Cover plate of safety airbag and steering wheel safety airbag device comprising cover plate

An airbag device and airbag technology, applied in vehicle safety arrangement, pedestrian/passenger safety arrangement, transportation and packaging, etc., to achieve the effect of improving appearance quality and manufacturing cost, and being easy to open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

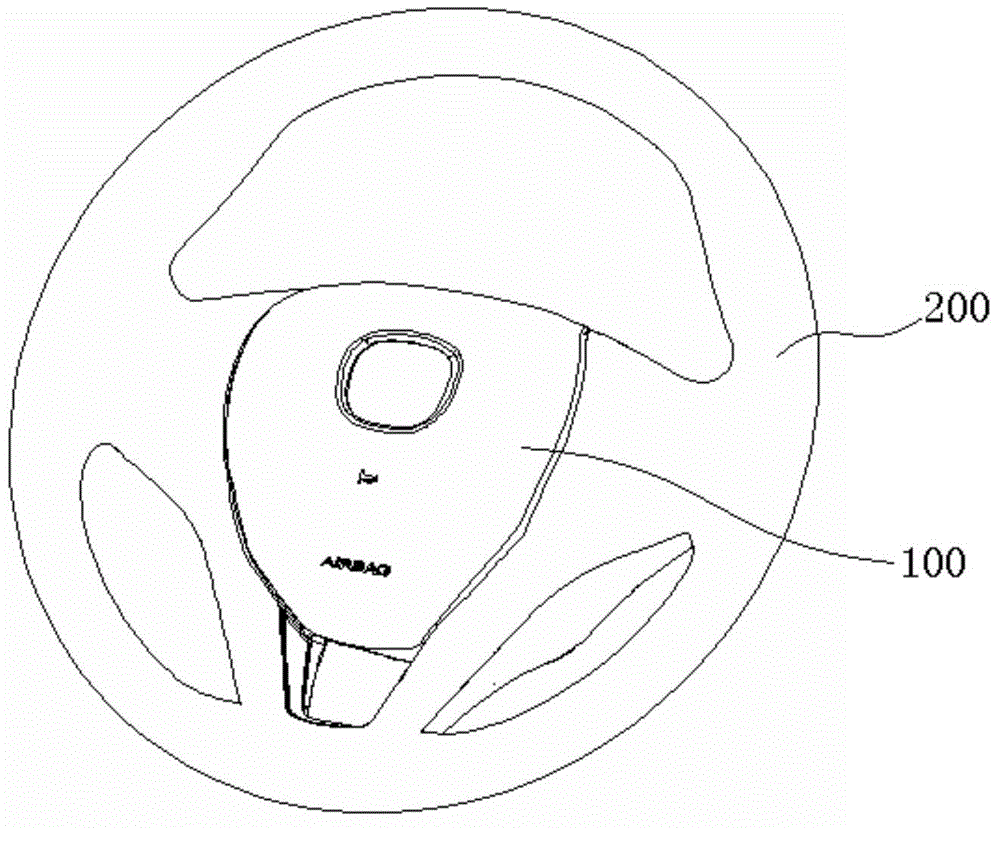

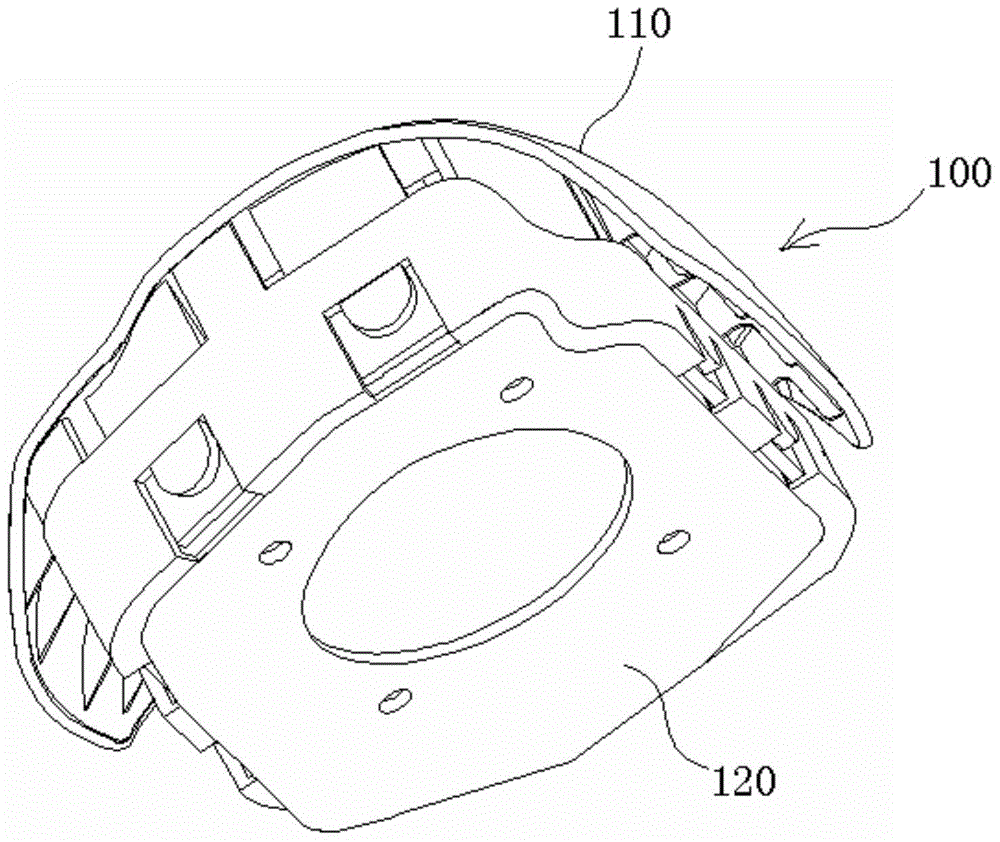

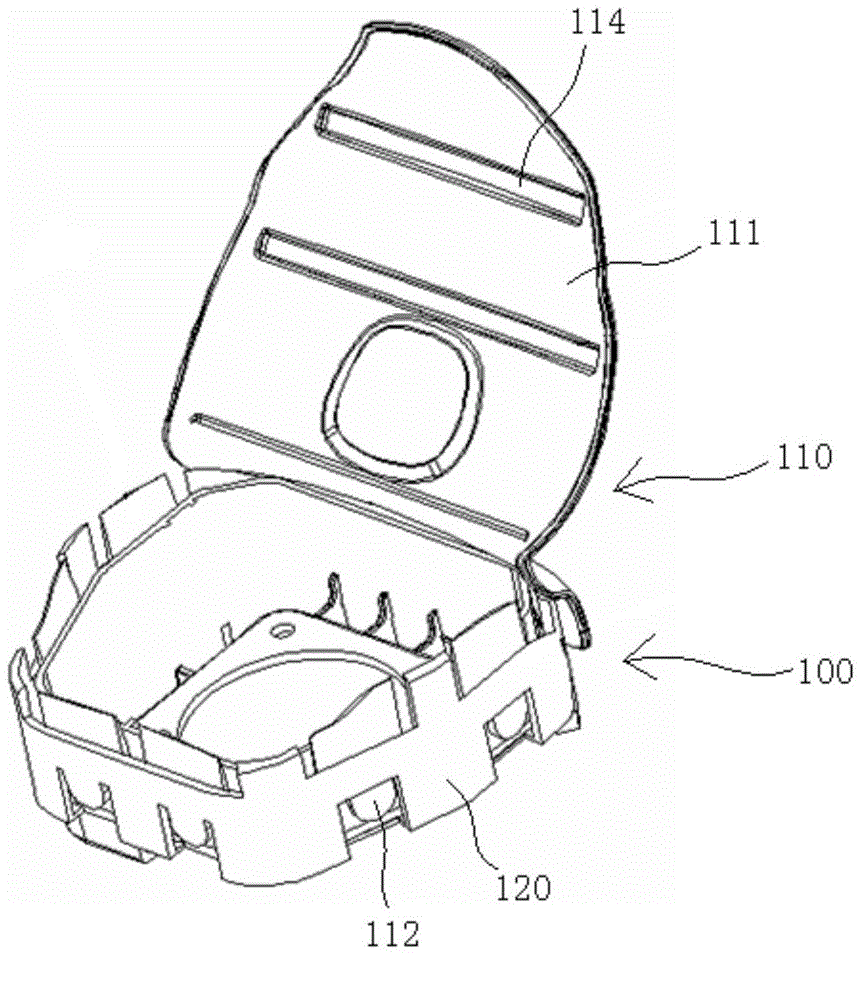

[0029] Referring to the accompanying drawings, the steering wheel airbag device provided in the figure, the whole airbag device 100 is installed in the steering wheel 200, which includes a cover plate 110, an air bag bracket 120 and an air bag (not shown in the figure) configured in the air bag bracket 120 ) and an inflatable component (not shown) installed on the airbag bracket 120, the airbag bracket 120 is fixed on the steering wheel 200.

[0030] The cover plate 110 includes a cover plate panel 111 and a cover plate wall 112 , the lower end of the cover plate wall 112 is fixedly connected with the airbag bracket 120 by clamping or riveting.

[0031] After the cover plate 110 is installed on the airbag support 120, after the cover plate panel 111 is subjected to a downward pressing force and the horn is sounded, the bottom surface of the cover plate panel 111 contacts the top edge of the airbag support 120, and the cover plate panel 111 The pressing force received is transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com