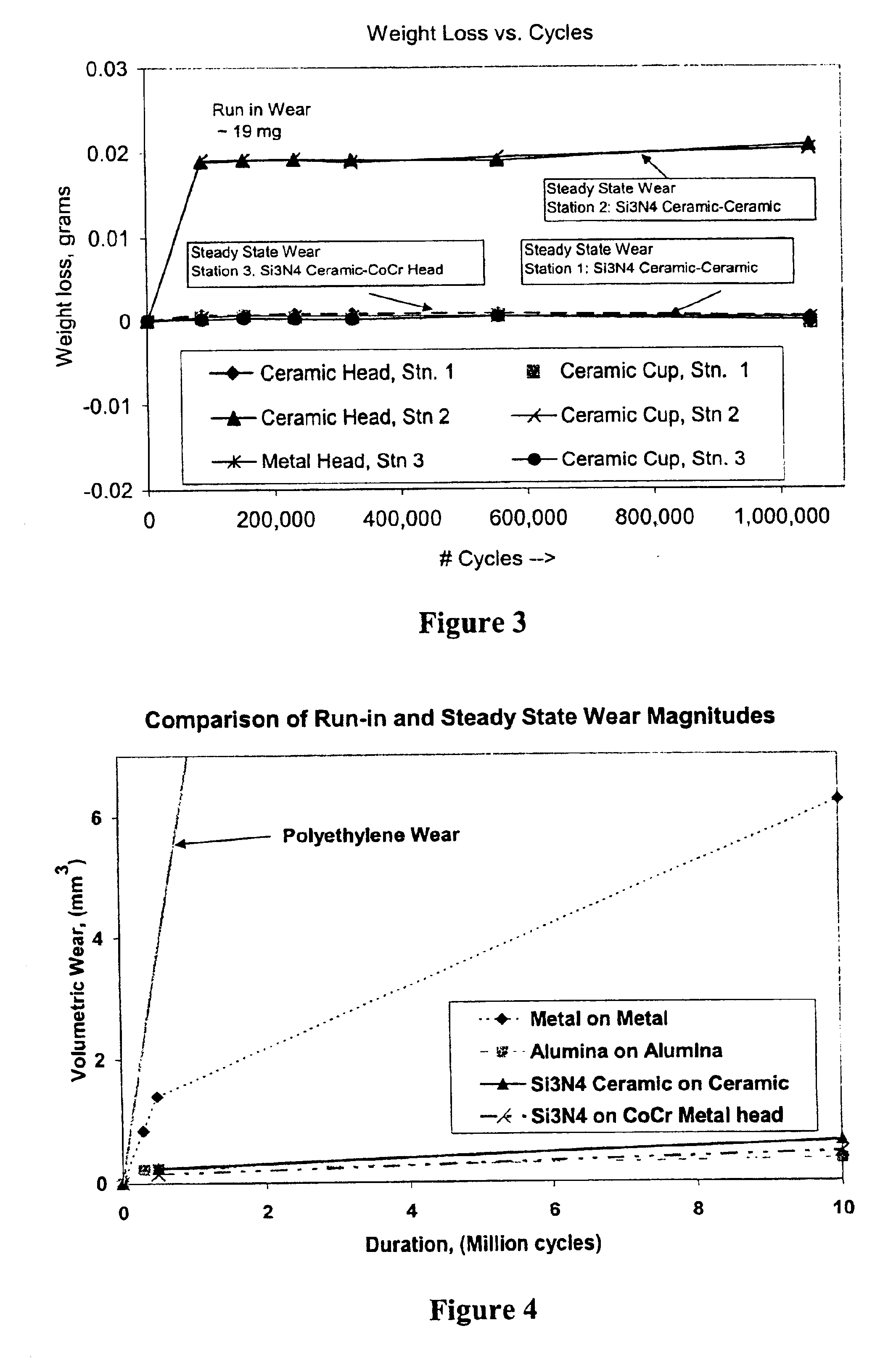

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPa1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate polyethylene (PE) wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

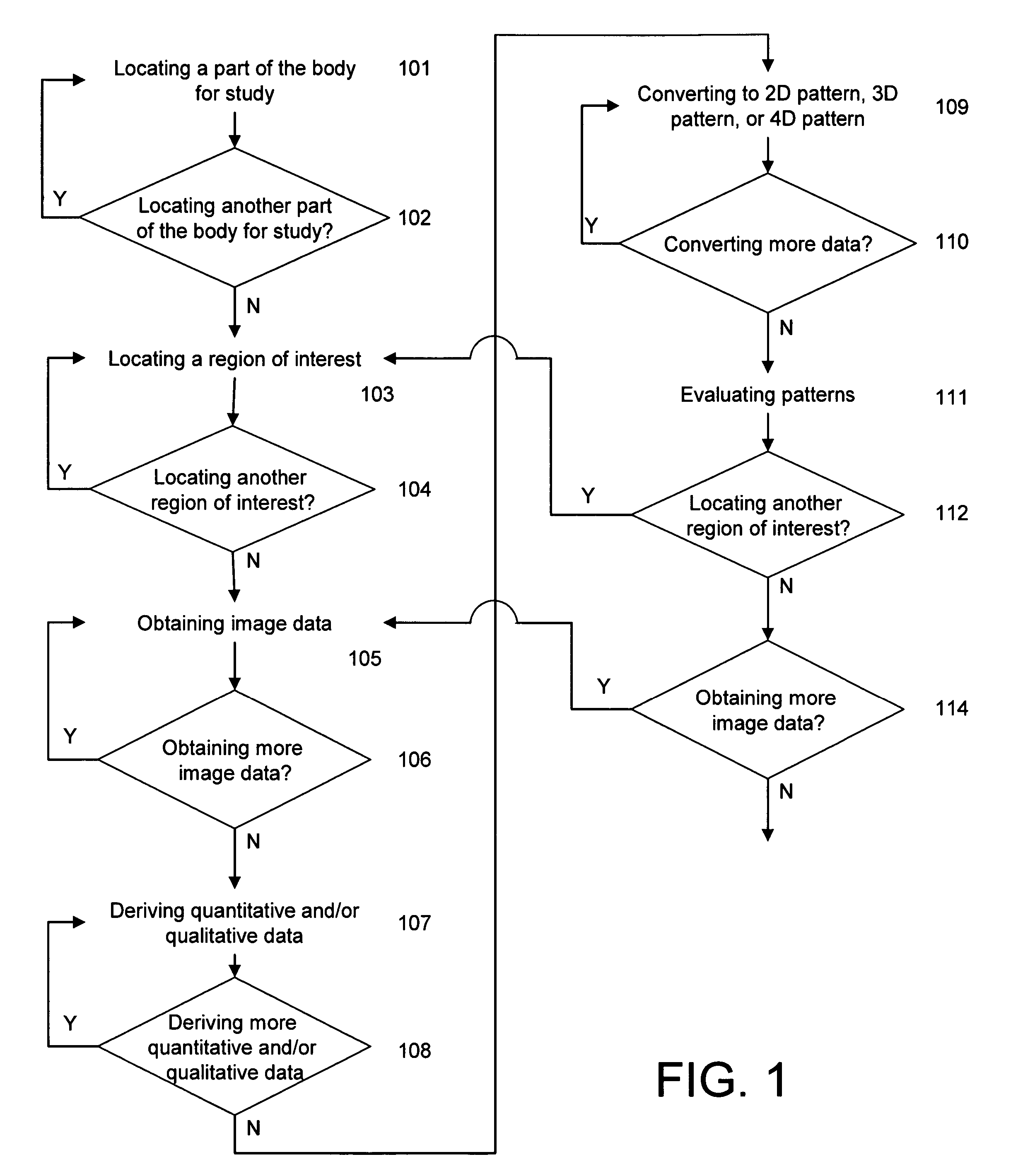

System and method of predicting future fractures

Methods of predicting fracture risk of a patient include: obtaining an image of a bone of the patient; determining one or more bone structure parameters; predicting a fracture line with the bone structure parameter; predicting a fracture load at which a fracture will happen; estimating body habitus of the patient; calculating a peak impact force on the bone when the patient falls; and predicting a fracture risk by calculating the ratio between the peak impact force and the fracture load. Inventive methods also includes determining the effect of a candidate agent on any subject's risk of fracture.

Owner:IMATX

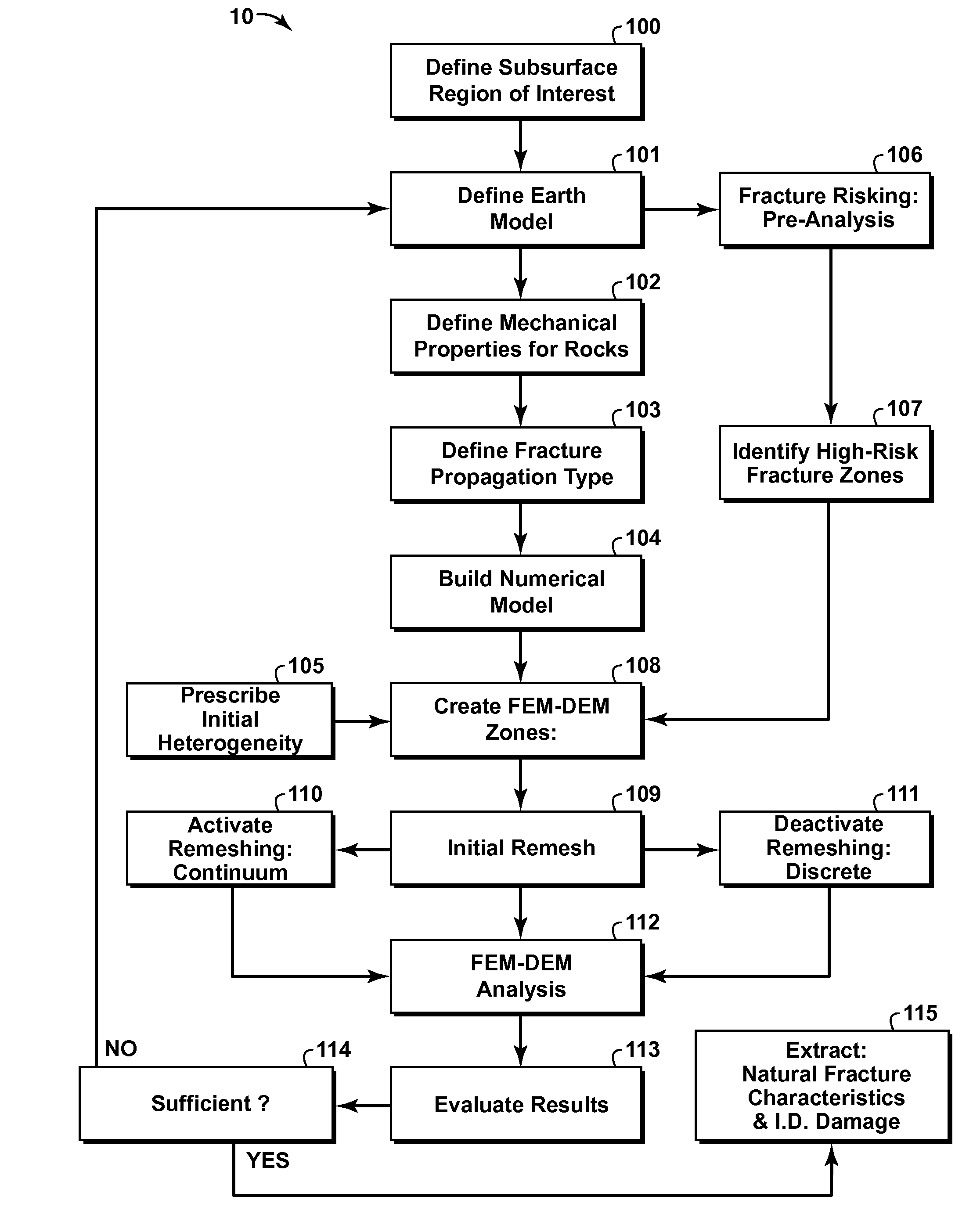

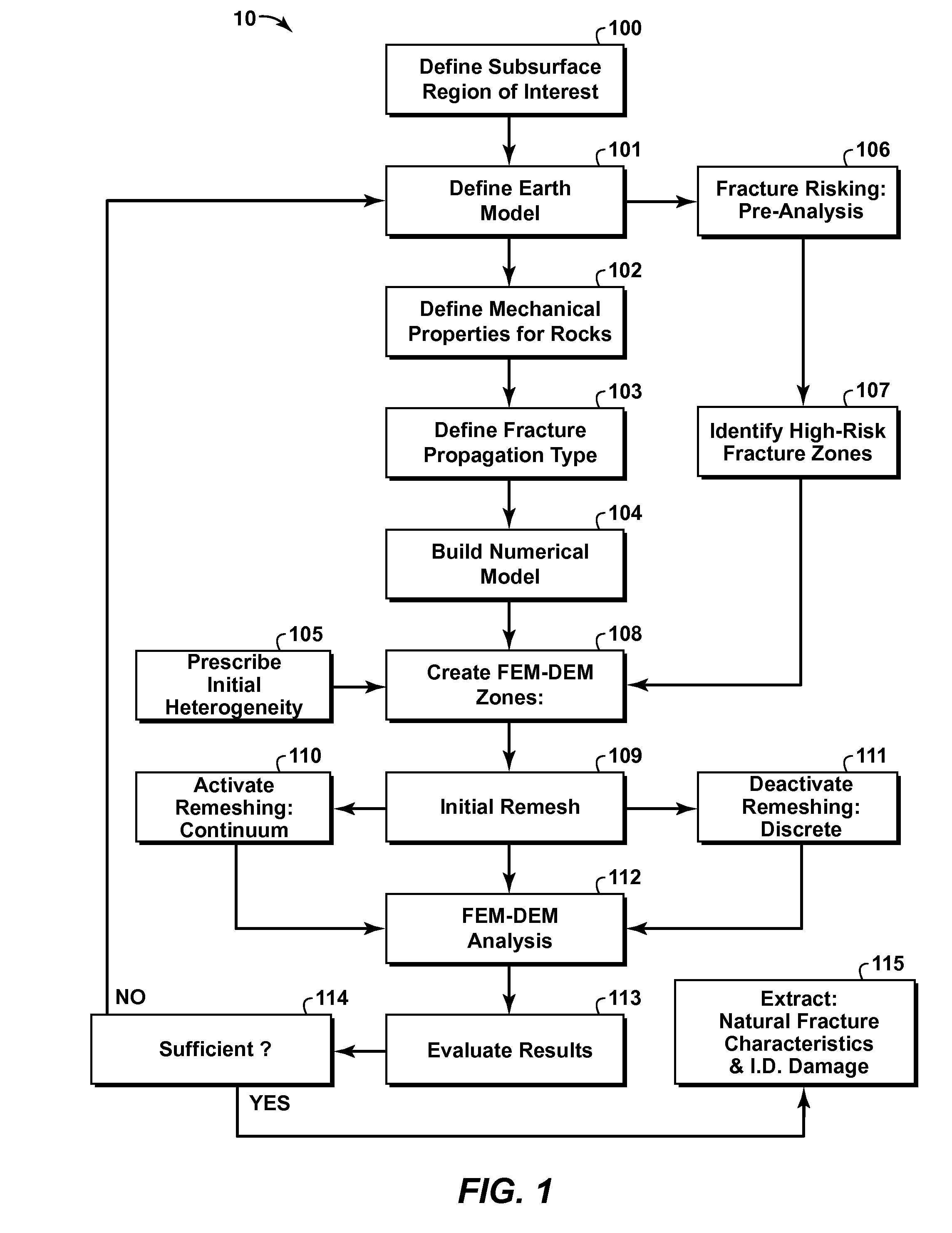

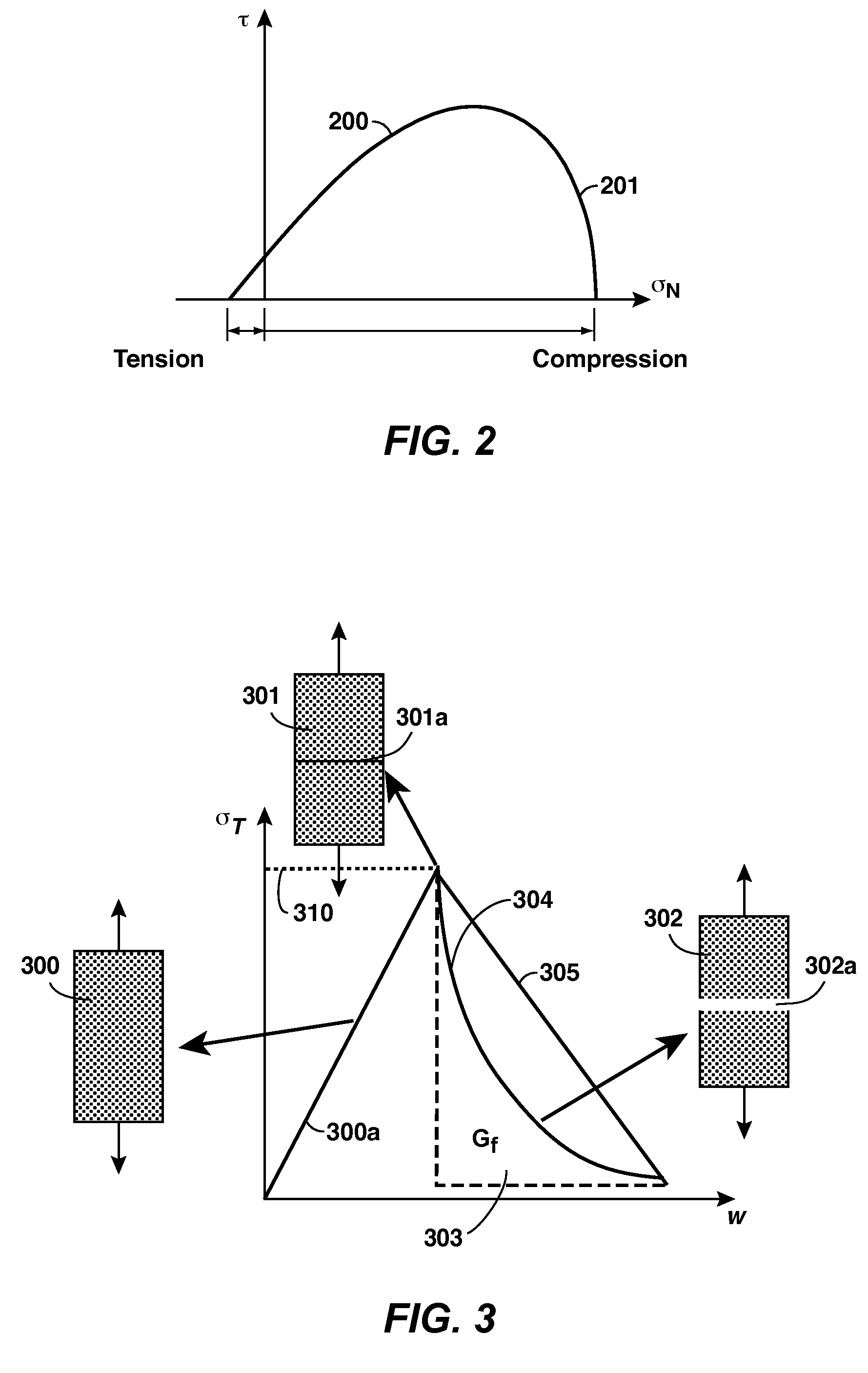

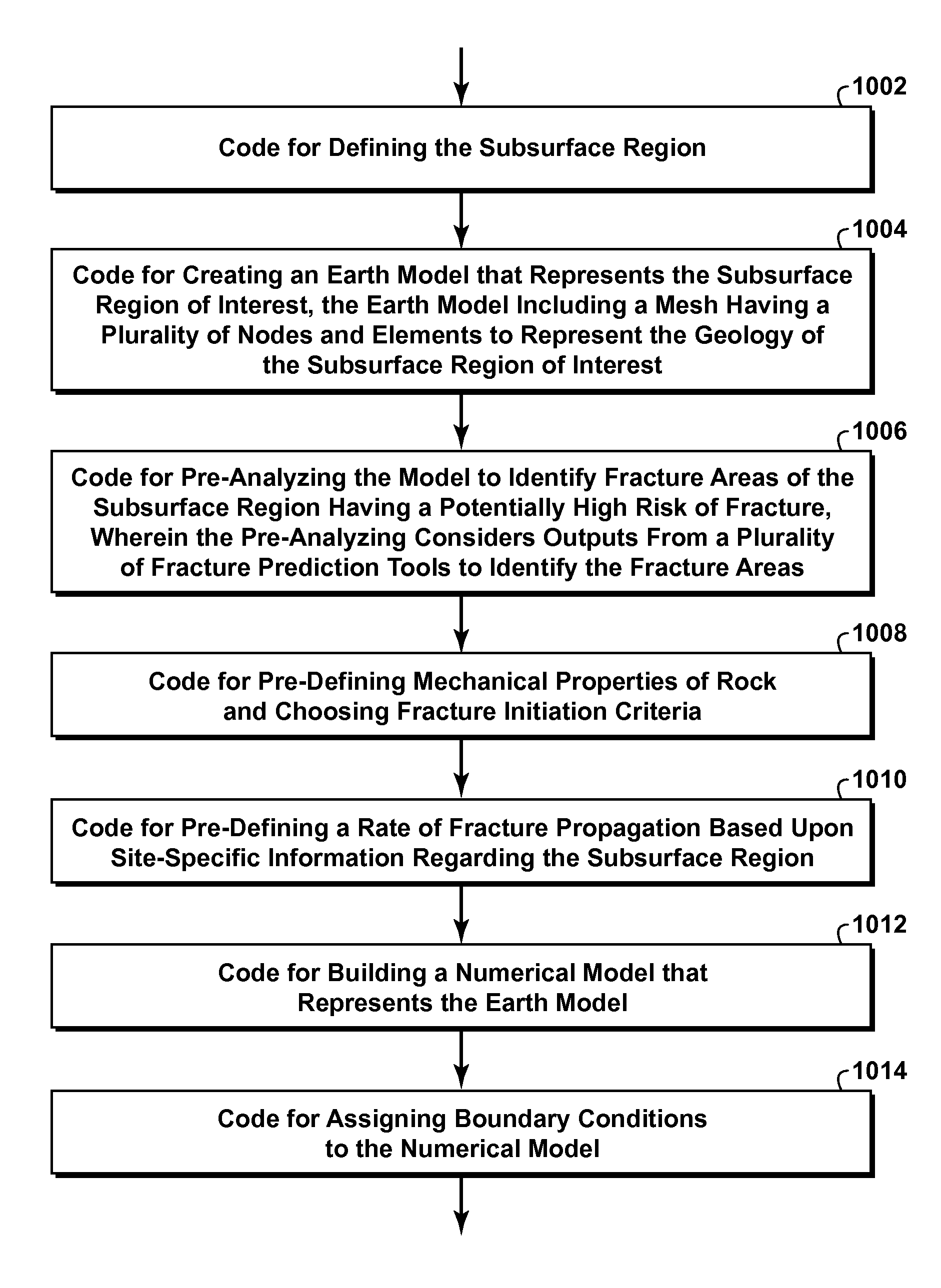

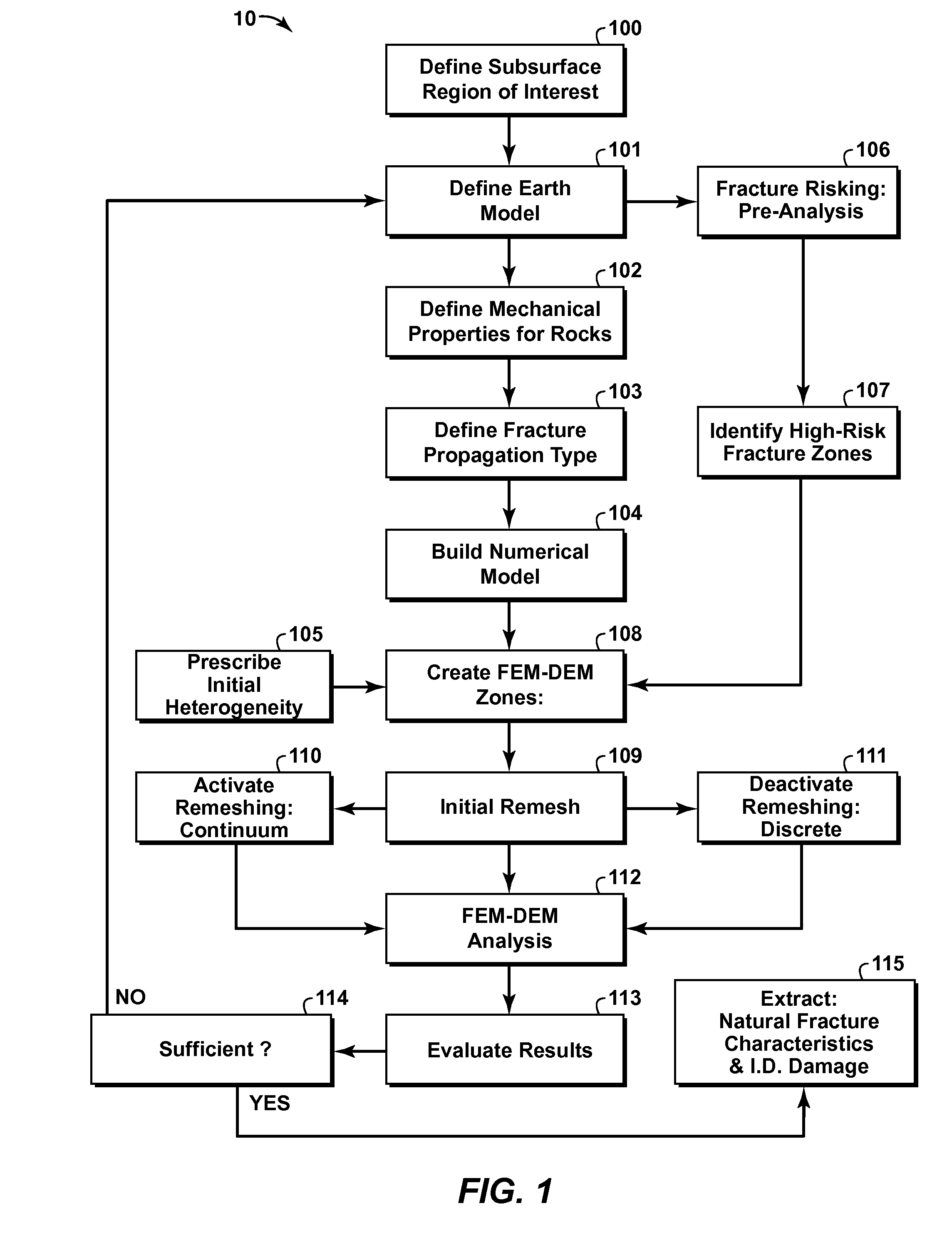

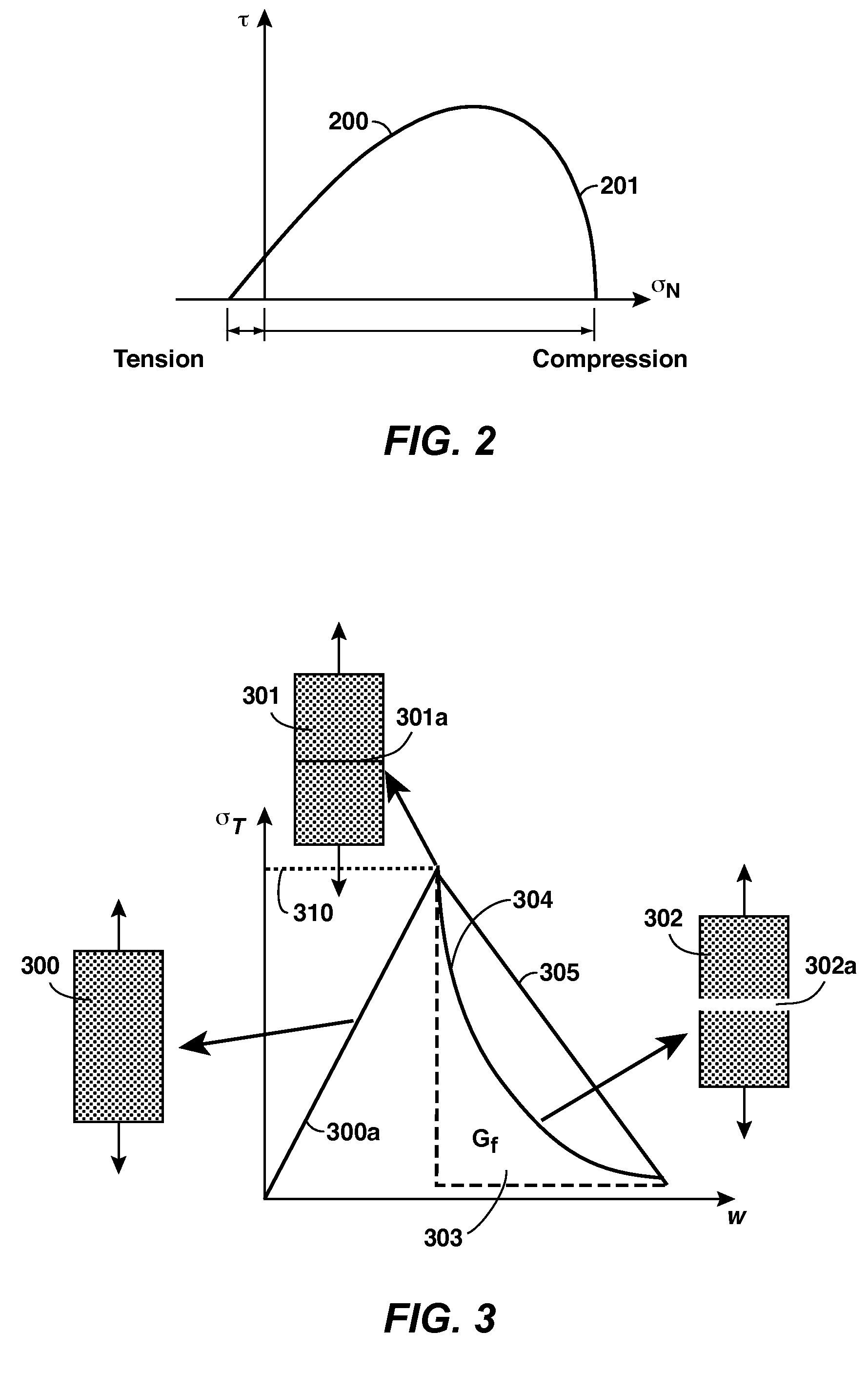

Method of Predicting Natural Fractures And Damage In A Subsurface Region

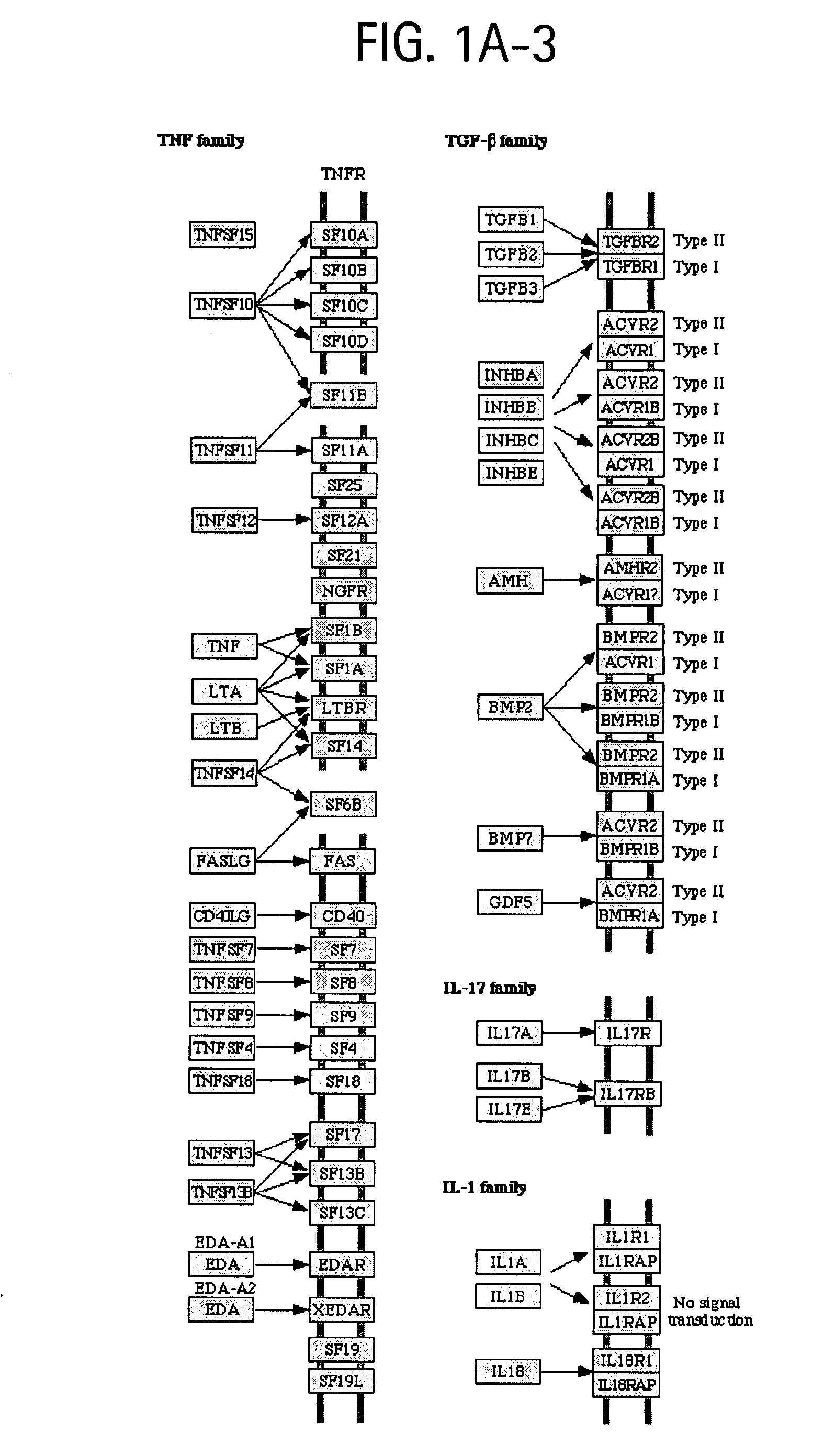

InactiveUS20110077918A1Limiting predictive capabilityComputation using non-denominational number representationDesign optimisation/simulationAnalysis toolsFracture risk

A method for predicting localized damage and naturally occurring fractures in a subsurface region is provided. This invention uses a hybrid FEM-DEM (i.e. finite-discrete element) framework combined with a fracture risking analysis and fracture initiation and propagation criteria, to model the transition of rock from a state of continuum to discontinuum. The risking analysis combines results from other natural fracture prediction tools (e.g. displacement discontinuity method, restoration analyses, curvature analysis, analytical solutions, continuum analysis) to augment FEM-DEM solutions, such as by providing remote and local boundary conditions and identifying potential regions of anticipated damage and fracturing. Natural fractures and damage information is extracted from the modeling results and may be used directly for predictions or used as input into other fracture analysis tools or techniques. The FEM-DEM and risking techniques can be incorporated into a variety of numerical simulation software packages that use a finite-discrete method solver.

Owner:EXXONMOBIL UPSTREAM RES CO

Methods for treating postmenopausal women using ultra-low doses of estrogen

The present invention provides methods for treating physical conditions resulting from postmenopausal estrogen decline in a postmenopausal subject, and in particular methods for reducing the risk of osteoporotic bone fractures in a postmenopausal subject. The present invention also provides a kit useful for carrying out the methods of the present invention.

Owner:RGT UNIV OF CALIFORNIA +3

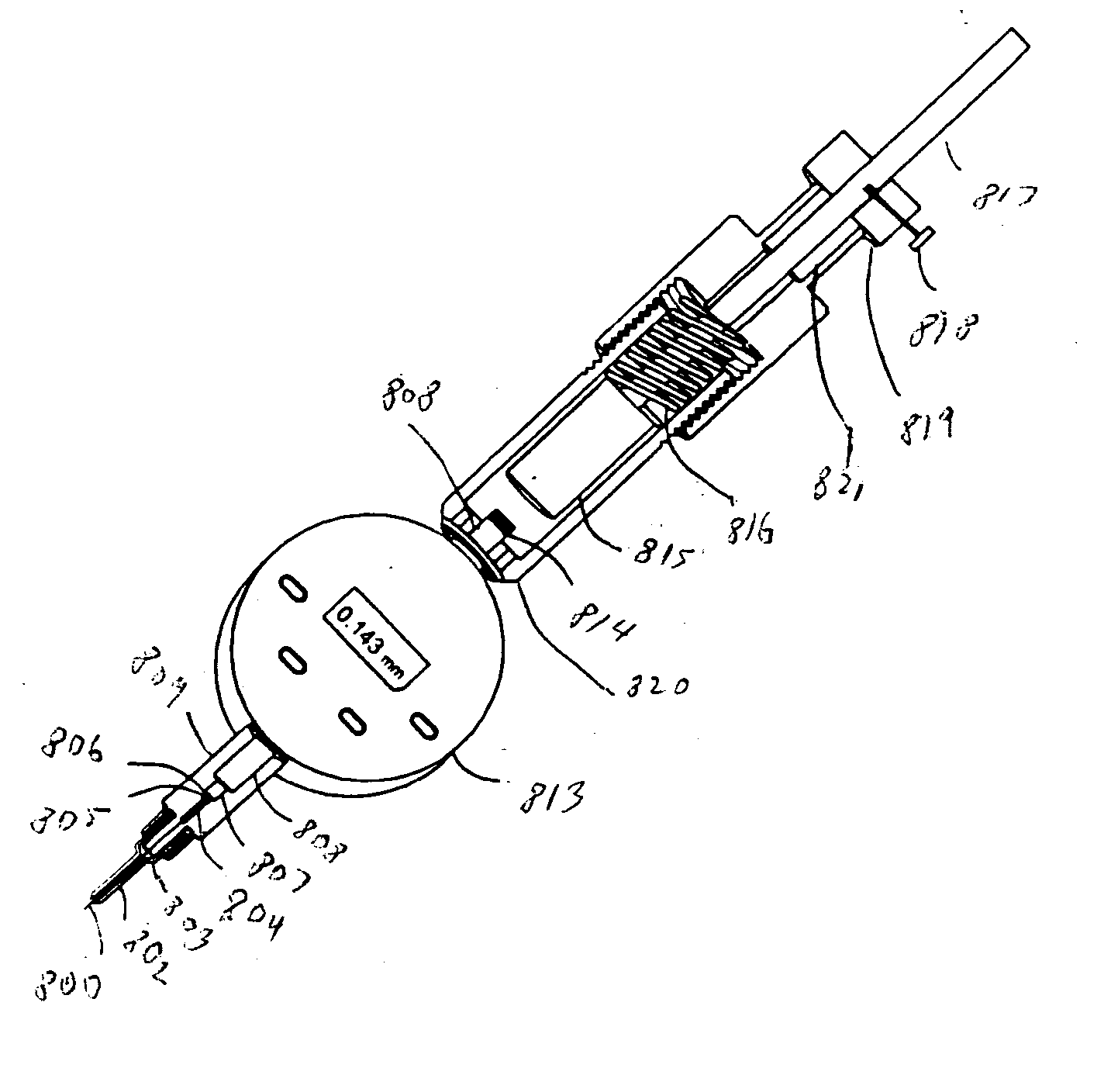

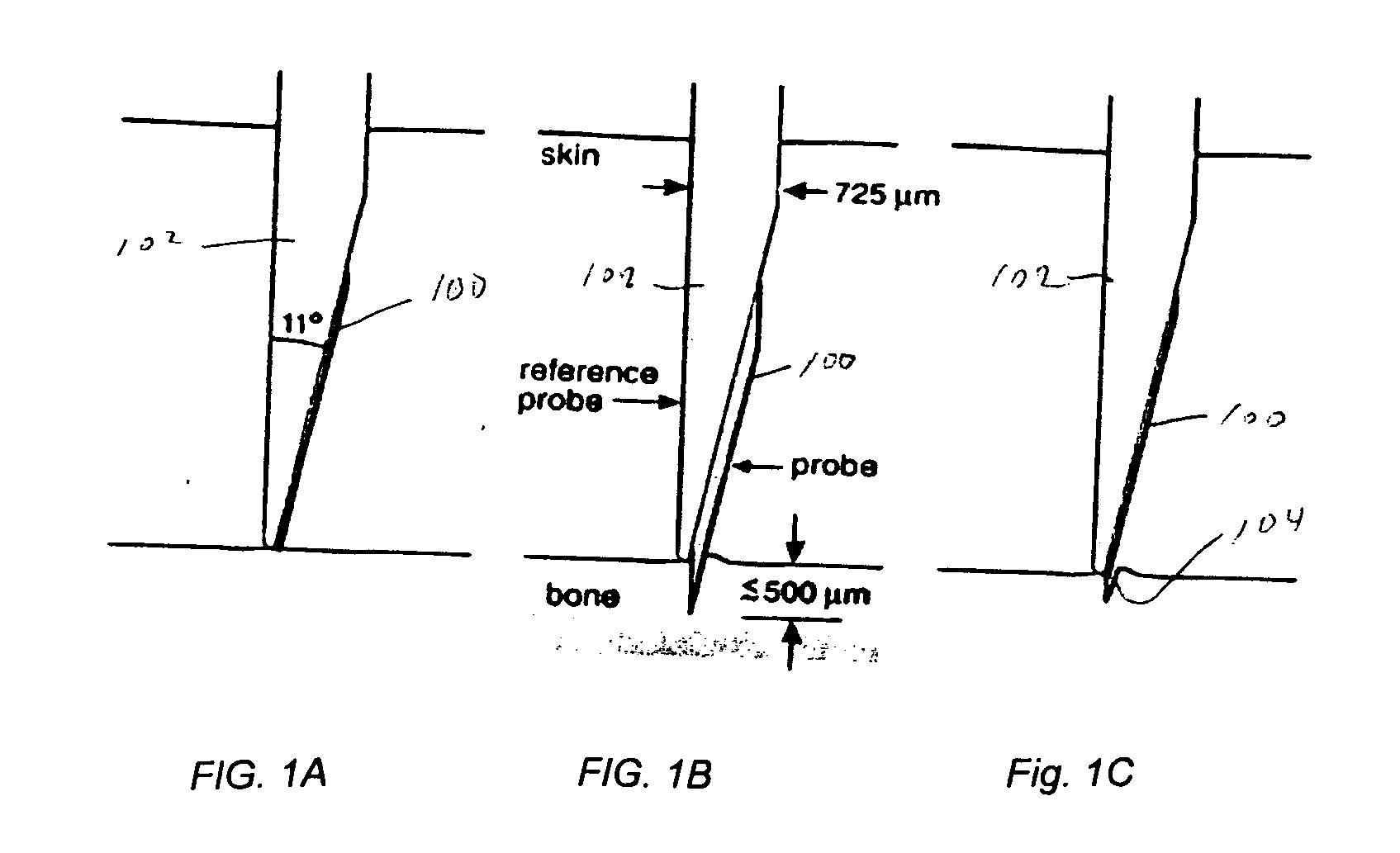

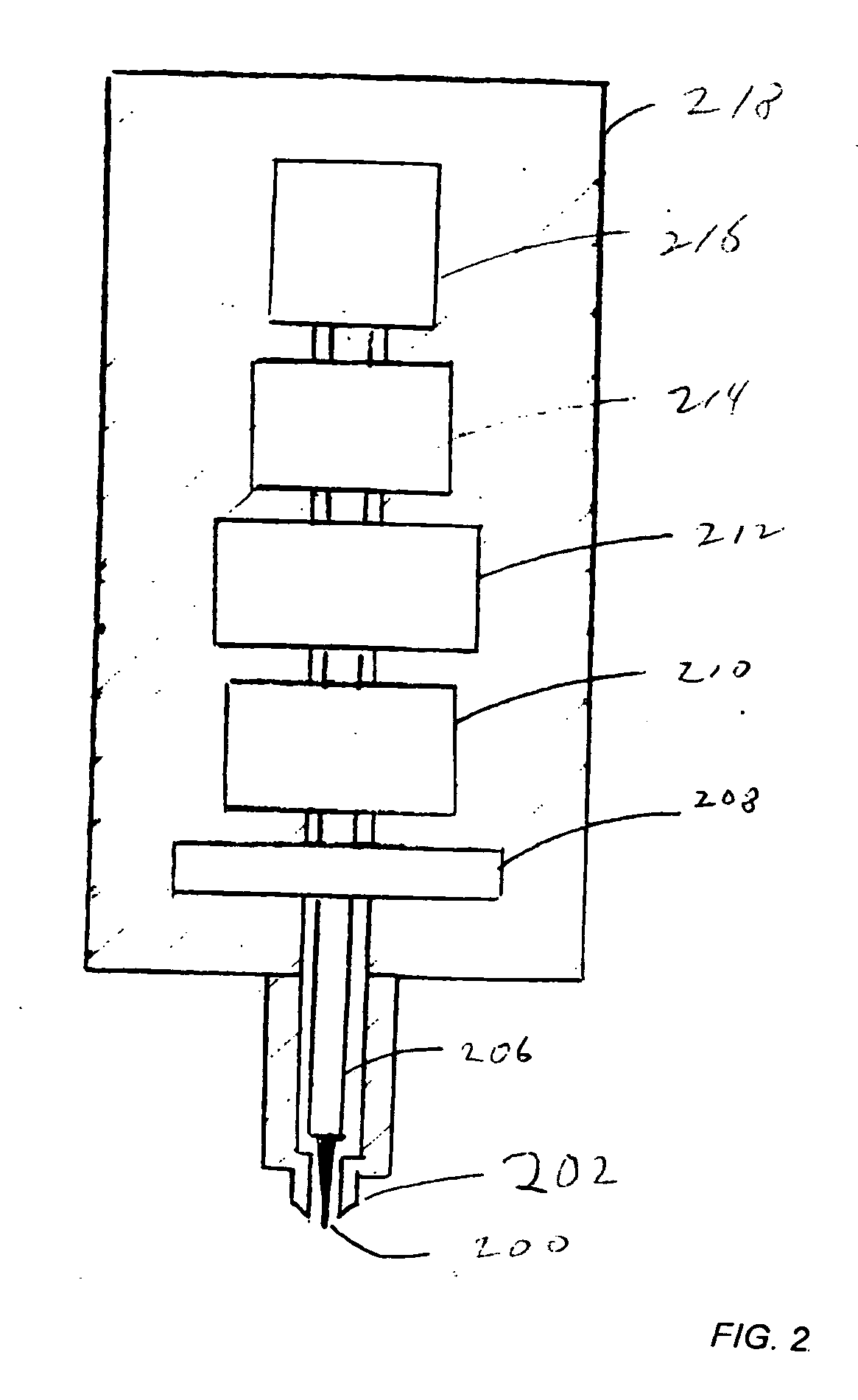

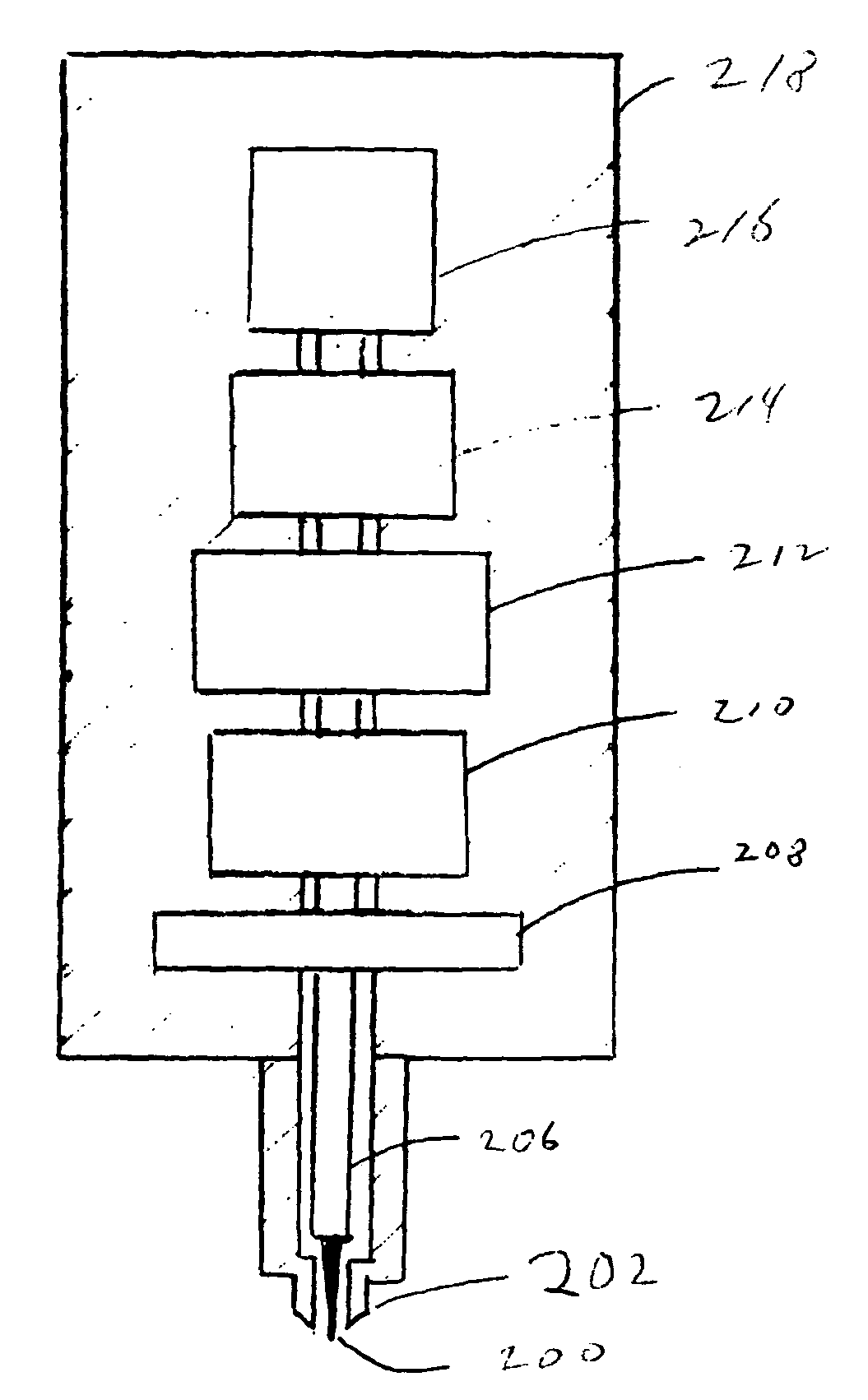

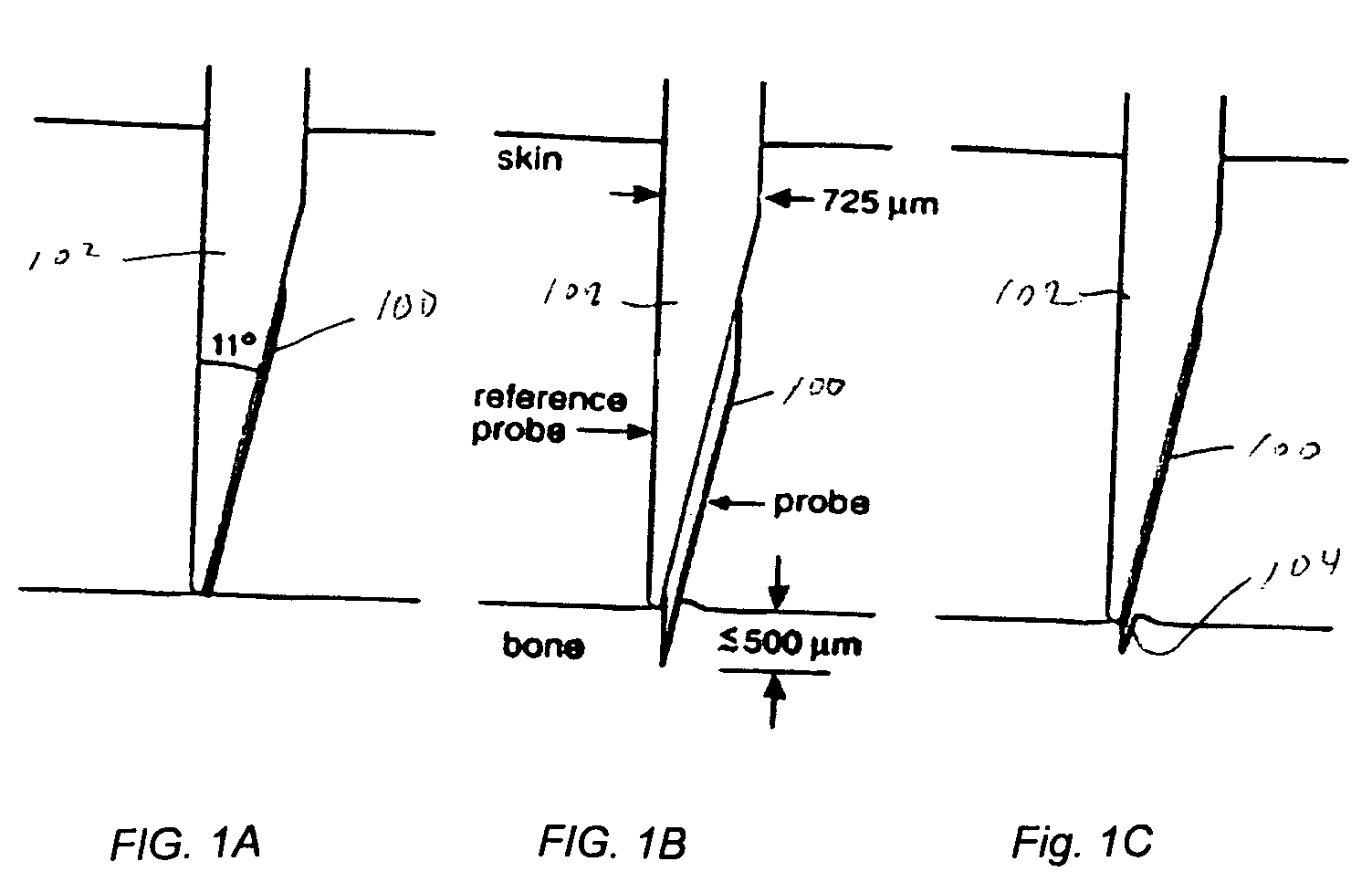

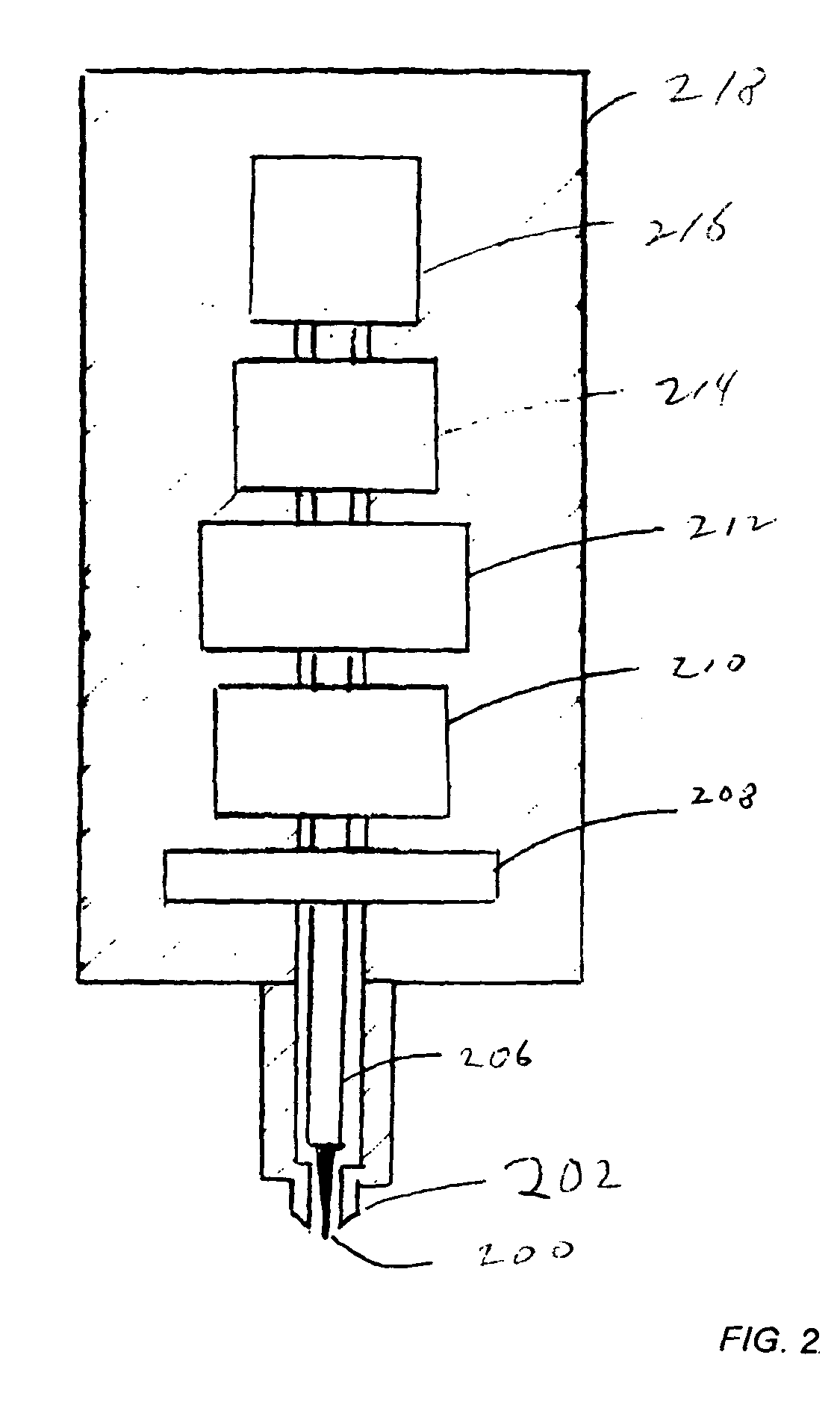

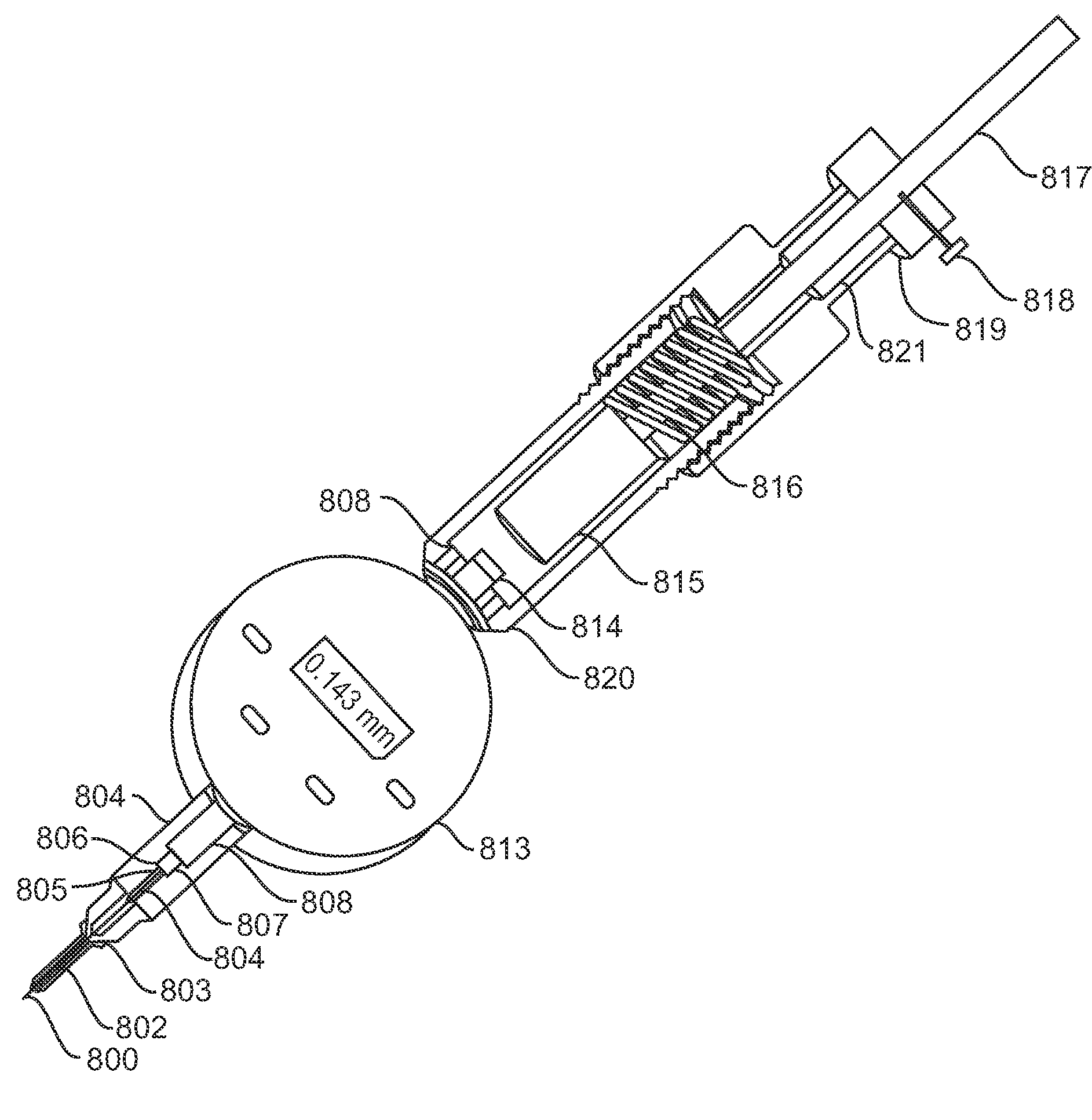

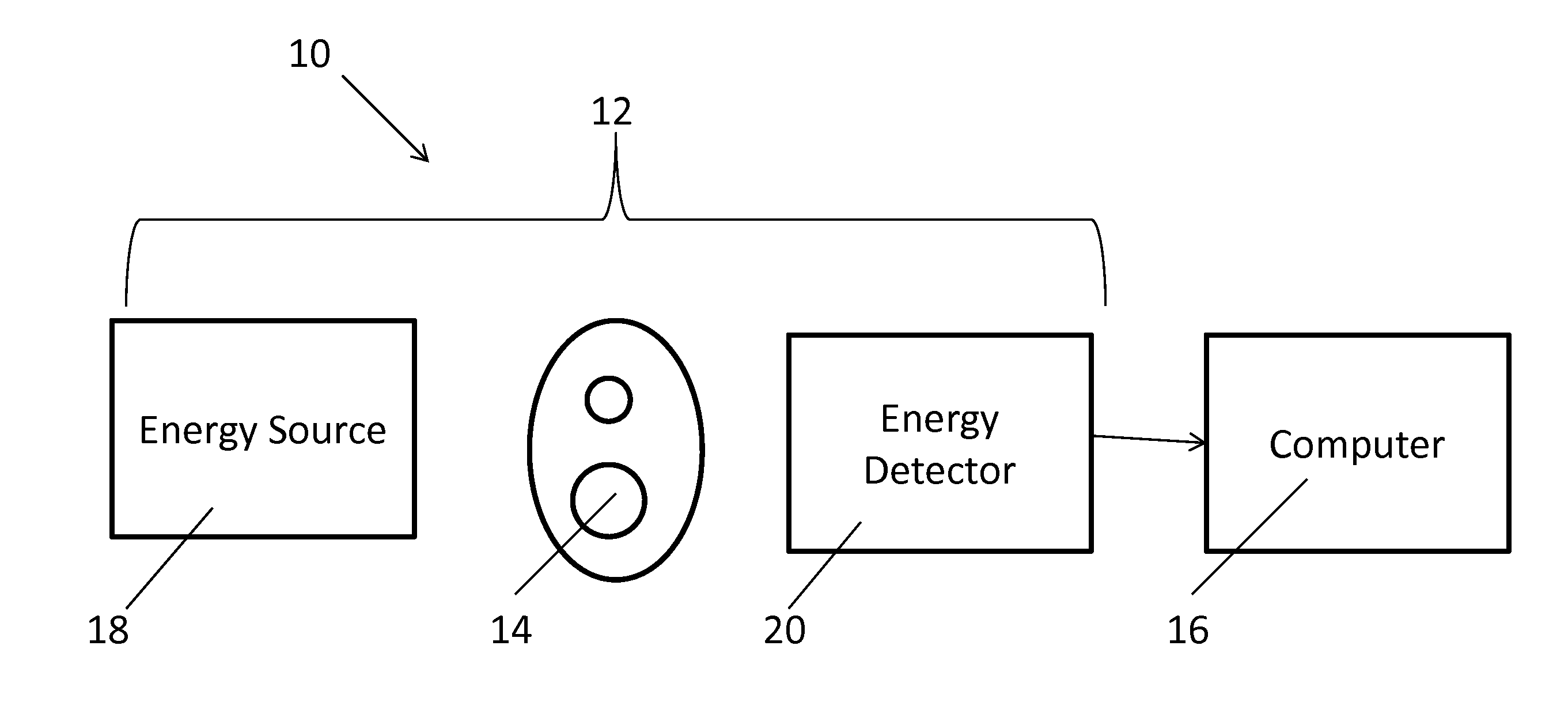

Methods and instruments for assessing bone fracture risk

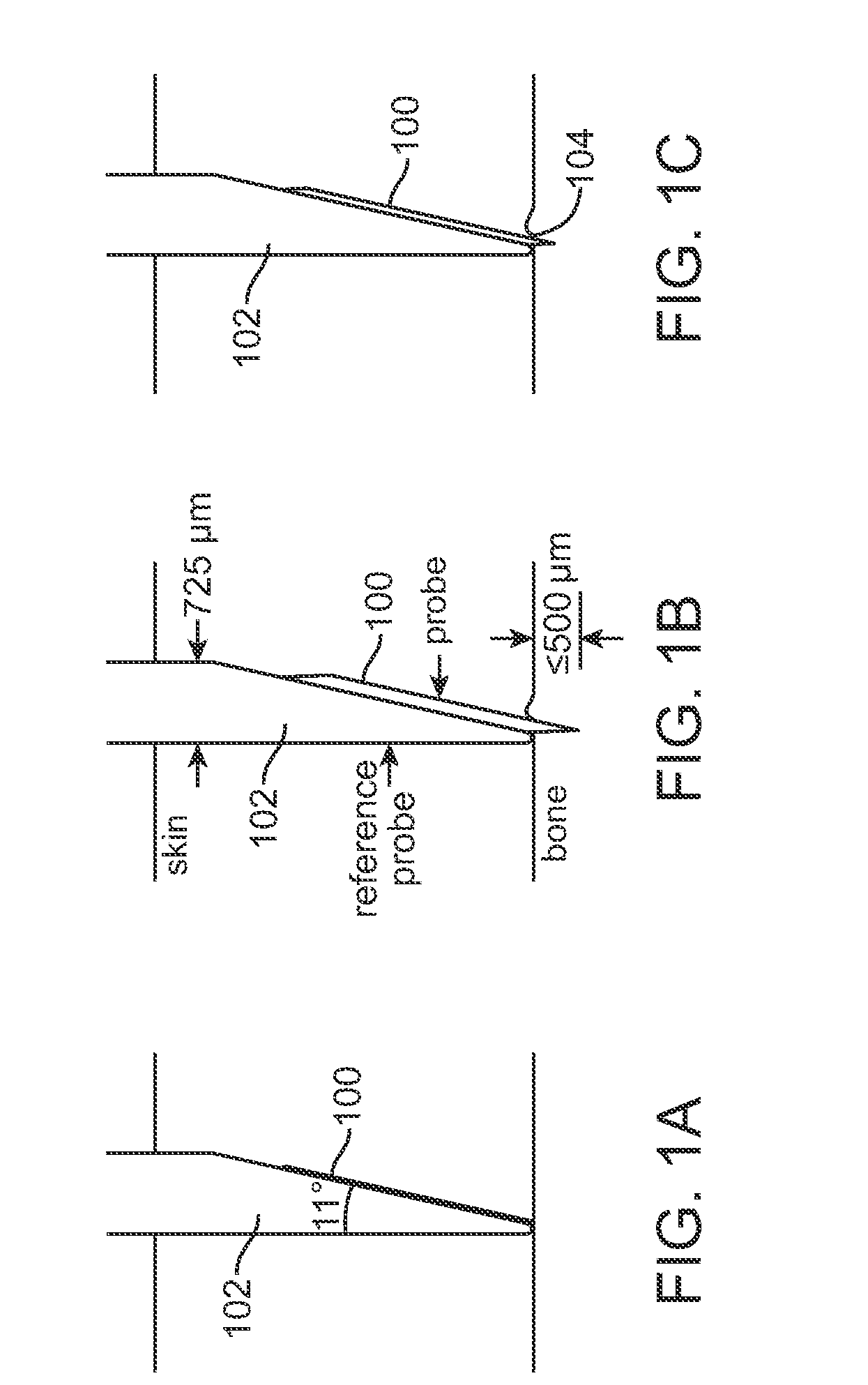

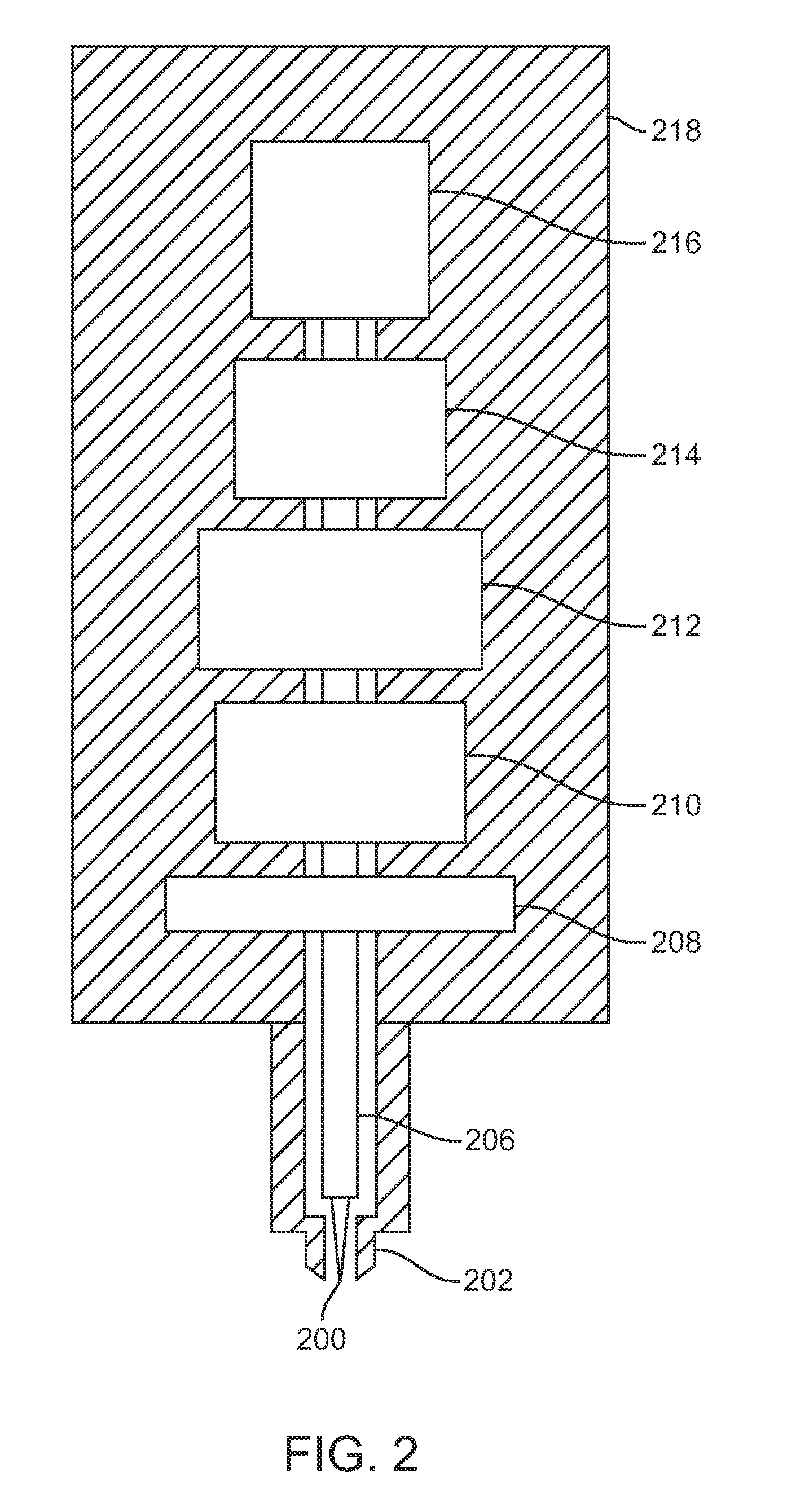

ActiveUS20070276292A1Quick and inexpensive testRisk of fracturePerson identificationSensorsHealth riskFracture risk

Methods and instruments for assessing bone, for example fracture risk, in a subject in which a test probe is inserted through the skin of the subject so that the test probe contacts the subject's bone and the resistance of the test bone to microscopic fracture by the test probe is determined. Macroscopic bone fracture risk is assessed by measuring the resistance of the bone to microscopic fractures caused by the test probe. The microscopic fractures are so small that they pose negligible health risks. The instrument may also be useful in characterizing other materials, especially if it is necessary to penetrate a layer to get to the material to be characterized.

Owner:RGT UNIV OF CALIFORNIA

Osteoporosis associated markers and methods of use thereof

InactiveUS20080171319A1Increased riskMicrobiological testing/measurementDisease diagnosisBone qualityBiologic marker

Disclosed are methods of identifying subjects with osteoporosis or osteopenia, subjects at risk for developing osteoporosis, osteopenia, and bone fractures, methods of evaluating the effectiveness of osteoporosis treatments in subjects with osteoporosis or osteopenia, and methods of selecting therapies for treating osteoporosis or osteopenia, using biomarkers.

Owner:TETHYS BIOSCI

Method of predicting natural fractures and damage in a subsurface region

InactiveUS8494827B2Computation using non-denominational number representationDesign optimisation/simulationAnalysis toolsFracture risk

A method for predicting localized damage and naturally occurring fractures in a subsurface region is provided. This invention uses a hybrid FEM-DEM (i.e. finite-discrete element) framework combined with a fracture risking analysis and fracture initiation and propagation criteria, to model the transition of rock from a state of continuum to discontinuum. The risking analysis combines results from other natural fracture prediction tools (e.g. displacement discontinuity method, restoration analysis, curvature analysis, analytical solutions, continuum analysis) to augment FEM-DEM solutions, such as by providing remote and local boundary conditions and identifying potential regions of anticipated damage and fracturing. Natural fractures and damage information is extracted from the modeling results and may be used directly for predictions or used as input into other fracture analysis tools or techniques. The FEM-DEM and risking techniques can be incorporated into a variety of numerical simulation software packages that use a finite-discrete method solver.

Owner:EXXONMOBIL UPSTREAM RES CO

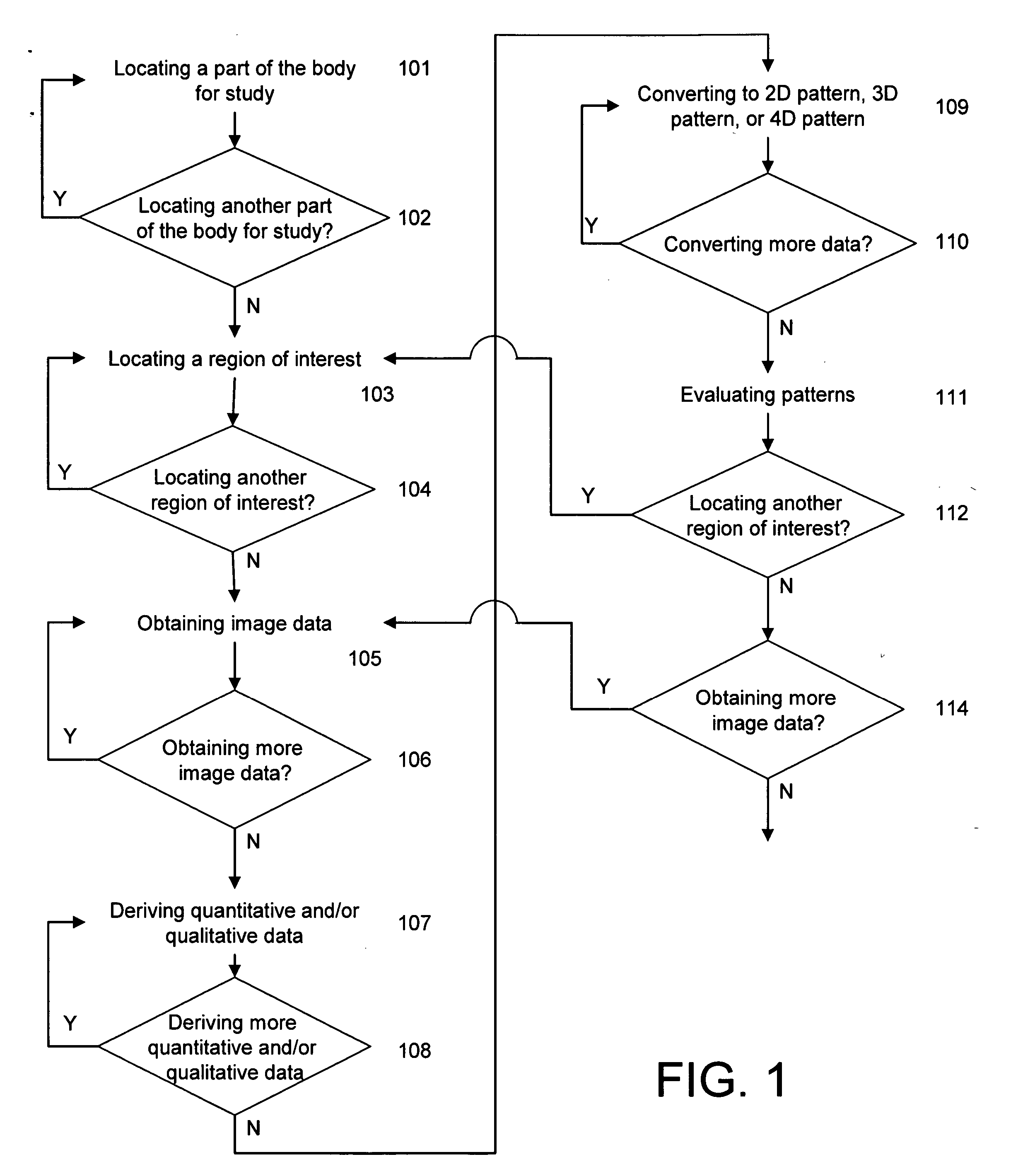

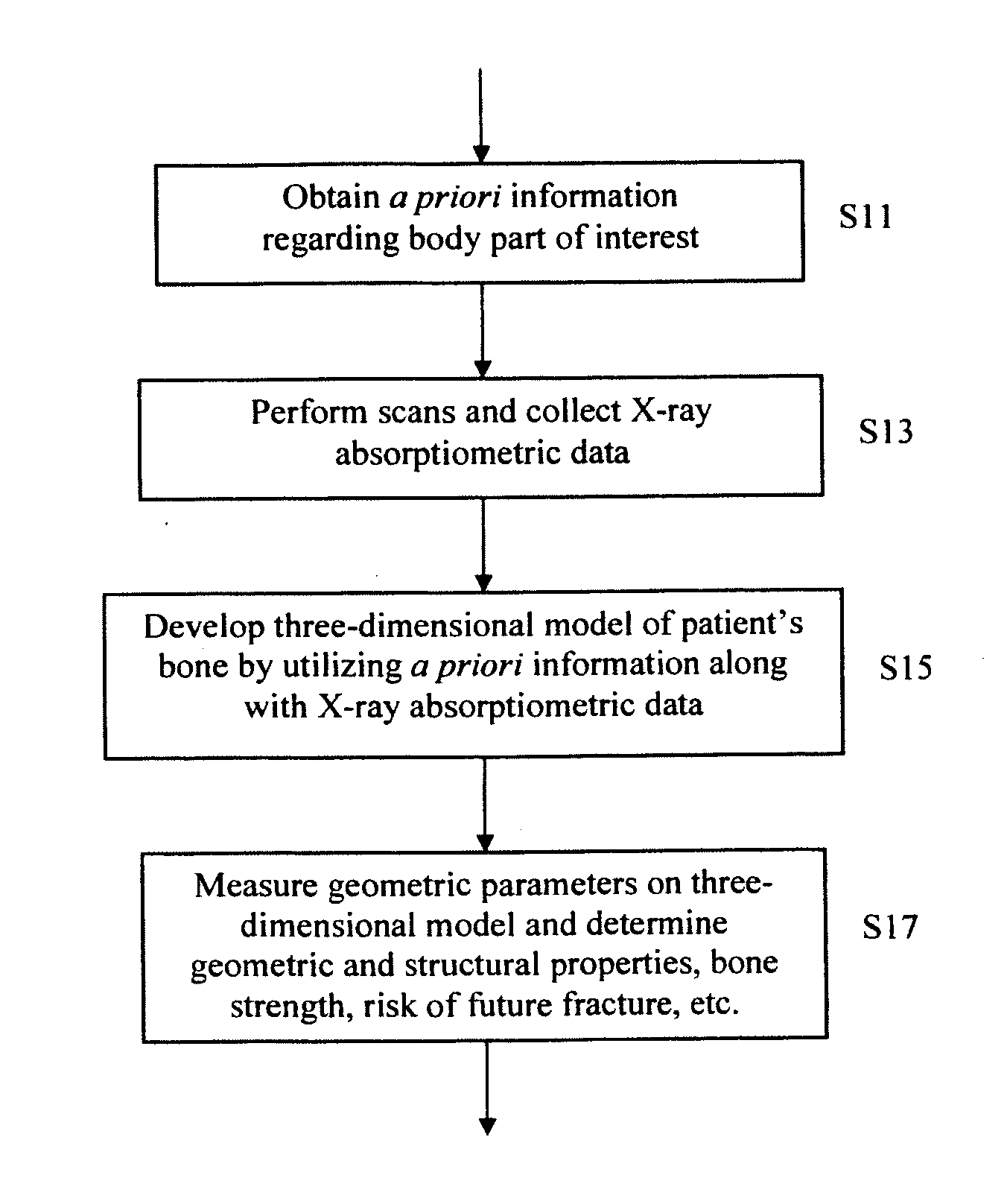

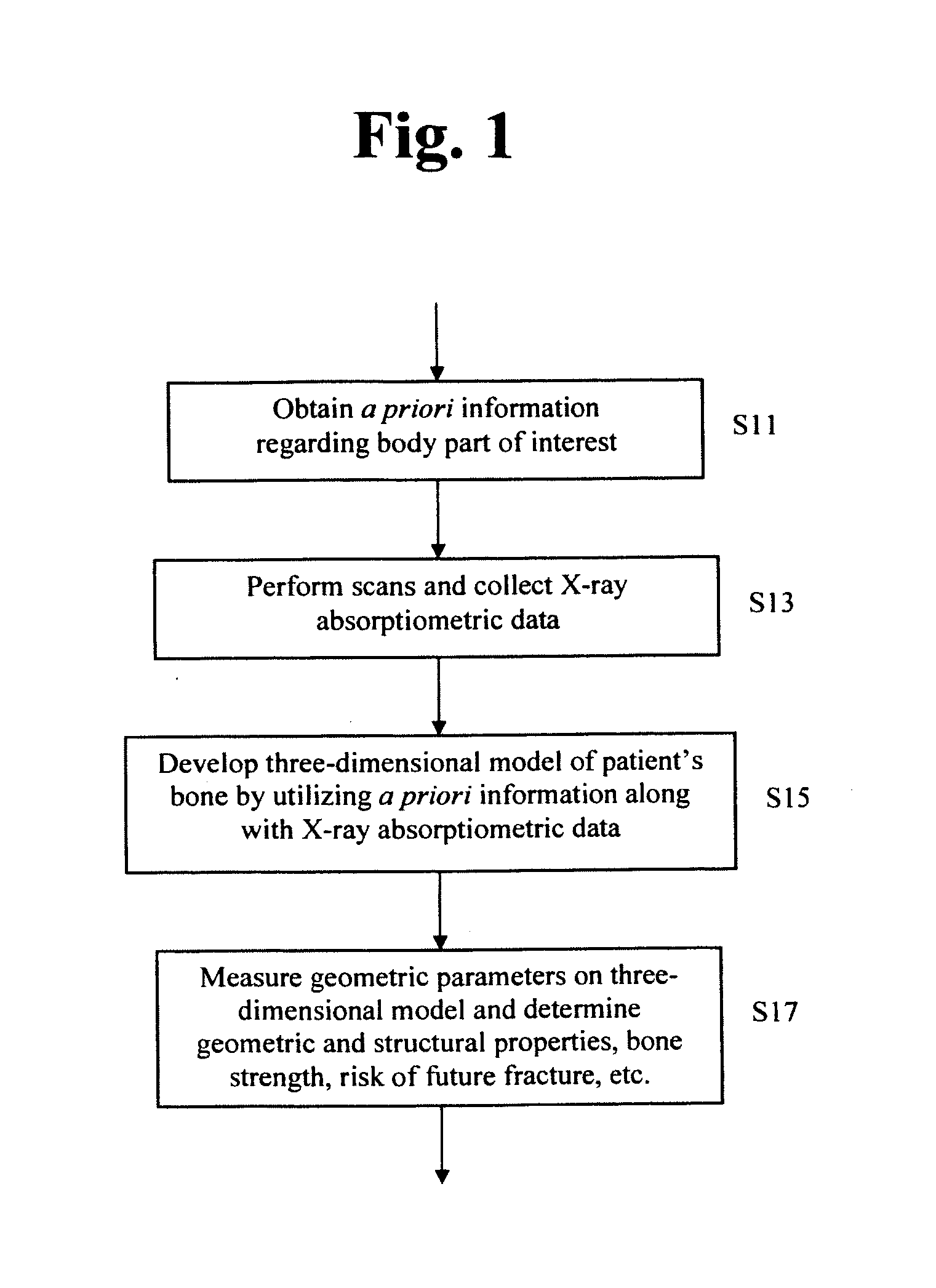

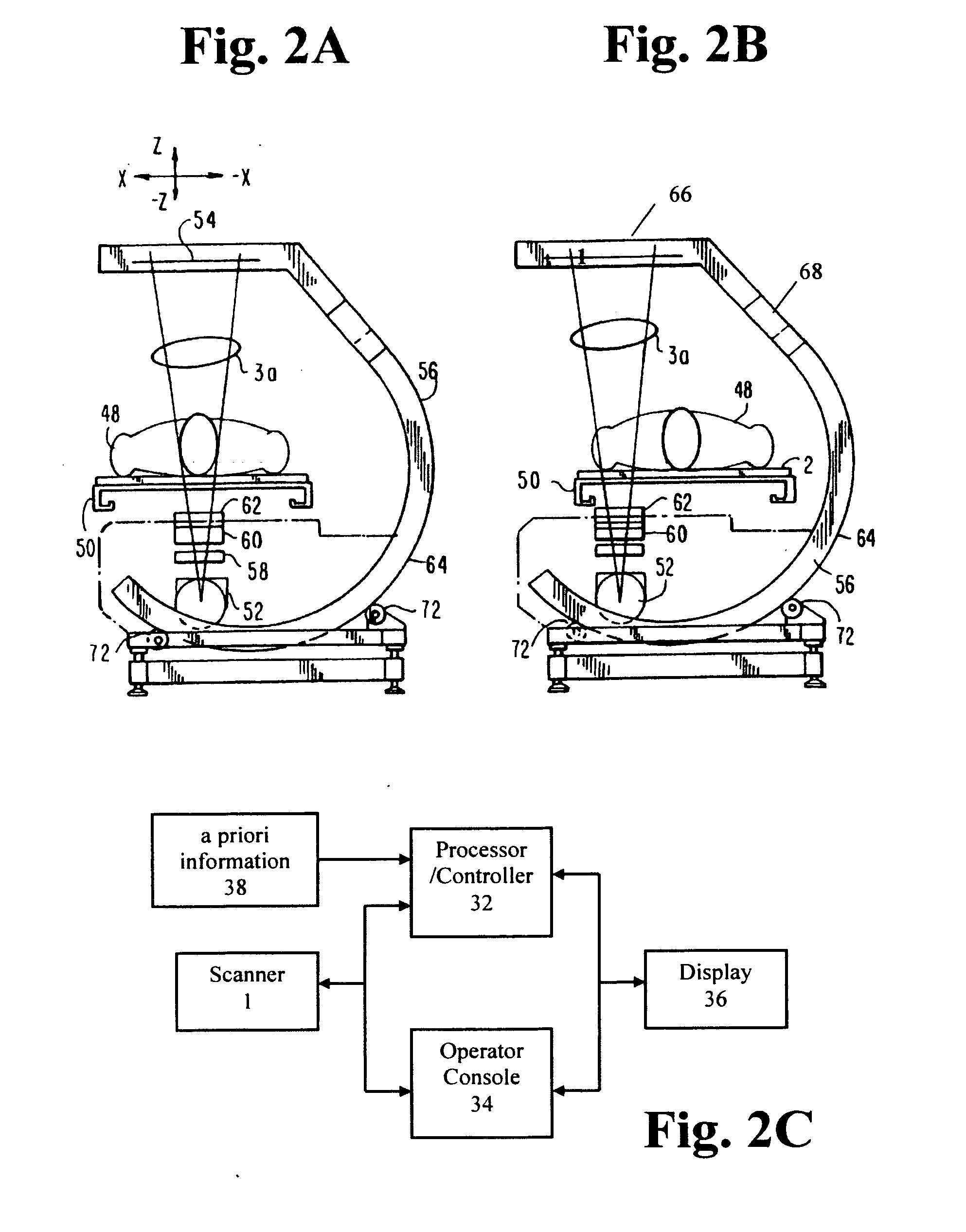

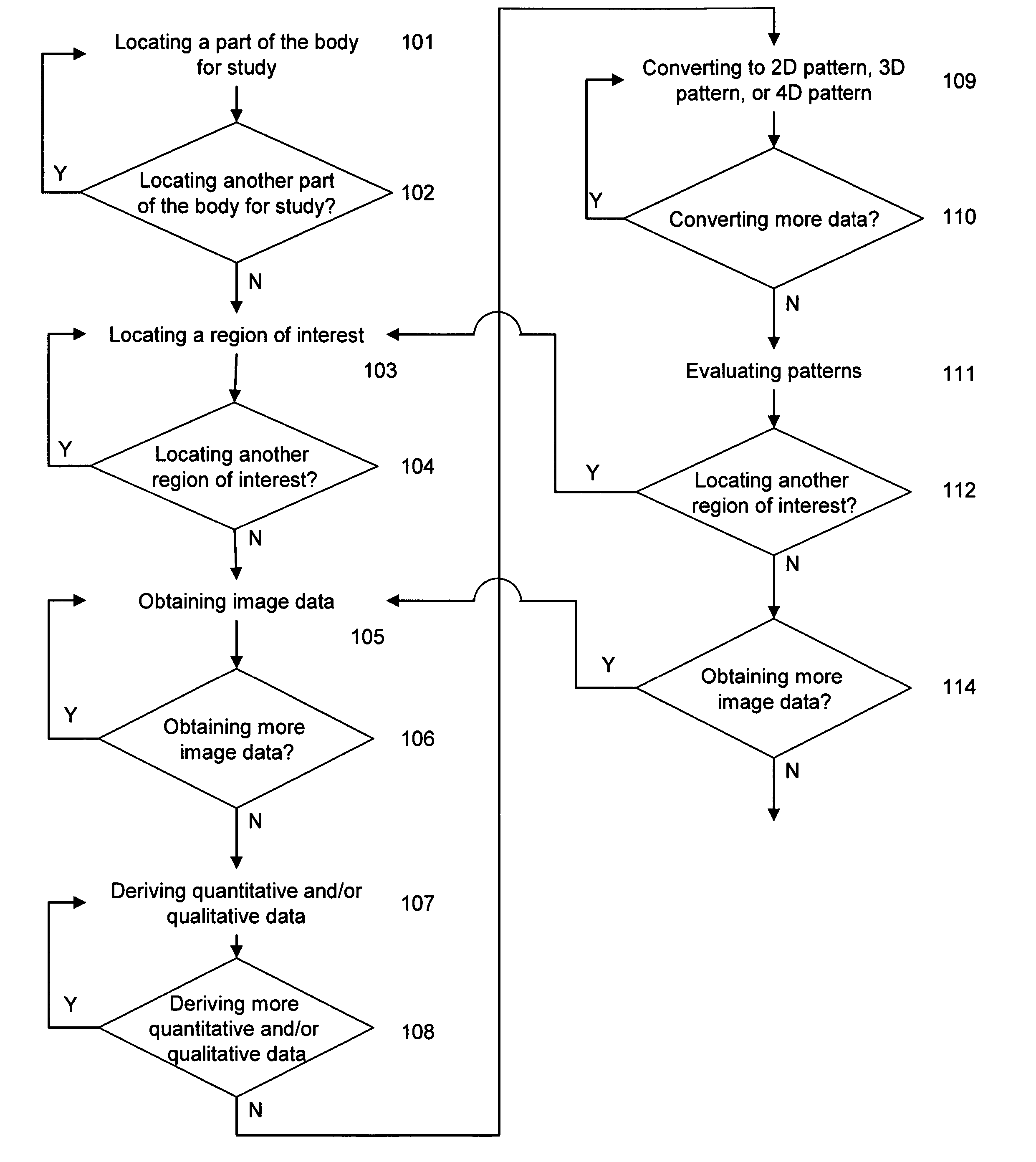

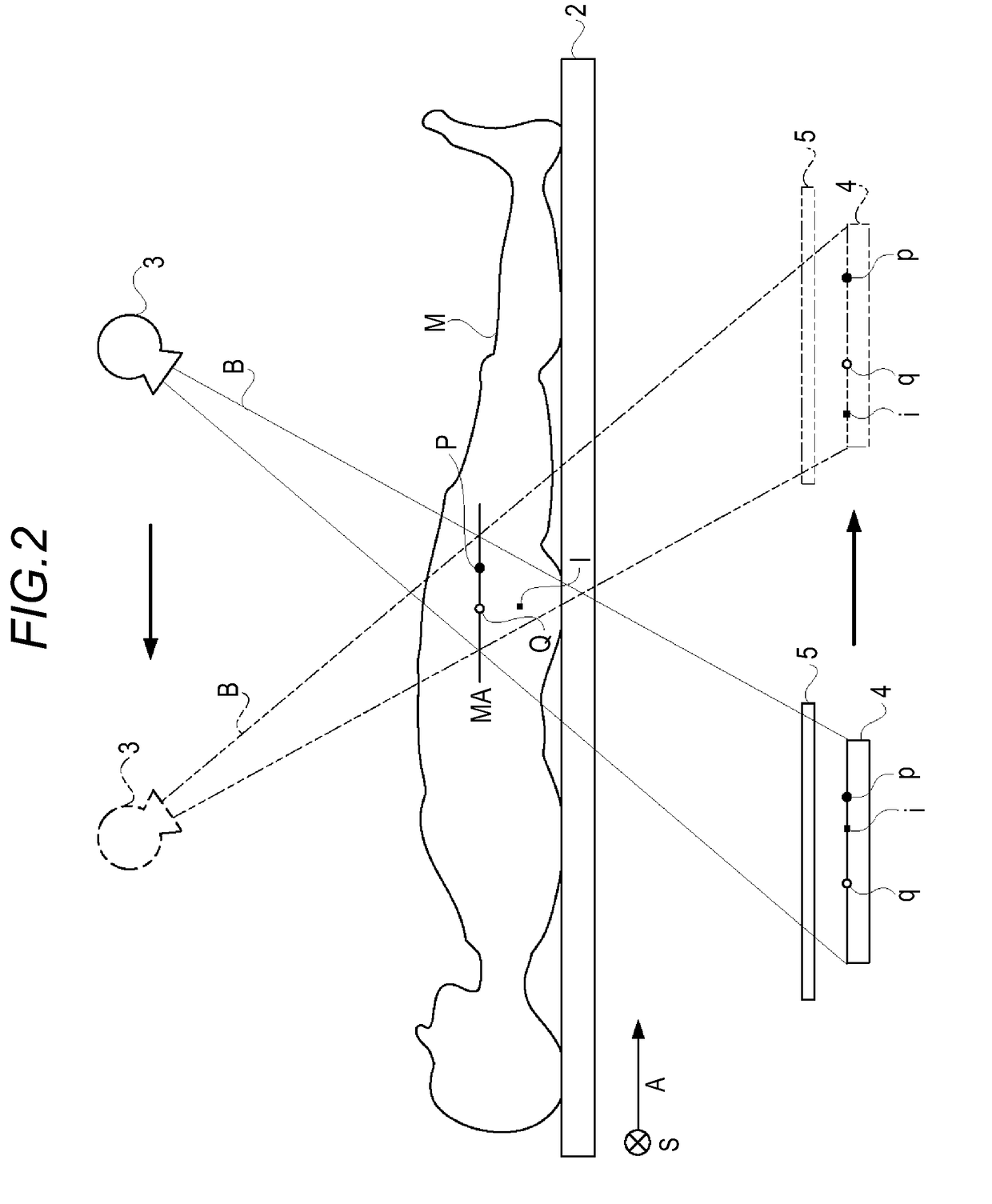

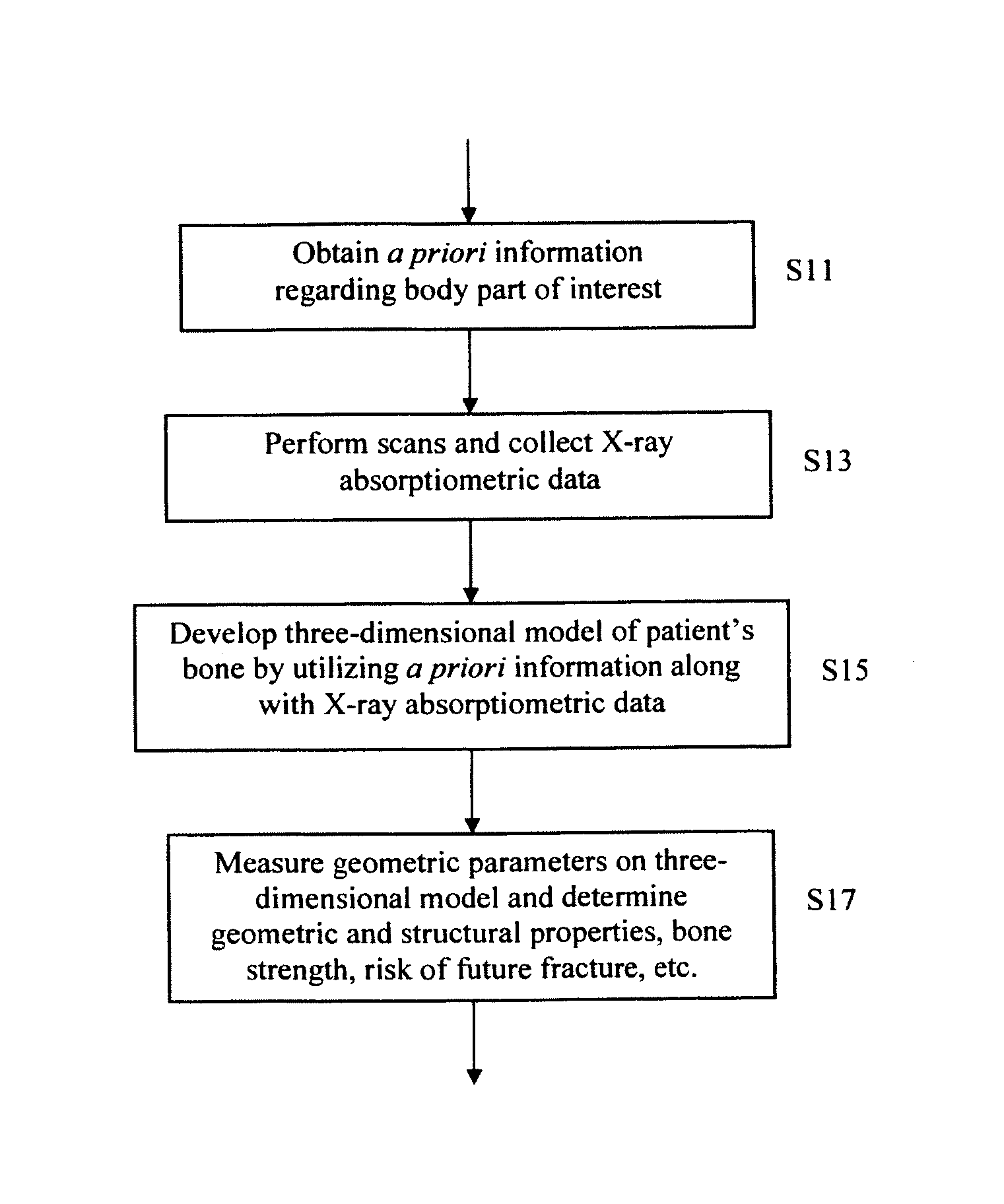

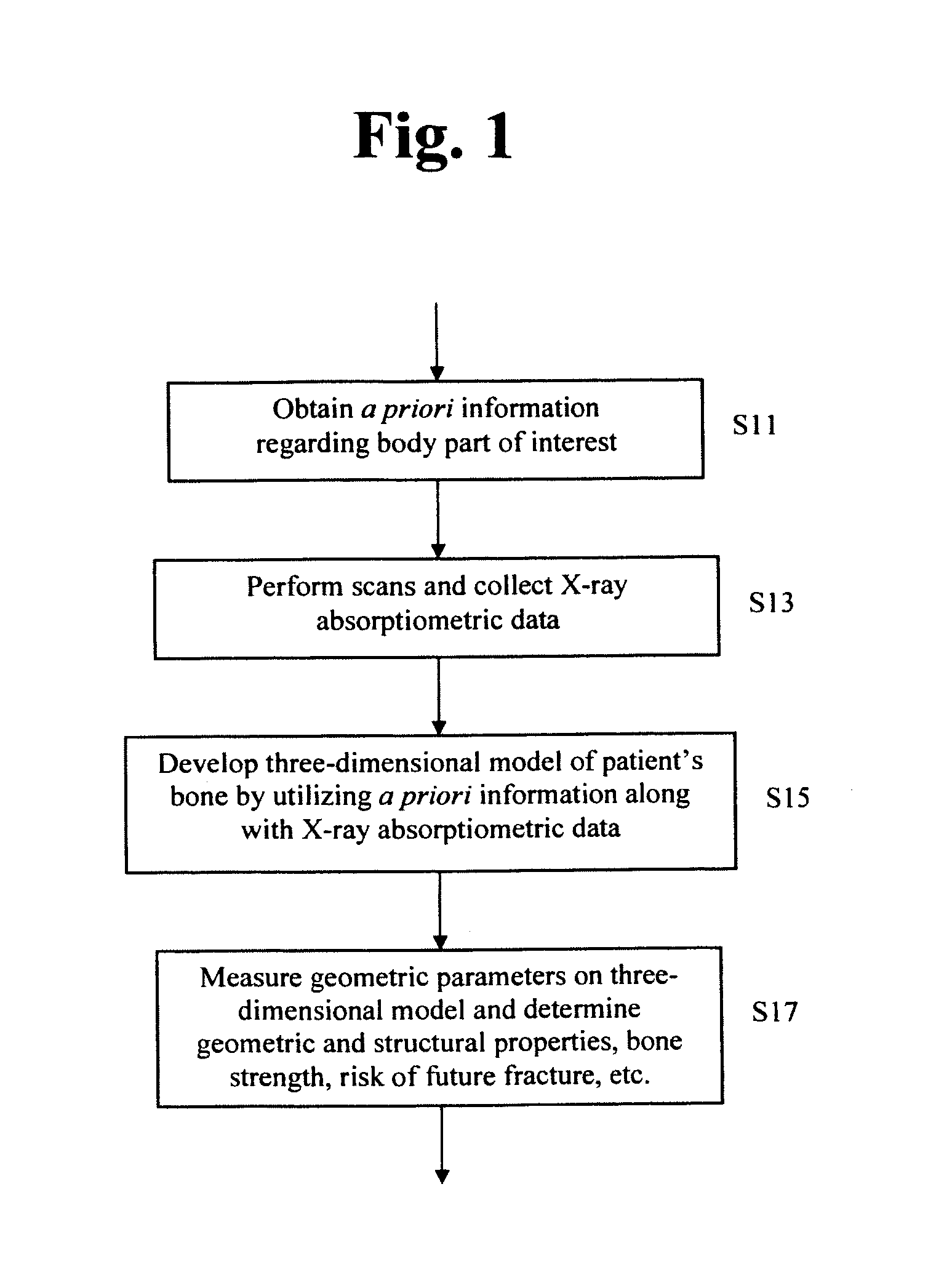

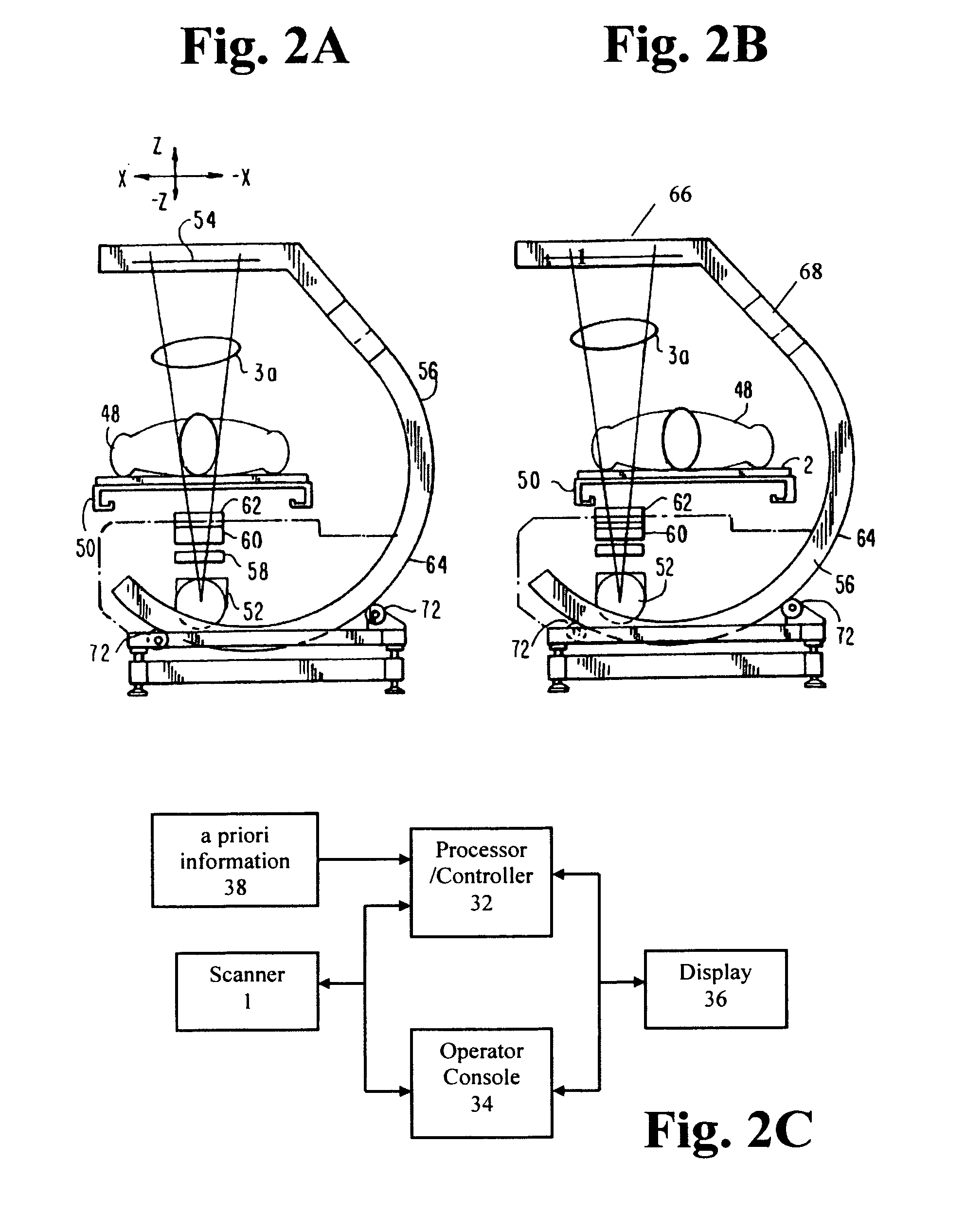

Estimating risk of future bone fracture utilizing three-dimensional bone density model

A novel approach for analyzing a patient's body part of interest to assess bone strength and / or risk of future fracture includes obtaining a priori information regarding the body part of interest, performing X-ray absorptiometric scans of the patient's body part of interest and collecting X-ray absorptiometry data from the scans, constructing a three-dimensional model of the patient's body part of interest, by utilizing the a priori information along with the X-ray absorptiometric data, and performing measurements of various geometric parameters on the three-dimensional model for determining geometric and structural properties.

Owner:HOLOGIC INC

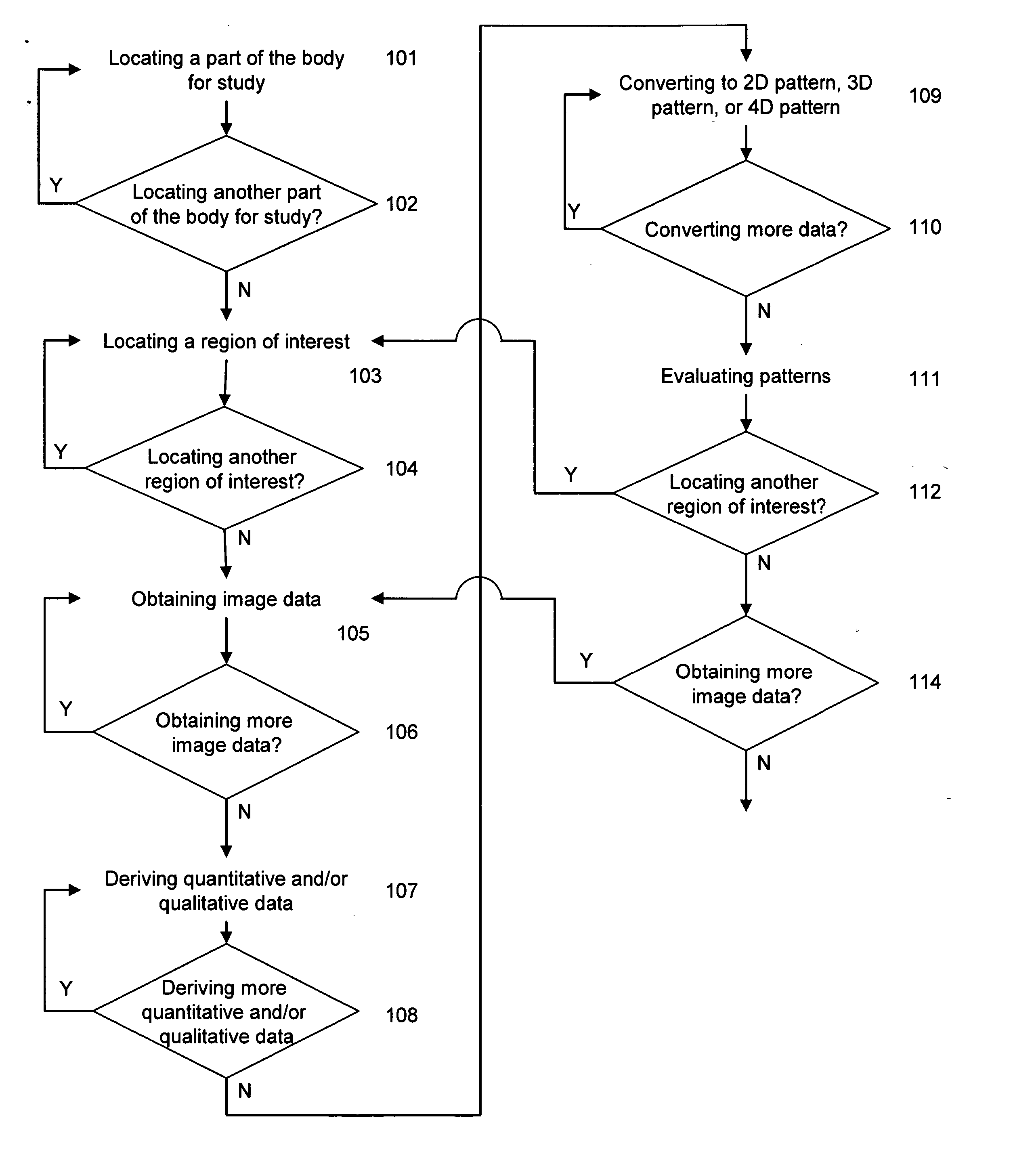

System and method of predicting future fractures

Methods of predicting fracture risk of a patient include: obtaining an image of a bone of the patient; determining one or more bone structure parameters; predicting a fracture line with the bone structure parameter; predicting a fracture load at which a fracture will happen; estimating body habitus of the patient; calculating a peak impact force on the bone when the patient falls; and predicting a fracture risk by calculating the ratio between the peak impact force and the fracture load. Inventive methods also includes determining the effect of a candidate agent on any subject's risk of fracture.

Owner:IMATX INC

Metal-ceramic composite articulation

InactiveUS20050090903A1Minimal productionIncrease resistanceBone implantJoint implantsHigh fractureIn vivo

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPam1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate PE wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

Methods and instruments for assessing bone fracture risk

ActiveUS7878987B2Quick and inexpensive testRisk of fracturePerson identificationSensorsHealth riskFracture risk

Methods and instruments for assessing bone, for example fracture risk, in a subject in which a test probe is inserted through the skin of the subject so that the test probe contacts the subject's bone and the resistance of the test bone to microscopic fracture by the test probe is determined. Macroscopic bone fracture risk is assessed by measuring the resistance of the bone to microscopic fractures caused by the test probe. The microscopic fractures are so small that they pose negligible health risks. The instrument may also be useful in characterizing other materials, especially if it is necessary to penetrate a layer to get to the material to be characterized.

Owner:RGT UNIV OF CALIFORNIA

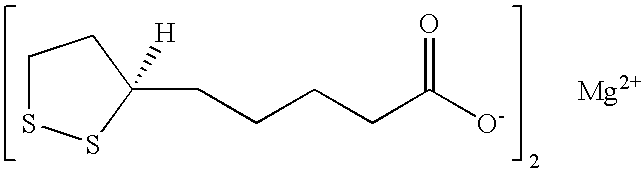

Combined calcium, magnesium and vitamin D supplements

ActiveUS20100009948A1Reduce the risk of fracturesPrevent and treat osteoporosisBiocideOrganic active ingredientsVolumetric Mass DensityAlpha-Lipoic Acid

The present invention relates to oral nutritional and therapeutic products which are useful for providing vitamins and minerals required for bone health. The present invention is an oral nutritional and therapeutic composition of calcium succinate, magnesium R-(+)-alpha-lipoate, and Vitamin D for use in the maintenance of bone health, the optimization of bone growth, reducing the risk of bone fracture, and the prevention and treatment of osteoporosis. The pharmaceutical products and methods of the present invention are particularly useful in building bone mass, quality, and density during growth, maintaining bone mass, quality, and density over time, reducing bone fracture risk, and treating osteoporosis in men and women.

Owner:BIOLINK LIFE SCI

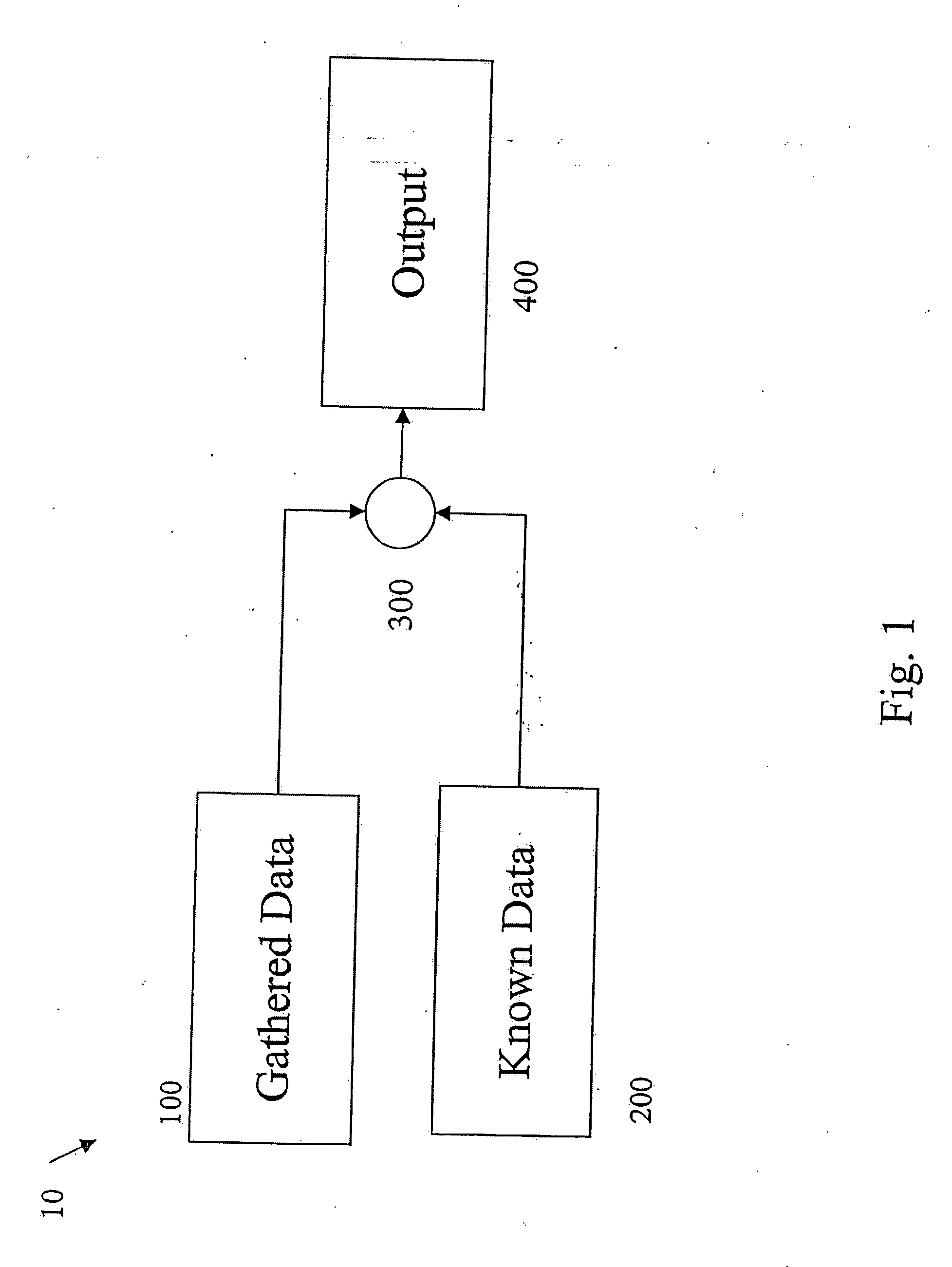

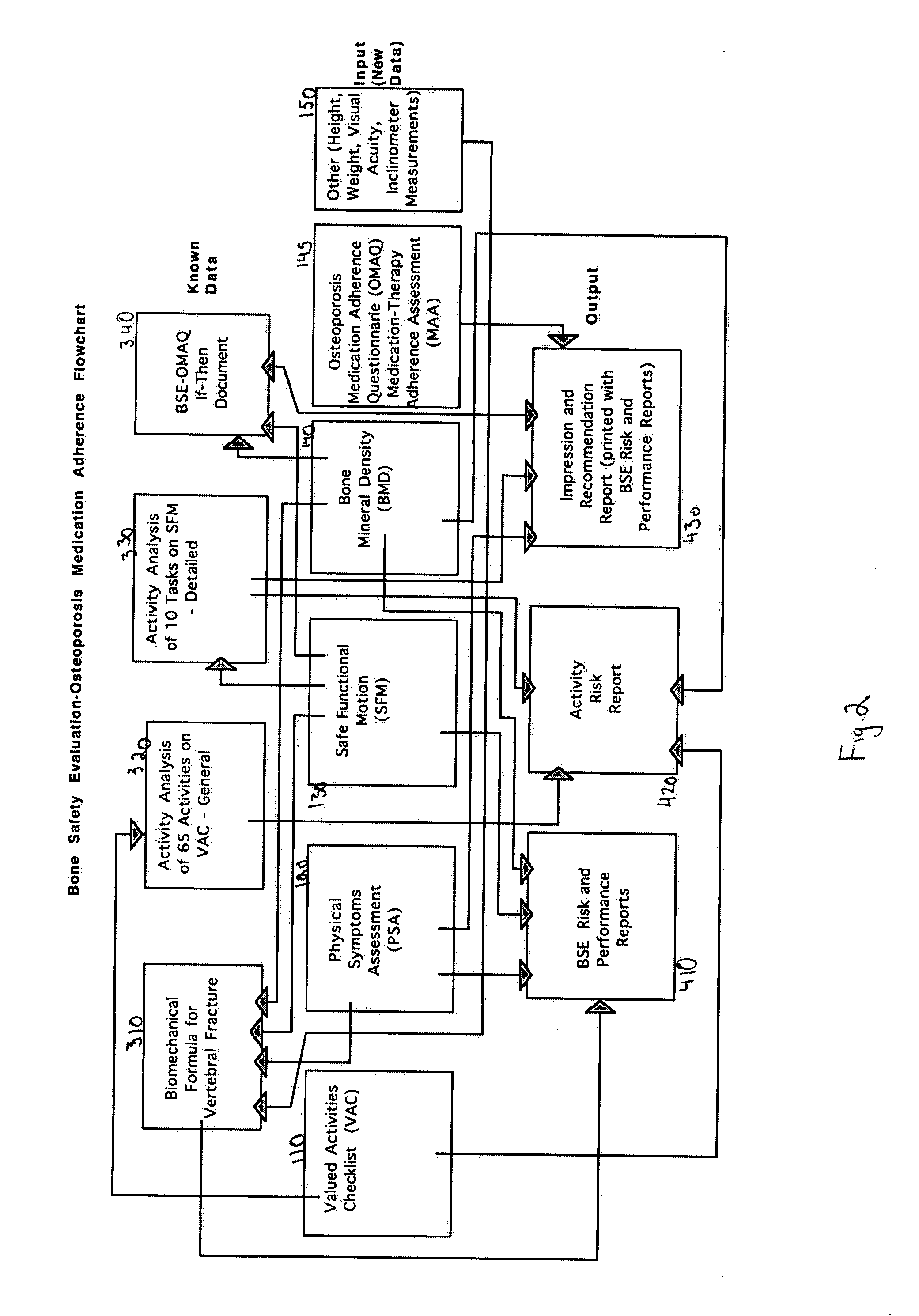

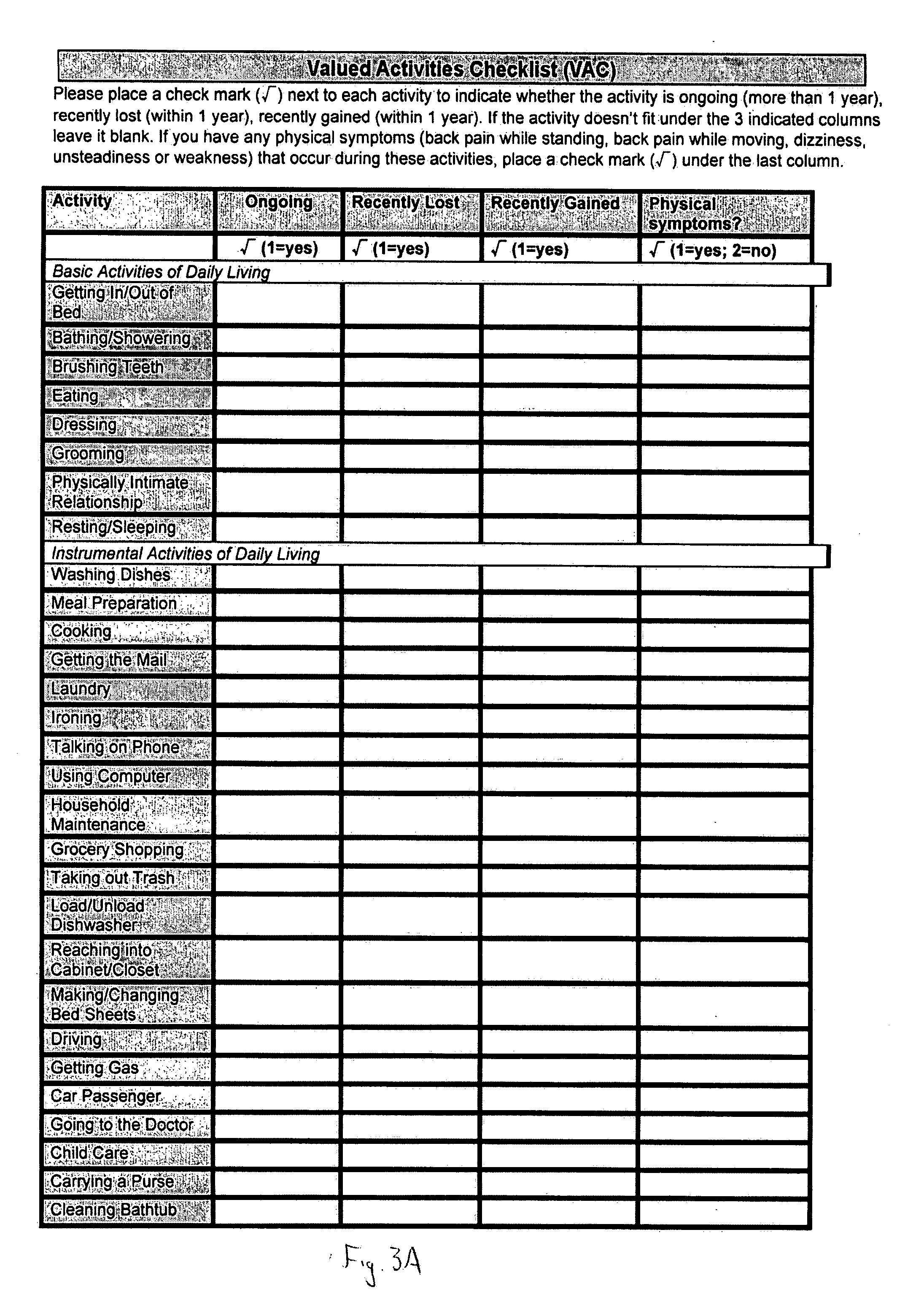

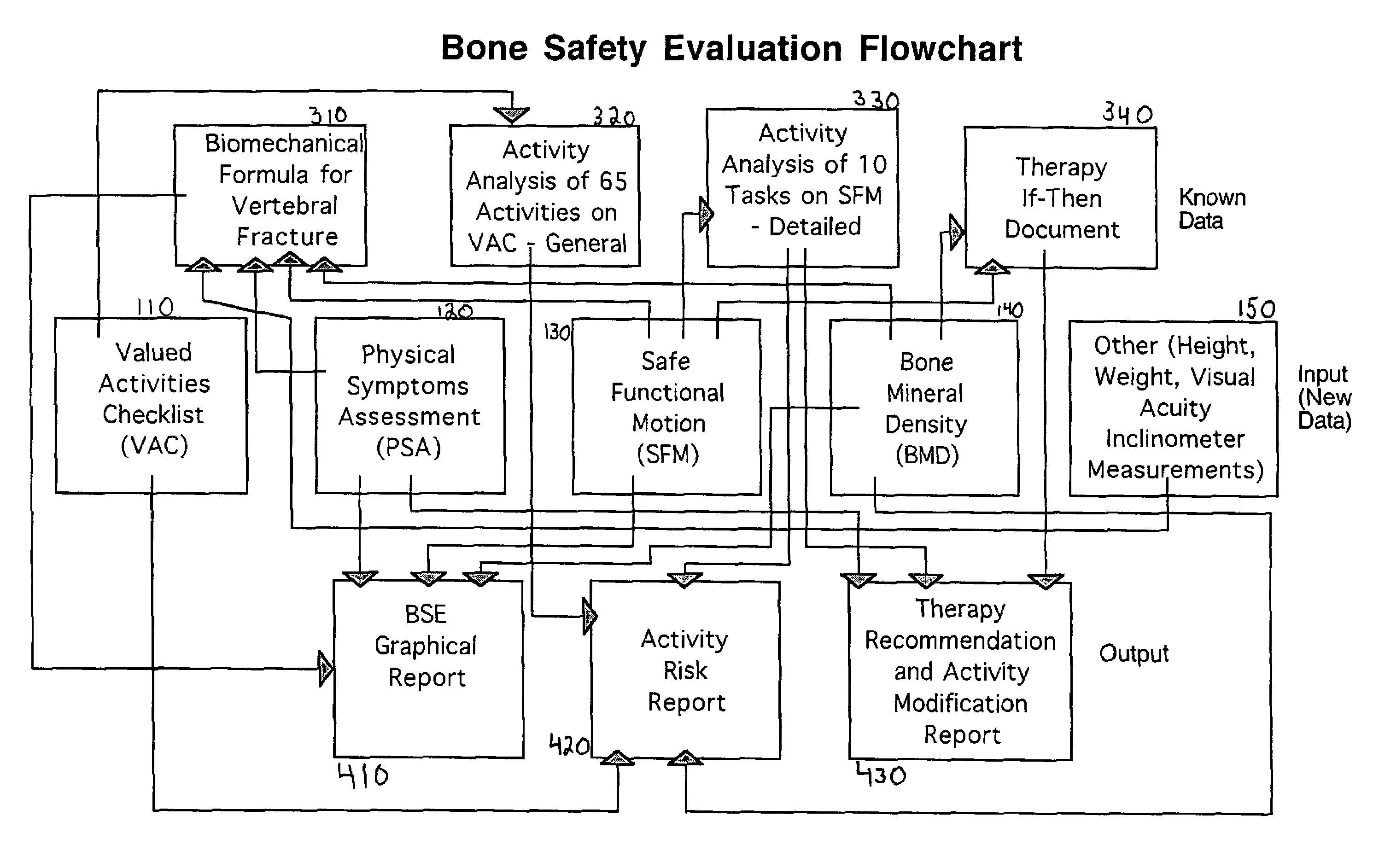

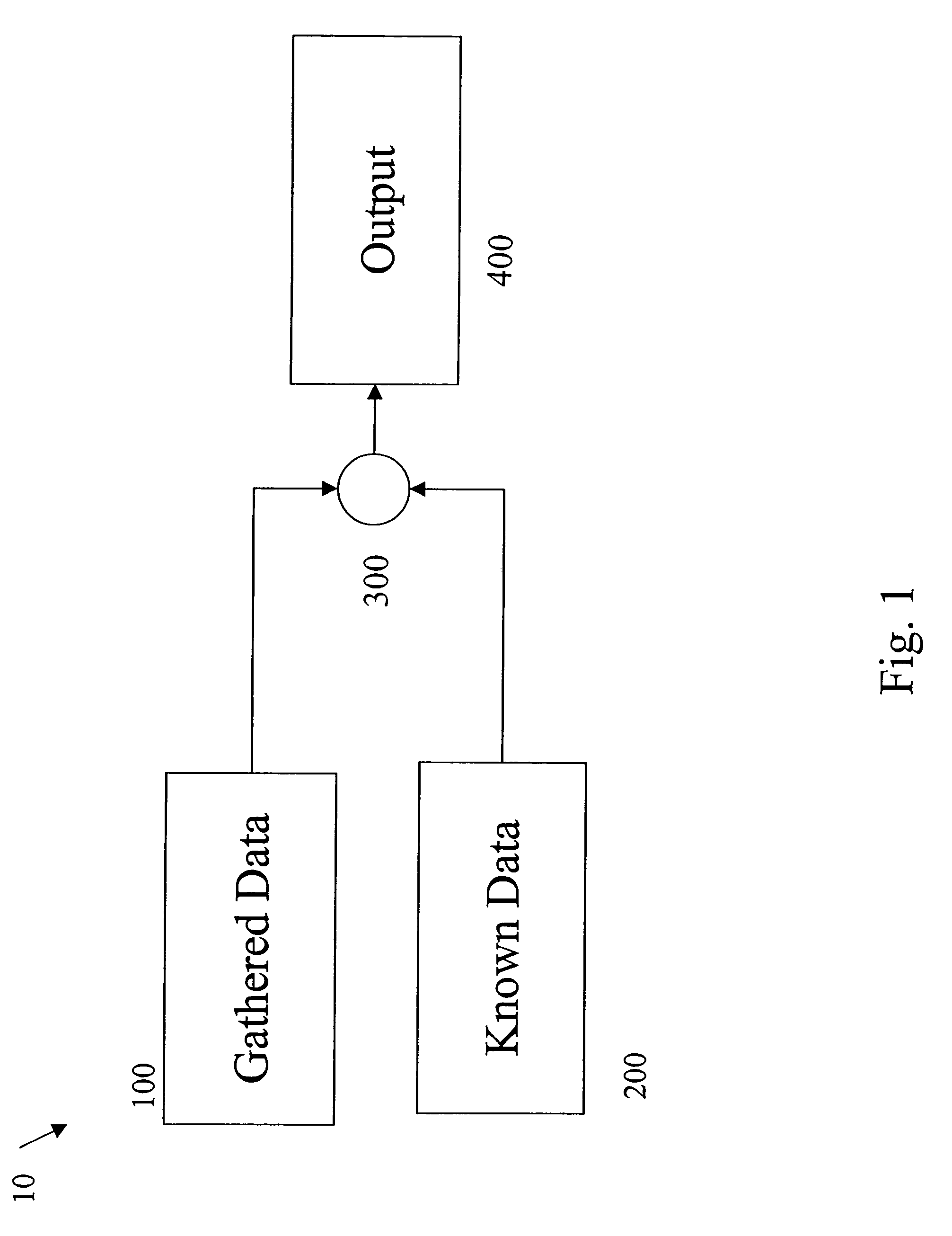

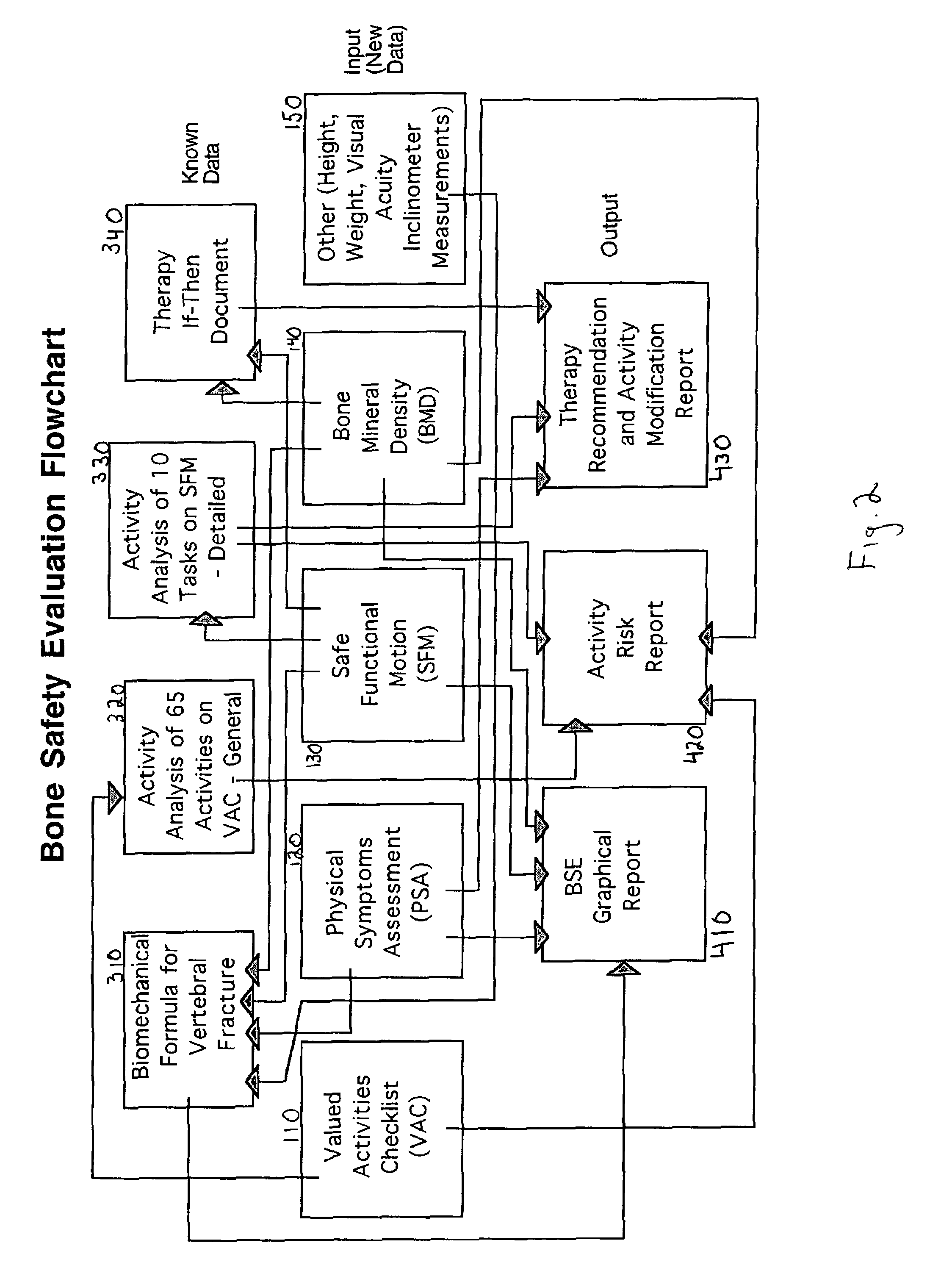

System and method for osteoporosis assessment and medication adherence evaluation

InactiveUS20070208597A1Medication adherence can be predictedIncrease probabilityPhysical therapies and activitiesData processing applicationsPersonalizationMedication adherence

An osteoporosis assessment system and method. The system and method generally include an input device that can be a computer that can be further connected to a network. The system can therefore be web-based. The system receives patient data and data related to osteoporosis. The method is implemented to correlate the patient data and the osteoporosis data and output is generated that personalizes the osteoporosis data to the patient based on the valued activities of the patient, so that the patient can understand his or her personal fracture risk assessment, therapy needs determination and therapy progress measurement. Therapy and treatment recommendations can also be generated.

Owner:RECKNOR CHRIS +1

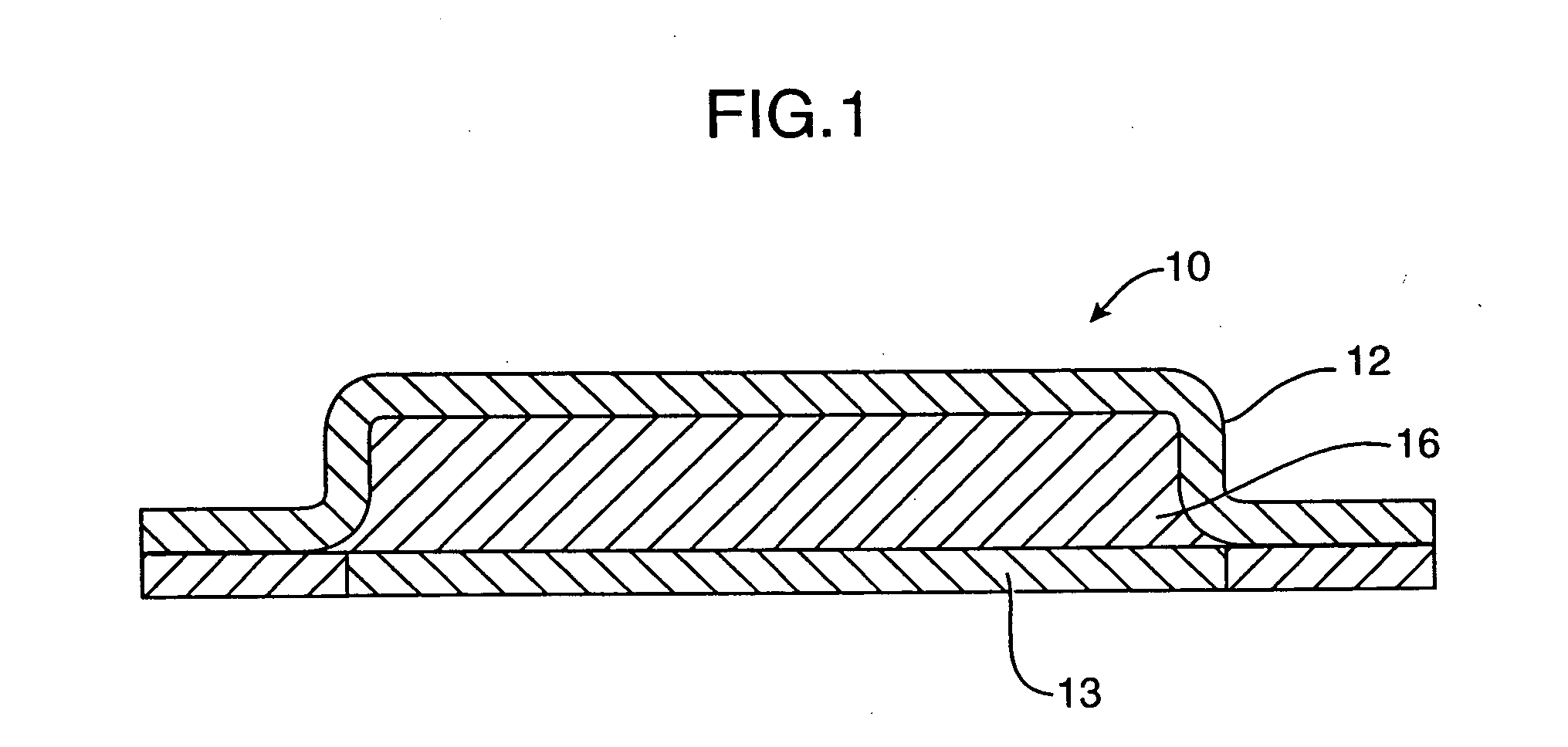

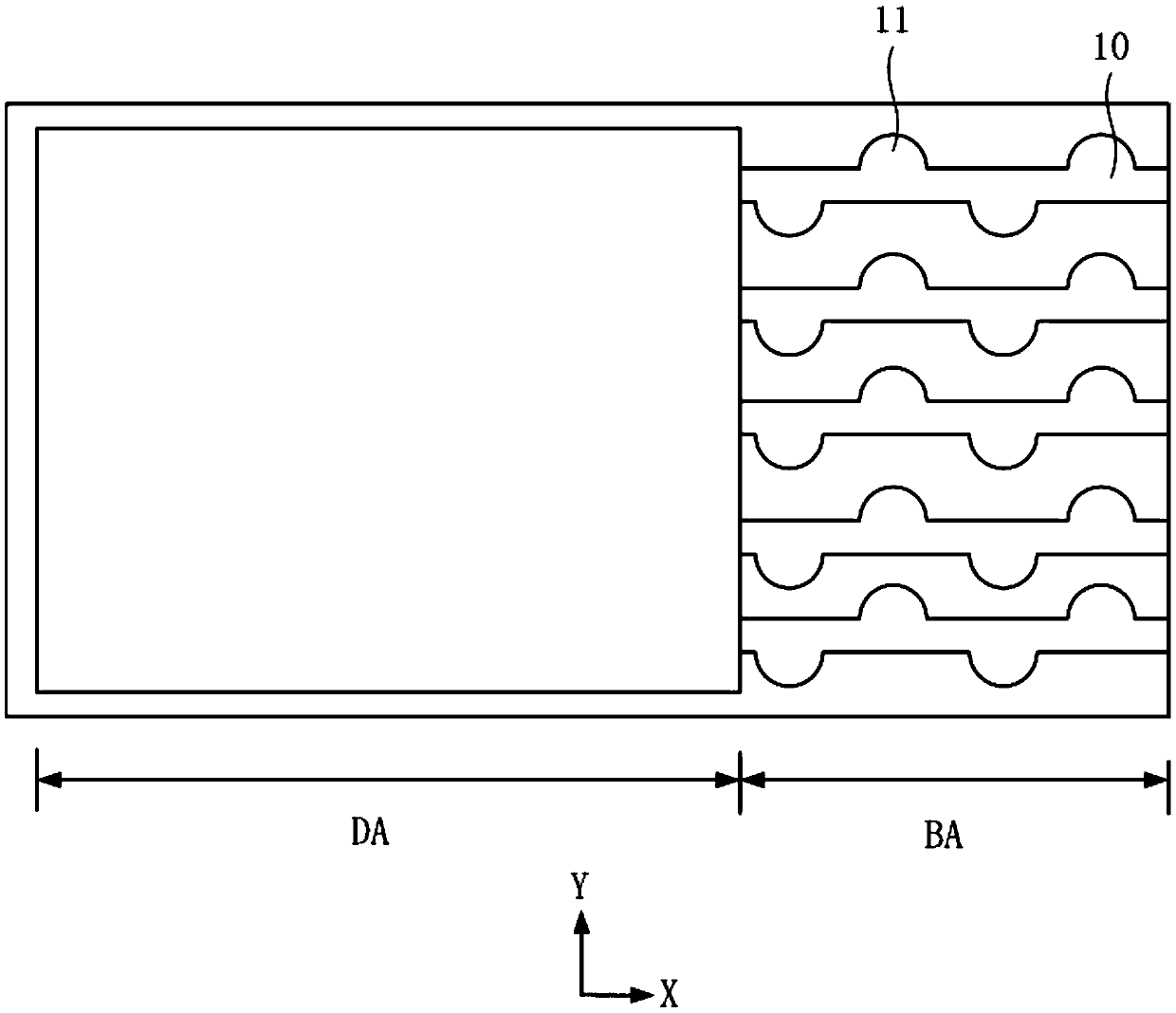

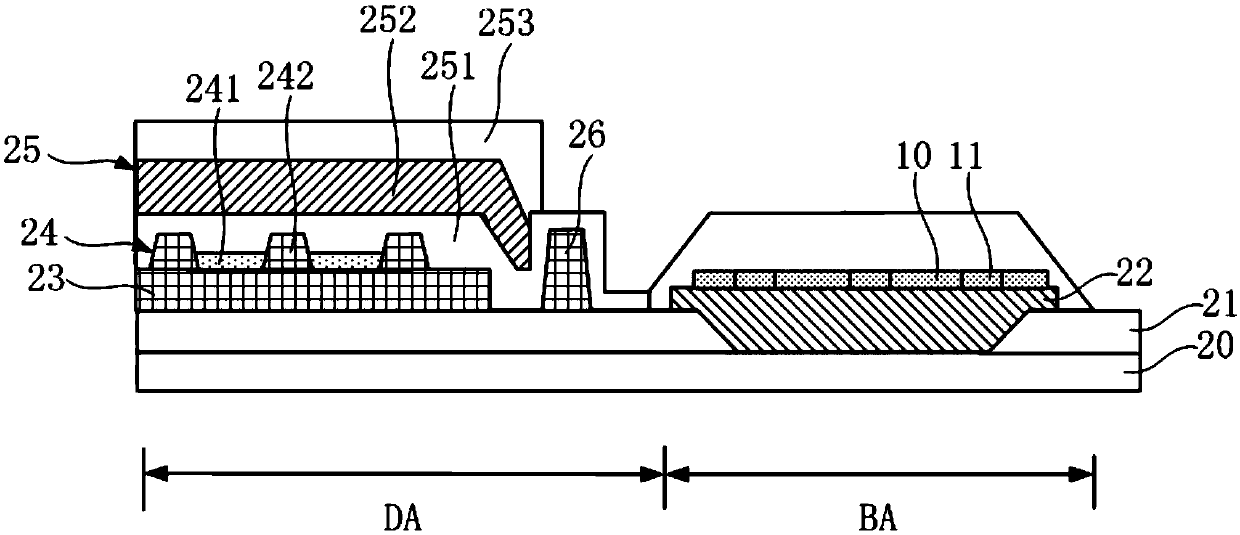

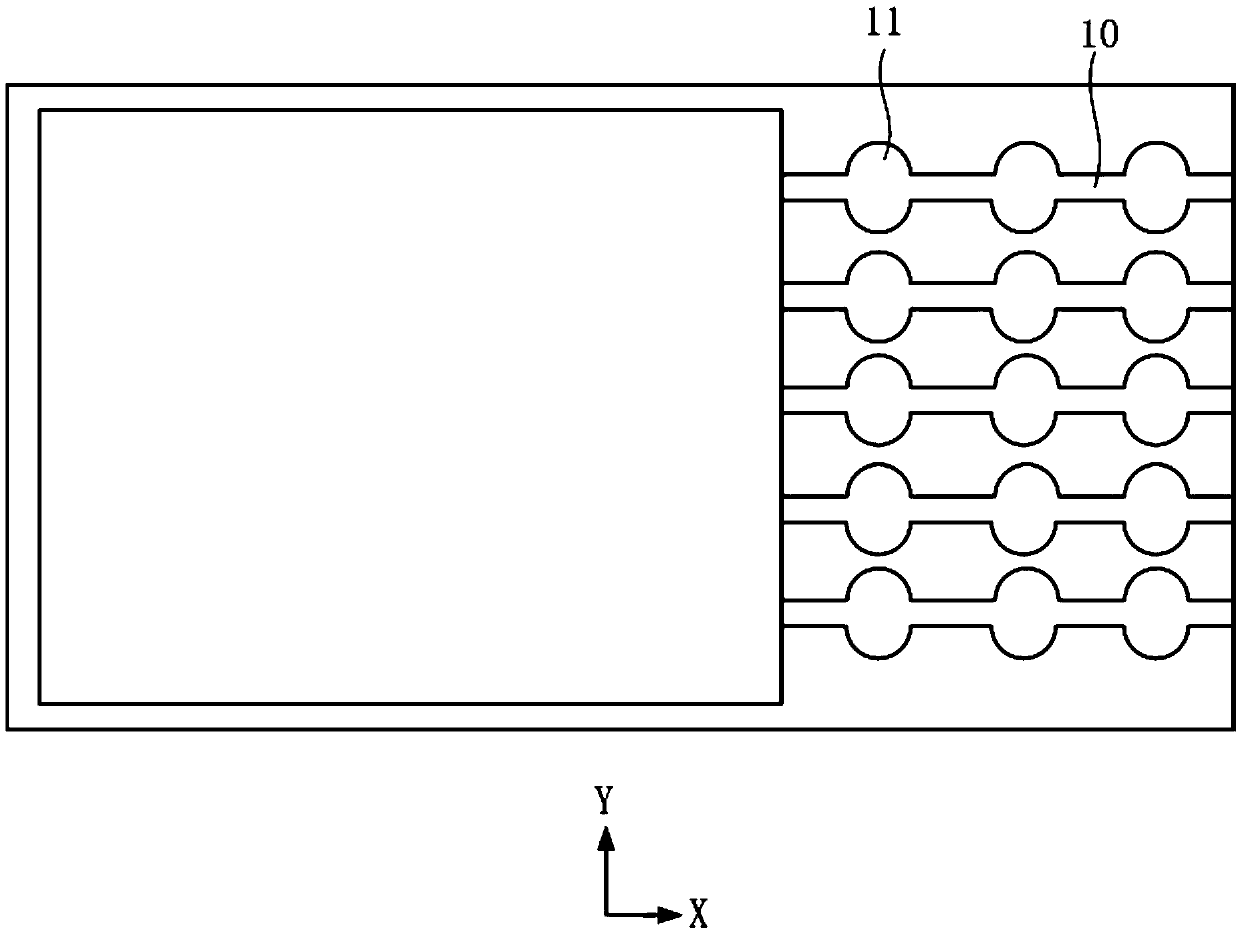

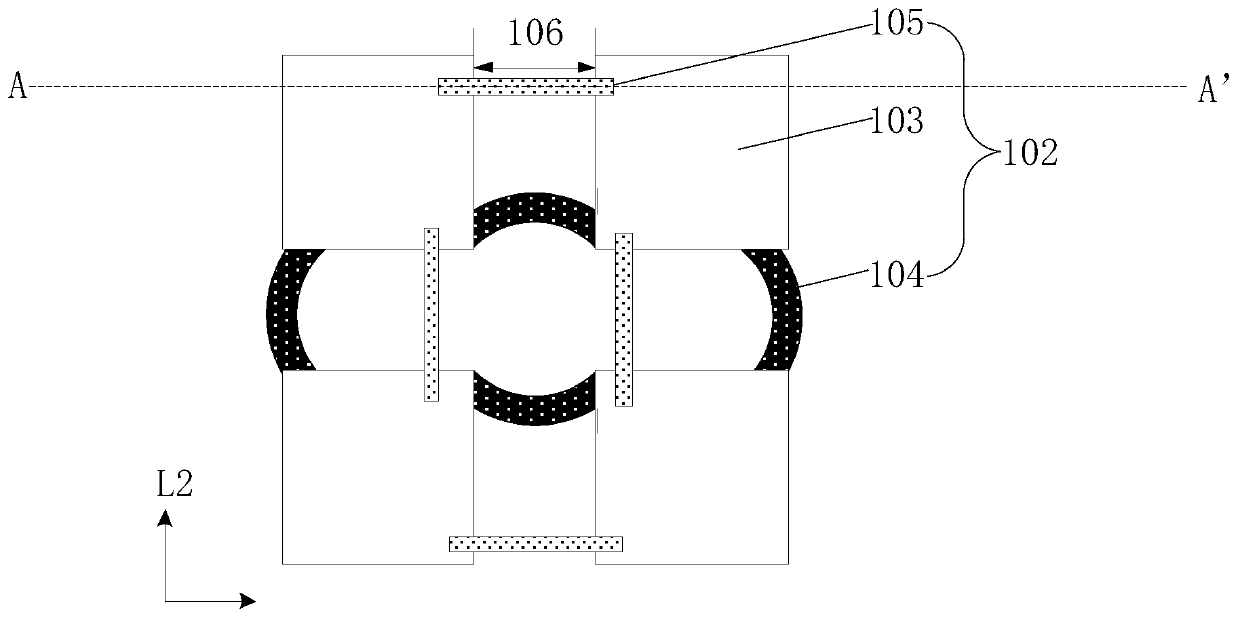

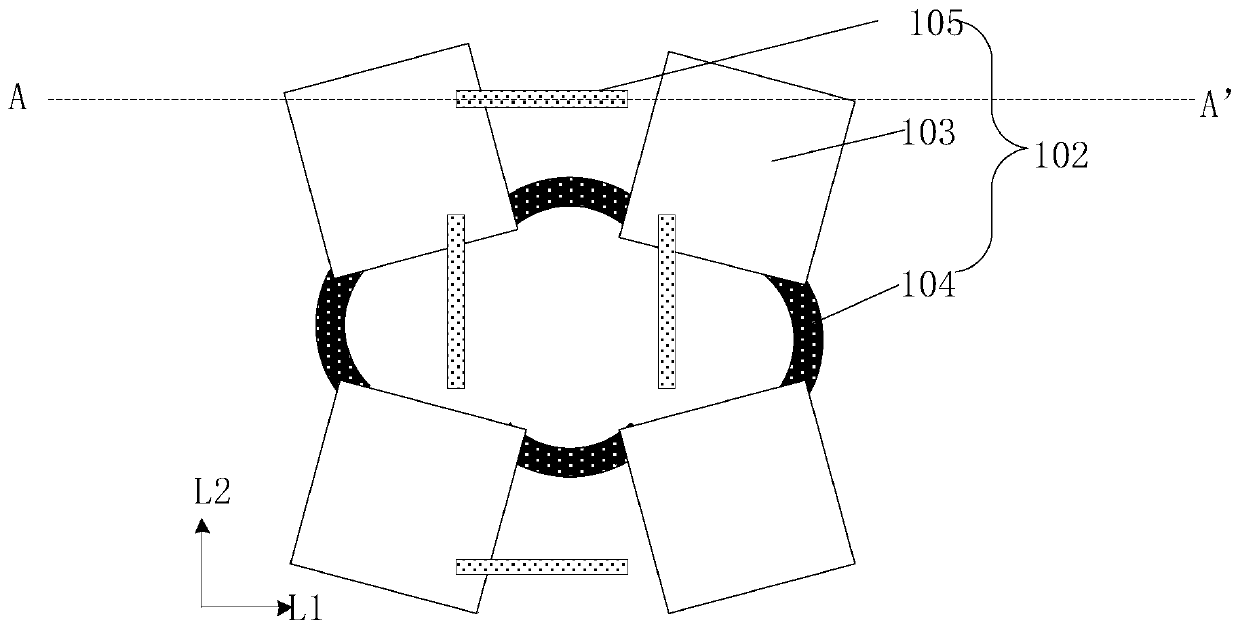

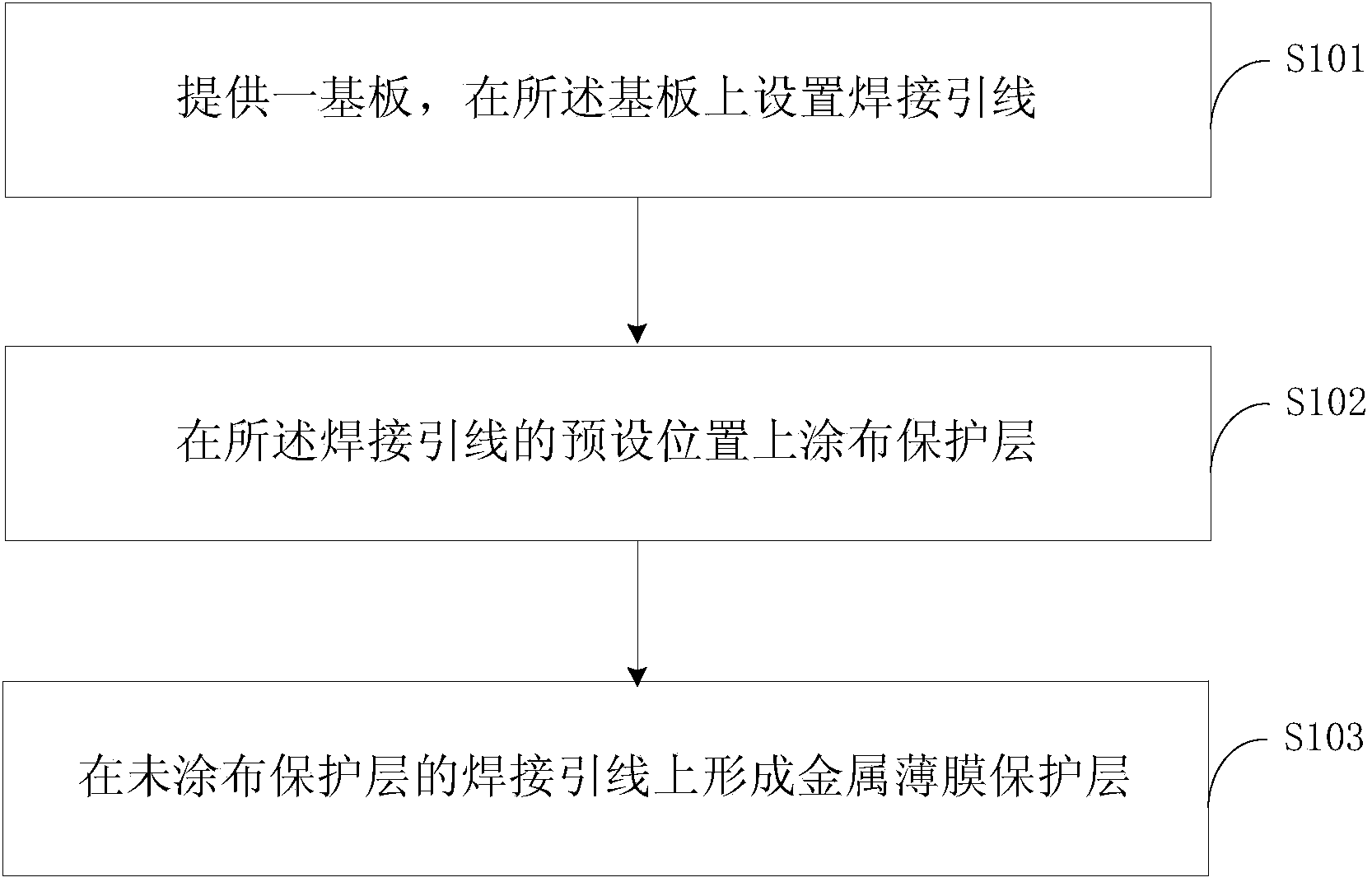

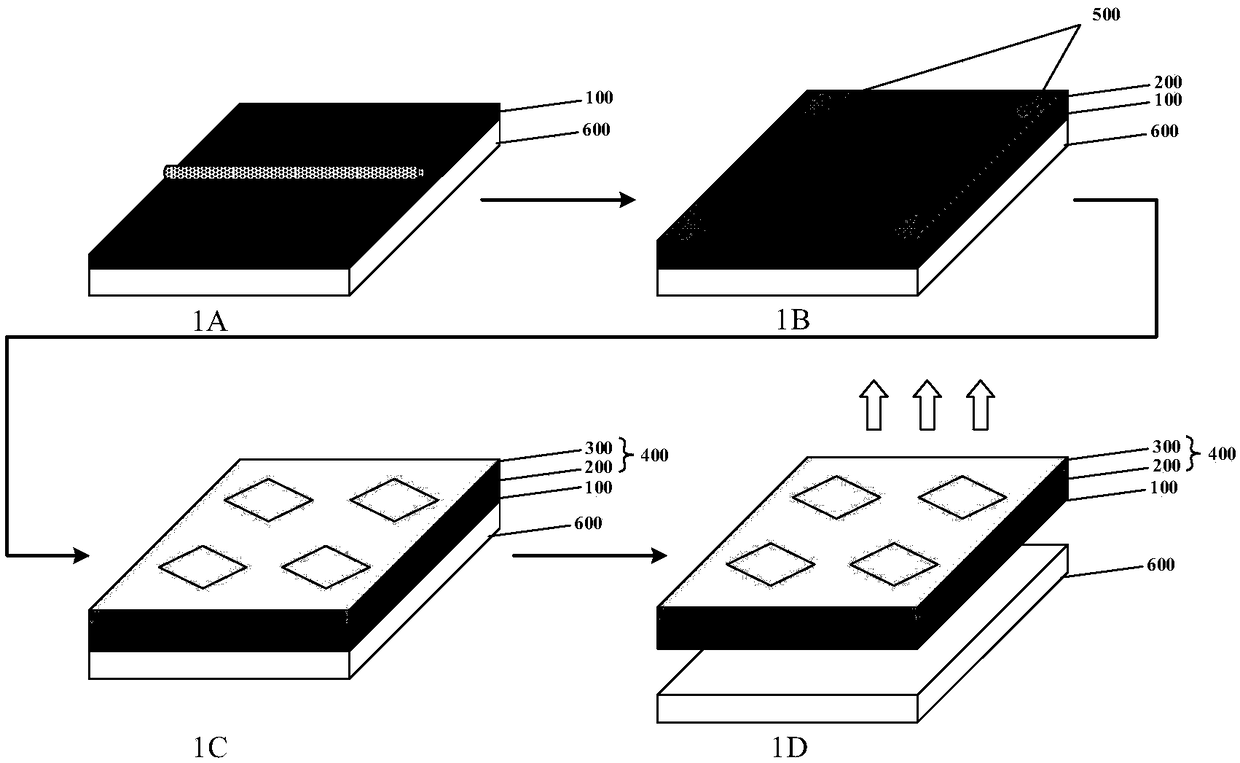

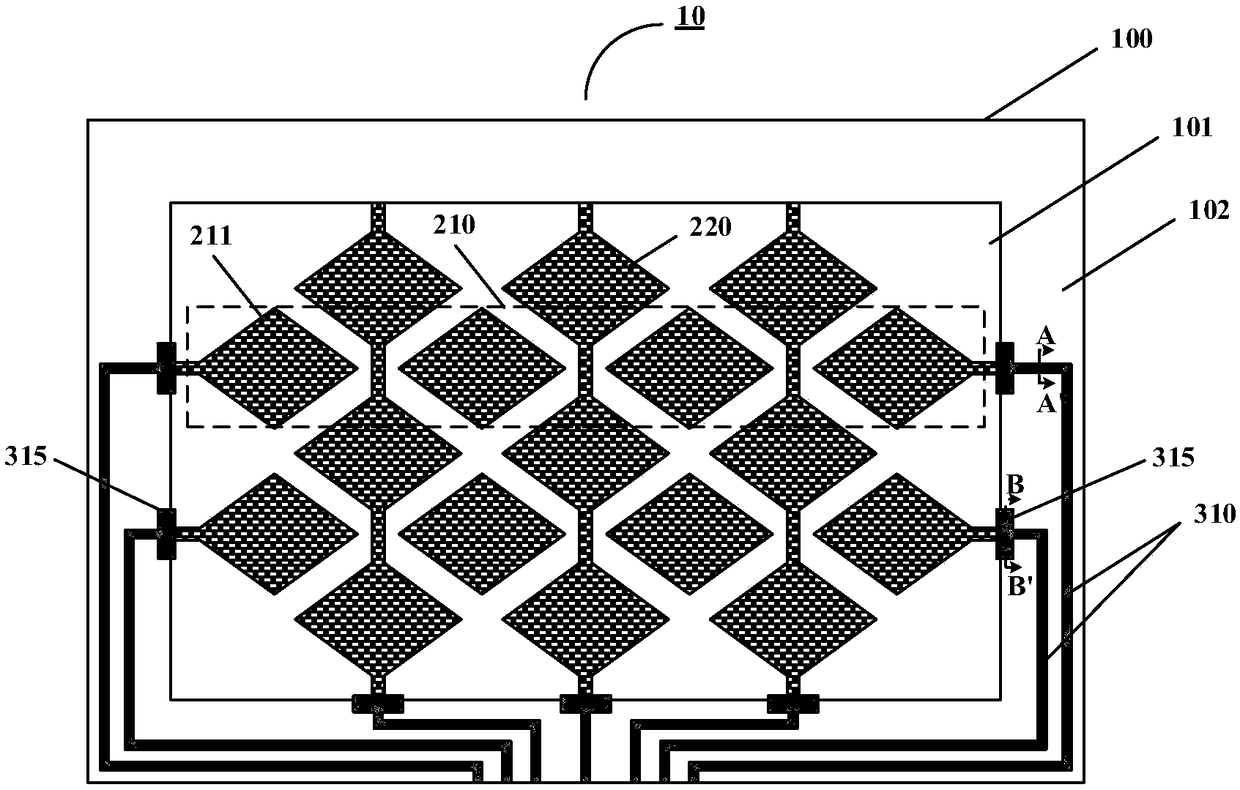

Display panel

InactiveCN109659337AEasy to extendPrevent vertical extensionSolid-state devicesIdentification meansEngineeringFracture risk

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Methods and instruments for assessing bone fracture risk

ActiveUS20110152724A1Quick and inexpensive testRisk of fracturePerson identificationSensorsHealth riskFracture risk

Methods and instruments for assessing bone, for example fracture risk, in a subject in which a test probe is inserted through the skin of the subject so that the test probe contacts the subject's bone and the resistance of the test bone to microscopic fracture by the test probe is determined. Macroscopic bone fracture risk is assessed by measuring the resistance of the bone to microscopic fractures caused by the test probe. The microscopic fractures are so small that they pose negligible health risks. The instrument may also be useful in characterizing other materials, especially if it is necessary to penetrate a layer to get to the material to be characterized.

Owner:RGT UNIV OF CALIFORNIA

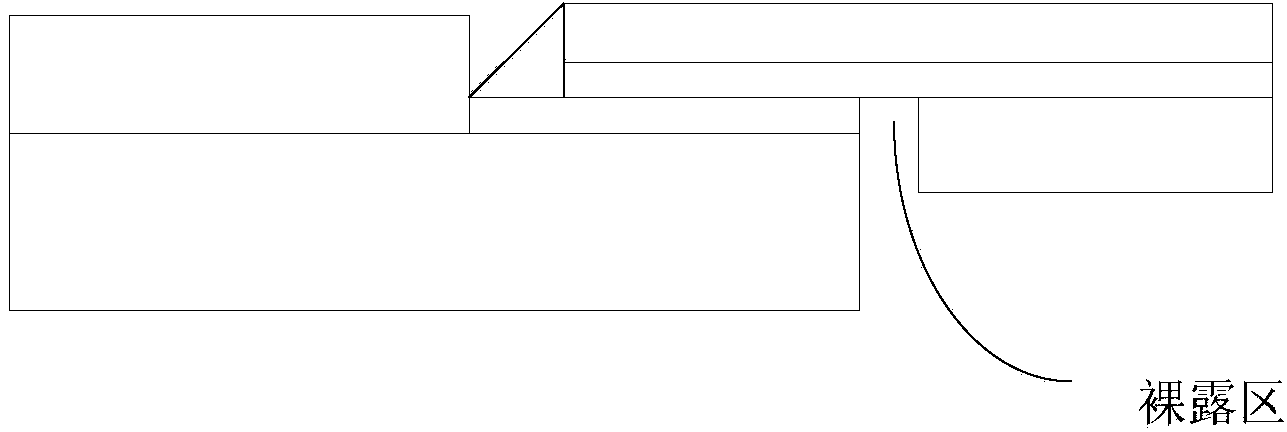

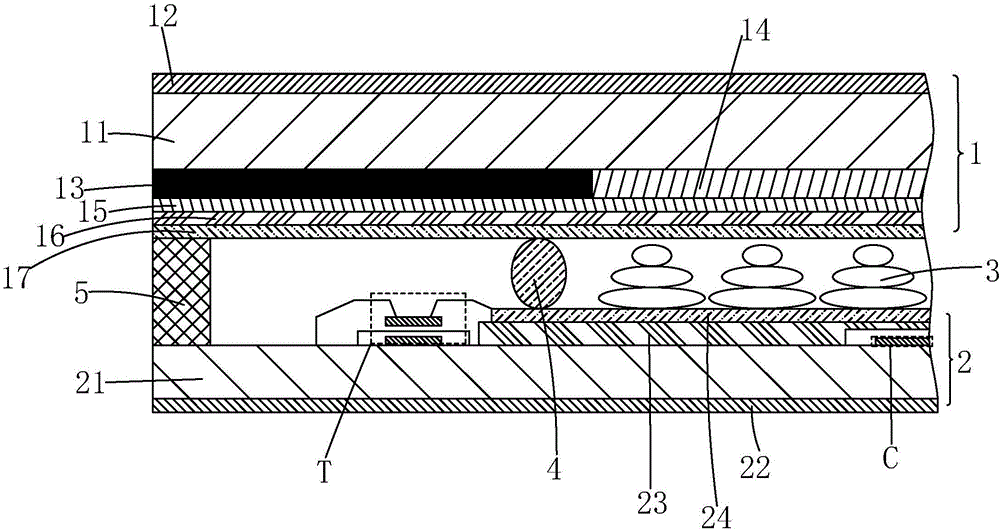

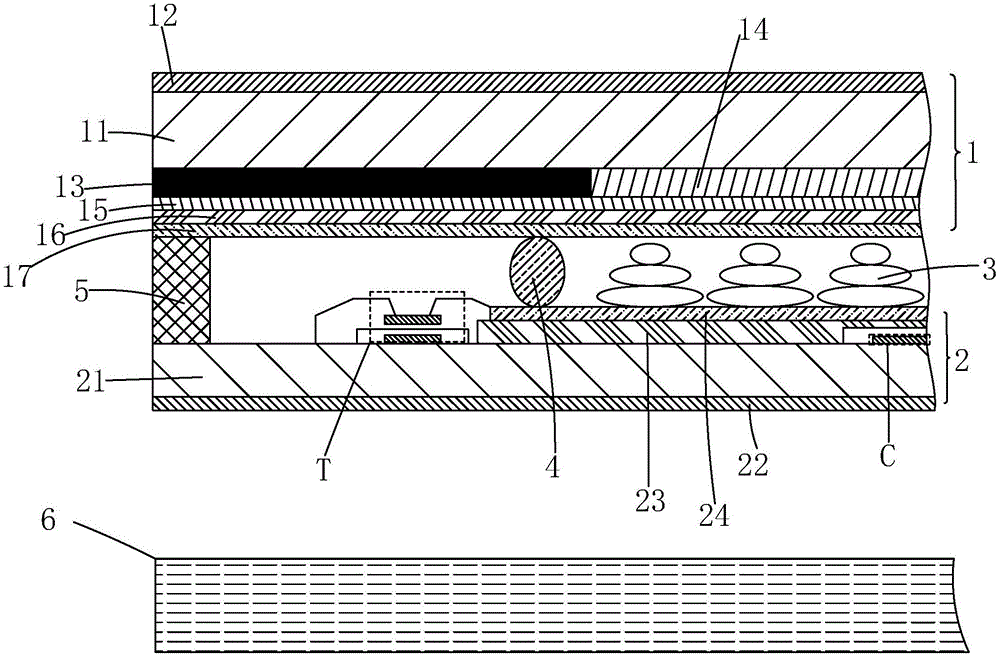

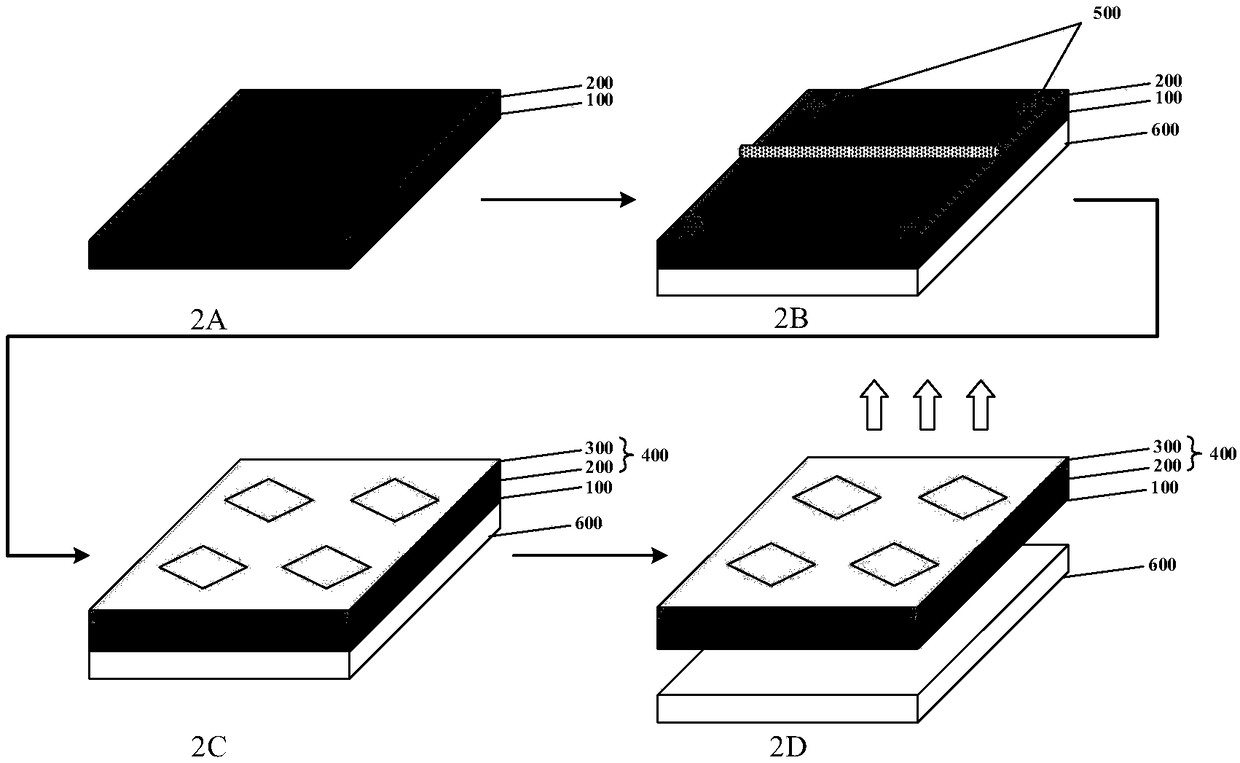

Flexible display panel and display device

ActiveCN110444577AReduced risk of breakageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceFracture risk

The invention discloses a flexible display panel and a display device. The flexible display panel comprises a flexible substrate. The flexible substrate comprises a preset area. The preset area comprises a plurality of display sub-areas, a plurality of flexible bridge parts and a plurality of connection parts, wherein an open gap is arranged between every two adjacent display sub-areas; every twoadjacent display sub-areas are connected by at least one flexible bridging part; and every two adjacent display sub-areas are connected by at least one connecting part. Due to the provision of the connecting parts, when the preset area of the flexible display panel is stretched, the connecting parts connected between the every two adjacent display sub-areas are fractured firstly to deform the preset area. Compared with support structures disposed between every two adjacent display sub-areas and instructed to fracture so as to deform the flexible display panel, the connecting parts are fractured firstly such that the deformation of the preset area can be controlled, thereby reducing a fracture risk of the flexible bridging parts during the stretching.

Owner:BOE TECH GRP CO LTD

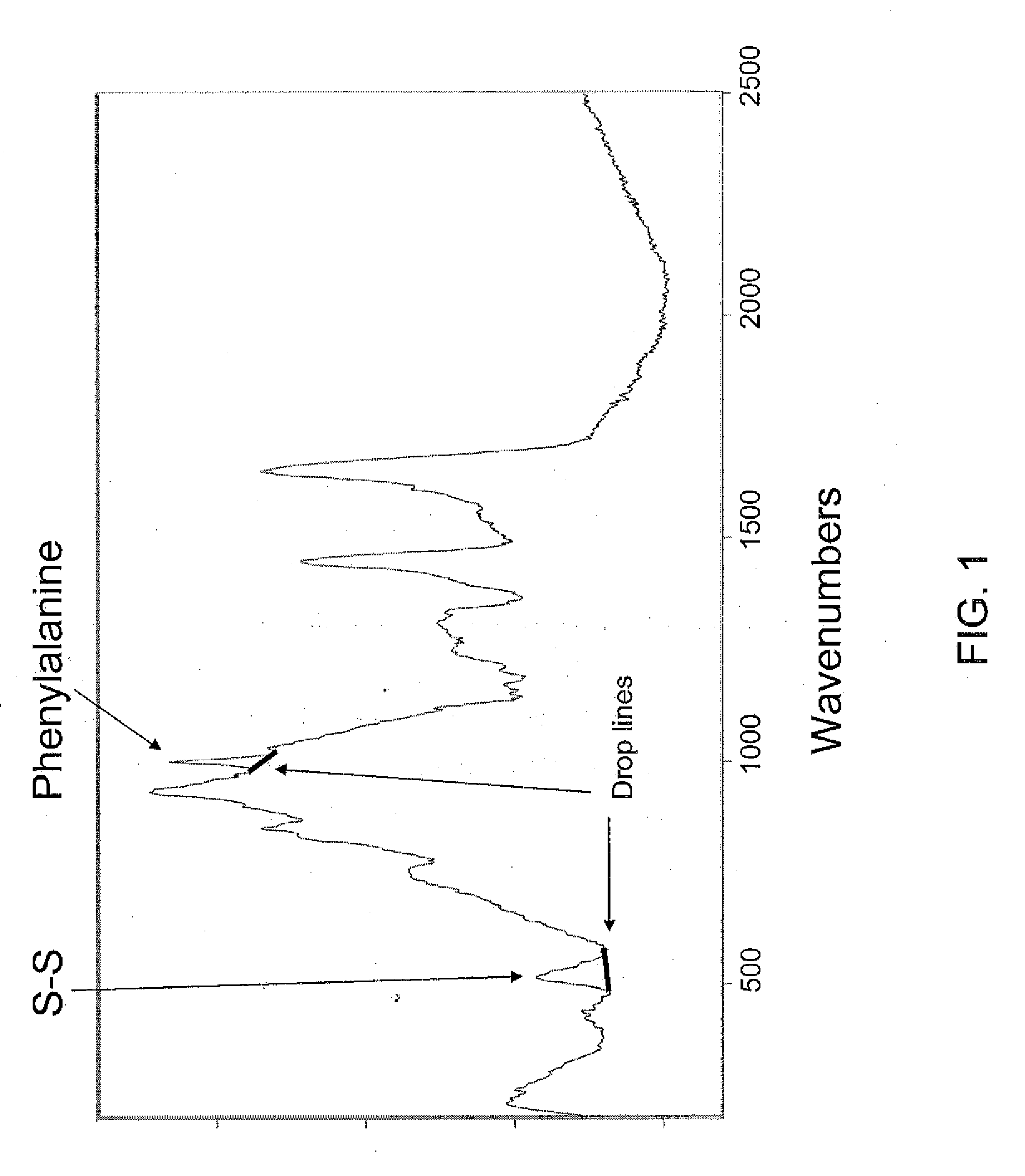

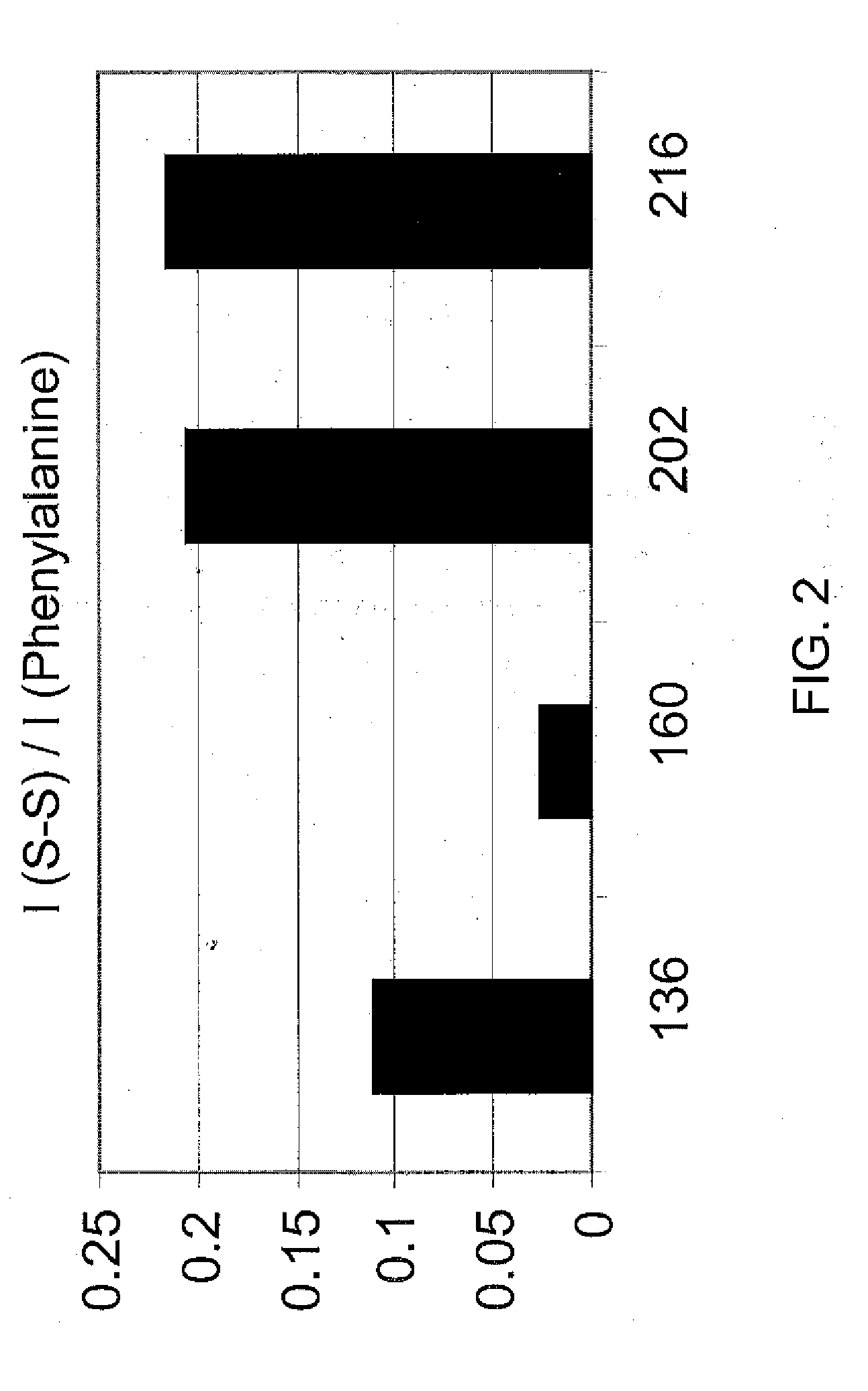

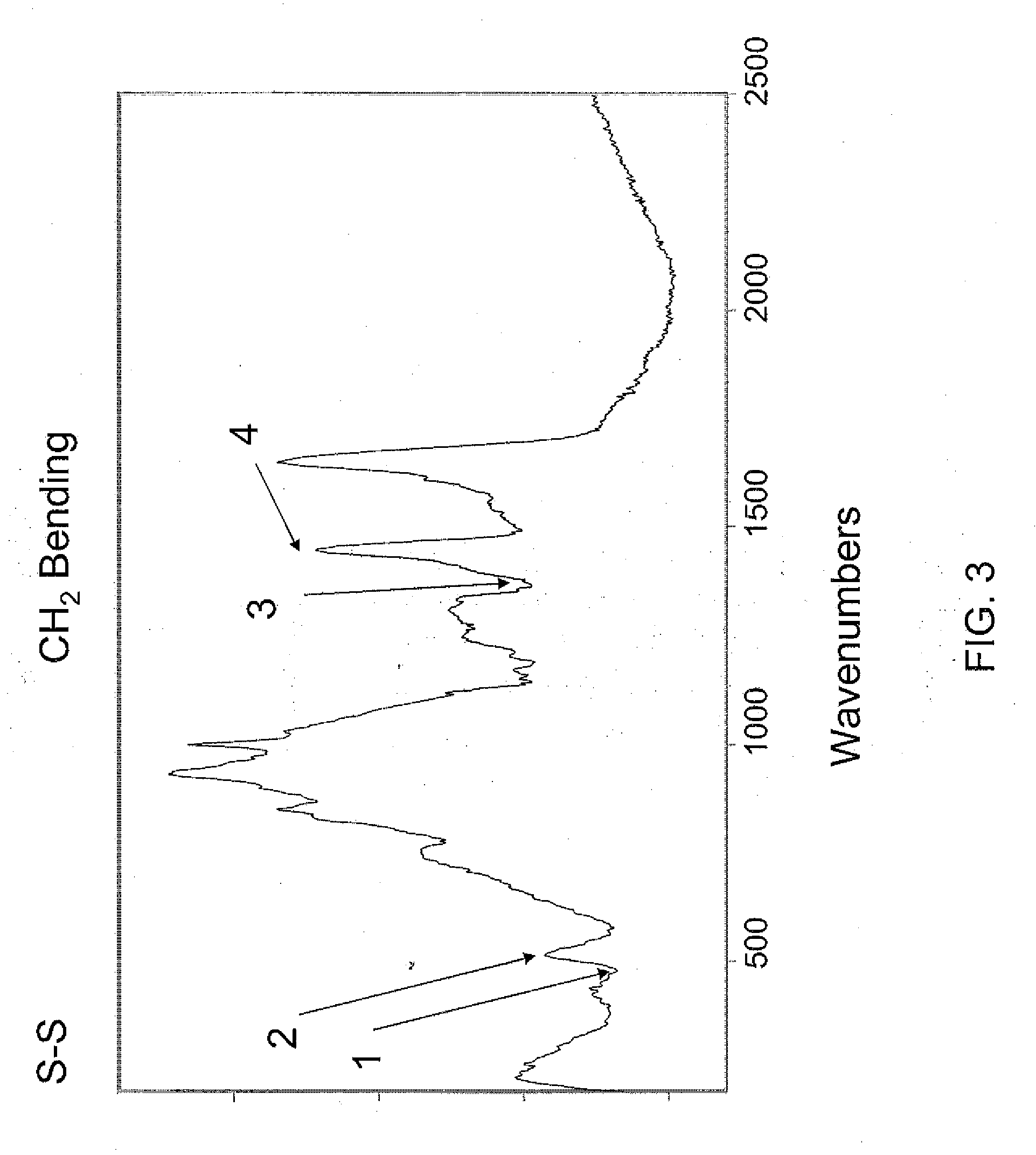

Method for determination of bone fracture risk using raman spectroscopy

InactiveUS20090012403A1Rapid of riskNon-invasiveRadiation pyrometryDiagnostics using lightDysostosisMedicine

A method is disclosed for analyzing keratinized tissue, particularly fingernails, of a subject to diagnose osteoporosis and bone fracture risk. A Raman spectrum of a sample of keratinized tissue is generated. Broad spectral background features of the spectrum are removed, preferably by using Fourier transform analysis. Peak heights of Raman features of interest, particularly the S—S bond of cystine, are measured. These peak height measurements are normalized using reference peak heights of Raman features that are invariant between normal and osteoporotic subjects, such as the CH2 bending peak.

Owner:UNIVERSITY OF WYOMING +1

System and method for osteoporosis assessment

An osteoporosis assessment system and method. The system and method generally include an input device that can be a computer that can be further connected to a network. The system can therefore be web-based. The system receives patient data and data related to osteoporosis. The method is implemented to correlate the patient data and the osteoporosis data and output is generated that personalizes the osteoporosis data to the patient based on the valued activities of the patient, so that the patient can understand his or her personal fracture risk assessment, therapy needs determination and therapy progress measurement. Therapy and treatment recommendations can also be generated.

Owner:CHRIS RECKNOR M D P C

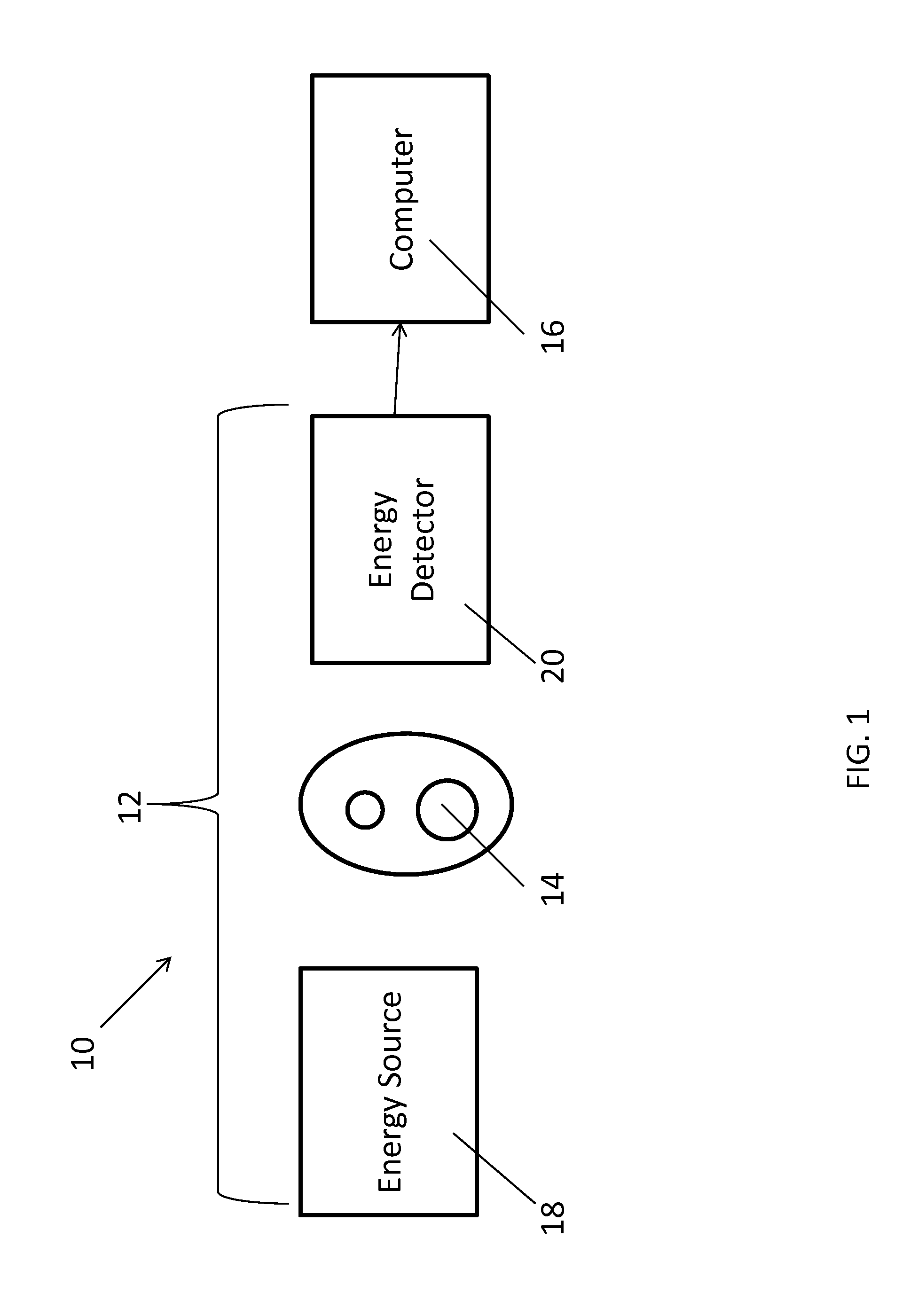

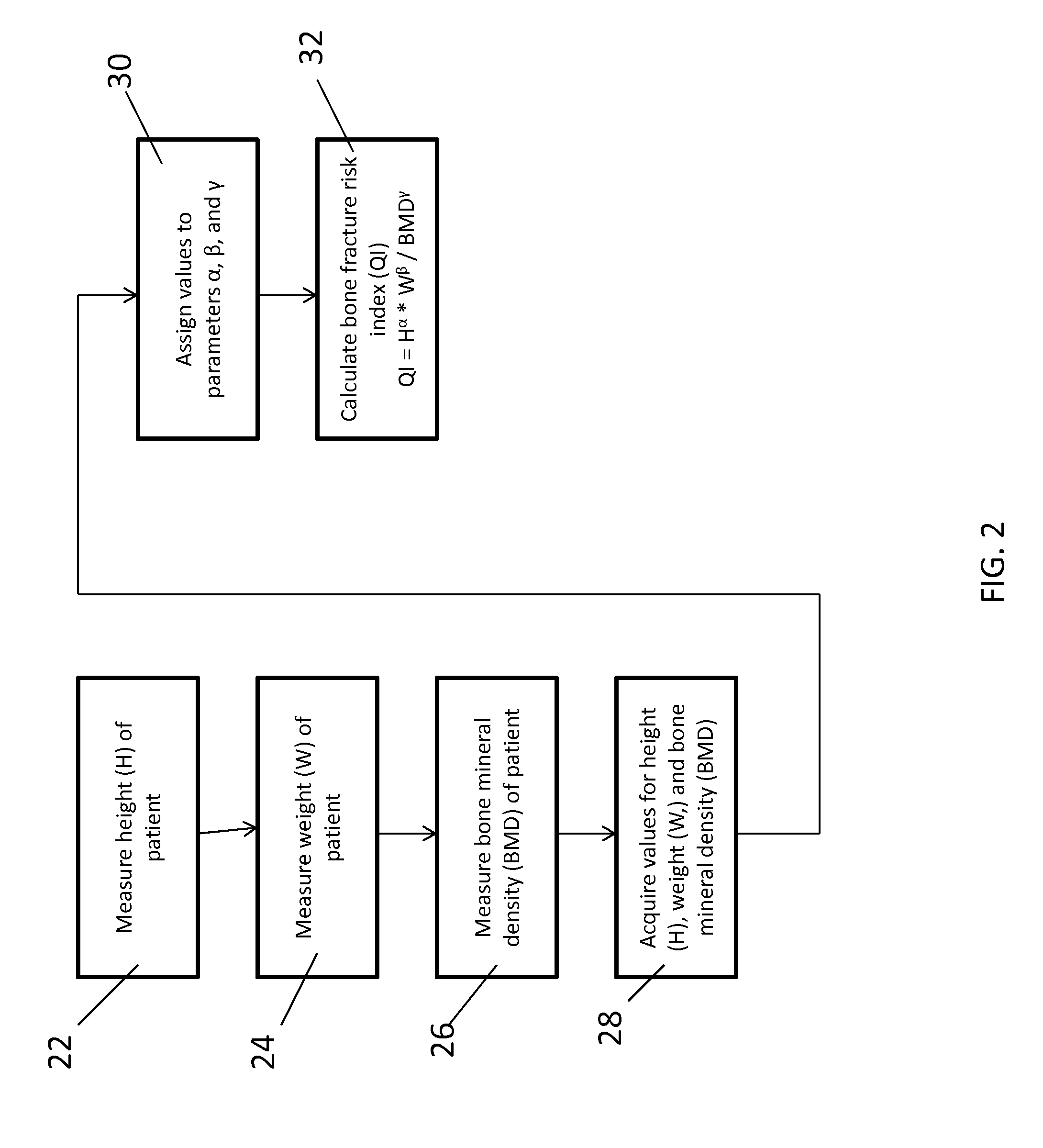

Method and System for Bone Fracture Risk Assessment

ActiveUS20150196264A1High indexRadiation/particle handlingHealth-index calculationBiological bodyVolumetric Mass Density

A method and system for quantitatively evaluating bone fracture risk in a living being are provided that generate a value for an index indicative of a degree of bone fracture risk. In one embodiment, the method includes the step of acquiring values for a height H, a weight W, and a bone mineral density BMD of the living being. The method further includes the step of calculating a quantitative bone fracture risk index QI associated with the living being in accordance with the formula QI=Hα*Wβ / BMDγ where α, β, and γ are constants selected based on previously obtained data indicative of bone fracture risk.

Owner:CYBERLOGIC

Chip on film (COF) substrate and manufacturing method thereof and display panel

InactiveCN104049393AReduce time to corrodeReduced risk of corrosion fracturesPrinted circuit assemblingNon-linear opticsChip on filmDisplay device

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

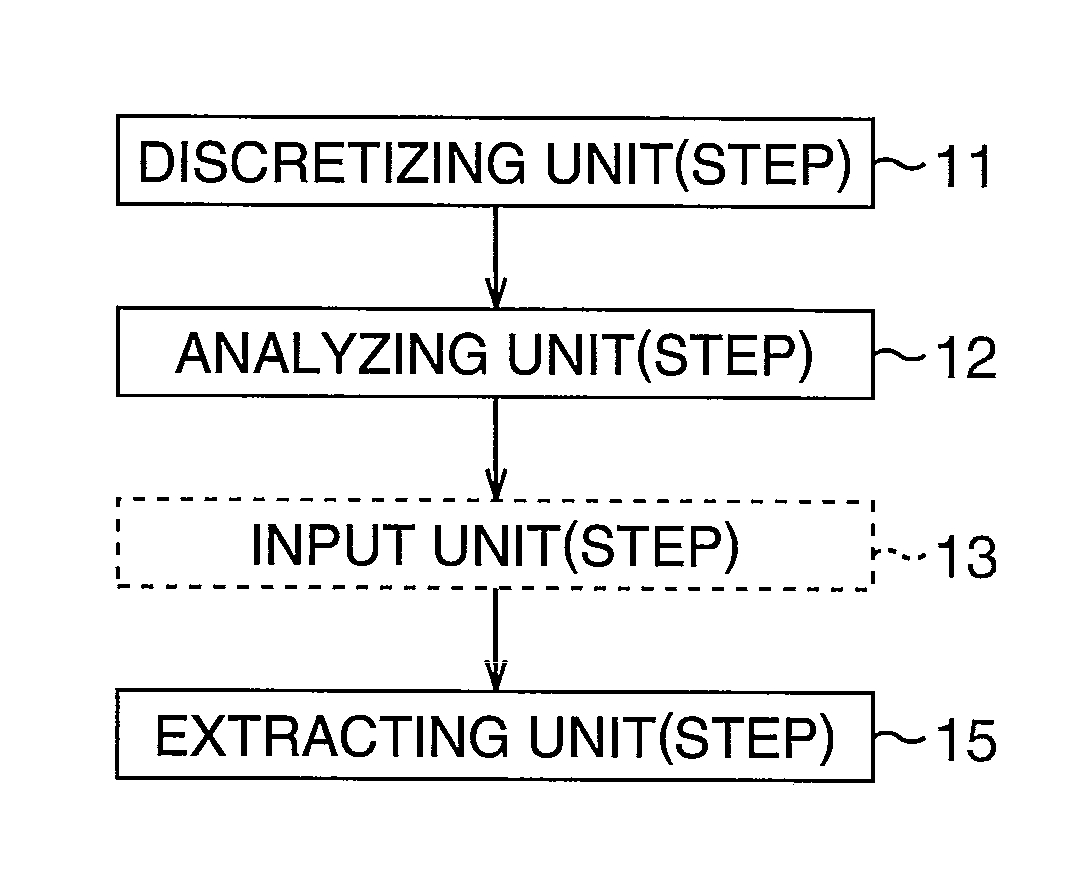

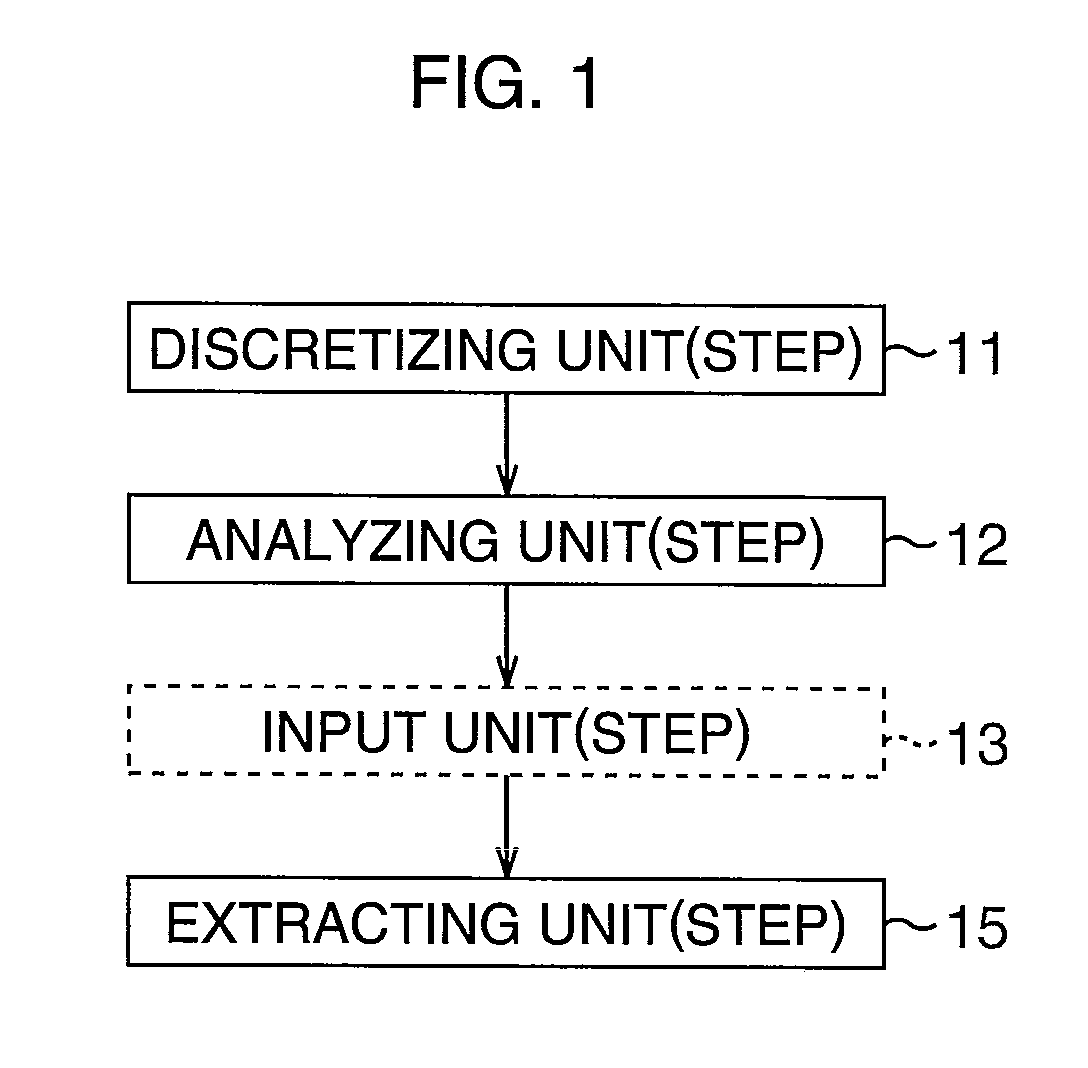

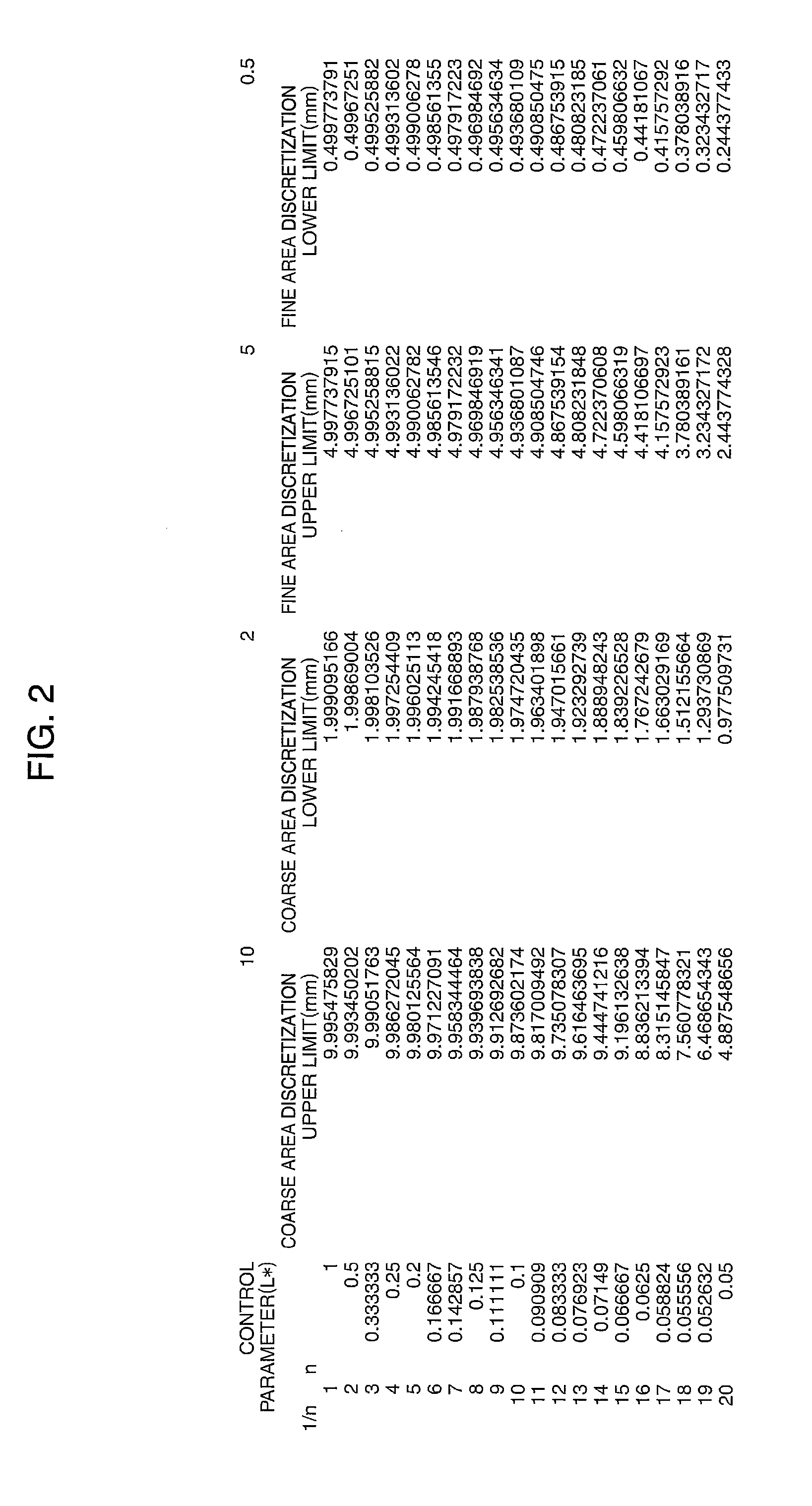

Fracture prediction method, processing device, program product and recording medium

ActiveUS20100121621A1Reduce selection requirementsExtracted easily and reliablyGeometric CADForce measurementReduction rateFinite element method

When discretizing an analysis target part into plural elements and performing analysis, sheet thickness reduction rate or maximum principal strain at an equivalent position including a same element is compared by either a manner of combining two adjacent elements after the analysis or a manner of changing an element discretization size with two types and performing the analysis, and the element where the difference is large is extracted as a fracture risk portion.With this structure, a fracture risk portion can be extracted reliably when a fracture is predicted by a finite element method.

Owner:NIPPON STEEL CORP

System and method for determining mechanical properties of bone structures

Systems and methods for characterizing bone structures are provided for characterizing bone structures. In the system and method, one or more 1H NMR or MRI signals associated with a bone structure are obtained. Thereafter one or more signal parameters are computed from the obtained signals, where each of the signal parameters comprising at least one of a relaxation rate constant or a corresponding signal amplitude associated with a component of the obtained signals defined by a T2 value or a range of T2 values. Finally, the mechanical properties or fracture risk for the bone structure are determined based on the computed signal parameters and stored correlation data.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

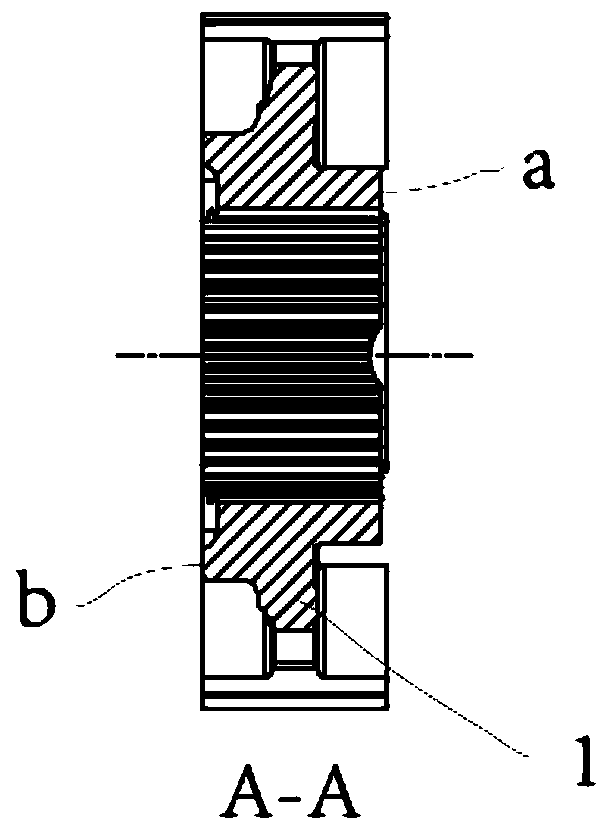

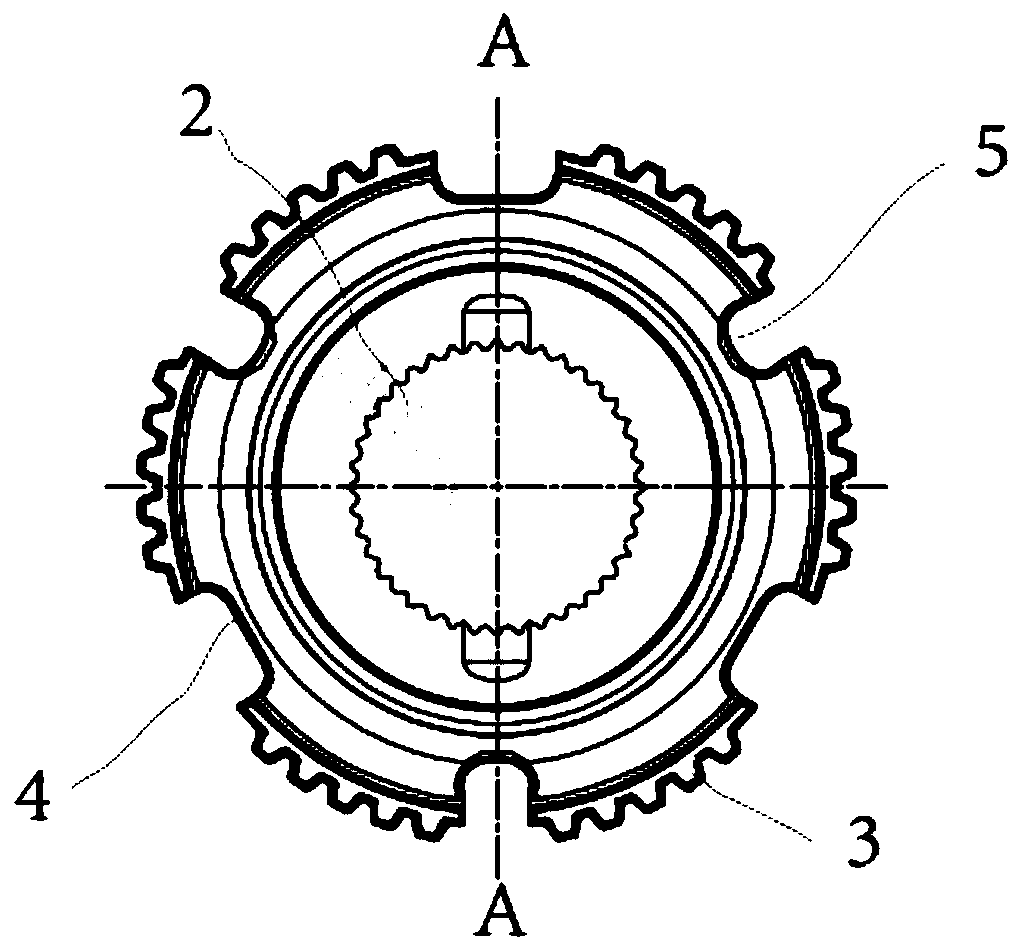

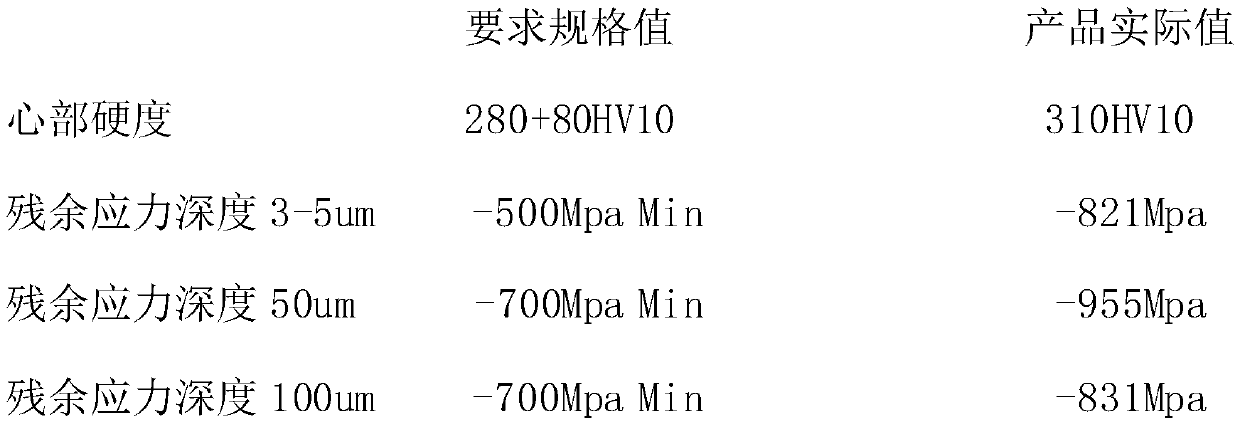

Powder metallurgy preparation method of double-clutch large-torque automatic gearbox synchronizer gear hub

The invention belongs to the technical field of powder metallurgy, and relates to a powder metallurgy preparation method of a double-clutch large-torque automatic gearbox synchronizer gear hub. The powder metallurgy preparation method comprises the following steps of material mixing, forming, pre-sintering, shaping, machining, deburring, sintering hardening, tempering, partial shot blasting, cleaning and packaging. According to the synchronizer gear hub produced by the preparation method, the tensile strength is increased, and the fracture risk caused by increase of the torque of a transmission is reduced; the production efficiency of shaping, machining and deburring is improved, the risk of shaping cracks is effectively avoided, loss of material of a machining tool, a deburring brush andthe like is greatly reduced, production energy consumption is greatly reduced, the high-frequency quenching process is omitted, the product quality is improved, the comprehensive cost is reduced by 20% or above on the basis of the original foundation, and the preparation method is suitable for large-scale production of the double-clutch large-torque automatic gearbox synchronizer gear hub throughpowder metallurgy.

Owner:江苏智造新材有限公司

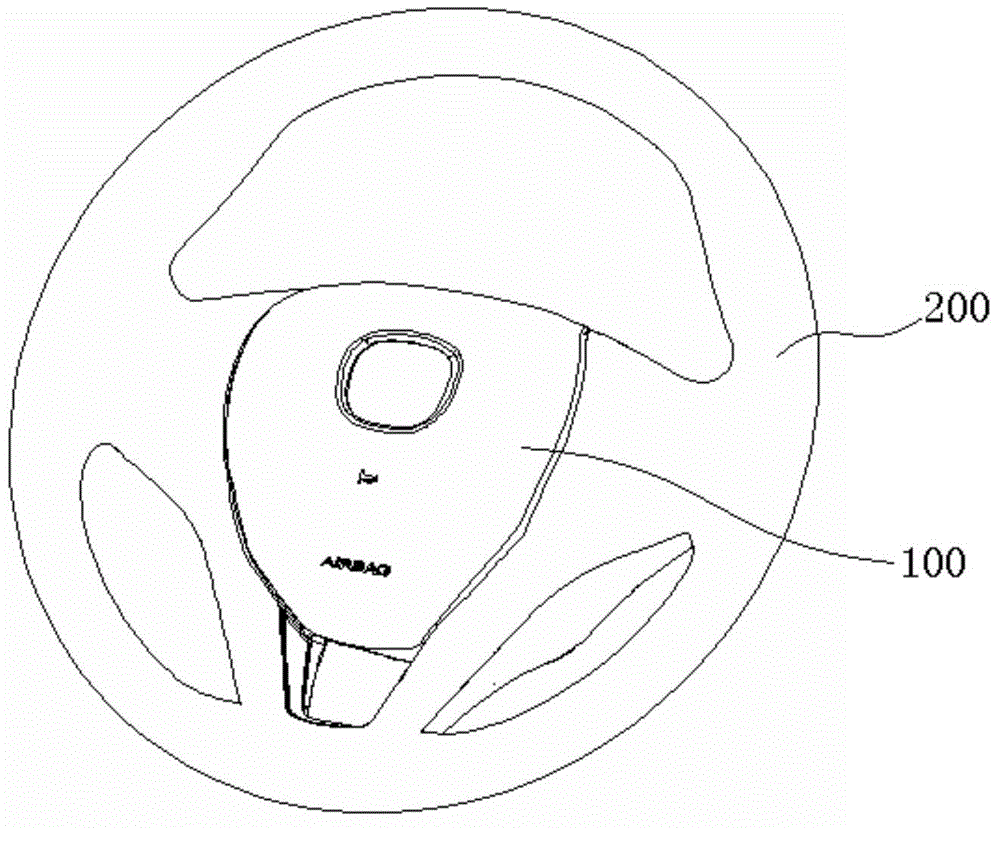

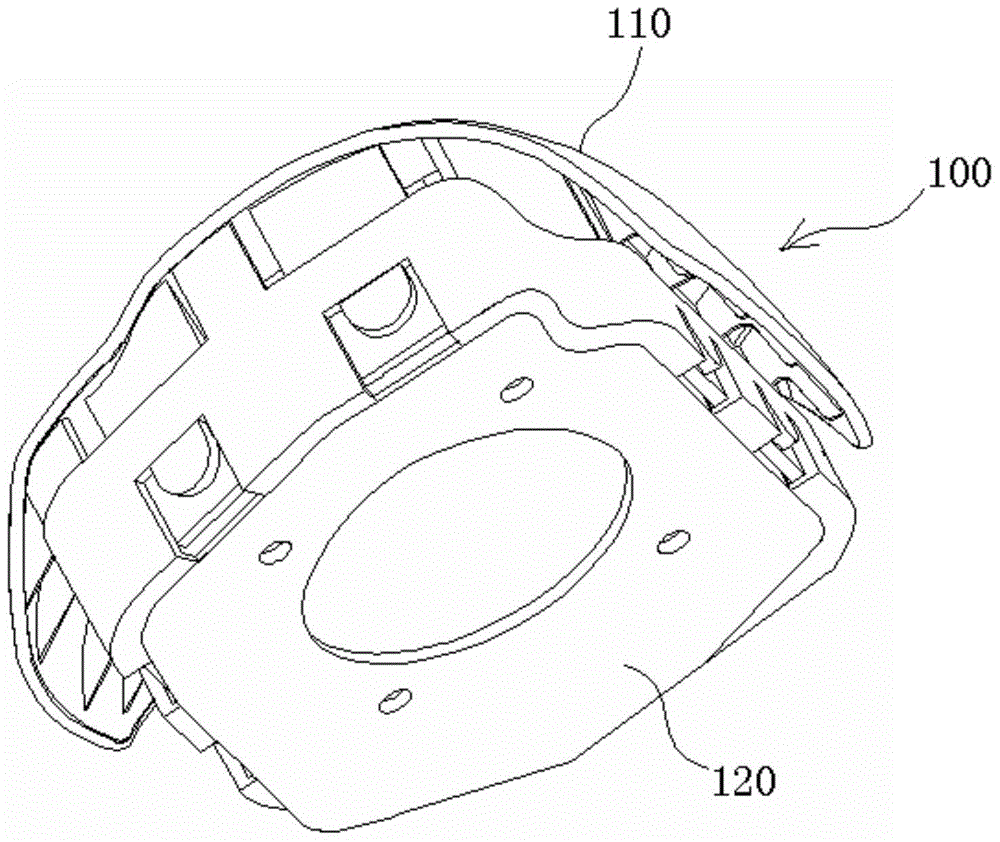

Cover plate of safety airbag and steering wheel safety airbag device comprising cover plate

ActiveCN104590196ANo risk of ruptureWeak designPedestrian/occupant safety arrangementSteering wheelEngineering

The invention discloses a cover plate of a safety airbag. The cover plate comprises a cover plate panel and a cover plate wall body which is connected to the side edge of the bottom surface of the cover plate panel, wherein a tear structure is arranged between the bottom surface of the cover plate panel and the cover plate wall body. The invention further discloses a steering wheel safety airbag device comprising the cover plate. According to the cover plate of the safety airbag, a tear line of the safety airbag cover plate is arranged on a joint part of the cover plate panel and the cover plate wall body. When a horn cover plate is pressed, pressing force is safely transmitted to the safety airbag bracket, the tear structure between the cover plate panel and the cover plate wall body does not bear pressure, does not have a fracture risk and can be designed to be relatively thin, so that a purpose of easily opening is achieved; moreover, the appearance quality is improved, and the manufacturing cost is reduced.

Owner:上海东方久乐汽车安全气囊有限公司

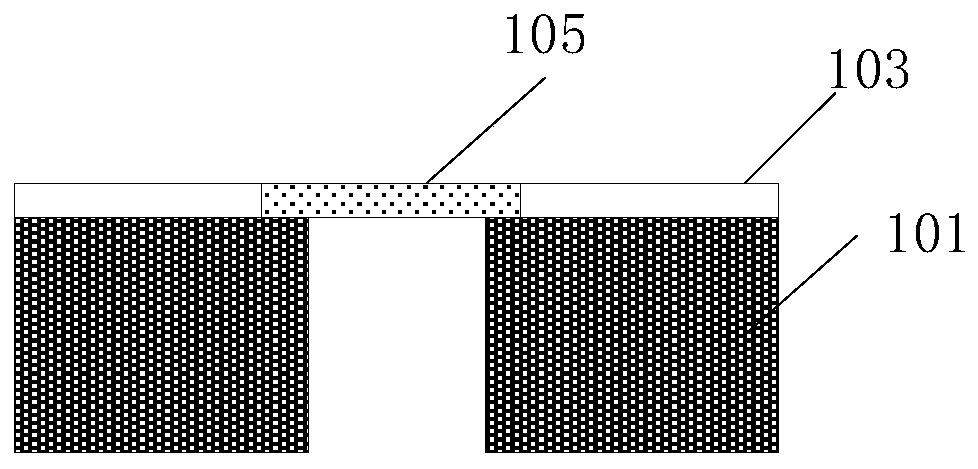

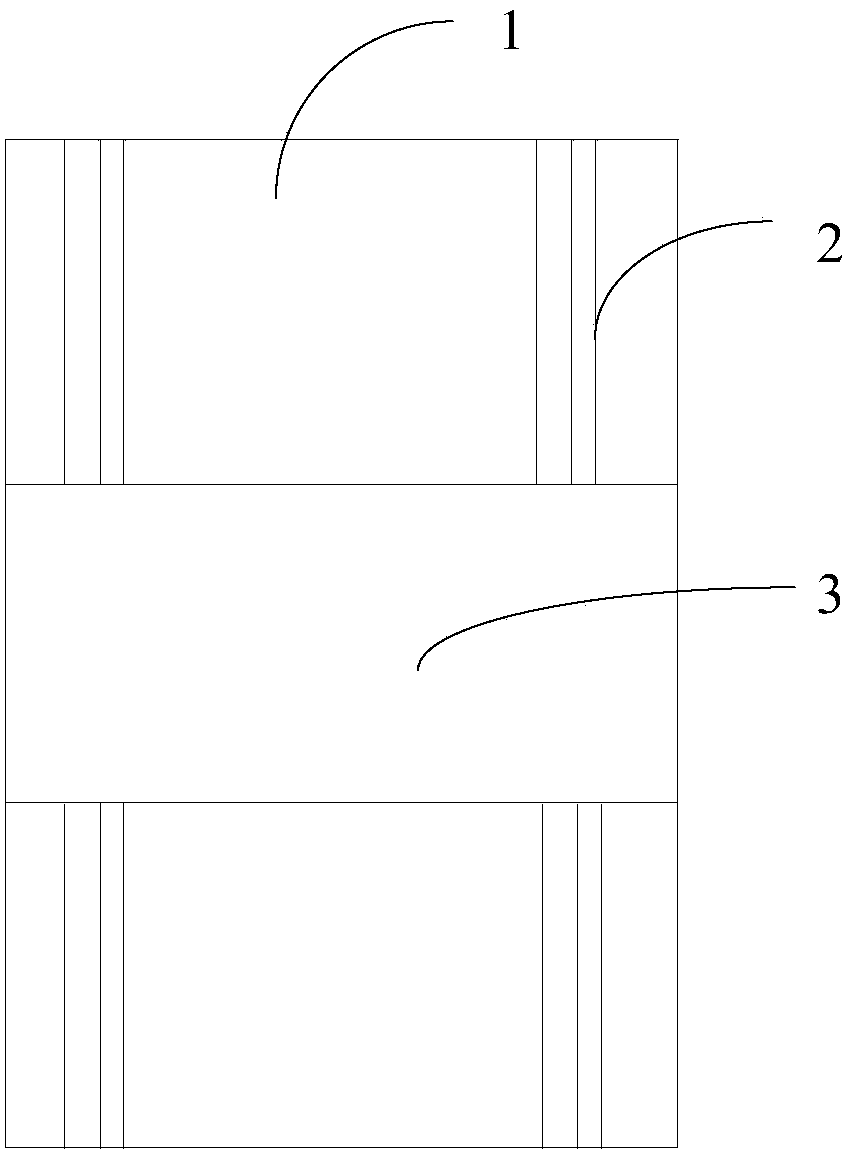

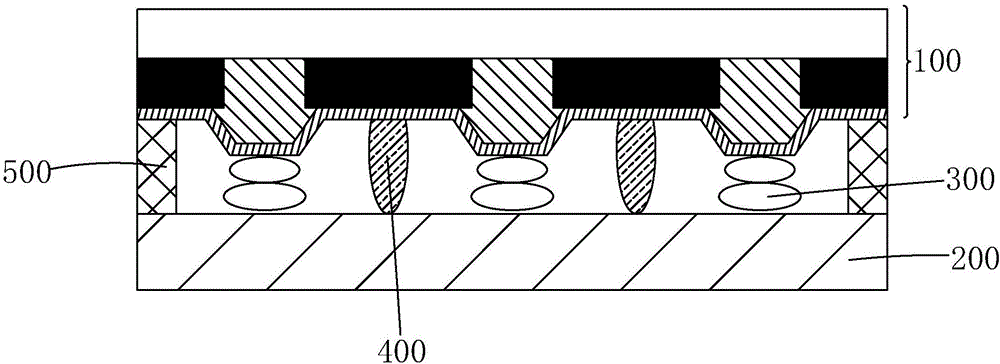

Liquid crystal display panel and liquid crystal display device

InactiveCN106773357AControl deformationUniform thicknessNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel and a liquid crystal display device. The liquid crystal display panel includes a color filter (1), a thin film transistor array substrate (2) facing the color filter (1), a liquid crystal arranged between the color filter (1) and the thin film transistor array substrate (2), and a plurality of light resistance spacing columns (4) which are supported between the color filter (1) and the thin film transistor array substrate (2) in a zone between the color filter (1) and the thin film transistor array substrate (2); and the light resistance spacing columns (4) are made of a glue material, one ends of the light resistance spacing columns (4) are fixedly attached on the color filter (1), and the other ends of the light resistance spacing columns (4) are fixedly attached on the thin film transistor array substrate (2). The liquid crystal display panel has high mechanical strength, can lower fracture risk, can allow even thickness of the liquid crystal, and can improve the product yield.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

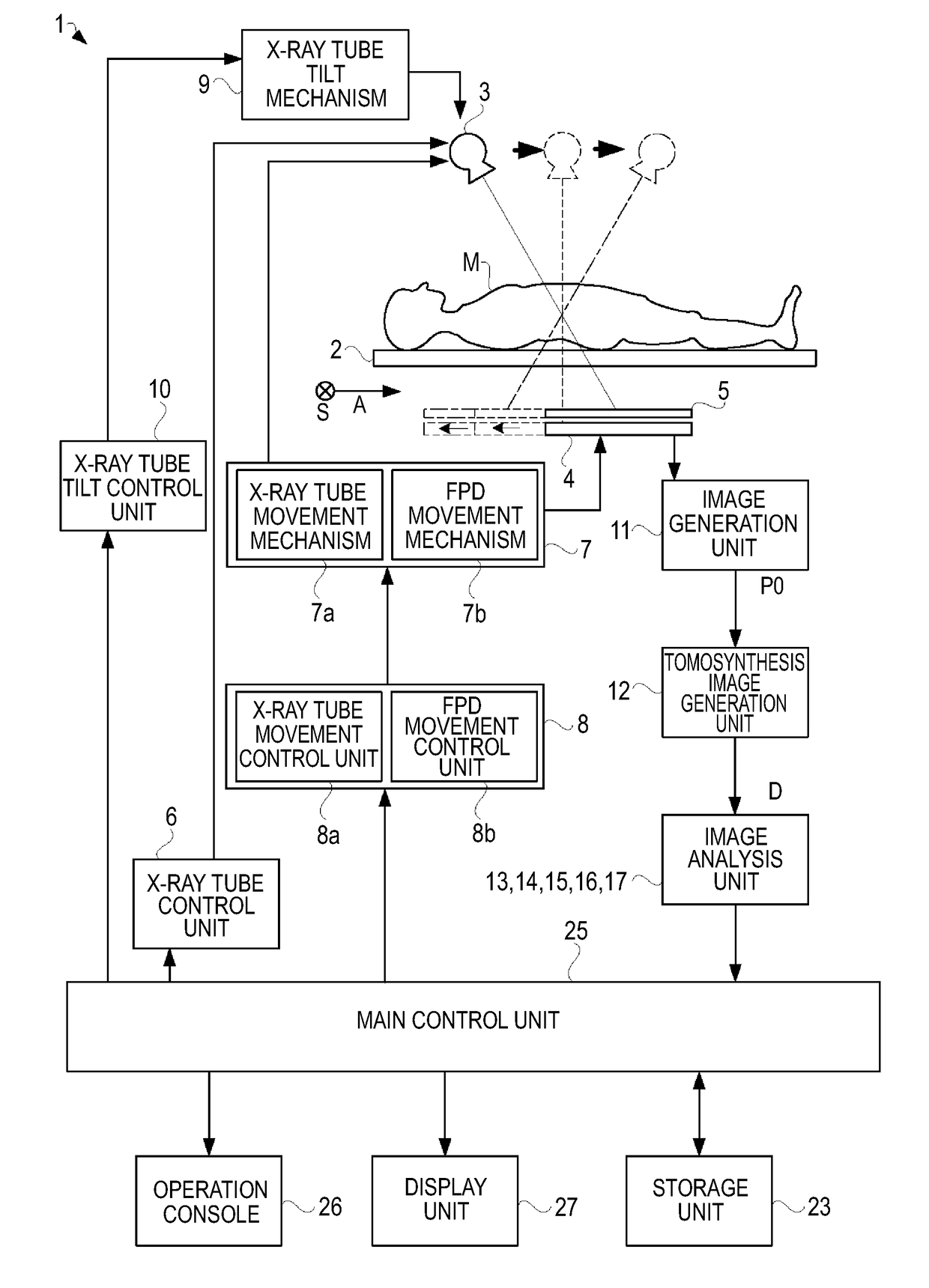

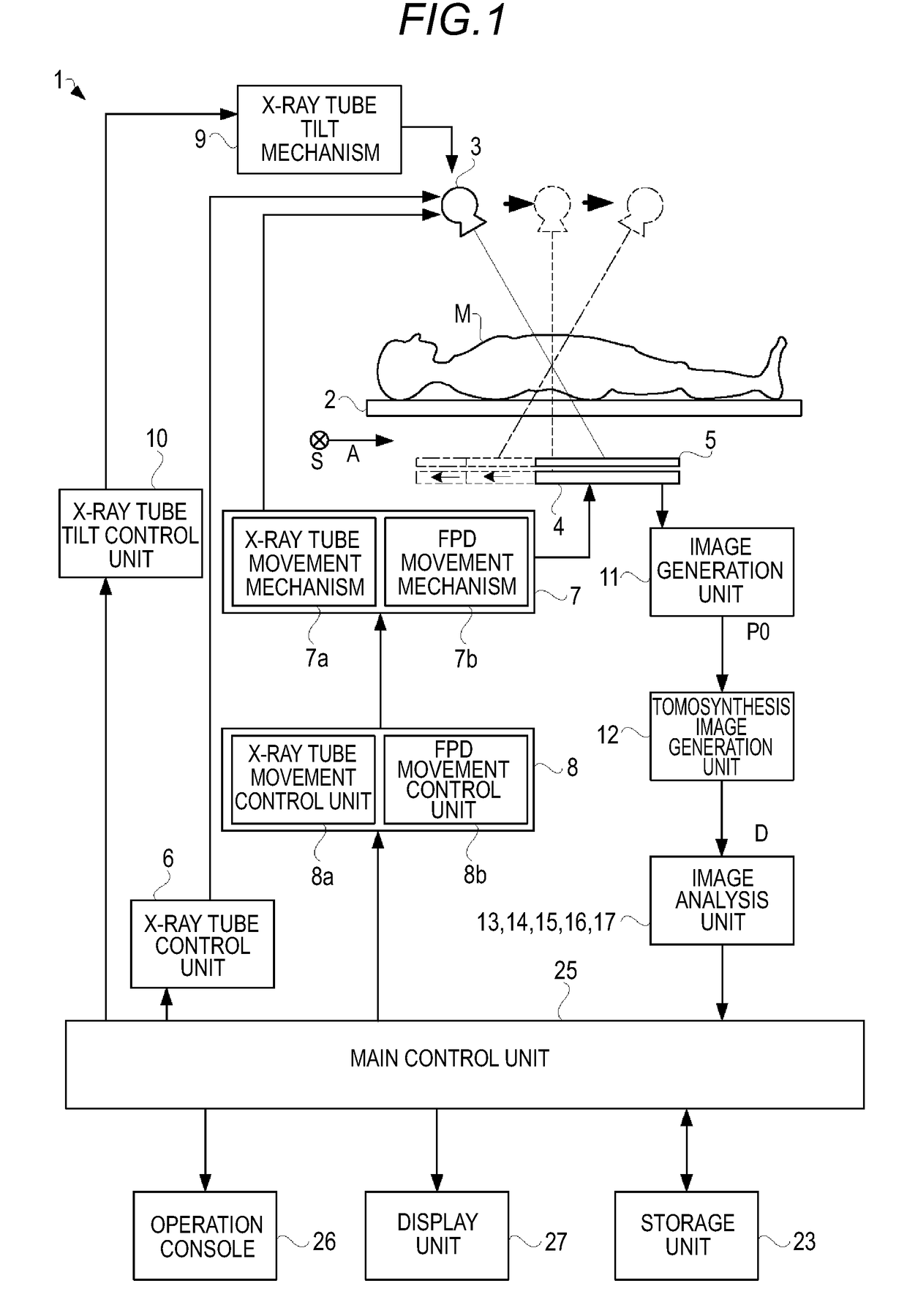

Bone analyzing device

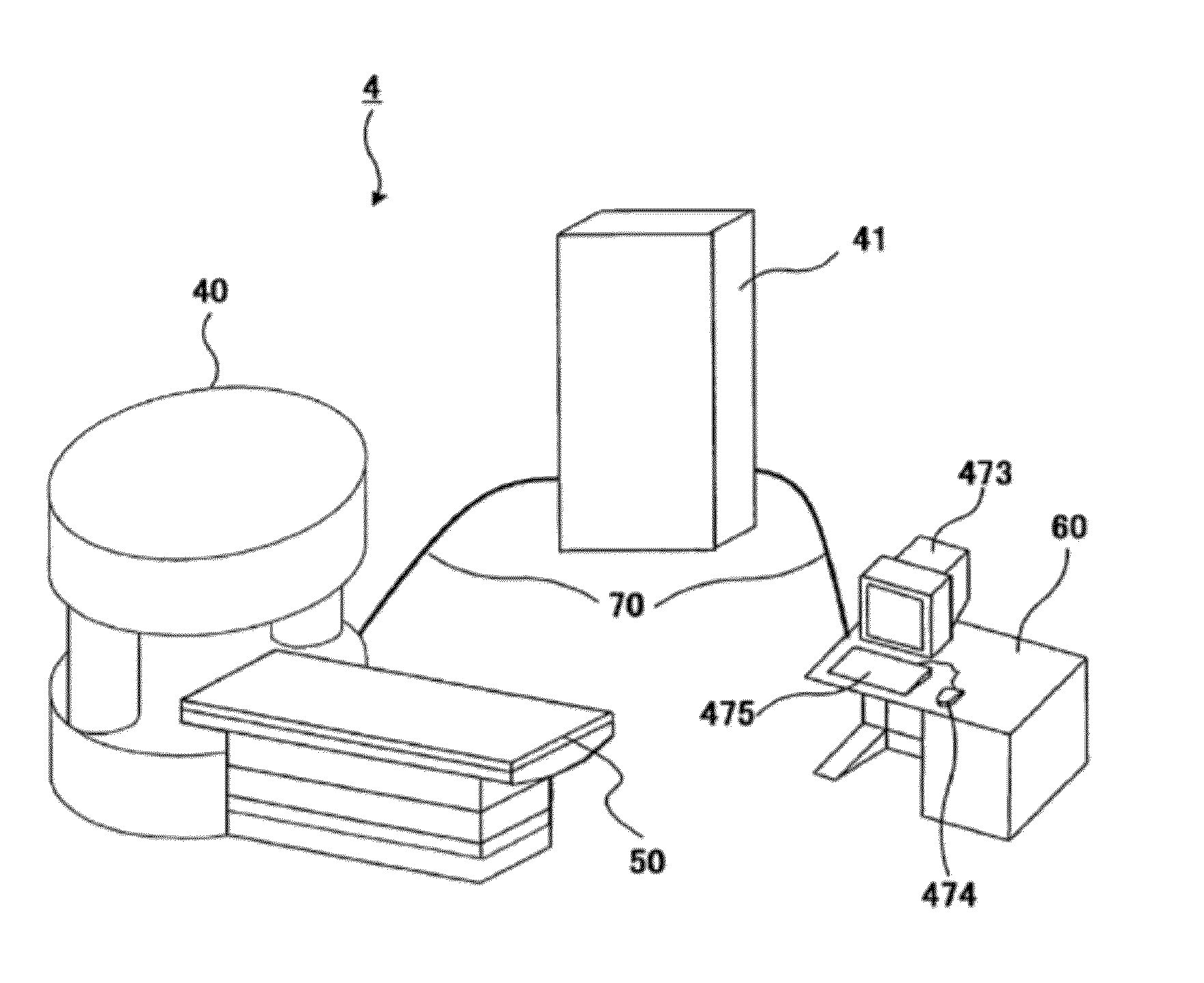

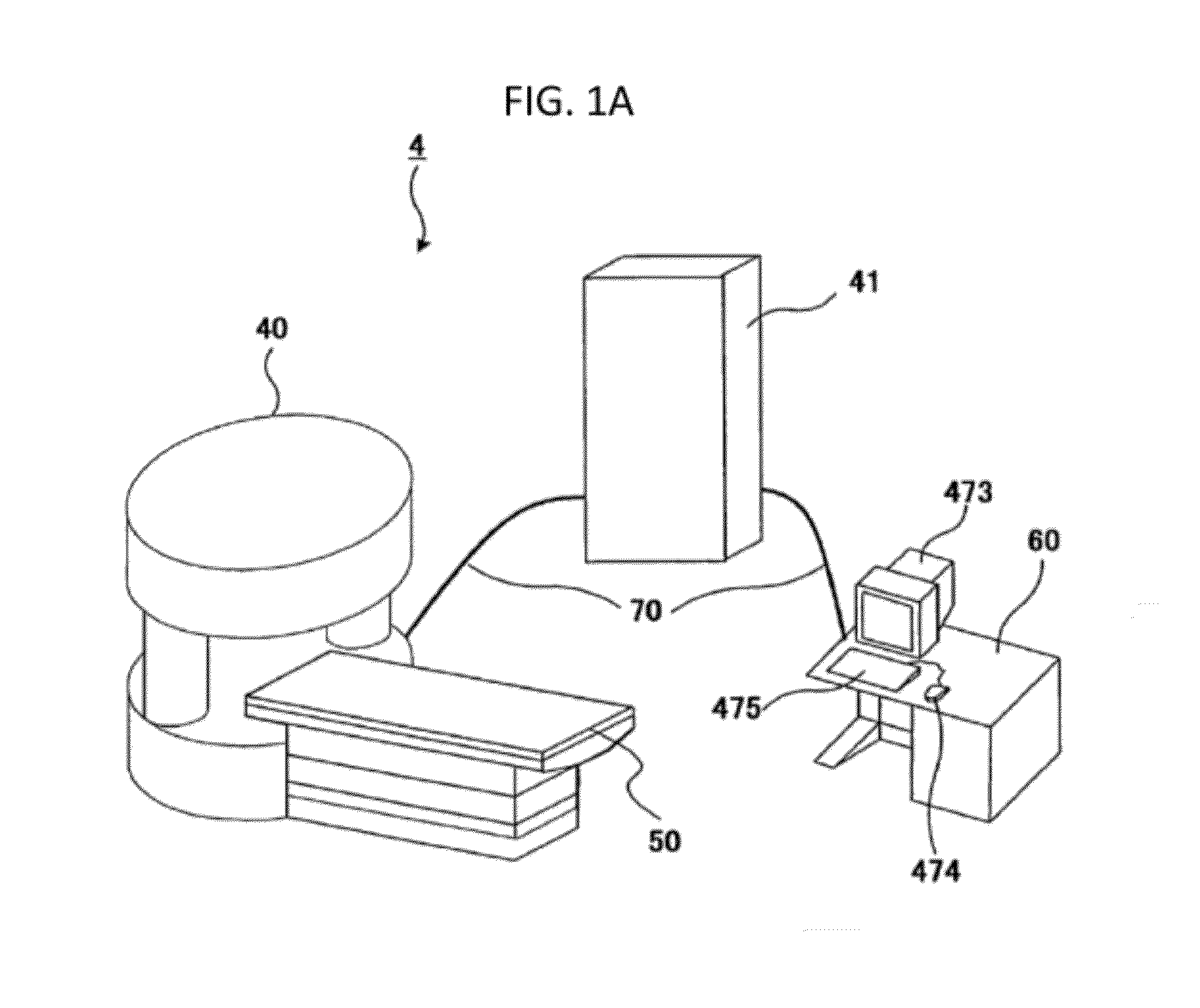

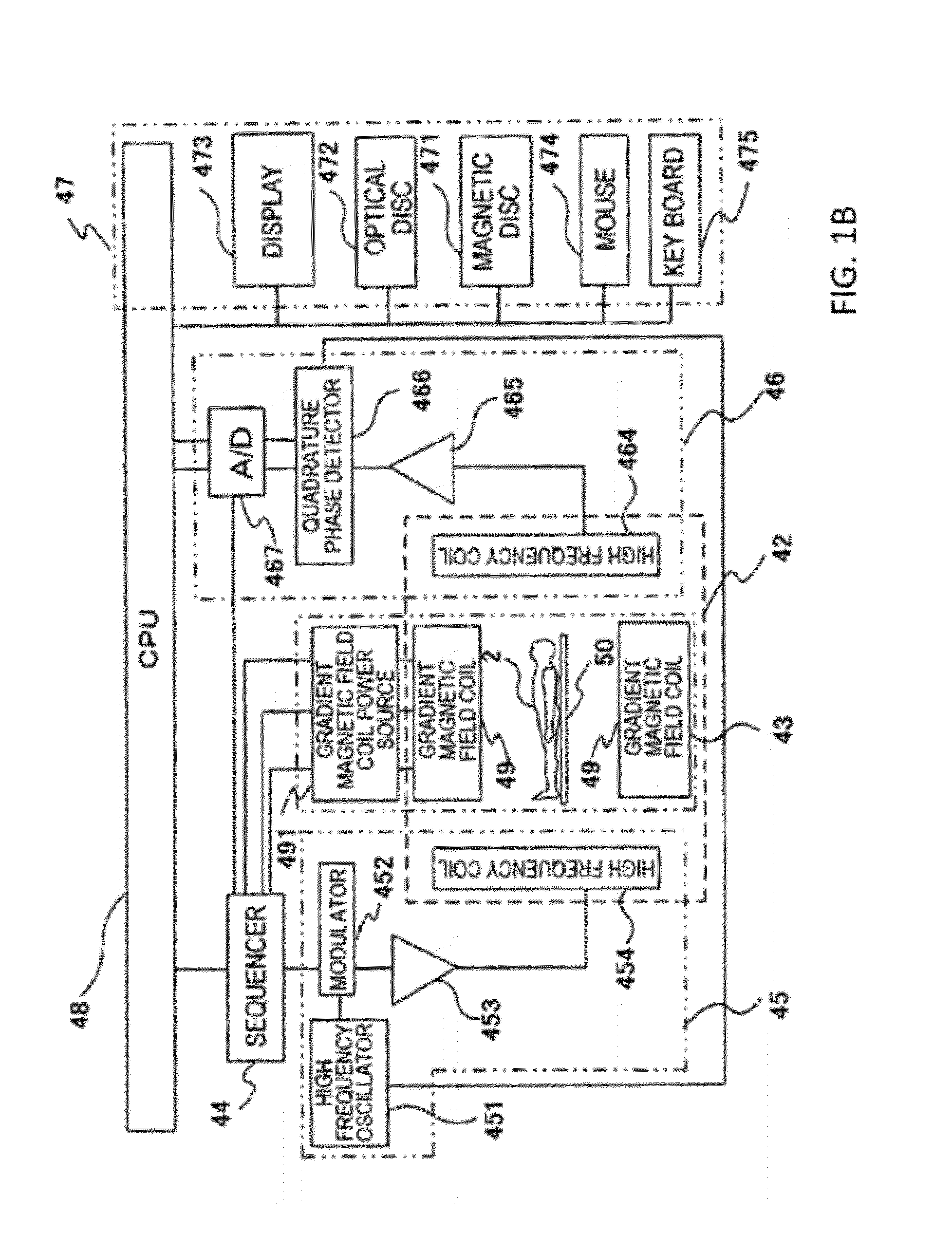

InactiveUS20180020999A1High reliability of resultsAccurate fracture riskHealth-index calculationRadiation diagnostic device controlBone densityFracture risk

A bone analysis apparatus capable of calculating a more highly reliable fracture risk evaluation value. A bone density of the invention is positioned for a partial description of a fracture risk. That is, in the invention, it is considered that an accurate fracture risk cannot be sufficiently obtained only by one of the bone density and a structural parameter although both the bone density and the structural parameter are important to know the fracture risk. According to the invention, the fracture risk is comprehensively evaluated on the basis of the structural parameter for evaluating a structure of a trabecular bone in addition to the bone density. With this configuration, since the fracture risk can be evaluated while also taking the structure of the trabecular bone into consideration, the fracture risk can be more accurately evaluated.

Owner:SHIMADZU CORP

Estimating risk of future bone fracture utilizing three-dimensional bone density model

Owner:HOLOGIC INC

Food composition beneficial to bone health

PendingCN106620659ACompensation for bone damageCompensate for joint wear and tearSugar food ingredientsPeptide/protein ingredientsJoint synovialBones joints

The invention provides a food composition beneficial to the bone health. The food composition is characterized by containing the following components in parts by weight: 1-5 parts of a cockscomb extract, 1-3 parts of non-degenerated type II collagen, 1-3 parts of vitamin K2 and 5-10 parts of micro-activated curcumin. The food composition provided by the invention has the following technical effects: (1) by adding joint synovia, bone injuries such as joint wear and bone spurs caused due to the loss of synovial are avoided; (2) by adding anti-inflammatory molecules, the arthritis paint is relieved, the degradation reaction of cartilages is reduced, and the long-term health of bone joints is promoted; (3) the osteoporosis is prevented, the fracture risk is reduced, a strong skeleton network is constructed, the concentration of blood calcium is reduced, and and cardiovascular calcification is prevented; and (4) by combining the cockscomb extract, the non-degenerated type II collagen and the curcumin for use, the joint synovial is supplemented, meanwhile, the inflammatory reaction is reduced, and the arthralgia can be prevented; and by adding the vitamin K2, the osteoporosis of middle aged and elderly people can be prevented.

Owner:江苏中雍红瑞制药有限公司

Touch control structure and preparation method thereof, and display device

ActiveCN109407869AConductive layers on insulating-supportsPlastic/resin/waxes insulatorsDisplay deviceFracture risk

The invention relates to a touch control structure and a preparation method thereof, and a display device. The preparation method of the touch control structure comprises the following steps of: providing a thin film substrate; a substrate is provided and that thin film substrate is adhered on the substrate; forming a laminated structure for realizing a touch function on the thin film substrate; removing the thin film substrate on which the laminated structure is formed from the substrate substrate. The preparation method of the touch control structure can make the functional layer of the touch control structure distribute on the same side of the film substrate, and the stress is the same when the film substrate is bent, so that the fracture risk can be reduced, and meanwhile, the preparation method can improve the alignment accuracy.

Owner:BOE TECH GRP CO LTD +1

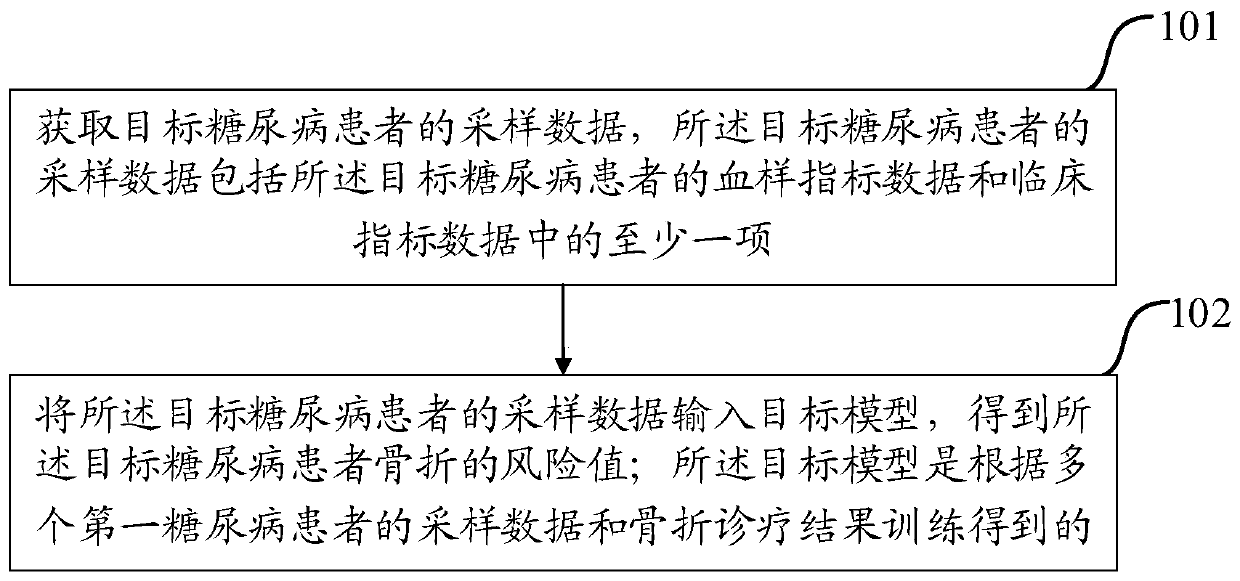

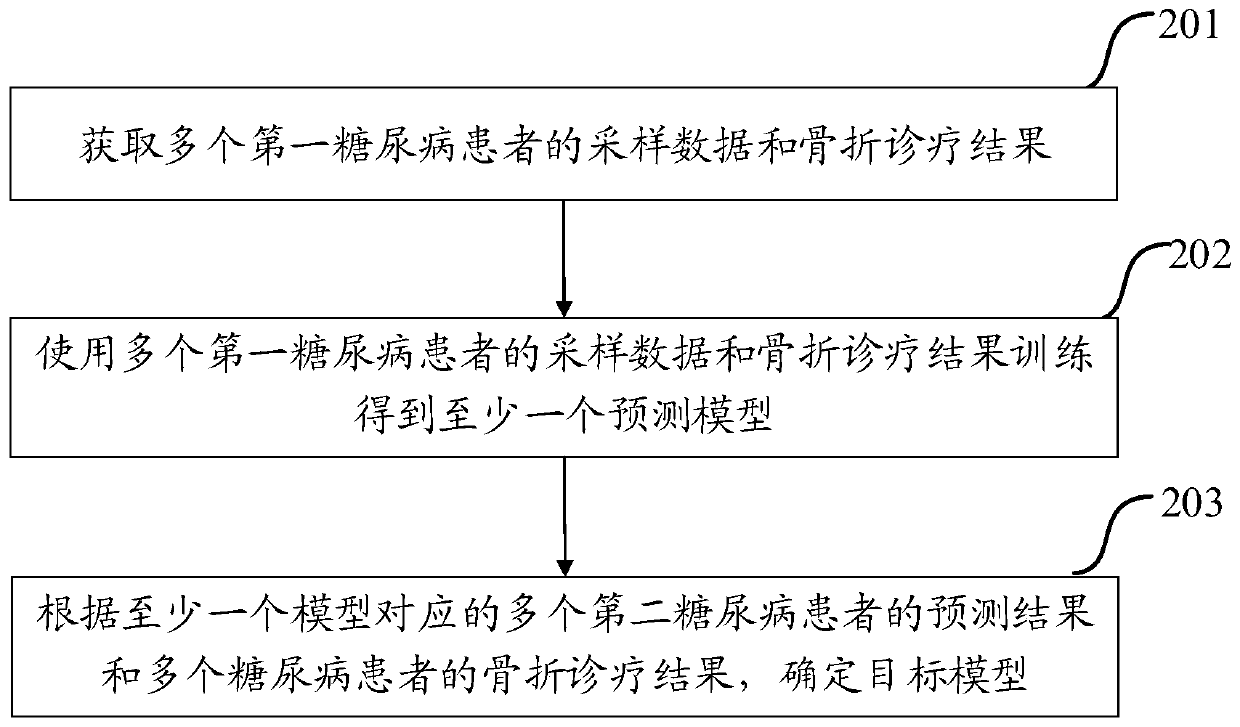

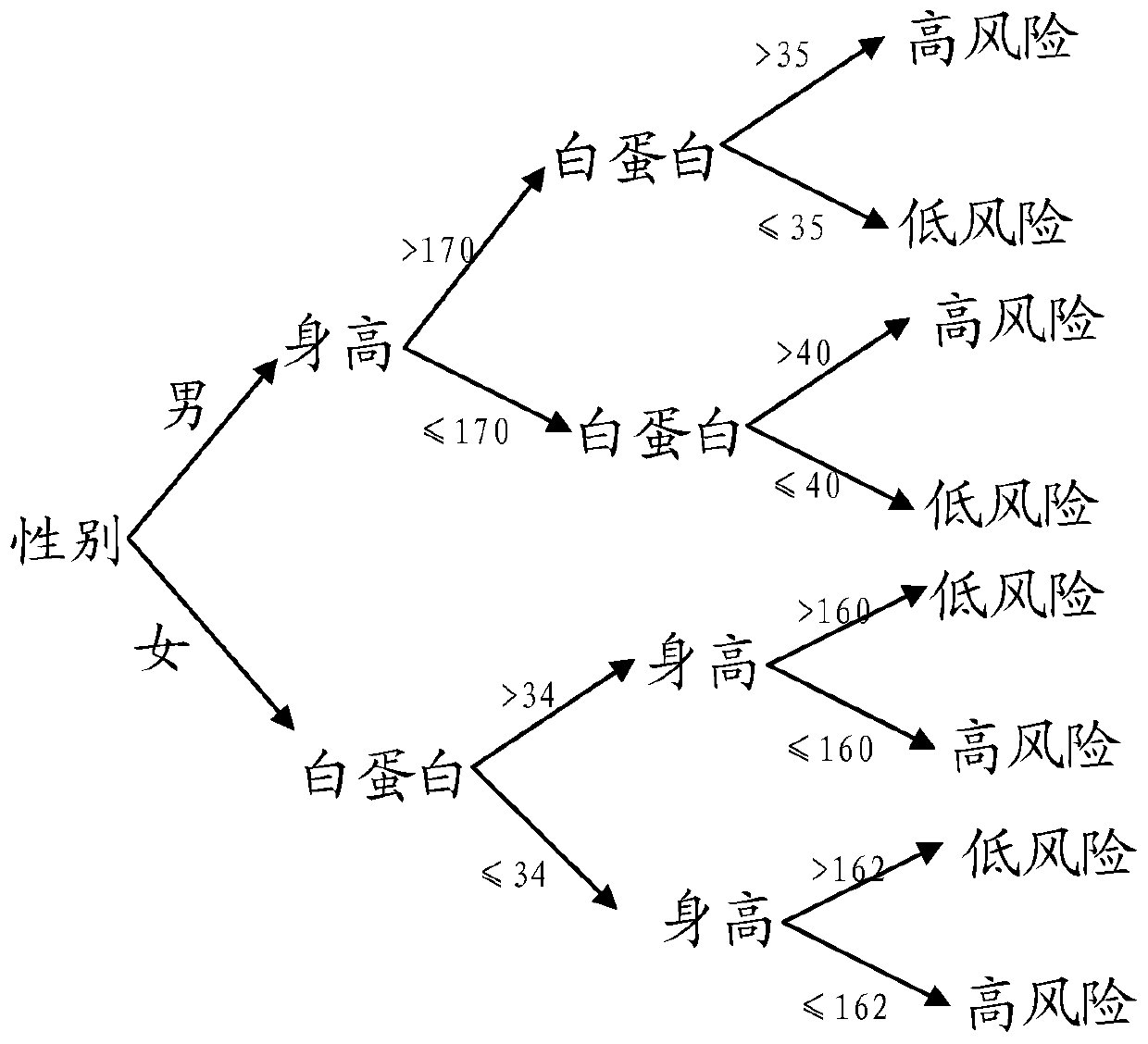

Method and device for determining bone fracture risk of diabetes patient

InactiveCN110176304AGood fracture riskSolving the technical problem of not being able to predict fracture risk in diabeticsHealth-index calculationMedical automated diagnosisFracture riskCvd risk

An embodiment of the invention discloses a method and a device for determining a bone fracture risk of a diabetes patient, wherein the method comprises the steps of acquiring sampling data of a targetdiabetes patient, and inputting the sampling data of the target diabetes patient into a target model for obtaining a bone fracture risk value of the target diabetes patient, wherein the sampling datacomprises at least one selected from blood sample index data and clinical index data, and the target model is obtained through training the sampling data and the bone fracture diagnosis-and-treatmentresults of multiple first diabetes patients. In the embodiment of the invention, the bone fracture risk of the target diabetes patient is analyzed through the blood sample index and / or the clinical index, and bone fracture prediction of the diabetes patient can be realized; and furthermore relatively high predicting effect for the bone fracture of the diabetes patient can be realized.

Owner:SHANGHAI YIZHI HEALTHCARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com