Snap hinge device

A device and buckle technology, which is applied to wing parts, door/window accessories, buildings, etc., can solve problems such as impact, damage to the extension arm, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

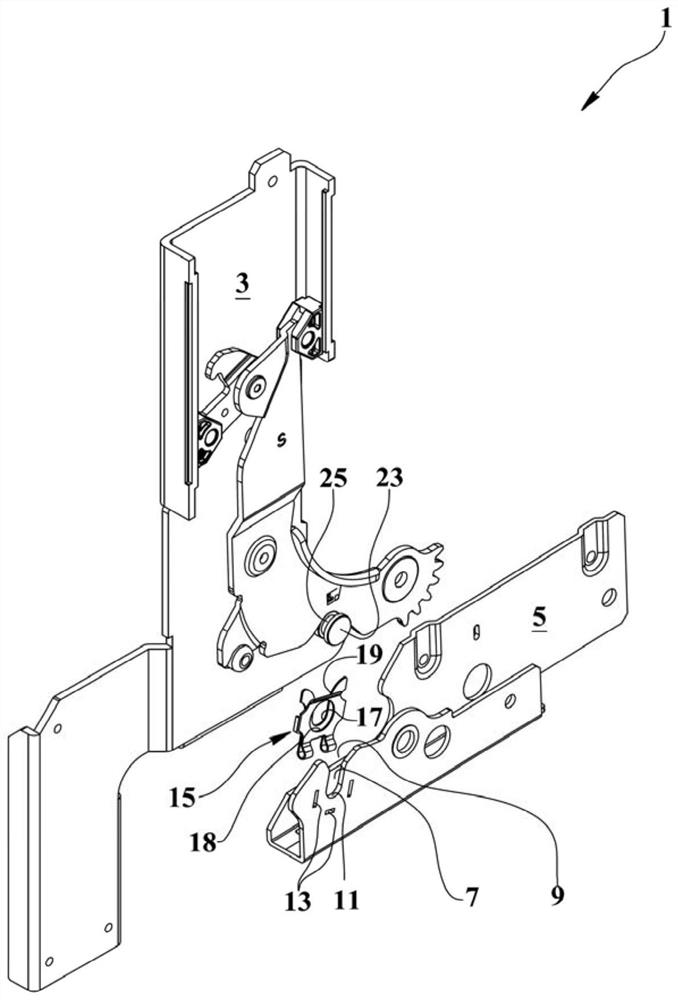

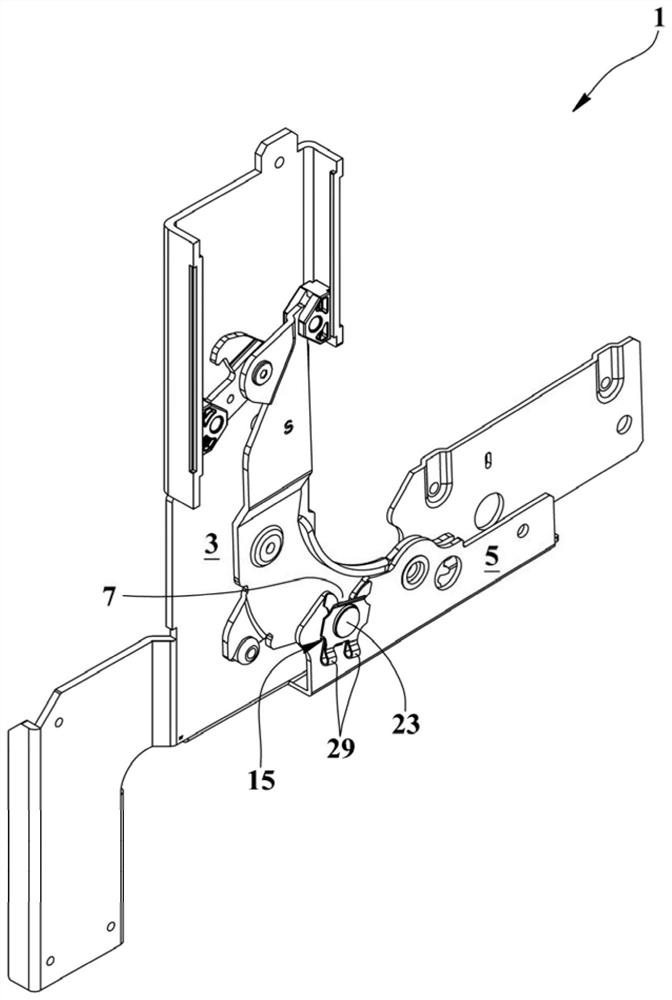

[0032] Please refer to Figure 1 to Figure 17 , reference numeral 1 denotes a snap-fit hinge device comprising a first element 3 for being fixed to a body of an apparatus and a second element 5 for being fixed to a door of said apparatus, wherein said first element 3 and said second element 5 are connected to each other in the assembled state of the device so that the door can be rotated about the axis of rotation.

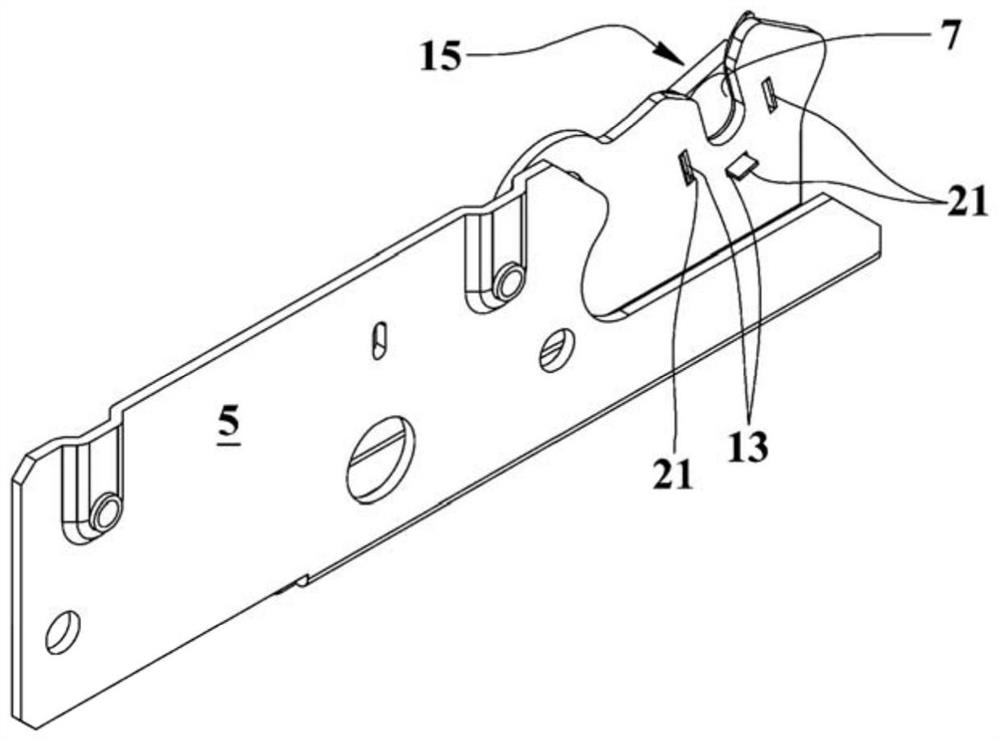

[0033] Said second element 5 is provided with an elongated groove 7 having an open end 9 and a closed end 11 .

[0034] The longitudinal axis of the elongated groove 7 can have almost any inclination with respect to the second element 5, and in the open state of the hinge means, the open end 9 can be as figure 2 Shown and preferably open upwards, or any other orientation.

[0035] Said second element 5 is also provided with a first connecting piece 13 made adjacent to the groove 7 and comprising, for example, a plurality of rectangular through-holes.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com