Guide Needle Assembly For A Jacquard Guide Bar And Jacquard Guide Bar

A technology for jacquard bars and bar needles is applied in the directions of knitting, warp knitting, textiles and paper making, etc., and can solve the problems of destruction, uneconomical removal of bar needles and shifting drive devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

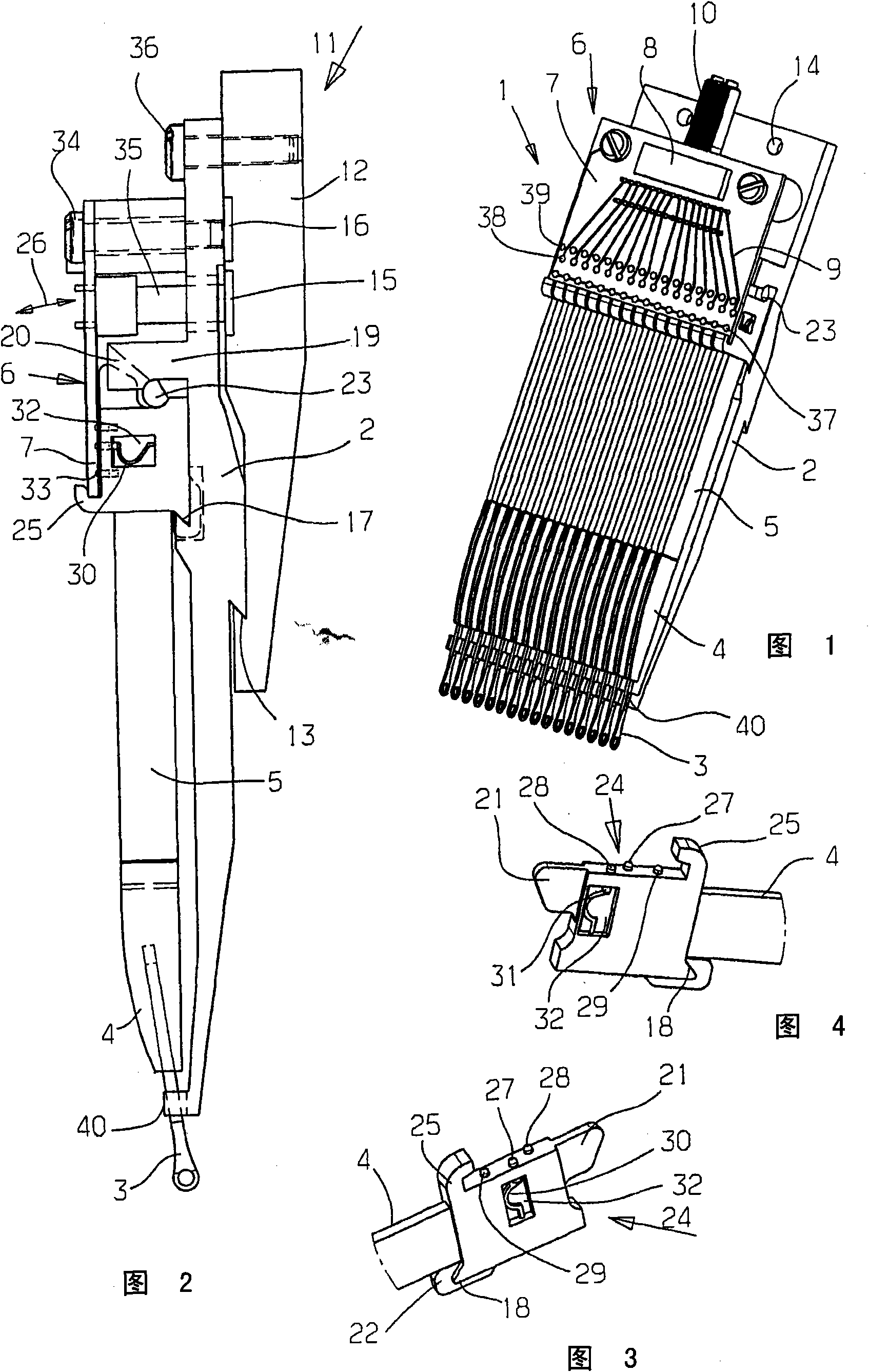

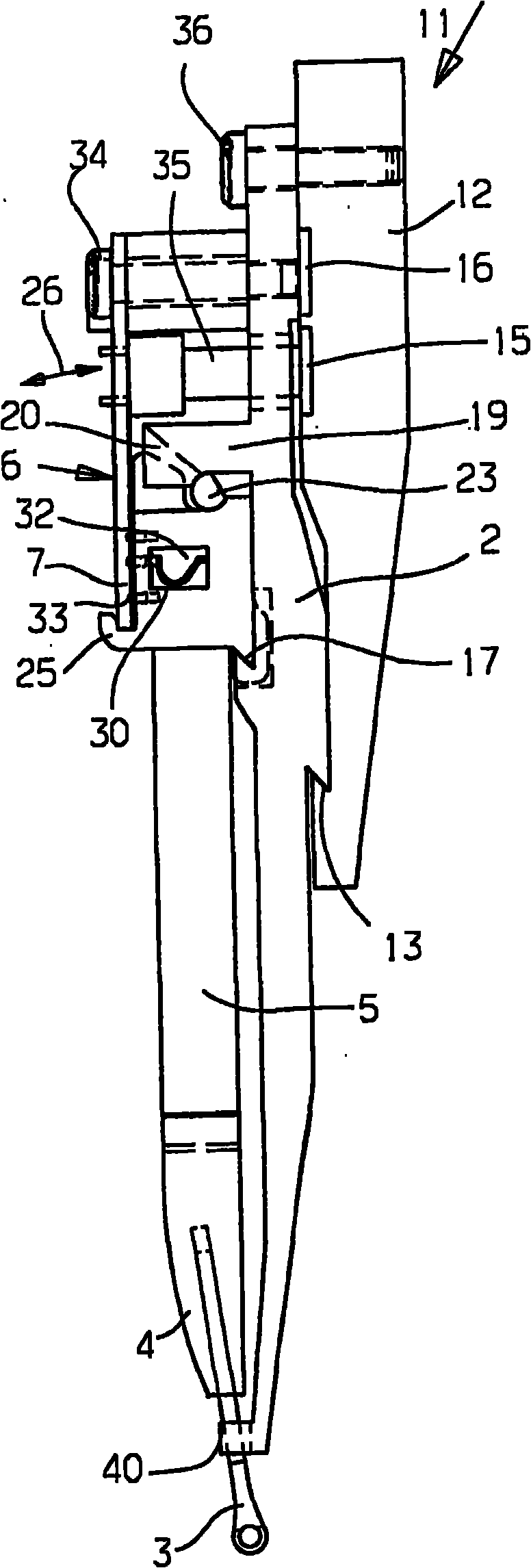

[0028] figure 1 The bar needle device 1 shown has a carrier 2 on which a number of bar needles 3 are arranged with the required stitch length. Each bar pin 3 is seated in a holder 4 , for example inserted in a hole in the tip of the holder 4 . Each holder 4 has two displacement drives 5, in figure 1 Only the displacement drive of the outer holder 4 of the two displacement drives can be seen. A displacement drive of the same type is arranged on the opposite side of the holder 4 .

[0029] The displacement drive 5 is designed in a known manner as piezoceramic bodies, which, when charged with a predetermined voltage, actuate the displacement of the holder 4 . This displacement causes the bar needles to move in one displacement direction. The displacement direction is the direction along which all the bar needles 3 of a bar needle device 1 are sequentially arranged.

[0030] The actuation of the displacement drives 5 of all the holders 4 of the bar needle device 1 takes place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com