Maintenance method of plant for forming containers, including resynchronisation procedure

A resynchronization, container technology, used in applications, home appliances, household components, etc., to solve problems such as danger, inaccessibility of models, cracked grasping members, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

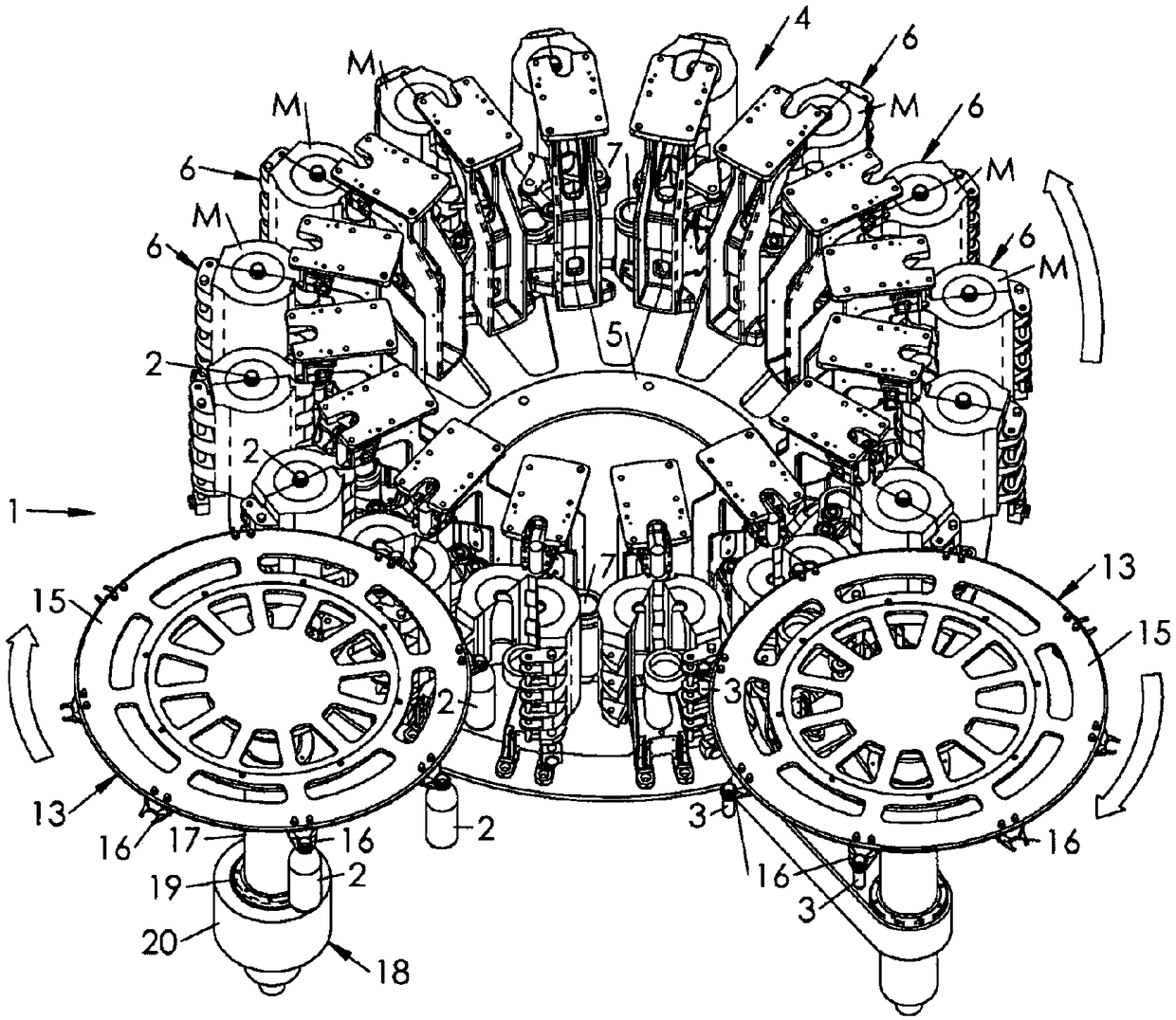

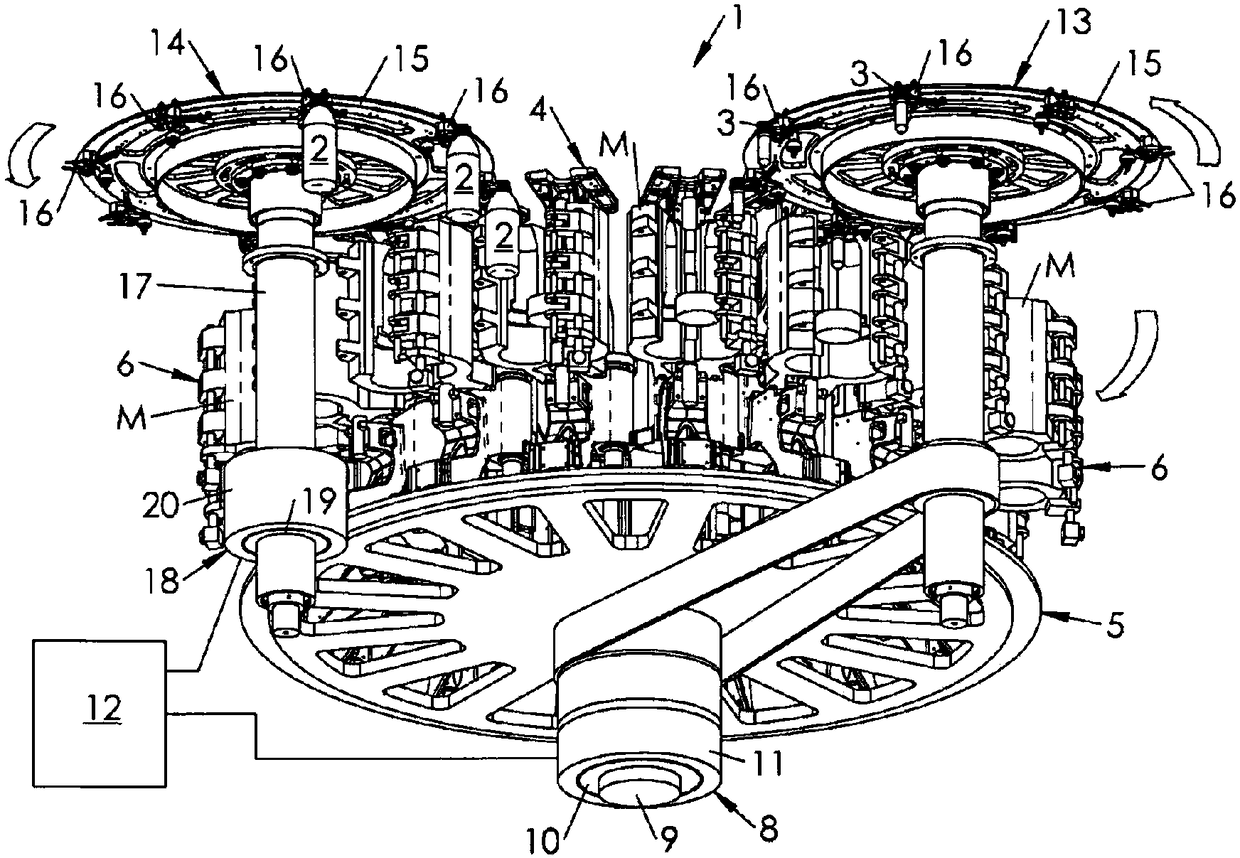

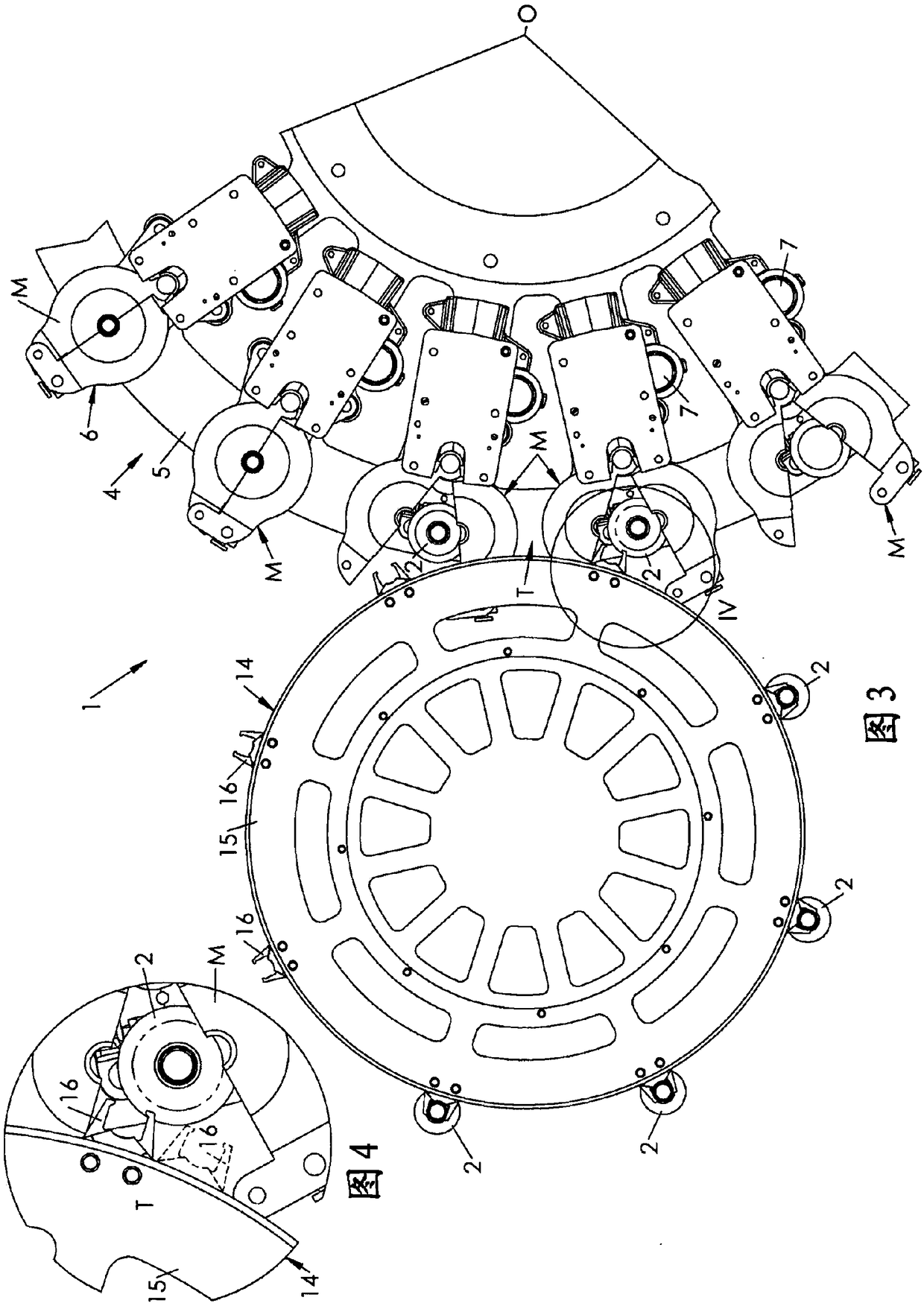

[0042] In particular, the drawing shows a container production plant 1 for producing containers 2 from plastic blanks 3 . According to an embodiment shown in the figures, the blank 3 is a preform directly from injection moulding. In other embodiments, however, the blank 3 may be an intermediate container that has undergone one or several prefabrication operations, such as preblowing. An example of a plastic is polyethylene terephthalate (PET).

[0043] The plant 1 firstly comprises a blow molding machine 4 equipped with a rotating conveyor 5 and a plurality of molding stations 6, each molding station comprising a mold M mounted on the conveyor 5, which can be in:

[0044] - an open position for allowing the blank 3 to enter and exit the formed container 2; and

[0045] - A closed position for allowing the container 2 to be formed from the blank 3 .

[0046] According to an embodiment shown in the accompanying drawings, in particular image 3 , each model M comprising two m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com